Anaerobic fluidized bed reactor

An anaerobic fluidized bed and reactor technology, which is applied in the field of anaerobic fluidized bed reactors, can solve the problems of low mass transfer efficiency and achieve the effects of thorough reaction, clear effluent and increased residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

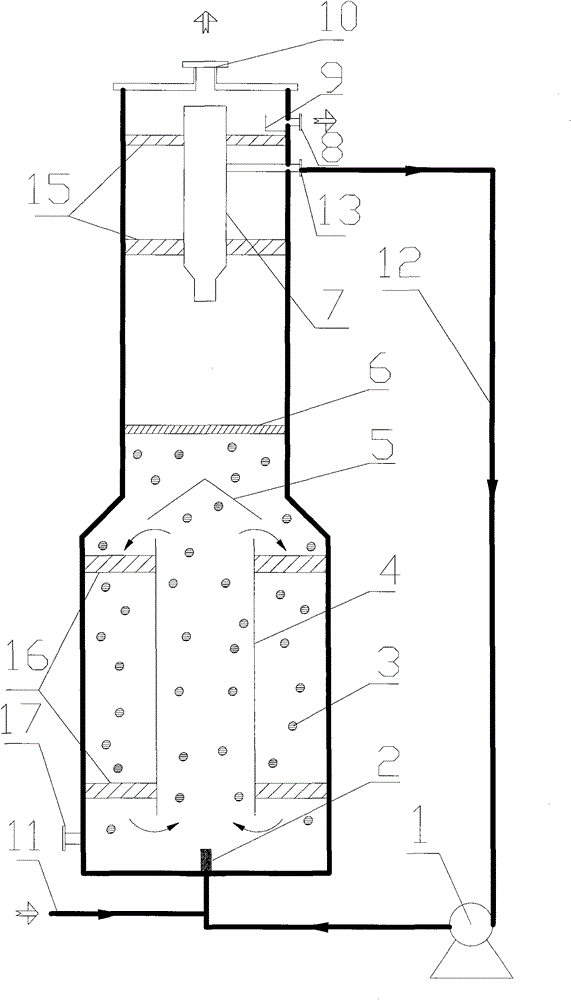

[0029] As shown in the figure, the figure is a schematic structural diagram of an anaerobic biological fluidized bed reactor of the present invention. The anaerobic fluidized bed reactor is a two-stage cylinder with a thin upper part and a thick lower part. The upper part and the lower part are connected by a tapered transition section. The reactor is provided with a complete mixing reaction zone and In the plug flow reaction zone, a jet nozzle 2 is installed at the center of the bottom of the anaerobic fluidized bed reactor, a filler 3 is installed in the complete mixing reaction zone, and a guide tube 4 is arranged 100-300mm directly above the jet nozzle 2, namely The vertical distance between the bottom of the guide tube 4 and the top of the jet nozzle 2 is 100-300 mm. The guide tube 4 is connected to the anaerobic fluidized bed reactor through the guide tube support 16. A cap 5 is provided at 40~200mm directly above the guide tube 4, and a liquid-solid separator 6 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com