Method for preparing three-dimensional bismuth ferrite visible light catalytic material by using direct-write forming technology

A three-dimensional bismuth ferrite, direct-writing molding technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the research of no three-dimensional bismuth ferrite catalyst, limited specific surface area improvement, etc. problems, to achieve the effect of improving light source utilization, increasing effective area, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

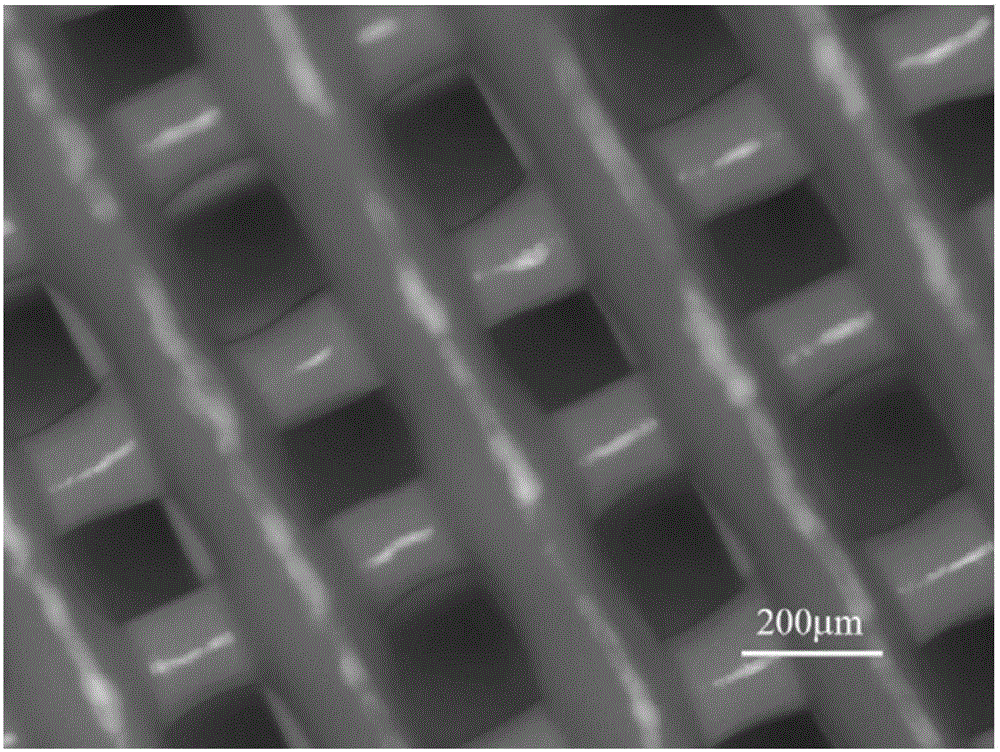

Image

Examples

Embodiment Construction

[0014] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0015] The embodiment of the present invention provides a method for preparing a three-dimensional bismuth ferrite visible light catalytic material by direct writing molding technology, comprising the following steps:

[0016] S01. Provide ferric nitrate, bismuth nitrate, nitric acid, potassium hydroxide, after dissolving them to form a mixed solution, prepare bismuth ferrite nanopowder through hydrothermal synthesis;

[0017] S02. After mixing the bismuth ferrite nanopowder with the additive, add it to deionized water to prepare a bismuth ferrite mixed slurry with a solid phase content of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com