Isocyanate derivative, preparation method and application thereof, and lubricating grease composition

A technology of isocyanate and diisocyanate, applied in the field of isocyanate derivatives, can solve problems such as improving the performance of lubricating grease compositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

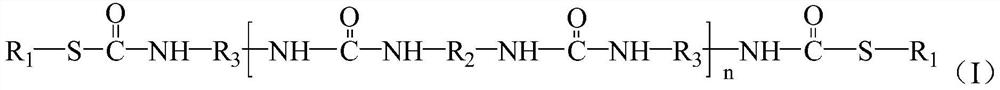

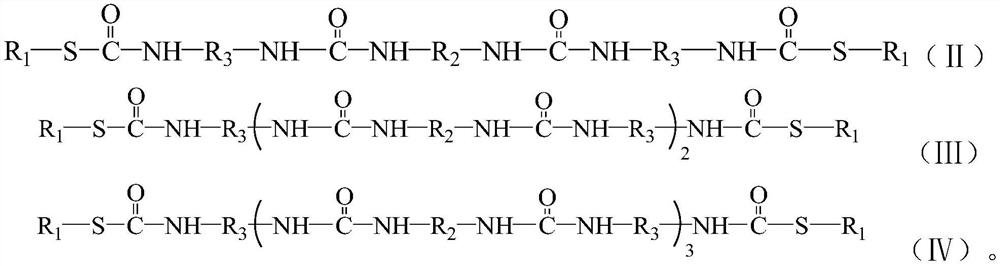

Method used

Image

Examples

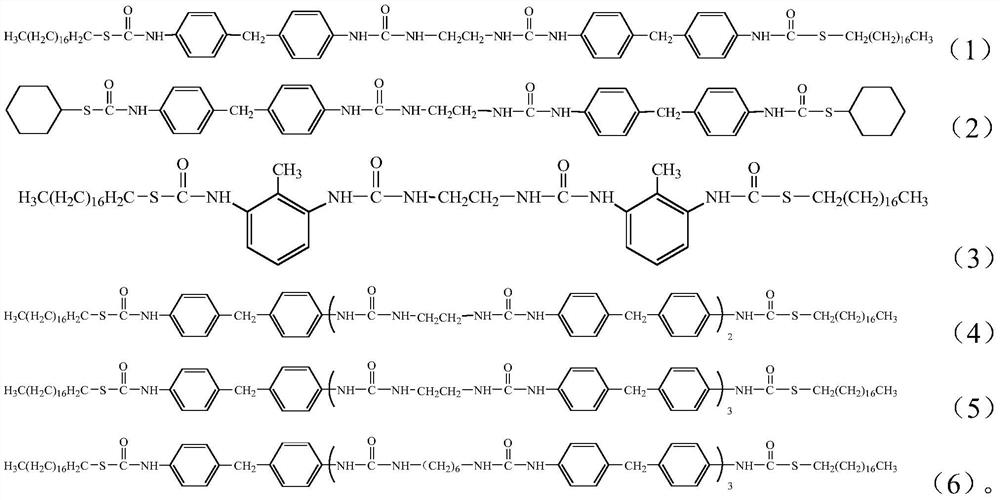

Embodiment 1

[0051] First mix 30g of 500N base oil and 6.62g of MDI and heat to 50°C, slowly add 0.80g of ethylenediamine, raise the temperature to 80°C, react for 0.5h, add 7.58g of n-octadecyl mercaptan, 0.1g of triethylenediamine to 30g After dissolving in 500N base oil, slowly add it dropwise to the above mixture under sufficient stirring conditions, keep the temperature at 80°C and stir for 1 hour, continue to raise the temperature to 185°C, keep it warm for 15 minutes, cool, and grind to obtain a grease composition. Its main reaction equation is as follows:

[0052]

[0053]

[0054]

Embodiment 2

[0056] First mix 30g of 500N base oil and 5.32g of TDI and heat to 50°C, slowly add 0.92g of ethylenediamine, raise the temperature to 80°C, react for 0.5h, add 8.76g of n-octadecanethiol, 0.1g of triethylenediamine to 30g After dissolving in 500N base oil, slowly add it dropwise to the above mixture under sufficient stirring conditions, keep the temperature at 80°C and stir for 1 hour, continue to raise the temperature to 185°C, keep it warm for 15 minutes, cool, and grind to obtain a grease composition.

Embodiment 3

[0058] First mix 20g of 500N base oil and 5.20g of MDI and heat to 50°C, add 5.95g of n-octadecanethiol and 0.1g of triethylenediamine into 20g of 500N base oil to dissolve, then slowly add to the above mixture and heat up to 80°C , reacted for 1 hour, quickly added 1.25g of ethylenediamine, kept the temperature at 80°C, reacted for 0.5h, mixed 20g of 500N base oil and 2.6g of MDI and heated to dissolve, and slowly added dropwise to the above mixture under sufficient stirring conditions, keeping the temperature at 80 °C, fully stirred and reacted for 1 hour, continued to heat up to 185 °C, kept the temperature for 15 minutes, cooled, and ground to obtain a grease composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com