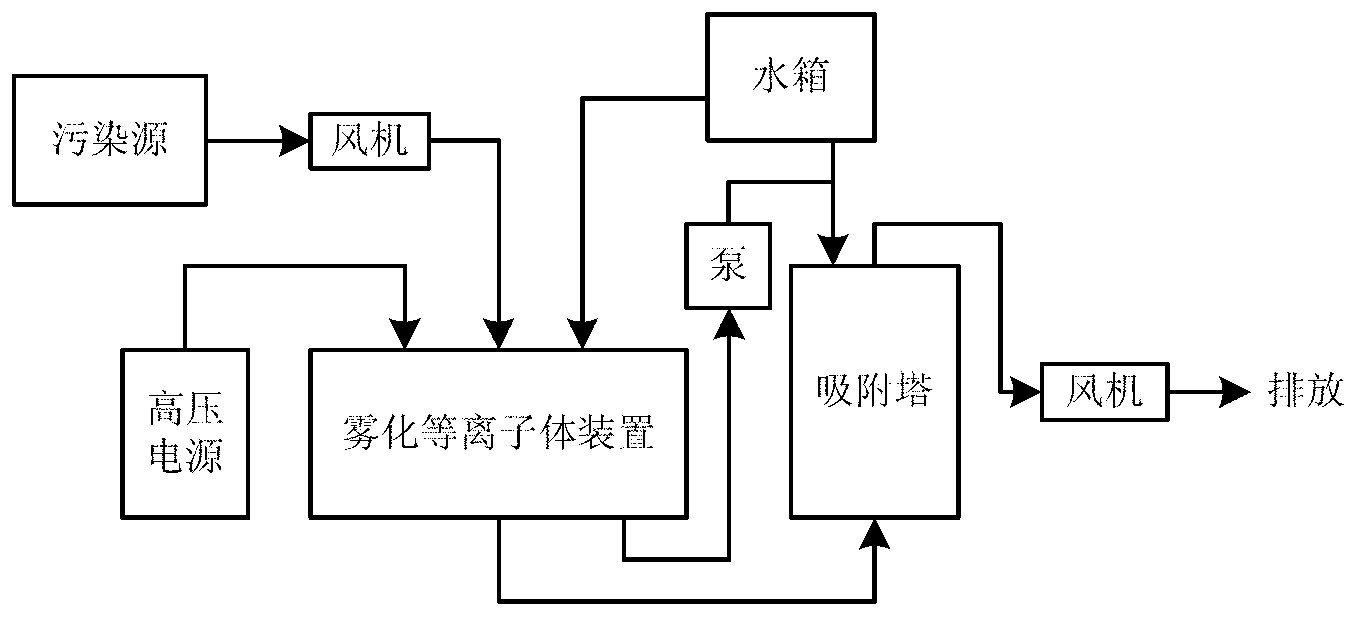

Method for dealing with foul smell through atomization plasma oxidation-biomass adsorption

A technology of biomass adsorption and plasma, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, etc., to achieve enhanced effect, enhanced removal effect, and high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

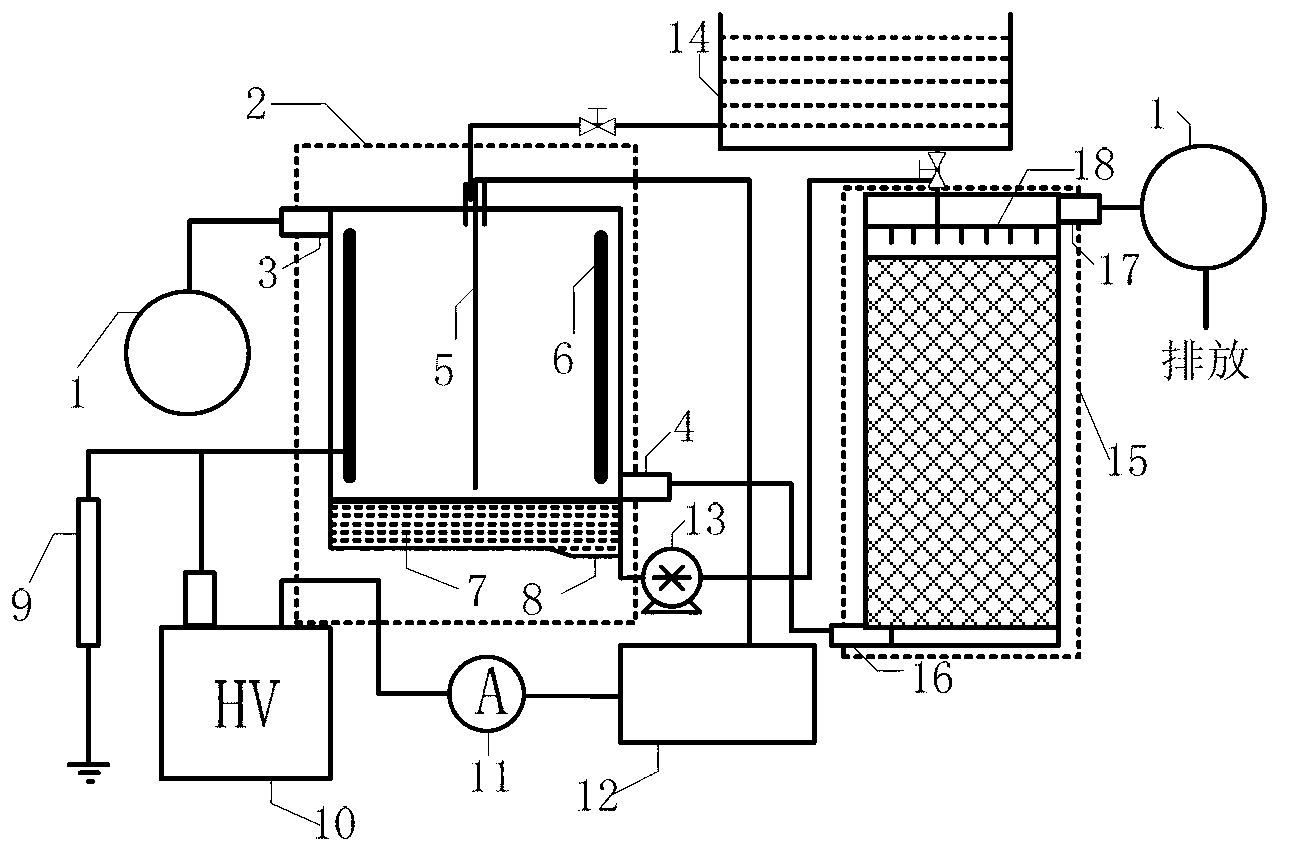

[0037] A method for treating malodorous gas with atomized low-temperature plasma oxidation-biomass adsorption combined technology, using atomized plasma oxidation-biomass adsorption device, according to the following steps:

[0038] The plant waste (corn cob) is crushed and screened for particles with a particle size of 7-10 mm. After humidification, it is put into the adsorption tower. The water for humidification is a mixture of algae and bacteria, among which algae are small particles with high specific surface area and high adsorption capacity. Chlorella, the fungus is Paenibacillus, which is highly efficient in producing flocs, and the volume ratio of water to algae in the humidification water (centrifuged at 15000r for 5min) is 9:1. At the same time, during the operation of the device, water spraying is properly carried out to continuously humidify, so that the mass of plant waste and the volume ratio of water w / v= 1 / (0.3~0.7) g / ml;

[0039] Turn on the water pump, conti...

Embodiment 2

[0043] A method for treating malodorous gas with atomized low-temperature plasma oxidation-biomass adsorption combined technology, using atomized plasma oxidation-biomass adsorption device, according to the following steps:

[0044] The plant waste is crushed and screened for particles with a particle size of 7-10mm. It is modified by microwave irradiation with a power of 800W for 5 minutes. After humidification, it is put into the adsorption tower. The medium algae is Crescent algae with small particles, high specific surface area and high adsorption capacity, and the fungus is Bacillus, which is highly efficient in producing flocculation. The volume ratio of water to algae in the humidification water (centrifuged at 15000r for 5min) is 9:1. At the same time, during the operation of the device, water spraying is properly carried out to continuously humidify, so that the mass of plant waste and the volume ratio of water w / v= 1 / (0.3~0.7) g / ml;

[0045] Turn on the water pump, c...

Embodiment 3

[0049] A method for treating malodorous gas with atomized low-temperature plasma oxidation-biomass adsorption combined technology, using atomized plasma oxidation-biomass adsorption device, according to the following steps:

[0050] The plant waste is crushed and screened for particles with a particle size of 5-7mm, modified by microwave irradiation with a power of 1000W for 10 minutes, and put into an adsorption tower after humidification, and the water for humidification is a mixed solution of algae and bacteria, wherein the algae and bacteria The algae in the mixed solution are cellulosic algae with small particles, high specific surface area and high adsorption, and the fungi are acidophilus with high efficiency of flocculation production. The volume ratio of water to algae in the humidification water (centrifuged at 15000r for 1min) is 7: 1. At the same time, during the operation of the device, water spraying is properly carried out to continuously humidify, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com