Method using microchannel reaction to prepare chloroethylene carbonate

A technology of chloroethylene carbonate and microchannel reaction, which is applied in chemical instruments and methods, chemical/physical/physical chemical reactors, chemical/physical/physical chemical processes, etc., and can solve cumbersome processes and low product yields, etc. Problems, to achieve sufficient raw material contact reaction, improve purity, and good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

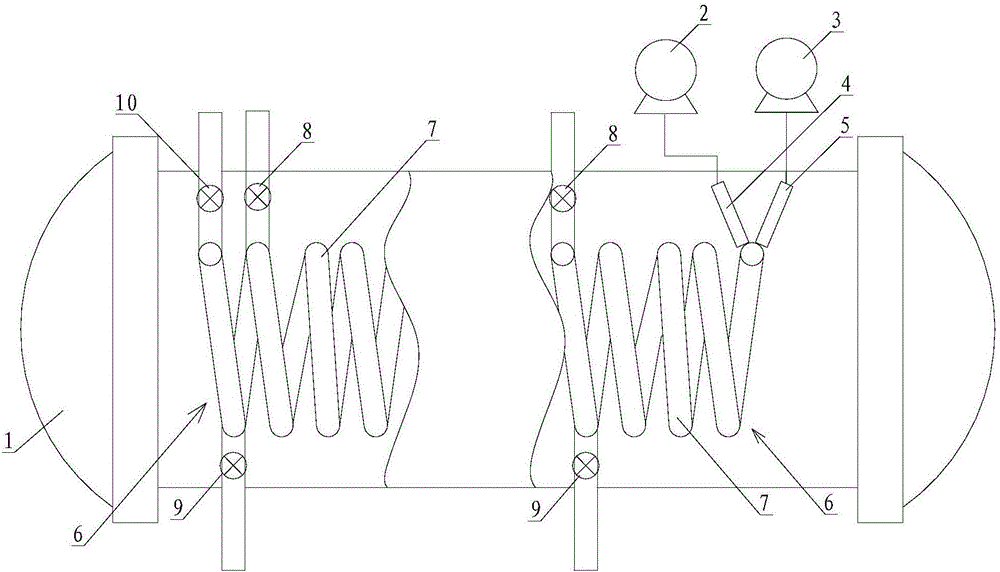

[0028] (1) The equipment that described method uses comprises enhanced mass transfer type microchannel reactor 1, metering pump one 2, metering pump two 3, enhanced mass transfer type microchannel reactor comprises preheater 4, storage tank 5, heat exchange The microchannel module 6 made of monocrystalline silicon is connected with several segments in sequence. Each microchannel module 6 includes a spiral tubular microchannel 7 with a heart-shaped internal structure and a hydraulic diameter of 0.5mm, an exhaust valve 8, Nitrogen replacement valve 9, one of the microchannel modules positioned at the outermost side is also provided with a discharge valve 10;

[0029] (2) Ethylene carbonate with a purity of more than 75% is heated from solid to 50°C to become a liquid, and after adding initiator benzoyl peroxide and catalyst aluminum trichloride, mix uniformly to obtain a mixed solution, catalyst aluminum trichloride, initiator The mass ratio of benzoyl peroxide and ethylene carb...

Embodiment 2

[0031] (1) The equipment that described method uses comprises enhanced mass transfer type microchannel reactor 1, metering pump one 2, metering pump two 3, enhanced mass transfer type microchannel reactor comprises preheater 4, storage tank 5, heat exchange Microchannel modules 6 made of monocrystalline silicon, connected in sequence, and several segments connected in sequence, each microchannel module 6 includes a spiral tubular microchannel 7 with a heart-shaped internal structure and a hydraulic diameter of 10 mm, an exhaust valve 8, nitrogen gas Displacement valve 9, one of the microchannel modules positioned at the outermost side is also provided with a discharge valve 10;

[0032] (2) Ethylene carbonate with a purity of more than 75% is heated from solid to 50°C to become a liquid, and after adding initiator benzoyl peroxide and catalyst aluminum trichloride, mix uniformly to obtain a mixed solution, catalyst aluminum trichloride, initiator The mass ratio of agent benzoy...

Embodiment 3

[0034] (1) The equipment that described method uses comprises enhanced mass transfer type microchannel reactor 1, metering pump one 2, metering pump two 3, enhanced mass transfer type microchannel reactor comprises preheater 4, storage tank 5, heat exchange Microchannel modules 6 made of monocrystalline silicon, connected in sequence, and several segments connected in sequence, each microchannel module 6 includes a spiral tubular microchannel 7 with a heart-shaped internal structure and a hydraulic diameter of 5 mm, an exhaust valve 8, nitrogen gas Displacement valve 9, one of the microchannel modules positioned at the outermost side is also provided with a discharge valve 10;

[0035](2) Ethylene carbonate with a purity of more than 75% is heated from solid to 50°C to become a liquid, and after adding initiator benzoyl peroxide and catalyst aluminum trichloride, mix uniformly to obtain a mixed solution, catalyst aluminum trichloride, initiator The mass ratio of benzoyl peroxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com