Annular multi-pipe embedded type cascade steam injection activation kiln device and control method and application thereof

A technology of steam injection and steam injection, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of unreasonable distribution of steam injection, poor quality, and low product activation degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

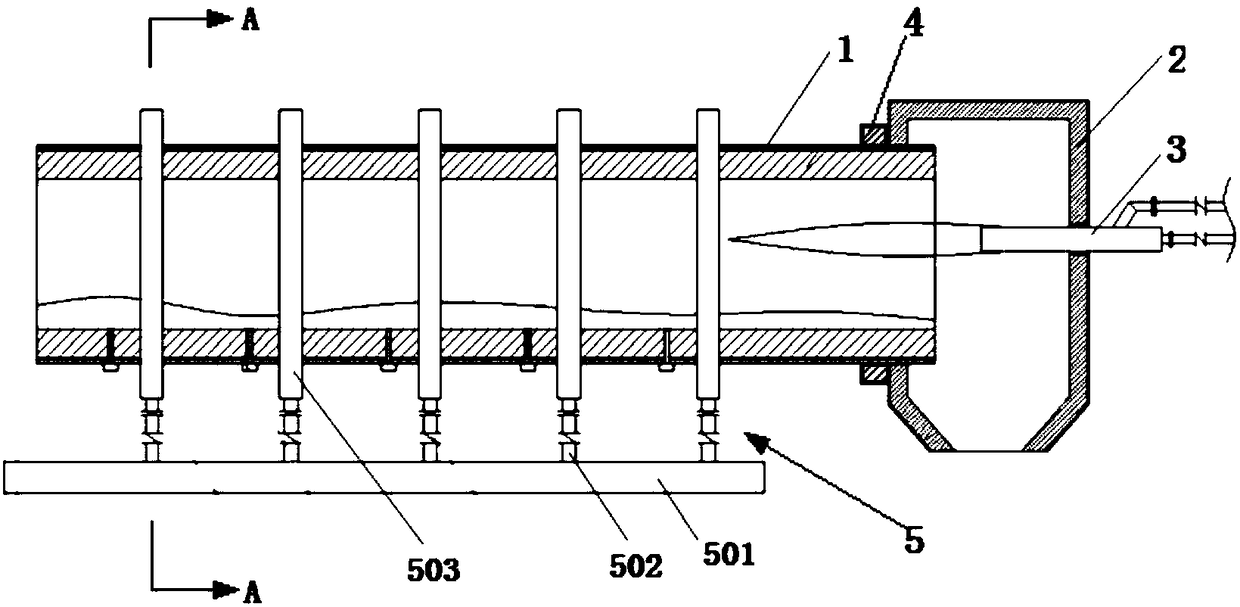

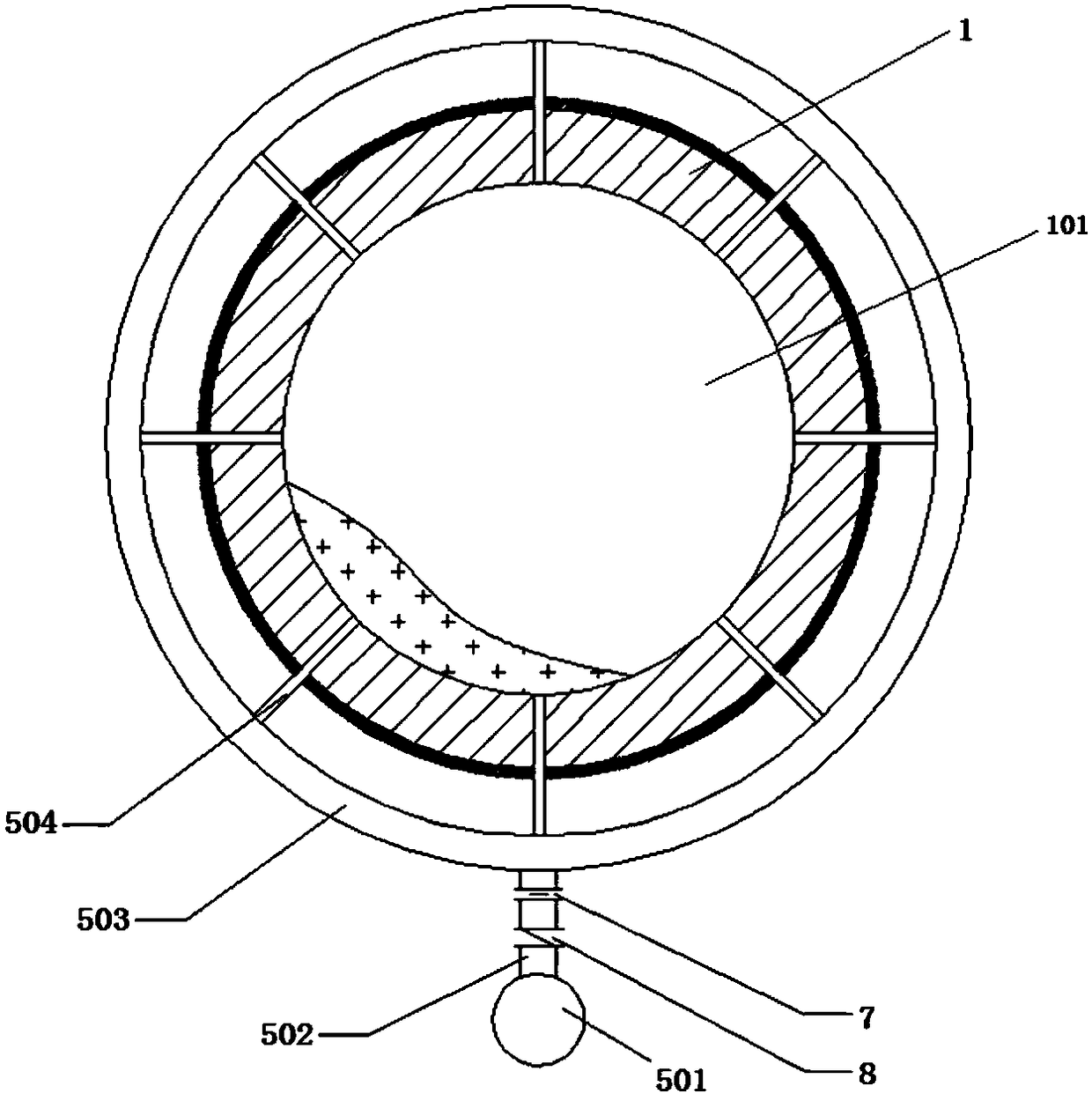

[0084] Such as figure 1 and 2 As shown, an annular multi-pipe pre-buried cascaded steam activation kiln device includes a kiln body 1, a kiln head box 2, a burner 3, a driving device 4, and a steam injection device 5. The end of the kiln body 1 is connected and communicated with the kiln head box 2 . The burner 3 is arranged on the axial side wall of the kiln head box 2. The driving device 4 is connected with the kiln body 1 and drives the kiln body 1 to rotate. The kiln body 1 is provided with an activation chamber 101 . The steam injection device 5 includes a steam delivery main pipe 501 , a steam delivery branch pipe 502 , a steam delivery ring 503 , and a steam injection pipe 504 . The steam conveying ring 503 is arranged concentrically with the kiln body 1 outside the kiln body 1 . One end of the steam injection pipe 504 passes through the kiln body 1 and communicates with the activation chamber 101 , and the other end of the steam injection pipe 504 is connected and...

Embodiment 2

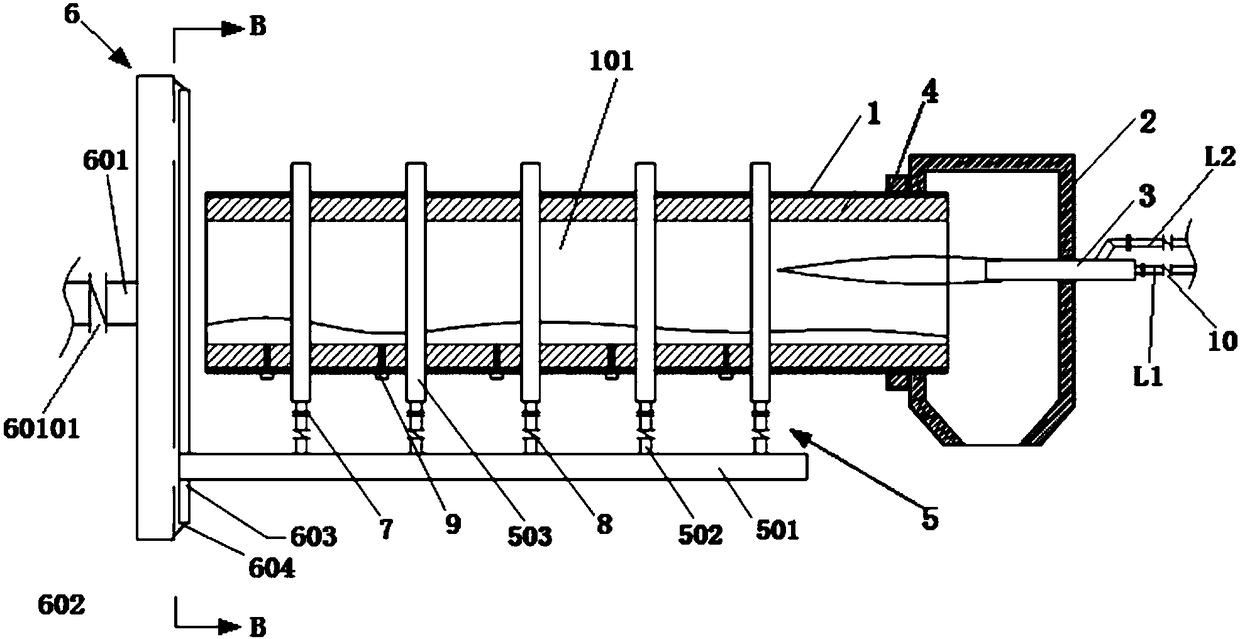

[0086] Such as image 3 and 4 As shown, embodiment 1 is repeated, except that the device also includes a static and dynamic sealing device 6 . The static and dynamic sealing device 6 includes an air supply main pipe 601 , a static disk 602 , a dynamic disk 603 and a seal 604 . The air supply manifold 601 is connected and communicated with the static disk 602 . The static disk 602 and the dynamic disk 603 are arranged in parallel, and a seal 604 is provided between the static disk 602 and the dynamic disk 603 . The dynamic disk 603 is fixedly connected with the steam delivery main pipe 501 . The static disk 602 is a hollow circular pie-shaped structure. The side of the static disk 602 close to the dynamic disk 603 is provided with an annular steam outlet 60201 . The inlet end of the steam delivery main pipe 501 corresponds to the position of the annular steam outlet 60201. The air supply main pipe 601 is provided with a main pipe control valve 60101 .

Embodiment 3

[0088] Repeat Example 2, except that the steam spraying device 5 includes five steam delivery rings 503 . The five steam delivery rings 503 are arranged concentrically with the kiln body 1 in the axial direction and evenly parallel to the outside of the kiln body 1 . Each steam delivery ring 503 is connected and communicated with the steam delivery main pipe 501 through an independent steam delivery branch pipe 502 . Each steam delivery ring 503 is provided with 6 steam injection pipes 504. One end of the 6 steam injection pipes 504 is evenly arranged on the kiln body 1, and the other end of each steam injection pipe 504 is connected with the steam delivery ring 503 and connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com