A kind of modified ceramsite ozone catalyst, preparation method and application

A catalyst and ceramsite technology, applied in chemical instruments and methods, physical/chemical process catalysts, oxidized water/sewage treatment, etc., can solve the problems of poor ozone catalyst performance and narrow application range, achieve excellent catalytic performance, and facilitate The effect of promotion and improvement of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

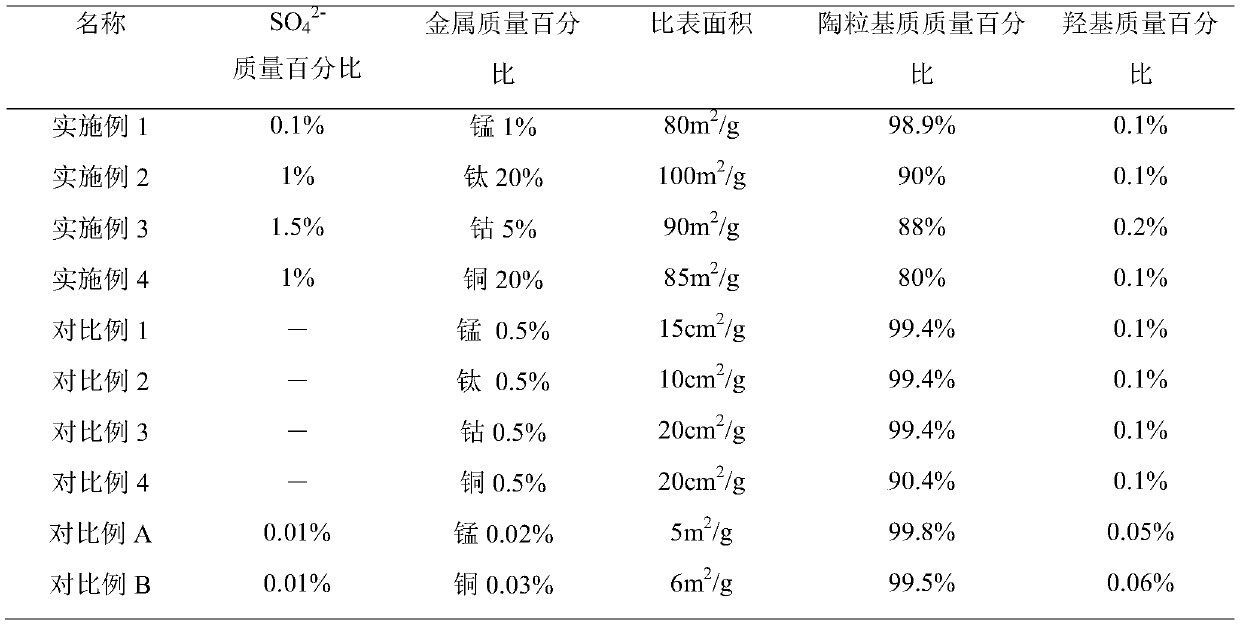

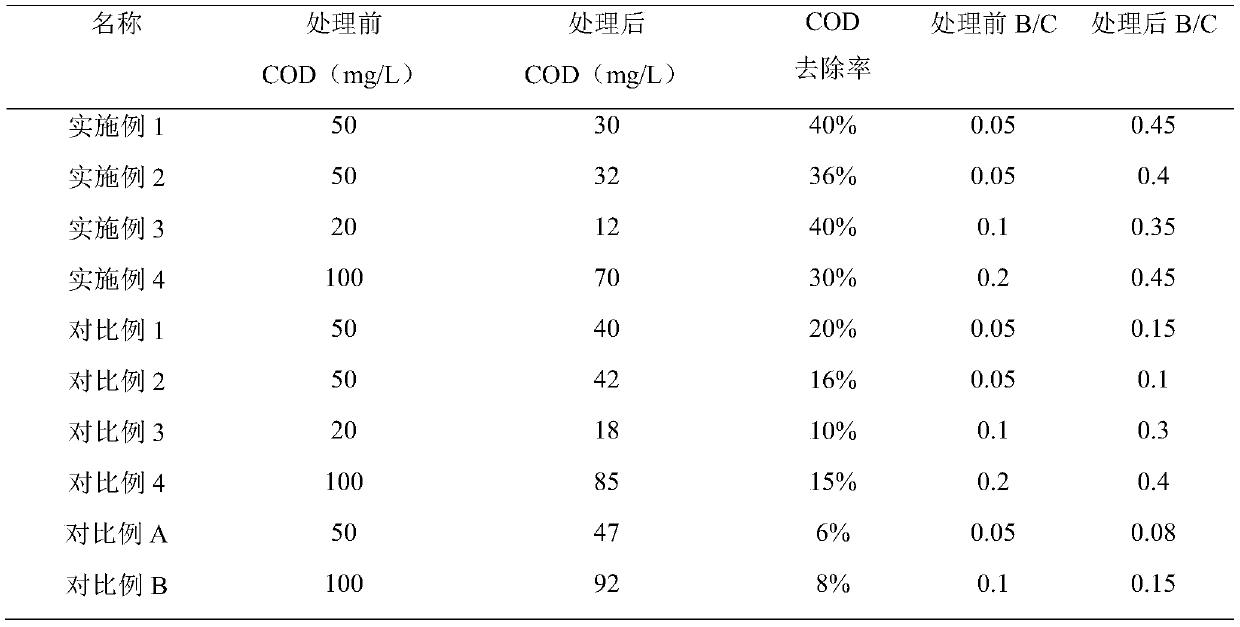

Embodiment 1

[0036] In this embodiment, the commercially available ceramsite ozone catalyst-Cat-O with a particle size of 3-5mm is selected. 3 (purchased from Guangzhou Hualv Environmental Protection Technology Co., Ltd.) 1kg as raw material, the commercially available ceramsite ozone catalyst-Cat-O 3 Its composition in terms of mass percentage is: Mn 0.5%, hydroxyl 0.1%, ceramsite matrix 99.4%; its specific surface area is 15cm 2 / g.

[0037] The preparation steps of modified ceramsite ozone catalyst in the present embodiment are as follows:

[0038] (1) The above-mentioned ceramsite ozone catalyst-Cat-O 3 Mixing with a mixed solution obtained by sulfuric acid with a pH of 3 and manganese sulfate with a mass concentration of 10%, the mass ratio of sulfuric acid and metal sulfate in the mixed solution is 1:1; the pH of the mixed solution is adjusted by sulfuric acid; Impregnating the Mixed Solution with Ceramsite Ozone Catalyst-Cat-O 3 , the impregnation is subject to the immersion of ...

Embodiment 2

[0043] In this embodiment, the commercially available ceramsite ozone catalyst-Cat-O with a particle size of 3-5mm is selected. 3 (purchased from Guangzhou Hualv Environmental Protection Technology Co., Ltd.) 1kg as raw material, the commercially available ceramsite ozone catalyst-Cat-O 3 Its composition in terms of mass percentage is: Mn 0.5%, hydroxyl 0.1%, ceramsite matrix 99.4%; its specific surface area is 15cm 2 / g.

[0044] The preparation steps of modified ceramsite ozone catalyst in the present embodiment are as follows:

[0045] (1) The above-mentioned ceramsite ozone catalyst-Cat-O 3 Mixing with a mixed solution obtained by sulfuric acid with a pH of 5 and titanium sulfate with a mass concentration of 15%, the mass ratio of sulfuric acid and metal sulfate in the mixed solution is 1:1.5; the pH of the mixed solution is adjusted by sulfuric acid; Impregnating the Mixed Solution with Ceramsite Ozone Catalyst-Cat-O 3 , the impregnation is based on the solution immer...

Embodiment 3

[0050] In this embodiment, the commercially available ceramsite ozone catalyst-Cat-O with a particle size of 3-5mm is selected. 3 (purchased from Guangzhou Hualv Environmental Protection Technology Co., Ltd.) 1kg as raw material, the commercially available ceramsite ozone catalyst-Cat-O 3 The components are as follows in terms of mass percentage: 0.5% of Mn, 0.1% of hydroxyl, and 99.4% of ceramsite matrix. The specific surface area is 15cm 2 / g.

[0051] The preparation steps of modified ceramsite ozone catalyst in the present embodiment are as follows:

[0052] (1) The above-mentioned ceramsite ozone catalyst-Cat-O 3 with H at pH 5 2 SO 4 The solution is mixed with a mixed solution obtained by cobalt sulfate with a mass concentration of 20%, and the mass ratio of sulfuric acid to metal sulfate in the mixed solution is 1:1.5; the pH value of the mixed solution is adjusted by sulfuric acid; the mixed solution is impregnated with pottery Granular Ozone Catalyst-Cat-O 3 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com