Combined blocking remover for polymer injection blocking well section plug and preparation method and application of combined blocking remover

A technology of plugging agent and well section, applied in the field of tertiary oil recovery, can solve the problem of difficult effective contact and reaction between chemical agents and corresponding blockages, ignore the characteristics of deep plugging in polymer injection plugged wells, and the plugging removal effect is far from indoor test results and other problems, to achieve the effect of improving plugging removal efficiency, removing oily dirt plugging, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

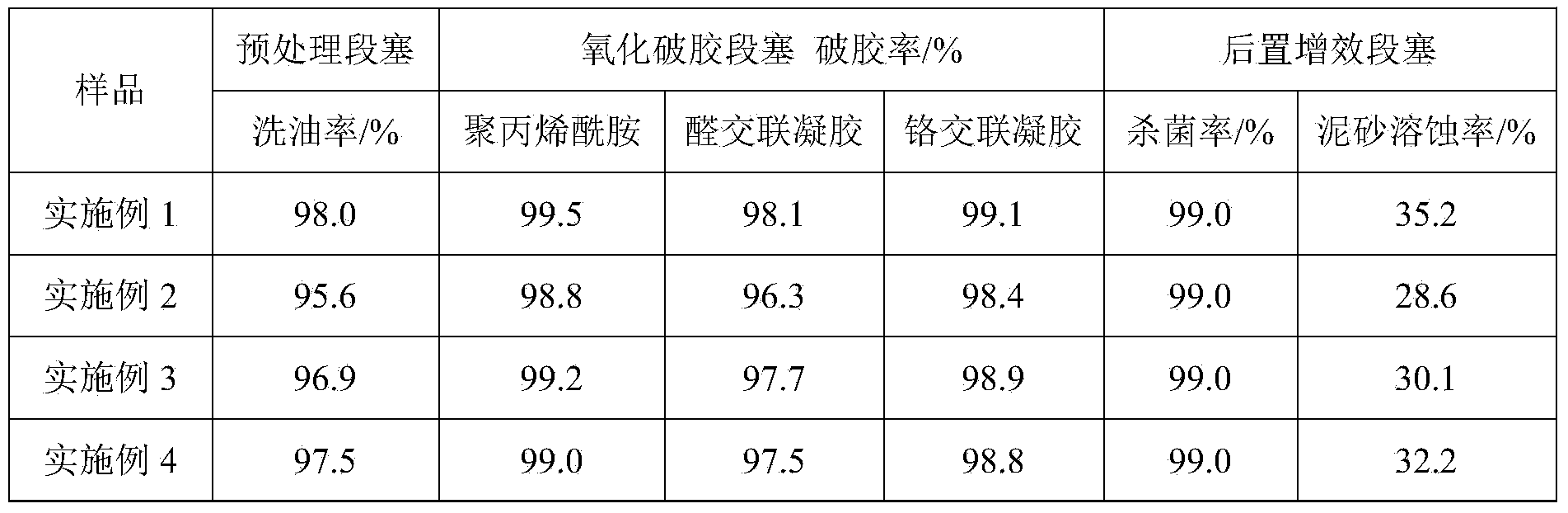

Embodiment 1

[0034] The combined slug removal agent for polymer injection plugging wells in this embodiment includes pretreatment slug removal agent, oxidative gel-breaking slug removal agent and post-position synergistic slug removal agent. Among them, the pretreatment slug remover is composed of the following components in weight percentage: JHB-1 type high-efficiency oil washing agent 5%, ammonium chloride 2%, and the balance is water; oxidative gel-breaking slug remover It is composed of the following components in percentage by weight: 20% sodium percarbonate, 2% active agent, 2% JHS-1 type steel oxidation and corrosion inhibitor, 5% ethanol, and the balance is water; post-position synergistic slug The plugging agent is composed of the following components in weight percentage: 10% sodium chlorite, 20% citric acid, 6% fluoroboric acid, 3% ammonium bifluoride, 1% ammonium chloride, JHB-1 type high-efficiency oil washing agent 3%, JHS-1 steel oxidation and corrosion inhibitor 2%, ethano...

Embodiment 2

[0041] The combined slug removal agent for polymer injection plugging wells in this embodiment includes pretreatment slug removal agent, oxidative gel-breaking slug removal agent and post-position synergistic slug removal agent. Among them, the pretreatment slug remover is composed of the following components in weight percentage: JHB-1 type high-efficiency oil washing agent 2%, ammonium chloride 1%, and the balance is water; oxidative gel-breaking slug remover It is composed of the following components in percentage by weight: 10% sodium percarbonate, 1% active agent, 0.5% JHS-1 steel oxidation and corrosion inhibitor, 2% ethanol, and the balance is water; post-position synergistic slug The blocking agent is composed of the following components in weight percentage: 5% sodium chlorite, 10% citric acid, 5% fluoroboric acid, 2% ammonium bifluoride, 1% ammonium chloride, JHB-1 type high-efficiency oil washing agent 2%, JHS-1 steel oxidation and corrosion inhibitor 0.5%, ethanol ...

Embodiment 3

[0044] The combined slug removal agent for polymer injection plugging wells in this embodiment includes pretreatment slug removal agent, oxidative gel-breaking slug removal agent and post-position synergistic slug removal agent. Among them, the pretreatment slug remover is composed of the following components in weight percentage: JHB-1 type high-efficiency oil washing agent 3.5%, ammonium chloride 1.5%, and the balance is water; oxidative gel-breaking slug remover It consists of the following components in percentage by weight: 15% sodium percarbonate, 1.5% active agent, 1.2% JHS-1 type steel oxidation and corrosion inhibitor, 3.5% ethanol, and the balance is water; post-position synergistic slug The blocking agent is composed of the following components in weight percentage: 7.5% sodium chlorite, 15% citric acid, 5.5% fluoboric acid, 2.5% ammonium bifluoride, 1.5% ammonium chloride, JHB-1 type high-efficiency oil washing agent 2.5%, JHS-1 steel oxidation and corrosion inhibi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com