High compatibility modifier for plastic processing

A technology of compatibility and modifying agent, which is applied in the field of plastic processing aids, can solve the problems that the product performance cannot meet expectations, the performance of the modifying agent is poor, and the effect of the application of the modifying agent is affected, etc., to achieve excellent whiteness enhancement And weather resistance, good fluidity and uniformity of modification, excellent compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

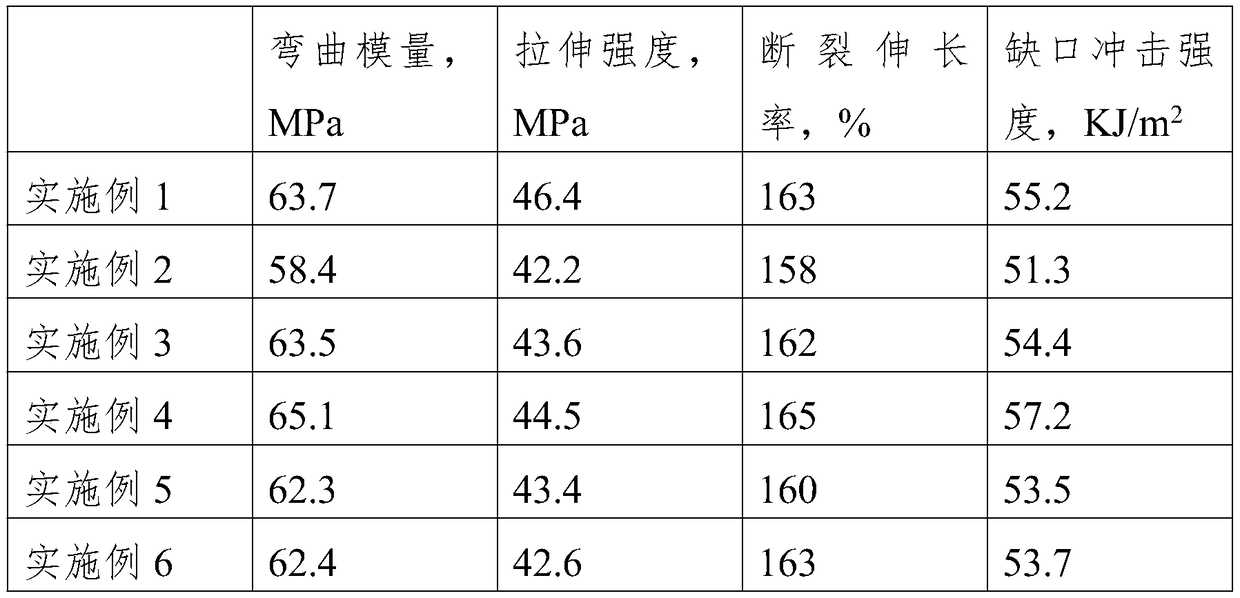

Examples

Embodiment 1

[0021] A highly compatible modifier for plastic processing, comprising the following components in parts by weight: 10 parts of nano-calcium carbonate, 8 parts of chlorinated polyethylene, 8 parts of silicon acrylic emulsion, 4 parts of polydimethylsiloxane copolyol, 1 part of branched polyether polyol, 6 parts of polyethylene glycol, 0.5 part of ethyl p-aminobenzoate, 0.5 part of heat stabilizer, 0.5 part of coupling agent, and 0.3 part of surfactant.

[0022] Among them: the grafted polyether polyol is made of methacrylate grafted polyether polyol, and the hydroxyl value is 34.5±0.3mgKOH / g; the heat stabilizer is compounded with calcium zinc stabilizer and organotin stabilizer, the quality The ratio is 1:0.8; the coupling agent is compounded with silane coupling agent and titanate coupling agent, and the mass ratio of the two is 1:3, of which A151 is used as the silane coupling agent, and TMC is used as the titanate coupling agent -105, TMC-114, TMC-TE composition, the molar...

Embodiment 2

[0029] A highly compatible modifier for plastic processing, comprising the following components in parts by weight: 5 parts of nano-calcium carbonate, 8 parts of chlorinated polyethylene, 5 parts of silicon acrylic emulsion, 4 parts of polydimethylsiloxane copolyol, 2 parts of branched polyether polyol, 6 parts of polyethylene glycol, 0.6 part of ethyl p-aminobenzoate, 0.4 part of heat stabilizer, 0.8 part of coupling agent, and 0.2 part of surfactant.

[0030] Among them: the grafted polyether polyol is made of methacrylate grafted polyether polyol, and the hydroxyl value is 34.5±0.3mgKOH / g; the heat stabilizer is compounded with calcium zinc stabilizer and organotin stabilizer, the quality The ratio is 1:0.5; the coupling agent is compounded with silane coupling agent and titanate coupling agent, and the mass ratio of the two is 1:2, of which A151 is used as the silane coupling agent, and TMC is used as the titanate coupling agent -105, TMC-114, TMC-TE composition, the molar...

Embodiment 3

[0037] A high-compatibility modifier for plastic processing, comprising the following components in parts by weight: 12 parts of nano-calcium carbonate, 6 parts of chlorinated polyethylene, 8 parts of silicon-acrylic emulsion, 3 parts of polydimethylsiloxane copolyol, 1.5 parts of branched polyether polyol, 6 parts of polyethylene glycol, 1 part of ethyl p-aminobenzoate, 0.5 part of heat stabilizer, 0.5 part of coupling agent, and 0.3 part of surfactant.

[0038] Among them: the grafted polyether polyol is made of methacrylate grafted polyether polyol, and the hydroxyl value is 34.5±0.3mgKOH / g; the heat stabilizer is compounded with calcium zinc stabilizer and organotin stabilizer, the quality The ratio is 1:0.6; the coupling agent is compounded with silane coupling agent and titanate coupling agent. The composition of TMC-105, TMC-114, and TMC-TE is selected, and the molar ratio of the three is 1:1:0.5; the surfactant is a combination of sorbitan monostearate and N-acyl amino...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com