Microminiature mixing device for strengthening fluid mixing by micronization boiling of steam bubbles

A fluid mixing and mixing device technology, applied in mixers, transportation and packaging, chemical instruments and methods, etc., can solve the problems of power mismatch of micro-devices, high production cost, pipeline blockage, etc., and achieve good mixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing example the present invention is described in more detail: the present embodiment is implemented under the premise of the technical solution of the present invention, has provided detailed implementation scheme and specific operation process, but the protection scope of the present invention is not limited to the following examples.

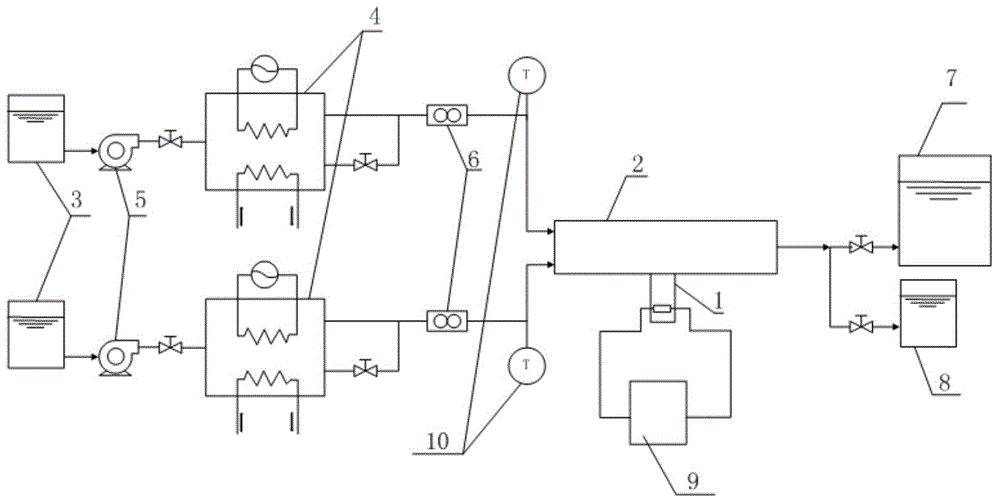

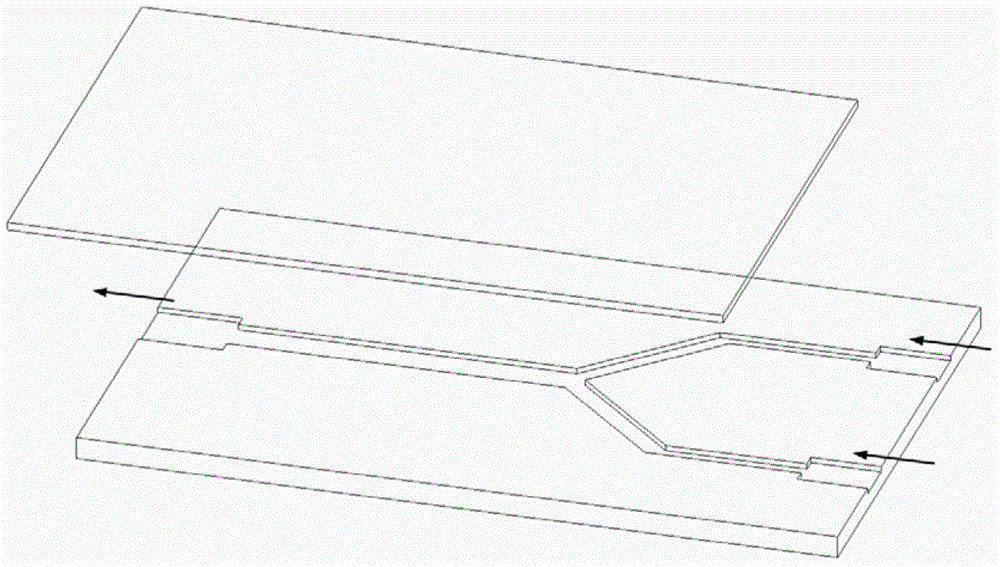

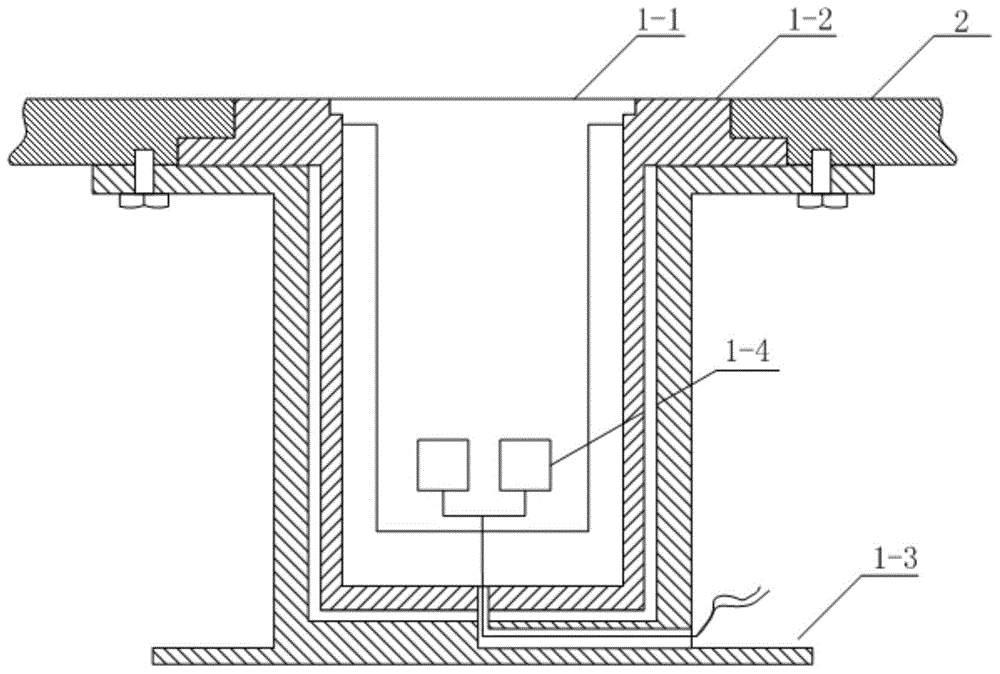

[0031] combine figure 1 and figure 2 , the system for achieving fast and uniform mixing of stratified fluids in pipelines using micro-bubble boiling mainly includes micro-bubble boiling heating part 1, micro-miniature mixing channel 2, water tank 3, temperature control box 4, pump 5, and flow meter 6. Mixed liquid storage tank 7, waste liquid tank 8, power controller 9, thermocouple 10, etc. The temperature control box 4 regulates the fluid inlet water temperature through an electric heater and a cooling water circuit. The micro-miniature mixing channel 2 is a herringbone-shaped micro-pipe,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com