Hydrogen breaking furnace

A hydrogen crushing furnace and furnace body technology, which is applied in the field of internal heating hydrogen crushing furnace, can solve the problems of poor safety, large contact area between alloy and hydrogen, and low vacuum degree, so as to avoid leakage or poor sealing, obvious cooling effect, and vacuum The effect of degree guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

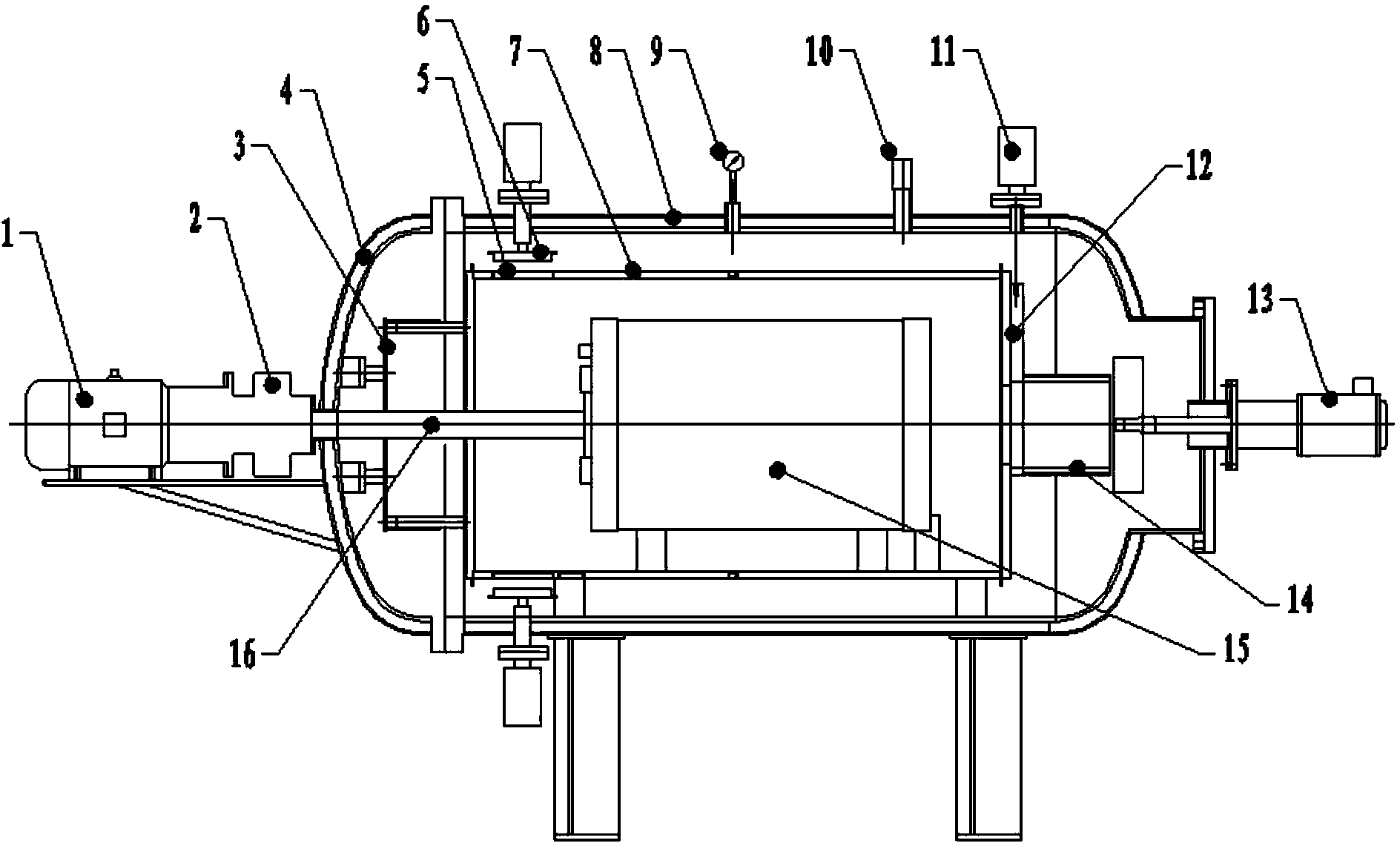

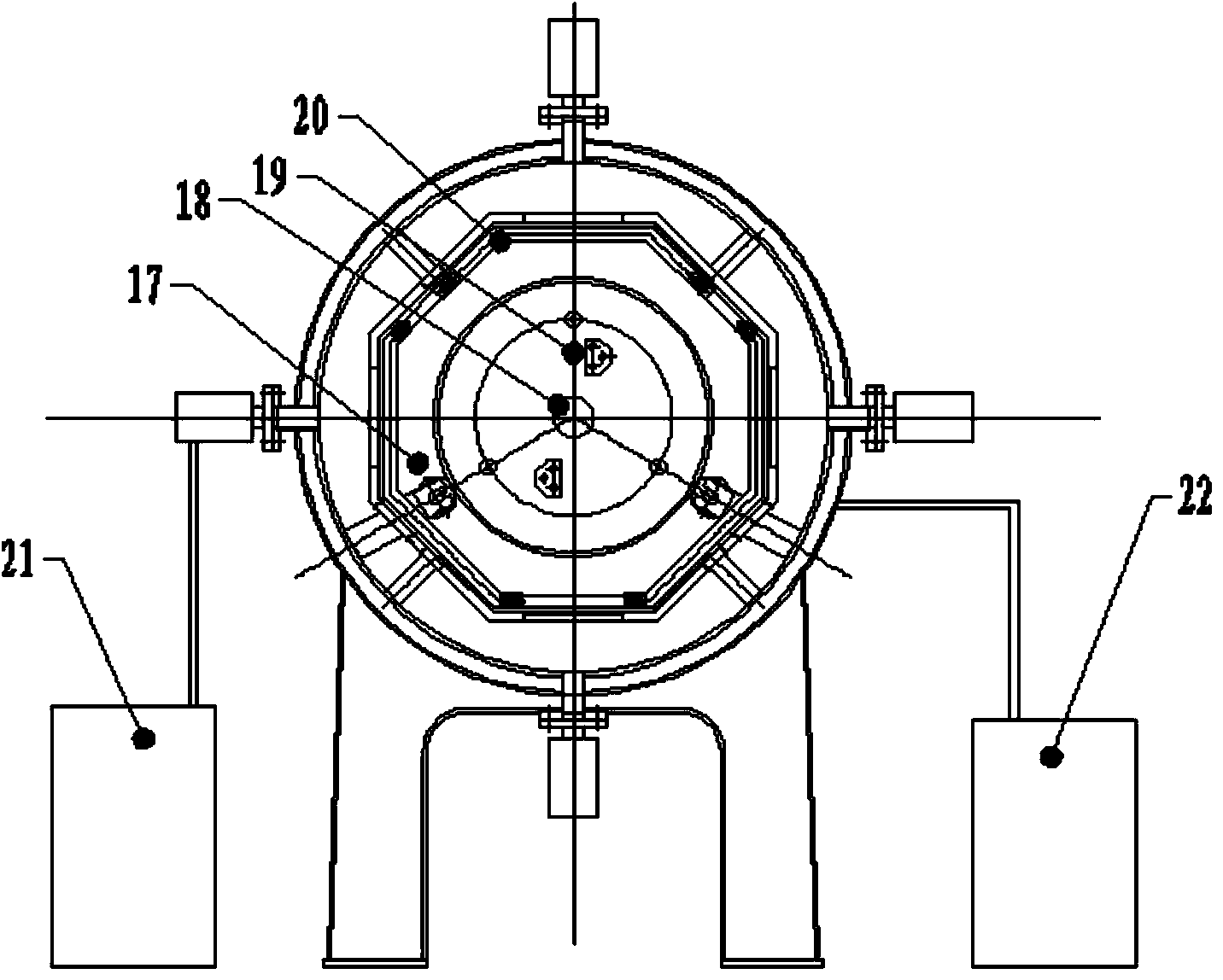

[0022] A hydrogen crushing furnace, including a furnace door 4 installed at the front end of the furnace body 8, a pneumatic control system 21 and a vacuum generating system 22 respectively communicated with the furnace body 8 through gas pipes; the furnace door 4 and the furnace body 8 both have a double-layer jacket structure , the outer wall is connected with water inlet and outlet. The furnace body 8 is equipped with an argon or helium port, a pressure gauge 9 and a safety relief valve 10 . A rotating system that drives the rotation of the reaction barrel is installed on the outside of the furnace door 4 . The rotation system includes a driving motor 1 installed on the outside of the furnace door 4 and a rotating transmission shaft 16 in the furnace; one end of the rotating transmission shaft 16 is movably connected with the shaft connection end of the driving motor 1, and the other end is movably connected with the reaction barrel 15, and the driving motor 1 The reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com