Secondary effluent regeneration treatment system for municipal sewage treatment plant and secondary effluent regeneration treatment method of secondary effluent regeneration treatment system

A secondary effluent and urban sewage technology, applied in water/sewage treatment, water/sewage multi-stage treatment, oxidized water/sewage treatment, etc., can solve the problems of not being universally applicable, large energy consumption, and high operating costs. Achieve the effects of dissolution and stability of effluent water quality, reduce electrode passivation, and improve the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

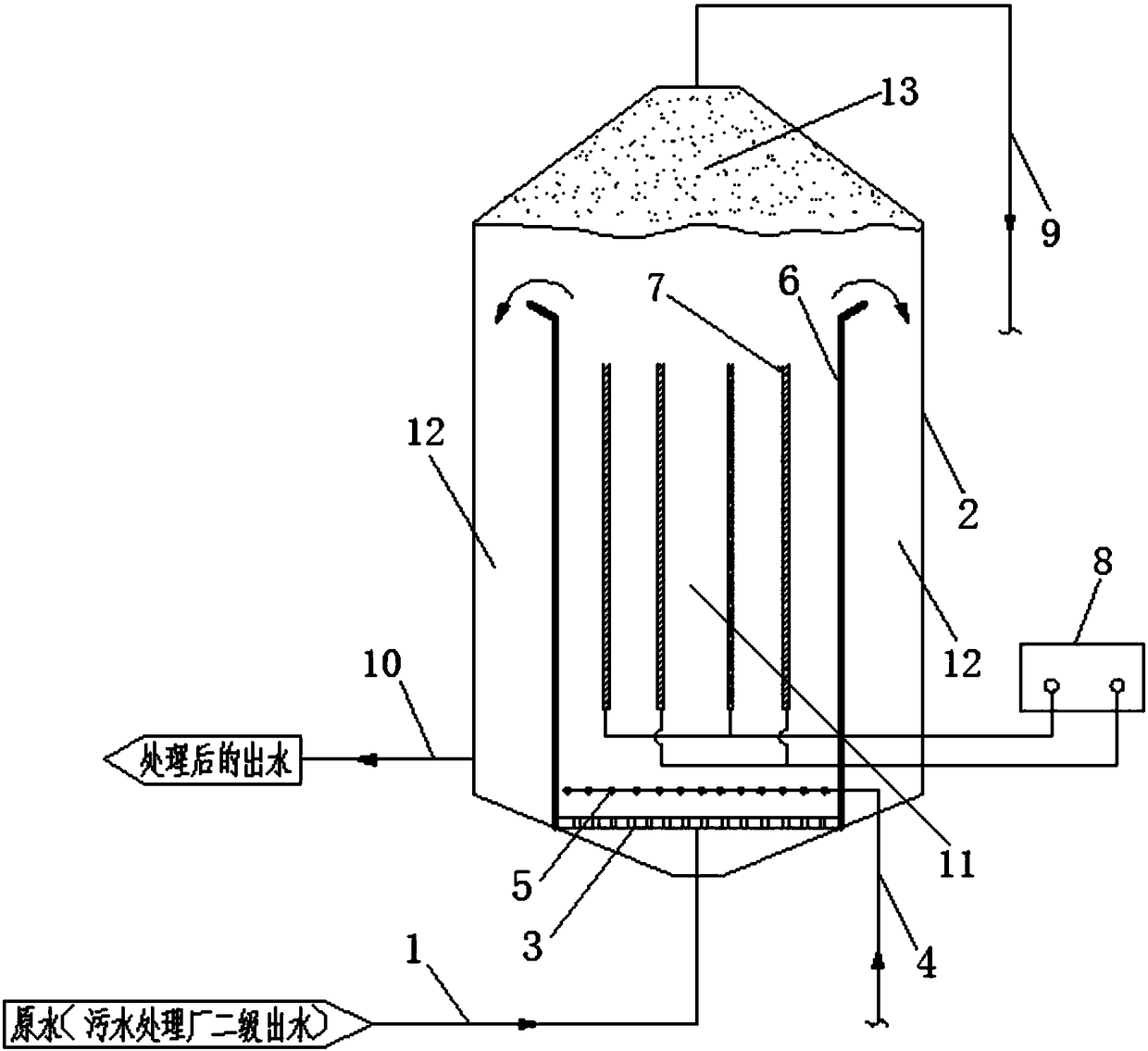

[0051] Such as figure 1 As shown, this embodiment provides a secondary effluent regeneration treatment system of an urban sewage treatment plant, the system includes: a device body 2, the device body 2 includes a main reaction zone 11, and an electrode plate is arranged in the main reaction zone 11 7. The electrode plate 7 includes a cathode plate and a soluble anode plate, and the cathode plate and the soluble anode plate are connected to a power source 8; water outlet areas 12 are arranged on both sides of the main reaction area 11, and the main reaction area 11 is connected to the A partition 6 is arranged between the water outlet areas 12 and is connected through the upper part; a scum area 13 is arranged on the upper part of the main reaction area 11 and the water outlet area 12; an ozone aeration head 5 is arranged on the lower part of the main reaction area 11 , the ozone aeration head 5 communicates with the ozone delivery pipe 4; the water inlet pipe 1, the output end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com