Patents

Literature

173results about How to "Adequate contact response" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

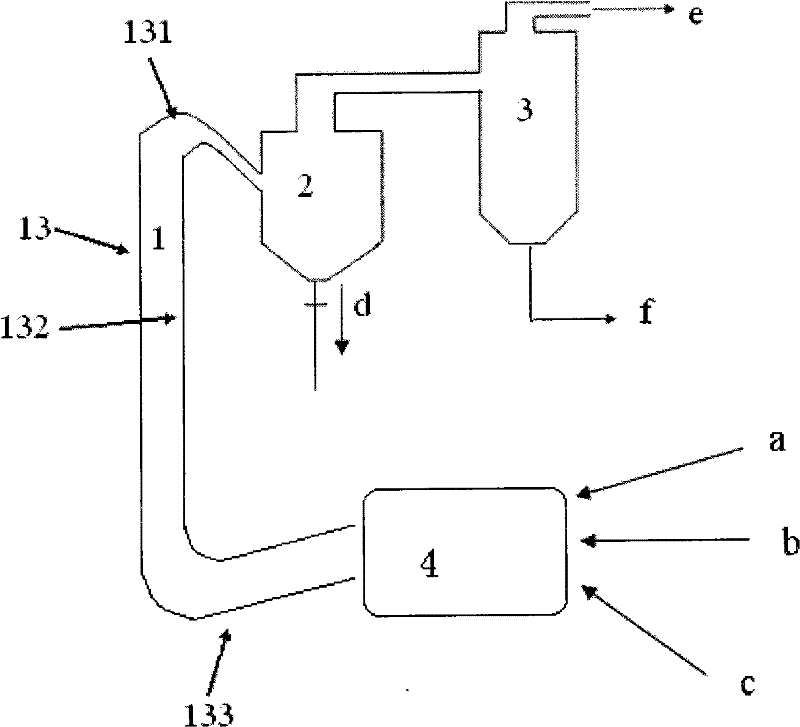

Method for preparing high silicon molecular sieve

ActiveCN102050459AAdequate contact responseContinuous contact reactionFaujasite aluminosilicate zeoliteMolecular-sieve compoundsMolecular sieveGas phase

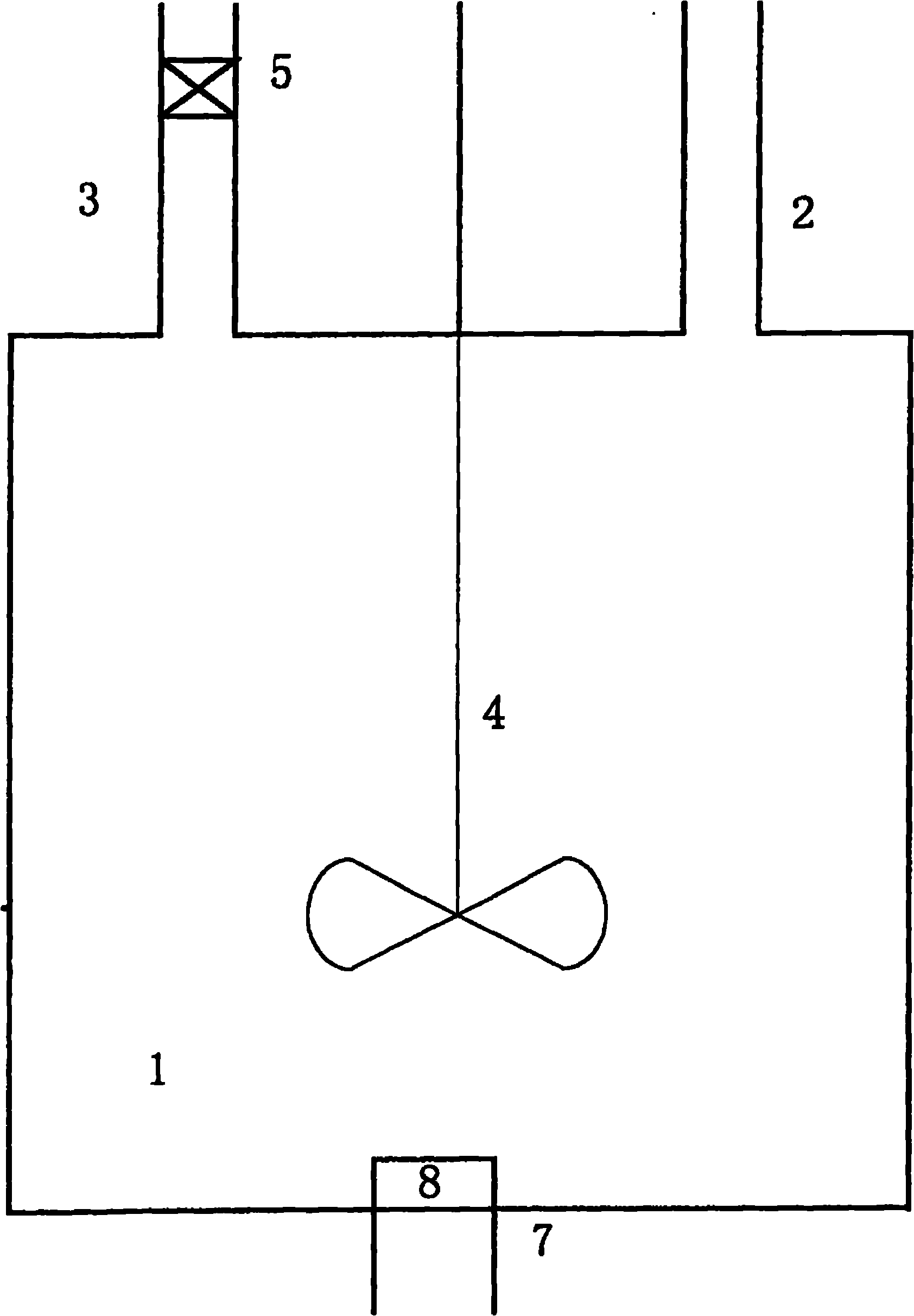

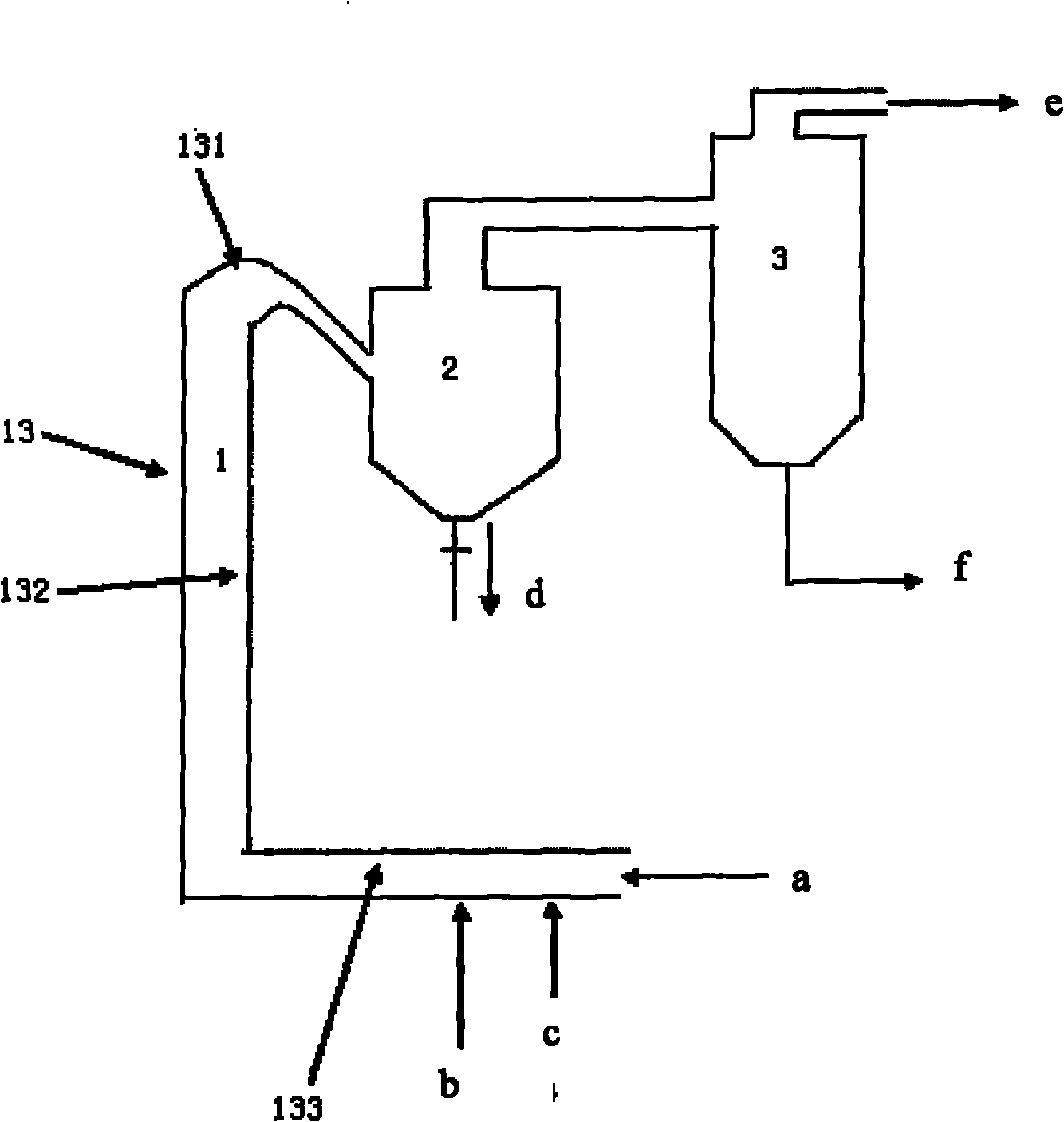

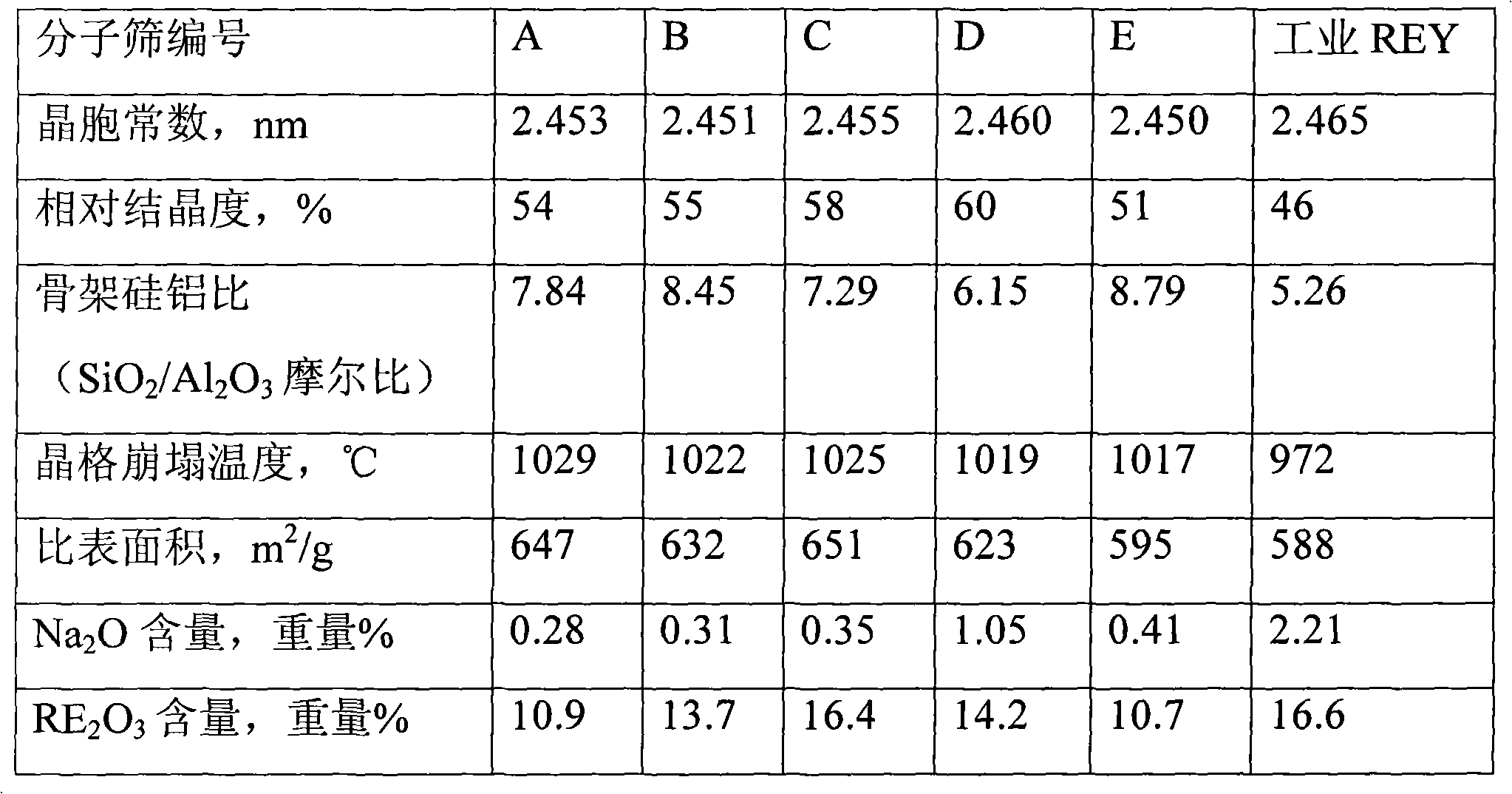

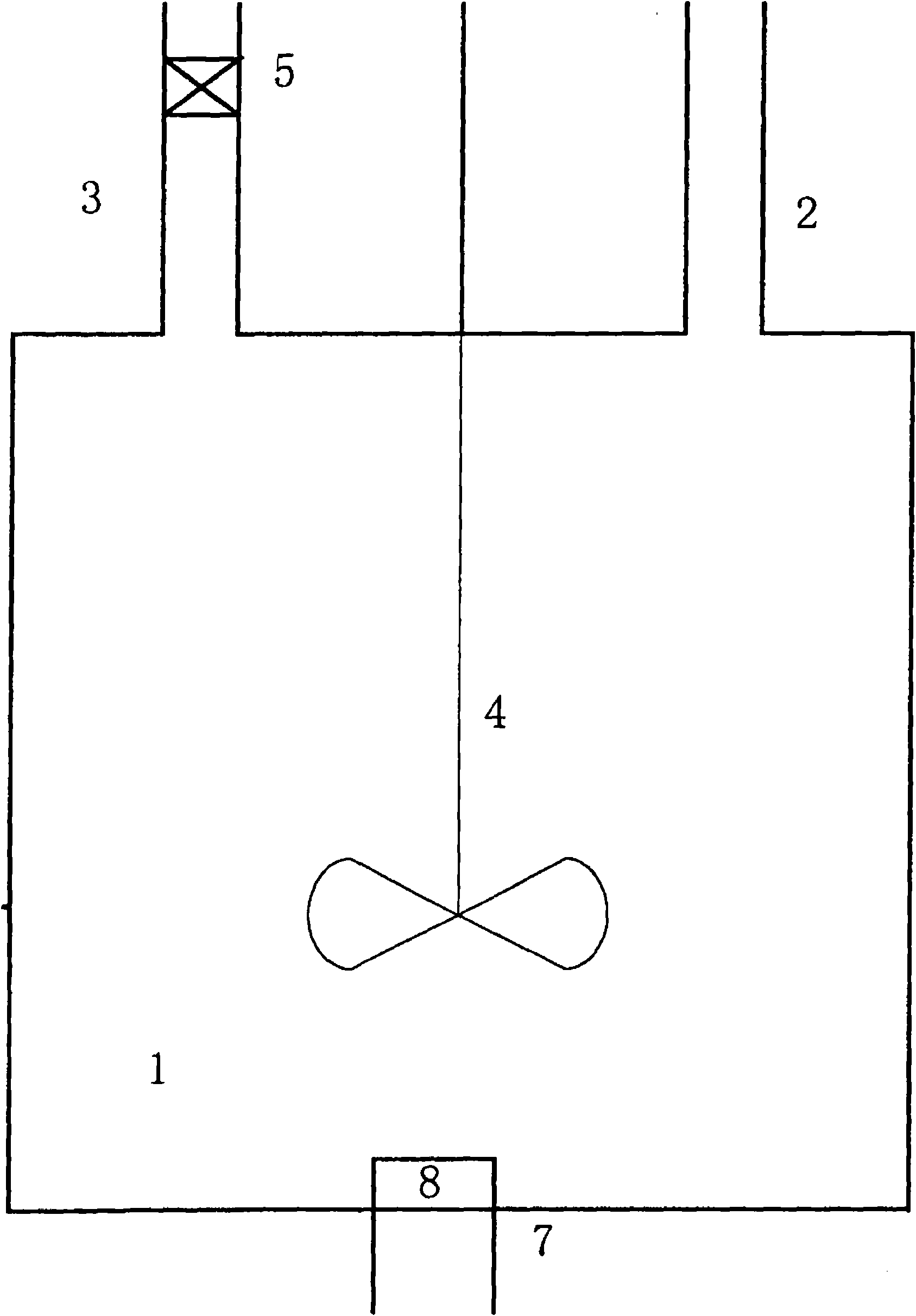

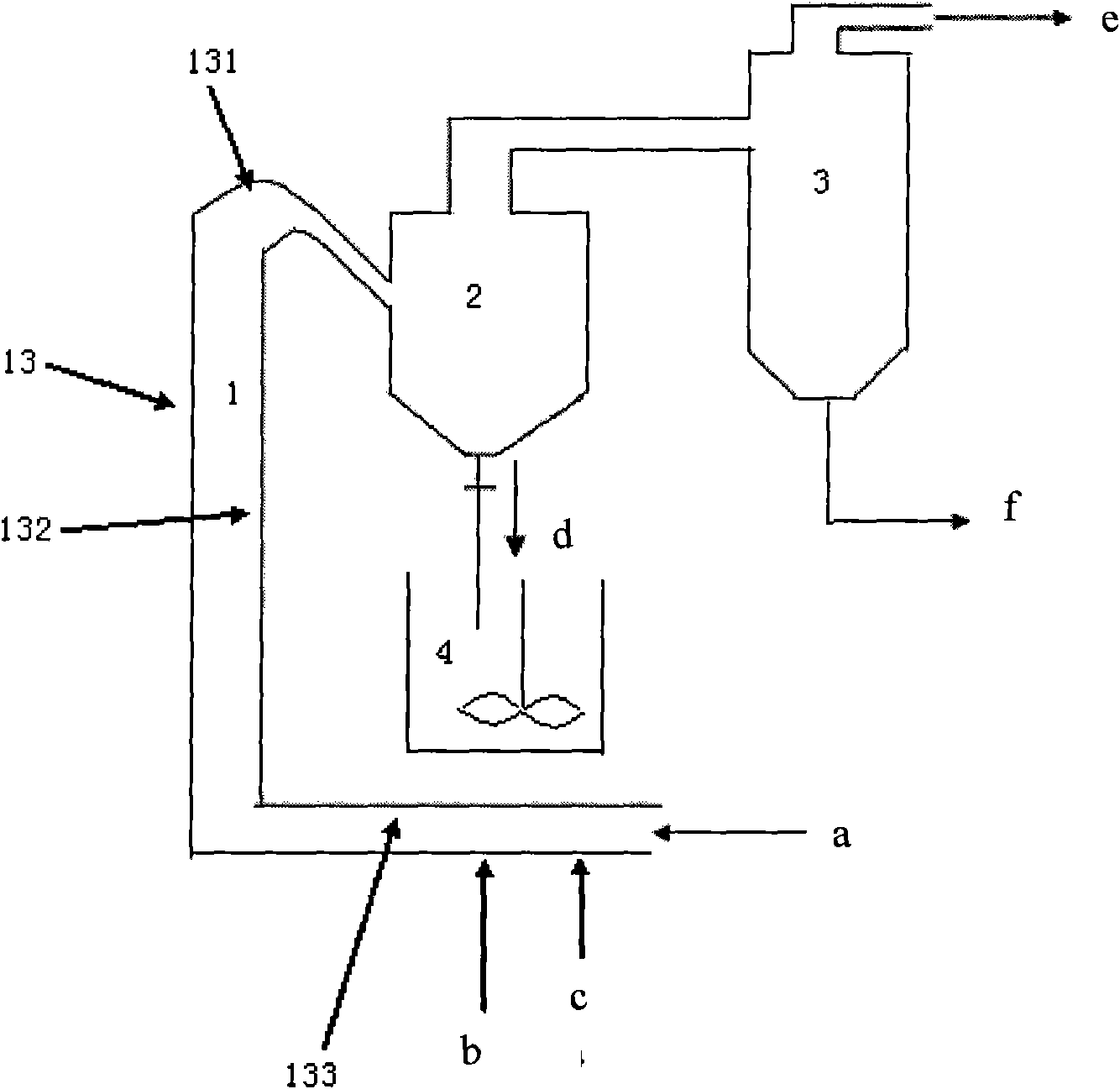

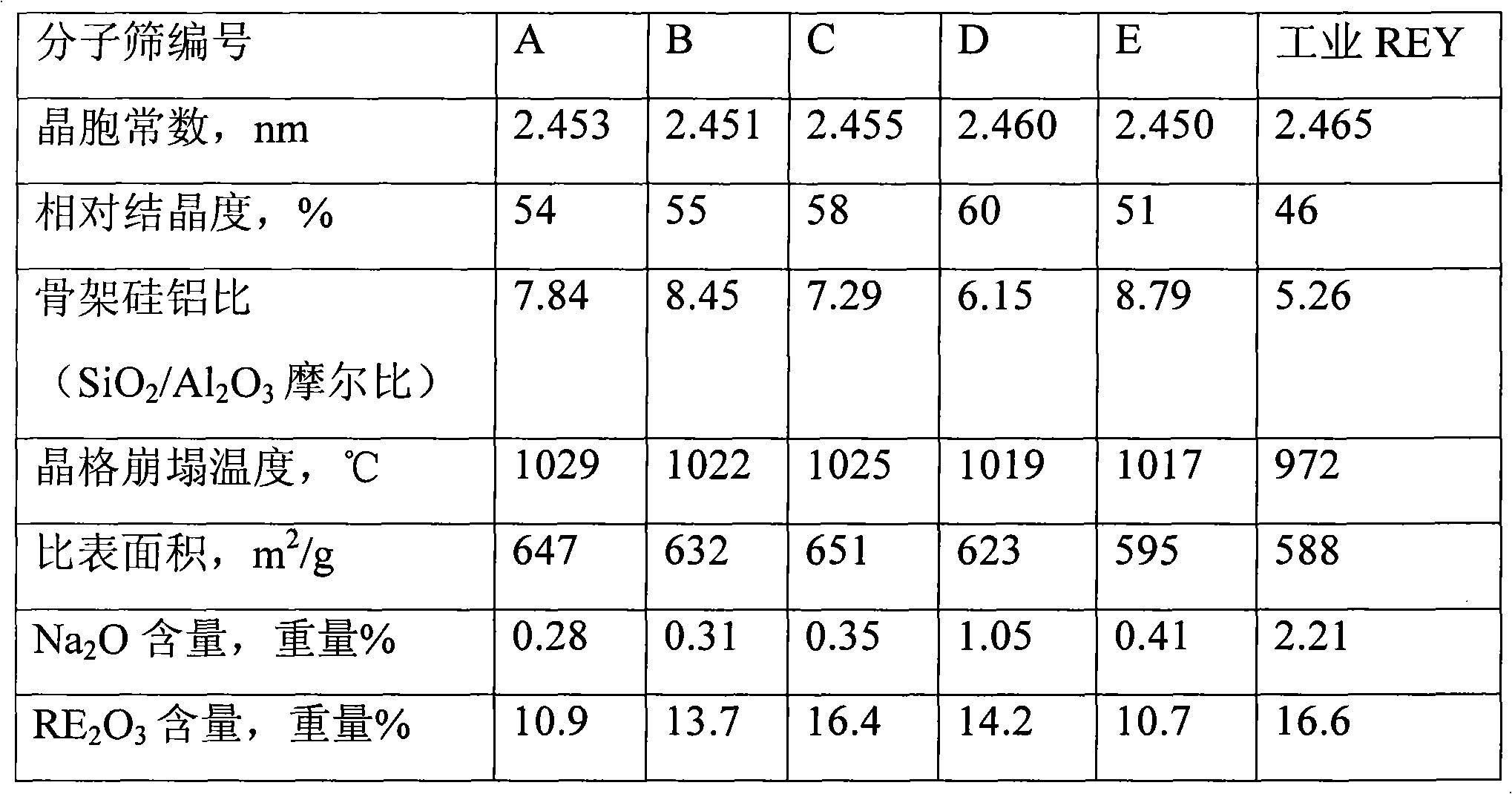

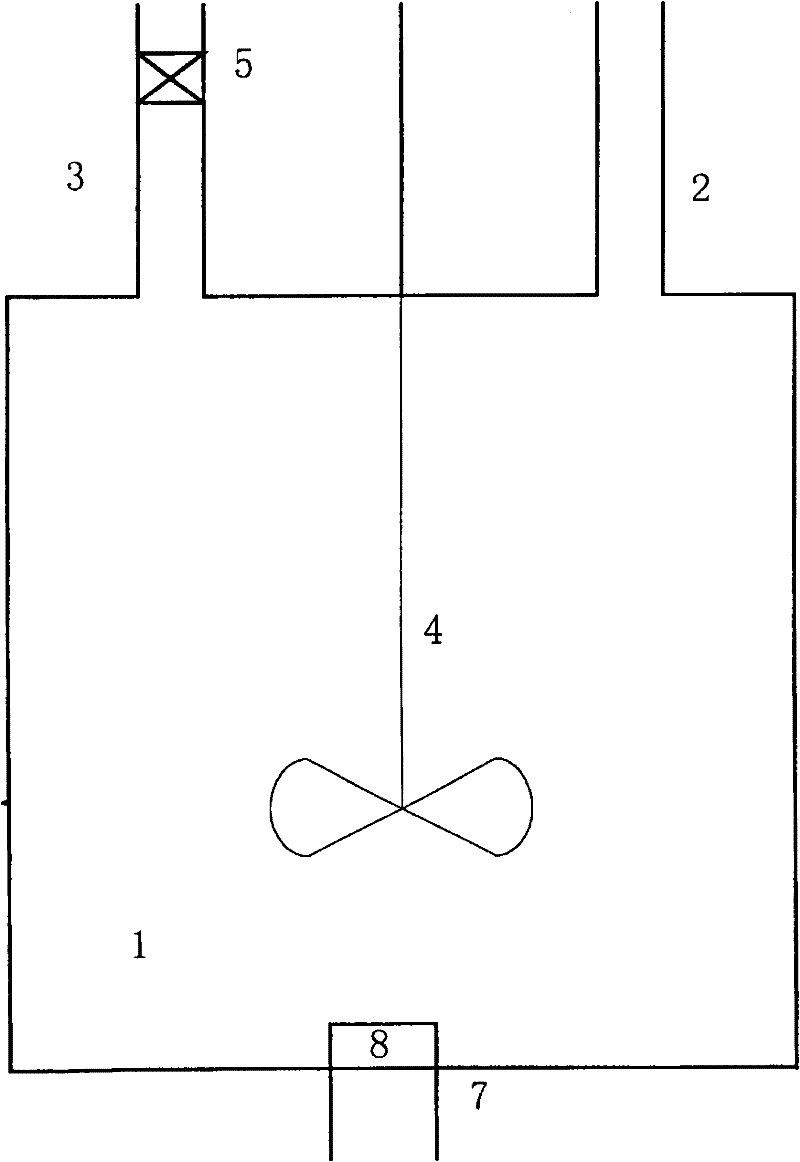

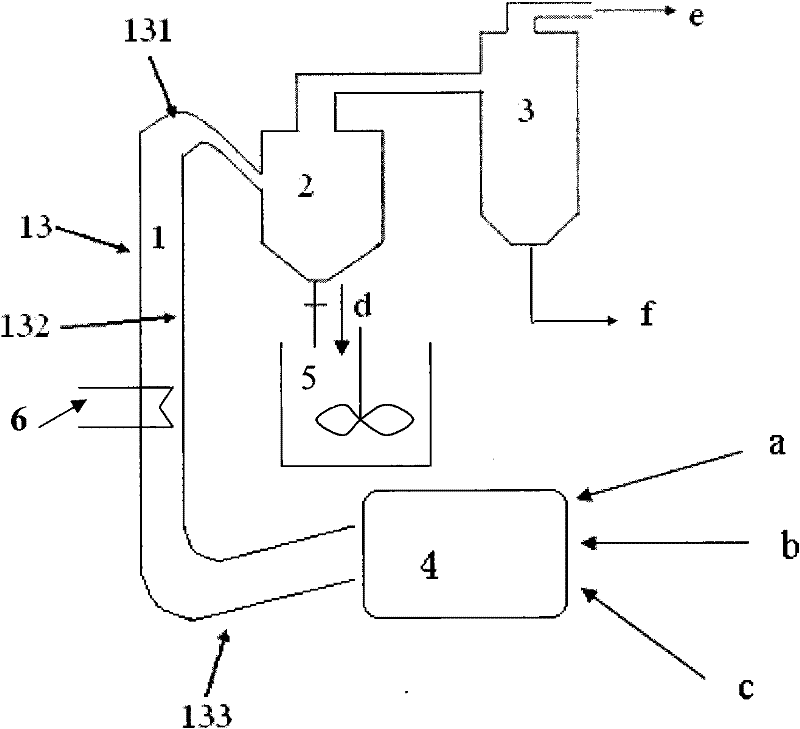

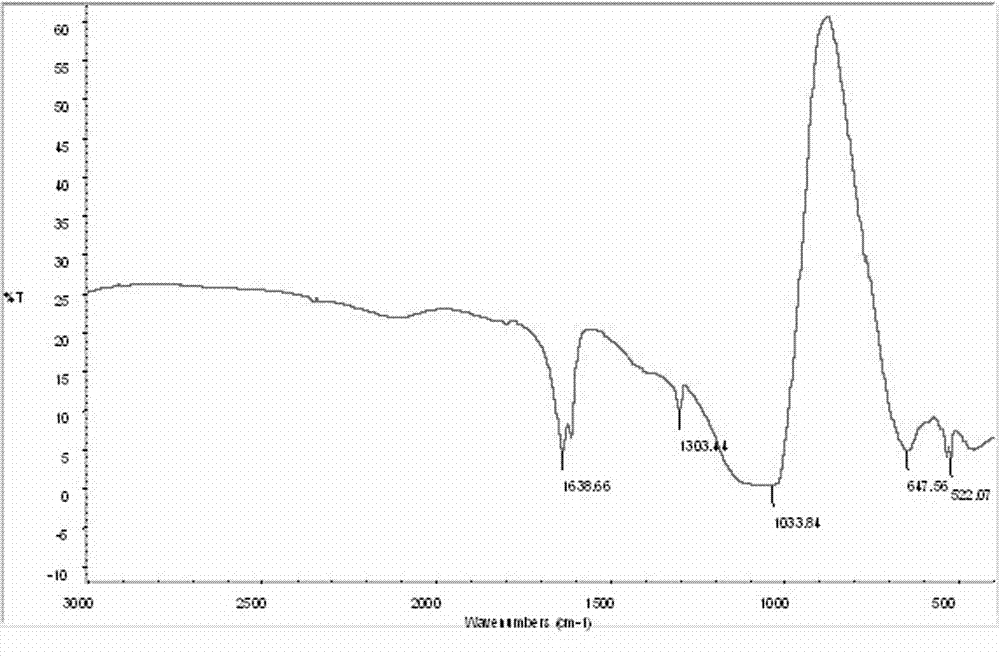

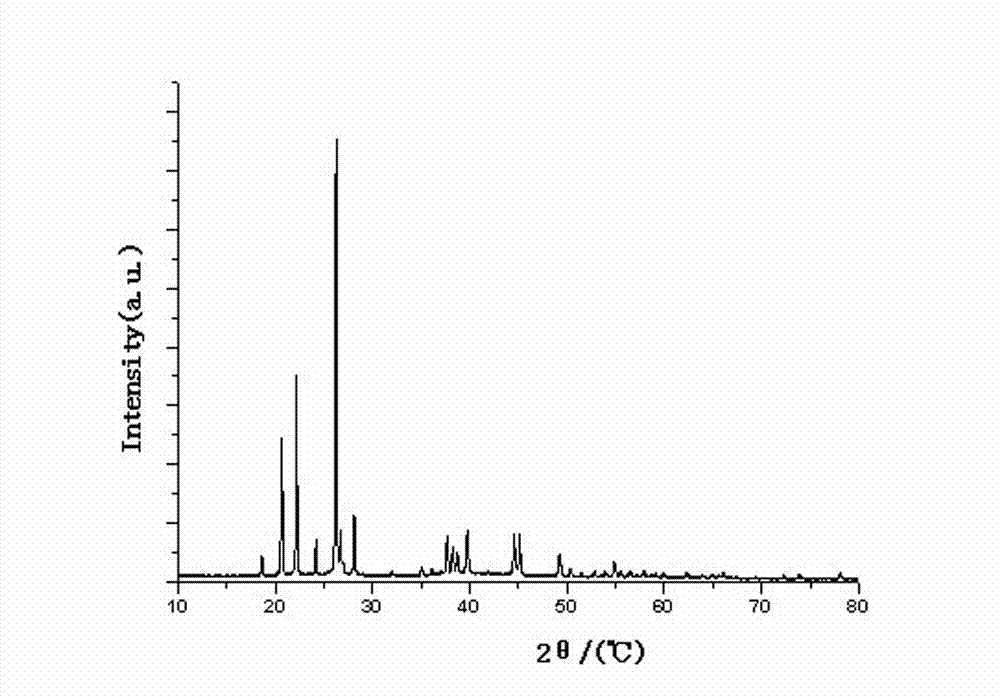

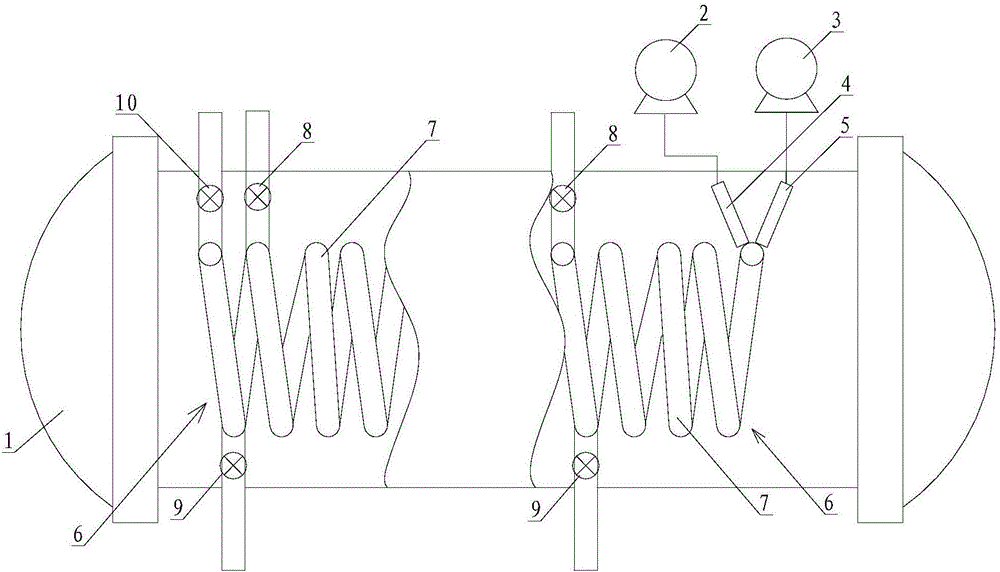

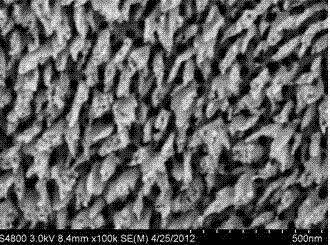

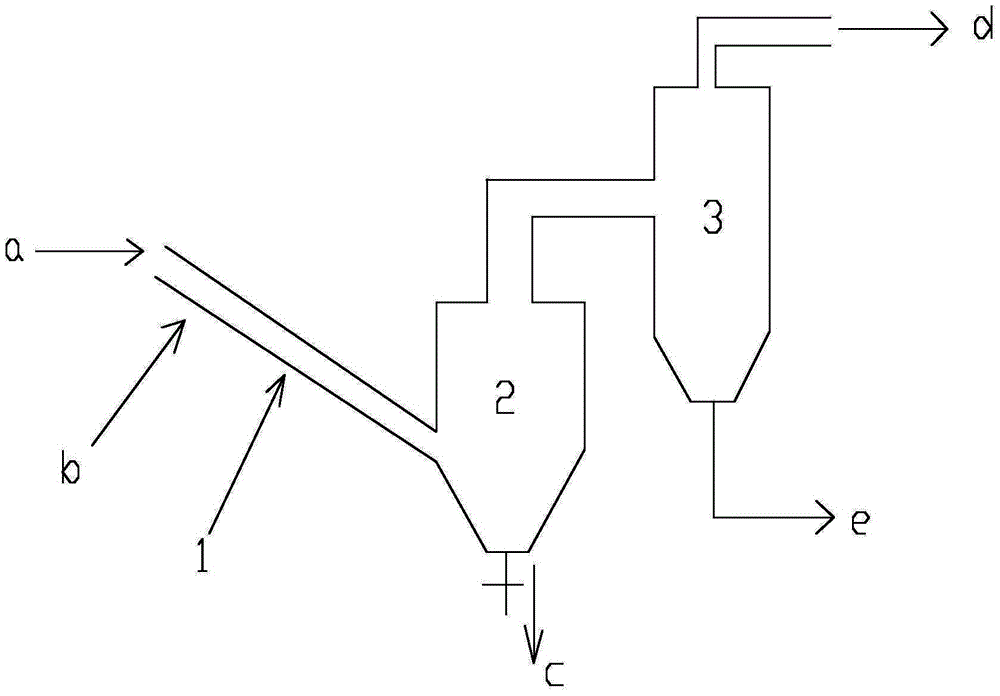

The invention relates to a method for preparing a high silicon molecular sieve. The method comprises the following steps: circulating a molecular sieve along with inert carrier air under the carrying of inert carrier air flow and contacting the molecular sieve with gas-phase SiCl4 in a flowing sate, wherein the contact time of the molecular sieve and the gas-phase SiCl4 is from 10 seconds to 100 minutes. By using the method for preparing the high silicon molecular sieve in the invention, the continuous contact reaction of the molecular sieve and the SiCl4 can be achieved, and the contact time of the molecular sieve and the SiCl4 can be controlled through controlling the flow speed of the carrier air and the length of a tubular reactor, thus the contact reaction of the molecular sieve and the SiCl4 can be fully carried out in the tubular reactor.

Owner:CHINA PETROLEUM & CHEM CORP

Method for preparing catalytic cracking catalyst

ActiveCN102049315AAdequate contact responseContinuous contact reactionCatalytic crackingMolecular sieve catalystsMolecular sieveContact time

The invention relates to a method for preparing a catalytic cracking catalyst. The method comprises the following steps: a molecular sieve flows along with inert carrier gas under the condition of being carried by the inert carrier gas flow, and is in contact with gas phase SiCl4 under the flow state; the contact time between the molecular sieve and the gas phase SiCl4 is 10 seconds to 100 minutes; and then the molecular sieve in contact with the gas phase SiCl4 is mixed with a binding agent, clay and water for pulping and pelleting to obtain the catalytic cracking catalyst. The provided preparation method for the catalytic cracking catalyst can realize the continuous contact reaction between the molecular sieve and the gas phase SiCl4 and can control the contact time between the molecular sieve and the gas phase SiCl4 by controlling the flow velocity of the carrier gas and the length of the tubular reactor, so that the contact reaction between the molecular sieve and the gas phase SiCl4 can be fully carried out in the tubular reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of catalytic cracking catalyst

ActiveCN102451736AHigh crystallinityStable qualityCatalytic crackingMolecular sieve catalystsMolecular sieveProduct gas

A preparation method of a catalytic cracking catalyst comprises the following steps: mixing a molecular sieve and gas containing gas-phase SiCl4 to form a mixture flow, allowing the molecular sieve and the gas-phase SiCl4 to contact at 250-700 DEG C for 10 seconds to 100 minutes, mixing the molecular sieve obtained after contacting with the gas-phase SiCl4 with a binder, clay and water, performing beating and granulation to obtain the catalytic cracking catalyst. The preparation method of the catalyst provided by the invention can realize the continuous proceeding of the contact reaction of the molecular sieve and SiCl4; by the uniform mixing of the molecular sieve and the gas containing gas-phase SiCl4, the silicon supplementing reaction is ensured to be performed uniformly and fully; therefore the prepared molecular sieve has a high crystallization degree, more stable quality, and better performance; by controlling the different contact temperatures of the molecular sieve and SiCl4, different reaction conditions and reaction degrees can be controlled; therefore molecular sieve products with different dealuminization degrees can be obtained, and the catalytic cracking catalyst can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

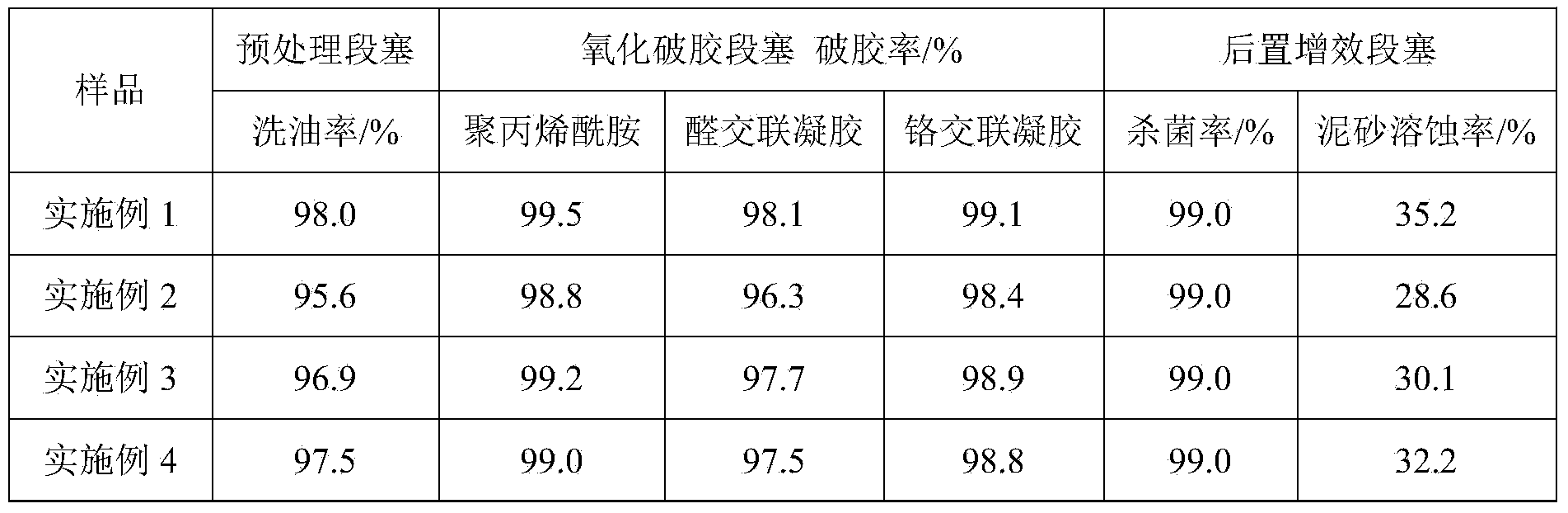

Combined blocking remover for polymer injection blocking well section plug and preparation method and application of combined blocking remover

ActiveCN103881674AOxidative gel breaking rate is highLess corrosiveCleaning apparatusFluid removalInjection wellSolvent

The invention discloses a combined blocking remover for a polymer injection blocking well section plug and a preparation method and application of the combined blocking remover, belonging to the technical field of tertiary oil recovery. The blocking remover comprises a blocking remover for an oxidizing and gel breaking section plug consisting of the following components in percentage by weight: 10-20 percent of sodium percarbonate, 1-2 percent of active agent, 0.5-2 percent of corrosion inhibitor, 2-5 percent of mutual solvent and the balance of water. According to the combined blocking remover for the polymer injection blocking well section plug, the blocking remover for the oxidizing and gel breaking section plug has the characteristics of high oxidizing and gel breaking rate, low corrosion and high safety. The oxidative decomposition and gel breaking rate on polyacrylamide and a cross-linking polymer gel system thereof which are commonly used in oilfield polymer flooding is over 96 percent, and the corrosion rate detected by adopting an N80 steel sheet standard test piece is 1g / m2.h below. After the polymer injection well blockage is decomposed and subjected to gel breaking, the original viscous black blockage is changed into a transparent aqueous solution, the blocking remover is high in liquidity and low in residue rate, the polymer injection well formation plugging can be efficiently removed, and the aims of removing blockage and increasing injection are achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

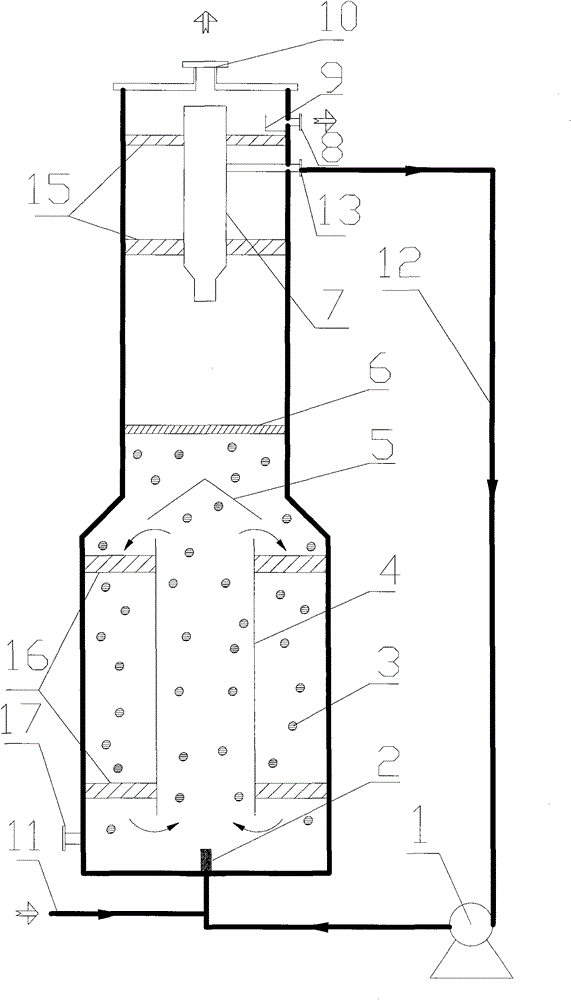

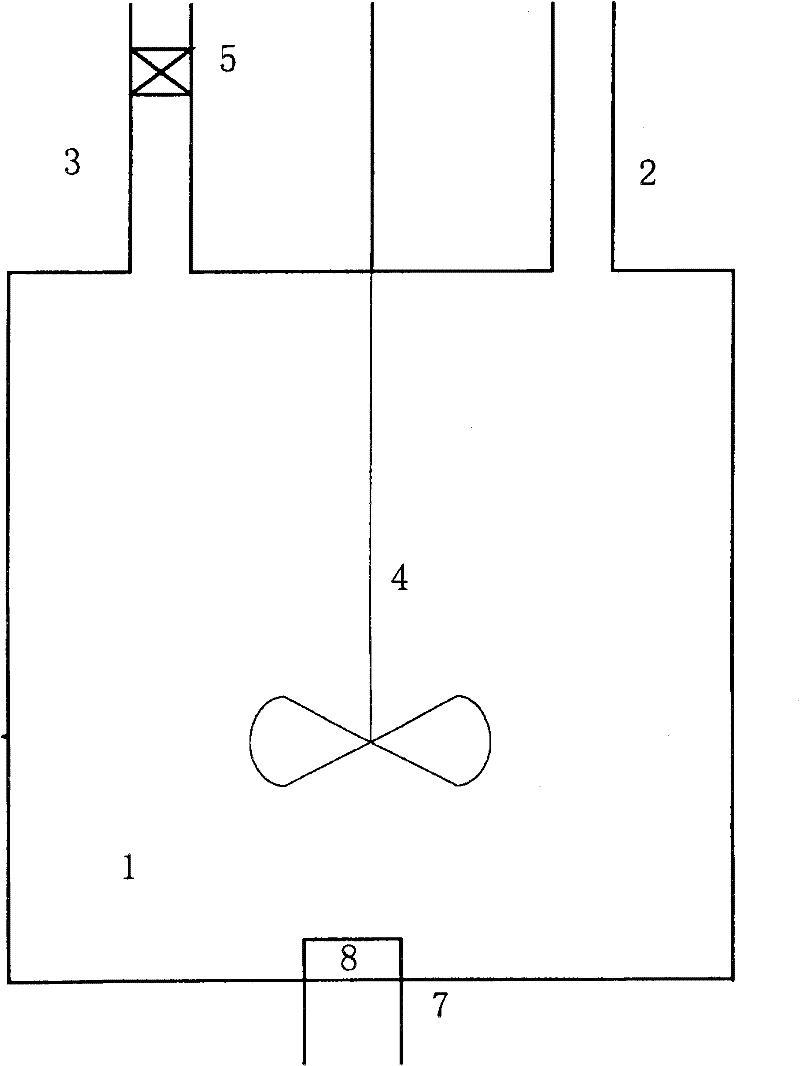

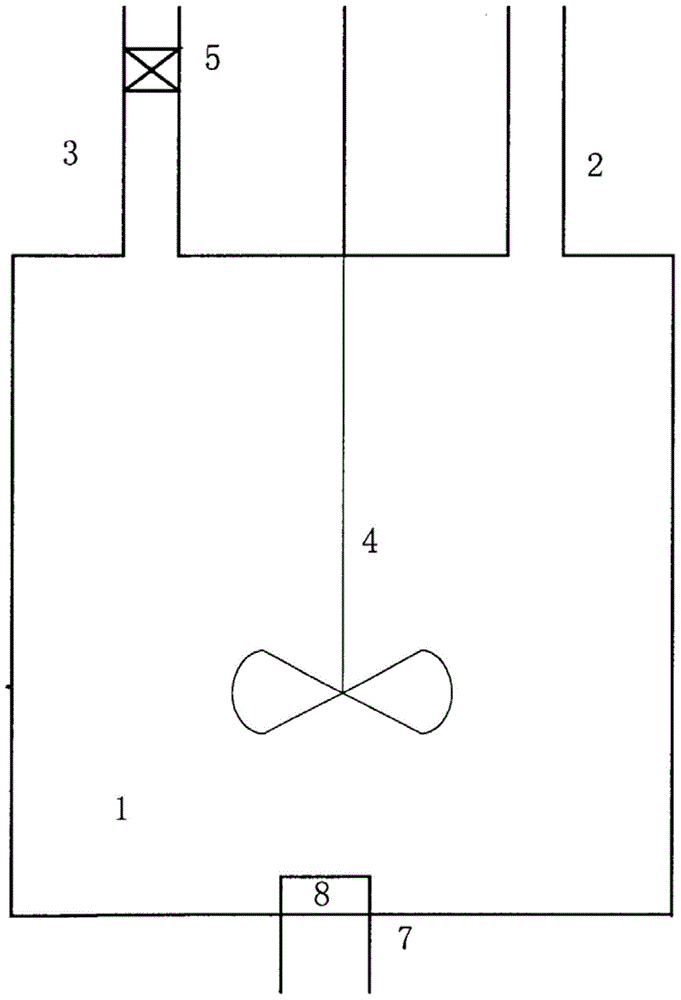

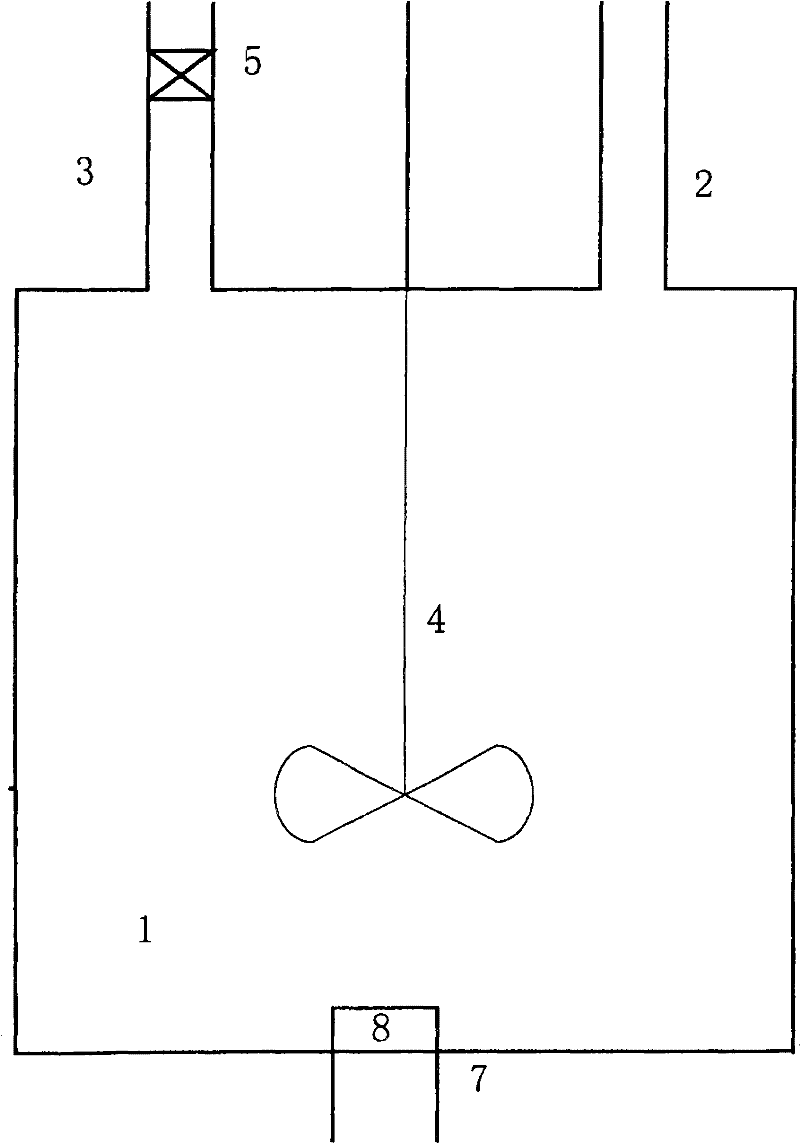

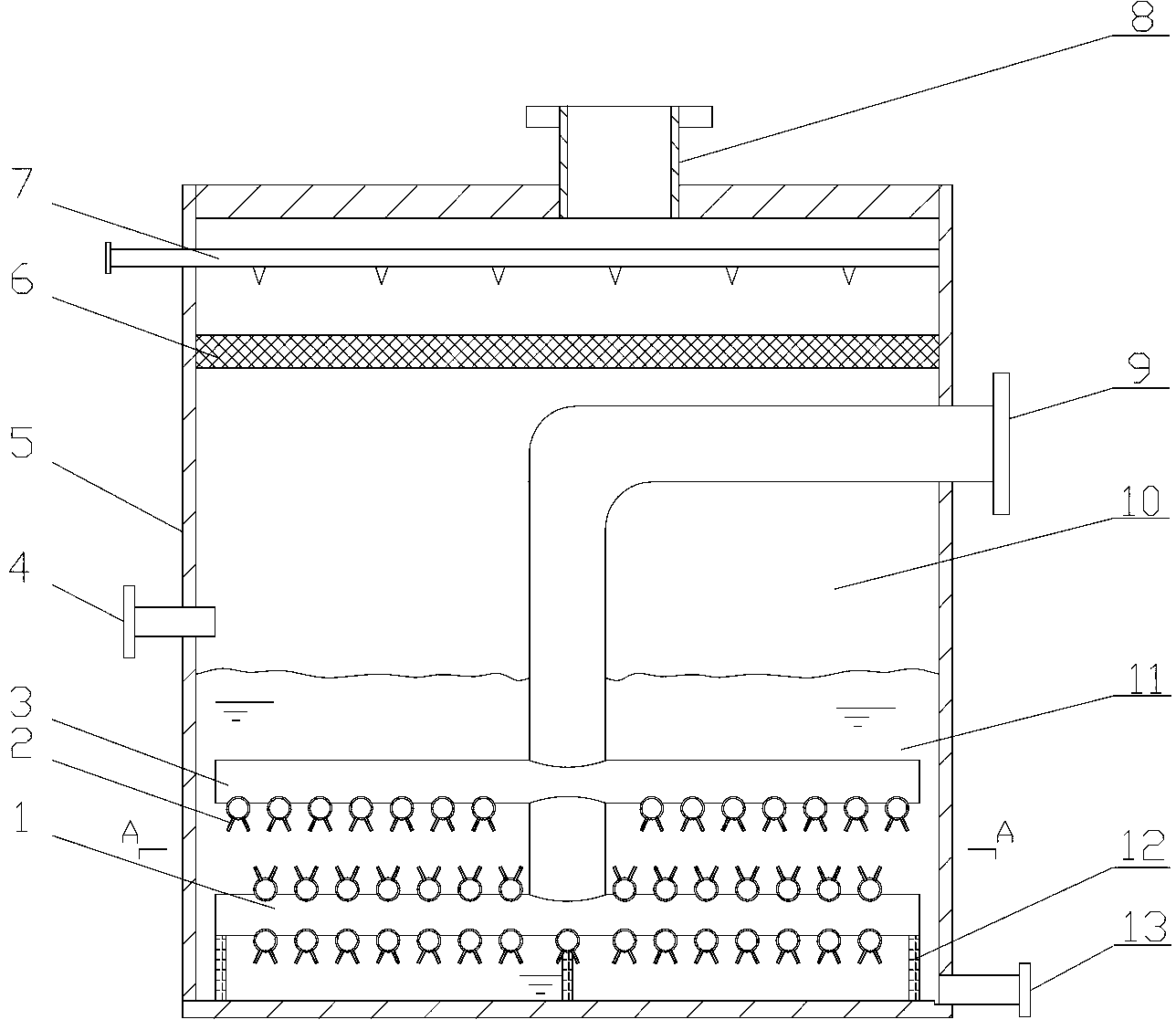

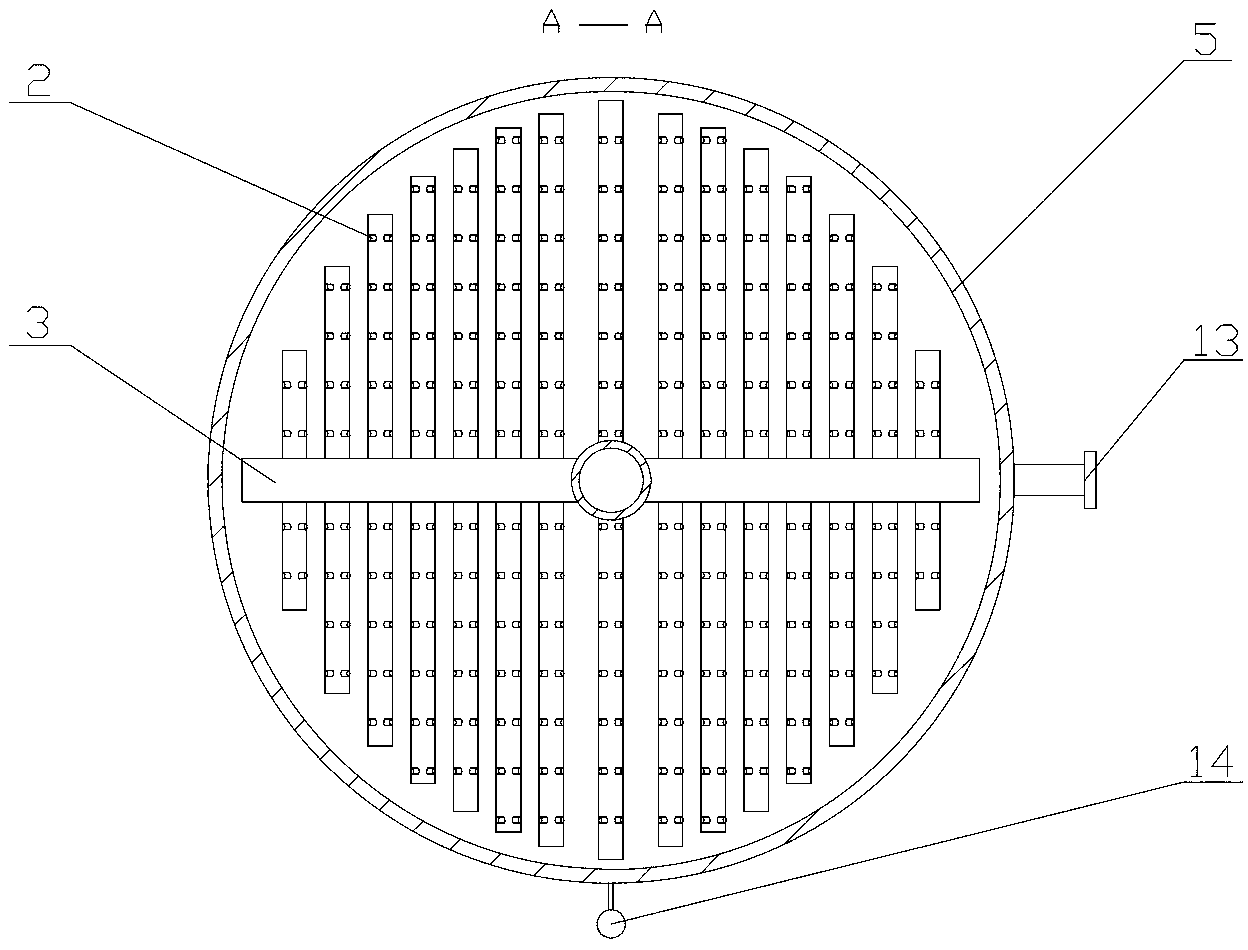

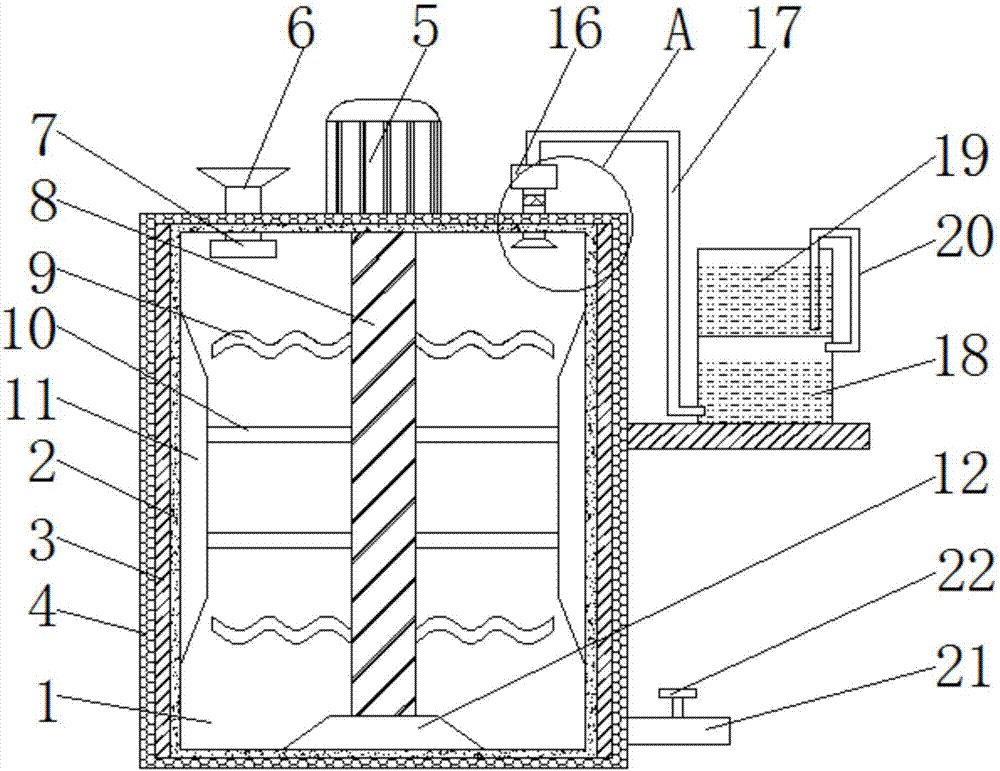

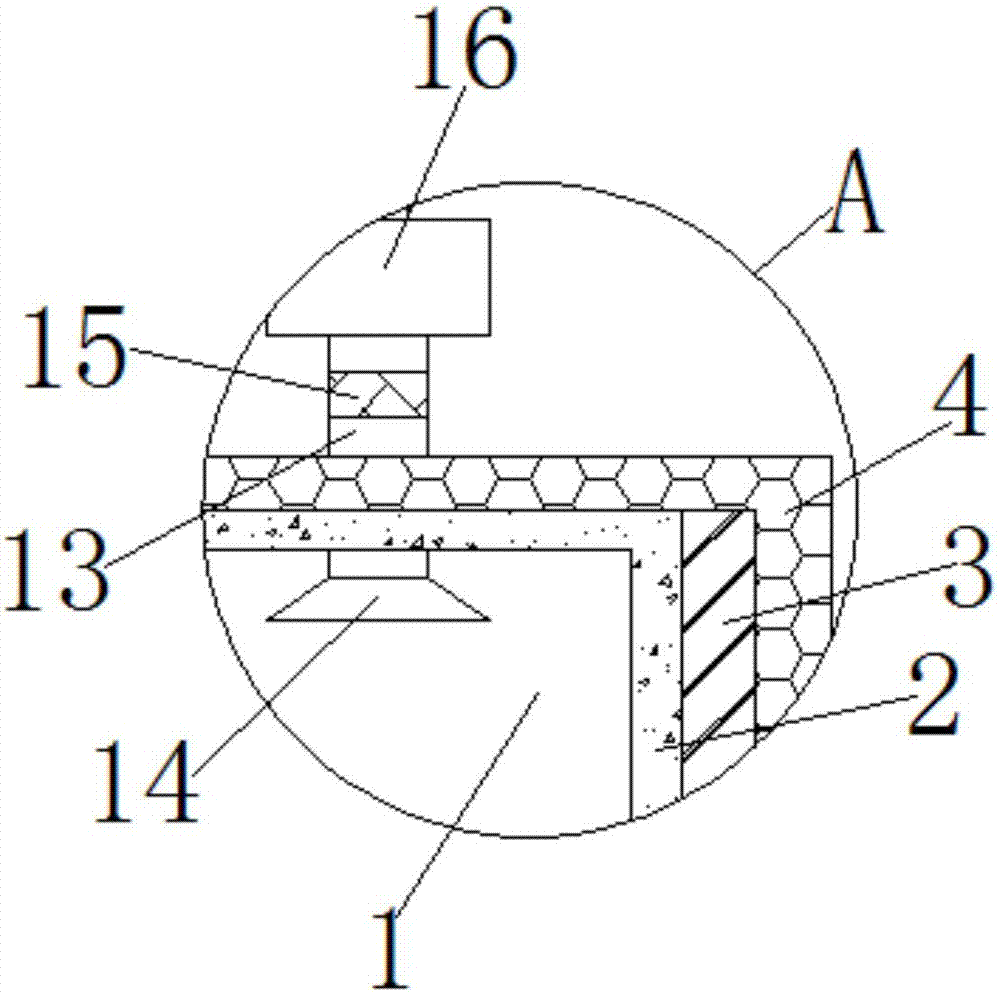

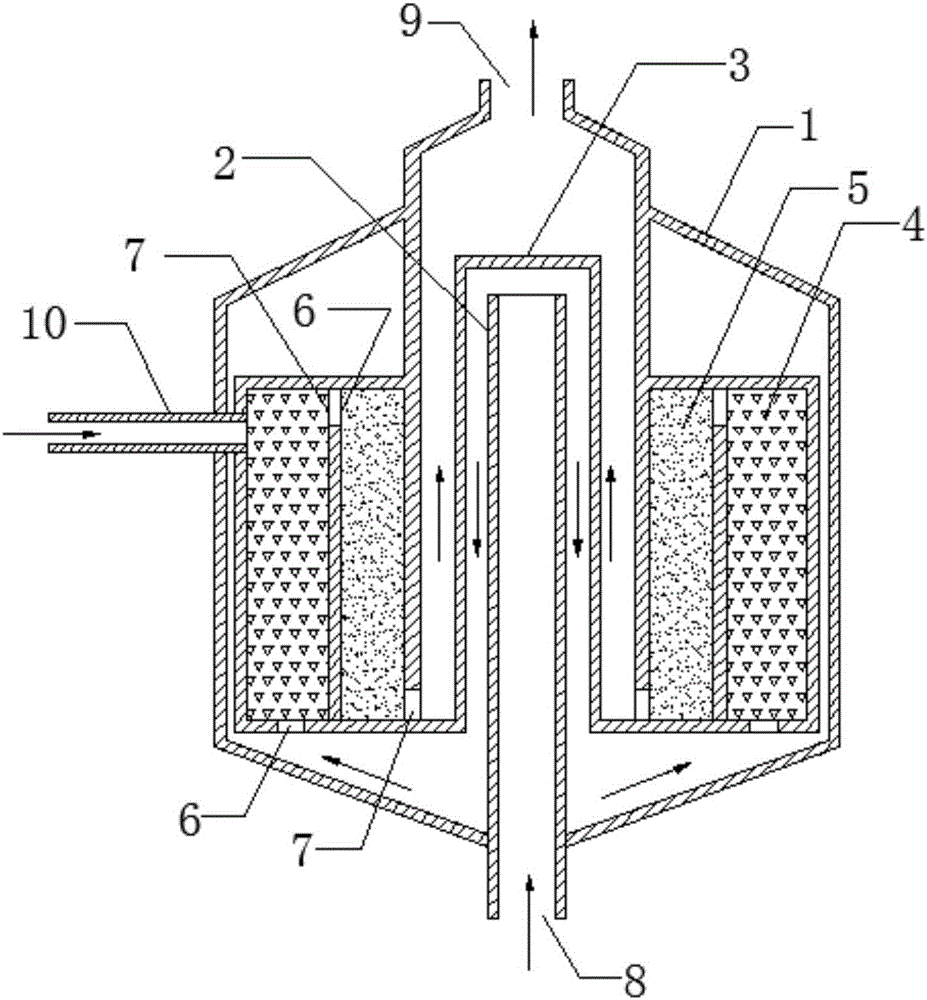

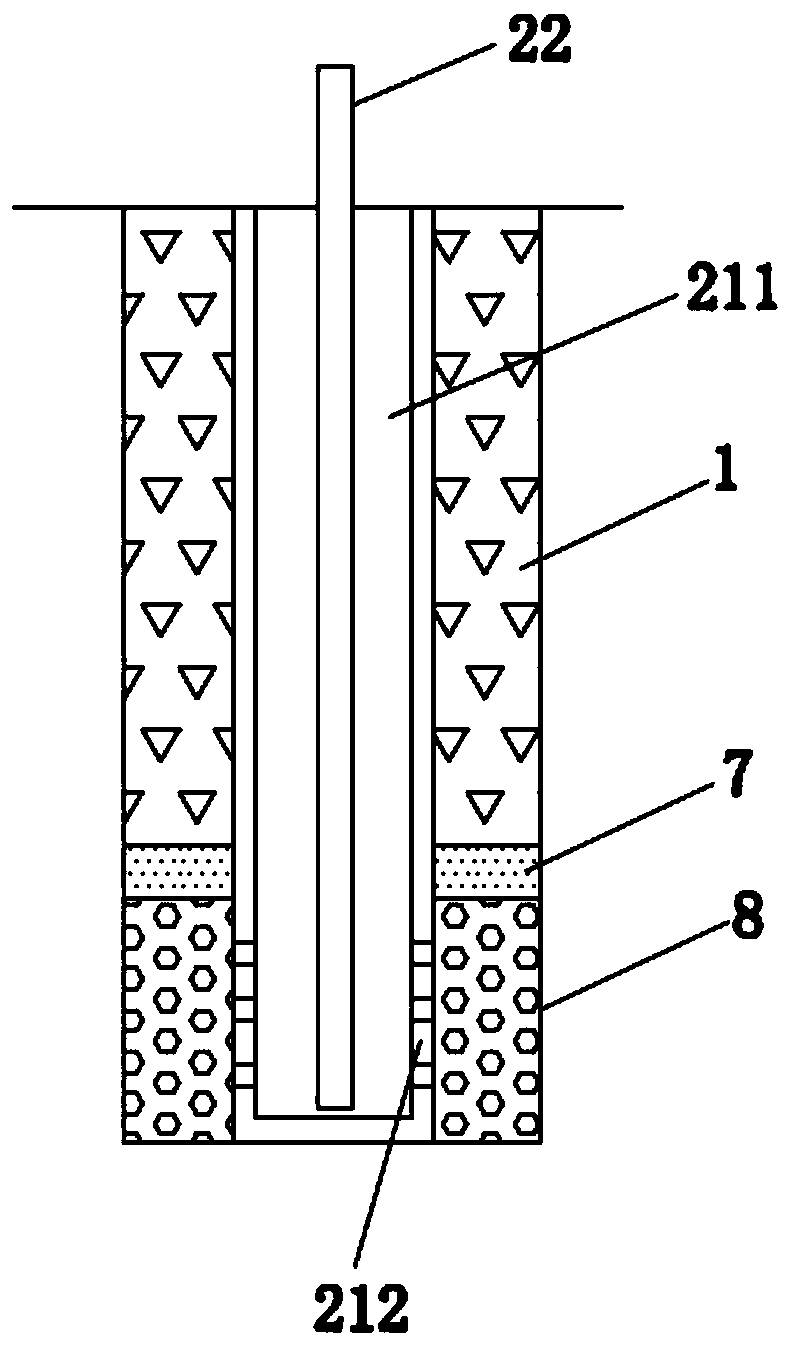

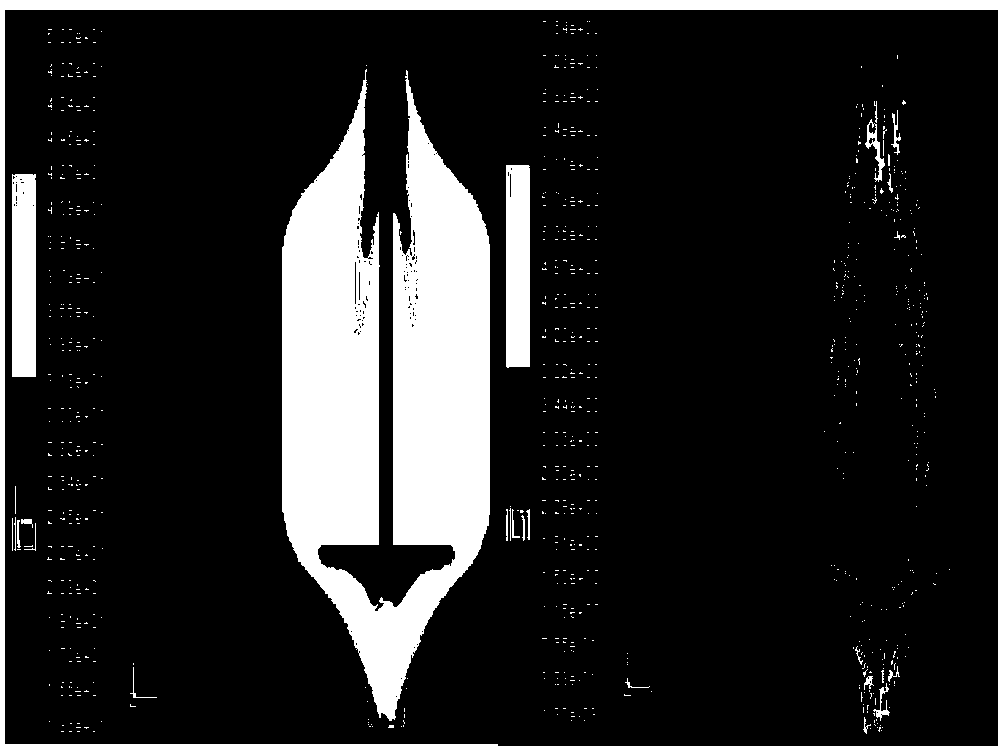

Anaerobic fluidized bed reactor

ActiveCN102745809AEnhanced mass transferExtended stayTreatment with anaerobic digestion processesProcess engineeringThree-phase

The invention discloses an anaerobic fluidized bed reactor, characterized in that: the anaerobic fluidized bed reactor is a two-section cylinder which is thin above and thick below, the upper section is connected with the lower section through a taper transition section, a completly mixed reaction zone and a plug flow reaction zone are arranged in the reactor from bottom to top, a guide cylinder is arranged in the completly mixed reaction zone, a cover hood is arranged above the guide cylinder, a liquid-solid separator is arranged in the plug flow reaction zone, a three-phase separator is arranged above the liquid-solid separator, the water outlet of the three-phase separator is successively connected with a circulating pump and a jet nozzle through a circulating pipeline, and a water inlet pipeline is connected with the jet nozzle. By using outer circulation to drive inner circulation, the efficiency of the reactor is greatly raised.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of high-purity lithium tetrafluoroborate

The invention provides a preparation method of high-purity lithium tetrafluoroborate; and the method comprises the following steps that high-purity lithium fluoride and a boron trifluoride coordination compound react in chain carbonate organic solvent, and lithium tetrafluoroborate is obtained after filtration, concentration, extractive crystallization, washing and drying. In the preparation method of high-purity lithium tetrafluoroborate, the boron trifluoride coordination compound has wide sources of raw materials and is low in price, the linear carbonate organic solvent has low toxin and is environment-friendly, the synthetic reaction conditions are mild, the operation is simple, the equipment investment is low, the lithium tetrafluoroborate productivity is high, the yield is high, the energy consumption is low, the post-treatment is simple, and the method is applicable to large-scale production.

Owner:GUANGZHOU TINCI MATERIALS TECH +1

Method using microchannel reaction to prepare chloroethylene carbonate

InactiveCN106810528AThe contact reaction of raw materials is sufficientImprove heat release efficiencyOrganic chemistryChemical/physical/physico-chemical microreactorsLiquid chlorineProcess engineering

The invention provides a method using microchannel reaction to prepare chloroethylene carbonate. Equipment used by the method comprises a mass transfer enhancing type microchannel reactor, a first metering pump and a second metering pump, wherein the mass transfer enhancing type microchannel reactor comprises a preheater, a second preheater, a heat exchanger and microchannel modules, and each microchannel module comprises a microchannel, an exhaust valve and a nitrogen displacement valve. The method includes: heating solid ethylene carbonate to allow the same to become liquid, adding an initiator and a catalyst to obtain mixed liquid, feeding the liquid into a preheater through the first metering pump, preheating, feeding liquid chlorine into a storage tank through the second metering pump, synchronously feeding into the microchannels in the microchannel modules, heating, performing mixed reaction, allowing products to flow out from a discharge valve after the reaction, cooling, and rectifying to obtain the chloroethylene carbonate. The method is simple and safe to operate, little in byproduct dichloro ethylene carbonate and high in product purity and yield.

Owner:江苏瀚康新材料有限公司

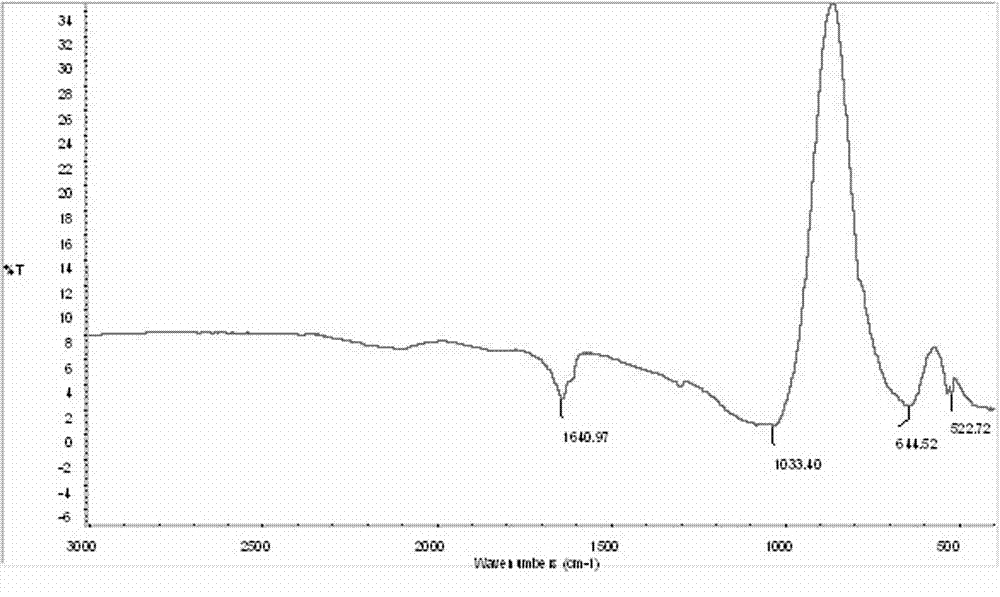

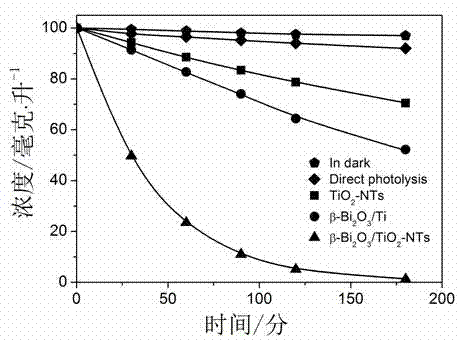

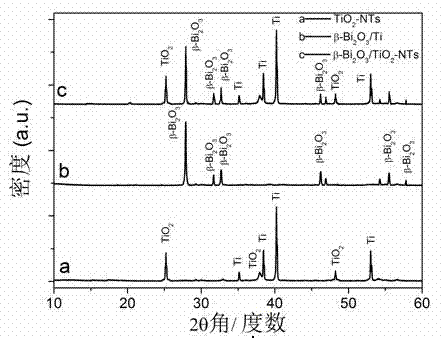

Method for preparing beta-Bi2O3/TiO2-NTs composite photocatalyst with high stability visible light catalytic activity

ActiveCN102962051AVisible light catalytic activity is highHigh visible light photocatalytic performanceCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsValence bandTube furnace

The invention relates to a method for preparing beta-Bi2O3 / TiO2-NTs composite photocatalyst with high stability visible light catalytic activity. The method is characterized in that an electrochemical anodization method is adopted; a layer of upright and orderly TiO2-NTs nanotubes are pre-grown on a Ti plate for serving as a middle layer; Bi nano-particles are subjected to pulse electrodeposition in bismuth nitrate solution; and then the mixture is finally placed in oxygen atmosphere of a tube furnace for calcining to form a beta-Bi2O3 crystal form to prepare the beta-Bi2O3 / TiO2-NTs composite photocatalyst. Compared with the conventional alpha-Bi2O3 and TiO2 photocatalysts, the visible-light response of the beta-Bi2O3 / TiO2-NTs composite photocatalyst is prolonged to 495nm. Compared with the conventional beta-Bi2O3 photocatalyst, the valence band electric potential of the beta-Bi2O3 / TiO2-NTs composite photocatalyst is increased to 2.28ev, the hole oxidative capacity is strengthened, and the stability is greatly improved.

Owner:TONGJI UNIV

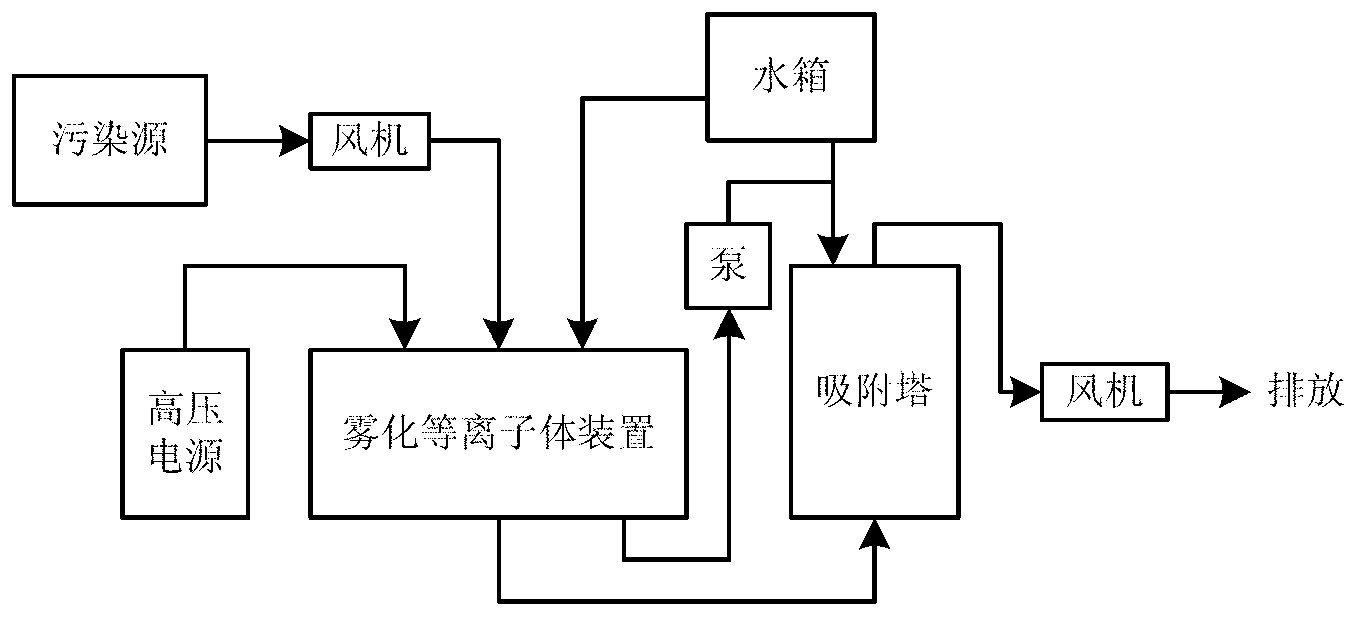

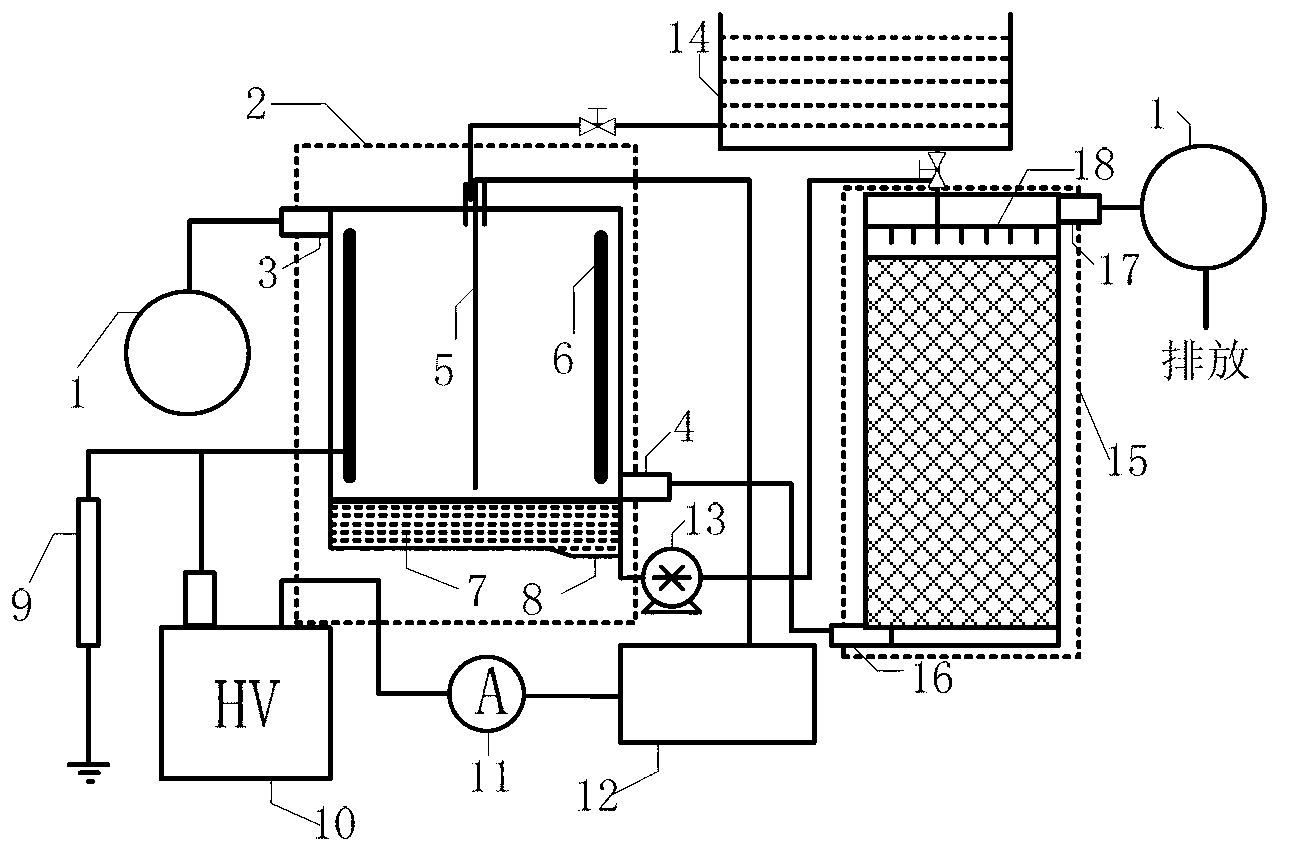

Method for dealing with foul smell through atomization plasma oxidation-biomass adsorption

InactiveCN103263830AEnhancement and effectAvoid secondary pollutionDispersed particle separationSorbentEnvironmental engineering

The invention discloses a method for dealing with foul smell through atomization plasma oxidation-biomass adsorption, belonging to the field of purification technology for removing foul gases. The method adopts an atomization plasma oxidation-biomass adsorption device and comprises the following steps of: (1) feeding: breaking the plant waste and performing microwave irradiation modification, humidifying and feeding into a biomass adsorption tower; (2) atomization low-temperature plasma oxidation: continuously pumping water into a low-temperature plasma reactor by a water pump, and atomizing immediately; and leading out foul gases from a pollution source by a fan to enter an atomization low-temperature plasma device; and (3) adsorption by the adsorption tower: enabling the gas after strong oxidation of the low-temperature plasma device to enter the biomass adsorption tower for absorption and adsorption to remove residual foul gases and oxidation byproducts in the incoming gas. The method disclosed by the invention combines the advantages of a low-temperature plasma and adsorption method in removing foul gases, and avoids the problem of byproduct secondary pollution caused by the low-temperature plasma and the problems of the adsorbent production and regeneration cost and secondary pollution.

Owner:NORTHEASTERN UNIV LIAONING +2

Atomic layer deposition device for coating large-scale micro-nano particles

ActiveCN108715998AIncrease profitHeating up fastChemical vapor deposition coatingMicro nanoReaction rate

The invention belongs to the field related to atomic layer deposition preparation instruments, and discloses an atomic layer deposition device for coating large-scale micro-nano particles. The devicecomprises a particle container and a reaction cavity, wherein a source inlet is formed in the lower end of the reaction cavity, an air inlet pipe used for inputting a precursor and a carrier gas is arranged in the source inlet in a sealed mode, the upper end of the reaction cavity is provided with a cavity door, the particle container can be freely placed in the reaction cavity, or is taken out ofthe reaction cavity, an air inlet hole is formed in the lower end of the particle container, and the air inlet pipe enters an inner cavity of the particle container through the air inlet hole. According to the atomic layer deposition device, the airflow internal circulation method and the airflow external circulation method can be effectively combined, so that the collision between the particlesand the contact probability between the particles and gas molecules are remarkably increased, the reaction rate and the precursor utilization rate are improved, and high-quality and high-efficiency coating of the large-scale micro-nano particles is realized.

Owner:HUAZHONG UNIV OF SCI & TECH

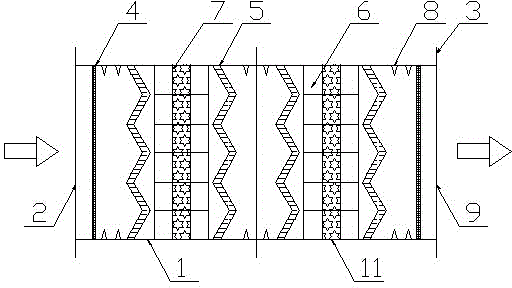

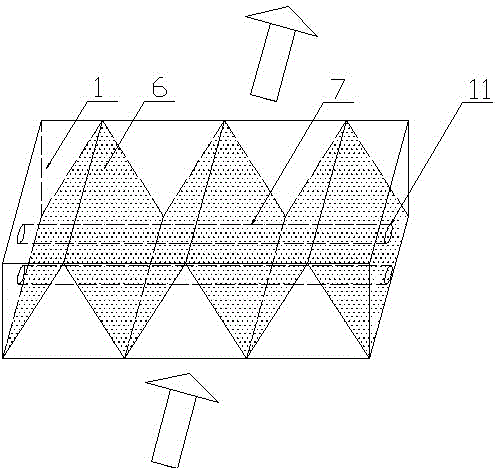

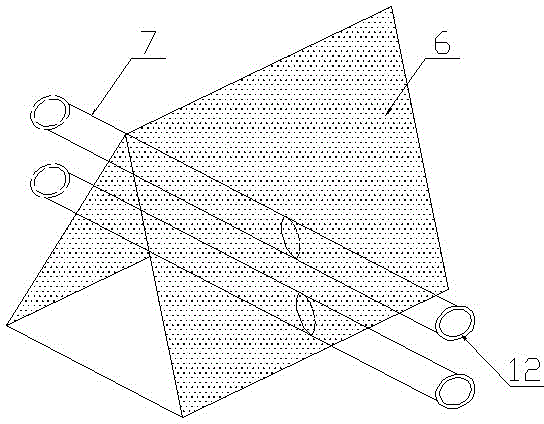

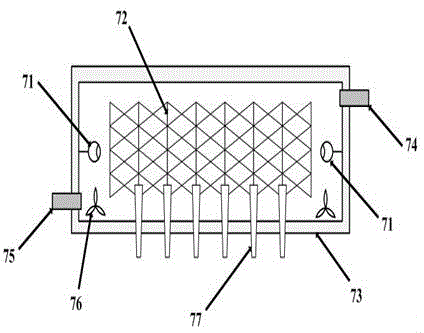

Air flue type photocatalysis air purifier

ActiveCN104089348ALarge processing areaIncrease the areaLighting and heating apparatusDispersed particle separationEngineeringAir purifier

The invention discloses an air flue type photocatalysis air purifier which comprises a shell. At least one photocatalysis structure is arranged inside the shell, and photocatalysis filter screens and an ultraviolet source are arranged in the photocatalysis structure. The air flue type photocatalysis air purifier is characterized in that, in the photocatalysis structure, the number of the photocatalysis filter screens is two, and the whole photocatalysis filter screens are in a back-and-forth zigzag W shape, a fin is arranged between the two photocatalysis filter screens, the fin is in a W shape in the length direction and is transversely connected to the interior of the shell, the width direction of the rib is coincident with the longitudinal direction of the shell, a transparent sleeve arranged in the transverse direction of the shell is installed in the middle of the fin in a penetrated mode, and the ultraviolet source is arranged in the transparent sleeve. The photocatalysis filter screens, the fin and the inner surface of the shell are all coated with photocatalysts. The air flue type photocatalysis air purifier can be installed in an air flue, and extra occupied space is not needed; meanwhile, the effective reaction area of the air flue type photocatalysis air purifier is large, the using efficiency of the ultraviolet source is high, the reaction-mass transferring capacity of the surface of the photocatalysts is high, energy consumption is small, the structure is simple, the reaction efficiency is high, and the air flue type photocatalysis air purifier is convenient to use and install.

Owner:CHONGQING UNIV

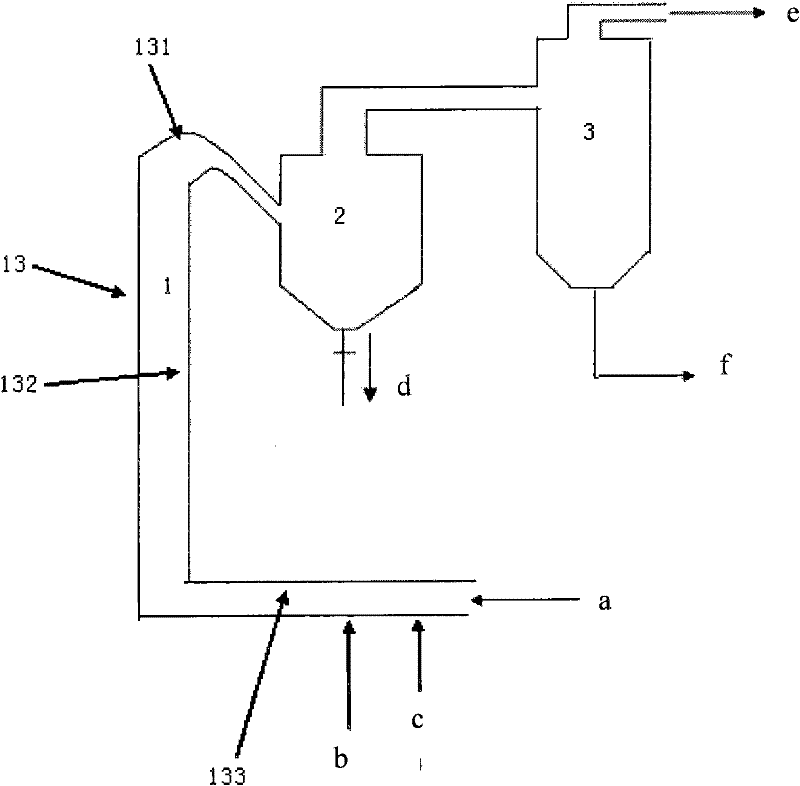

Method for preparing molecular sieve

ActiveCN102452661AContinuous contact reactionAdequate contact responseMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveGas phase

The invention relates to a method for preparing a molecular sieve. The method comprises that: with carrying by inert carrier gas flow, a molecular sieve flows along with the inert carrier gas, and contacts gas phase SiCl4 for 10 s-100 min under a flowing state; the molecular sieve and the gas phase SiCl4 are heated during the contacting process, such that the contacting temperature of the molecular sieve and the gas phase SiCl4 is 250-700 DEG C. According to the method for preparing the molecular sieve, the molecular sieve can contact the gas phase SiCl4 under the flowing state, such that the contact reaction of the molecular sieve and the SiCl4 can be continuously performed; with controlling the flow rate of the carrier gas, the contacting time of the molecular sieve and the SiCl4 can be controlled, such that the contact reaction of the molecular sieve and the SiCl4 can be completely performed in a tubular reactor; with heating the molecular sieve and the gas phase SiCl4 during the contacting process, the molecular sieve can contact the gas phase SiCl4 at the different temperatures so as to obtain the molecular sieves with different silica alumina ratios.

Owner:CHINA PETROLEUM & CHEM CORP +1

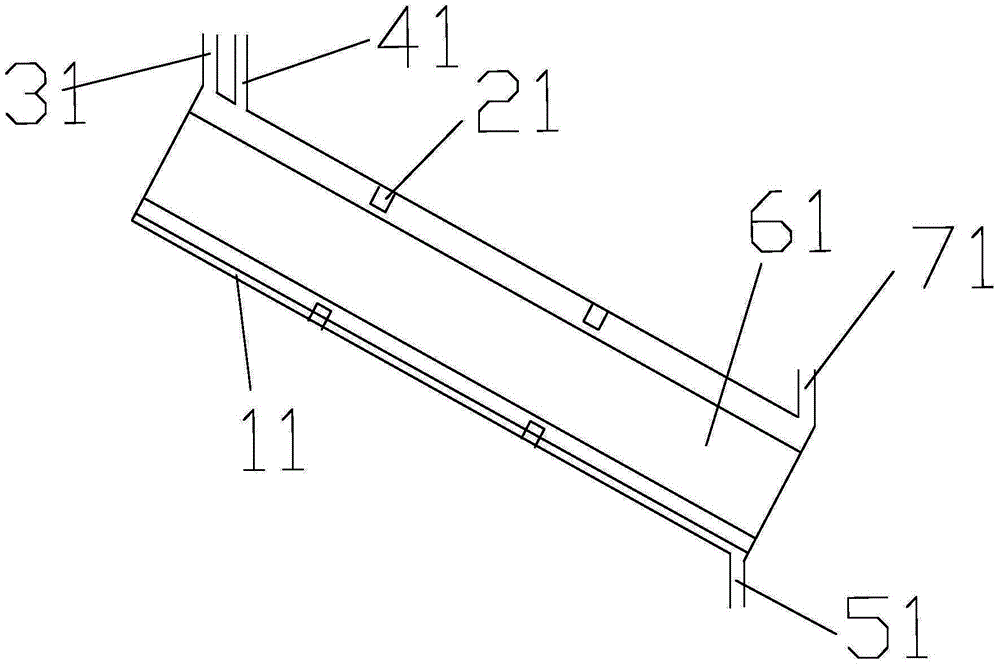

Preparation method of catalytic cracking promoter

ActiveCN104549445AAdequate contact responseControl dwell timeMolecular sieve catalystsBulk chemical productionMolecular sieveGas phase

The invention relates to a preparation method of a catalytic cracking promoter. The method comprises the following steps: preparing a high-silicon ZSM-5 molecular sieve, and mixing and pulping and pelletizing the high-silicon ZSM-5 molecular sieve and a binder and clay, wherein the preparation method of the high-silicon ZSM-5 molecular sieve comprises the following steps: introducing NaZSM-5 molecular sieve crude powder into a gaseous-phase ultra-stable reactor, moving the NaZSM-5 molecular sieve crude powder to a molecular sieve outlet of the gaseous-phase ultra-stable reactor from a molecular sieve inlet of the gaseous-phase ultra-stable reactor under the situation of no carrier gas conveying, and performing contact reaction of the NaZSM-5 molecular sieve crude powder and gaseous phase SiCl4 in the gaseous-phase ultra-stable reactor. According to the preparation method, the ZSM-5 molecular sieve with high silica-alumina ratio can be continuously prepared, and apropylenecatalytic cracking promoter can be further prepared.

Owner:CHINA PETROLEUM & CHEM CORP +1

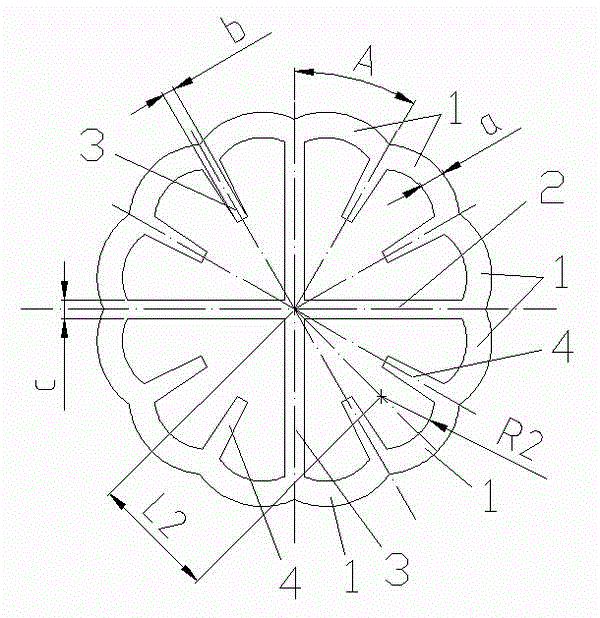

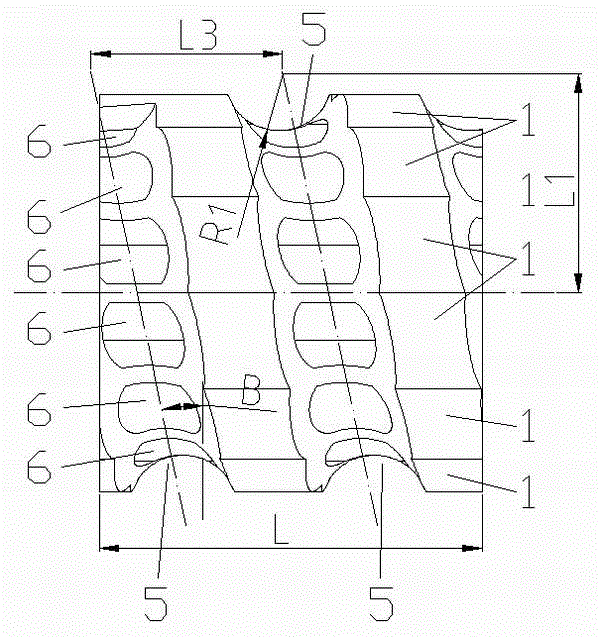

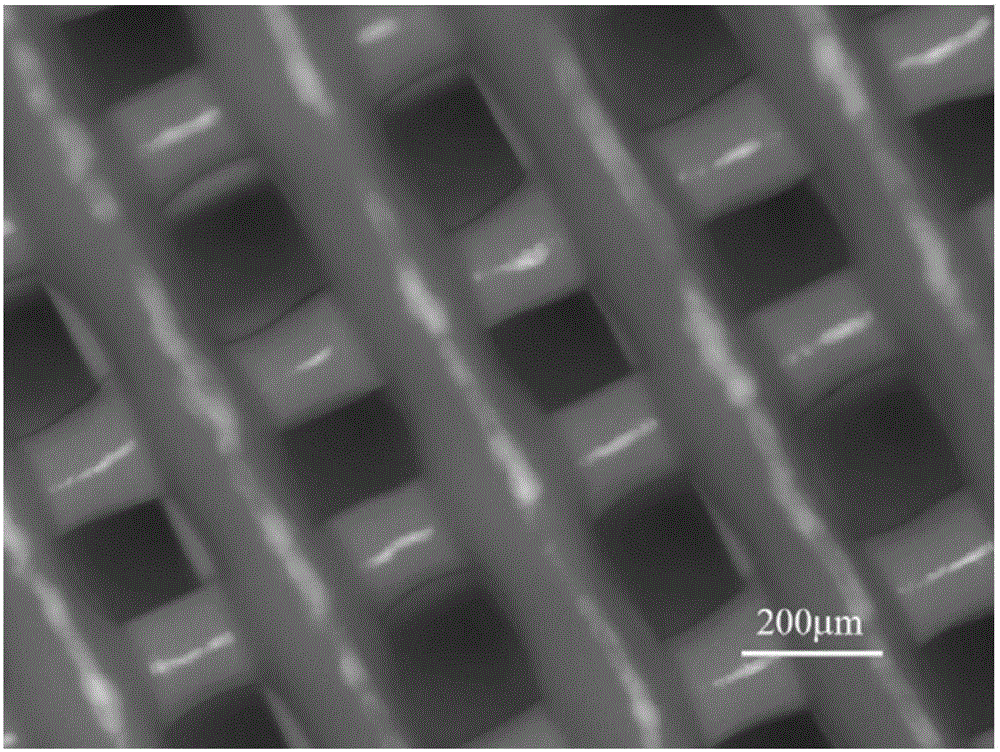

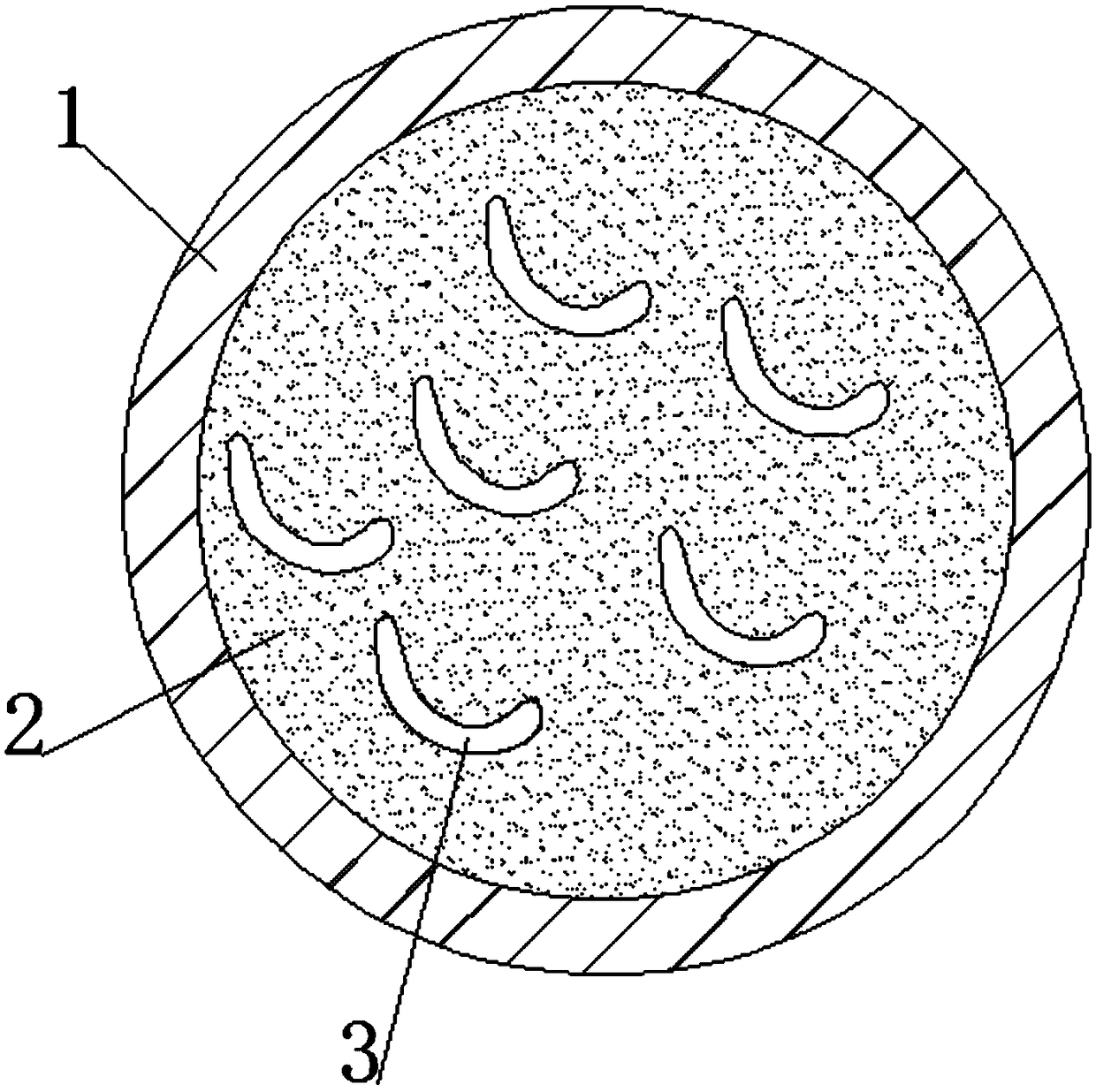

Multi-phase flow dynamic membrane microbial carrier filler

InactiveCN104787874AGood flexibilitySolve the problem of not being able to aggressively tumbling fluidizeSustainable biological treatmentBiological water/sewage treatmentPliabilityEngineering

The invention discloses multi-phase flow dynamic membrane microbial carrier filler and belongs to the technical field of environmental protection and water treatment. The carrier filler with high-density polyethylene as a main material and calcium carbonate and starch as auxiliary materials adopts a thin-wall tubular structure, wherein reinforcing ribs forming 90-degree angles mutually and a plurality of inner rib plates are arranged in the thin-wall tubular structure, and spiral grooves are formed in the outer wall of the thin-wall tubular structure. The carrier filler solves the problem of incapability of positive rolling fluidization under the actions of hydraulic power, stirring, aeration and the like of conventional biological filler and makes up the defects of poor attaching force due to the smooth surface, poor hydrophobicity, small specific surface area and the like of the conventional filler. The filler with uniform small holes in the outer wall is in a suspended state in water and can vertically roll in a tank under the action of external force to have a sufficient contact reaction with the water; the carrier filler has a rough surface and is suitable for microbial membrane hanging; the filler has high flexibility, is suitable for a high-strength fluidization reaction and is made of a hydrophilic material, and the membrane hanging time is greatly shortened.

Owner:大连爱特流体控制有限公司

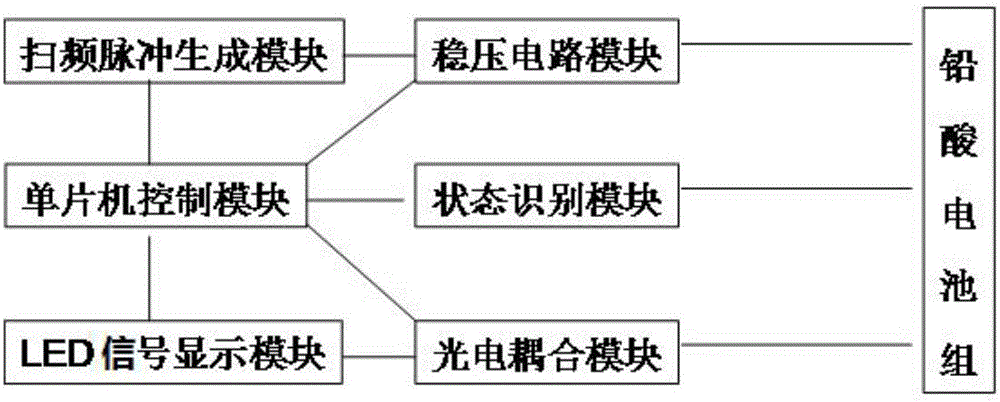

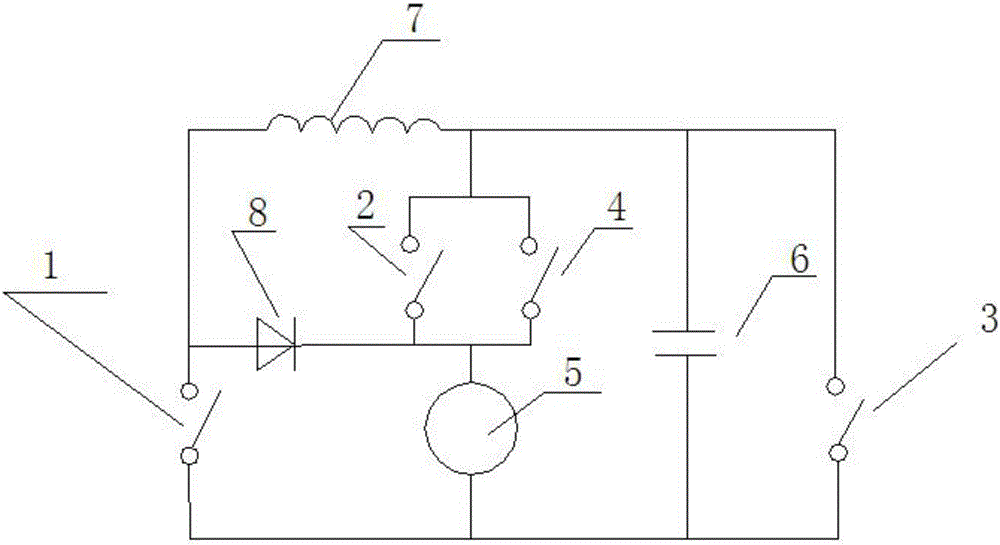

Lifetime prolonging and repairing device of lead-acid battery

ActiveCN106129498AExtended service lifeAvoid depositionFinal product manufactureElectrolyte/reactants regenerationElectrical batteryMedium frequency

The invention discloses a lifetime prolonging and repairing device of a lead-acid battery. The device comprises a regulated power supply module, a single chip microcomputer control module, a frequency sweep pulse wave generation module, a battery state identification module and a photoelectric coupling module, wherein the single chip microcomputer control module is connected with the frequency sweep pulse wave generation module, the regulated power supply module, the battery state identification module, an LED signal display module and the photoelectric coupling module via a circuit separately; the frequency sweep pulse wave generation module can generate a low-medium frequency pulse wave and a medium-high frequency pulse wave for pulse treatment on a pole plate of the battery for various states of the lead-acid battery. The device can maintain the lead-acid storage battery through being connected to the lead-acid storage battery and can repair the waste lead-acid battery.

Owner:HAISAIPU NEW ENERGY HIGH TECH JIANGSU CO LTD

Method for preparing three-dimensional bismuth ferrite visible light catalytic material by using direct-write forming technology

InactiveCN106391039AImprove scattering efficiencyLarge specific surface areaCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPotassium hydroxideSlurry

The invention provides a method for preparing a three-dimensional bismuth ferrite visible light catalytic material by using a direct-write forming technology. The method comprises the following steps: providing and dissolving ferric nitrate, bismuth nitrate, nitric acid and potassium hydroxide into a mixed solution, and preparing bismuth ferrite nano powder through a hydrothermal synthesis method; after mixing the bismuth ferrite nano powder with an additive, adding the mixture into deionized water, and preparing bismuth ferrite mixed slurry of which the solid phase content is 40 to 80 wt percent; pre-designing a three-dimensional structural drawing through CAD (Computer Aided Design) software, converting the three-dimensional drawing into a code language capable of being recognized by a computer, putting the bismuth ferrite mixed slurry in a forming needle cylinder, enabling the forming needle cylinder to move along a path designated by the computer under the driving of a direct-write platform, extruding and forming layer by layer at the same time, periodically overlaying back and forth, and forming a mult-layer ordered three-dimensional porous structure blank; carrying out pre-sintering and sintering thermal treatment on the three-dimensional porous structure blank, thus obtaining a three-dimensional bismuth ferrite body having a visible light photocatalysis characteristic.

Owner:SHENZHEN UNIV

Method for preparing catalytic cracking catalyst

ActiveCN102451729AHigh crystallinityQuality improvementCatalytic crackingMolecular sieve catalystsMolecular sieveContact time

The invention relates to a method for a catalytic cracking catalyst, which comprises the following steps: a molecular sieve and gas containing gas phase SiCl4 to form mixed flow, the gas containing gas phase SiCl4 is gas phase SiC4 or a mixed gas of gas phase SiCl4 and inert carrier gas, the molecular sieve in the mixed flow flows with gas, and is contacted with gas phase SiCl4 under a flowing state, wherein the contact time of the molecular sieve and the gas phase SiCl4 is 10 seconds to 100 minutes, then the obtained reactant is contacted with mixed with the molecular sieve contacted with gas phase SiCl4, a binder, clay and water, and granulated to obtain the catalytic cracking catalyst. The preparation method has the advantages that the continuous contact reaction of the molecular sieveand SiCl4 can be realized, the contact time of the molecular sieve and SiCl4 can be controlled by controlling the velocity of the mixed gas and the length of a tubular reactor, so that the contact reaction of the molecular sieve and SiCl4 can be fully carried out in the tubular reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

Bubbler with novel structure

InactiveCN103055680AEvenly distributedShorten the lengthDispersed particle separationSlag (welding)Engineering

The invention relates to a bubbler with a novel structure. The bubbler with a novel structure comprises a cylindrical shell, an air inlet pipe, primary gas distribution pipes, secondary gas distribution pipes, jet pipes, an air exhaust opening, a liquid desulfurizer inlet, a slag liquid outlet, etc., wherein the lower part of the cylindrical shell is an absorption liquid chamber, the upper part of the cylindrical shell is a purified gas chamber, the air inlet pipe and the wall of the cylindrical shell are connected through welding, one end of the air inlet pipe is vertically welded with and communicated with the primary gas distribution pipes, the primary gas distribution pipes and the secondary gas distribution pipes form a disc type gas distributor apparatus which comprises an upper gas distributor and a lower gas distributor, the jet pipes are welded on the secondary gas distribution pipes, the welded jet pipes form a shape resembling the Chinese character Ba in a same cross section of the secondary gas distribution pipes, the air exhaust opening is welded on an end cap of the cylindrical shell, the liquid desulfurizer inlet is located at a center point position at a height direction of the cylindrical shell, and the slag liquid outlet is located at a lowest position of the cylindrical shell. The bubbler provided by the invention can greatly increase a total area of a gas outlet, which enables great exhaust-gas treatment capacity and improved desulphurization efficiency to be obtained, and the bubbler has a compact and reasonable structure and is convenient to install.

Owner:天津天雷科技有限公司

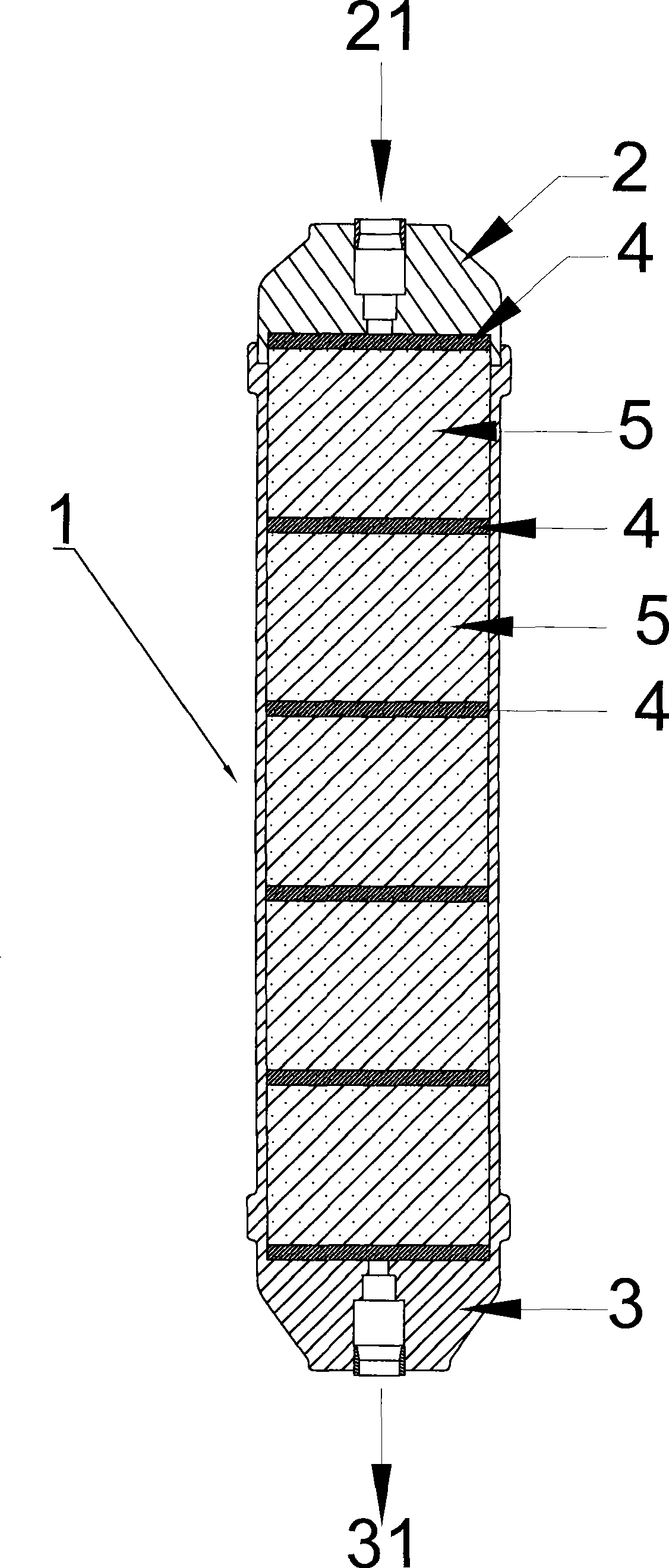

Filling method of KDF dechloridation combined filter element

InactiveCN101422664AReduce exposureReduce stickinessLoose filtering material filtersWater/sewage treatment using germicide/oligodynamic-processRedoxZinc alloys

The invention relates to a filling method for KDF dechlorination compositive filter elements, which can effectively stop the filter element from being blocked by copper zinc alloy stuck together with undissolved substance which is produced in redox reaction when KDF is used for dechlorination, so that complete contact reaction between filter materials and water can be ensured. The filling method for KDF dechlorination compositive filter elements comprises: (1) filter layers are respectively arranged at the water inlet end and water outlet end of the inner chamber of a filtering shell; and (2) a plurality of layers which are filled with filtering materials separated by filtering layers are filled between the two filtering layers at the water inlet end and the water outlet end of the inner chamber of the filtering shell.

Owner:SHENZHEN INIKE ELECTRICAL APPLIANCES

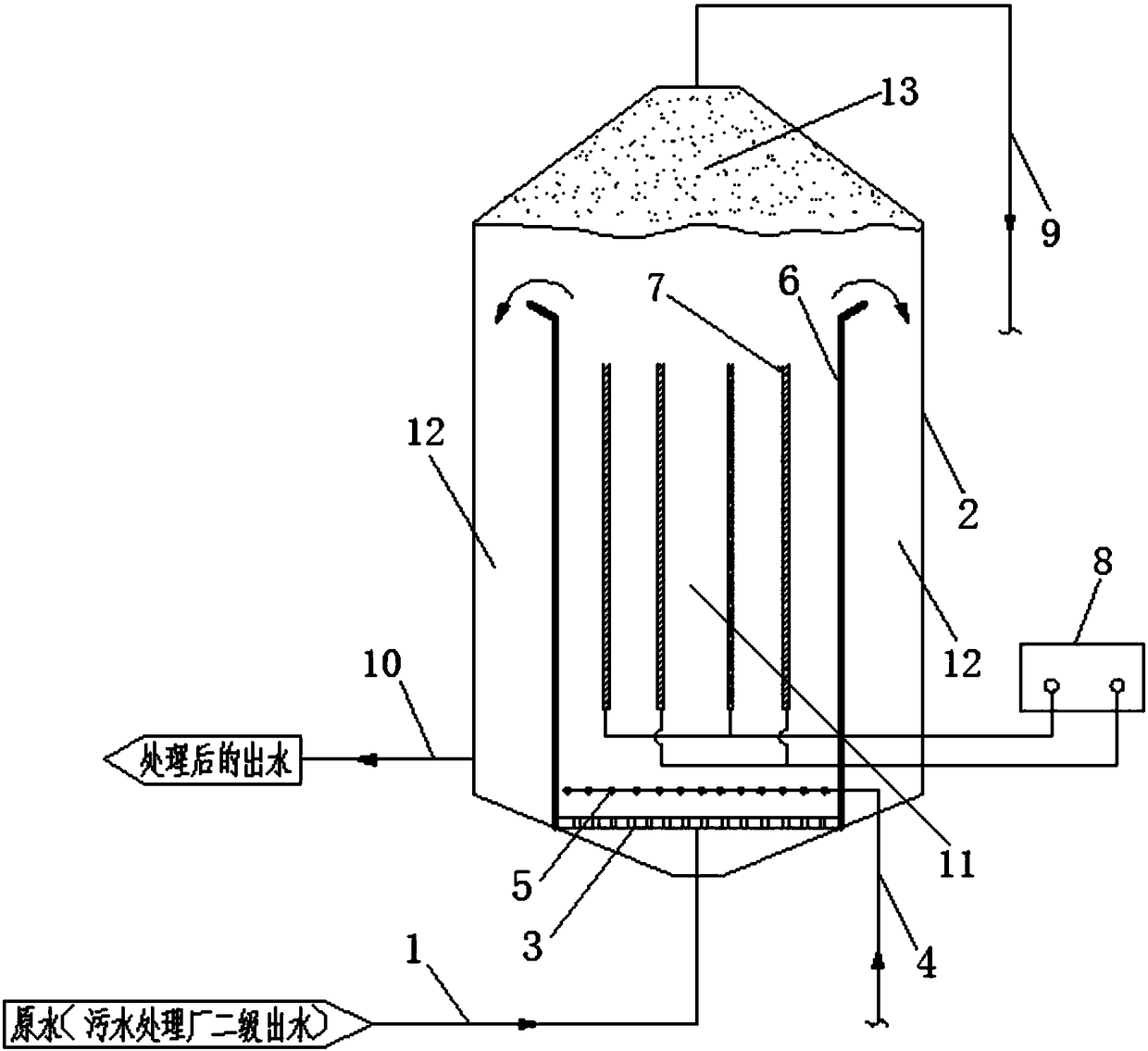

Secondary effluent regeneration treatment system for municipal sewage treatment plant and secondary effluent regeneration treatment method of secondary effluent regeneration treatment system

InactiveCN108423893AAvoid pollutionReduce solubilityMultistage water/sewage treatmentRunoff/storm water treatmentMunicipal sewageReaction zone

The invention discloses a secondary effluent regeneration treatment system for a municipal sewage treatment plant and a secondary effluent regeneration treatment method of the secondary effluent regeneration treatment system. The system comprises an equipment body, wherein the equipment body comprises a main reaction zone, an electrode plate is arranged in the main reaction zone and comprises a negative plate and a soluble positive plate, and the negative plate and the soluble positive plate are connected with a power supply; water outlet zones are arranged on two sides of the main reaction zone, partition boards are arranged between the main reaction zone and the water outlet zones and communicated through upper parts; a dross zone is arranged at upper parts of the main reaction zone andthe water outlet zones; an ozone aeration head is arranged at the lower part of the main reaction zone and communicated with an ozone conveying pipe; an output end of a water inlet pipe is communicated with a water outlet of the equipment body and extends into the main reaction zone; a water outlet pipe is communicated with bottom water outlets of the water outlet zones; a dross discharge pipe iscommunicated with a dross outlet of the dross zone. Secondary effluent is regenerated by use of the synergistic effect of ozonation and coagulation, an ozone floatation technology and the like, and organic matter, colloidal substances, suspended substances and other stink substances in water can be effectively removed.

Owner:WUHAN POLYTECHNIC UNIVERSITY

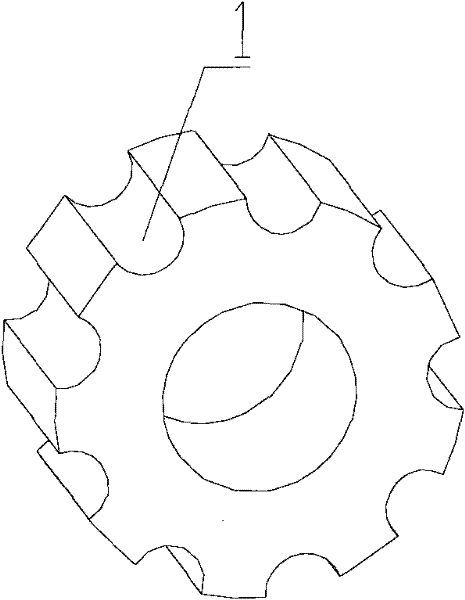

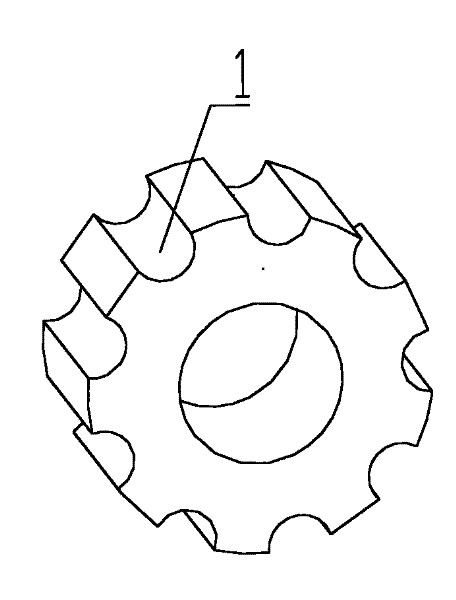

Micro-electrolysis filling material

InactiveCN101746856ALarge specific surface areaAdequate contact responseWater/sewage treatmentElectrolysisFilling materials

The invention relates to the technical field of micro-electrolysis filling material used in wastewater treatment. The filling material has a cylinder structure, and the lateral wall of the filling material is uniformly provided with grooves which can make the end face of the filling material be in a gear shape. The regulated structure of the filling material keeps an adequate gap between the cumulated filling materials, thereby ensuring the complete catalyzed reaction of the filling materials and the water and simultaneously reducing the flow resistance of the water, the physical form of the filling material increases the specific surface area of the filling material as far as possible, and therefore, the micro-electrolysis effect is obvious, and the bio-film can be applied easily.

Owner:常州海龙环保设备厂

Rice husk carbonization device

PendingCN107880916APlay the role of heating carbonizationGood carbonization effectGas treatmentDispersed particle filtrationInsulation layerHeat conducting

The invention discloses a rice husk carbonization device comprising a carbonization furnace; the outer surface of the carbonization furnace is fixedly connected with a heat conducting layer; two sidesof the heat conducting layer are fixedly connected with heating resistance wires; the outer surface of the heat conducting layer is fixedly connected with a heat insulation layer; the top of the carbonization furnace is provided with a motor; the output end of the motor is fixedly connected with a rotating shaft; the outer surface of the rotating shaft is fixedly connected with a stirring paddleand a stirring rod; and one end of the stirring rod is fixedly connected with a first scraper. Due to the adoption of the heating resistance wires, the effects of heating and carbonizing rice husks can be achieved; due to the adoption of the heat conducting layer prepared from graphite, and heat of the heating resistance wires can be rapidly and effectively transferred to the rice husks, so that the carbonization effect of the rice husks is more obvious; due to the adoption of the heat insulation layer, the heat is prevented from being rapidly diffused, so that the aim of saving energy is achieved; and due to the arrangement of the motor, the rotating shaft, the stirring paddle and the stirring rod, the contact among materials can be increased, and the materials can be uniformly stirred toensure that the materials sufficiently contact to react.

Owner:建始惠万农生物科技有限公司

Catalytic combustion treatment device

InactiveCN106352359AImprove volume utilizationAdequate contact responseIncinerator apparatusAir quality improvementExhaust fumesEngineering

The invention discloses a catalytic combustion treatment device. The catalytic combustion treatment device comprises a catalytic combustion treater and an oxygen generator, wherein the catalytic combustion treater comprises a central pipeline, a central heat exchange cavity, a low-temperature catalyst bed layer, a high-temperature catalyst bed layer, a waste gas inlet and a purified air outlet. In the catalytic combustion treatment device, the low-temperature catalyst bed layer is taken as an outer layer, the high-temperature catalyst bed layer is taken as an inner layer, and the catalyst bed layers are arranged annularly, so that the utilization rate of a catalytic combustor is increased greatly, VOCs (Volatile Organic Compounds) perform full contact reaction with a catalyst, the treatment efficiency is increased, and the purifying quality is improved; meanwhile, the central heat exchange cavity can be used for recycling energy of high-temperature gas, so that the catalytic combustion treatment device is environmental-friendly and saves energy, the temperature of exhausted gas is lowered, and safety and stability are achieved.

Owner:苏州聚贝机械设计有限公司

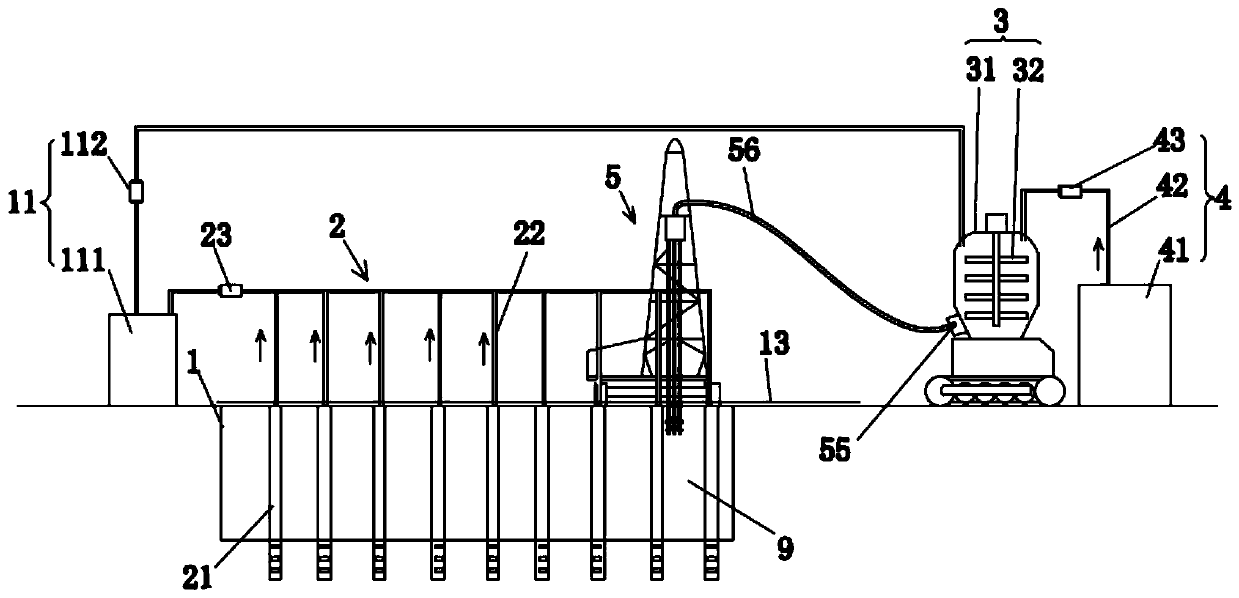

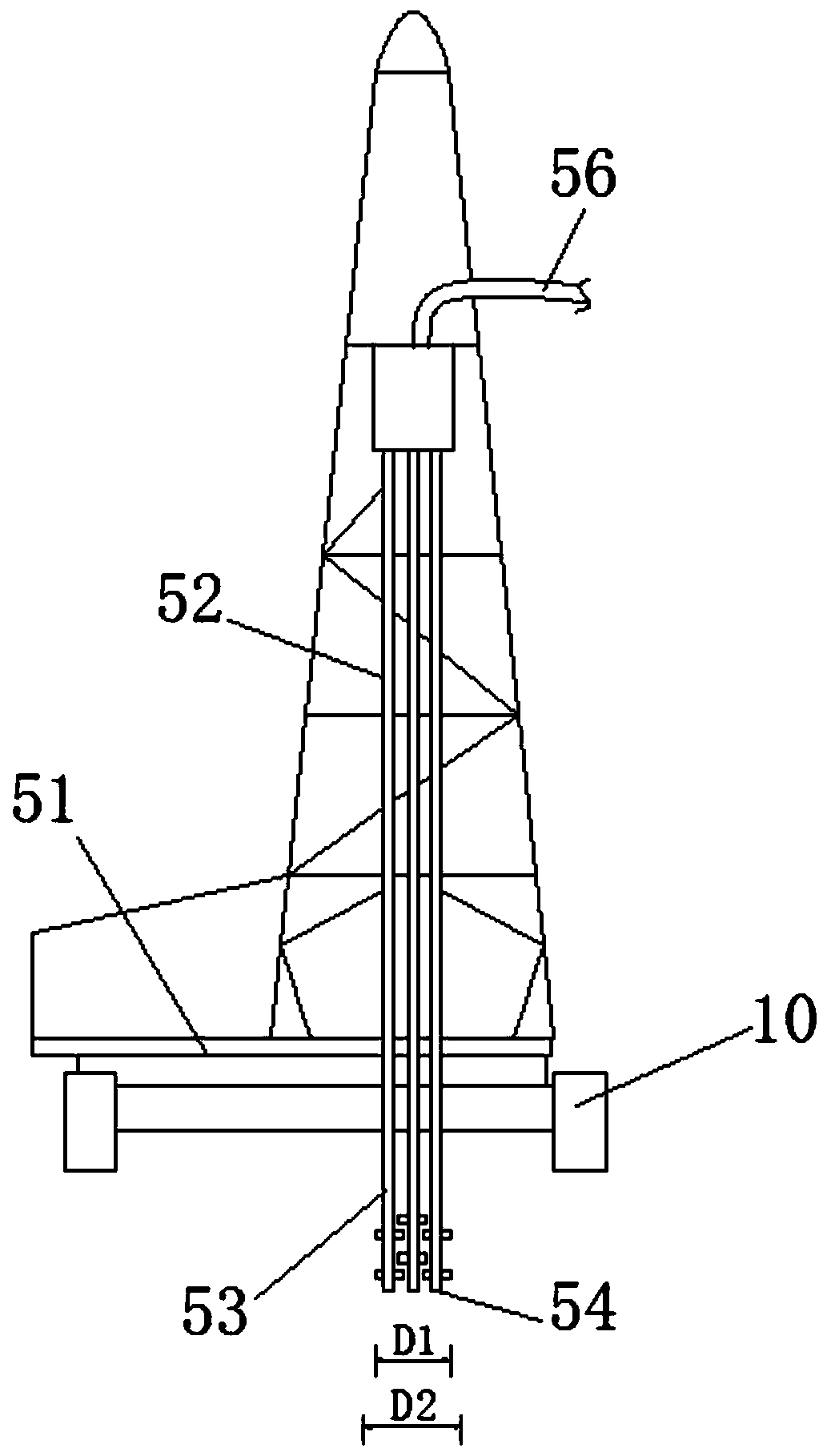

System and method for local ex-situ remediation of irritant peculiar smell site

PendingCN110802109AEasy transferAvoid injection and stagnationContaminated soil reclamationEarly warning systemWater storage

The invention discloses a system and method for local ex-situ remediation of an irritant peculiar smell site. The method comprises the following steps: pumping out underground water in the irritant peculiar smell site, and preparing a remediation agent by utilizing original underground water of the site; and adding the remediation agent in a manner of in-situ injection and stirring in order to remediate irritant peculiar smell soil and underground water. The remediation system comprises a tube well dewatering system, a water storage system, an agent dispensing system and an injecting and stirring system which are sequentially connected in the liquid flow direction; the medicine dispensing system is also connected with an agent storage system; and the restoration system further comprises aflexible isolation system and a peculiar smell monitoring and early warning system. The system and the method for local ex-situ remediation of the irritant peculiar smell site can greatly reduce the remediation water consumption, reduce the water treatment work amount and reduce the remediation cost, and can realize efficient, safe, low-cost and low-disturbance remediation of the irritant peculiarsmell site by reasonably adjusting the agent concentration and the disturbance strength to soil.

Owner:广州市璞境生态保护技术有限公司

A method for producing clean fuel oil from waste plastics and high aromatic components

ActiveCN104611060BHigh yieldMelt and mix wellTreatment with hydrotreatment processesHydrocarbon oils treatment productsPtru catalystFluid phase

Owner:CHINA PETROLEUM & CHEM CORP +1

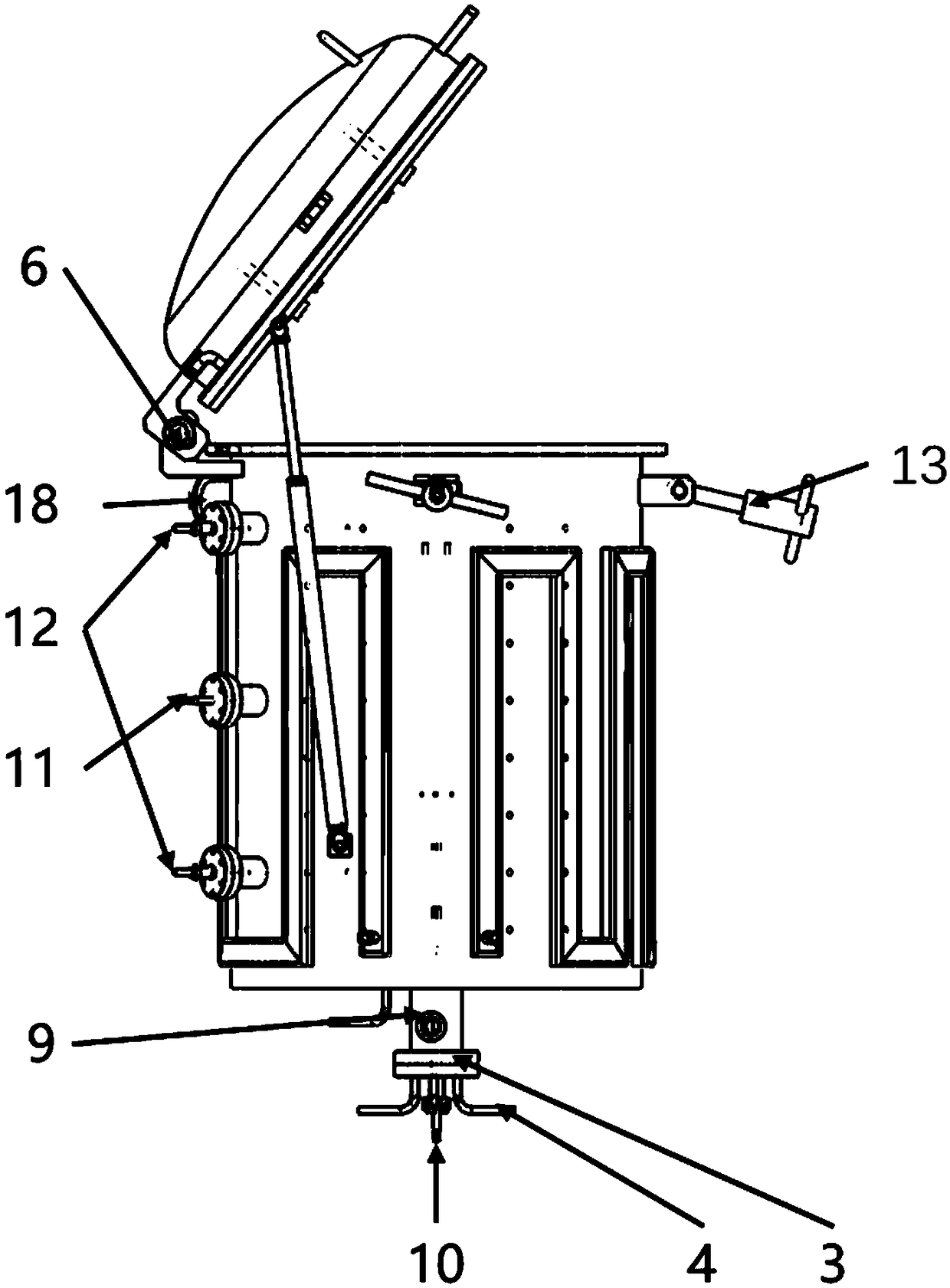

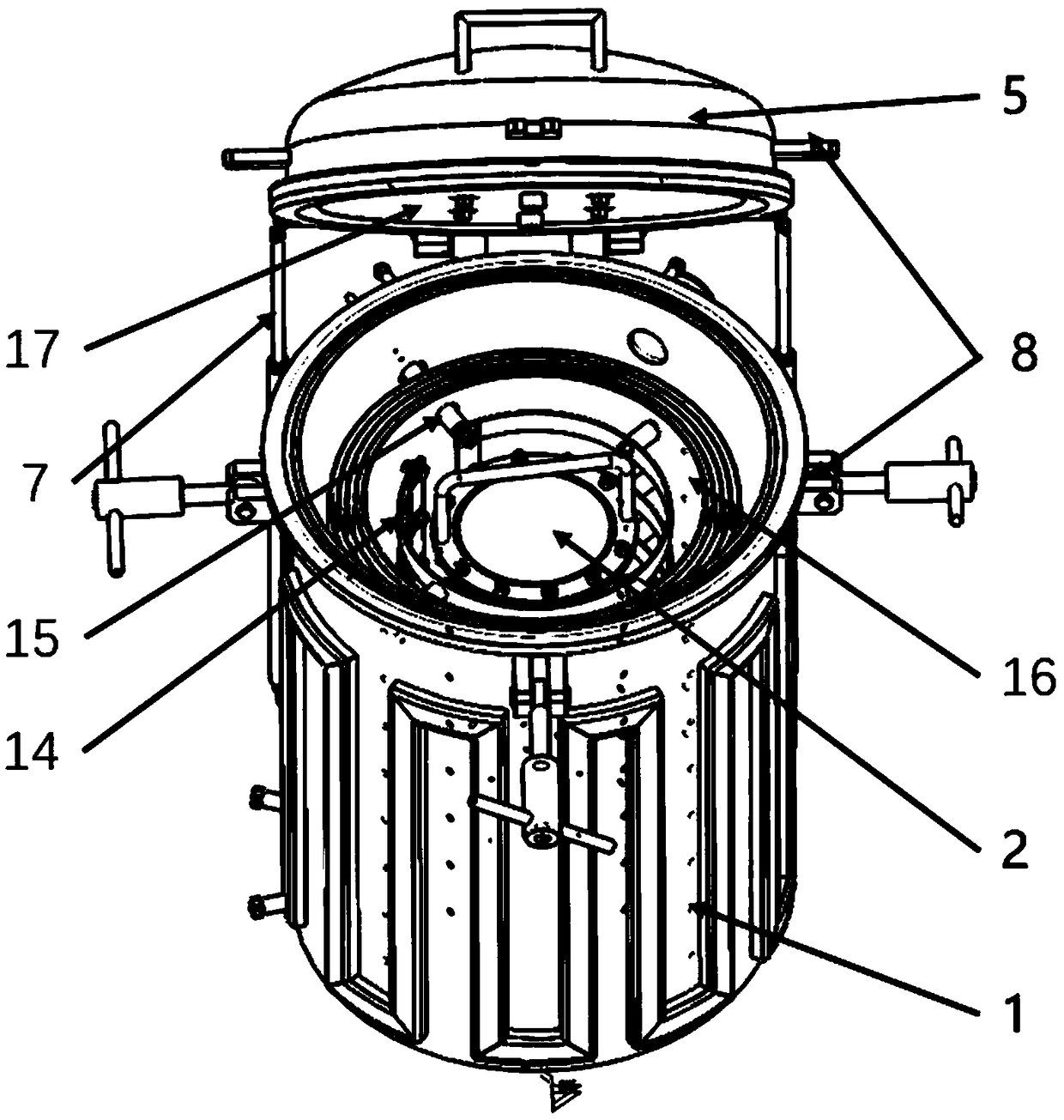

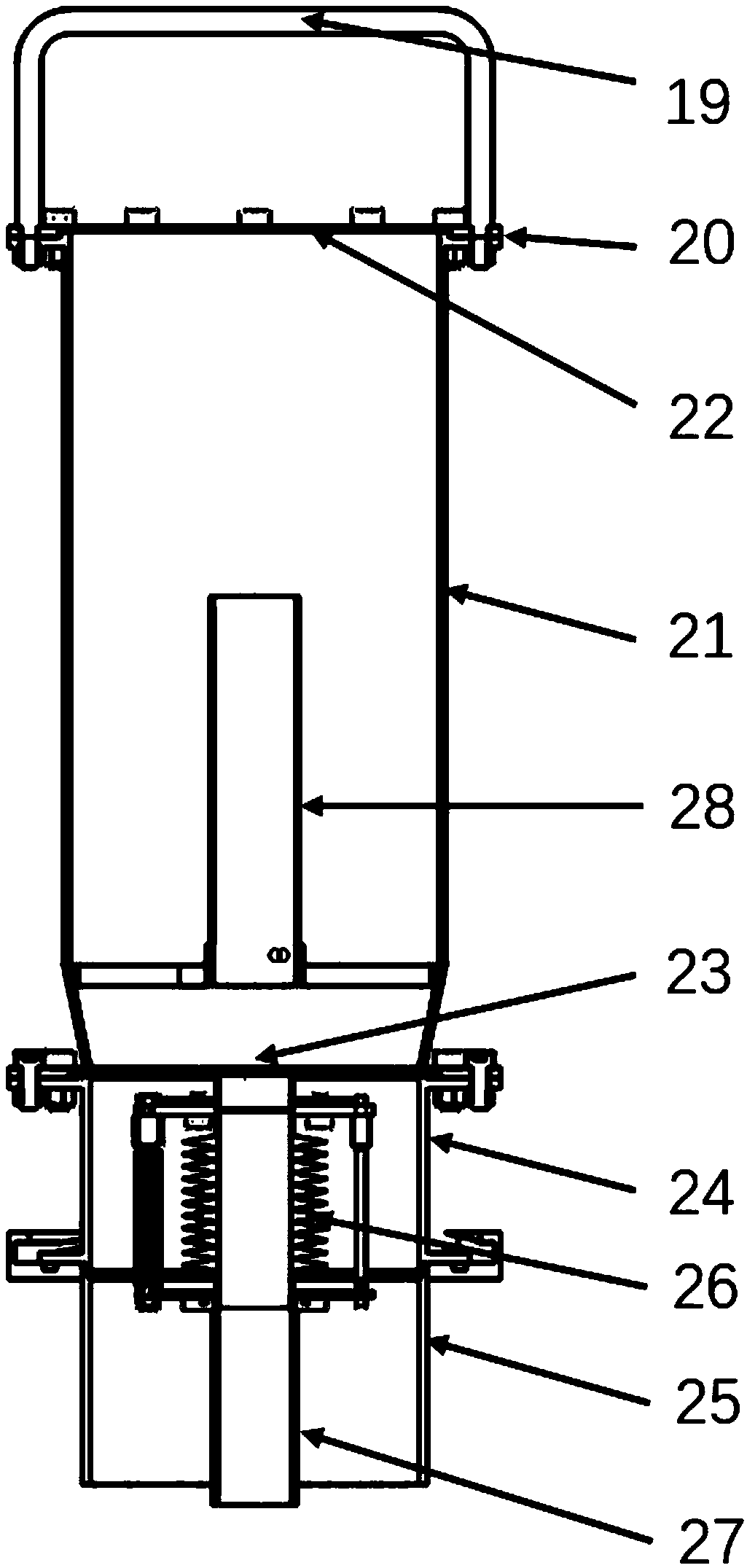

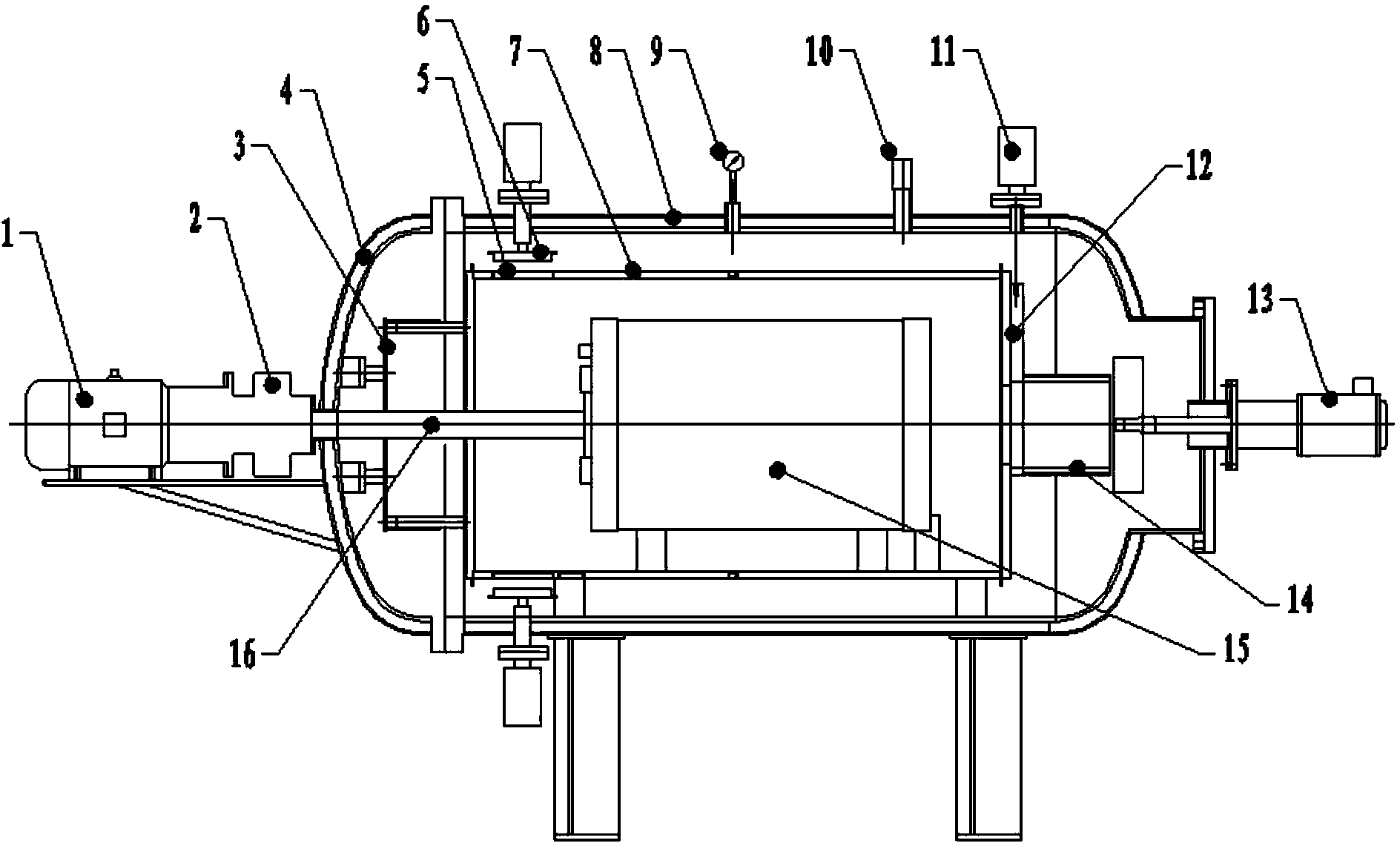

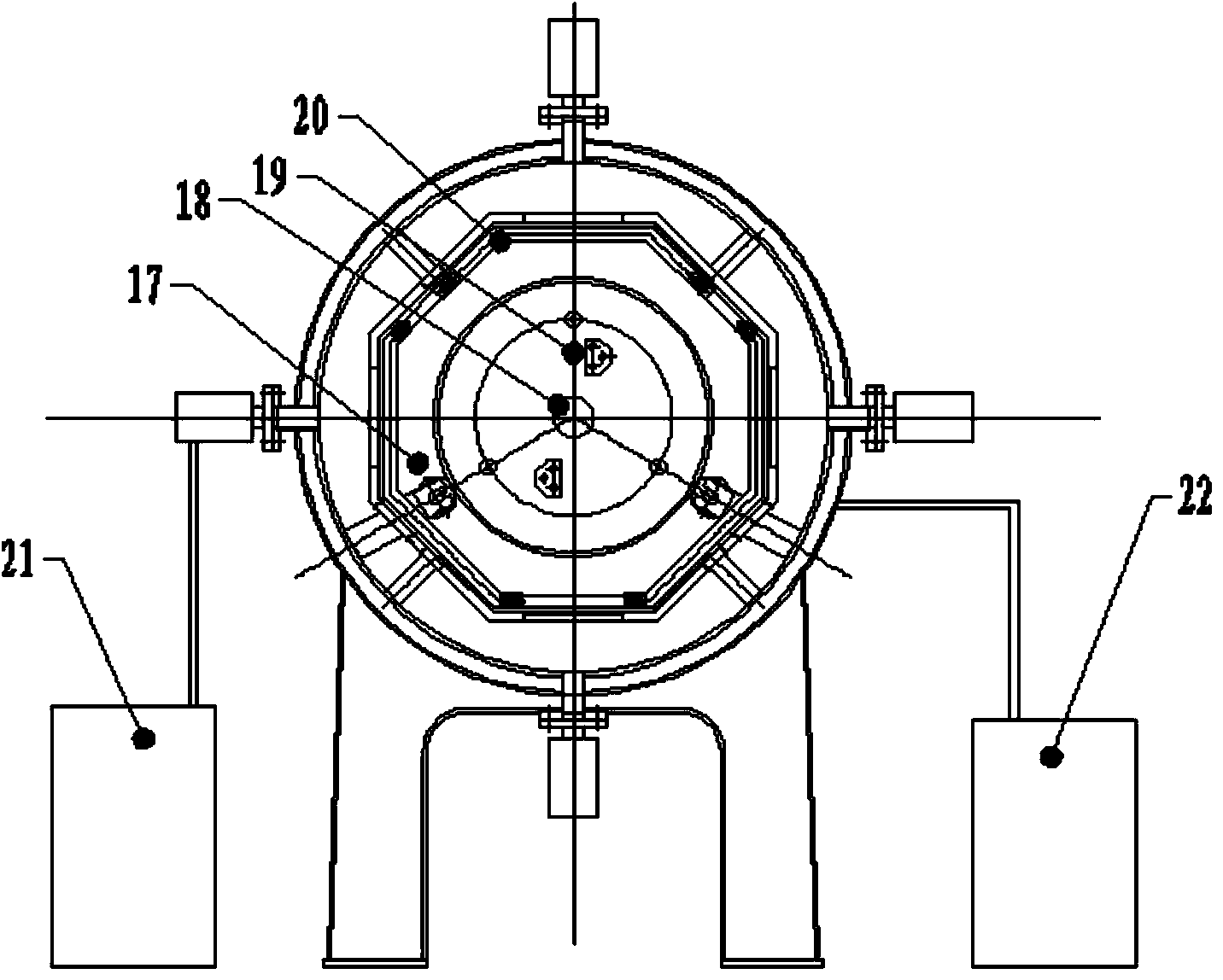

Hydrogen breaking furnace

The invention relates to a hydrogen breaking finance. According to the hydrogen breaking furnace, a furnace door 4 is arranged at the front end of a furnace body 8; a pneumatic control system 21 and a vacuum generation system 22 are respectively communicated with the furnace body 8 through gas pipelines; a heating chamber 7 is arranged in the furnace body 8; a reaction material barrel 15 is arranged in the heating chamber 7; a water-cooling air fan 13 is arranged at the back end of the furnace body 8; gas filter plates 18 are respectively arranged at the two ends of the reaction material barrel 15; a ventilation hole 5 is formed in the front end of the heating chamber 7; a circular hole is formed in the back end of the heating chamber 7; a rotating system for driving the reaction material barrel to rotate is arranged outside the furnace door 4. The invention aims to provide equipment for crushing a rare earth alloy, which has a better vacuum effect, higher safety, higher hydrogen breaking efficiency, and smaller and more uniform hydrogen crushed powder particle size. According to the equipment, full-automatic operation process is adopted; at a standard operating temperature, continuous processes of fully absorbing hydrogen and expanding, and completely dehydrogenating and decomposing of the rare earth alloy, particularly a neodymium-iron-boron alloy, are realized in a closed environment.

Owner:QIANDONG RARE EARTH GRP

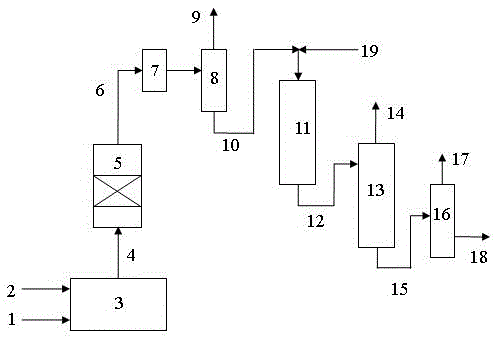

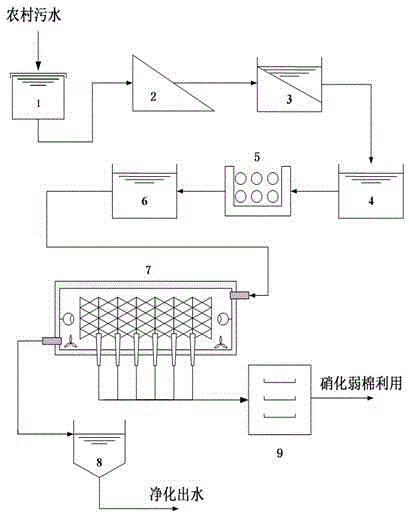

Rural sewage denitrification treatment system

InactiveCN105417873AAchieve recyclingAdequate contact responseWater treatment parameter controlTreatment using aerobic processesSimple Organic CompoundsSewage

The invention discloses a rural sewage denitrification treatment system which comprises a buffer tank, a coarse screen, an inclined plate sedimentation tank, an aeration nitrification tank, a biological dephosphorization tank, a pH regulating tank, a high voltage discharge organic rhodium catalysis polymerization reaction tank, a water purification tank and a weak nitrocotton drying forming system and the like. According to the system, the high energy discharge capacity effect generated by high-voltage arc is utilized creatively, nitrate ions under the conditions undergo a catalytic polymerization reaction on the surface of an organic compound of transition metal element rhodium, so that ionic bonds in the nitrate ions in the sewage undergo bond fission and recombination, cellulose nitrate can be generated and collected, and the resource recycle is achieved. Since the reaction is performed in a liquid state substrate, the reaction efficiency and speed are controlled, only the weak nitrocotton can be generated, the generation of strong nitrocotton or collodion with a higher nitrogen content is avoided, and thus the risk of explosion in running is eliminated.

Owner:陈杰

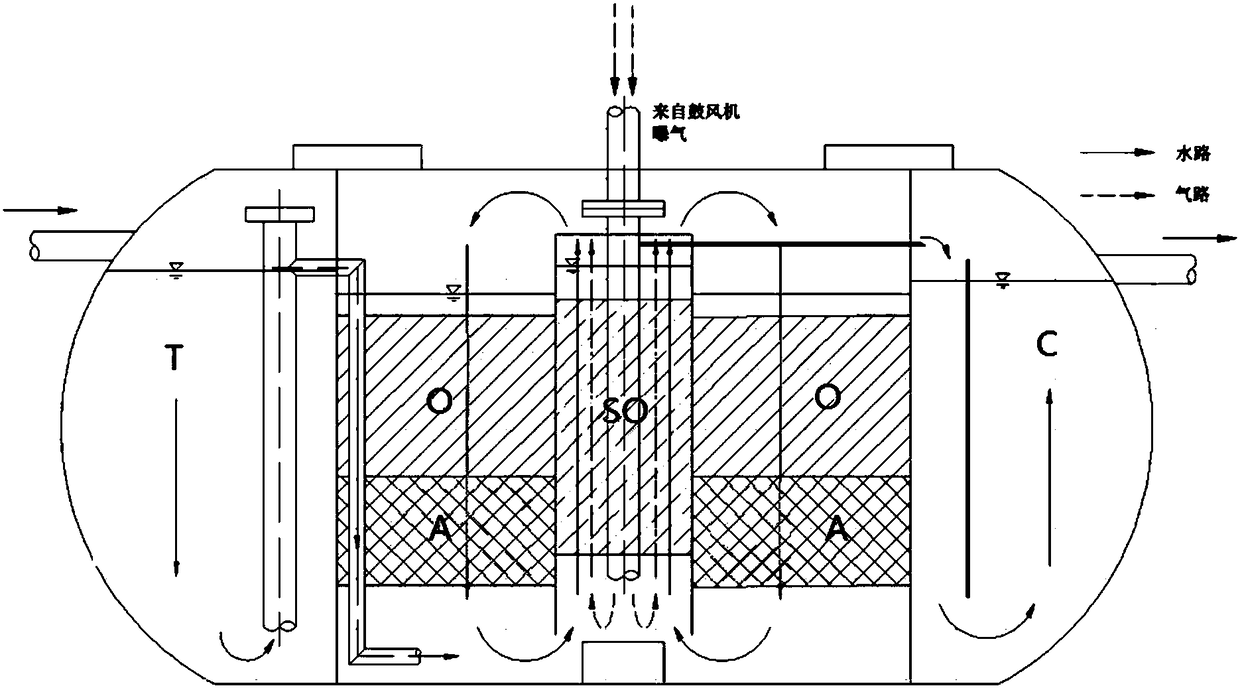

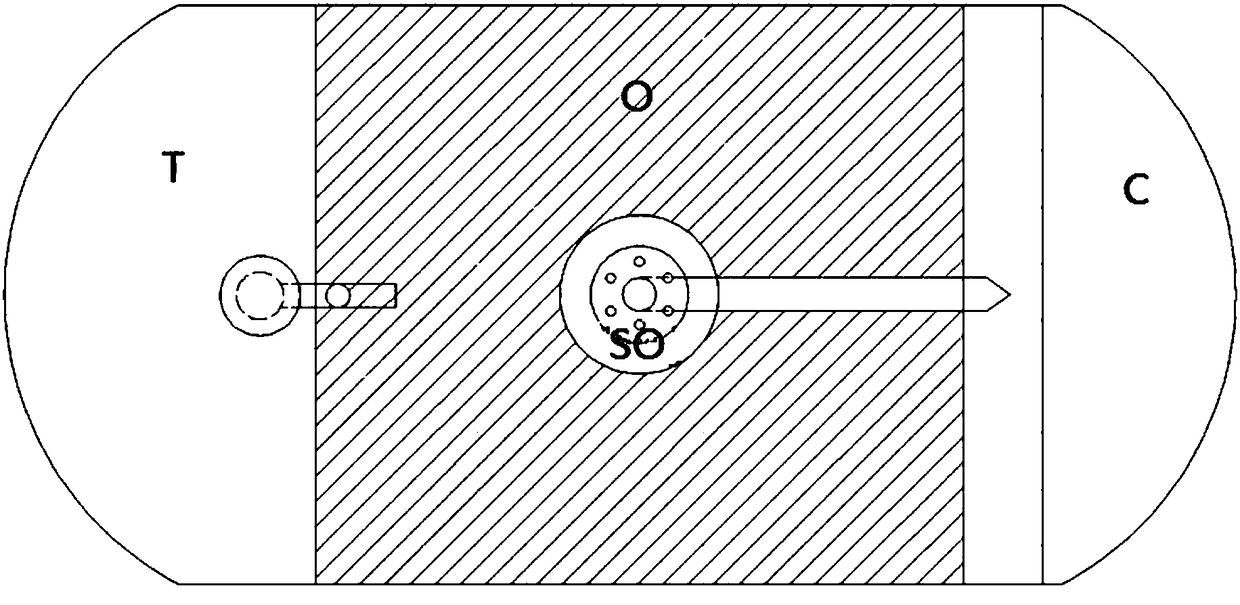

Treatment technology suitable for high ammonia nitrogen dispersed domestic sewage

ActiveCN108358378AFavorable for attachment growthIncrease roughnessWater treatment parameter controlTreatment using aerobic processesNitrationNitrifying bacteria

The invention relates to a treatment technology suitable for high ammonia nitrogen dispersed domestic sewage. The technology comprises the following steps: the high ammonia nitrogen domestic sewage isfirstly homogenized by a regulating tank, then flows into a circulating biological reaction area composed of an aerobic decarbonization zone, an anoxic denitrification zone and a super oxygen nitrification zone, is cyclically treated multiple times, is treated by a precipitation area, and is discharged. Nitrifying bacteria and decarburization heterotrophic grow in the super oxygen area and an aerobic area separately, so the mutual competition is reduced. Hydraulic driving needed by the circulating biological reaction area is provided by the gas stripping effect generated by strong aeration ofthe super oxygen nitrification zone without mounting a stirred reactor. The sewage undergoes a super oxygen-aerobic-anoxic cycle multiples to achieve ammonia nitrogen nitration conversion and organicmatter removal. Compared with the prior art, the technology in the invention has the advantages of strong nitrification ability, efficient and intensive process, simplicity in operation and maintenance, high efficiency in treatment of the high ammonia nitrogen dispersed domestic sewage, and realization of the recycling of nitrogen and phosphorus in the dispersed sewage.

Owner:TONGJI UNIV

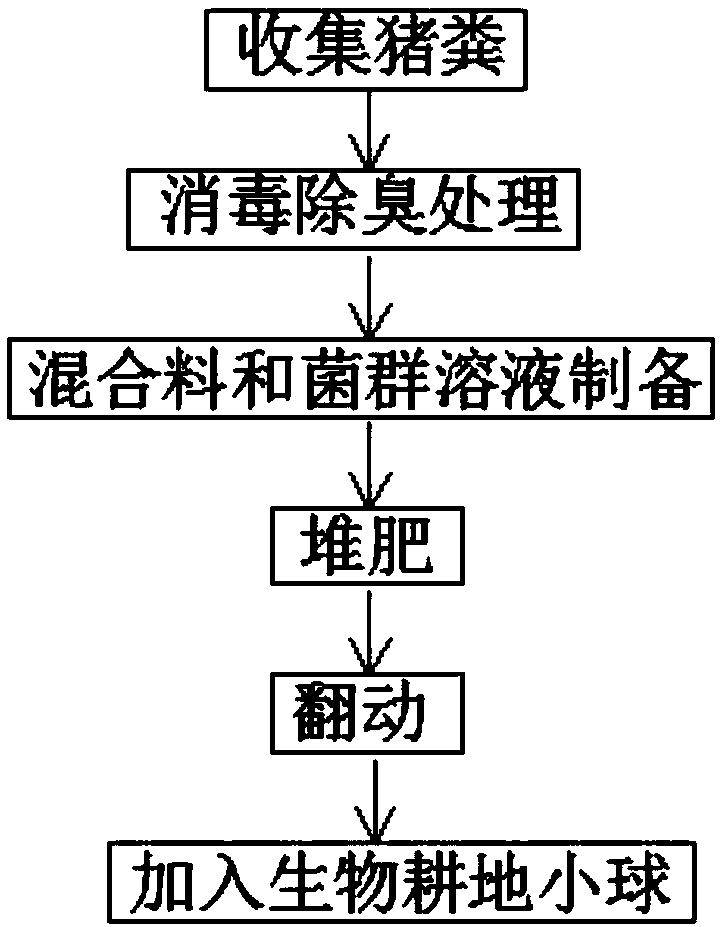

Method for making bio-organic fertilizer by utilizing pig manure

InactiveCN109438015APromote absorptionFewer crushing stepsExcrement fertilisersBioloigcal waste fertilisersMicroorganismBiotechnology

The invention discloses a method for making a bio-organic fertilizer by utilizing pig manure, and belongs to the field of organic fertilizers. The method for making the bio-organic fertilizer by utilizing the pig manure is characterized in that the organic fertilizer comprises the following ingredients in parts by mass: 200-220 parts of pig manure, 60-80 parts of plant ash, 100-110 parts of pond bottom sludge, 20-30 parts of oil cakes, 50-60 parts of crop straw, 3-5 parts of microbial flora, 20-30 parts of rotted crop fruits, 8-10 parts of wormcast and 30-40 parts of rice bran; an effect of processing the pig manure into the organic fertilizer in the form of composting is realized; through the use of biological land cultivating balls, earthworm cocoons in the biological land cultivating balls are hatched into earthworms, and biological soil digging can be performed on soil near the organic fertilizer and roots and stems of crops, so that the cost and the sum of labor of artificial soildigging are greatly reduced, the absorption of the organic fertilizer by the roots and stems of the crops is more easily, the step of crushing the organic fertilizer after composting is omitted, andthus the work efficiency is significantly increased.

Owner:广东巴斯德环境科技有限公司

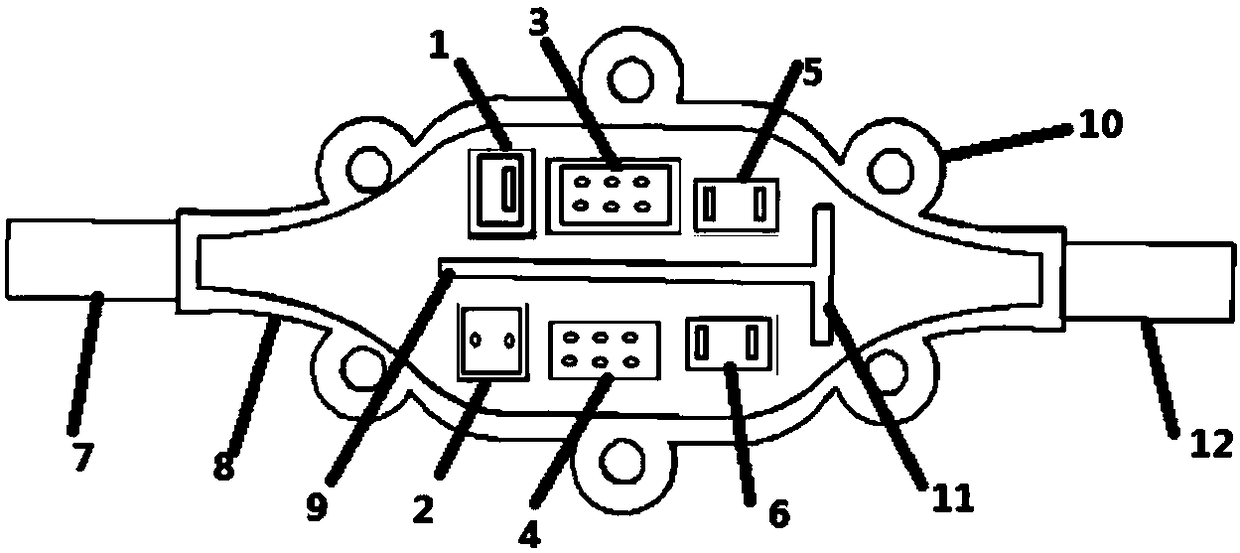

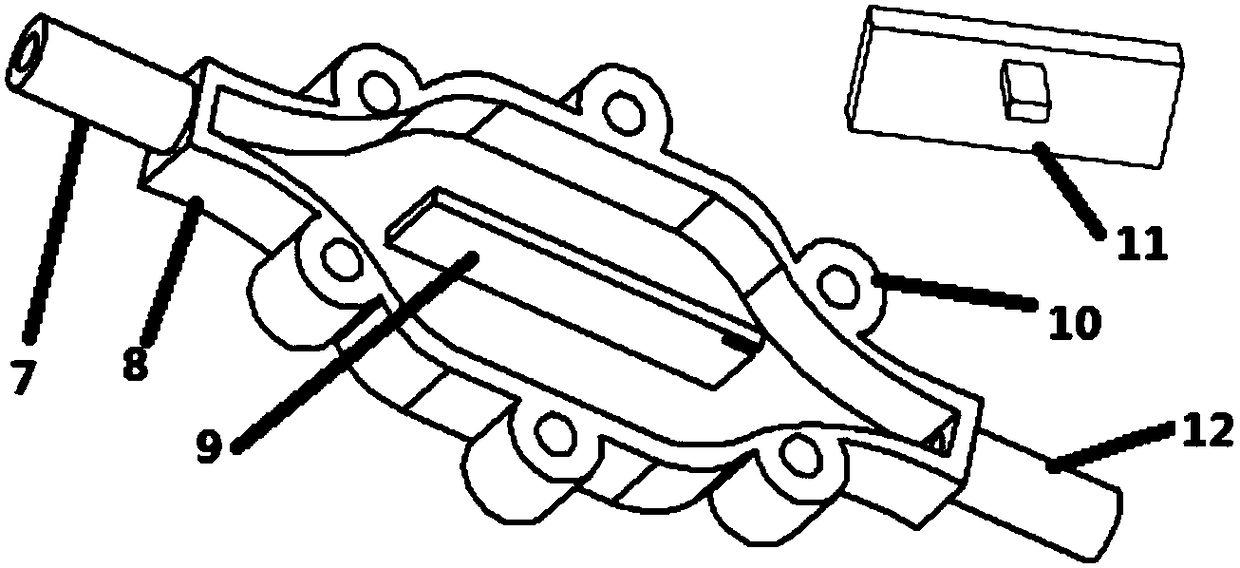

Bionic air chamber used for hand-held electronic nose

The invention relates to a bionic air chamber used for a hand-held electronic nose. The bionic air chamber used for the hand-held electronic nose comprises an air chamber wall and a bottom, a paster sensor is fixed at the bottom, the bionic air chamber is characterized in that a shape from an inlet to an outlet at the inner surface of the wall of the air chamber is a streamline, the middle size inthe air chamber is greater than the inlet size and the outlet size, and the bionic air chamber has the characteristics of small port and large chamber. The middle separation plates are vertically distributed in the air chamber, a slot used for fixing a baffle plate is arranged at the middle separation plate near the outlet end, a plugboard cooperated with the slot is arranged at the baffle plate,and the air pressure in the air chamber and the air-flow speed at the outlet can be adjusted by adjusting the height of the baffle plate.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com