A kind of oxidized gel breaker for polymer injection well and preparation method thereof

A technology of gel breaker and polymer injection well, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of difficult to effectively guarantee construction safety, corrosion of construction equipment and downhole pipe strings, construction equipment and measure wells Scrap and other problems, to achieve good fluidity, low corrosion, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

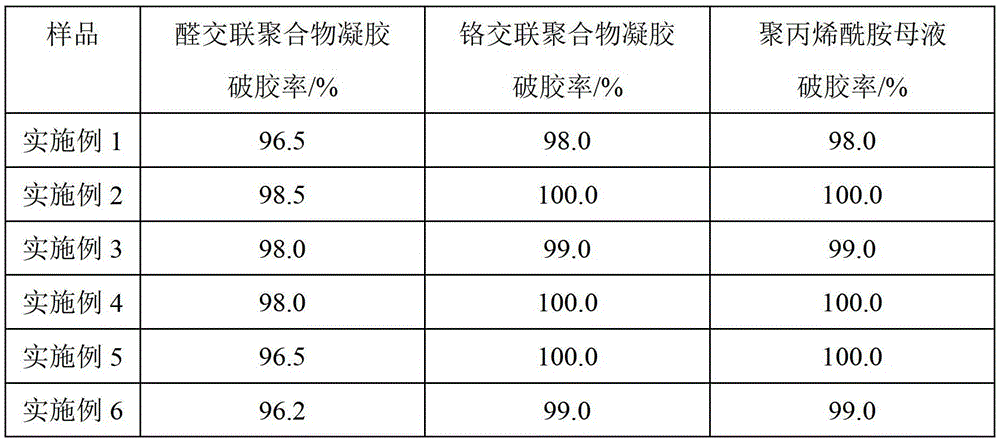

Examples

Embodiment 1

[0027] The oxidative breaker for polymer injection wells in this example consists of the following components in weight percent: 10% ammonium persulfate, 2% potassium persulfate, 0.1% borax, 1% sodium carbonate, and 2% sodium hydroxide , JHS-1 Iron and Steel Oxidation and Corrosion Inhibitor (provided by the School of Petrochemical Engineering, China University of Petroleum) 0.5%, ethanol 2%, and the balance is water.

[0028] In this embodiment, the preparation steps of the oxidized breaker for polymer injection wells are as follows: stir and add borax, sodium carbonate and sodium hydroxide in water until completely dissolved, then stir and add ammonium persulfate, potassium persulfate, ethanol and corrosion inhibitor in turn to Dissolve completely and the solution becomes uniform and transparent.

Embodiment 2

[0030] The oxidative breaker for polymer injection wells in this example consists of the following components in weight percent: 20% ammonium persulfate, 5% potassium persulfate, 0.5% borax, 3% sodium carbonate, and 5% sodium hydroxide , JHS-1 Iron and Steel Anti-Oxidation and Corrosion Inhibitor (provided by the School of Petrochemical Engineering, China University of Petroleum) 2%, ethanol 5%, and the balance is water.

[0031] In this embodiment, the preparation steps of the oxidized breaker for polymer injection wells are as follows: stir and add borax, sodium carbonate and sodium hydroxide in water until completely dissolved, then stir and add ammonium persulfate, potassium persulfate, ethanol and corrosion inhibitor in turn to Dissolve completely and the solution becomes uniform and transparent.

Embodiment 3

[0033] The oxidative breaker for polymer injection wells in this example consists of the following components in weight percent: 15% ammonium persulfate, 4% potassium persulfate, 0.4% borax, 3% sodium carbonate, and 4% sodium hydroxide , JHS-1 Iron and Steel Anti-Oxidation and Corrosion Inhibitor (provided by the School of Petrochemical Engineering, China University of Petroleum) 1%, ethanol 4%, and the balance is water.

[0034] In this embodiment, the preparation steps of the oxidized breaker for polymer injection wells are as follows: stir and add borax, sodium carbonate and sodium hydroxide in water until completely dissolved, then stir and add ammonium persulfate, potassium persulfate, ethanol and corrosion inhibitor in turn to Dissolve completely and the solution becomes uniform and transparent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com