Filling method of KDF dechloridation combined filter element

A technology of combining filter elements and filling methods, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of high cost, complicated reverse pressure flushing operation, etc., and achieve the effect of reducing contact and stickiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with accompanying drawing:

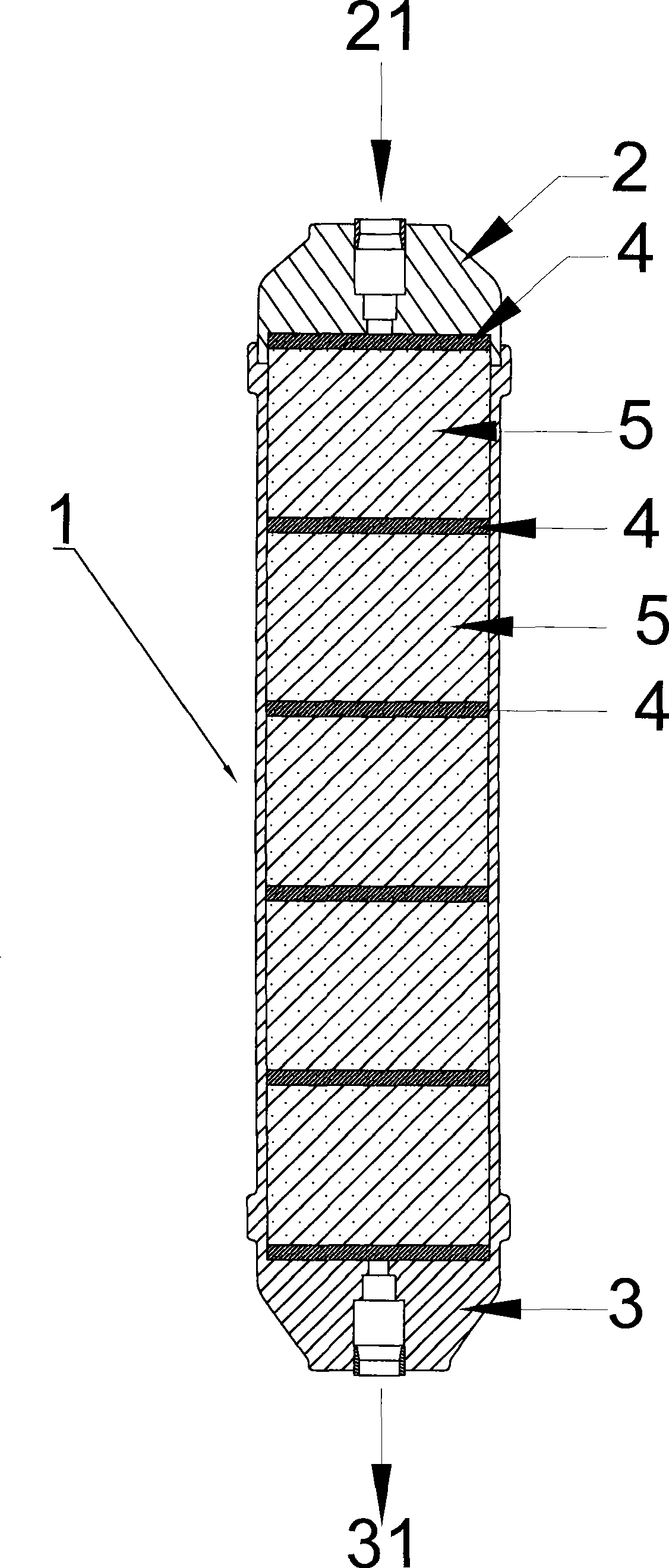

[0031] see figure 1 As shown, the filter housing of the KDF dechlorination combined filter element consists of a shell-shaped housing 1, an end cover 2 sleeved on its open end, a water inlet 21 opened on the end cover, and a valve at the other end of the housing opposite to the end cover 2. The end 3 is formed with a water outlet 31 coaxial with the water inlet 21 .

[0032] The filling method of described KDF dechlorination combined filter element comprises the following steps:

[0033] (1) A filter layer 4 is respectively provided at the water inlet end and the water outlet end of the inner cavity of the filter housing 1;

[0034] (2) Five layers of filter materials 5 separated by filter layers 4 are respectively filled between the two filter layers 4 at the water inlet end and the water outlet end of the inner chamber of the filter housing 1 .

[0035] in: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com