High-wear-resistance lubricating oil and preparation method thereof

A lubricating oil, high wear-resistant technology, applied in the field of lubricating oil, can solve the problems of difficult mixing and exerting effect, and achieve the effect of improving dispersion, excellent anti-wear and anti-friction performance, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] A preparation method of high wear-resistant lubricating oil, comprising the steps of:

[0047] Step S1, weighing each raw material according to parts by weight;

[0048] Step S2, take half of the base oil, slowly drop the surfactant into the base oil, mix evenly, then add the nano-tungsten disulfide powder and anti-wear additives into the mixed oil of the base oil and the surfactant, and then Add the remaining half of the base oil to get a premix;

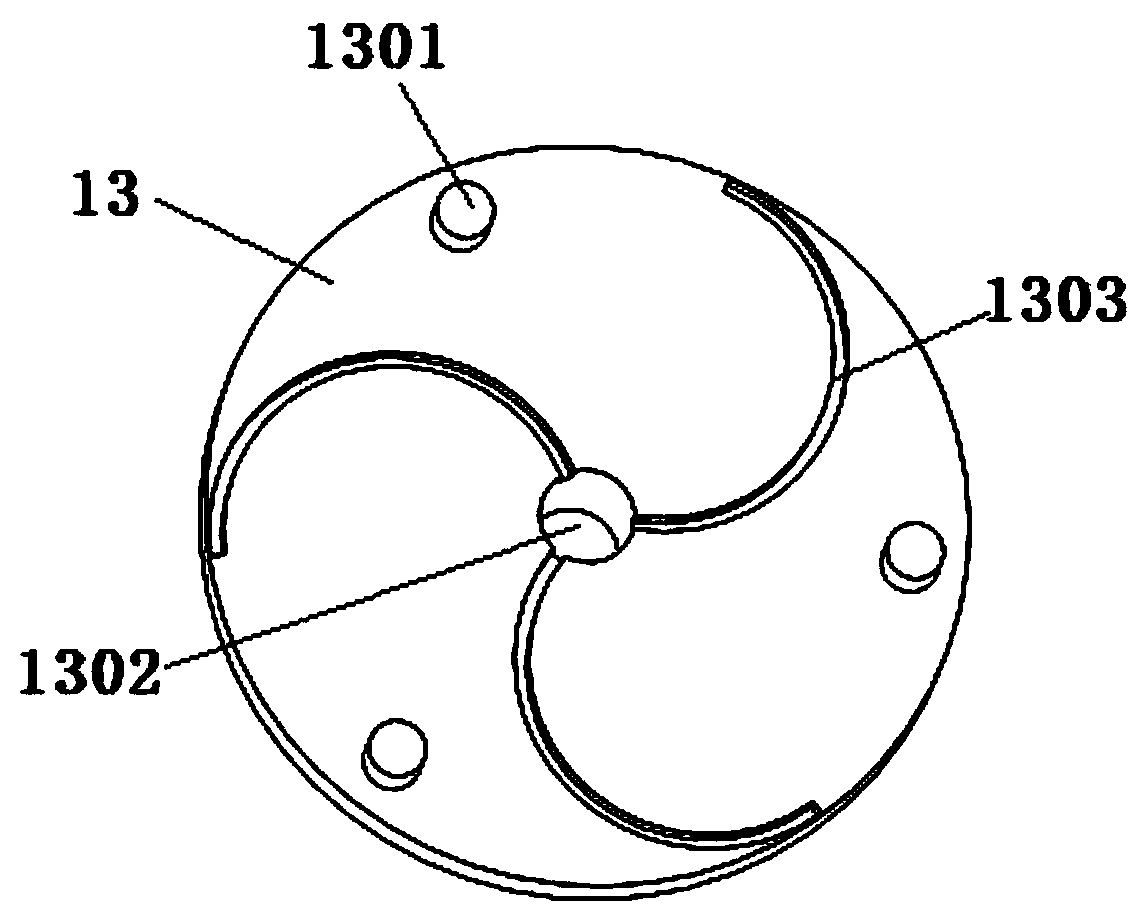

[0049] Step S3, add the premix into the lubricating oil blending tank 1 of the high-efficiency processing equipment, and simultaneously turn on the motor connected to the first stirring shaft 21 and the air pump connected to the pulse air pipe 1304, blend for 55-65 minutes, discharge the material, and process to obtain lubricating oil ;

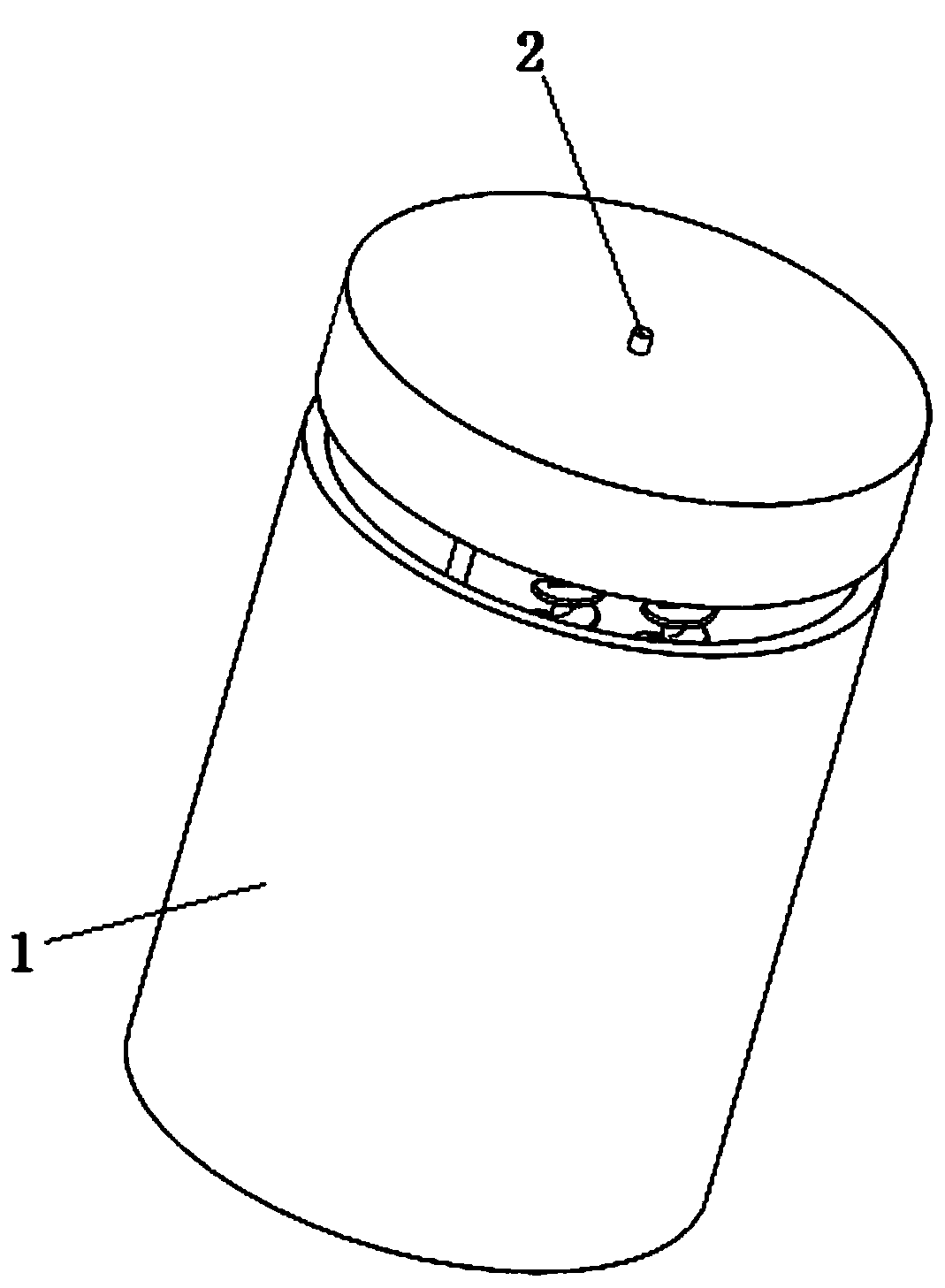

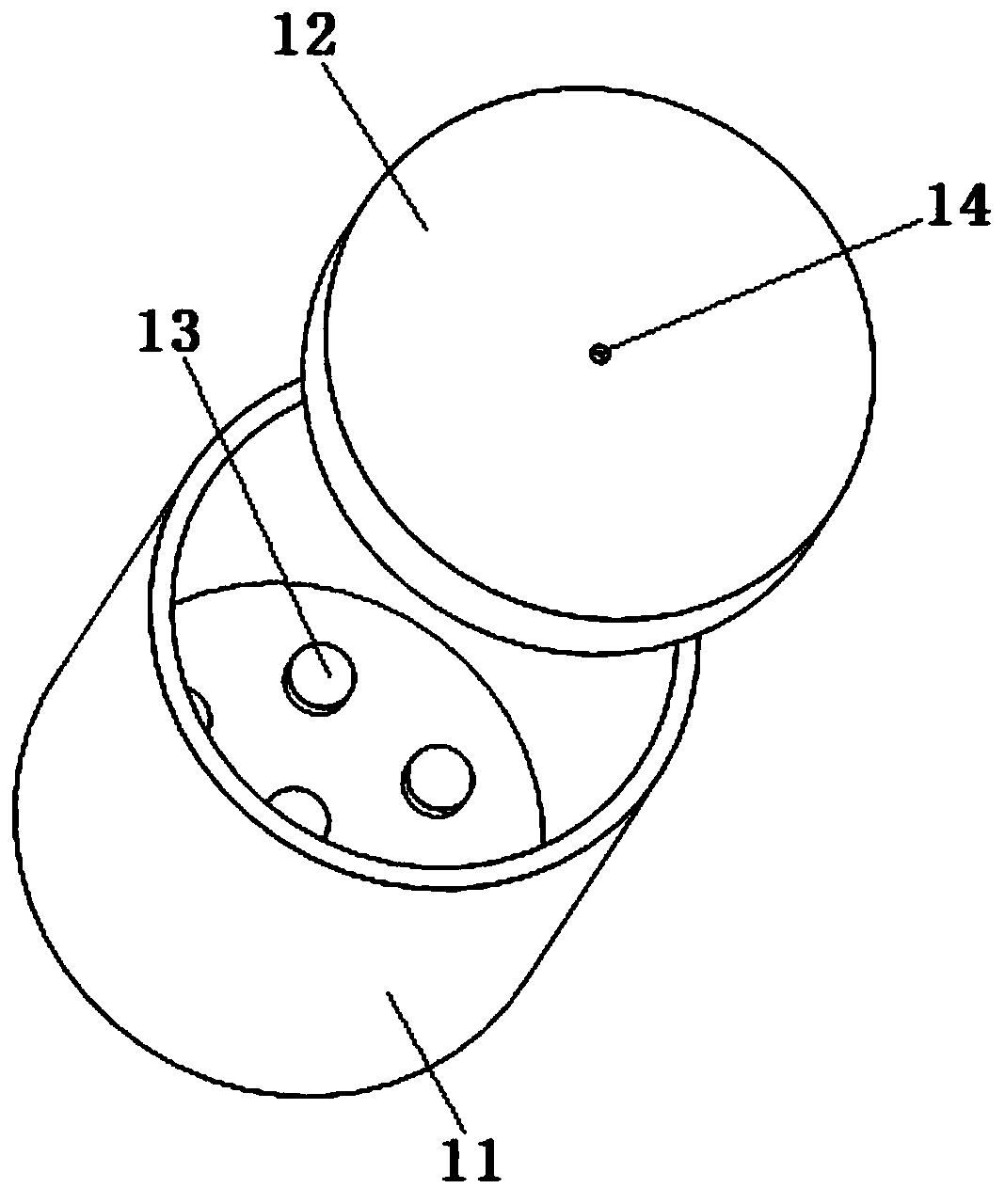

[0050] see Figure 1-8 As shown, the high-efficiency processing equipment, such as figure 1 As shown, it includes a lubricating oil blending tank 1 and a linkage device 2 installed in t...

Embodiment 1

[0060]A high wear-resistant lubricating oil made of the following raw materials in parts by weight: 80 parts of base oil, 2 parts of nano-tungsten disulfide, 0.4 part of surfactant, 0.8 part of defoamer, and 1.5 parts of anti-wear additive;

[0061] The lubricating oil is made by the following steps:

[0062] Step S1, weighing each raw material according to parts by weight;

[0063] Step S2, take half of the base oil, slowly drop the surfactant into the base oil, mix evenly, then add the nano-tungsten disulfide powder and anti-wear additives into the mixed oil of the base oil and the surfactant, and then Add the remaining half of the base oil to get a premix;

[0064] Step S3, add the premix into the lubricating oil blending tank 1 of the high-efficiency processing equipment, and simultaneously turn on the motor connected to the first stirring shaft 21 and the air pump connected to the pulse air pipe 1304, blend for 55 minutes, discharge, and process to obtain lubricating oil...

Embodiment 2

[0066] A high wear-resistant lubricating oil, made of the following raw materials in parts by weight: 85 parts of base oil, 2.5 parts of nano-tungsten disulfide, 0.5 parts of surfactant, 0.9 parts of defoaming agent, and 1.7 parts of anti-wear additive;

[0067] The lubricating oil is made by the following steps:

[0068] Step S1, weighing each raw material according to parts by weight;

[0069] Step S2, take half of the base oil, slowly drop the surfactant into the base oil, mix evenly, then add the nano-tungsten disulfide powder and anti-wear additives into the mixed oil of the base oil and the surfactant, and then Add the remaining half of the base oil to get a premix;

[0070] Step S3: Add the premix into the lubricating oil blending tank 1 of the high-efficiency processing equipment, and simultaneously turn on the motor connected to the first stirring shaft 21 and the air pump connected to the pulse air pipe 1304, blend for 60 minutes, discharge, and process to obtain lu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com