Patents

Literature

34results about How to "Reduce corrosion wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame-retardant polyamide composition

InactiveUS20110257313A1Improve mechanical propertiesImprove thermal stabilityGroup 5/15 element organic compoundsThermoplasticHalogen

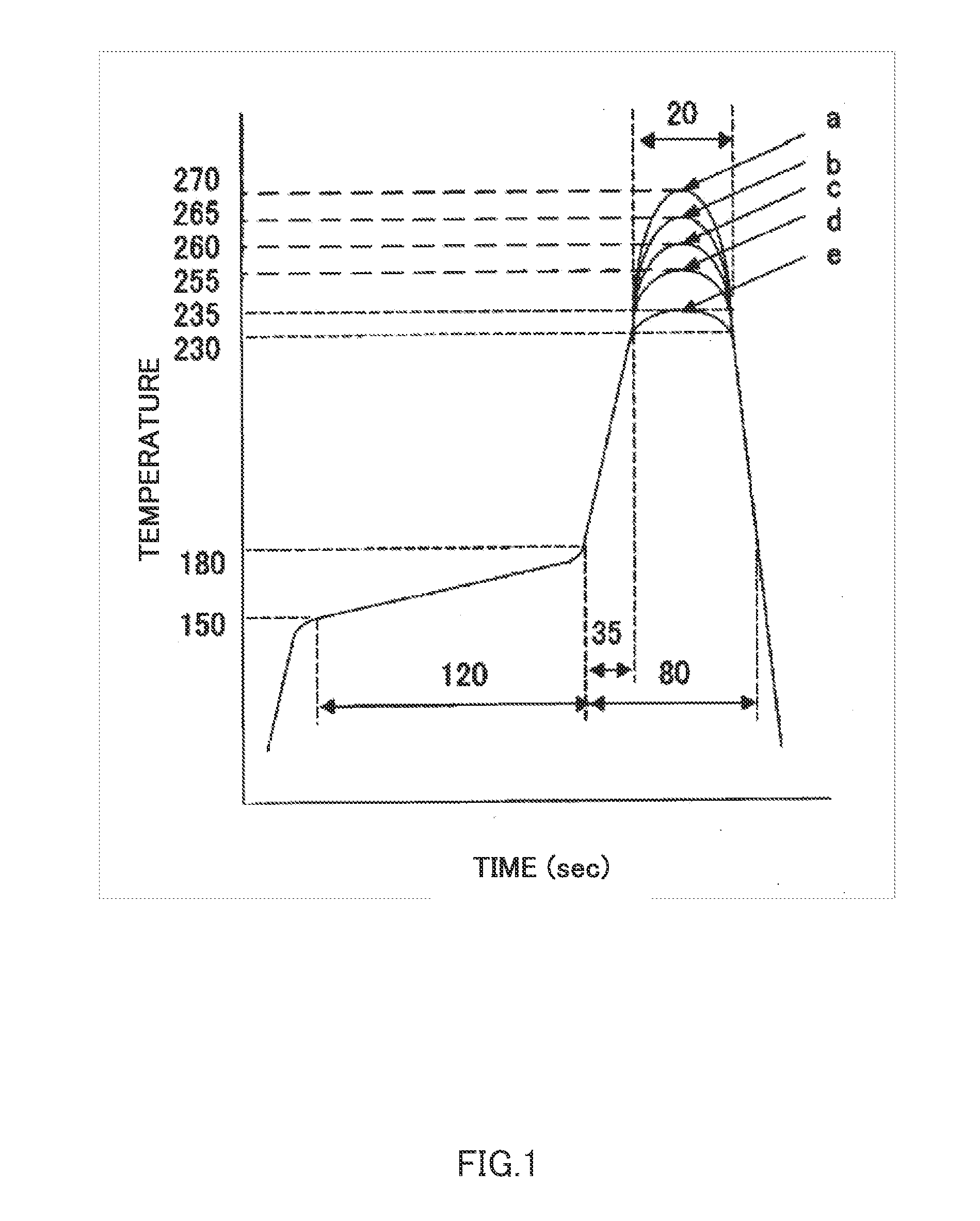

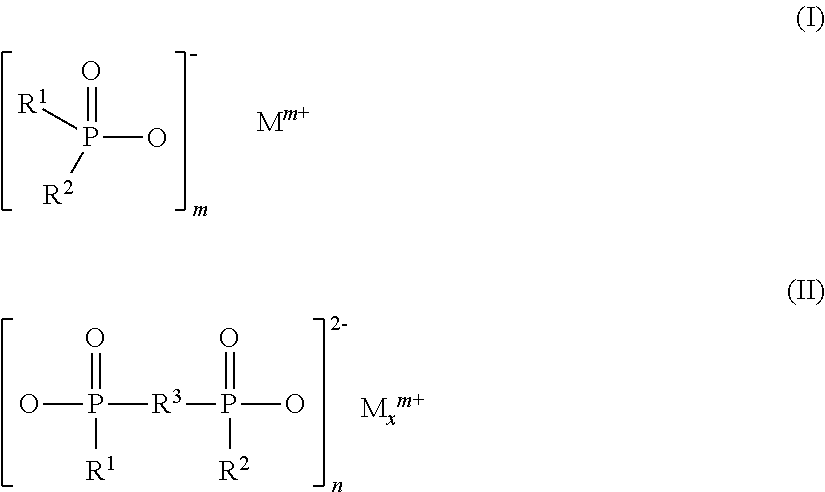

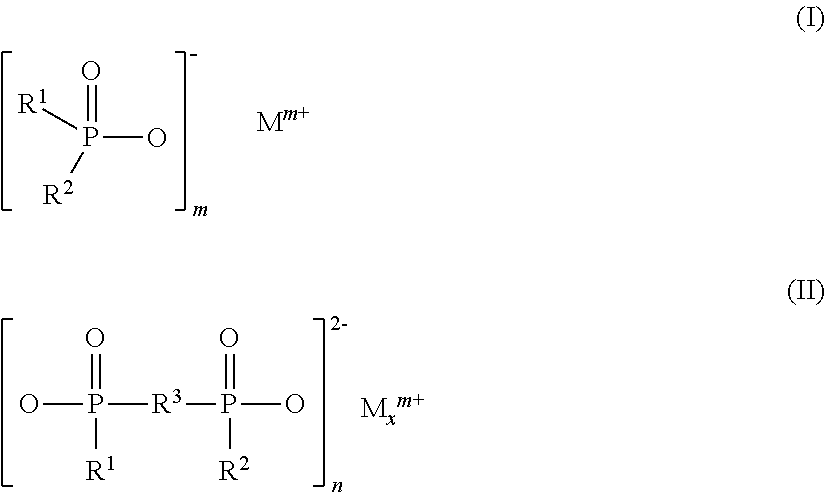

A halogen-free flame-retardant polyamide composition which generates no halogen compound during combustion. The composition has excellent thermal stability during high-temperature molding and is capable of showing high flame retardancy when burned. The composition is effective in inhibiting steel materials, such as the screw or cylinder of an extruder or molding machine, from corroding or wearing. The flame-retardant polyamide composition in a preferred embodiment comprises 20-60 mass % polyamide resin (A), 5-40 mass % thermoplastic resin (B) other than (A), 3-15 mass % flame retardant (C) having no halogen radicals in the molecule, and 0-50 mass % reinforcement (D), wherein the thermoplastic resin (B) satisfies the UL94V-0 standards, the flame retardant (C) is a phosphinic acid salt compound, and the sum of the thermoplastic resin (B) and the flame retardant (C) is 16-45 mass %.

Owner:MITSUI CHEM INC

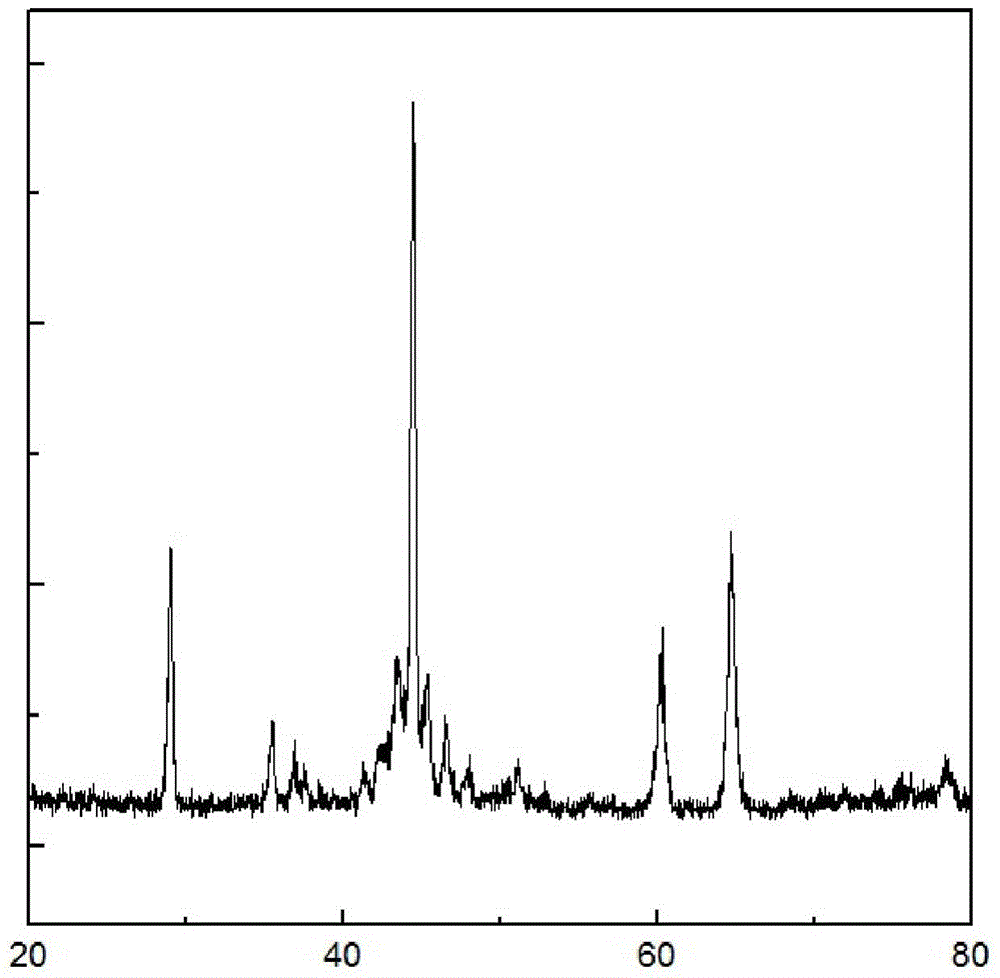

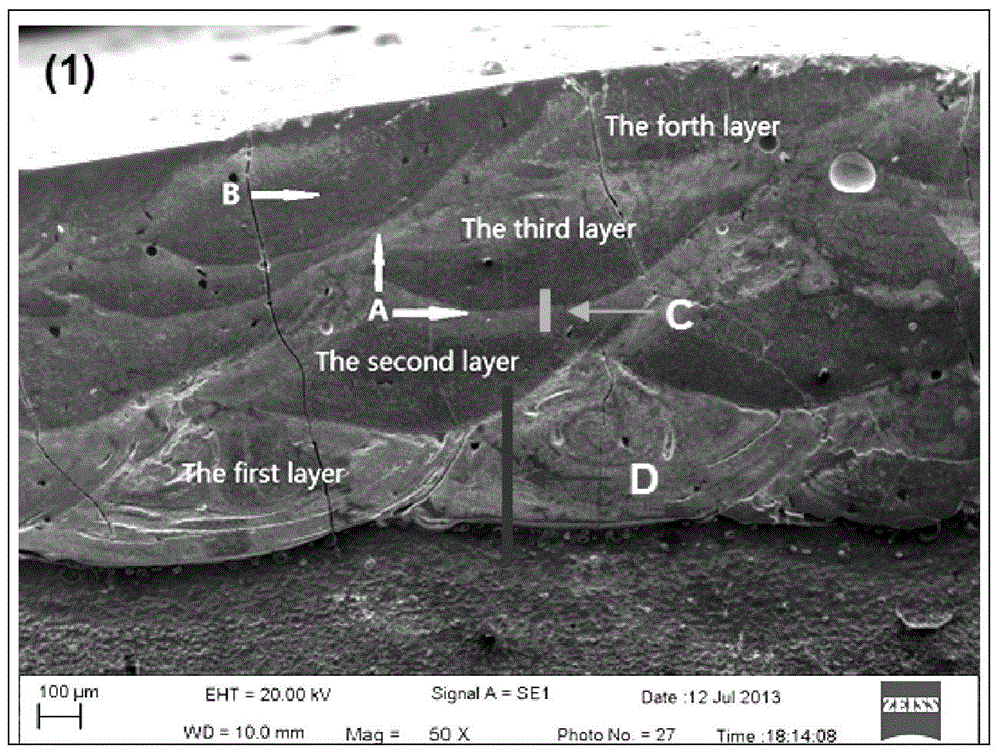

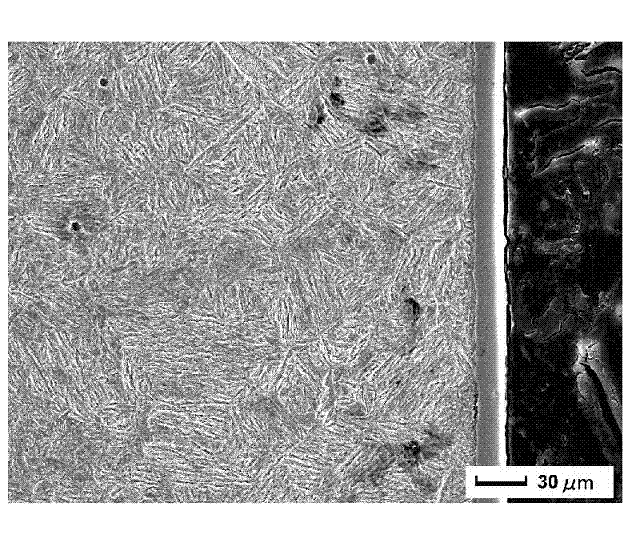

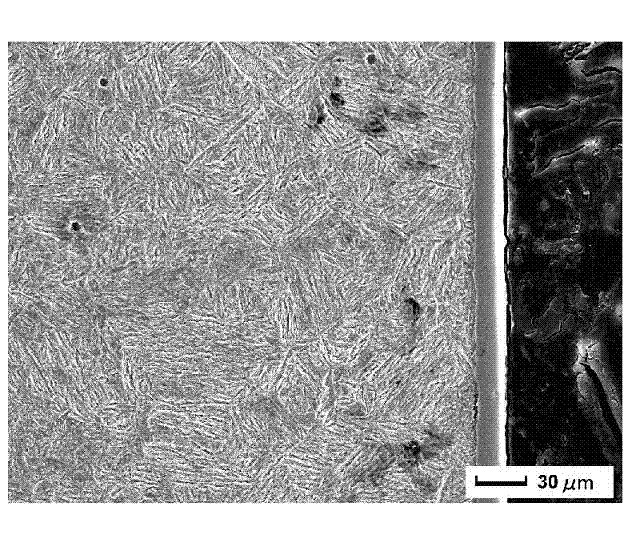

Iron-based nanocrystalline composite coating for protecting boiler tail heating surface and laser-cladding forming process of iron-based nanocrystalline composite coating

ActiveCN104357748AImprove wear and corrosion resistanceReduce corrosion wearMetallic material coating processesRare-earth elementAlloy

The invention discloses an iron-based nanocrystalline composite coating for protecting a boiler tail heating surface and a laser-cladding forming process of the iron-based nanocrystalline composite coating. The iron-based nanocrystalline composite coating comprises the following components in percentage by weight: 49.9-62.8% of Fe, 14.2-20.4% of Cr, 9.0-16.3% of Mo, 2.9-4.1% of B, 0.6-1.3% of C, 1.0-2.4% of Mn, 3.4-8.0% of W, 1.0-1.9% of Si and 0-3.9% of RE, wherein RE is a rare earth element. The forming process comprises the following steps: preparing alloy powder of the iron-based nanocrystalline composite coating; treating the surface of the boiler tail heating surface; preparing the iron-based nanocrystalline composite coating through a simultaneous powder feeding method and a laser-cladding method, wherein the laser cladding is performed for multiple times. The formed iron-based nanocrystalline composite coating is 1 mm above in thickness. The iron-based nanocrystalline composite coating can obviously enhance the wear resistance and corrosion resistance of the boiler tail heating surface, and reduce maintenance costs of worn and corroded parts and consumption of raw materials of a power plant.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

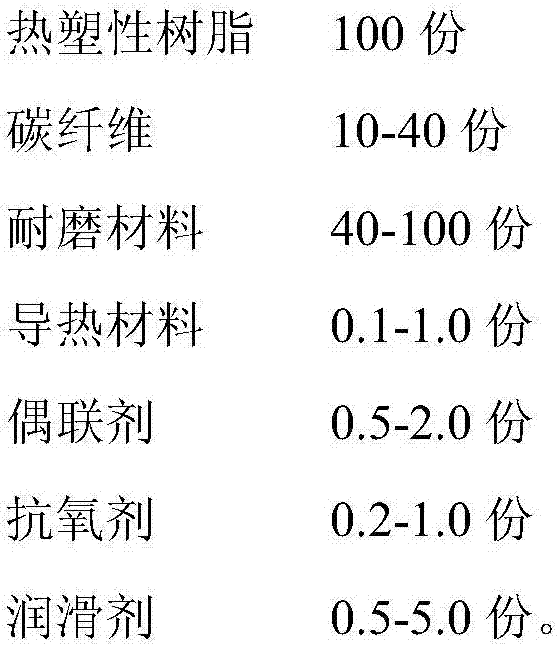

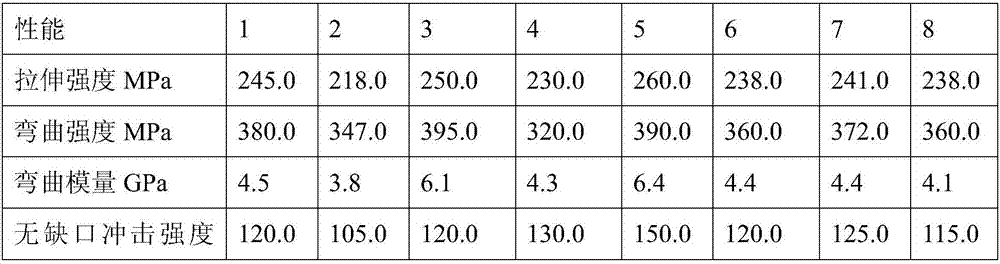

Heat-resistant and wear-resistant composite material and preparation method and application thereof

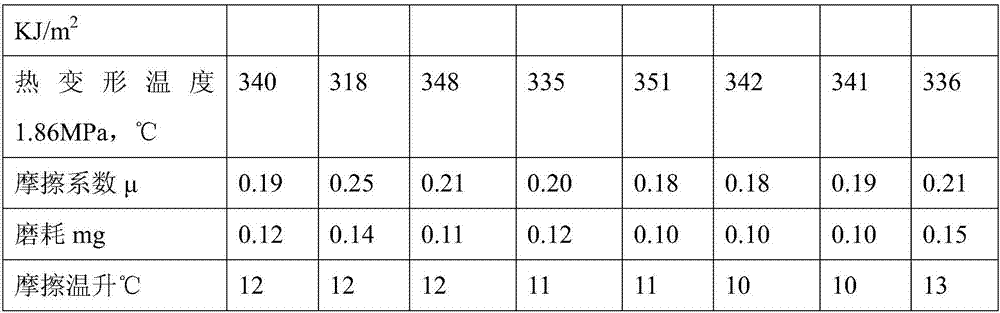

The invention discloses a heat-resistant and wear-resistant composite material and a preparation method and an application thereof and belongs to the field of high polymer wear-resistant materials. The heat-resistant and wear-resistant composite material is prepared from the following raw materials in parts by weight: 100 parts of thermoplastic resin, 10-40 parts of carbon fiber, 40-100 parts of a wear-resistant material, 0.1-1.0 part of a heat conduction material, 0.5-2.0 parts of a coupling agent, 0.2-1.0 part of an antioxidant and 0.5-5.0 parts of a lubricant. The heat-resistant and wear-resistant composite material has the characteristics of light specific gravity and high strength, the properties, such as the wear resistance, the corrosion resistance and the ageing resistance, are improved, and the heat-resistant and wear-resistant composite material is a composite material with excellent overall performance and can effectively replace metal alloy and ceramic materials.

Owner:长沙五犇新材料科技有限公司

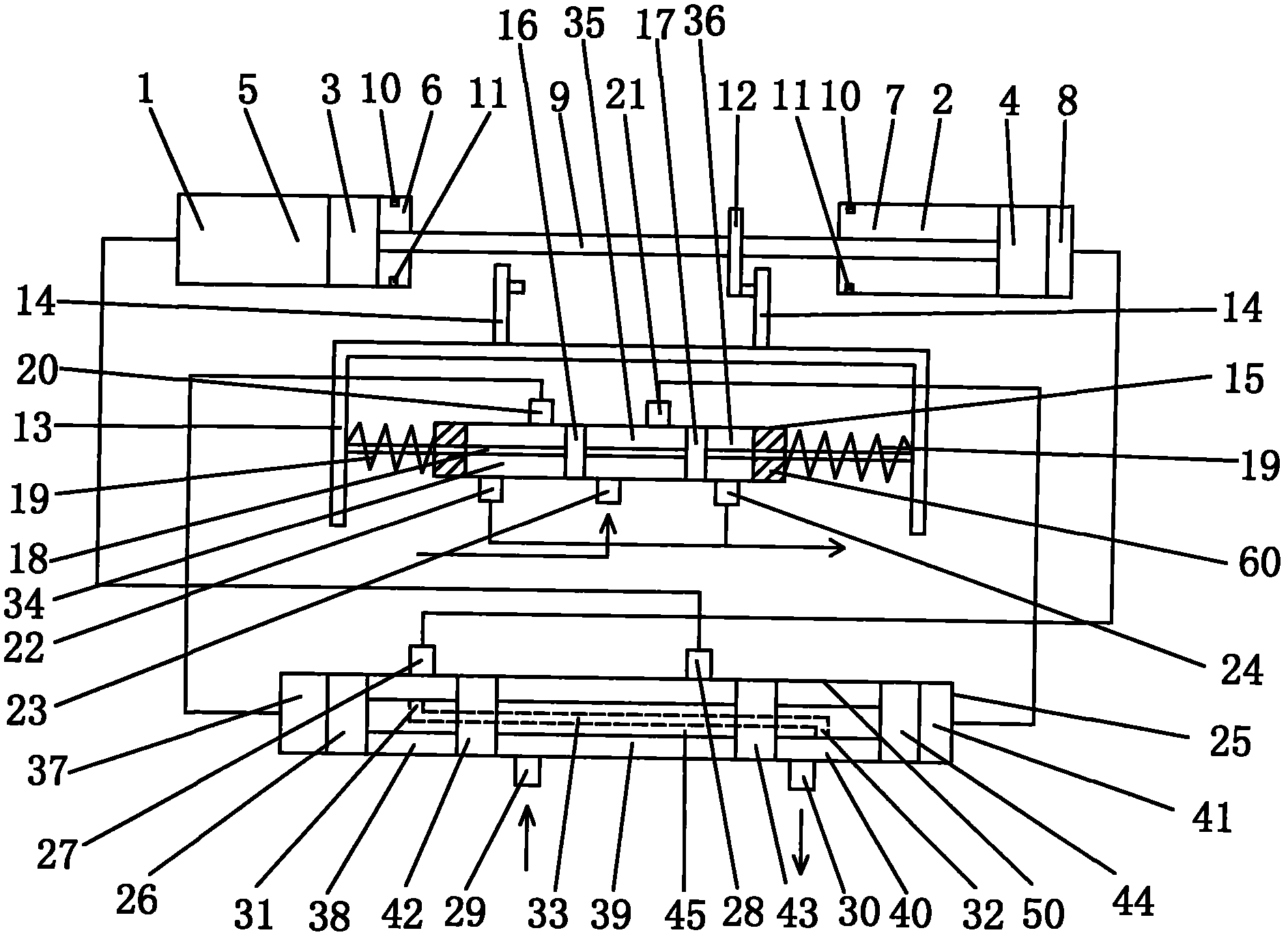

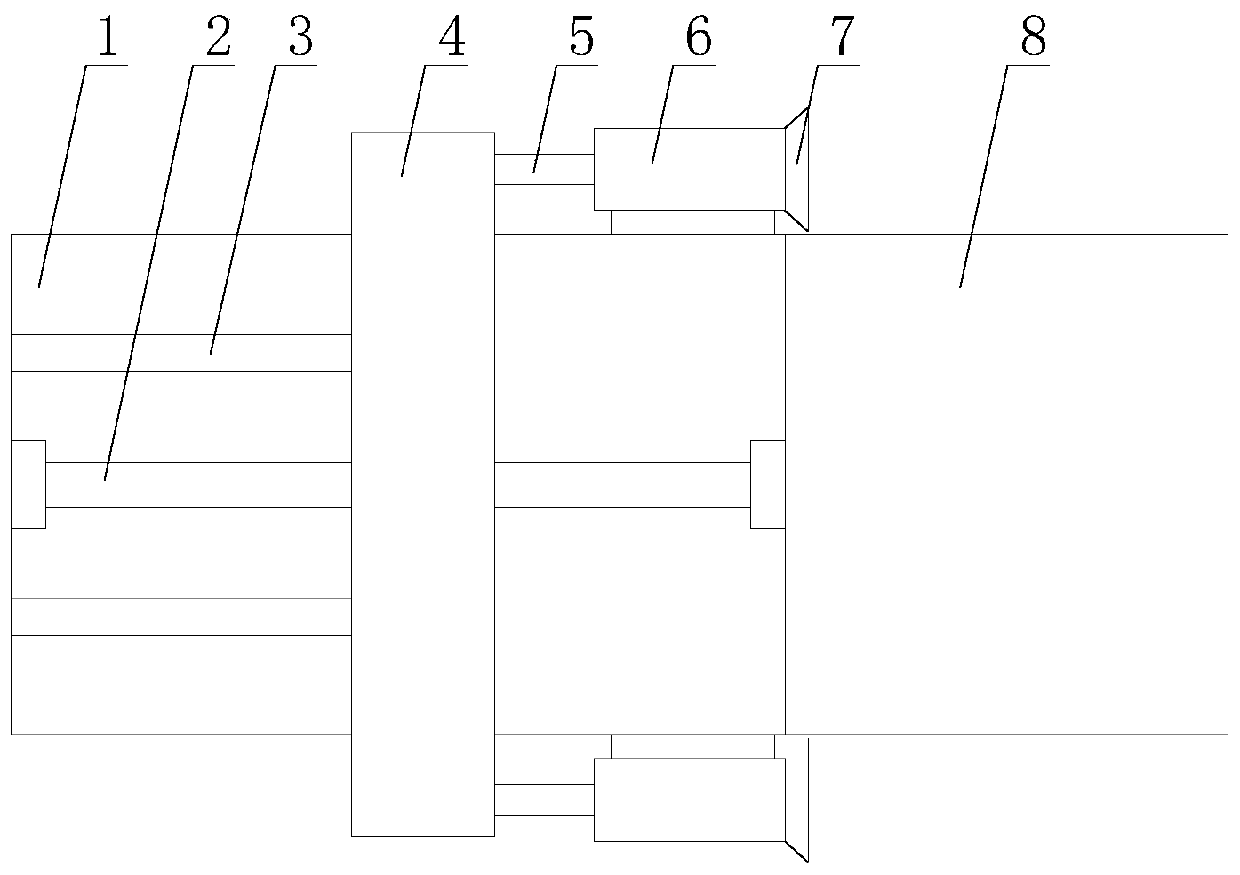

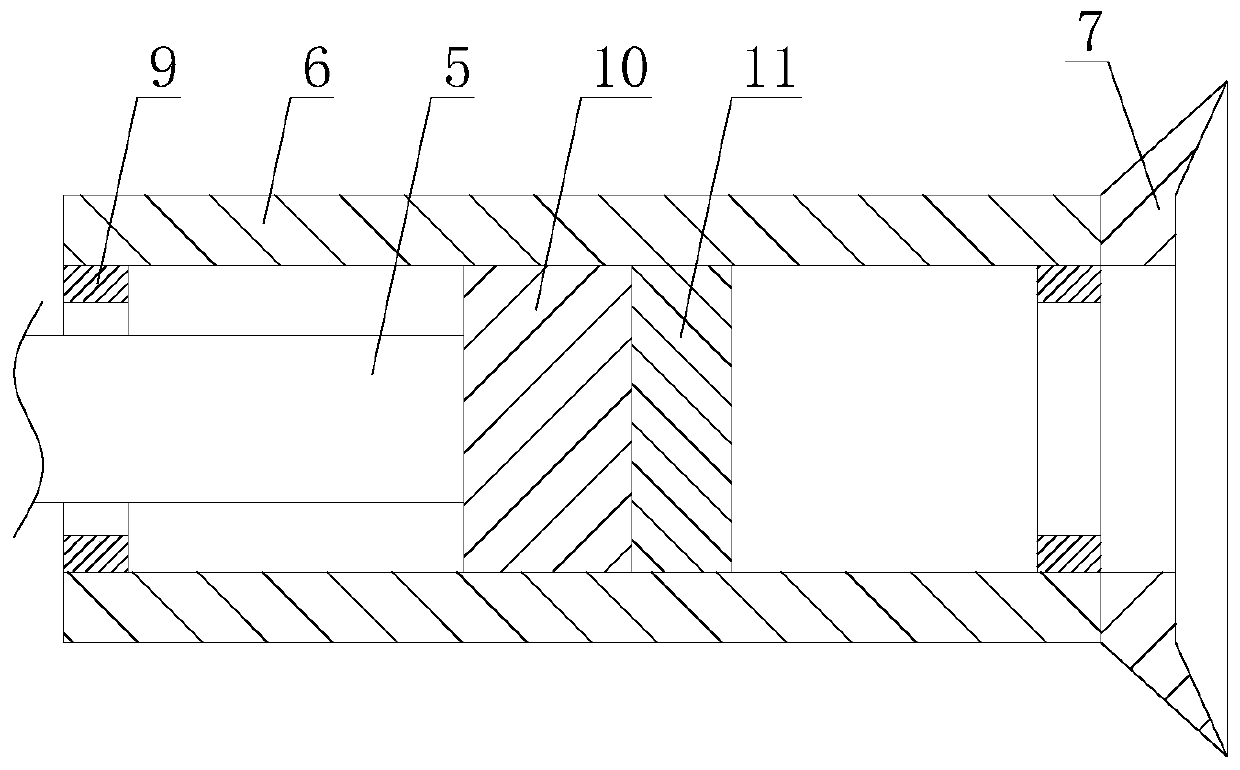

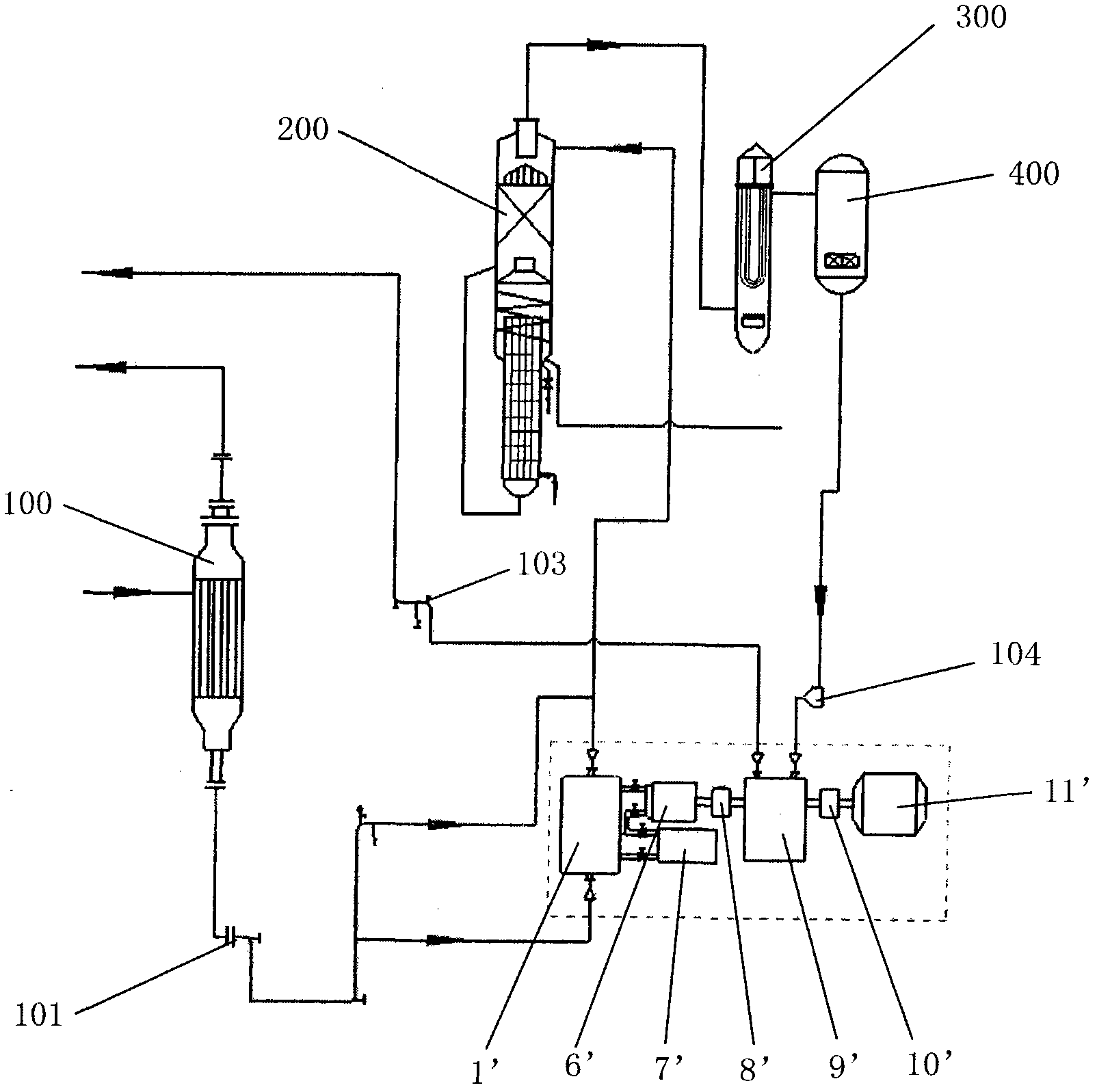

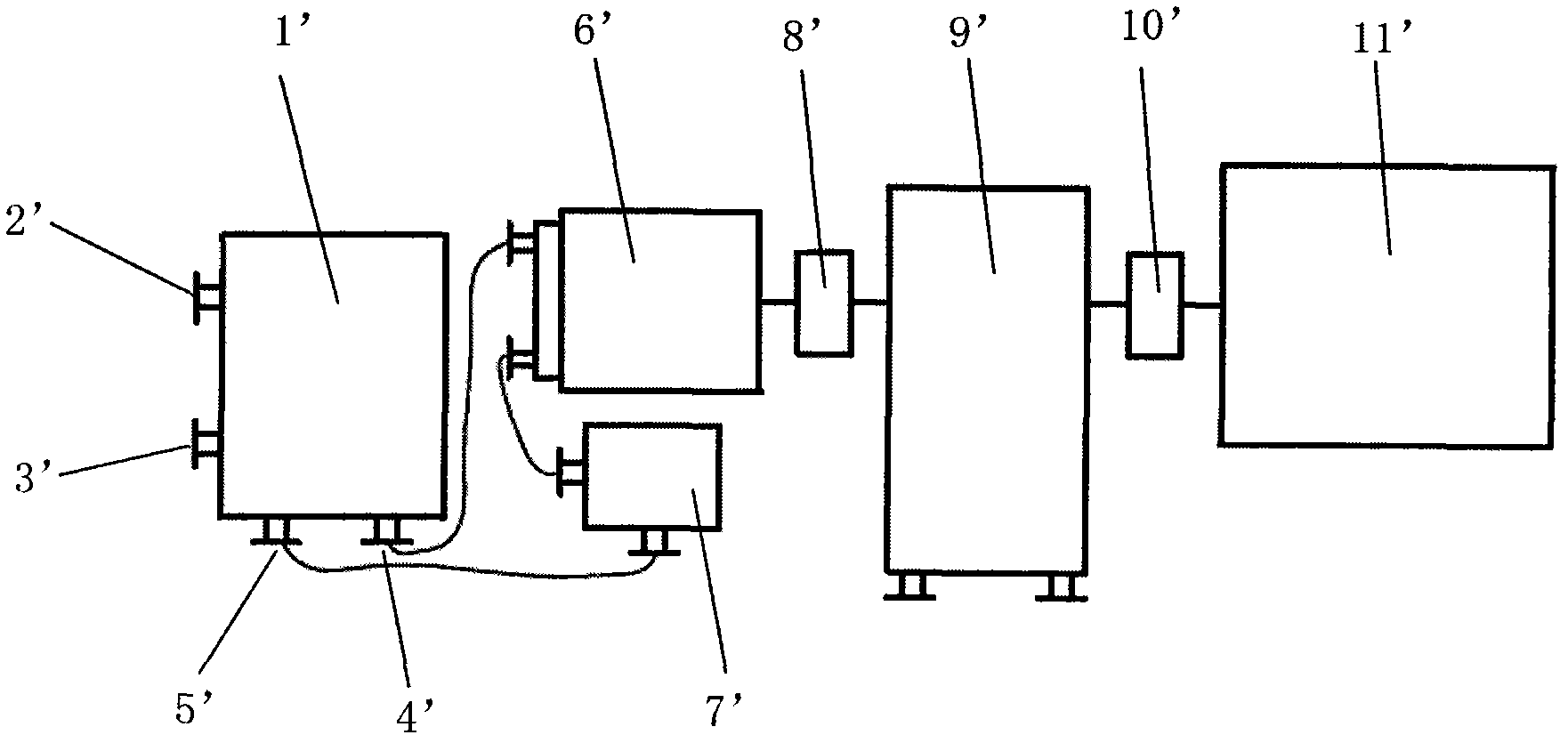

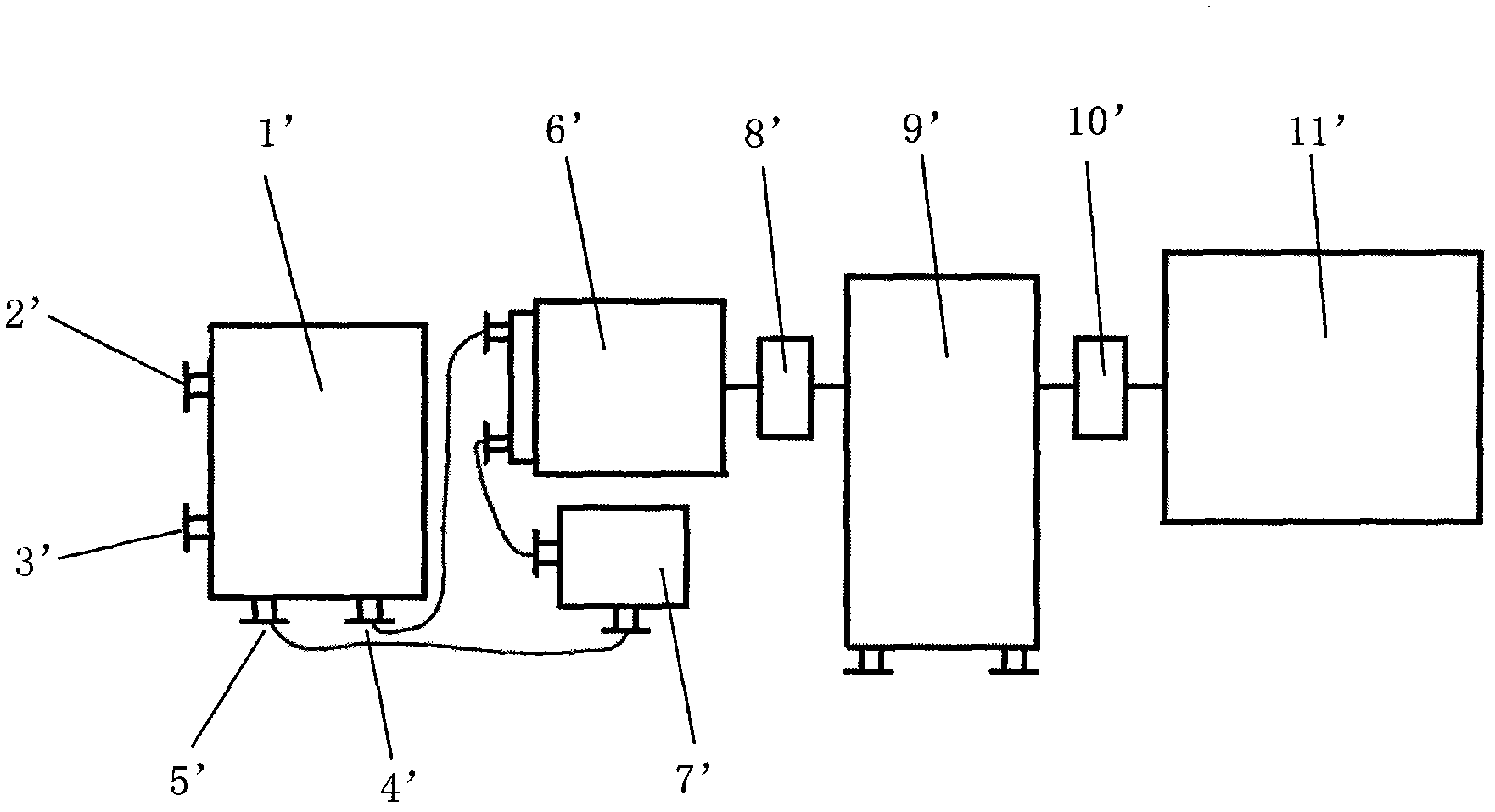

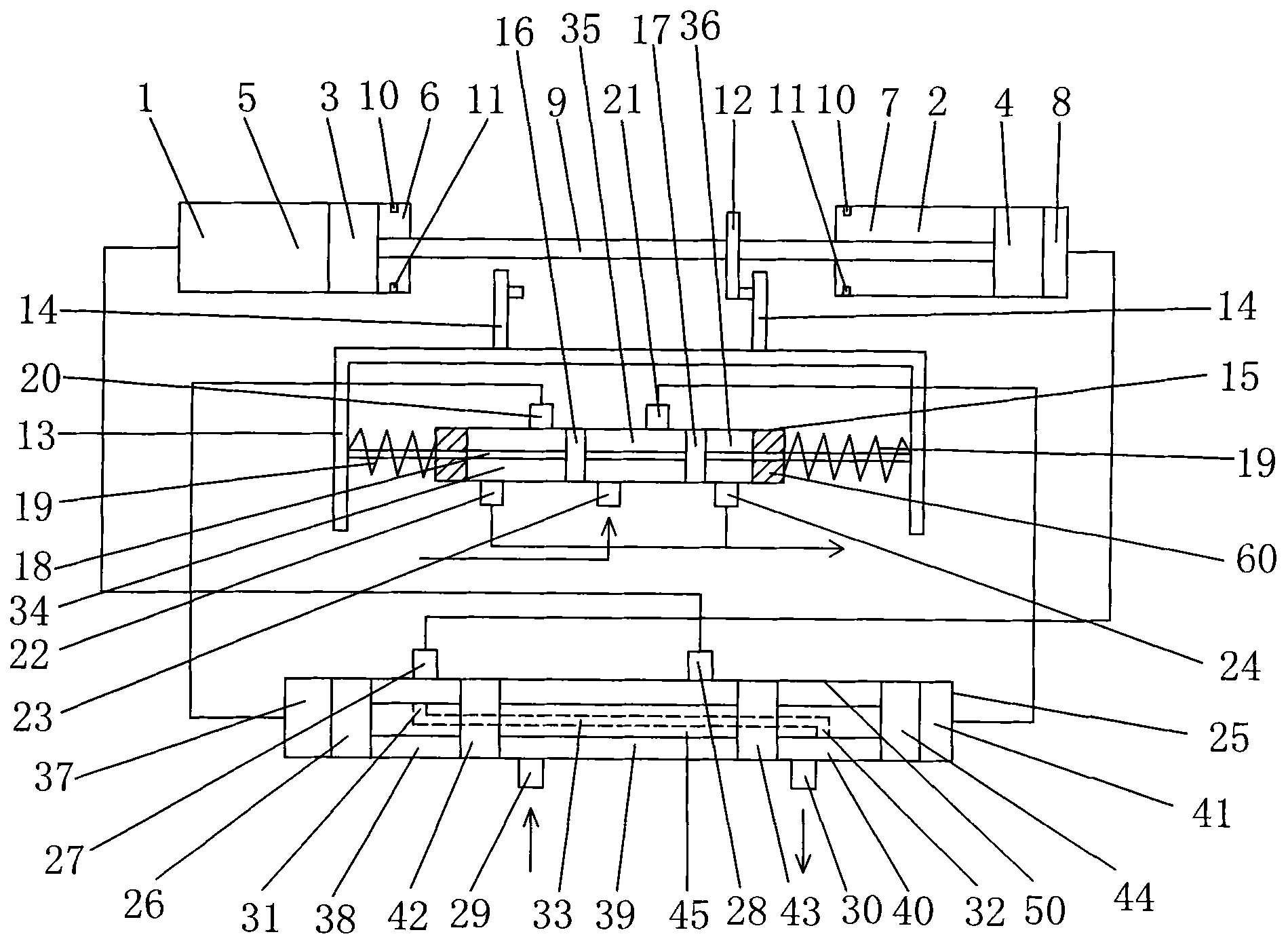

High-pressure energy recovering system for urea solution

InactiveCN102434544AImprove efficiencySimple and clear configurationProductsReagentsCarbamateFluid coupling

A high-pressure energy recovering system for urea solution is characterized by comprising a piston type exchanger with four ports, namely a high-pressure solution inlet, a high-pressure solution outlet, a hydraulic oil outlet and a hydraulic oil inlet. Two ports of a hydraulic motor are respectively connected with the hydraulic oil outlet and a port of a hydraulic oil tank, and the other port of the hydraulic oil tank is connected with the hydraulic oil inlet. The hydraulic motor is also sequentially connected with a fluid coupling, a high-pressure carbamate pump, a clutch and a variable frequency motor in series. The piston type exchanger comprises five pairs of piston cylinders and a steering system. The energy recovering system is simple in structure and capable of effectively converting high pressure energy generated in the production process of urea into kinetic energy so as to replace electric energy for driving the high-pressure carbamate pump to work normally, thereby saving electricity and reducing production cost.

Owner:季裕成

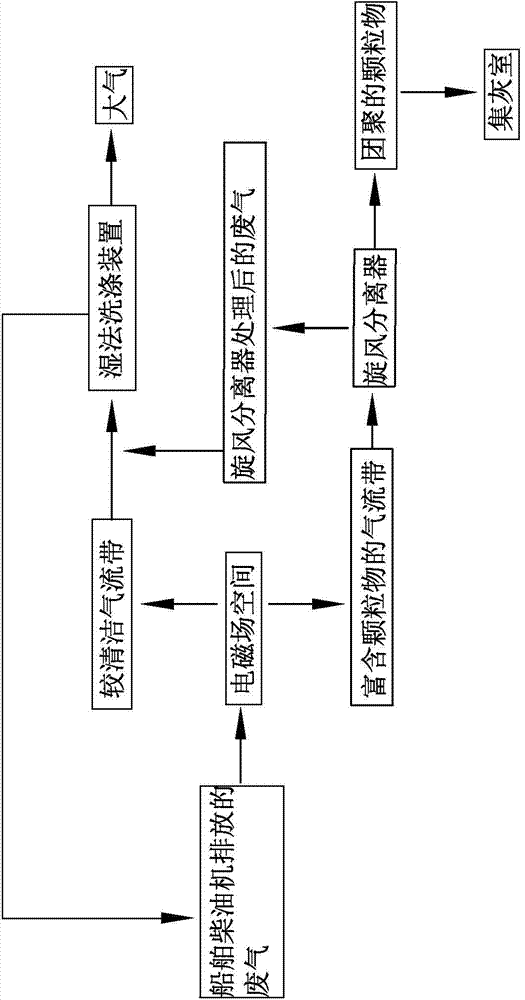

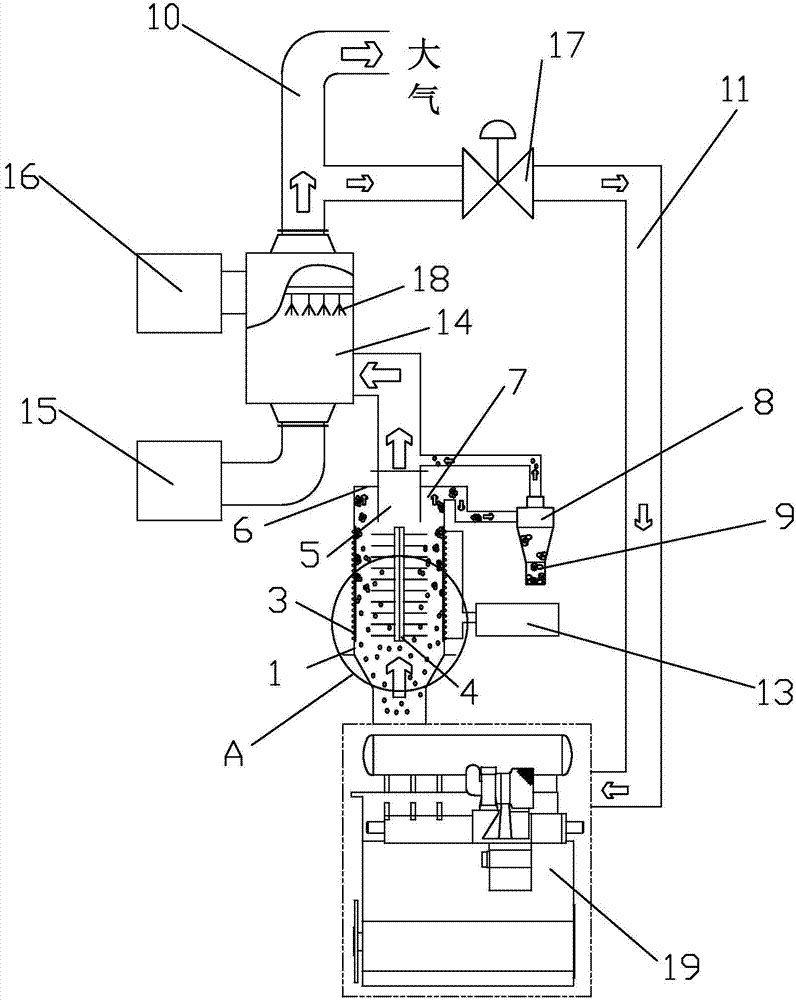

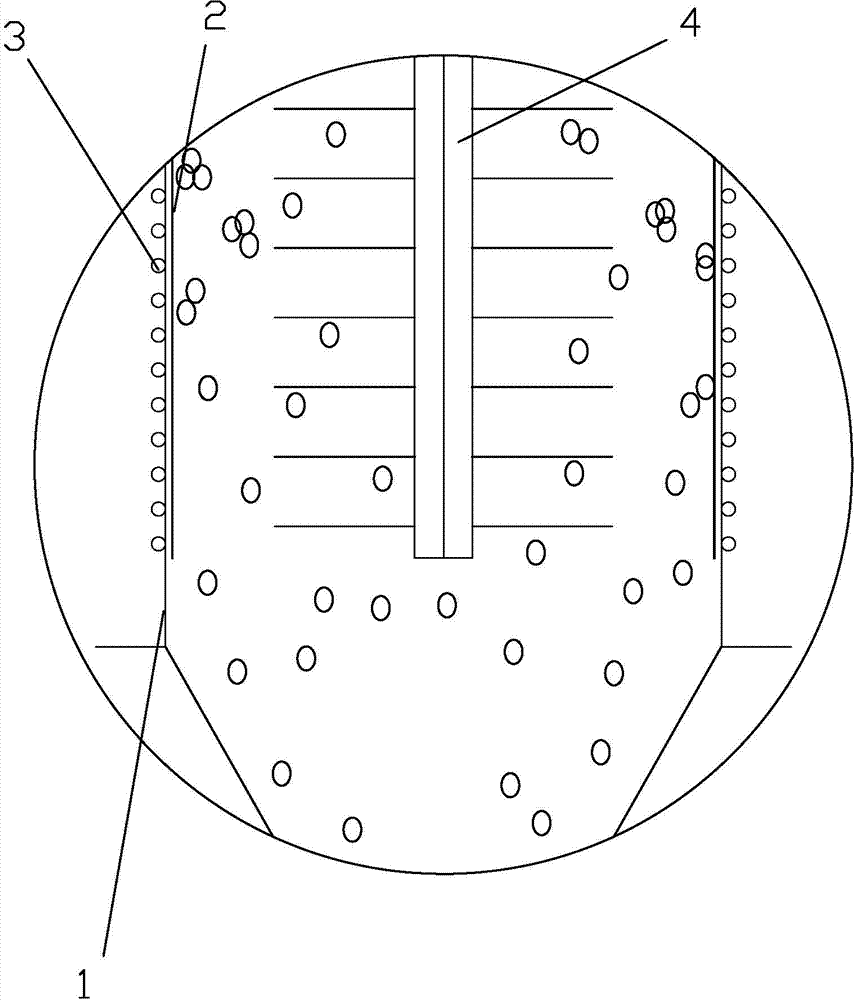

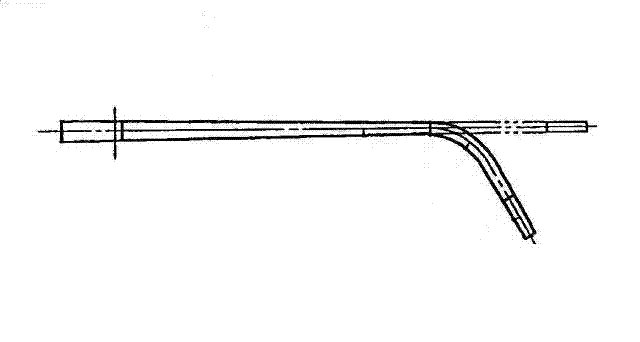

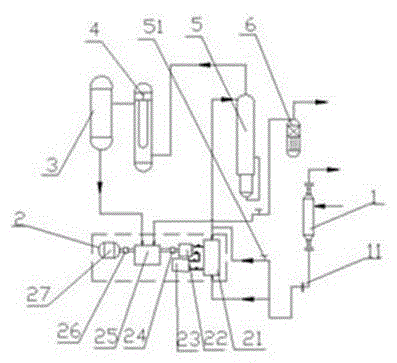

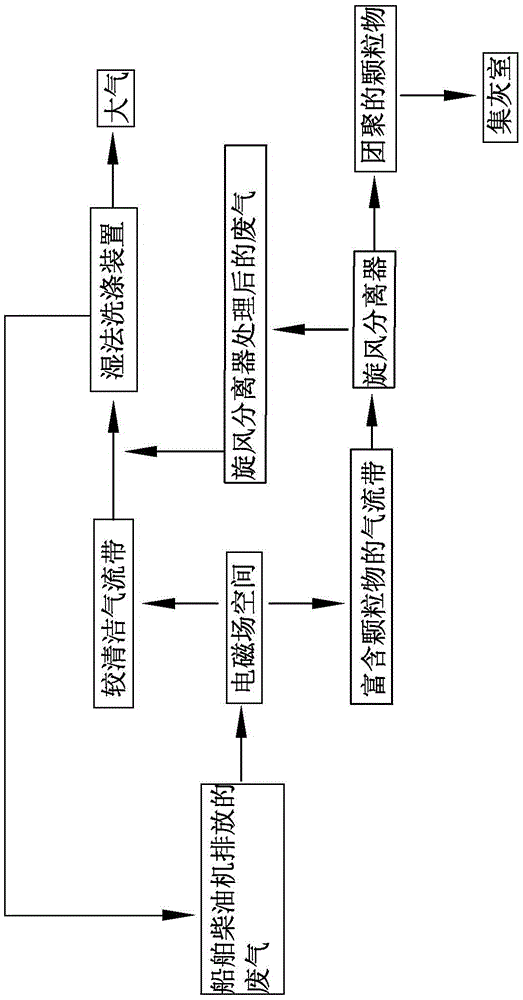

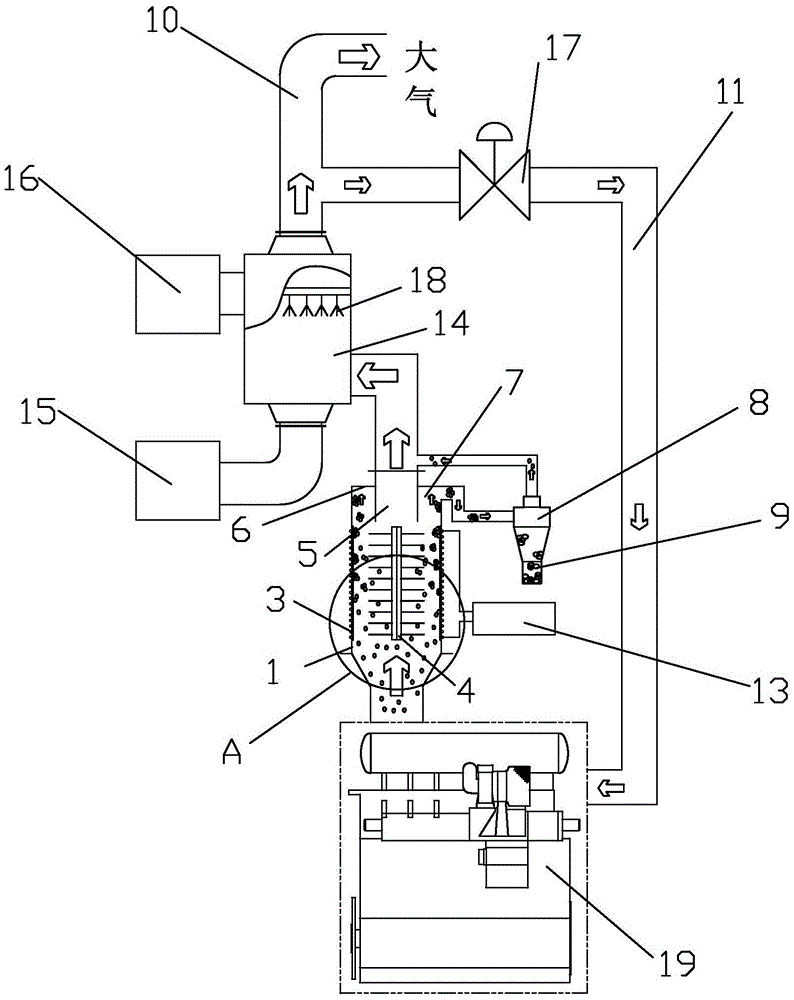

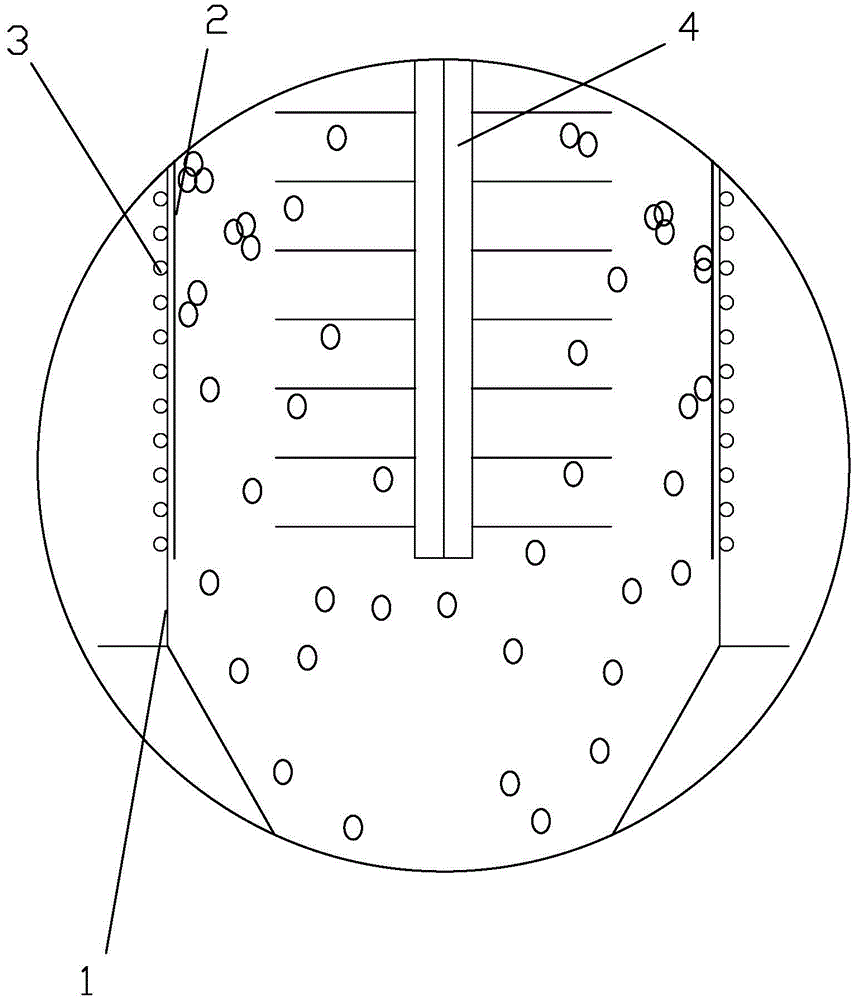

Novel ship exhaust gas multi-pollutant combined removing method and apparatus thereof

InactiveCN104492211AReduce volumeSmall pressure drop lossCombination devicesLiquid wasteParticulates

The invention discloses a novel ship exhaust gas multi-pollutant combined removing method. The novel ship exhaust gas multi-pollutant combined removing method comprises following steps: exhaust gas discharged by a ship diesel engine is delivered through an electromagnetic field, and is separated into relatively clean gas flow and particle-enriched gas flow; the particle-enriched gas flow is delivered into a cyclone separator, is processed, and then is mixed with the relatively clean gas flow; obtained gas flow is delivered into a wet washing device, and is processed using the wet washing device; a part of obtained waste gas is discharged into the air directly, and the other part of the obtained waste gas is delivered into the ship diesel engine via a recirculation bypass pipe. The invention also discloses a novel ship exhaust gas multi-pollutant combined removing apparatus comprising a cylindrical flue gas channel; and the wet washing device is communicated with the cyclone separator. The novel ship exhaust gas multi-pollutant combined removing method is capable of reducing secondary pollution of impurity components of waste liquid such as oil-containing particles on ocean environment, and separating recovery difficulty of solid particles, increasing clean degree of recirculated exhaust gas, and minimizing corrosion wearing of diesel engines.

Owner:DALIAN MARITIME UNIVERSITY

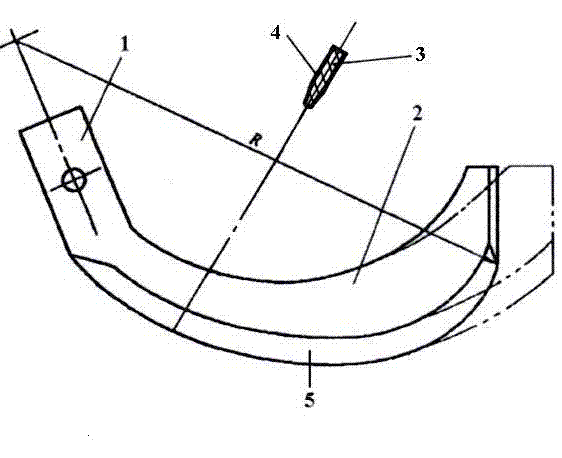

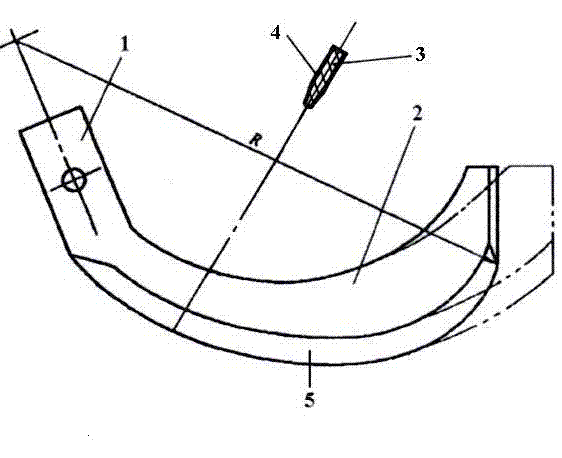

Re-manufacturable large tillage depth rotary tillage blade suitable for returning whole straws to field

The invention discloses a remanufacturable large tillage depth rotary tillage blade suitable for returning whole straws to a field. The blade provided by the invention is characterized in that the blade point rotation radius R is not less than 280 millimeters, and is manufactured through the following steps: firstly forging 65Mn or 60Si2Mn utilized as a raw material to obtain a blank satisfying the requirements on size and shape; then carrying out whole hot dipping on the blank; forming a hot-dipped hardened layer with the depth of 10-150 microns and the hardness no less than 1000HV to obtainan intermediate blank the whole surface of which is provided with the hardened layer; and thirdly, carrying out heat treatment on the intermediate blank the whole surface of which is provided with the hardened layer, wherein the heat treatment process comprises whole quenching and medium temperature tempering, so as to obtain a large tillage depth rotary tillage blade the center of which is tempering troostite and the surface of which is the hot-dipped hardened layer. The rotary tillage blade provided by the invention has the characteristics of high-strength surface, high tenacity, high strength, capability of ensuring the requirement on one-time continuous or 150-hour 20cm large tillage rotary tillage operation; and meanwhile, the rotary tillage blade can be repeatedly manufactured, thusgreatly lowering the comprehensive cost of the rotary tillage blade.

Owner:JIANGSU UNIV

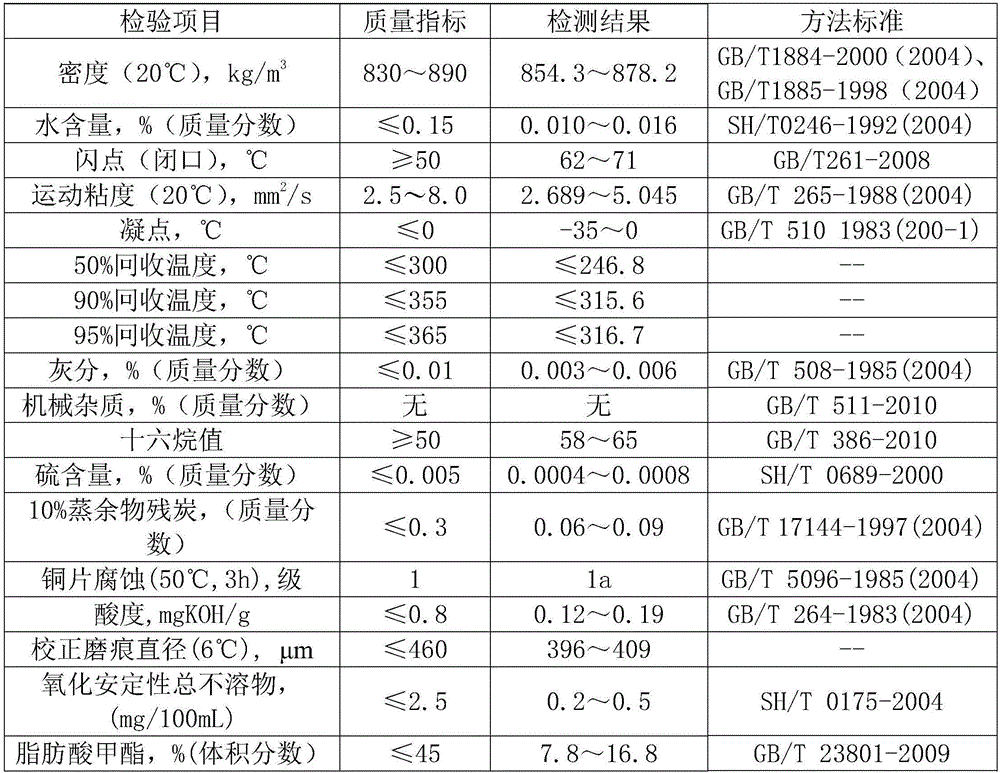

Coal-based biofuel for vehicle

The invention belongs to the technical field of fuel, and particularly relates to coal-based biofuel for a vehicle. The coal-based biofuel is prepared from the following raw materials in percentage by mass: 35 to 45 percent of fatty acid methyl ester, 10 to 15 percent of alcohol and the balance of hydrogenization coal tar; the total mass percentage is 100 percent. The coal-based biofuel for the vehicle has the advantages that the raw material matching is simple; crude oil resources are not needed; diesel oil can be replaced for hundred percent; the hexadecane number is high; the thermal value is high; the power is strong; the combustion is sufficient; the tail gas exhaust quantity is low; all technical indexes reach or exceed the national standard.

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

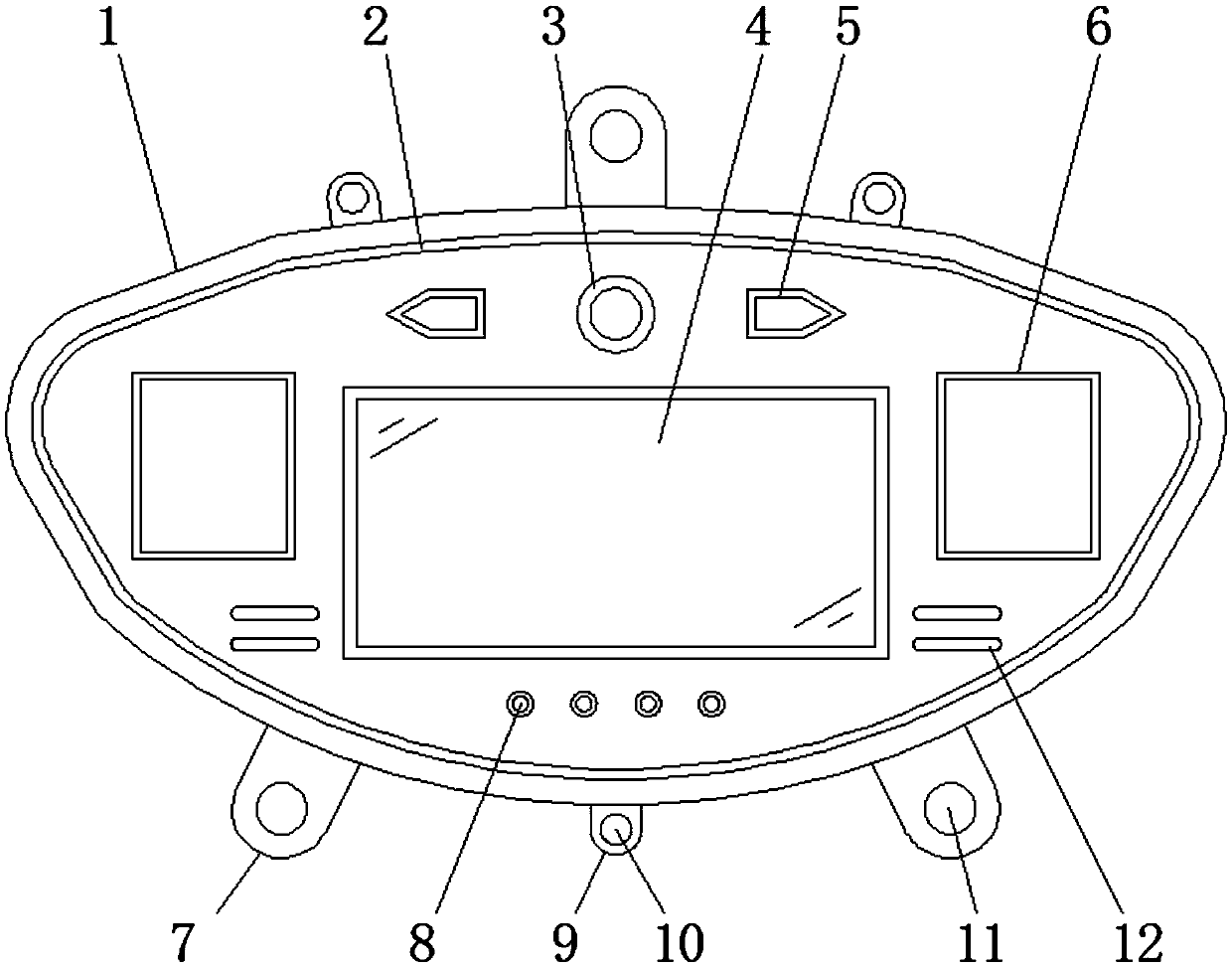

Instrument for electric bicycle

PendingCN111332393AEasy to fixEasy to disassemble and fixCycle equipmentsModifications for power electronicsLED displayEngineering

The invention discloses an instrument for an electric bicycle. The instrument comprises an instrument base, a protective cover, an LED display screen and a fixing base. A fixed seat is arranged in thecenter of one side of the protective cover; a single-chip microcomputer and an exhaust fan are arranged at the two ends of one side of the interior of the instrument base correspondingly. An LED display screen is arranged in the center of the other side of the instrument seat; an illuminating lamp is arranged on the instrument base on one side of the LED display screen, direction lamps are arranged on the instrument base at the two ends of the illuminating lamp, display lamps are evenly arranged on the instrument base on the other side of the LED display screen, and a protective cover is fixed to the outer side of the instrument base on one side of the LED display screen through a clamping block. By installing the instrument base, the protective cover, the fixing part, the connecting partand the fixing base, the instrument base and the protective cover can be fixedly disassembled and assembled conveniently through cooperation of the connecting part and the locking bolt, the instrument base, the handlebar and the frame can be fixedly arranged conveniently through the fixing part and the fixing base, the device can be arranged and disassembled conveniently, and disassembly, assembly and maintenance of the device are facilitated.

Owner:NANJING DMHC SCI & TECH CO LTD

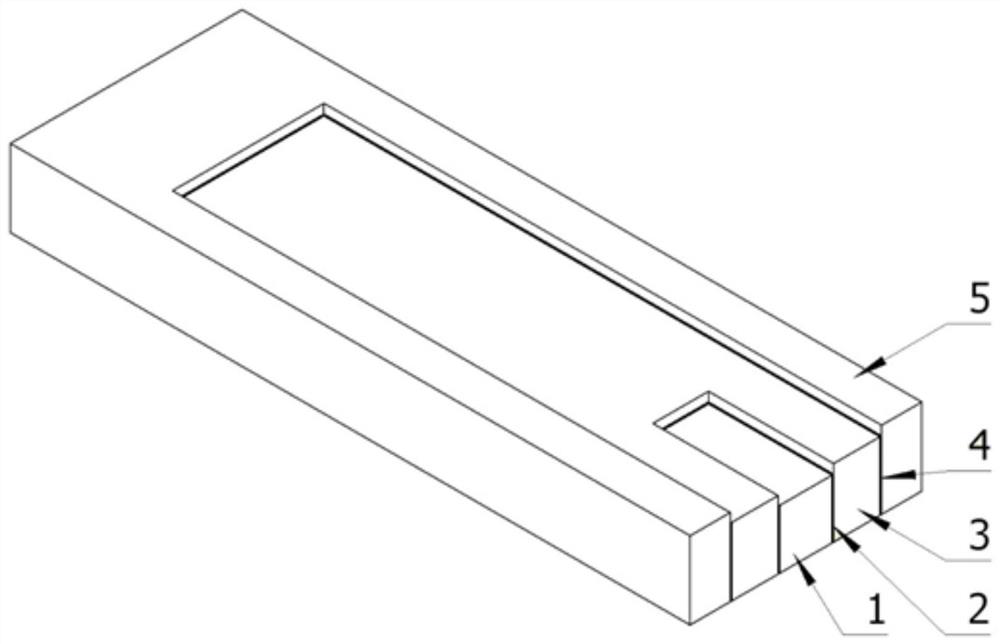

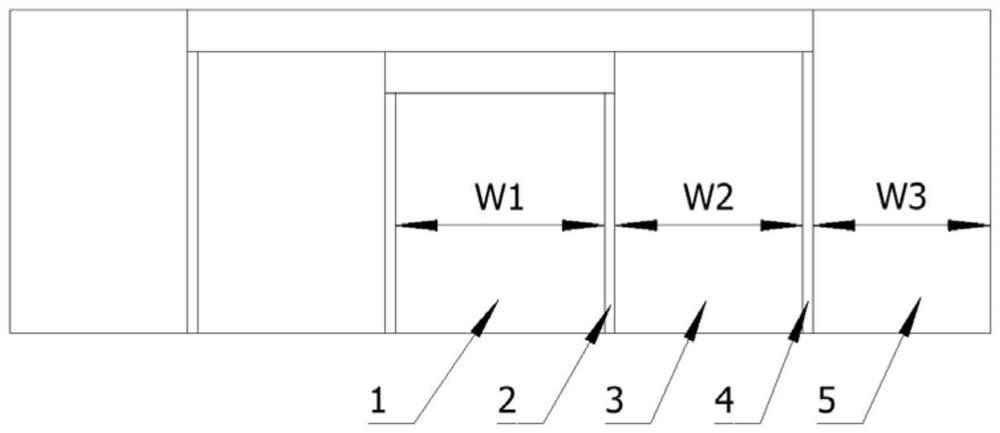

5G wireless network card with protection function and firm plug-in connection

InactiveCN110099463AImprove practicalitySimple structureCouplings bases/casesCoupling parts mountingProtection mechanismEngineering

The invention relates to a 5G wireless network card with a protection function and firm plug-in connection. The 5G wireless network comprises a main body, a USB connector, a connecting mechanism and aprotection mechanism. The connecting mechanism comprises a moving ring, an elastic rope and two adsorption assemblies. Each adsorption assembly comprises a suction pipe, a transmission rod, a pistonblock and a suction cup. The protection mechanism comprises a protection cover and two connection assemblies. Each connecting assembly comprises a moving block, a spring, a connecting line and a strip-shaped hole. According to the 5G wireless network card with the protection function and firm plug-in connection, the wireless network card is adsorbed on a computer through the connecting mechanism,the stability of connection between the wireless network card and a computer is improved, and the practicability of the wireless network card is improved; through the protection effect of the protection mechanism, abrasion and corrosion of the USB connector are relieved, the service life of the USB connector is prolonged, and the practicability of the wireless network card is further improved.

Owner:SHENZHEN LVYUAN HUIZHI TECH CO LTD

High-wear-resistance composite material for preparing porcelain teeth and preparation method of high-wear-resistance composite material

ActiveCN114804863AReduce corrosion wearExtend the life cycleImpression capsDentistry preparationsArtificial salivasSilver preparation

The invention relates to the technical field of medical materials, in particular to a high-wear-resistance composite material for preparing porcelain teeth and a preparation method of the high-wear-resistance composite material. The high-wear-resistance composite material is prepared from the following raw materials in parts by weight: 20 to 30 parts of metal oxygen compound, 8 to 15 parts of metal nitride whisker, 18 to 30 parts of titanium dioxide, 10 to 30 parts of silicon dioxide, 30 to 40 parts of zirconium dioxide, 5 to 8 parts of silver preparation, 120 to 160 parts of 80% ethanol and 50 to 70 parts of deionized water. The titanium dioxide modified by the titanate coupling agent is added, so that the corrosive wear of the artificial saliva to the porcelain tooth material can be slowed down to a certain extent, and the life cycle of the porcelain tooth is prolonged; the silane coupling agent modified zirconium dioxide is added, so that the mechanical property of the porcelain tooth material can be enhanced, and the porcelain tooth material can meet the use requirements of people in daily life.

Owner:中山市邦特生物科技有限公司

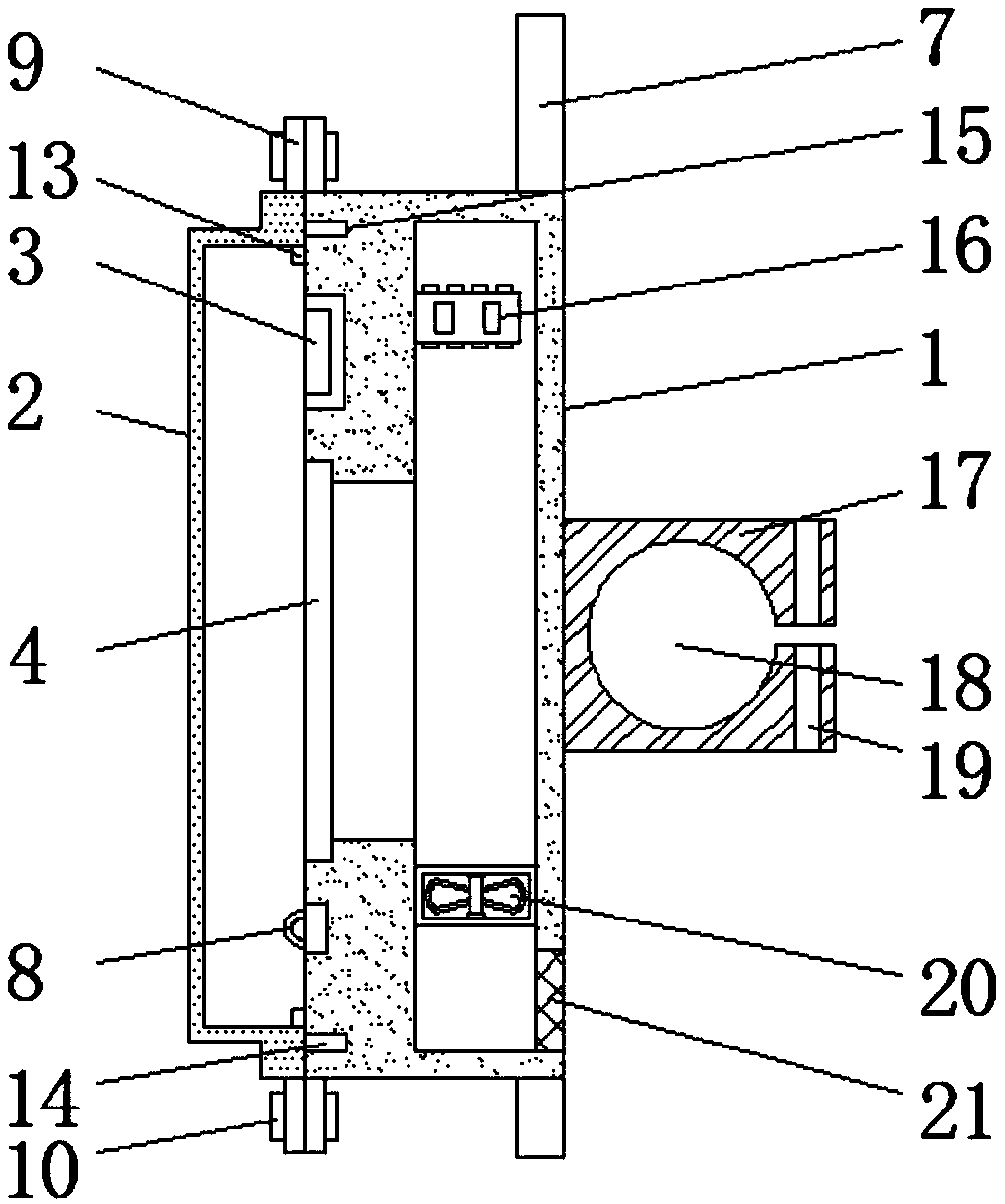

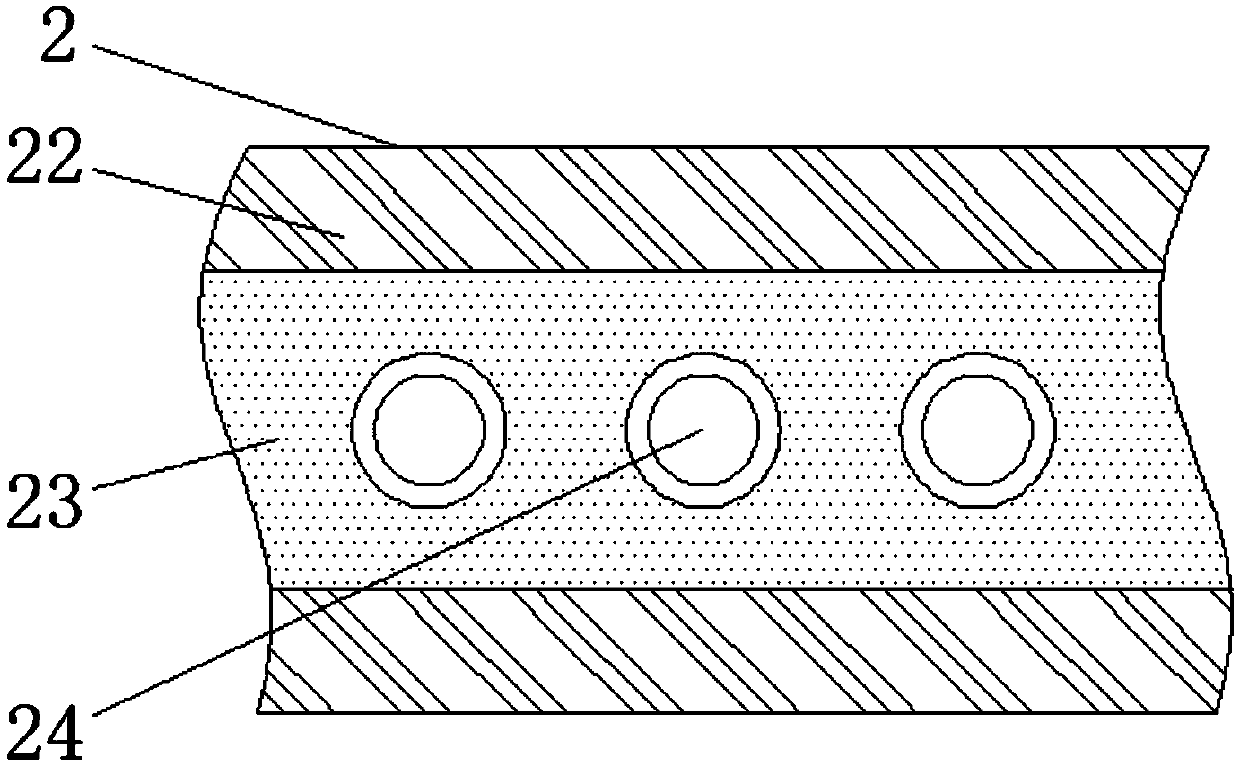

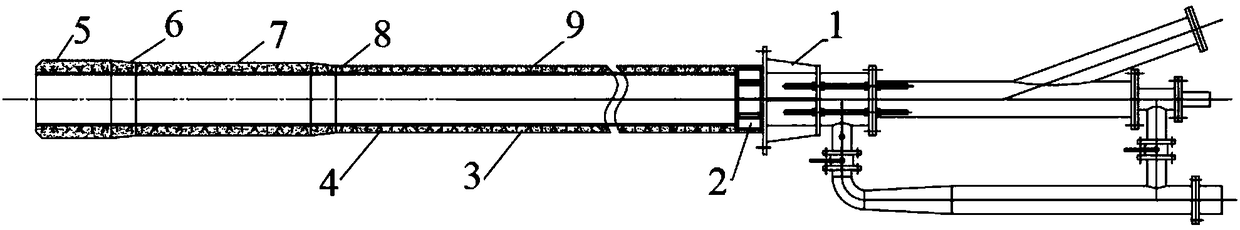

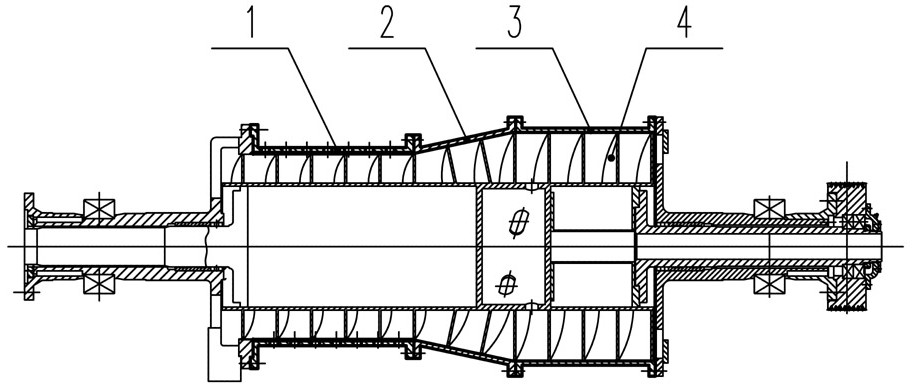

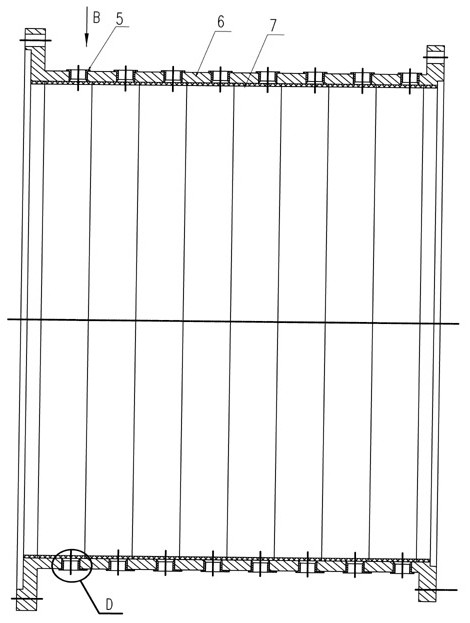

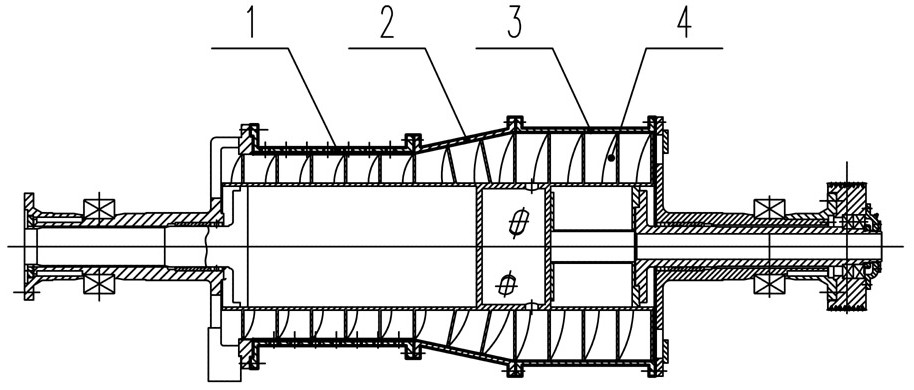

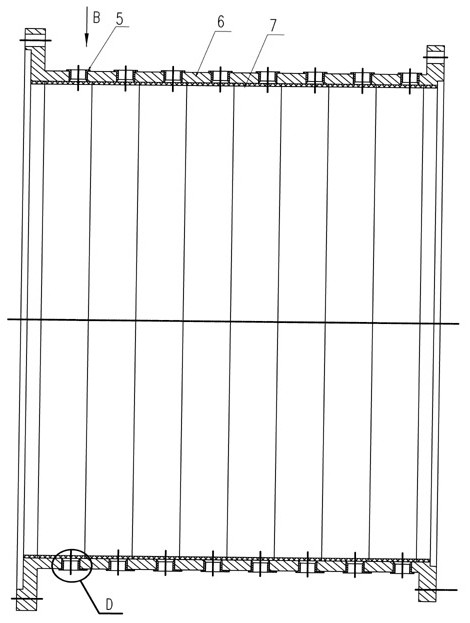

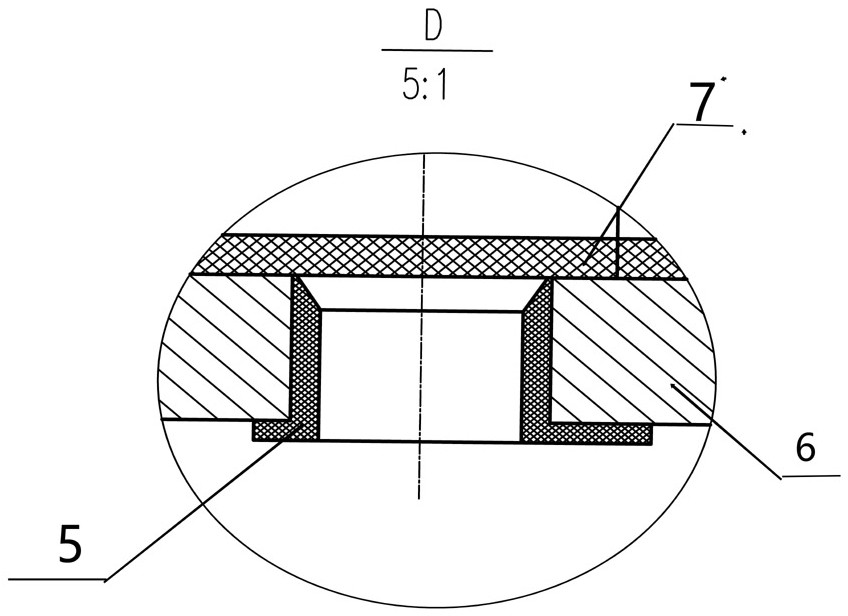

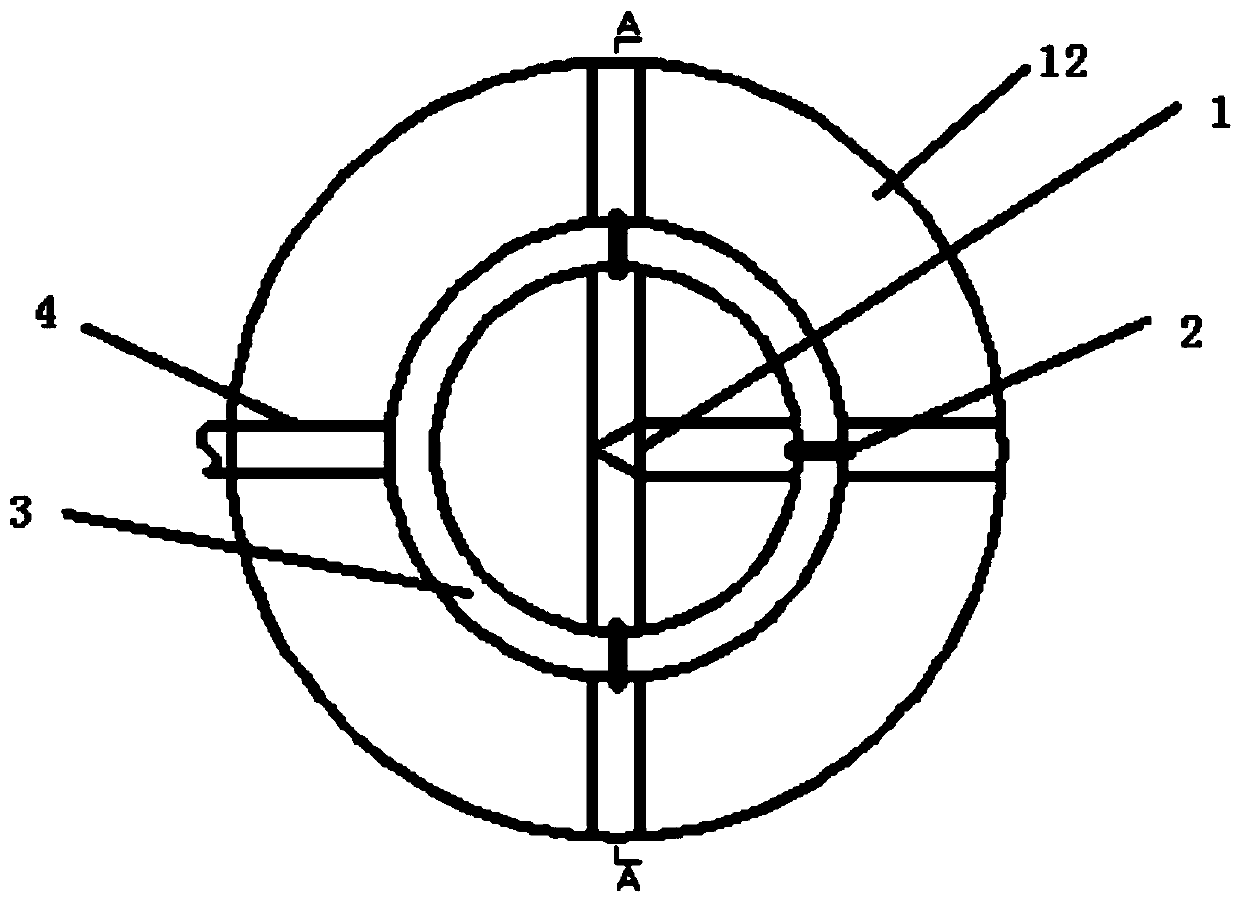

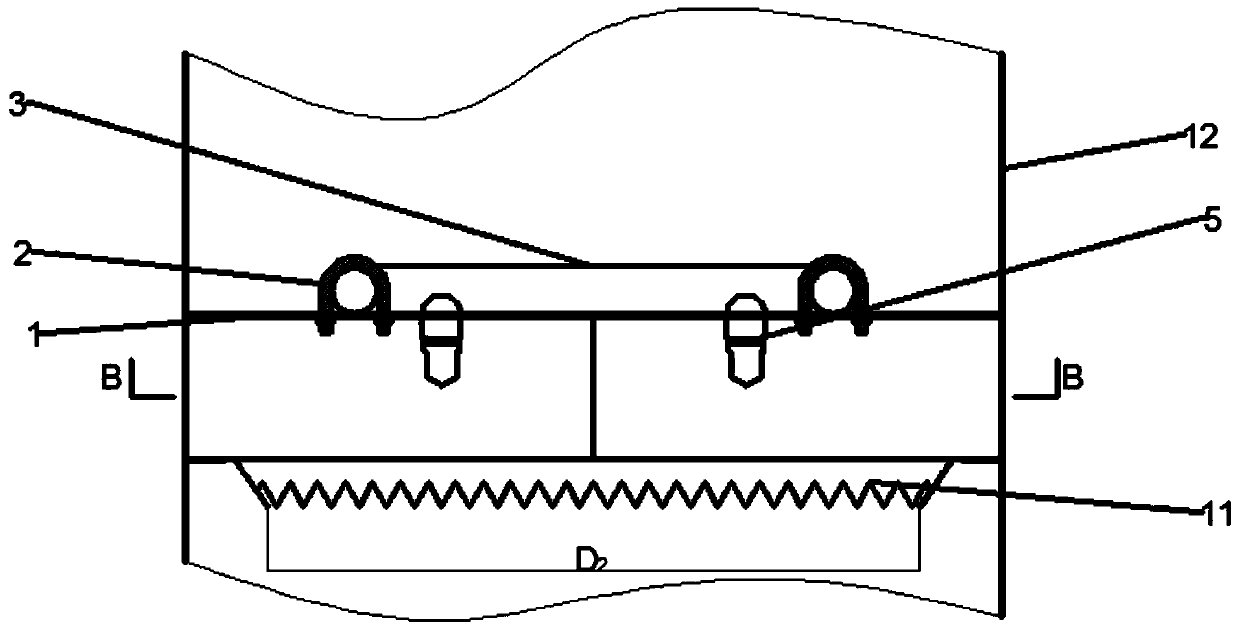

Mold for vertical stepped pouring of rotary kiln burner and pouring method of mold

ActiveCN108214871AReduce washoutReduce corrosion wearMouldsSurface layering apparatusMaterials scienceRotary kiln

The invention relates to a mold for vertical stepped pouring of a rotary kiln burner. The mold includes five segments, namely, mold I, reducing mold II, mold II, reducing mold II and mold III from front to rear from the end of the rotary kiln burner, wherein the mold I is positioned at the end of the burner, and the end of the mold I is chamfered to 45 degrees, the reducing mold I is connected with the mold I, the mold II is connected with the reducing mold I, the reducing mold II is connected with the mold II, and the mold III is positioned behind the reducing mold II until the rear of the burner. The invention further relates to a vertical stepped pouring method of a rotary kiln burner, using the mold herein.

Owner:HANDAN JINYU TAIHANG CEMENT

Urea production line

InactiveCN104478761ARun satisfiesSimple and clear configurationUrea derivatives preparationProductsProduction lineDecomposition

A urea production line is disclosed. An outlet of a gas stripping tower is respectively connected with an energy recovery device and a low-pressure decomposition tower. An outlet of the low-pressure decomposition tower is connected with an inlet of a low-pressure methylamine condenser, an outlet of which is connected with a level tank and low-pressure absorber. An outlet of the level tank and low-pressure absorber is connected with an inlet of a high-pressure methylamine pump in the energy recovery device. An outlet of the high-pressure methylamine pump is connected with a high-pressure methylamine condenser. High pressure energy generated during the production process of urea is recovered and converted to kinetic energy used for a production system for producing urea. Thus, consumption of electric energy during the production process is minimized, and production cost is reduced.

Owner:JIANGSU FEIXIANG PUMP IND MFG CO LTD

A combined removal method and device for multiple pollutants in ship exhaust gas

InactiveCN104492211BReduce volumeSmall pressure drop lossCombination devicesParticulatesLiquid waste

Owner:DALIAN MARITIME UNIVERSITY

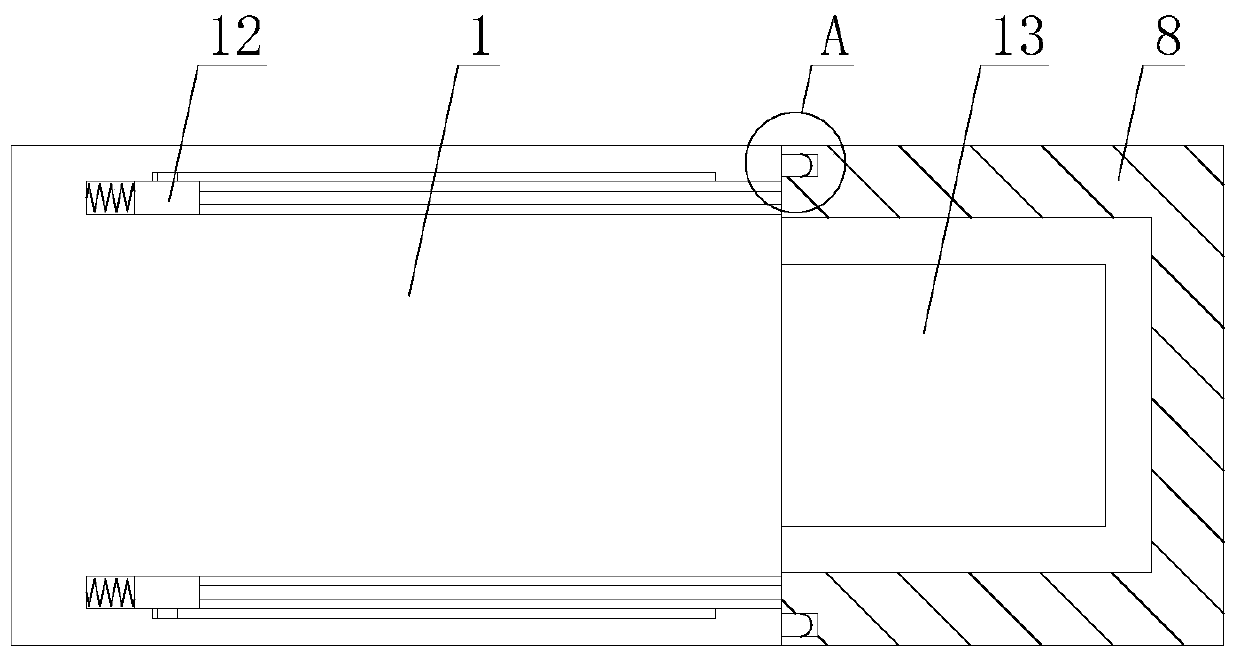

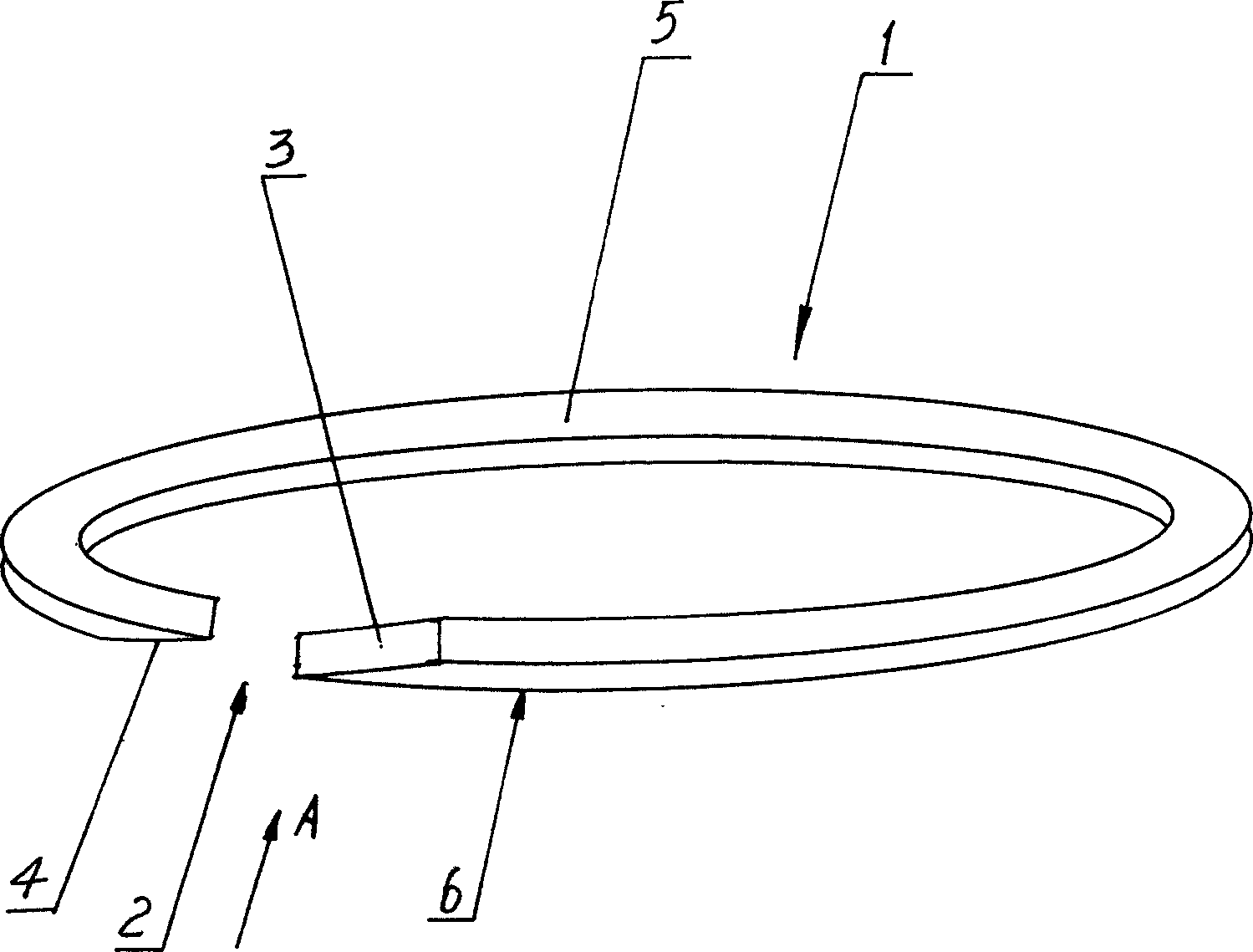

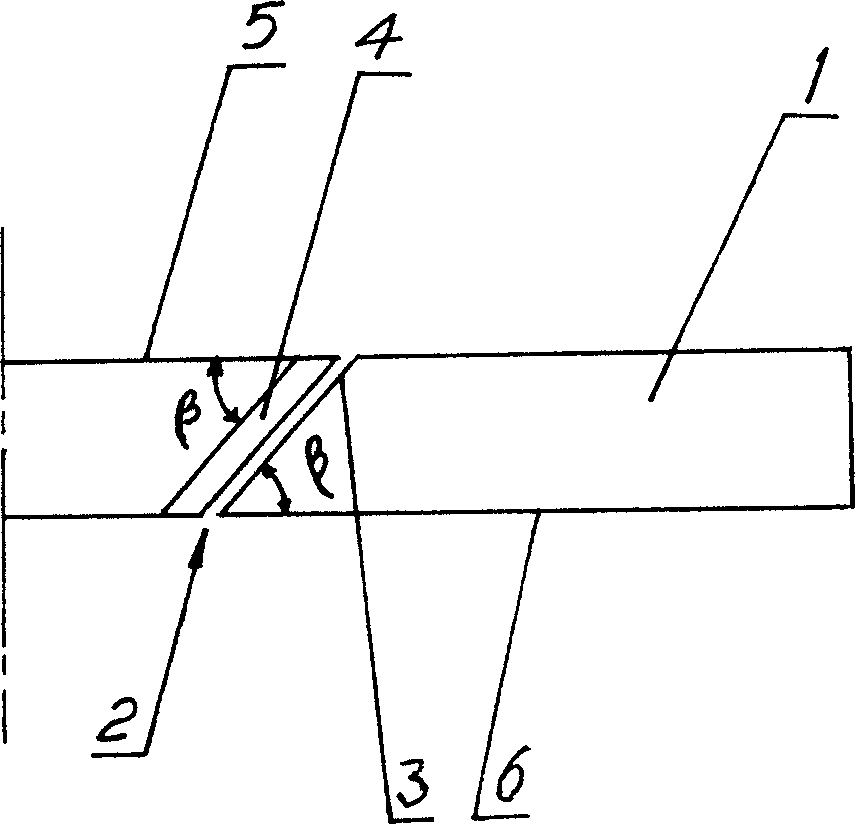

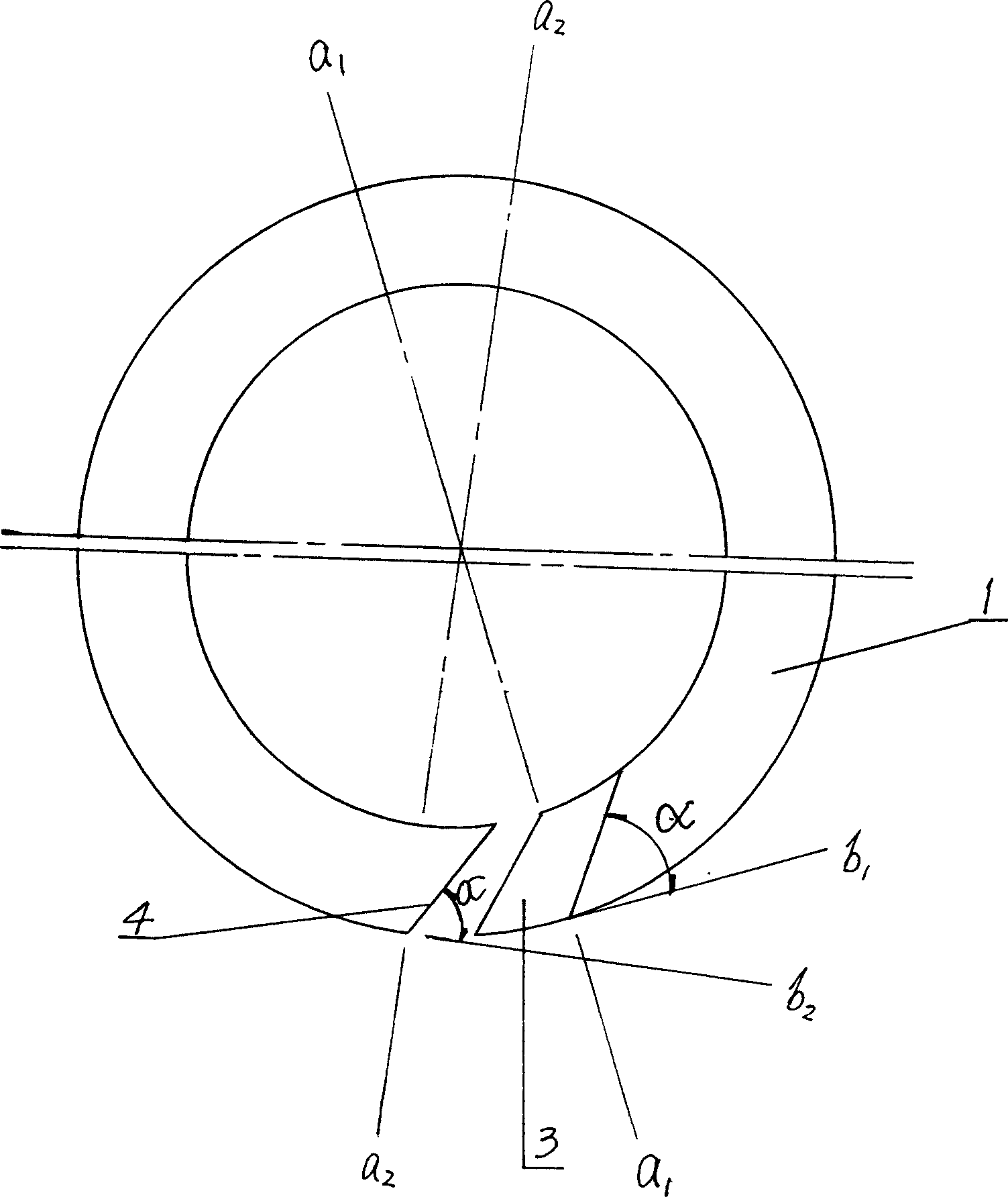

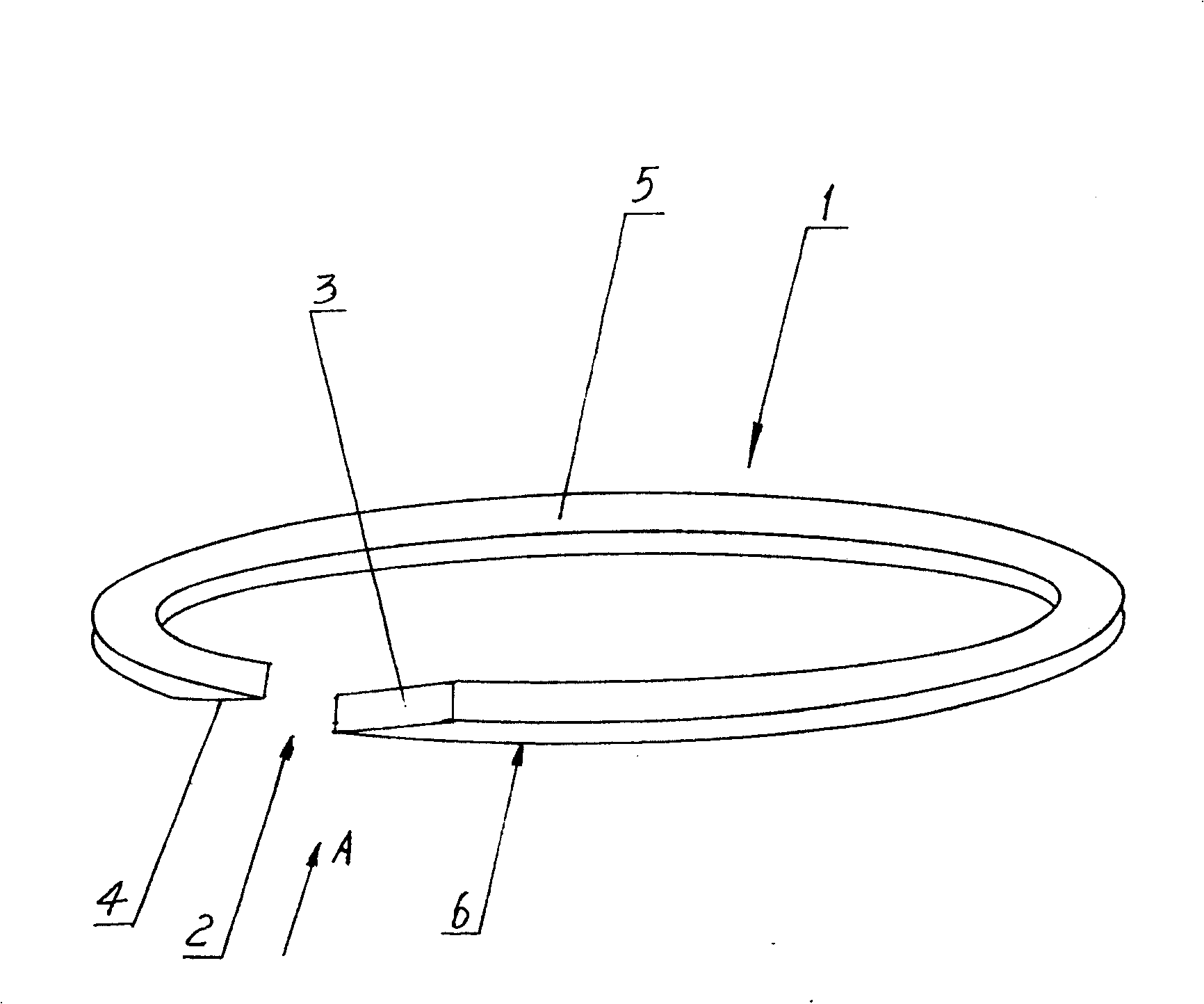

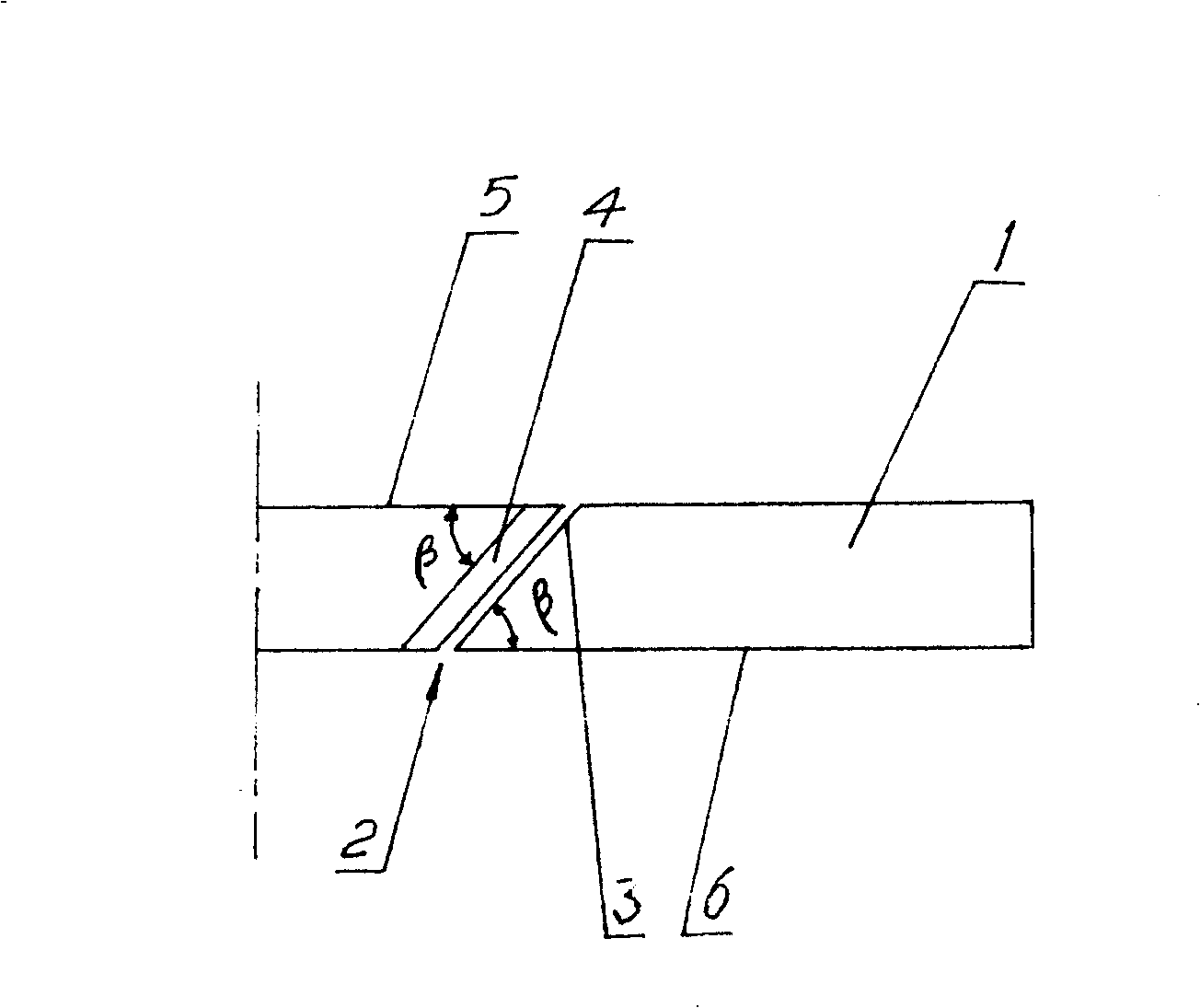

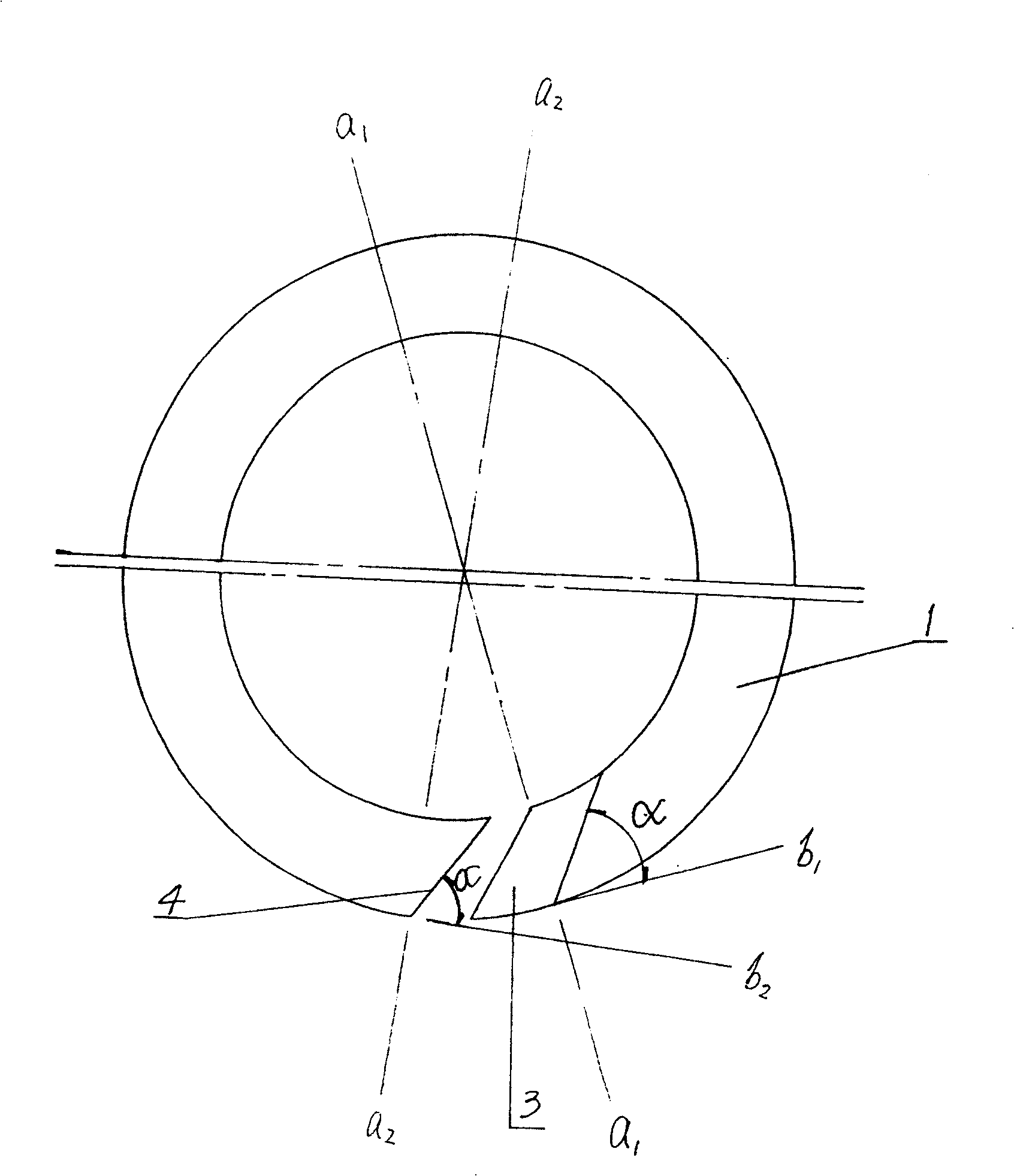

Piston ring for automatically closing and adjusting clearance

InactiveCN1544805ASolve the problem of air leakageSolve the phenomenon of eccentric wearPiston ringsMachines/enginesPiston ringEngineering

The invention discloses a Cr plating hanger of inner holes of cylinder sleeve, composed of anode, cathode guide rod, anode insulating sleeve, primary guide ring, and clamp ring and screw of cylinder sleeve, where the anode insulating sleeve is set with top power line shield cap, the bottom end of the anode is set with bottom power line shield disc, the anode is set with holes, the outer diameter at the bottom end of the anode is less than that on the top, there is an anode positive sleeve fixed with the cathode outside the top of the anode, there is a gas roundabout cavity formed between the top power line shield cap and the primary guide ring. It has the characters of fixed position of cathode and anode, high plating efficiency, accurate positioning cylinder sleeve, a little deformation, etc.

Owner:张有汉

Re-manufacturable large tillage depth rotary tillage blade suitable for returning whole straws to field

InactiveCN102224773BCut soil sharpReduce resistanceTilling equipmentsTemperingAgricultural engineering

A remanufacturable large-plow deep-plow rotary tiller suitable for full straw returning to the field is characterized in that its turning radius R of the knife tip is not less than 280 mm, and it is manufactured by the following method: first, use 65Mn or 60Si2Mn As a raw material, a billet that meets the size and shape requirements is obtained by forging; then, the obtained billet is subjected to an overall hot-impregnation treatment, and a layer of hot-dipping hardened layer with a depth of 10-150 microns and a hardness of not less than 1000HV is formed on the billet surface as a whole. Obtain an intermediate blank with a hardened layer on the entire surface; thirdly, heat treat the intermediate blank with a hardened layer on the entire surface. The heat treatment process is overall quenching+medium temperature tempering, so that the core is tempered troostite and the surface is hot. Deep tillage rotary blade for impregnating the hardened layer. The rotary tiller of the present invention has the characteristics of high hardness on the surface, high toughness and high strength of the core, which can meet the needs of a continuous or accumulated 150 hours of rotary tillage operations with a large depth of tillage (>20cm); at the same time, the rotary tiller of the present invention can be repeated Manufacturing greatly reduces the overall cost of the rotary tiller.

Owner:JIANGSU UNIV

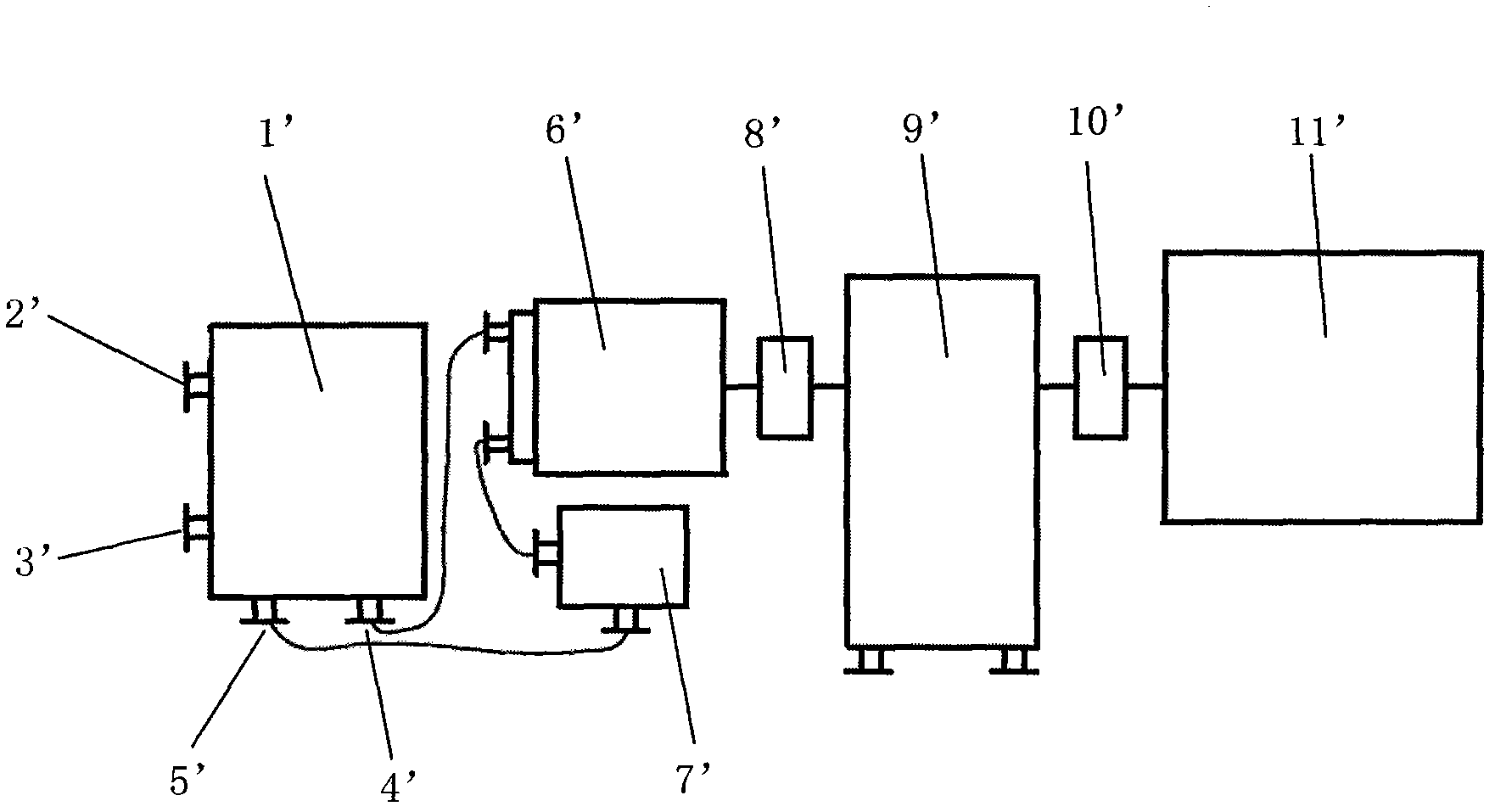

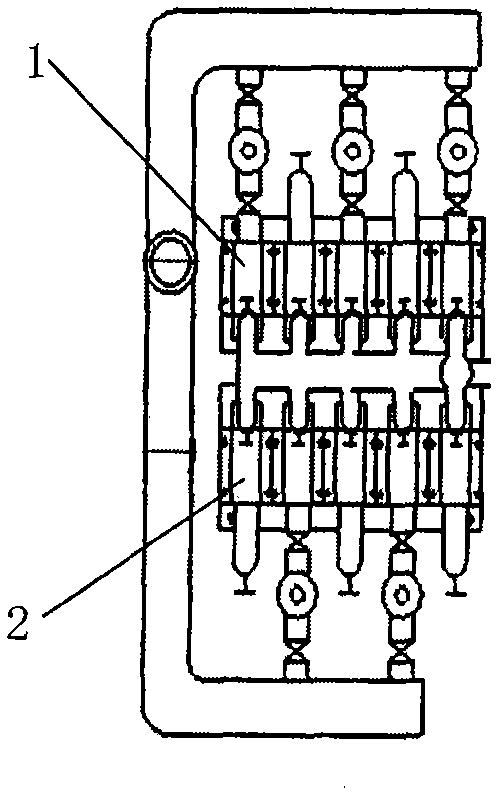

Production system of urea

InactiveCN102516129BRun satisfiesSimple and clear configurationUrea derivatives preparationProductsFluid couplingDecomposition

The invention relates to a production system of urea, which comprises a stripper which is sequentially connected with a low pressure decomposition tower, a low pressure methylamine condenser and a low pressure methylamine condenser level tank in series, and is characterized by also comprising an energy recovery system which comprises a piston power exchanger with a high pressure liquid inlet, a high pressure liquid outlet, a hydraulic oil outlet and a hydraulic oil inlet, and two ports of a hydraulic motor are respectively connected with one port of the hydraulic oil outlet and a hydraulic oil tank; the other port of the hydraulic oil tank is connected with the hydraulic oil inlet, and the hydraulic motor is also connected with a fluid coupling, a high pressure methylamine pump, a clutch and a variable frequency motor in series sequentially; and the piston power exchanger is connected between the stripper and the low pressure decomposition tower in parallel, and the high pressure methylamine pump is respectively connected with the low pressure methylamine condenser level tank and a methylamine fluid high pressure scrubber. The whole system is controlled by a PLC (Programmable Logic Controller), and the high pressure energy generated in the production process can be converted into kinetic energy, so the use of electric energy is reduced, and the production cost is reduced.

Owner:季裕成

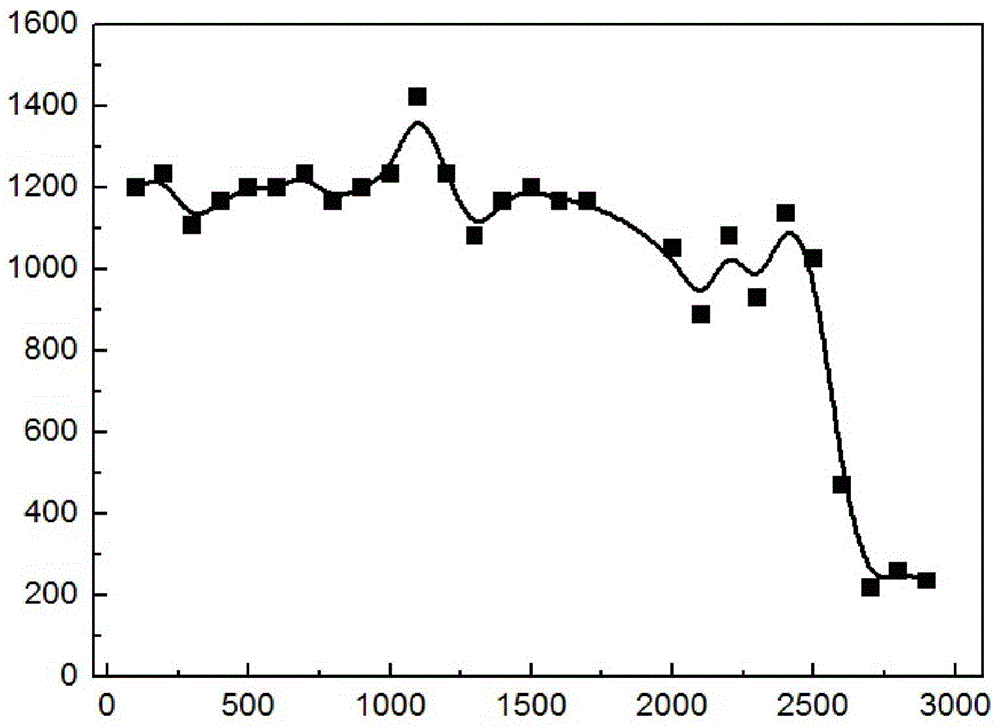

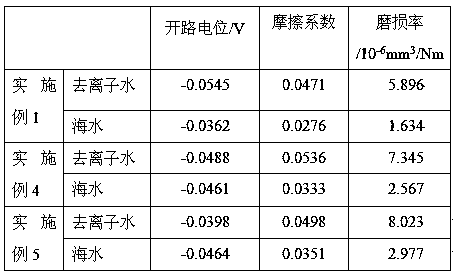

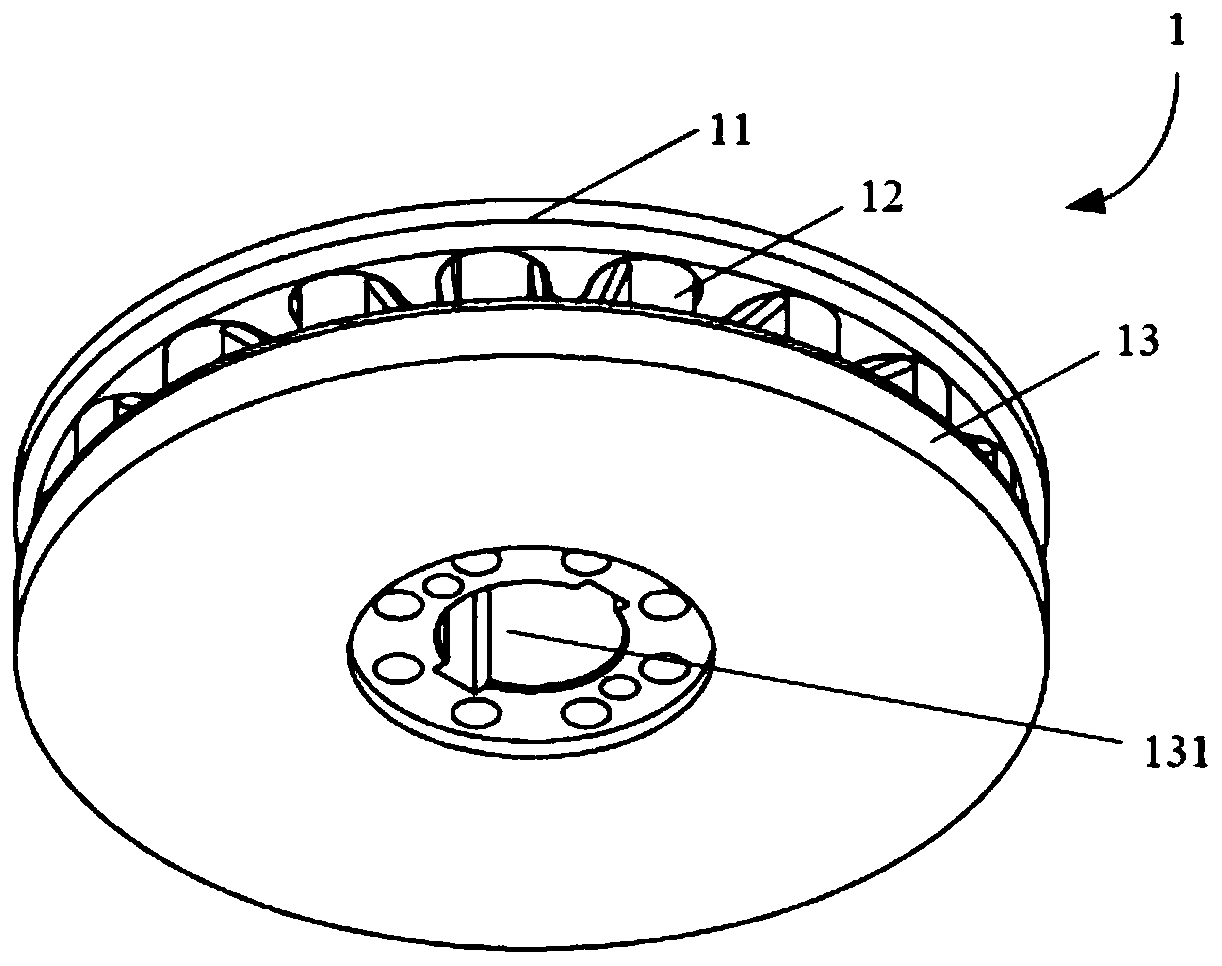

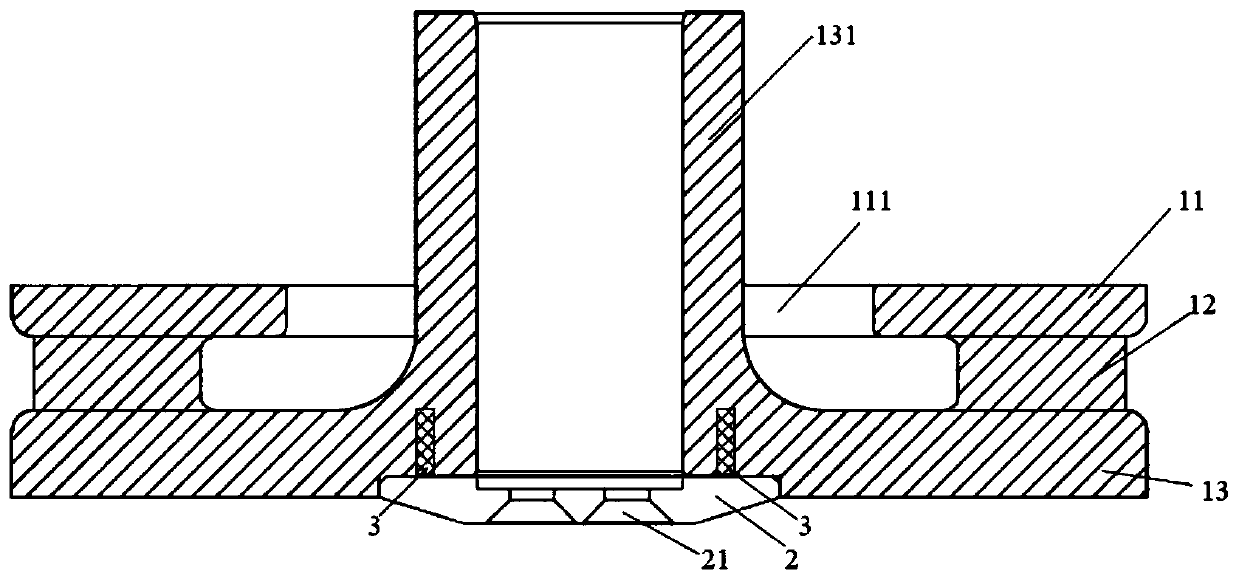

A multi-component nanocomposite of ultra-high molecular weight polyethylene suitable for water lubrication

The invention discloses an ultrahigh molecular weight polyethylene multi-element nanocomposite applicable to the water lubrication condition. While reinforcing fiber is added into an ultrahigh molecular weight polyethylene material, nano-particles with the modified surface and the friction hydrolysis performance are added. The nanocomposite has the good wear-resisting performance under the water lubrication condition, when the nanocomposite is used in a seawater medium, a boundary film on a friction interface can effectively protect a metal pairing surface while abrasion of the polymer composite is lowered, and the metal corrosion wear is lowered.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

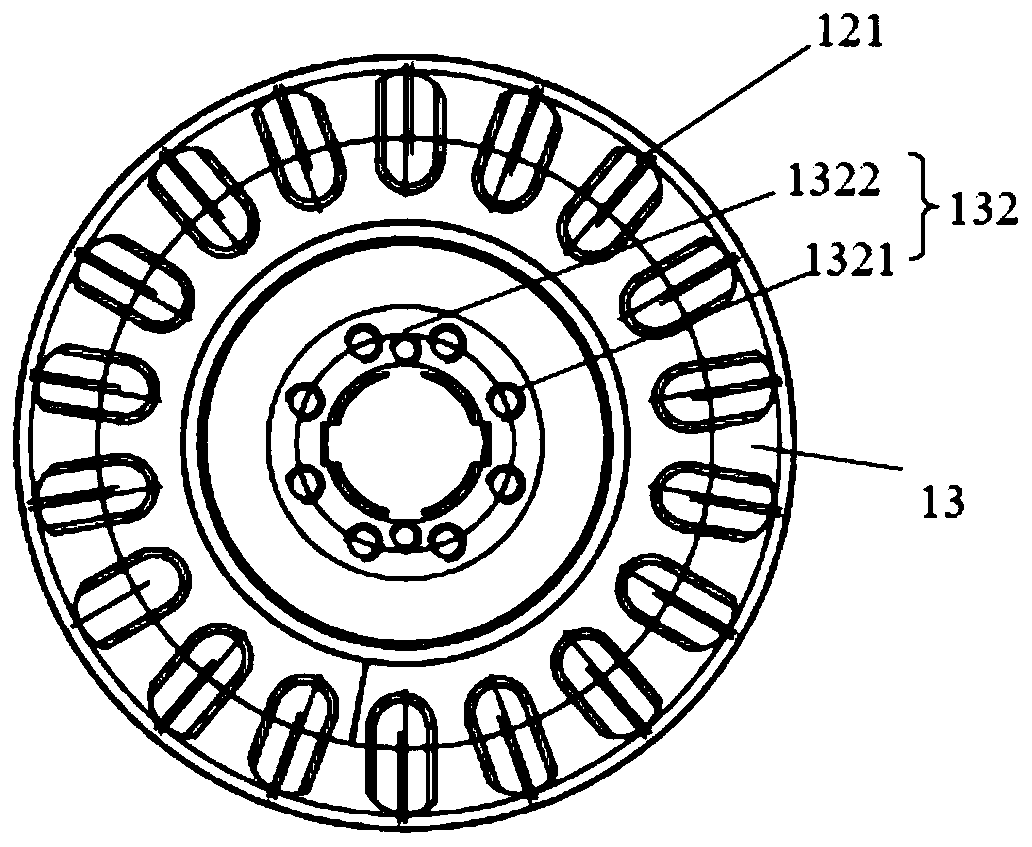

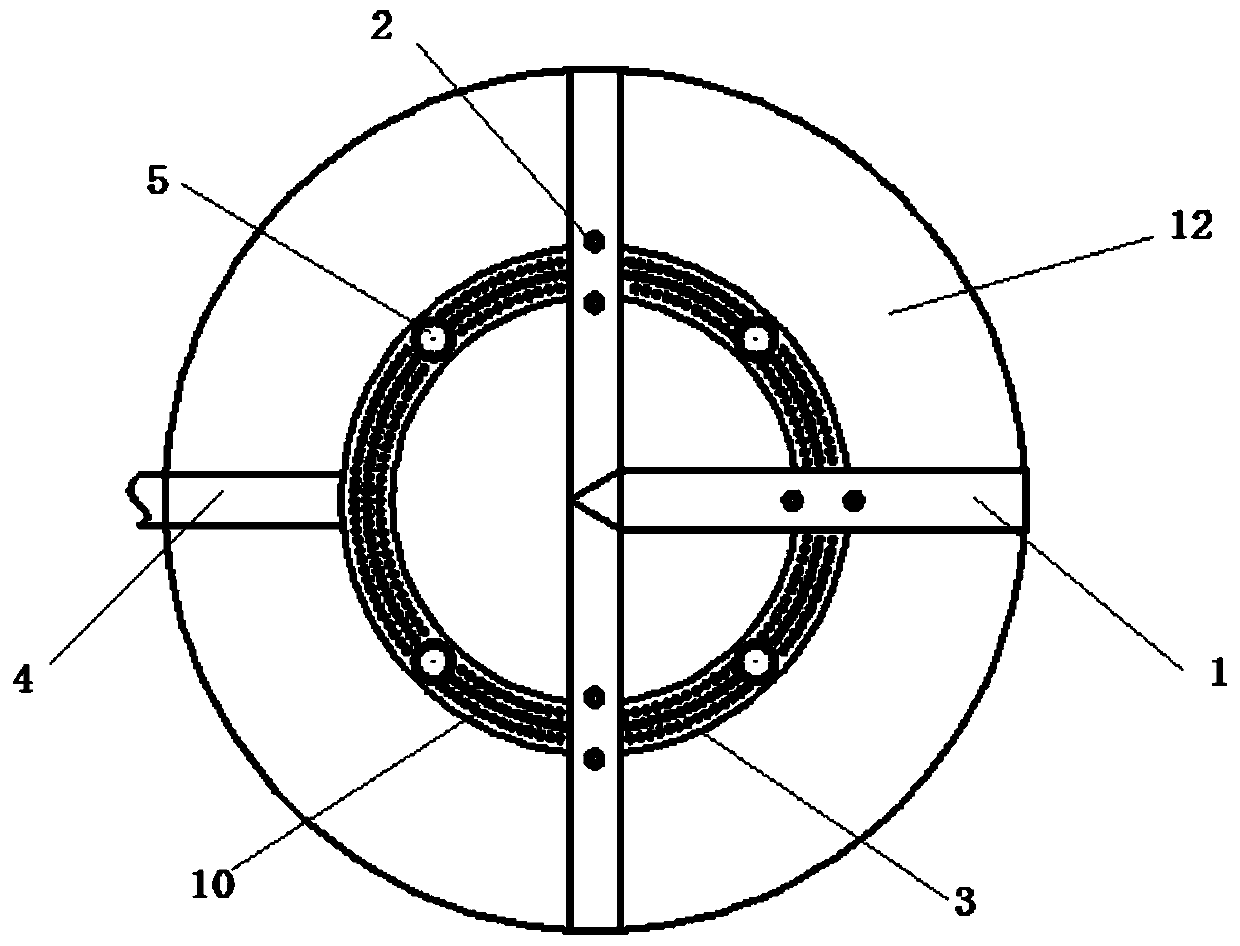

Integrated atomization disc

PendingCN110404720AExtended service lifeReduce installation stepsLiquid spraying apparatusDynamic balanceEngineering

The invention provides an integrated atomization disc. The integrated atomization disc comprises a body, and the body comprises an upper-layer disc, a middle disc and a lower-layer disc which are integrally formed from top to bottom. The center part of the lower-layer disc upwards extends out of the upper-layer disc, and a barrel is formed. The upper-layer disc surrounds the barrel, and a fluid inlet is formed between the upper-layer disc and the barrel and used for inputting to-be-atomized fluid. A guiding module is arranged on the middle disc and used for guiding the fluid. According to theintegrated atomization disc, the atomization disc body is set into the upper-layer disc, the middle disc and the lower-layer disc which are integrally formed, gaps between the guiding module and the upper-layer disc and between the guiding module and the lower-layer disc are avoided, accordingly, abrasion and corrosion in the slurry atomization process are reduced, and the service life of the atomization disc is prolonged. Meanwhile, through the integrally-formed atomization disc, the installing step is omitted, the problem about instable dynamic balance of an atomization disc due to the installing process is solved, the atomization disc is more stable in structure, and atomization is more uniform.

Owner:EVERBRIGHT ENVIRONMENTAL TECH EQUIP CHANGZHOU

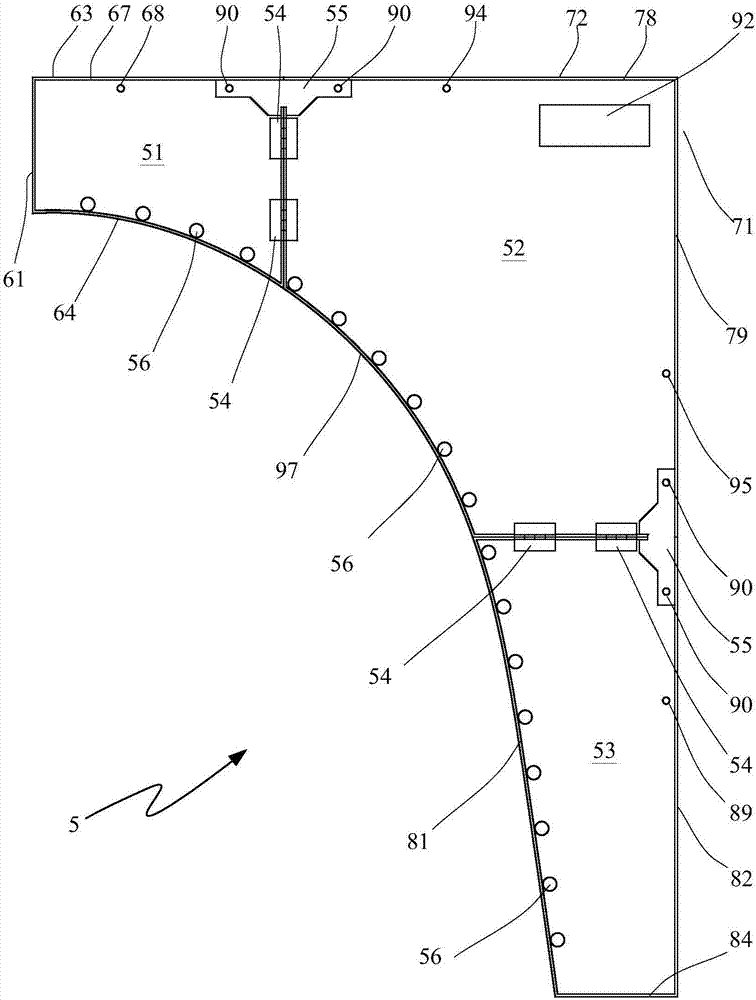

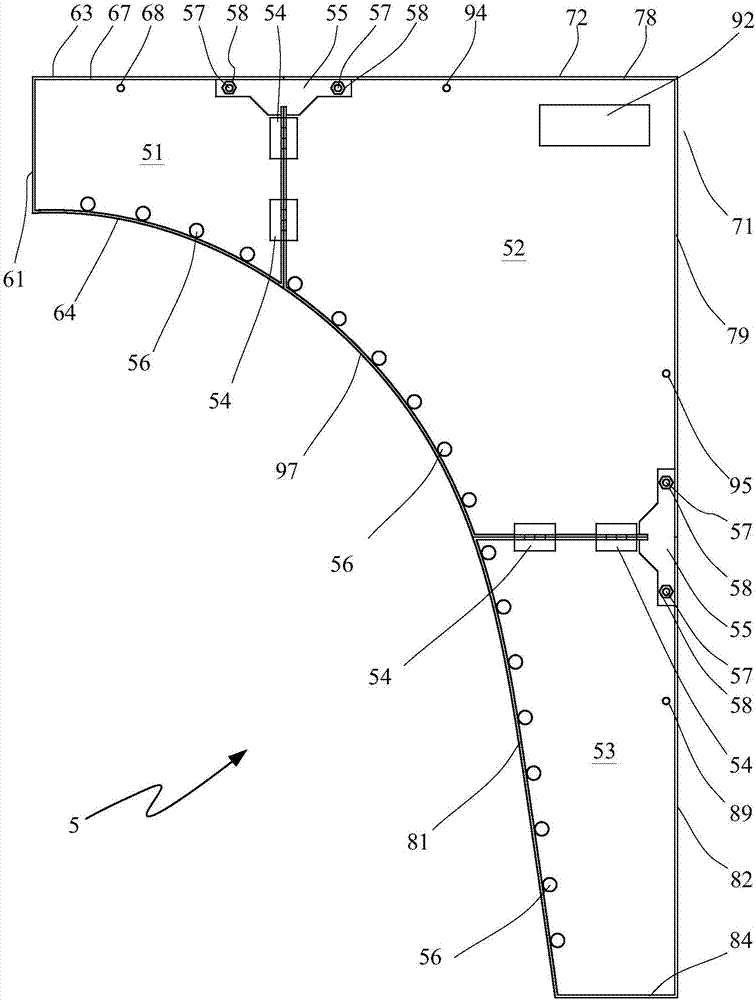

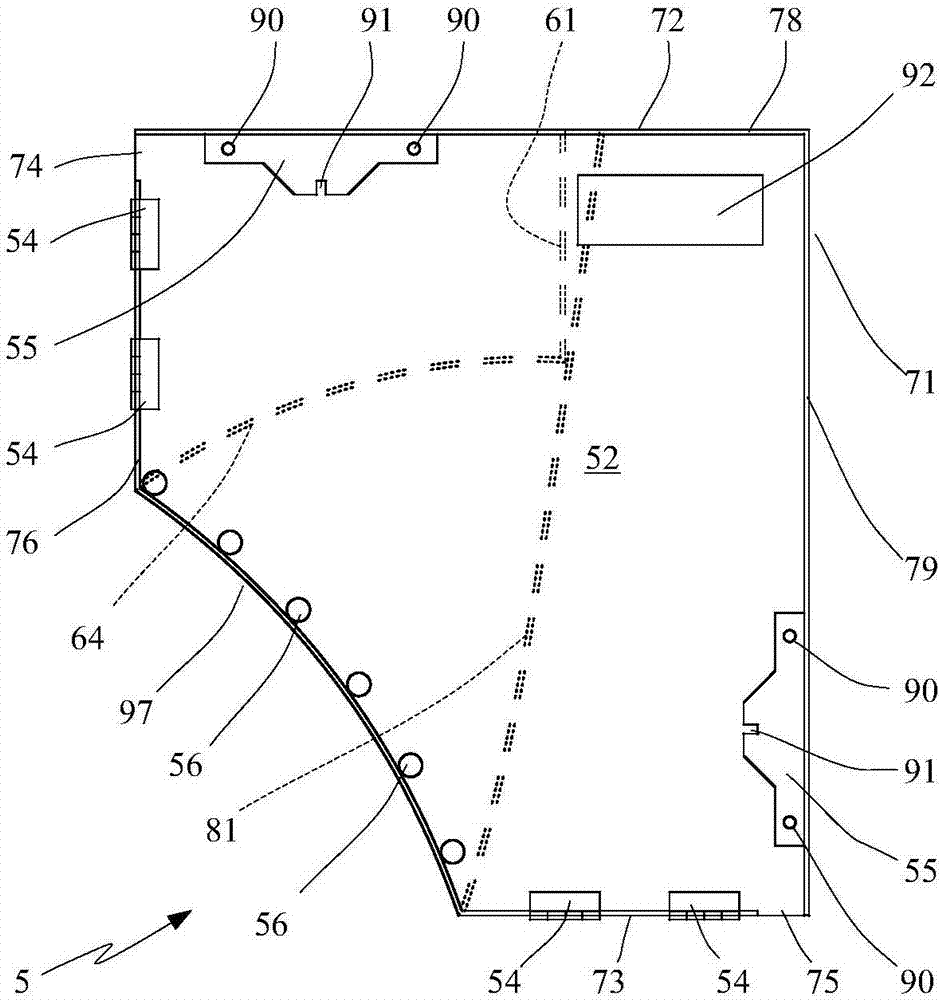

Foldable positioning plate for reamer

The invention relates to a foldable positioning plate for a reamer, and belongs to the technical field of reamer positioning. According to the foldable positioning plate for the reamer, a main plate and an inner plate are connected through a hinge, and the main plate and a lower plate are connected through a hinge. When the positioning plate is unfolded, the main plate and the inner plate are connected through a fixing plate, and the main plate and the lower plate are connected through a fixing plate. When the positioning plate is folded, the inner plate is connected and attached to the main plate through the hinge, and the lower plate is connected and attached to the main plate through the hinge. The lower edge of the inner plate is provided with an arc boundary, a check plate is arranged, a distance is kept between the check plate and the arc boundary of the lower edge of the inner plate, and the boundary of the inner plate is provided with a rib plate. The main plate is provided with an arc positioning boundary, a check plate is arranged, a distance is kept between the check plate and the arc positioning boundary, and a rib plate is arranged on the boundary of the main plate. The inner edge of the lower plate is provided with an arc boundary, a check plate is arranged, a distance is kept between the check plate and the arc boundary of the inner edge of the lower plate, and the boundary of the lower plate is provided with a rib plate. The foldable positioning plate has the advantages that the structure is simple, on-site construction is achieved, disassembly and assembly are convenient, conveying is convenient, and the positioning precision is high.

Owner:CCCC TIANJIN ECO ENVIRONMENTAL PROTECTION DESIGN & RES INST CO LTD

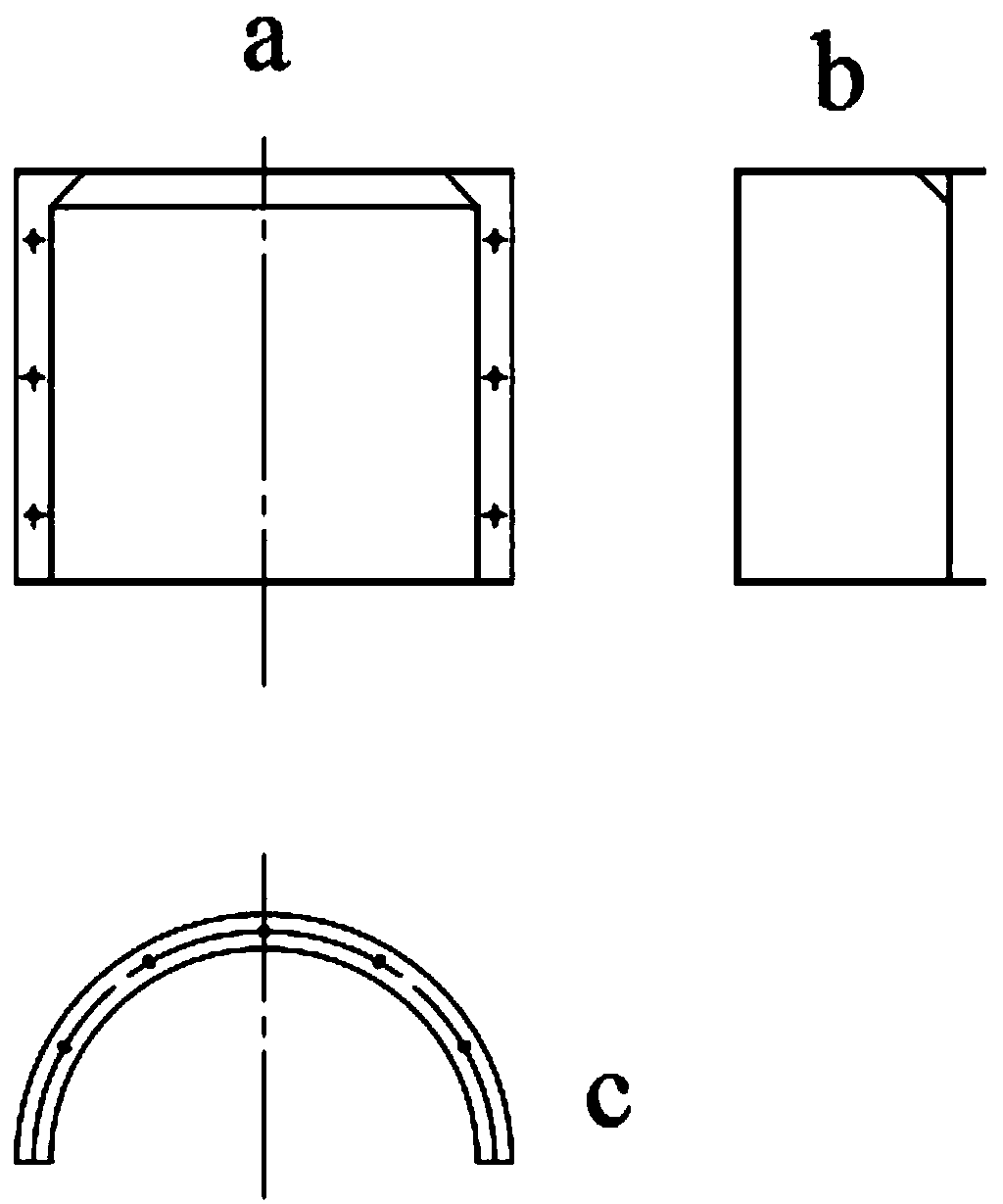

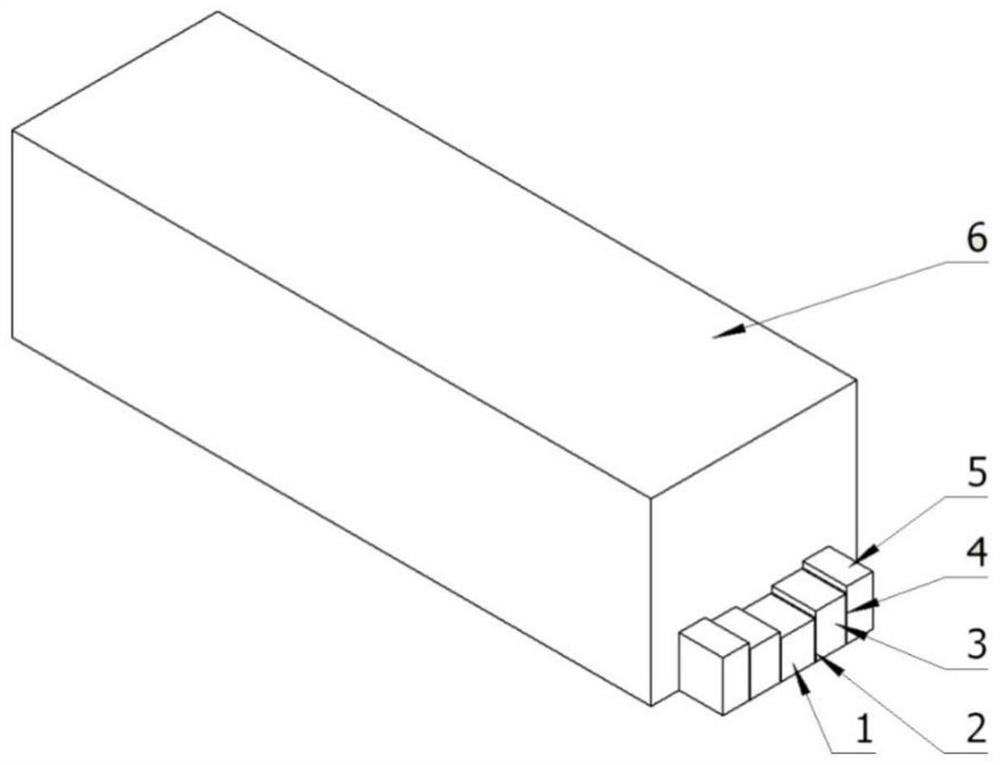

Cathode steel bar structure capable of reducing horizontal current of molten aluminum for aluminum electrolysis cell

ActiveCN113445079AImproved current distributionExtend your lifeAluminium electrolysisElectric current flow

The invention discloses a cathode steel bar structure capable of reducing horizontal current of molten aluminum for an aluminum electrolysis cell. The cathode steel bar structure comprises a first cathode steel bar (strip-shaped), a second cathode steel bar, a third cathode steel bar (U-shaped) and separation layers for separating the three cathode steel bars. The cathode steel bar structure is integrally embedded into the bottom of a cathode carbon block, one end of the cathode steel bar structure is embedded into the position, close to the middle section of the cathode carbon block, of the cathode carbon block, and the other end of the cathode steel bar structure is provided with an electricity outlet end which extends and exceeds the corresponding side face of the cathode carbon block. According to the cathode steel bar structure, a separation layer is arranged between two adjacent cathode steel bars, the three cathode steel bars are separated by the separation layers, and the top surfaces of the three cathode steel bars are arranged in a step shape. According to the cathode steel bar structure, the horizontal current density in a molten aluminum layer of the aluminum electrolysis cell is greatly reduced, only the structural configuration of the cathode steel bars and the cathode carbon block is adjusted, the structure is simple, and industrial implementation is easy.

Owner:HEFEI UNIV OF TECH

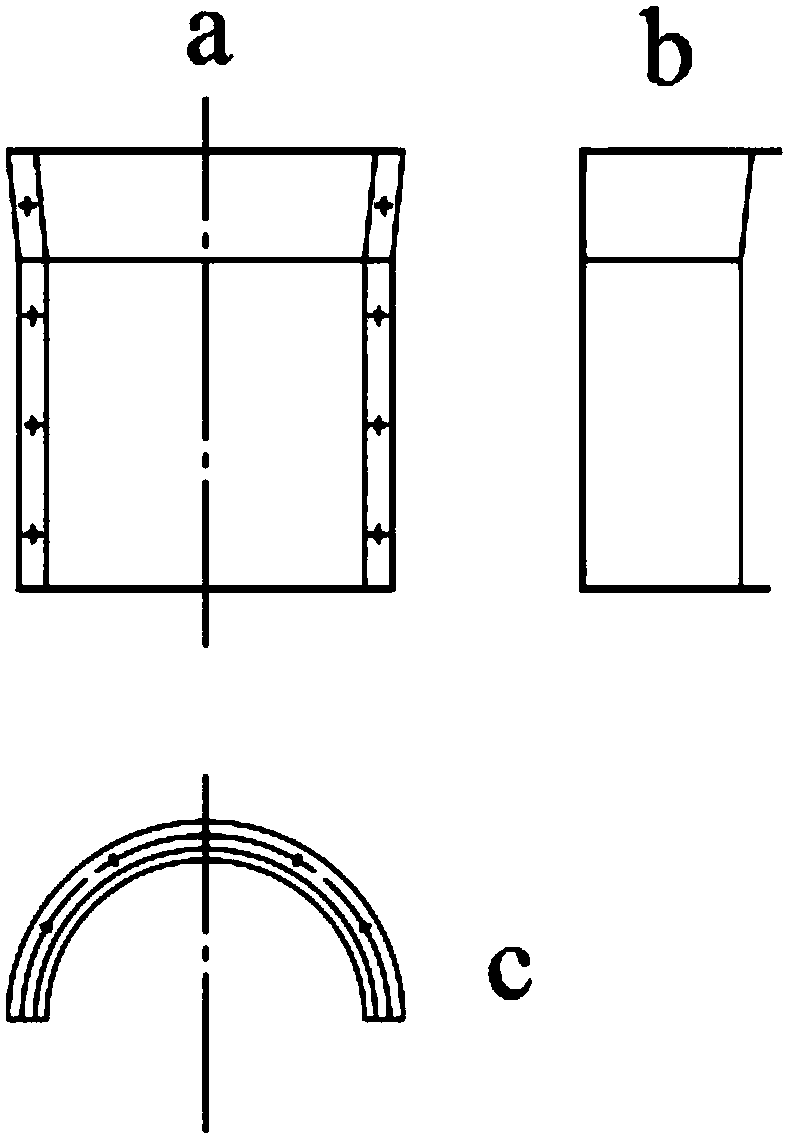

Protection device and protection method of centrifuge filter drum

ActiveCN113171888BSimple structureImprove the protective effectCentrifugesWear corrosionStructural engineering

A protection device and a protection method for a filter drum of a centrifuge, comprising a special-shaped sheath positioned at a filter hole of the filter drum of a centrifuge, and a filter hole sheath is arranged in the special-shaped sheath, the shape, size and thickness of which are the same as those of the filter. The holes are adapted to be embedded in the filter holes. The area of each special-shaped sheath is larger than and can only cover one filter hole, and is attached to the outer wall of the filter drum. The special-shaped sheath is embedded in the filter drum hole to protect the cylinder hole and metal outer wall of the filter drum, which can effectively protect the filter drum cylinder, slow down the wear and corrosion of the cylinder, and maximize the shape and arrangement of the protective device. It covers the outer wall of the cylinder and protects the filter hole and the drum wall. The filter hole sheath is tapered in the direction of the outer extension of the drum hole, which can effectively prevent the liquid thrown out of the filter drum from splashing to the surface of the drum. On the outer wall of the drum, the abrasion of the drum is further reduced. The protective device has a simple structure and a remarkable protective effect.

Owner:TANGSHAN SENPU MINING EQUIP CO LTD

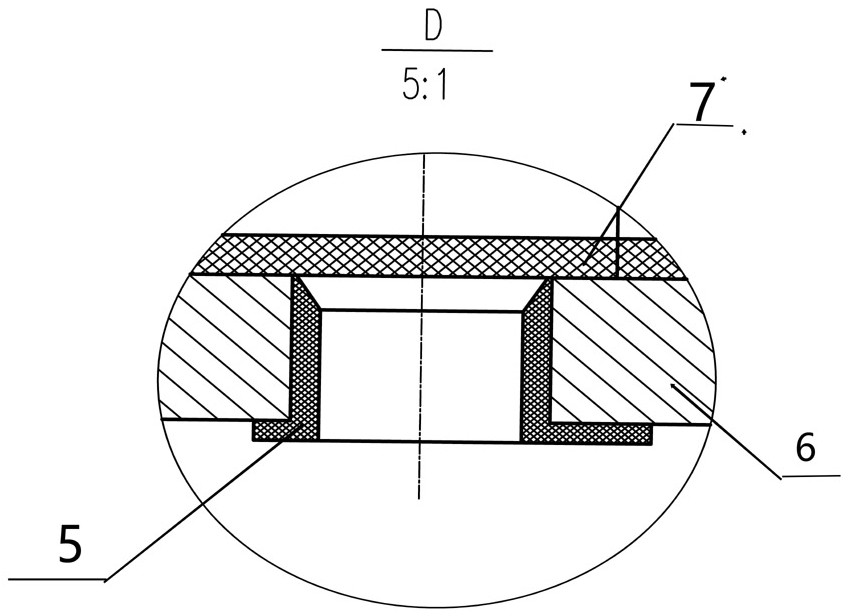

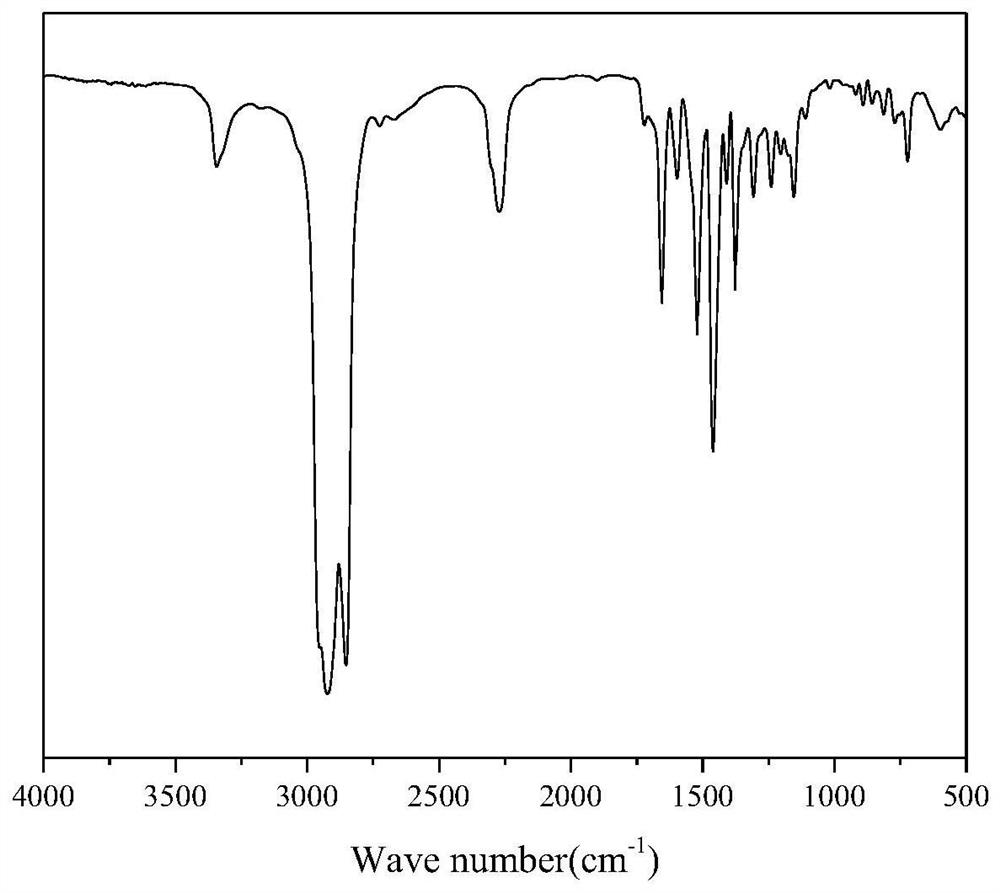

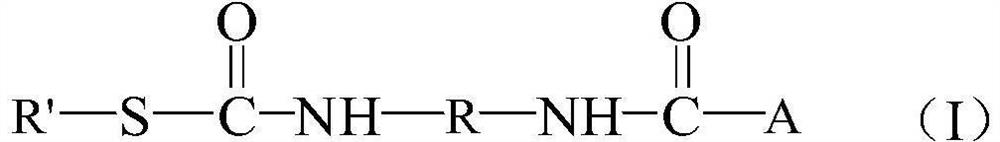

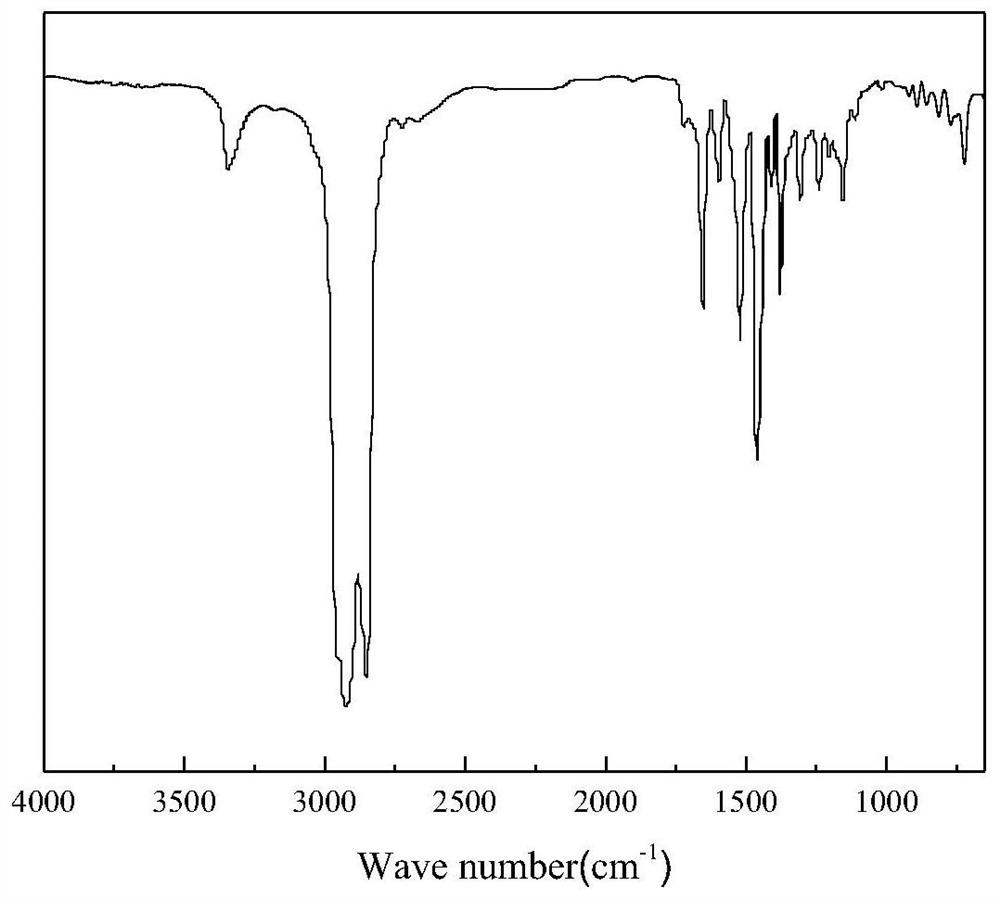

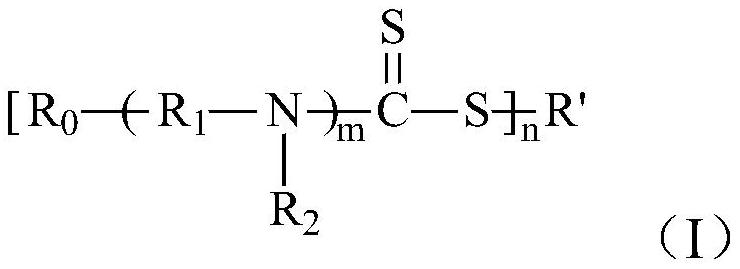

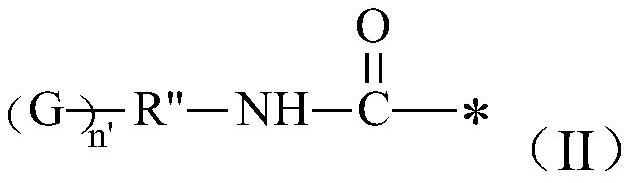

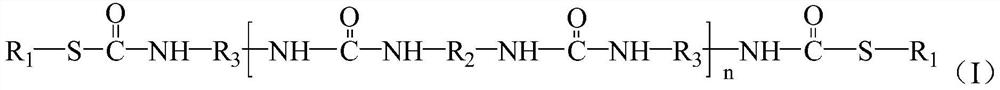

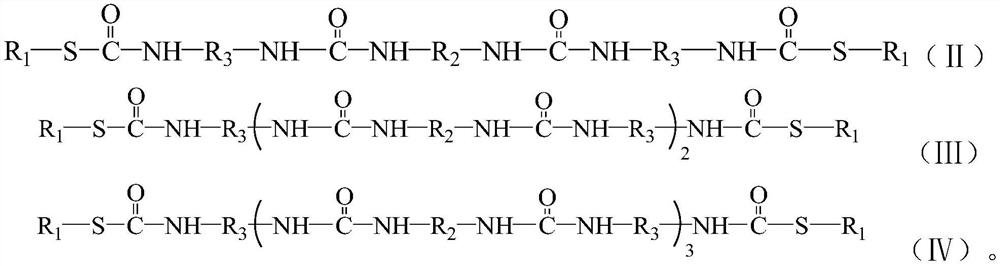

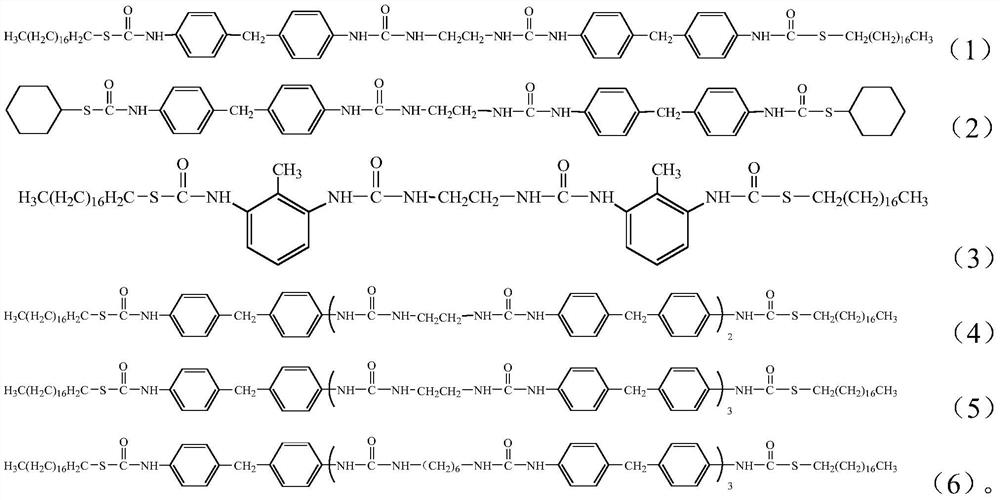

Isocyanate derivative, preparation method and application thereof, and lubricating grease composition

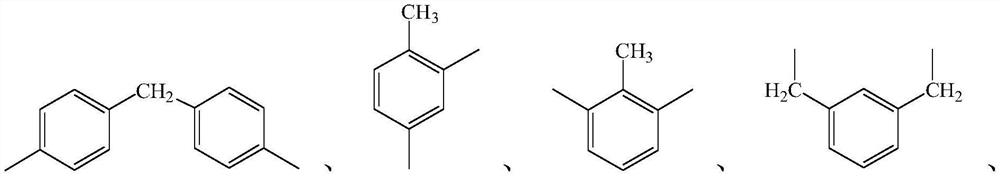

PendingCN114507168AImprove anti-wear and anti-friction performanceImprove extreme pressure wear resistanceOrganic chemistryThickenersArylPolymer science

The invention provides an isocyanate derivative as well as a preparation method and application thereof and a lubricating grease composition. The structure of the isocyanate derivative disclosed by the invention is shown as a formula (I), wherein an R group is selected from C1-C30 alkylene groups; the R'group is selected from alkyl of C1 to C30; the A group is selected from a group shown in a formula (II) and a group shown in a formula (III); in the formula (II), R ''groups are selected from alkyl groups, cycloalkyl groups or aryl groups of C1 to C30, R'' groups are selected from alkyl groups, cycloalkyl groups or aryl groups of C1 to C30, and R ''groups are selected from alkyl groups, cycloalkyl groups or aryl groups of C1 to C30; in the formula (III), the R ''group is selected from C1-C30 alkyl, cycloalkyl or aryl. The isocyanate derivative has excellent extreme pressure anti-wear performance and can be used as a thickening agent of a lubricating grease composition or an additive of lubricating grease, the lubricating grease composition prepared by taking the isocyanate derivative as the thickening agent has excellent extreme pressure anti-wear performance, and the service life of lubricating grease can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Protection device and protection method for filtering rotary drum of centrifugal machine

ActiveCN113171888ASimple structureImprove the protective effectCentrifugesWear corrosionStructural engineering

The invention discloses a protection device and a protection method for a filtering rotary drum of a centrifugal machine. The protection device comprises special-shaped protection sleeves positioned in filtering holes of the filtering rotary drum of the centrifugal machine, a filtering hole protection sleeve is arranged in each special-shaped protection sleeve, the shape, size and thickness of each filtering hole protection sleeve are matched with those of the filtering holes, the filtering hole protection sleeves are embedded in the filtering holes, the area of each special-shaped sheath is larger than and can only cover one filtering hole, and is attached to the outer wall of a cylinder body of the filtering rotary drum. The special-shaped protective sleeves are embedded in the filtering rotary drum holes to protect the cylinder body holes and the metal outer wall of the filtering rotary drum, the cylinder body of the filtering rotary drum can be effectively protected, abrasion and corrosion of the cylinder body are relieved, the outer wall of the cylinder body is covered with the shape and arrangement of the protection device to the maximum extent, the filtering holes and the wall of the rotary drum are protected, and the filtering hole protection sleeves are in the shape of a cone which is gradually reduced in the outward extending direction of the rotary drum hole, so that liquid thrown out of the filtering rotary drum can be effectively prevented from splashing to the outer wall of the rotary drum, and the abrasion of the rotary drum is further reduced. The protection device is simple in structure and remarkable in protection effect.

Owner:TANGSHAN SENPU MINING EQUIP CO LTD

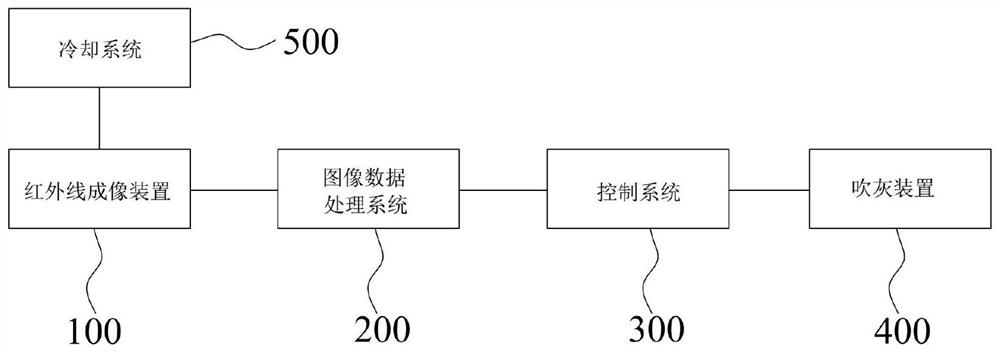

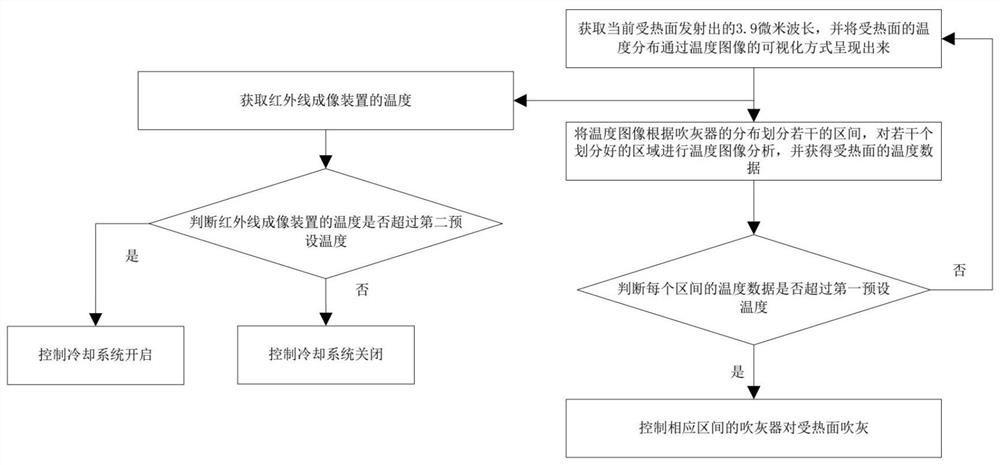

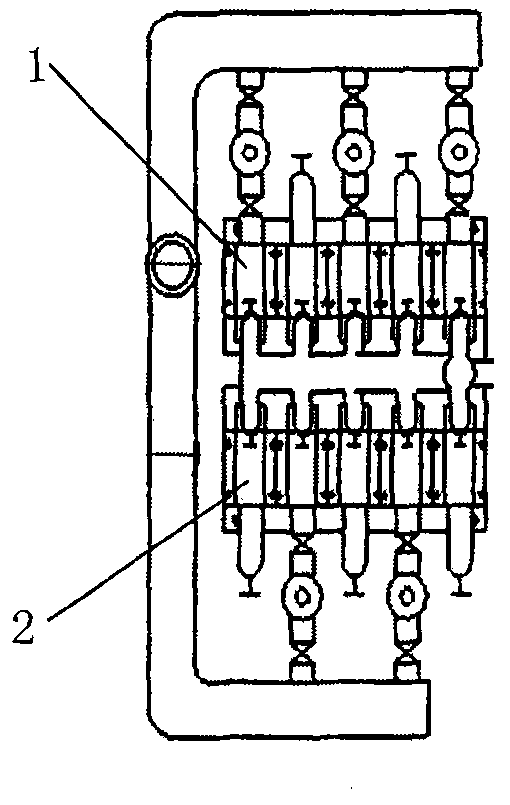

Soot blowing control system and method for heating surface of boiler

PendingCN113551245AGuaranteed service lifeReduce corrosion wearTemperatue controlSolid removalInfraredData processing system

Owner:YANTAI LONGYUAN POWER TECH

High-pressure energy recovering system for urea solution

InactiveCN102434544BImprove efficiencySimple and clear configurationUrea derivatives preparationProductsFluid couplingCarbamate

A high-pressure energy recovering system for urea solution is characterized by comprising a piston type exchanger with four ports, namely a high-pressure solution inlet, a high-pressure solution outlet, a hydraulic oil outlet and a hydraulic oil inlet. Two ports of a hydraulic motor are respectively connected with the hydraulic oil outlet and a port of a hydraulic oil tank, and the other port of the hydraulic oil tank is connected with the hydraulic oil inlet. The hydraulic motor is also sequentially connected with a fluid coupling, a high-pressure carbamate pump, a clutch and a variable frequency motor in series. The piston type exchanger comprises five pairs of piston cylinders and a steering system. The energy recovering system is simple in structure and capable of effectively converting high pressure energy generated in the production process of urea into kinetic energy so as to replace electric energy for driving the high-pressure carbamate pump to work normally, thereby saving electricity and reducing production cost.

Owner:季裕成

Isocyanate derivative, preparation method and application thereof, and lubricating grease composition

PendingCN114763332AImprove anti-wear and anti-friction performanceImprove extreme pressure wear resistanceOrganic chemistryThickenersIsocyanatePerylene derivatives

The invention provides an isocyanate derivative as well as a preparation method and application thereof and a lubricating grease composition. The structure of the isocyanate derivative disclosed by the invention is shown as a formula (I), wherein the definition of each group is shown in the specification. The isocyanate derivative has excellent extreme pressure anti-wear performance and can be used as a thickening agent of a lubricating grease composition or an additive of lubricating grease, the lubricating grease composition prepared by taking the isocyanate derivative as the thickening agent or the additive has excellent extreme pressure anti-wear performance, and the service life of lubricating grease can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Carbonization tower feeding device for coil pipe type liquid distributor

The invention discloses a carbonization tower feeding device for a coil pipe type liquid distributor. The carbonization tower feeding device is arranged on the top of a carbonization tower, and comprises a pipeline support frame, a U-shaped pipe clamp, the coil pipe type liquid distributor and a liquid inlet pipe, wherein the pipeline support frame is fixed on the top of the carbonization tower; the coil pipe type liquid distributor is fixed on the pipeline support frame through the U-shaped pipe clamp; the liquid inlet pipe is connected and communicated with the coil pipe type liquid distributor; and a plurality of single guide pipe pressure spray nozzles are arranged at the bottom of the coil pipe type liquid distributor. Liquid is uniformly and fast sprayed into the carbonization towerin a spray mode, and is in sufficient contact with carbon dioxide; a carbonization process is accelerated; and the carbonization time is reduced. The wall flow of the liquid in the carbonization toweris reduced, so that the corrosion abrasion of the inner wall of the carbonization tower is reduced, and resource waste is prevented.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Isocyanate derivative, preparation method and application thereof, and lubricating grease composition

PendingCN114507167AImprove anti-wear and anti-friction performanceImprove extreme pressure wear resistanceUrea derivatives preparationOrganic compound preparationPolymer sciencePerylene derivatives

The invention provides an isocyanate derivative, a preparation method and application thereof, and a lubricating grease composition containing the isocyanate derivative. The structure of the isocyanate derivative disclosed by the invention is shown as a formula (I), wherein the definition of each group is shown in the specification. The isocyanate derivative has excellent extreme pressure anti-wear performance and can be used as a thickening agent of a lubricating grease composition or an additive of lubricating grease, the lubricating grease composition prepared by taking the isocyanate derivative as the thickening agent has excellent extreme pressure anti-wear performance, and the service life of lubricating grease can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

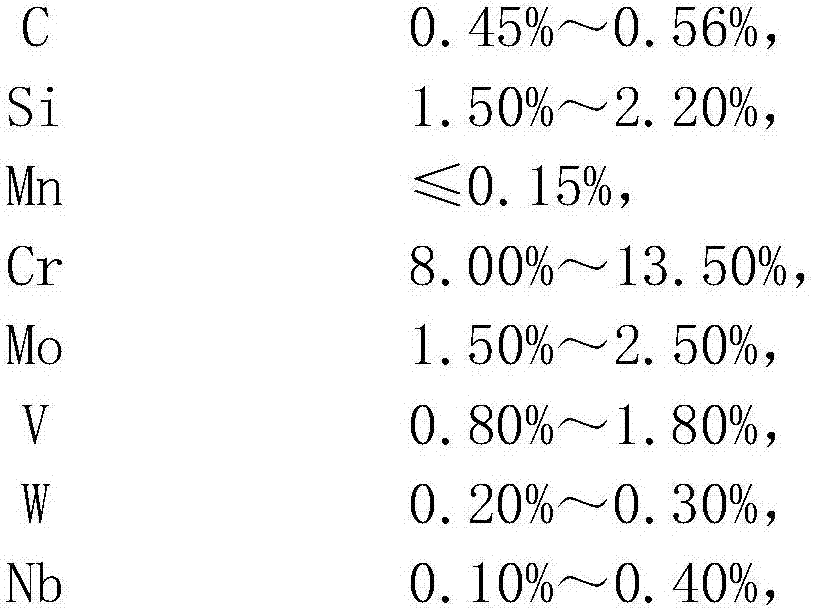

A kind of preparation method of hot straightening roll for medium and thick plate

ActiveCN105648349BImprove hardenabilityHigh strengthFurnace typesRollsIngot castingMaterials science

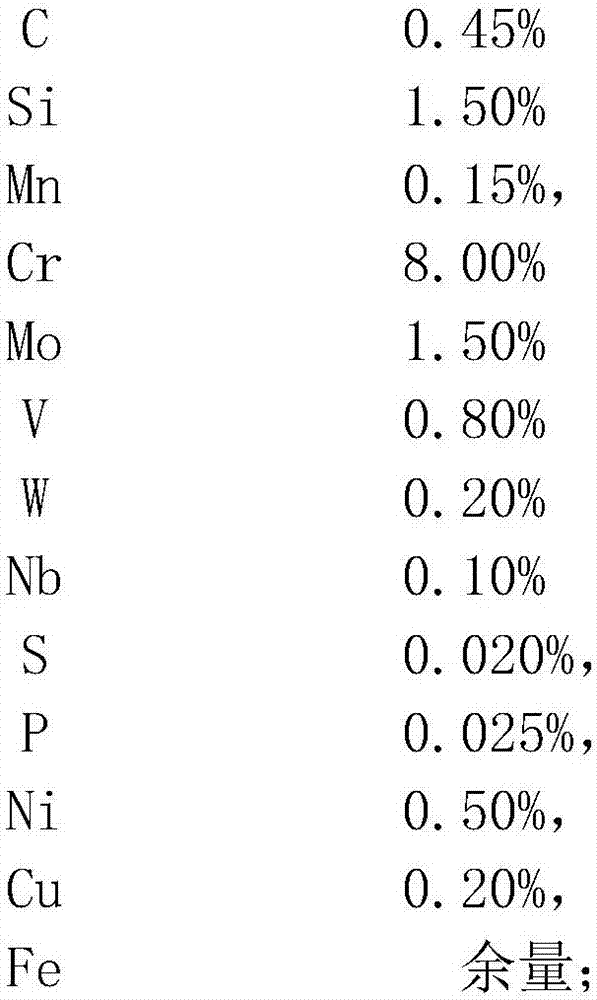

The invention discloses a preparation method of a medium-thickness plate hot straightening roll. The preparation method is characterized by comprising the following steps: 1. smelting of roll billet steel, wherein the steel comprises the following components in percentage by weight: 0.45-0.56% of C, 1.50-2.20% of Si, at most 0.15% of Mn, 8.00-13.50% of Cr, 1.50-2.50% of Mo, 0.80-1.80% of V, 0.20-0.30% of W, 0.10-0.40% of Nb, at most 0.020% of S, at most 0.025% of P, at most 0.50% of Ni, at most 0.20% of Cu and the balance of Fe; 2. ladle refining; 3. ingot casting; 4. roll billet forging, and annealing after forging; and 5. surface heat treatment. The medium-thickness plate hot straightening roll prepared by the preparation method can bear the high-temperature impact and abrasion, and high-temperature heat alternation and stress alternation fatigue.

Owner:宝武特冶航研科技有限公司

Piston ring for automatically closing and adjusting clearance

InactiveCN100476187CSolve the problem of air leakageSolve the phenomenon of eccentric wearPiston ringsMachines/enginesPiston ringEngineering

Owner:张有汉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com