Patents

Literature

167 results about "Suspension substance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A suspension is a mixture between two substances, one of which is finely divided and dispersed in the other. Common suspensions include sand in water, dust in air, and droplets of oil in air.

Microbial flocculating agent, and preparation and use thereof

ActiveCN103214101AImprove flocculation efficiencyPrecipitation is easyBacteriaMicroorganism based processesBacillus megateriumBacilli

The invention provides a microbial flocculating agent prepared through using two bacilli. The bacilli comprise Bacillus megaterium and Bacillus subtilis, wherein the Bacillus subtilis can generate a high-molecular biobased material gamma-polyglutamic acid, and two broths of the two bacilli are mixed and are added with a suspension substance to flocculate the suspension substance and generate a solid flocculating constituent. The microbial flocculating agent can substitute chemical flocculating agents, can be safely used in various industrial sewage processing industries, the food industry and the medicine industry, and has a popularization prospect.

Owner:中国中化股份有限公司 +1

Combination of disinfectors and its applications used in aquiculture

InactiveCN1430896AInhibits and hinders synthesisStunted growthBiocideAnimal repellantsDisinfectantAdhesive

A composite disinfectant for culturing aquatic products contains potassium (or sodium) perferrite, excipient, and / or pH regulator, stabilizer, adhesive, talc powder and magnesium stearate. Its advantages are high effect on disinfecting, enriching oxygen in water, and removing heavy metals, organic substances and harmful suspended substances, and no poison.

Owner:王永东

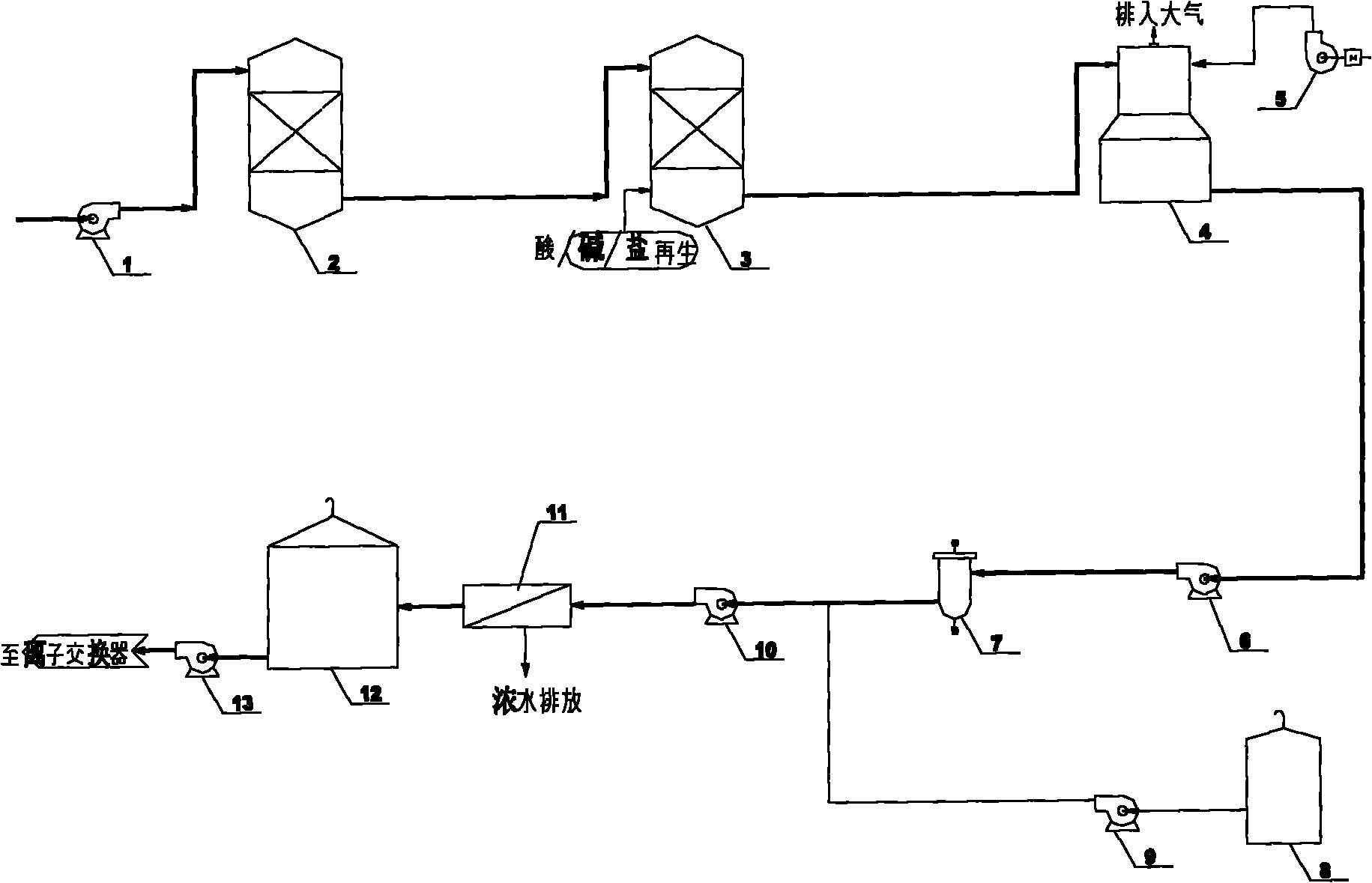

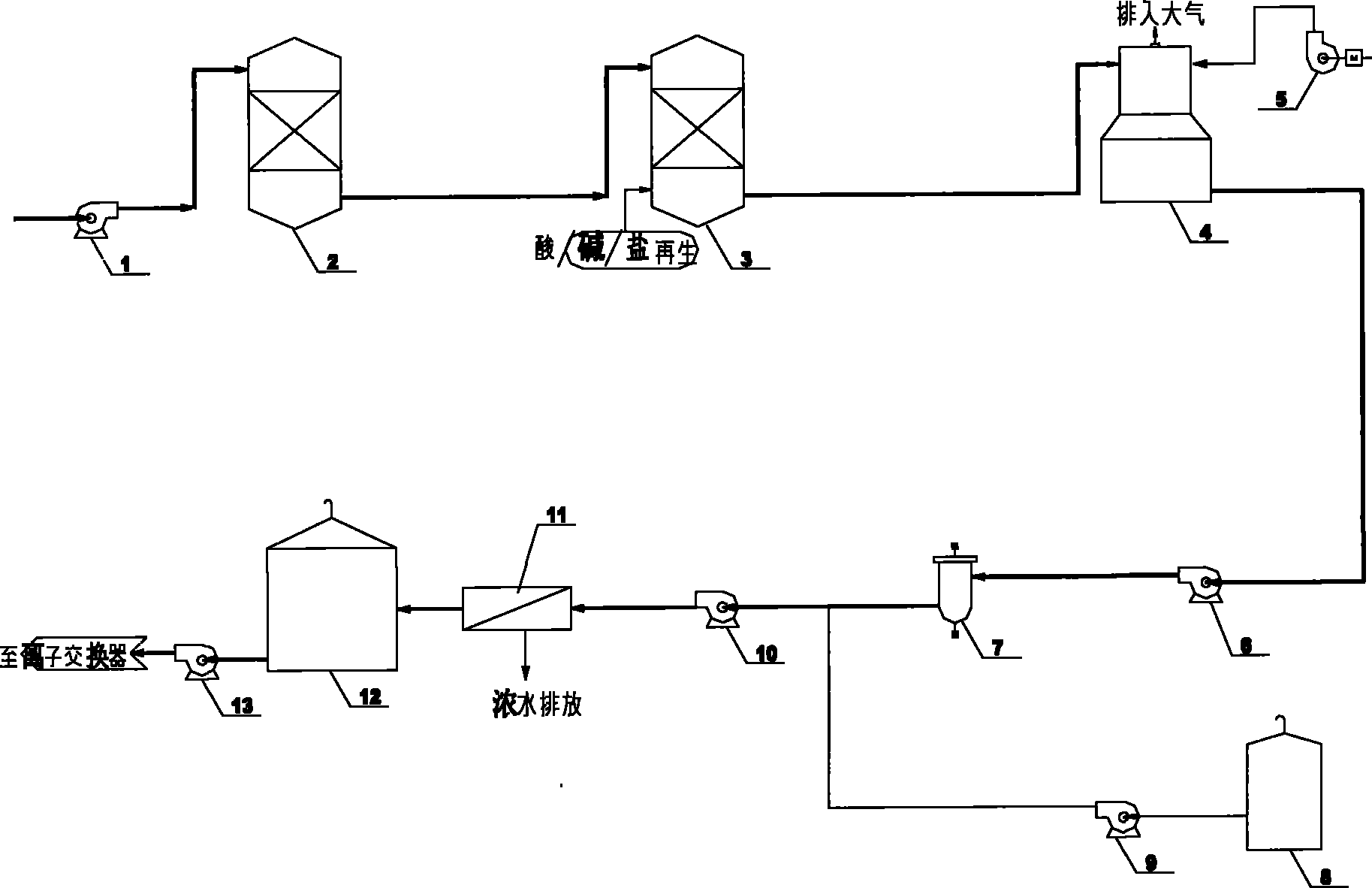

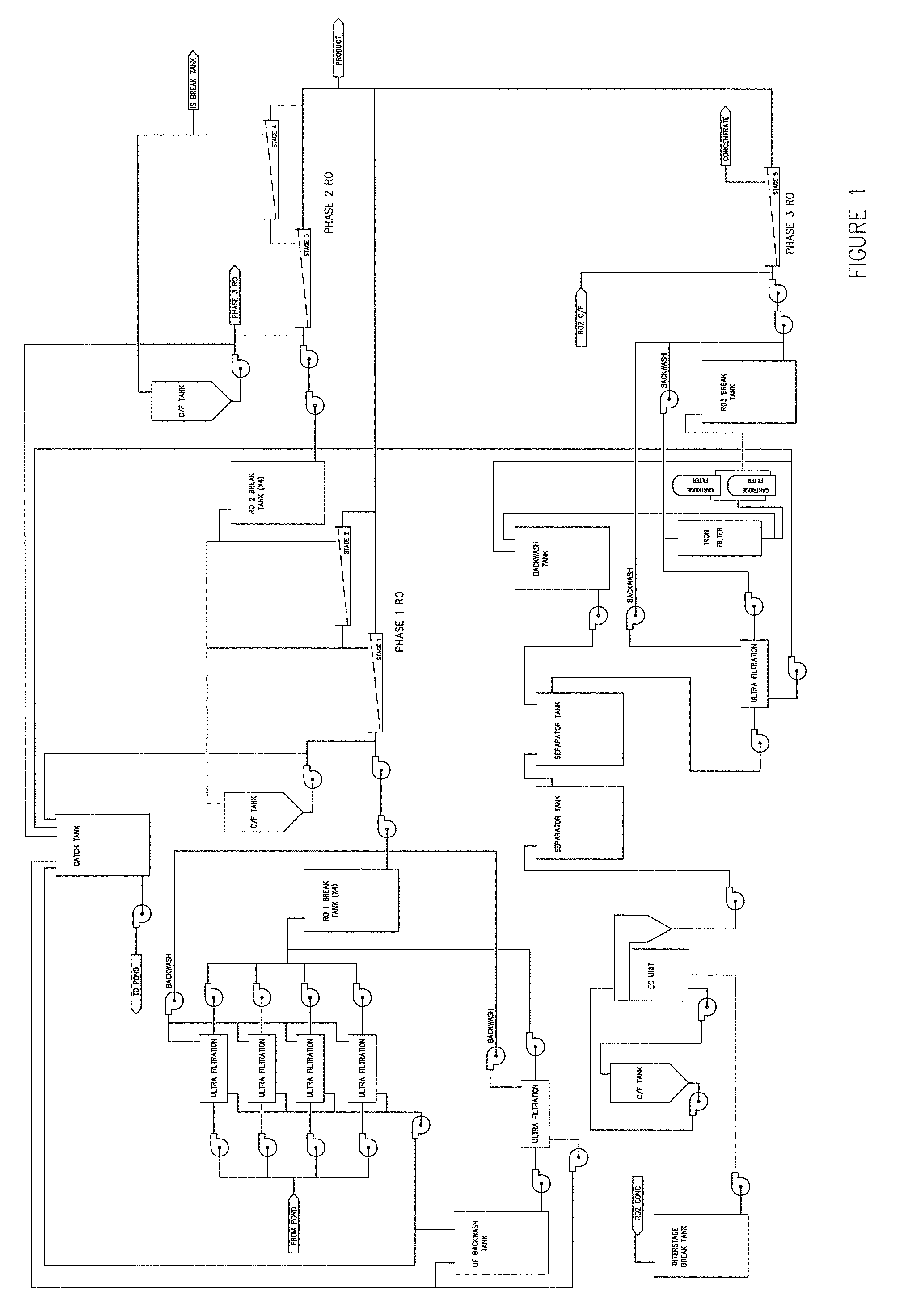

Wastewater recycling treatment process

InactiveCN101767888AImprove throughputEliminate scalingWater/sewage treatment by ion-exchangeWater/sewage treatment bu osmosis/dialysisFiltration membraneReverse osmosis

The invention discloses a wastewater recycling treatment process, which comprises the following steps: leading raw water to pass through a filter for removing suspended matters and solid particles in the raw water, leading outlet water of the filter to enter into an ion exchanger, removing calcium and magnesium ions in the raw water through ion exchange, further removing the hardness in the water, leading the outlet water of the ion exchanger to enter into a decarbonizing tower, and removing the alkalinity of the raw water under the air stripping action of a rotary fan; leading the raw water out of the decarbonizing tower to enter into a precision filter under the action of a lifting pump, lifting the outlet water of the precision filter to a nano-filtration / reverse osmosis system which is mainly formed by parallel connection and / or series connection of a nano-filtration membrane and a reverse osmosis membrane under the action of a high pressure pump, leading the nano-filtration / reverse osmosis system to discharge concentrated water, leading the nano-filtration / reverse osmosis system to drain produced water into a produced water tank, and becoming the final outlet water. The process can effectively avoid the membrane pollution, improve the recycling rate, further greatly reduce the discharge amount of wastewater, simultaneously reduce the using amount of membranes due to the improvement of running conditions of a membrane system and further reduce the investment and the running cost.

Owner:郑理慎

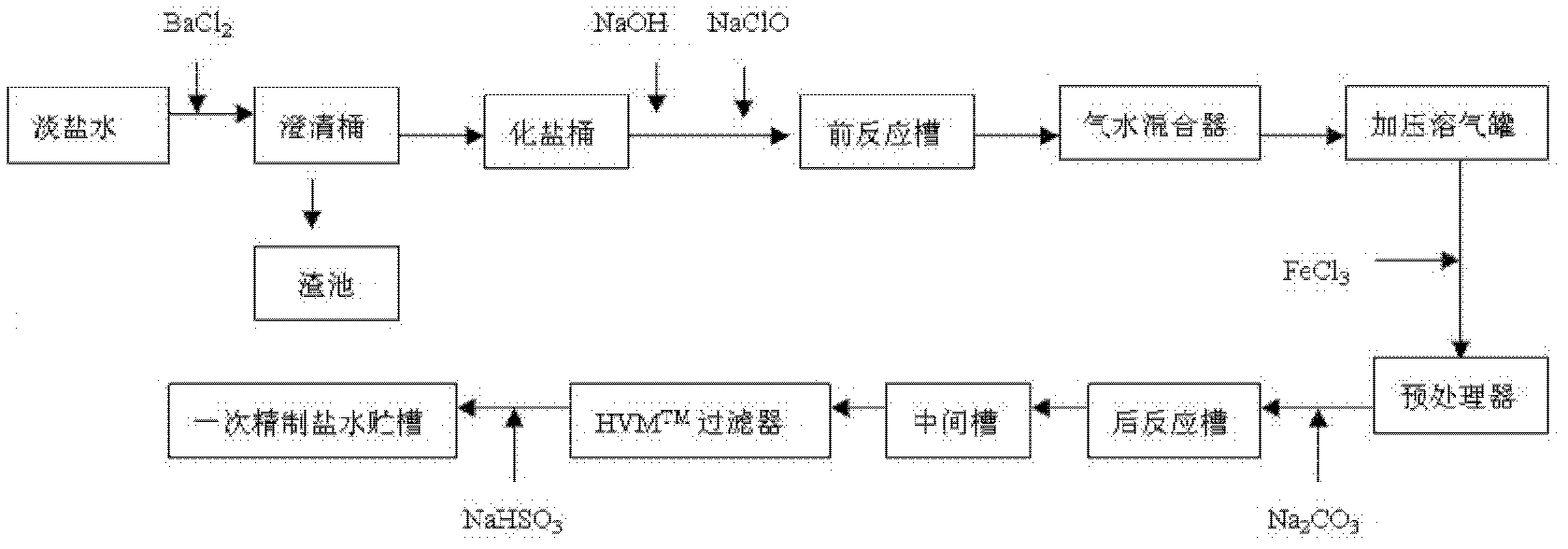

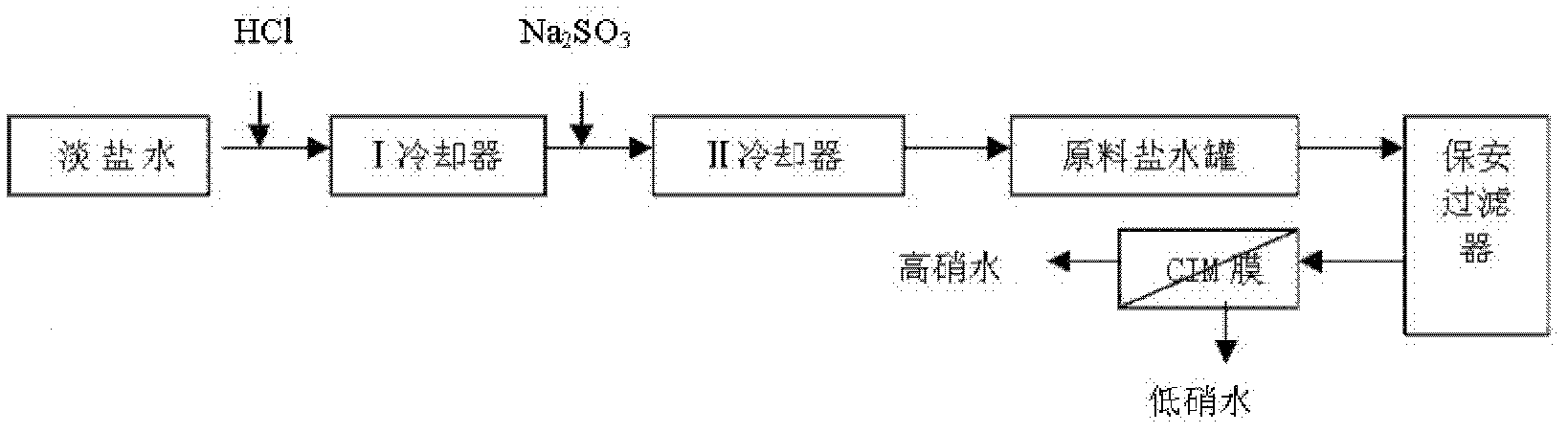

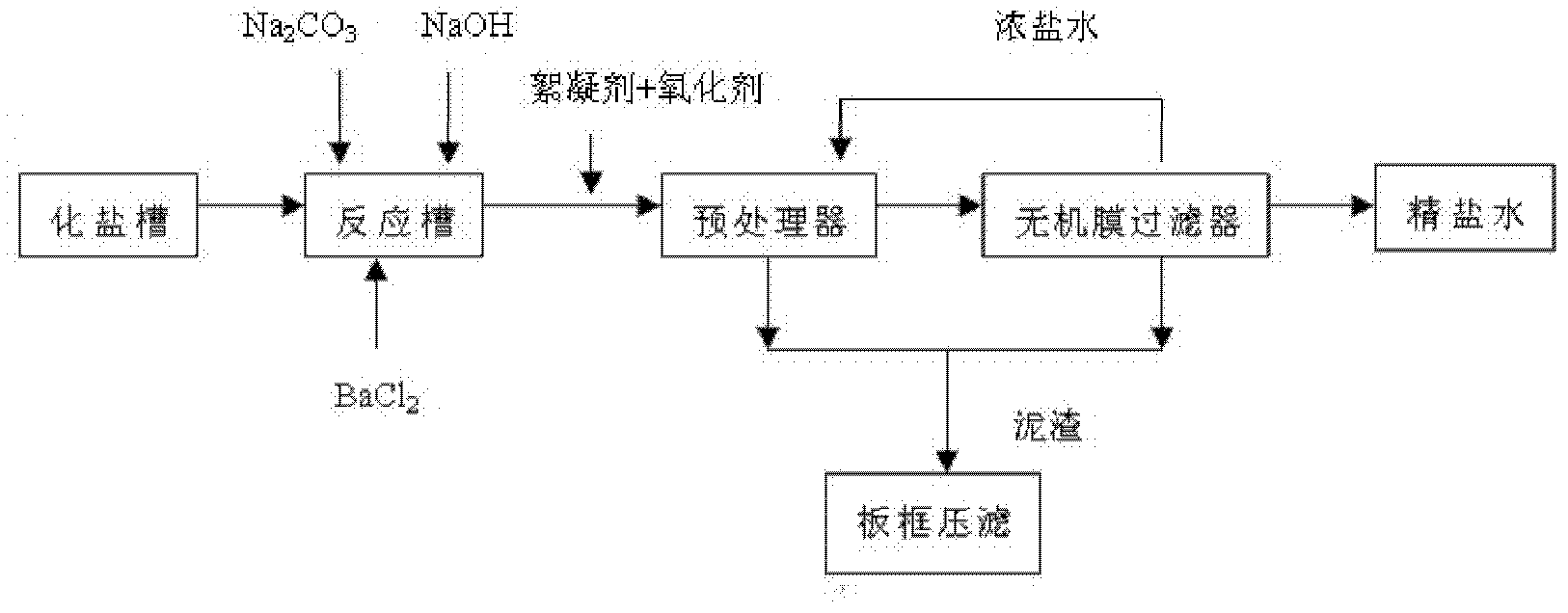

Double-membrane-method technology for refining brine and equipment for the same

ActiveCN102627300AAvoid secondary pollutionReduce manufacturing costAlkali metal halide purificationHigh concentrationUltrafiltration

The invention relates to double-membrane-method technology for refining brine and equipment for the same. After pretreatment, brine to be treated enters a filtration procedure to form high-concentration nitrate-containing water and refined brine; pretreatment refers to carrying out a removal procedure of calcium and magnesium ions, a removal procedure of ammonium, a reduction procedure and a pH adjusting procedure to the brine to be treated; the filtration procedure refers to the steps that: the pretreated brine is pumped to gas-stripping tubular type membrane module for ultrafiltration, thereby organic impurities, suspended matters and partial precipitates of the brine are intercepted; pressure raising is carried out to the brine which permeates a tubular type membrane, then the brine directly enters nanofiltration membrane module for nanofiltration; the brine which can not permeate the tubular type membrane returns the removal procedure of calcium and magnesium ions; and in a high pressure state, sulfate ions are intercepted by a nanofiltration membrane to form high-concentration nitrate-containing water, and chloride ions and sodium ions permeate smoothly the nanofiltration membrane to form refined brine. The technology in the invention is simple, low energy consumption, small land-occupation area, low investment and low production cost, a stable operation system, strong impact-resistance load capability and no secondary pollution.

Owner:CHINA PETROCHEMICAL CORP +3

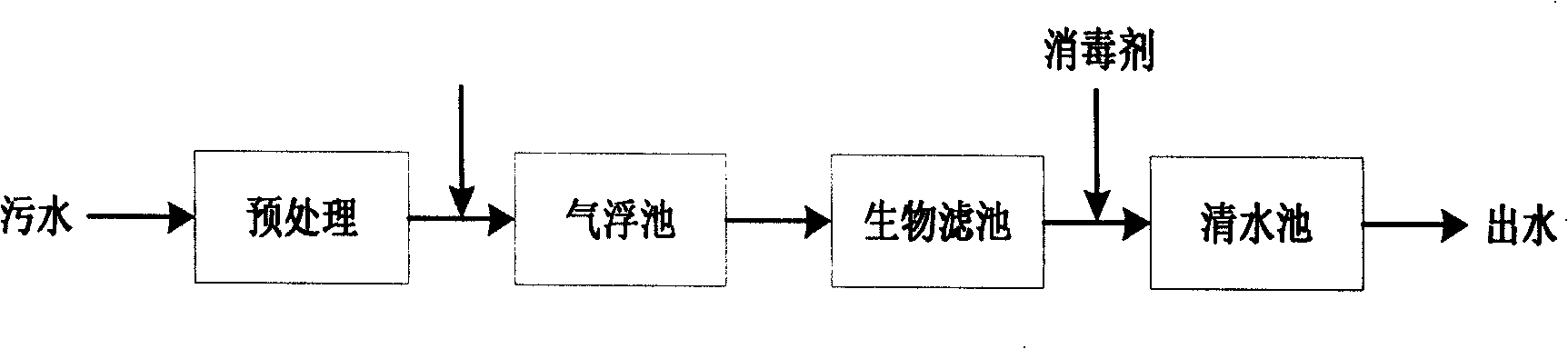

Air-float and bio-filter combined water treatment process

InactiveCN101318758AImprove water purification effectEasy loadingTreatment using aerobic processesMultistage water/sewage treatmentWater qualityEmission standard

The invention discloses a water treatment process by combining an air floatation tank with a biofilter and relates to a water treatment process. The aim of the invention is to organically combine the air floatation with the biofilter to reach the comprehensive improvement of the water quality of the treated water. The process provided by the invention comprises the following steps that: (1) sewage water after pretreatment is introduced into an air flotation tank, and is subject to dephosphorization by the air flotation; simultaneously, a part of suspended substances are removed; (2) the sewage water is sent to the biofilter and subject to biological denitrification, and organisms and suspended substances of the sewage water are further removed; and (3) finally, effluent water is subject to disinfection treatment, wherein, the biofilter adopts a common biofilter, a high-load biofilter, a tower-type biofilter or an aerated biofilter. The process is suitable for a water body containing various organic pollutants, has low total energy consumption of aeration and high purification efficiency and can reach the first grade A emission standard and the aim of recycling.

Owner:BEIJING UNIV OF TECH

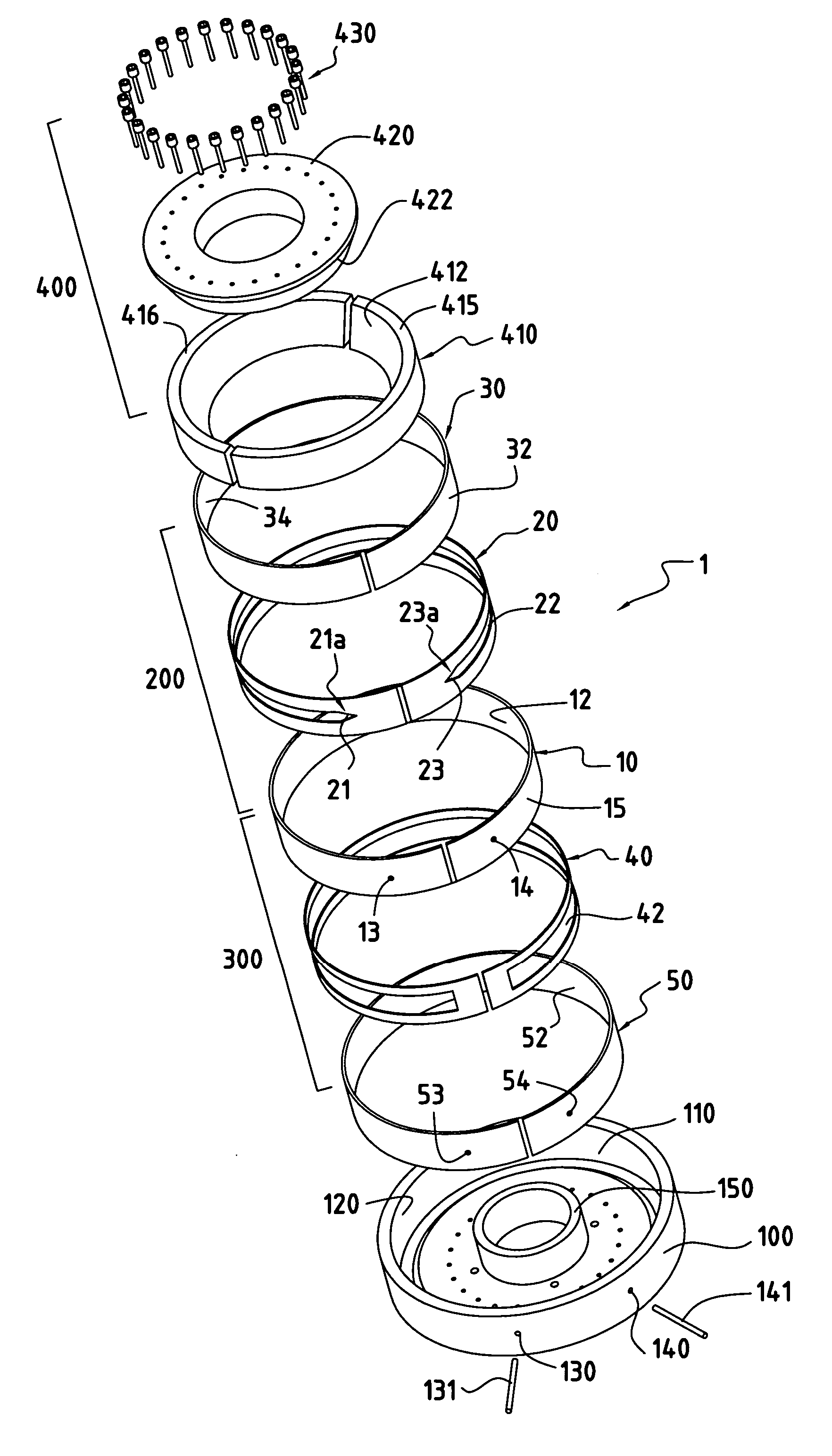

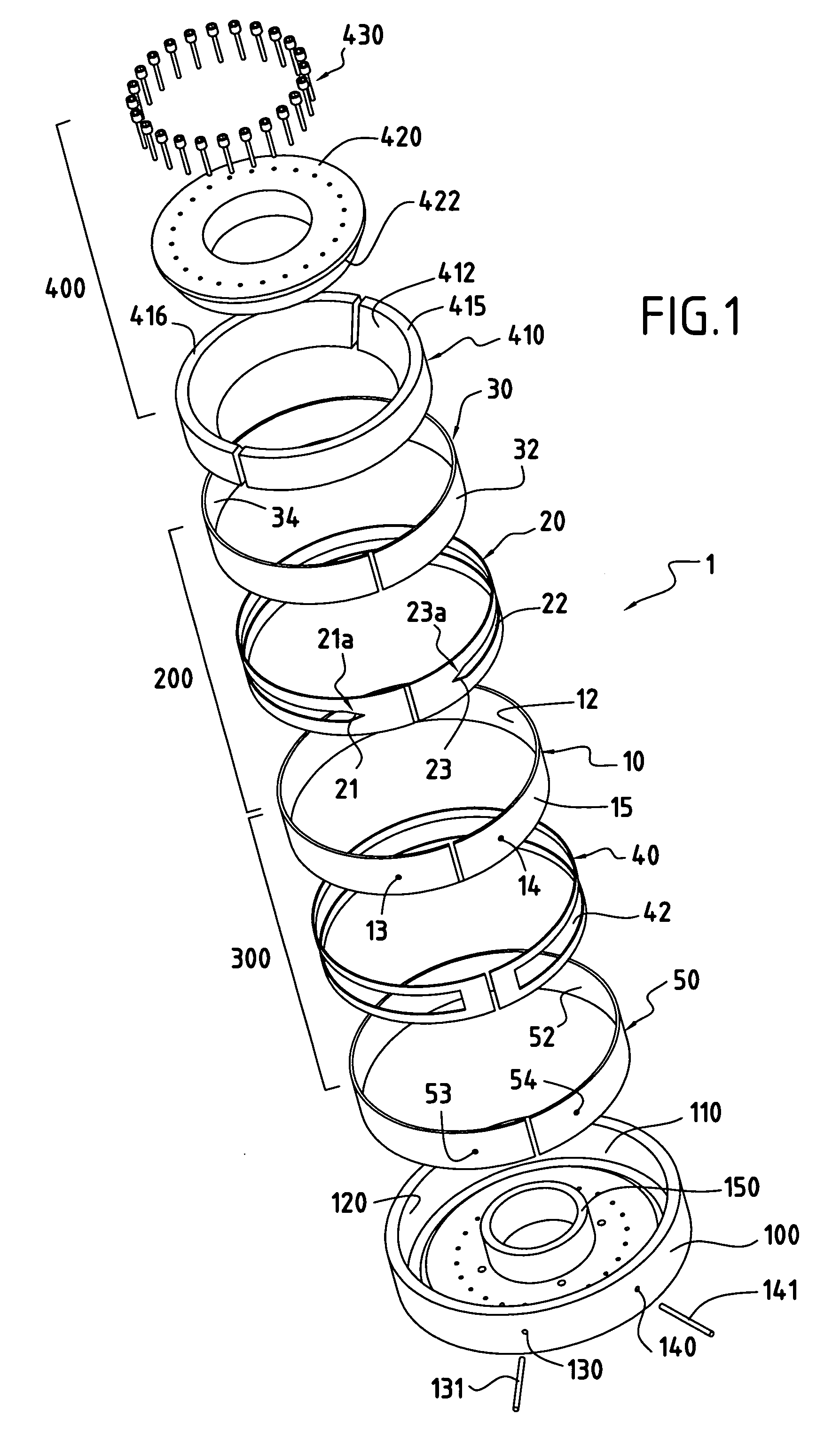

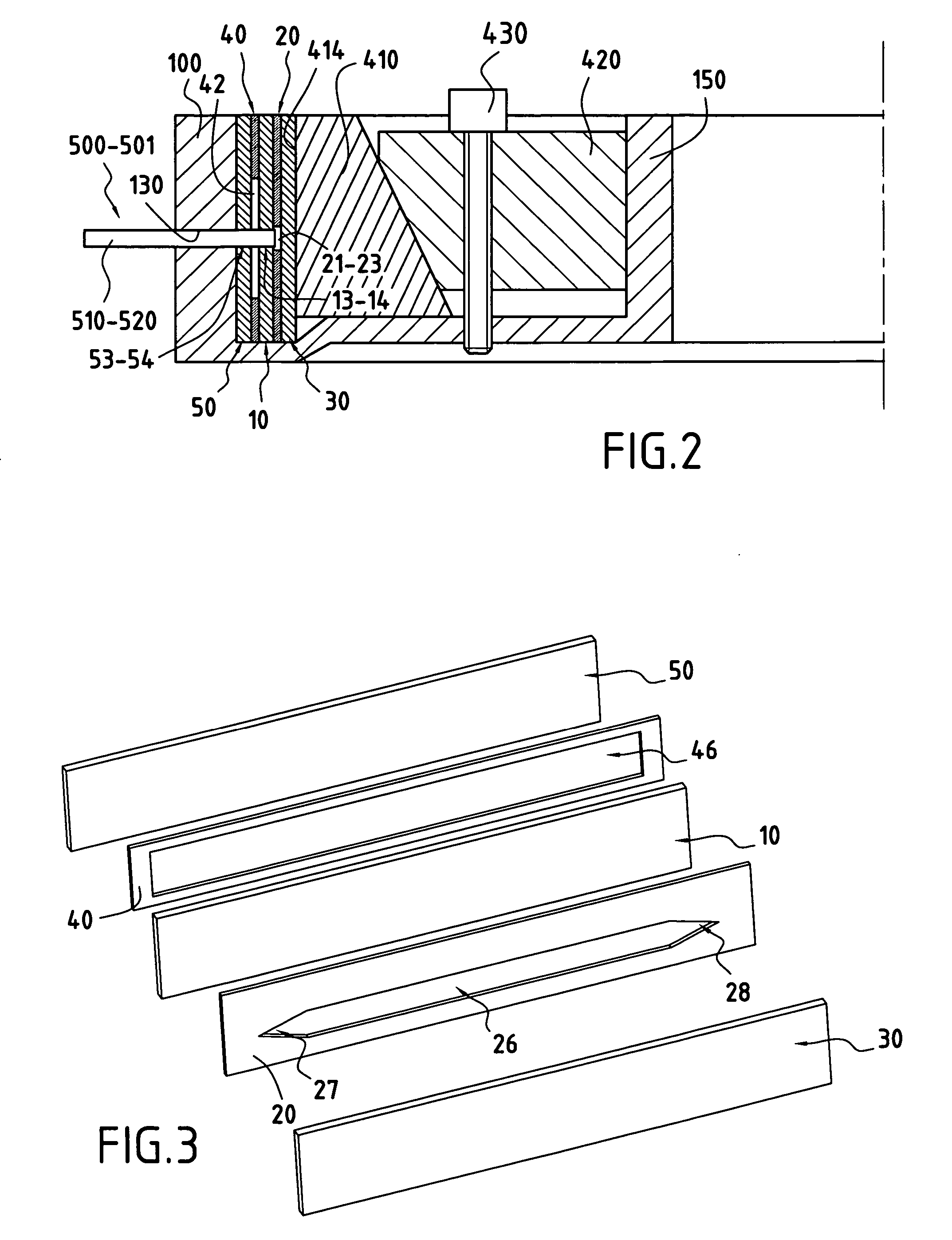

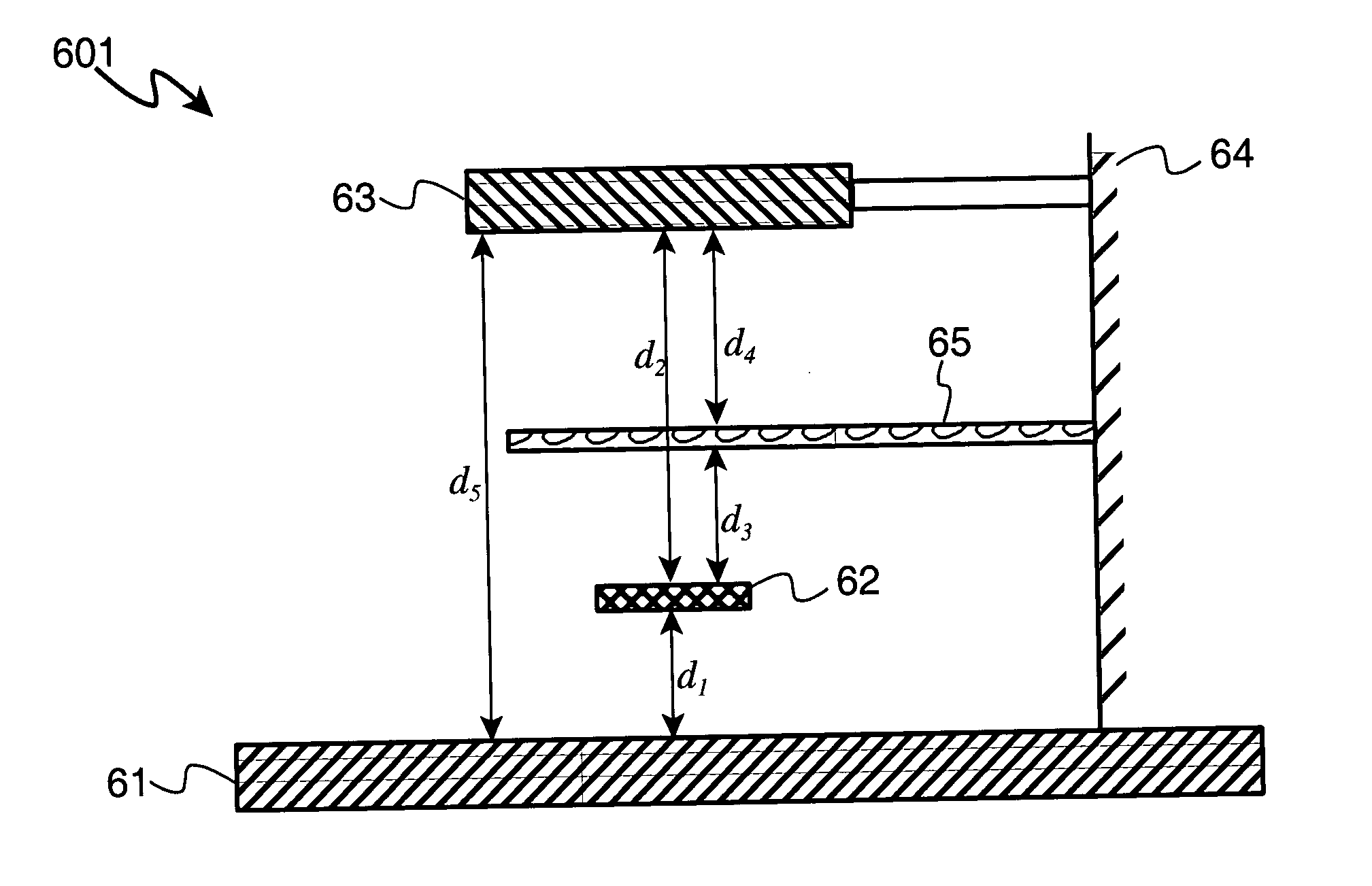

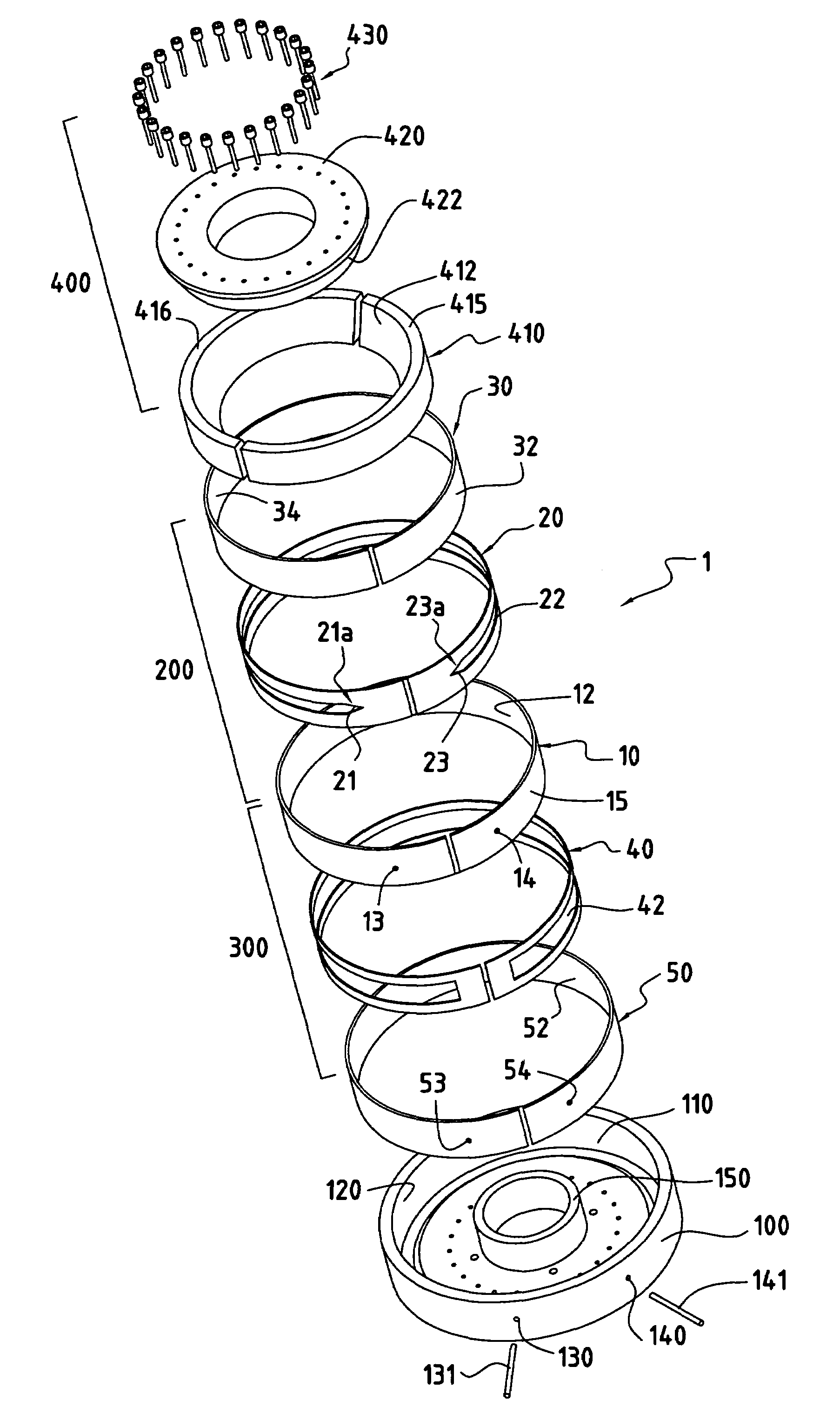

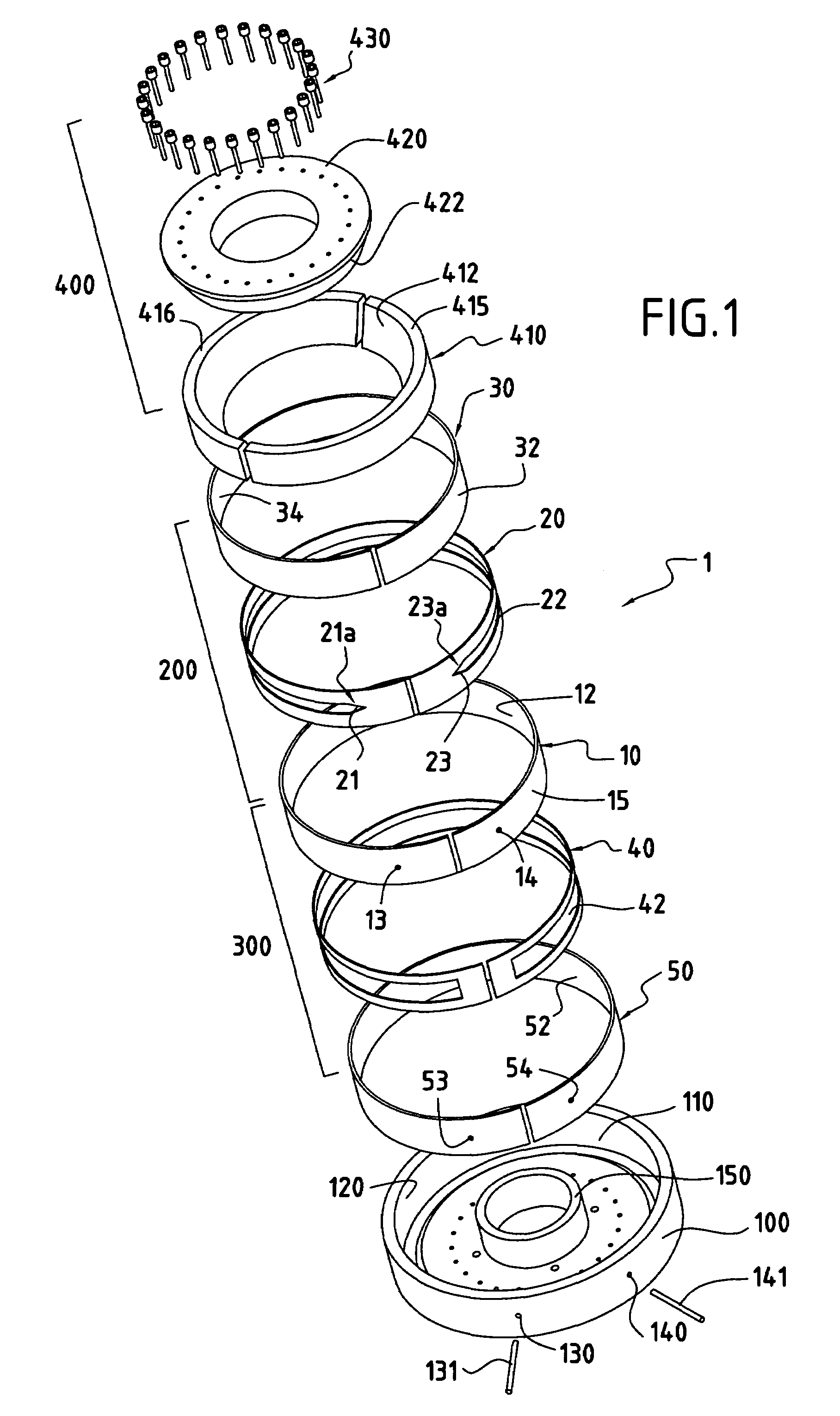

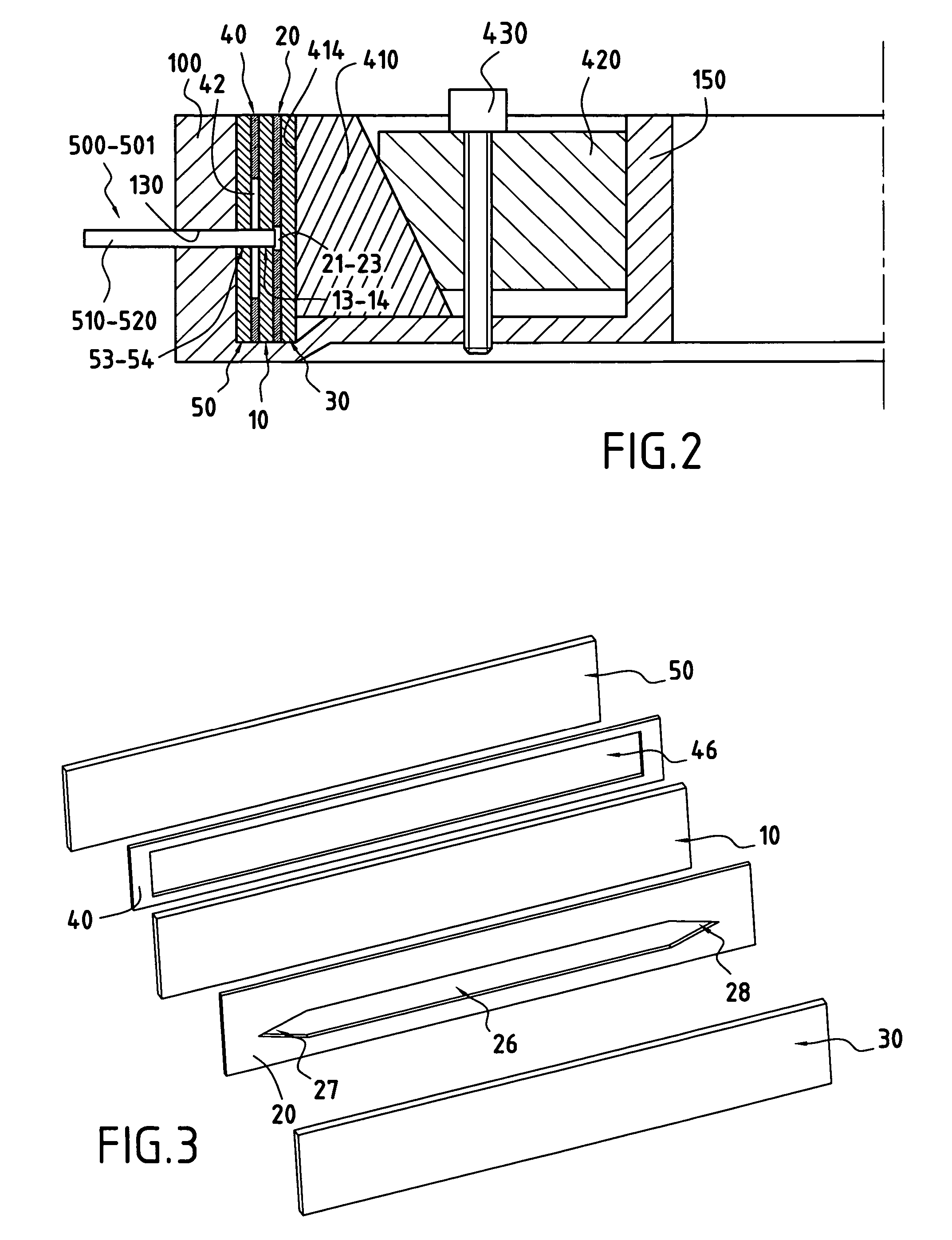

Separation device comprising a separation channel and a counter-channel

ActiveUS20060151403A1Avoid deformationEasy to disassembleBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringBody fluid

The present invention relates to a separation device notably for a flow-force fractionation of suspended substances in a liquid carrier, said separation device comprising a separation channel and a counter-channel. The object of the present invention is mainly the separation of living cells, preferably of human origin, in particular cells which are found in body fluids.

Owner:UNIV DE LIMO

Porous separation article

The invention relates to a porous separation article having a fluoropolymer or polyamide binder interconnecting one or more types of interactive powdery materials or fibers. The interconnectivity is such that the binder connects the powdery materials or fibers in discrete spots rather than as a complete coating, allowing the materials or fibers to be in direct contact with, and interact with a fluid. The resulting article is a formed multicomponent, interconnected web, with porosity. The separation article is useful in water purification, as well as in the separation of dissolved or suspended materials in both aqueous and non-aqueous systems in industrial uses. The separation article can function at ambient temperature, as well as at elevated temperatures.

Owner:ARKEMA INC

Boron-containing polysilic aluminum ferric sulfate composite flocculant

InactiveCN101077803AWater/sewage treatment by flocculation/precipitationTreated waterSodium hydroxide

The present invention is composite flocculant of boron-containing aluminum iron silicosulfate polymer for treating coking waste water, and belongs to the field of environment protecting engineering technology. The boron-containing aluminum iron silicosulfate polymer has the molar ratio Fe / Si of 0.4-0.6, Si / (Al+Fe) of 0.7-0.9, and B / Si of 0.25-0.35. The composite flocculant is compounded through the following steps: compounding 2-3 wt% concentration distilled water solution of sodium silicate, regulating pH value with sulfuric acid and sodium hydroxide to 2-3, and polymerizing at room temperature for 20-40 min; and adding ferric sulfate, aluminum sulfate and sodium tetraborate in certain molar ratio and through stirring, and standing to activate for 1-2 days. Treating waste water with the composite flocculant has low flocculant throwing amount of 9-11 mg / l and no need of regulating the pH value of the waste water, and the treated water has suspended matter less than 70mg / l and COD concentration lower than 150mg / l.

Owner:UNIV OF SCI & TECH BEIJING +1

Method for preparing Carthaginian apple raw juice

InactiveCN101273790AImprove qualityAccess to avoid and minimizeFood preparationPectinaseNutritive values

The invention relates to a preparing method for pomegranate juice; the method comprises the following steps that a fresh pomegranate is soaked by disinfecting solution, soaked and washed by ultrasonic wave and clear water and then washed by clear water; grains of the pomegranate are peeled after being cut, and the pomegranate juice is squeezed out by beating; a method adopting the combination of vacuum degassing and antioxidant is used for degassing; pectin of the pomegranate juice is hydrolyzed by adding pectinase; diatomaceous earth is used for removing suspended matters; colloidal particles, microorganisms and enzymes are removed by ultrafiltration; the ingredients are regulated; a method of riadiationsterilization is used for sterilizing, and then sterile filling and covering are carried out, thus preparing the pomegranate juice. The highest temperature of processing is less than 50 DEG C in the whole process of production of the pomegranate juice, thus keeping the color, flavor, nutritive value and functional ingredients of fresh pomegranate extracted juice furthest, leading the products to have longer guarantee period and realizing industrial production at the same time.

Owner:吐地·艾力

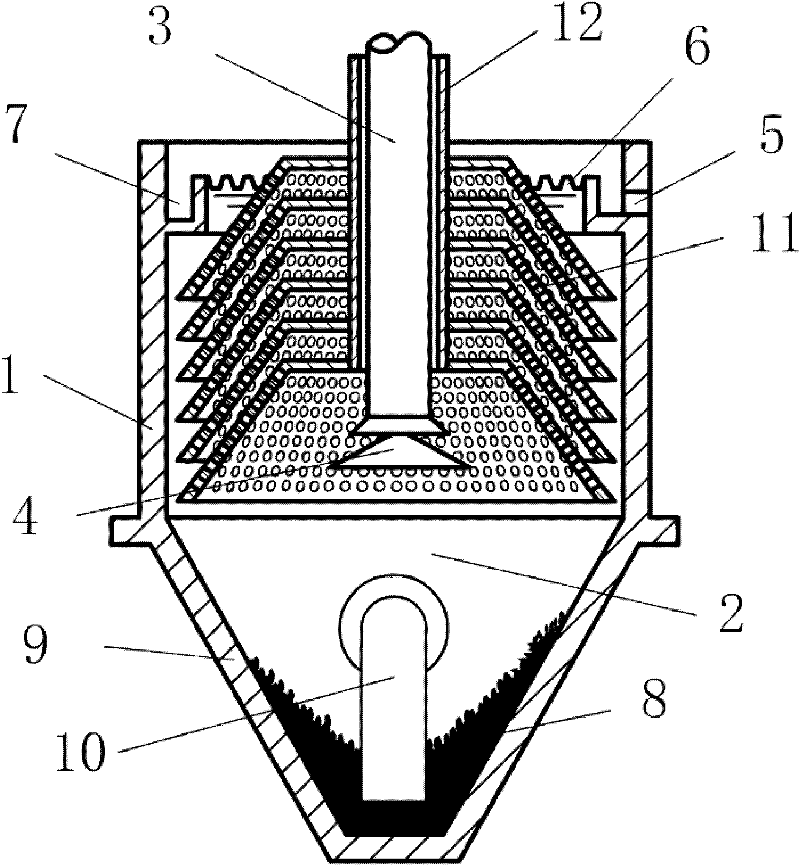

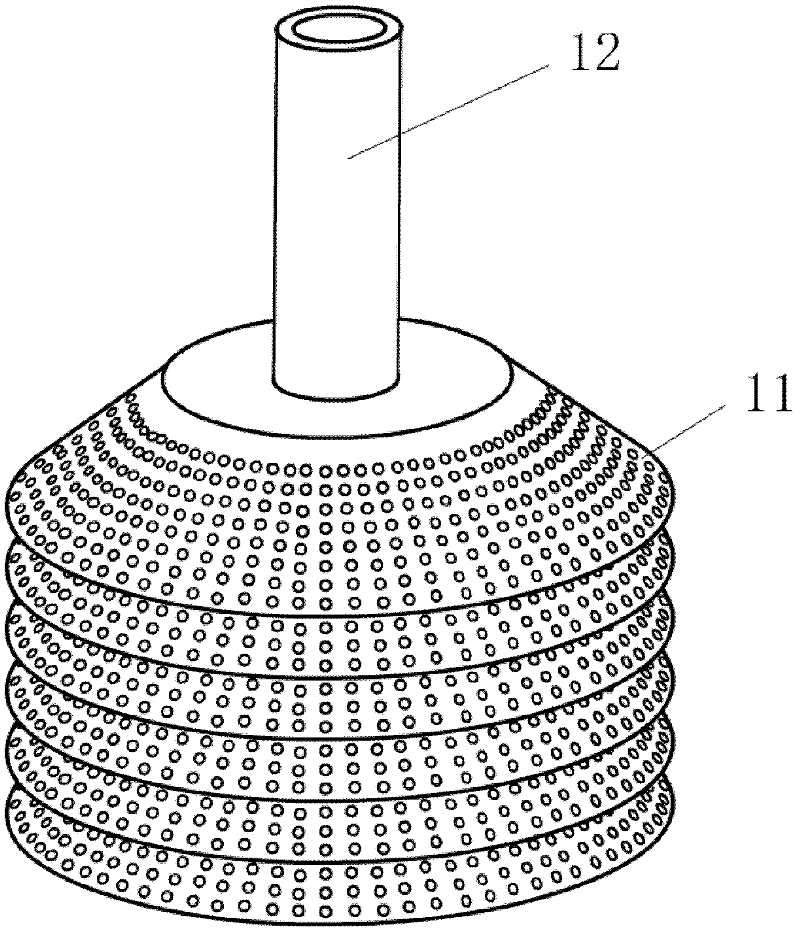

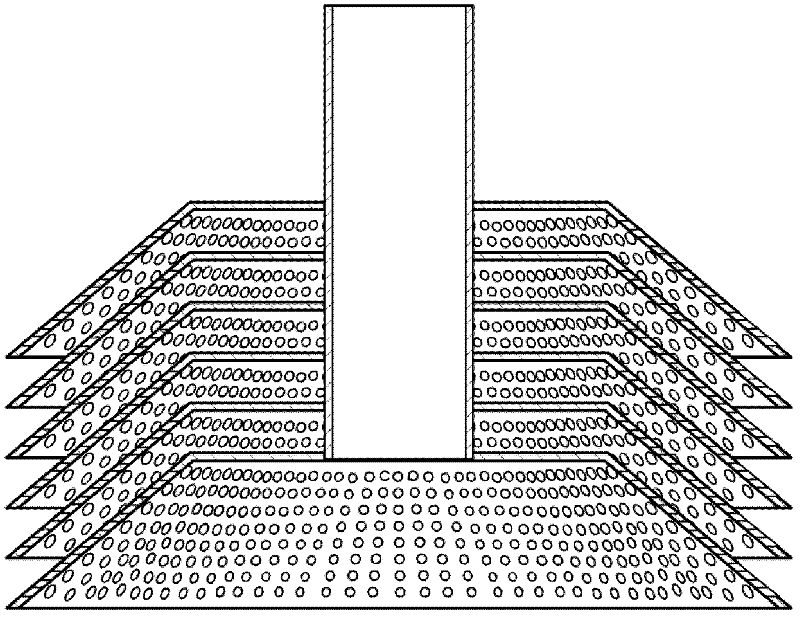

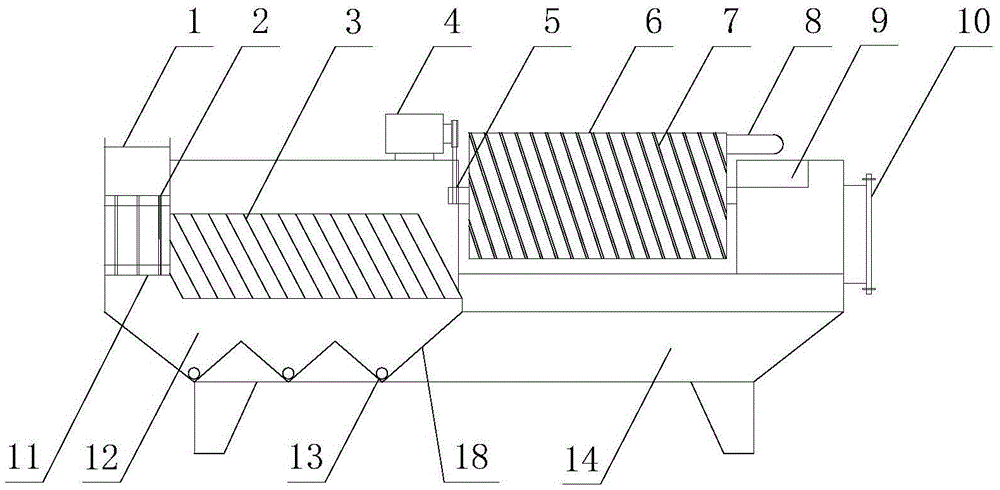

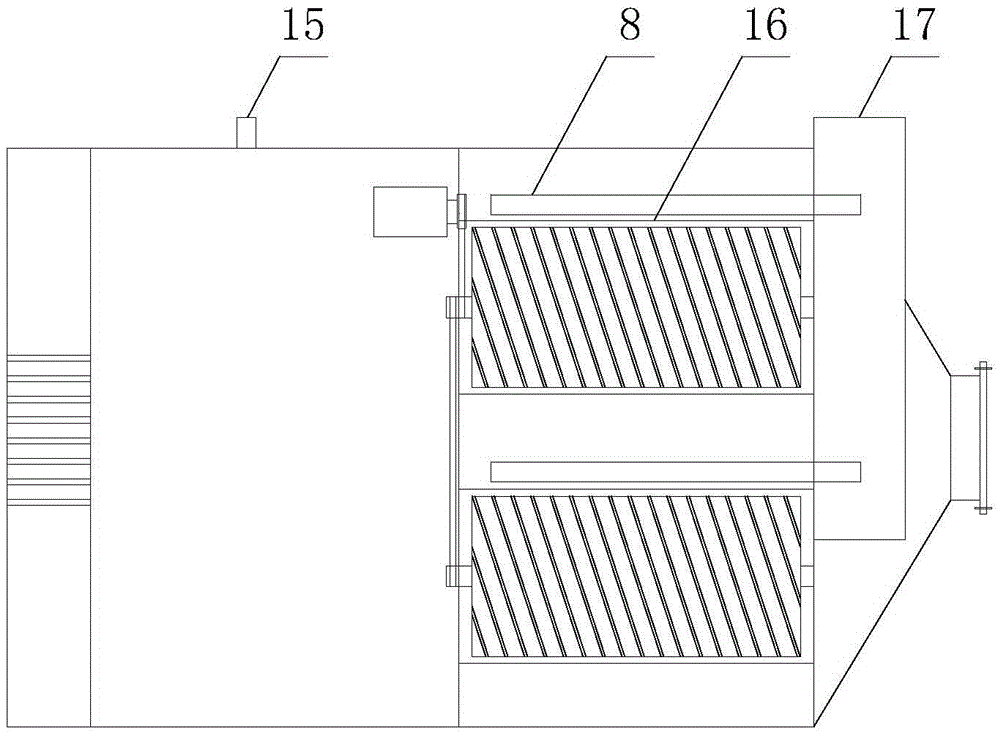

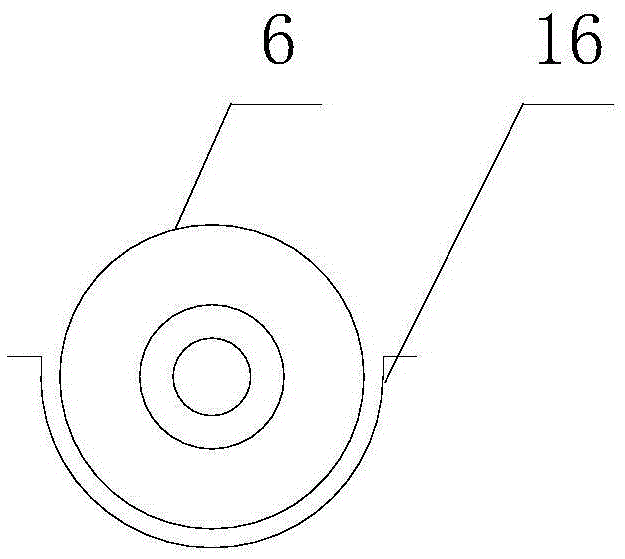

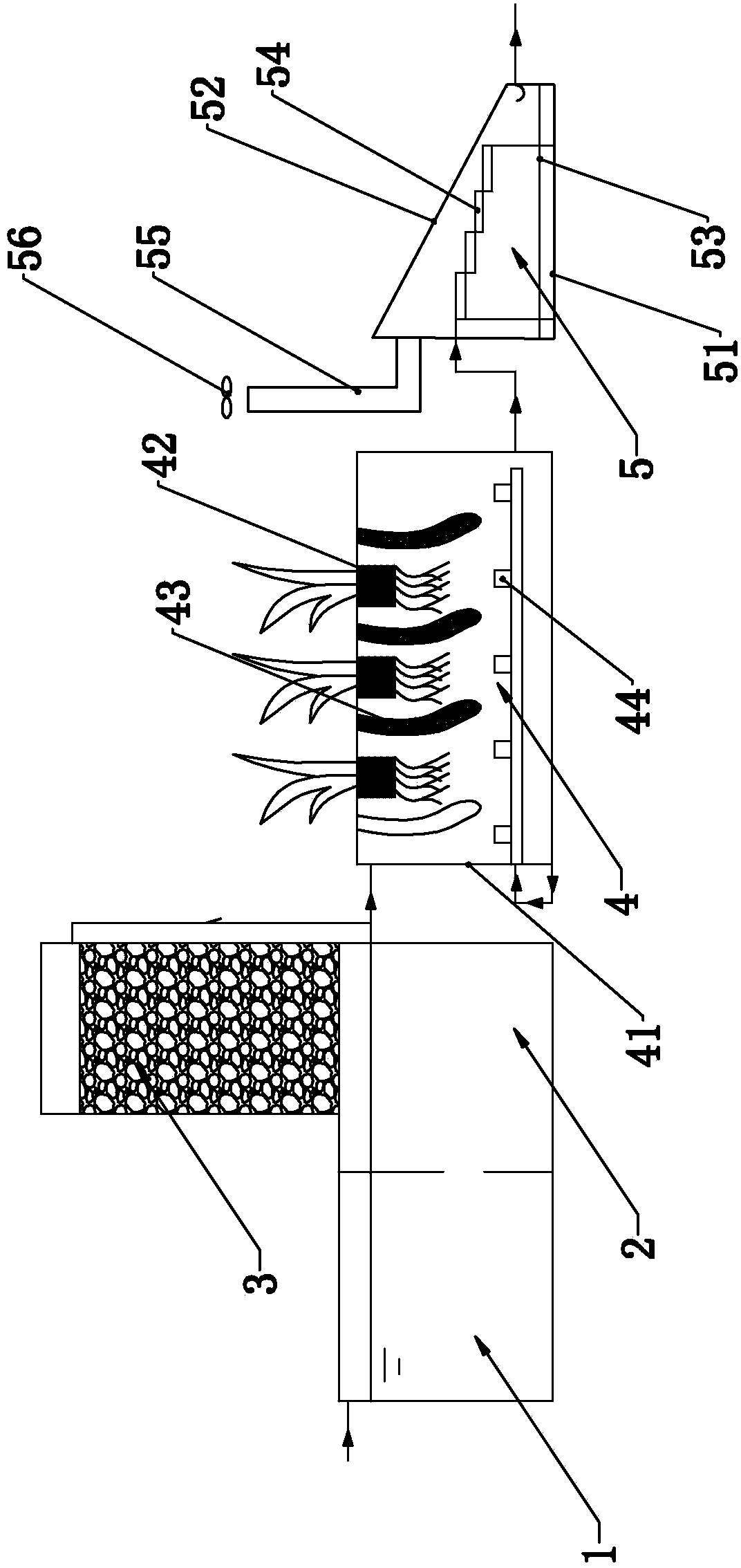

Sewage filter

InactiveCN102228759AImprove purification efficiencySS reductionFiltration separationSedimentation settling tanksFlocculationWater flow

The invention provides a sewage filter, which synthesizes a shallow tank theory, a dynamic coagulation theory, an accelerated coagulation theory and an inclined plate technology, effectively solves the problem of easiness in blockage of the traditional inclined plate. The sewage filter is used for subdividing raw motion water through by using filter masks and a plurality of through hole structures; and the raw water forms stable eddies at rear edges of plate holes of filter mask bodies. Under the entrainment action of the eddies, non-fluidic substances in the raw water are collected at centers of the eddies and get in continuous contact and collision with one another in eddy cores to undergo a flocculation reaction, and slides down along the mask bodies under the gravity action to settle into a mud collecting hopper, so that the purposes of removing suspended substances in the raw water and cleaning a water body are achieved. The sewage filter can rotate around an axis of a rotating shaft; and a strongly turbulent shear flow is formed through left and right repeated quick rotation to scour an inclined plate at a high speed and to clean deposits and blockages very conveniently.

Owner:韦志锋 +1

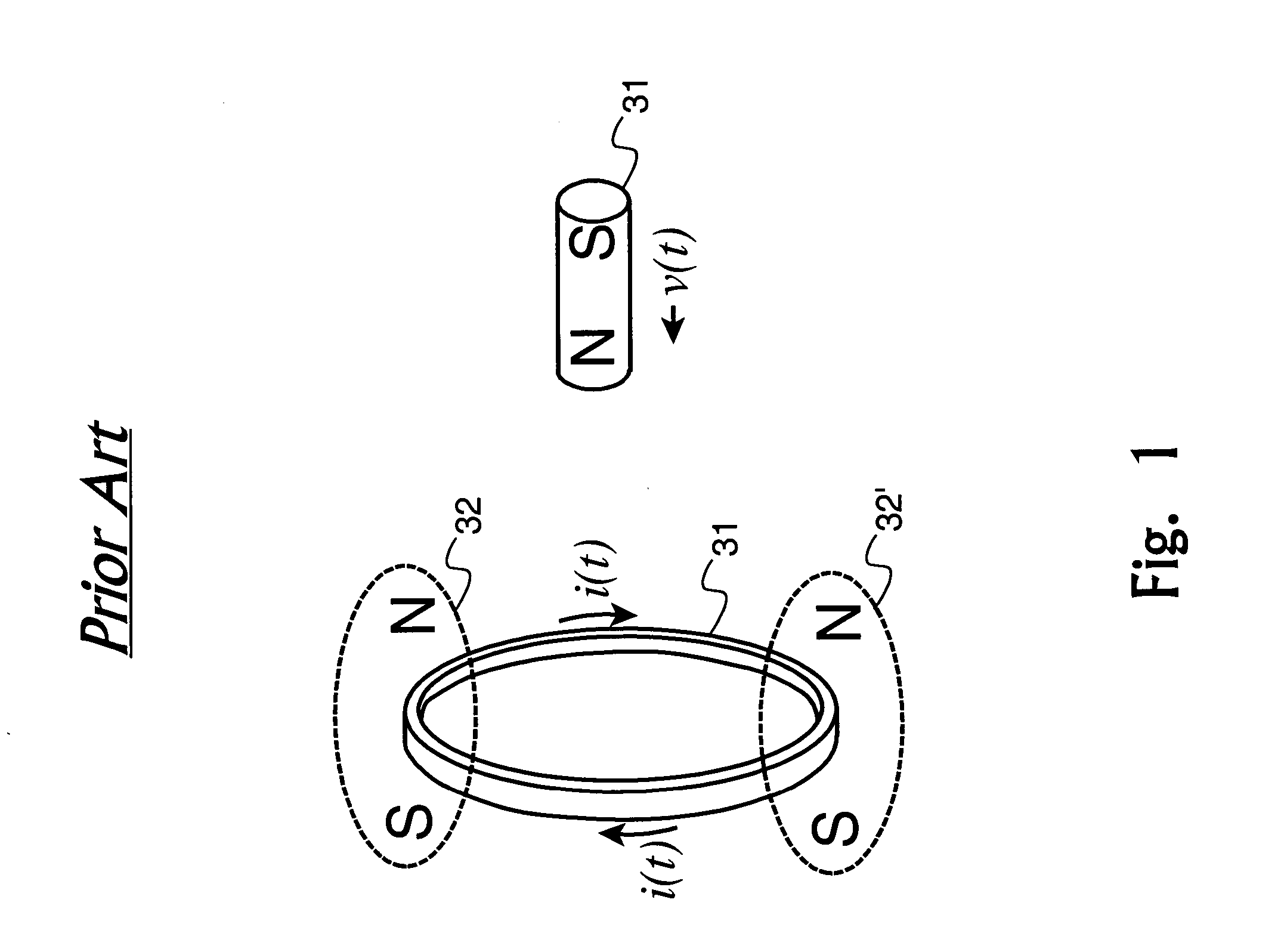

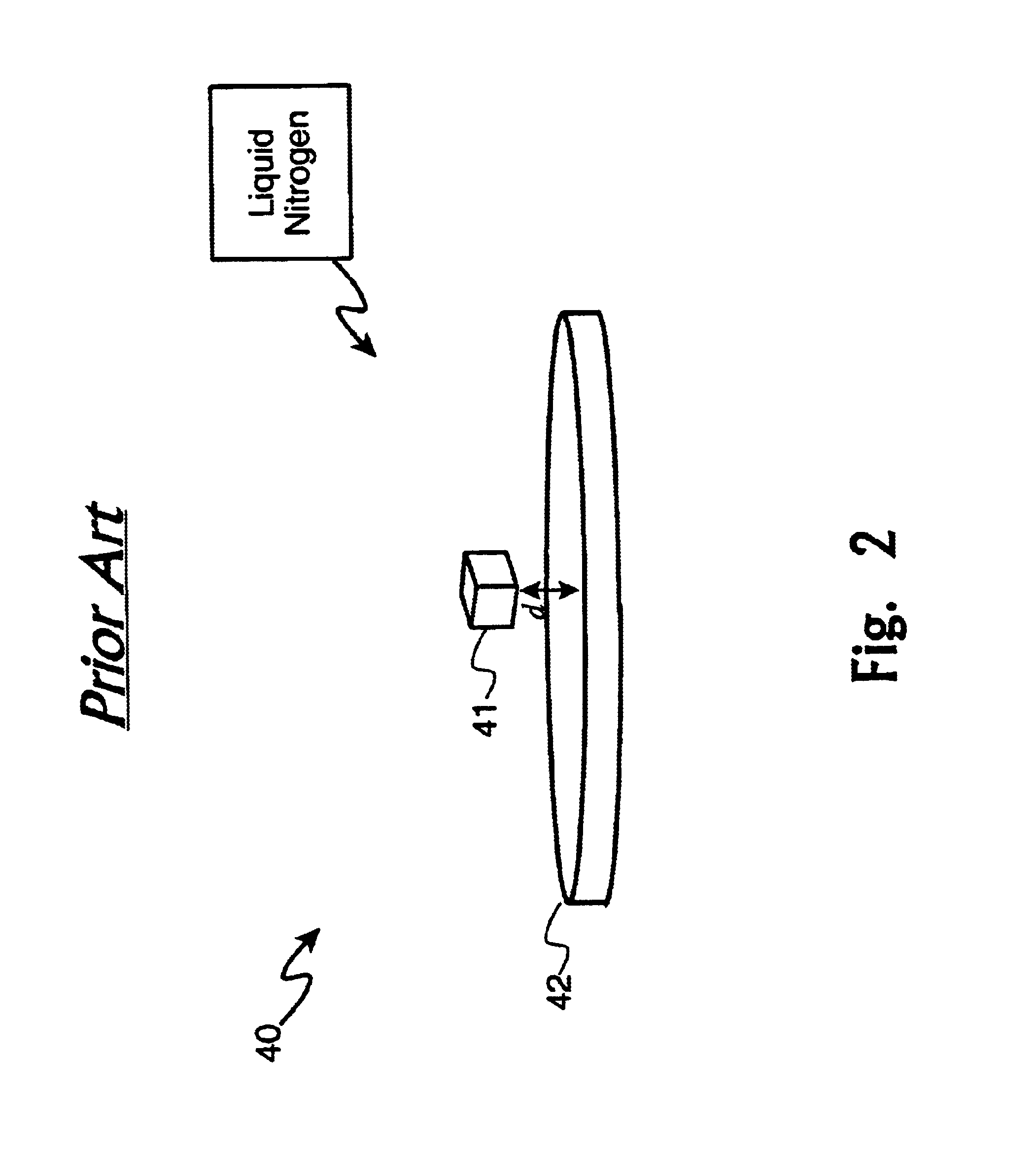

Pressure wave sensor using levitated mass

InactiveUS20040244492A1Vibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesCapacitanceLevitation

A mass is levitated with respect to a base, at least one of which is comprised of a diamagnetic material, with the levitated mass also having a permanent magnetic property. A second permanent magnet is optionally configured such that it attracts the levitation mass away from the base to overcome gravitational force on the mass, thereby suspending the mass over the surface of the base. The mass is contained in a nonmagnetic, non-shielding and optionally optically-transparent housing so as to limit its excursion within a range of levitation positions. A position measurement means such as a laser interferometer, capacitance detector, or pickup coil is configured to measure positional deviations of the mass in response to incident pressure wave, the output of which being an electronic signal representing the pressure wave.

Owner:IBM CORP

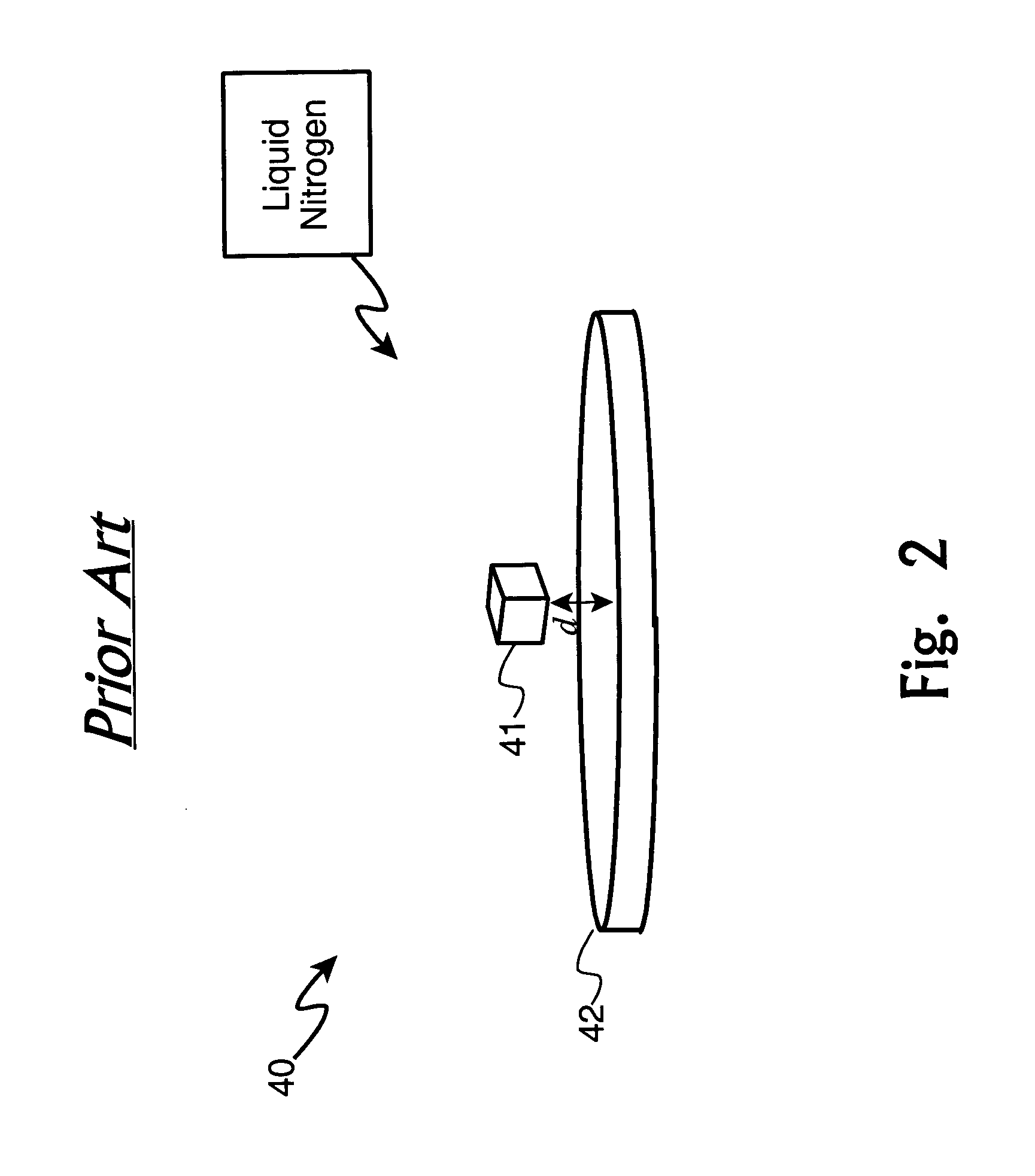

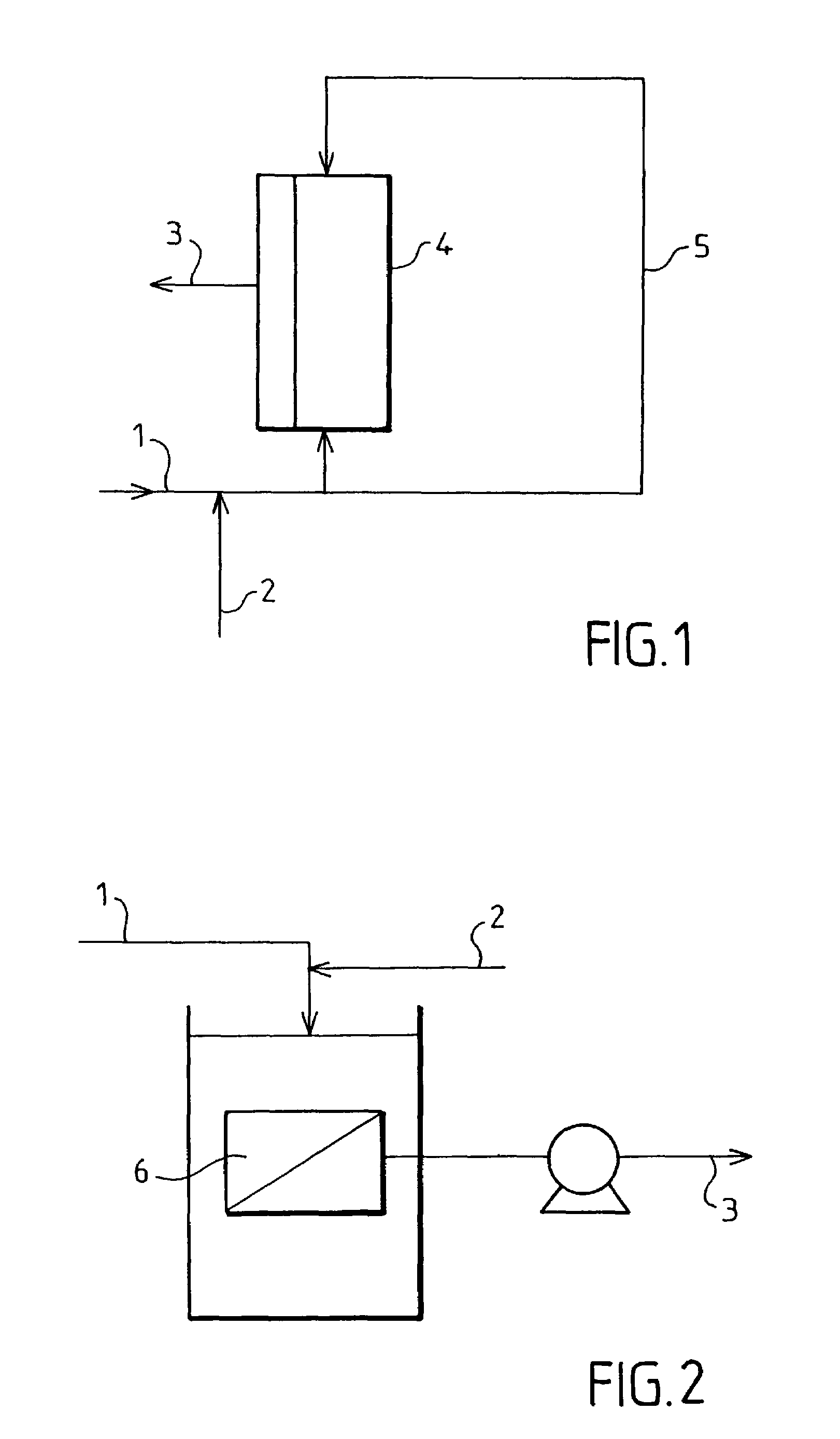

Membrane filtration

A method for membrane filtration of effluent water containing suspended matter reduces membrane clogging and improves filtration capacity of the membrane. The method includes adding a dose of a preselected coagulation reactant to the effluent before the effluent passes over the membrane. The added dose is a fraction of the coagulating reactant dose (X) that would render the zeta potential of the effluent equal to zero. The range of the added dose is X / 30-X / 80. The suspended matter in the effluent is subjected to the added dose of coagulation reactant for destabilizing the suspended matter.

Owner:ONDEO DEGREONT

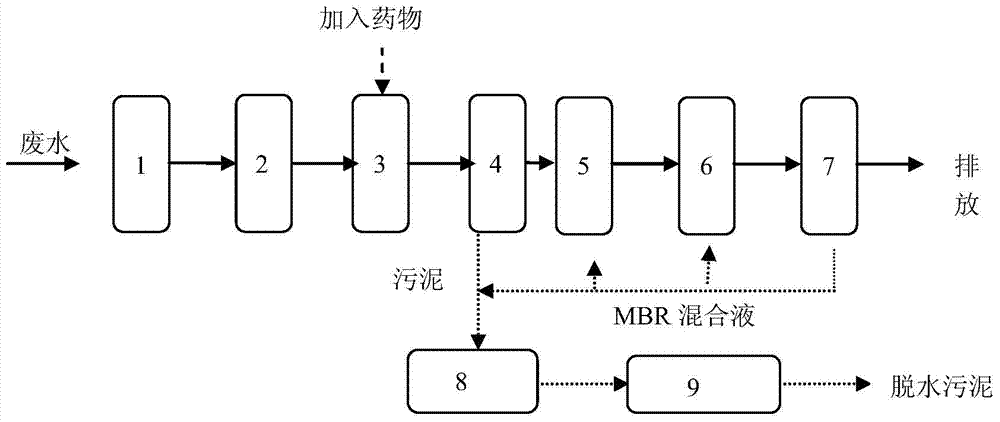

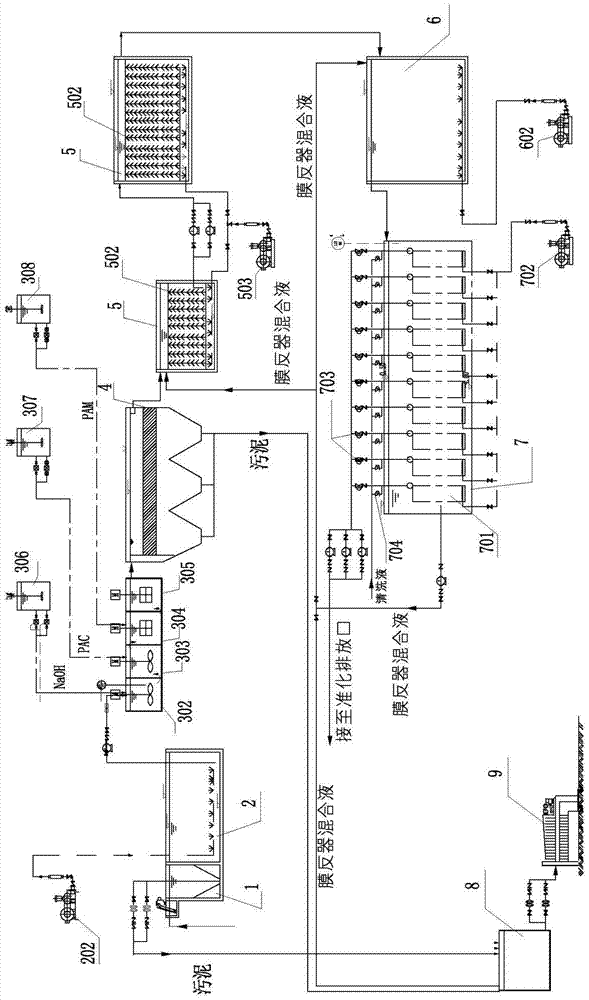

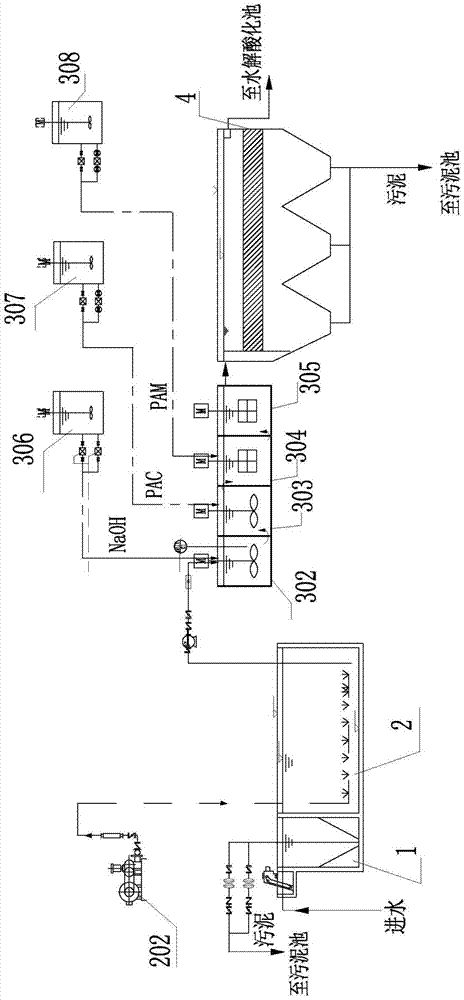

Device and process for treating photovoltaic organic wastewater

InactiveCN103613252AEasy to removeReduce pollutionWater contaminantsMultistage water/sewage treatmentSludgeOxygen

The invention discloses a device and a process for treating photovoltaic organic wastewater. According to the process, the photovoltaic organic wastewater passes through a grid water collection tank and is lifted to an adjusting tank by a water pump; then the photovoltaic organic wastewater is lifted into a reaction tank; an alkali, a flocculating agent and a coagulant aid are added by a medicament adding system to carry out coagulation and flocculation reaction; then the wastewater flows into a sedimentation basin by gravity for removing suspended matters in the wastewater; then the wastewater enters a hydrolysis acidification tank and hydrolysis acidification of the wastewater is carried out to convert macromolecular organic matters into micro-molecular easily-degradable matters; after BOD (Biochemical Oxygen Demand) / COD (Chemical Oxygen Demand) is improved, the wastewater flows into a pre-aeration tank by the gravity to carry out aerobic microorganism degradation; mixed liquid flows into a membrane reactor tank and organic matters are further degraded; the mixed liquid is filtered by the membrane reactor tank and effluent is pumped; the effluent is discharged after reaching the standards. The sludge mixed liquid in the membrane reactor tank flows back to the hydrolysis acidification tank and the pre-aeration tank according to a certain ratio. Sludge and one part of the sludge mixed liquid in the sedimentation basin are discharged into a sludge tank; the dehydrated sludge contains a lot of silicon powder and silicon carbide powder and can be recycled or sold.

Owner:SHANGHAI OCEAN UNIV

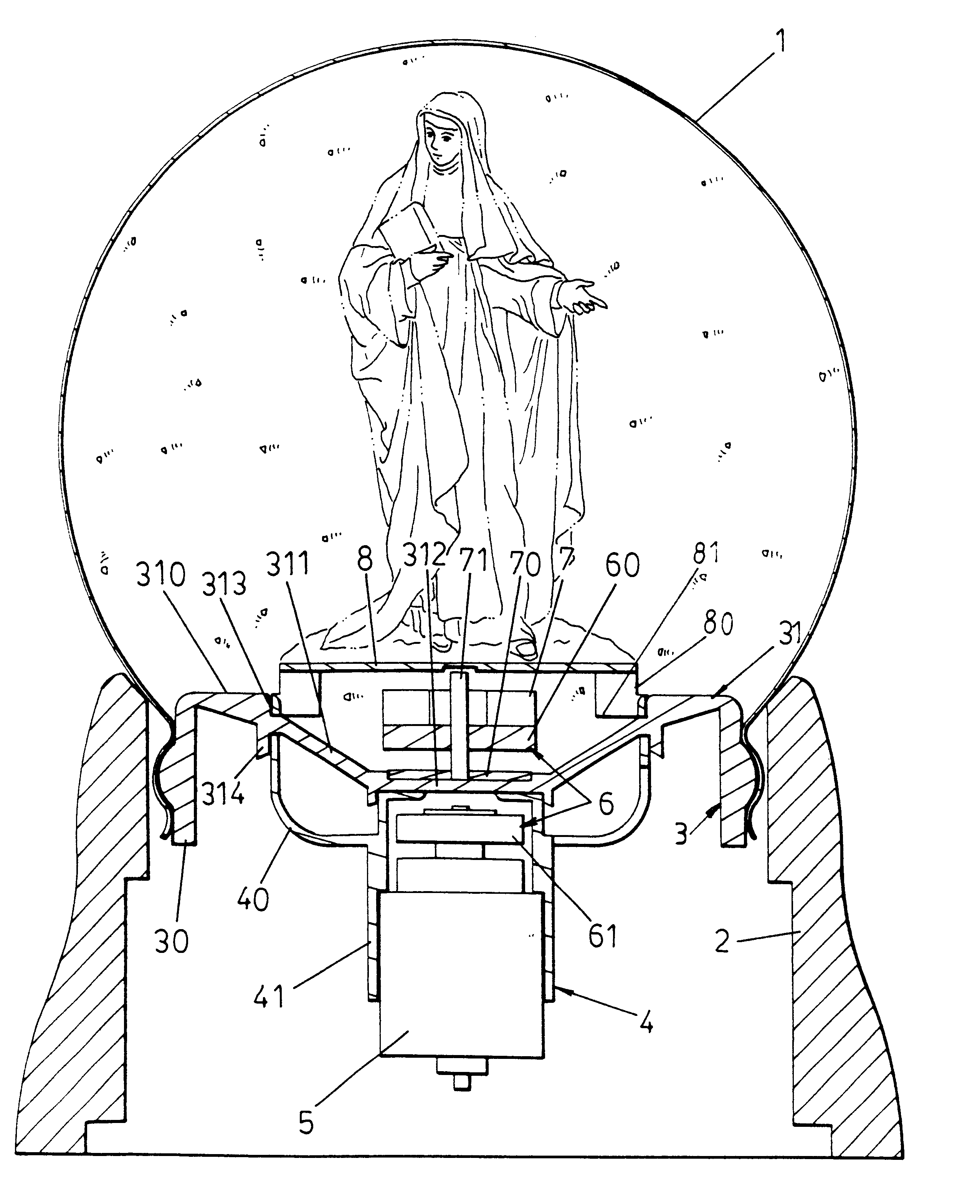

Fixed supported structure of crystal ball transmission

The invention relates to a fixed supporting structure of a crystal ball transmission, comprising a crystal ball, a base, a soft rubber sealed-spigot, a fixed seat and a driven motor, a magnet set, disturbing vane and a fixed disc of decoration and so on installed on above rubber sealed-spigot and fixed seat; characterized in that the rubber sealed-spigot is designed to have a circular sealed-spigot body for sealing the crystal ball opening and a disk-shaped elastic buffer body, wherein, the buffer body further comprises an upper section planar disc edge, a middle section inclined disc edge and a lower section planar disc bottom; and by means of pushing upward a cup-shaped supporting body of the fixed seat and stopping at the buffer body so as to form selected point supporting; when heat expansion and cold contraction are happened due to temperature difference of liquid within the crystal ball, the middle section inclined disc edge of the buffer body will stretch elastically and automatically to absorb the change of volume, by using the upward supporting force of the cup-shaped supporting body under the buffer body to ensure the horizontal position of the fixed disc of decoration unchanged, so as to further ensure the decoration does not incline for buffer body deformation due to the change of liquid volume and to maintain the flowing out-in passage of suspended substance being smooth.

Owner:LIU JACK

Pressure wave sensor using levitated mass

Owner:INT BUSINESS MASCH CORP

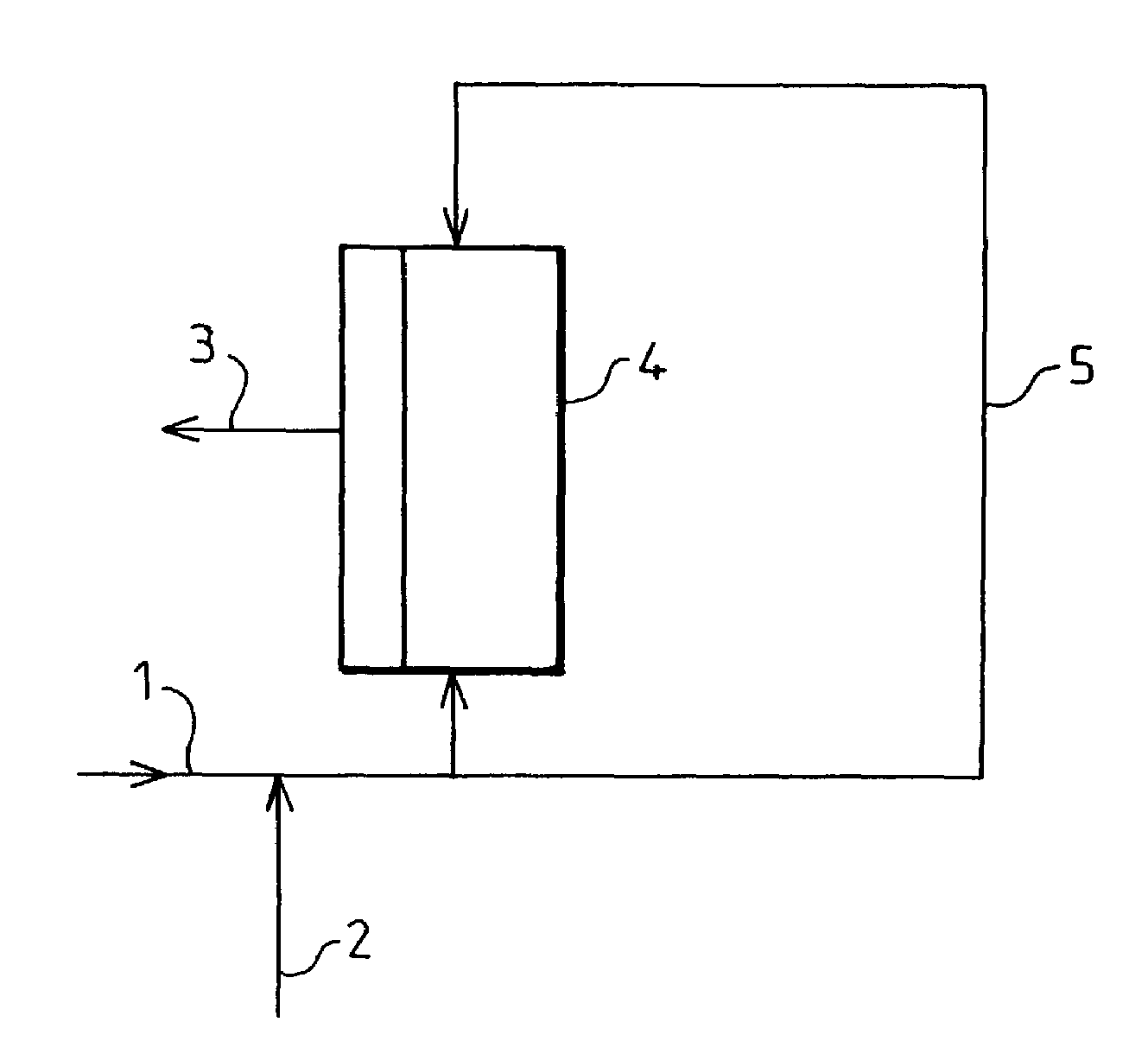

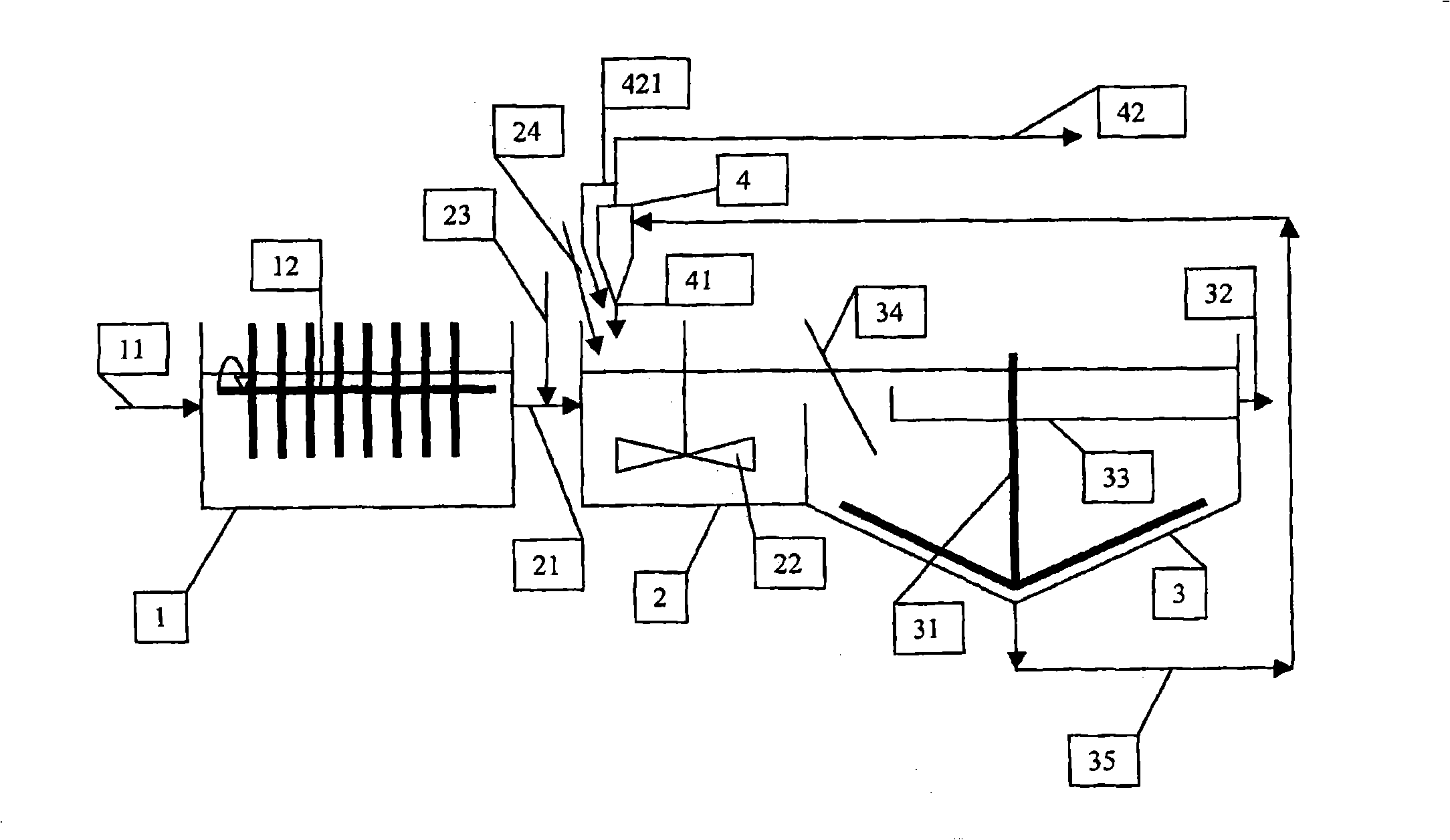

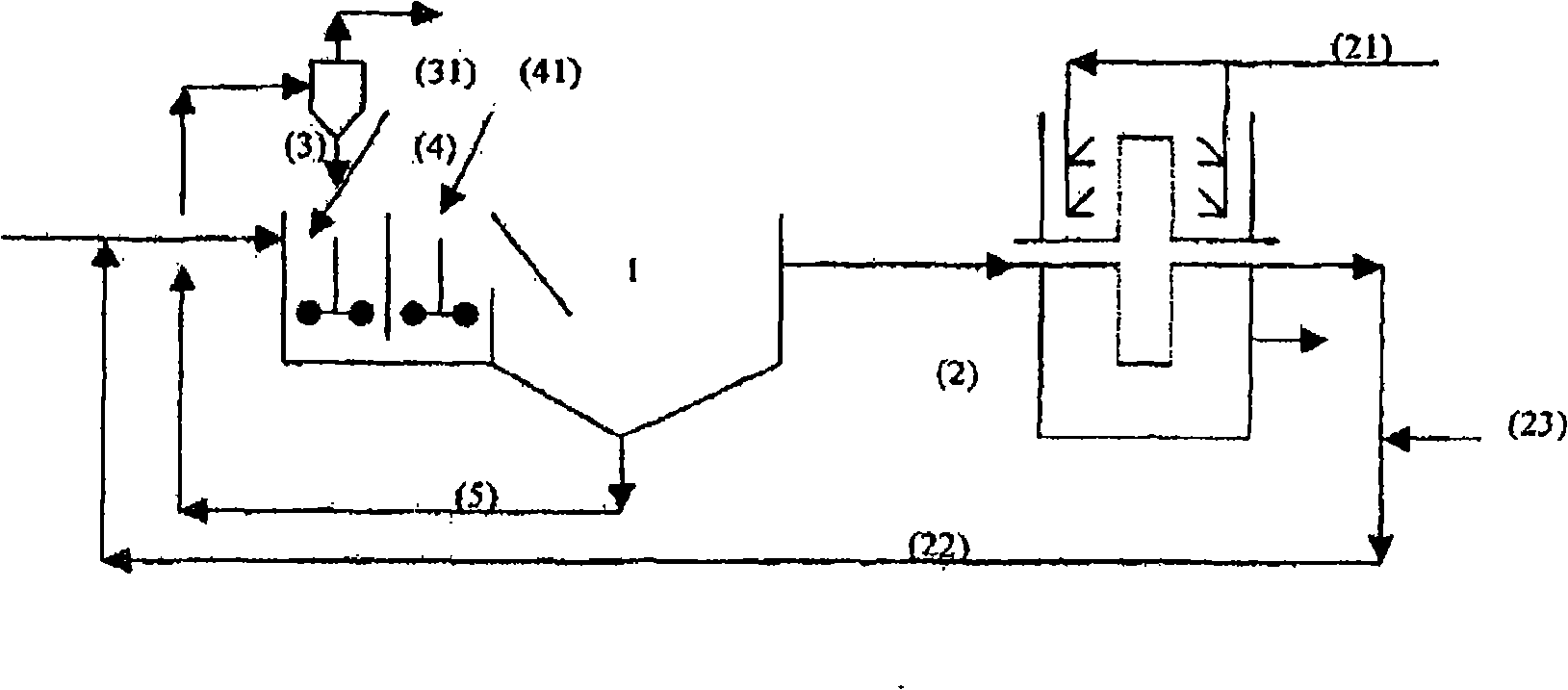

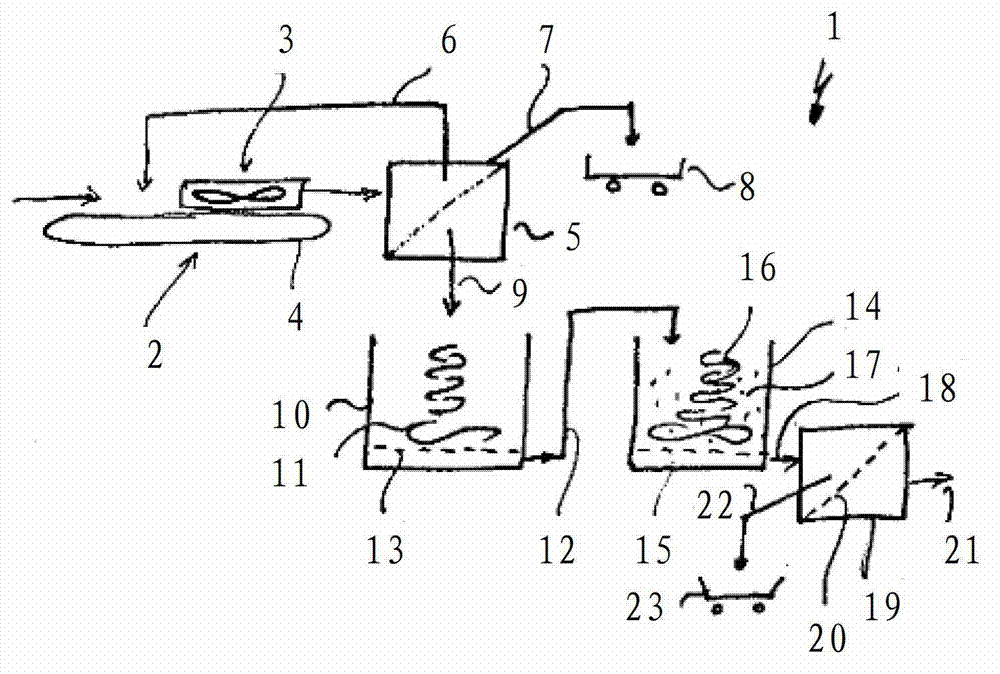

Water treating method and arrangement integrating a fixed-bacteria biological treatment and flocculation-decantation

InactiveCN101296870ASmall sizeLess quantityTreatment using aerobic processesWater treatment compoundsSludgeWater insoluble

The inventive water treating method and arrangement successively combine at least one step consisting in biological treating at least one part of pollution contained in said waters by a fixed biomass, wherein a bio-cleaned flow logically obtainable at the and of said step, prior to the entry thereof to a next step, contains less than 2 mg / l of MES, and at least one stage for carrying out a flocculation-decantation by ballasted flocs consisting in transferring biologically treated flow to a mixing area (2), preferentially at a velocity gradient ranging from 10 s-<1> to 1000 s<-1>, wherein at least one type of denser than water insoluble granulated material is injected and suspended matters are aggregated around said granulated material particles, in transferring the flow issued from the mixing area (2) to a decantation area, wherein the clarified flow and decantation sludges mixed with the granulated material are separated, in extracting granulated material from the decantation sludges, in recycling major part thereof is in the mixing area (2) and in removing the decantation sludges separated form the granulated material.

Owner:ODISHA TV

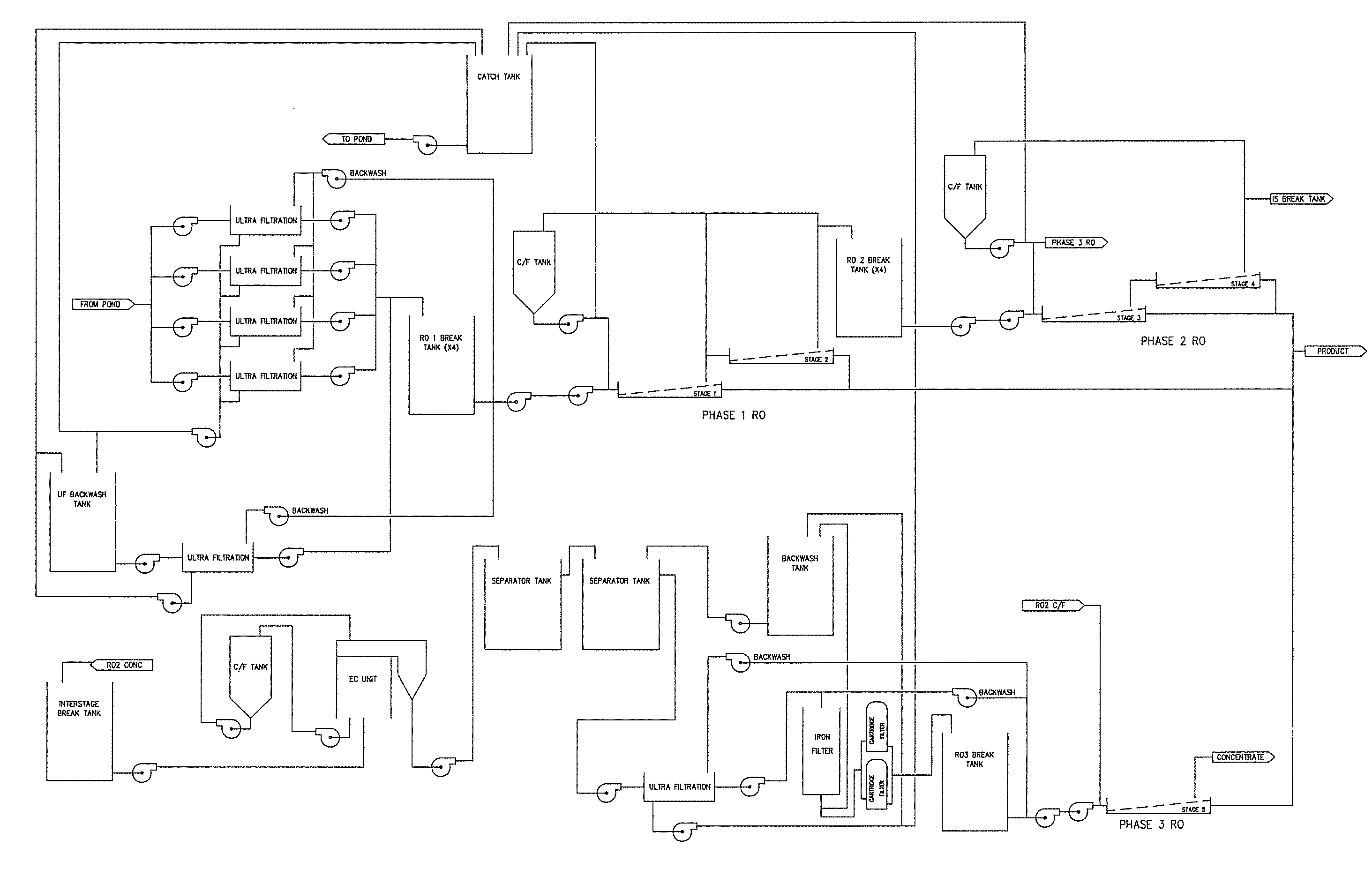

Fluid Purification Methods and Devices

ActiveUS20080087603A1Good coagulationMembranesWater/sewage treatment by irradiationPurification methodsElectrolysis

Disclosed is a method of purifying fluid by reverse osmosis whereby the recovery rate of the fluid processed is increased over conventional applications by incorporating methodologies to achieve the maximum recovery of a fluid stream conventionally processed by reverse osmosis. The resultant concentrate solution is subjected to additional electrolytic treatment to remove dissolved and suspended matter. It is then further processed by reverse osmosis to attain greater overall recovery than previously possible.

Owner:POWELL WATER SYST

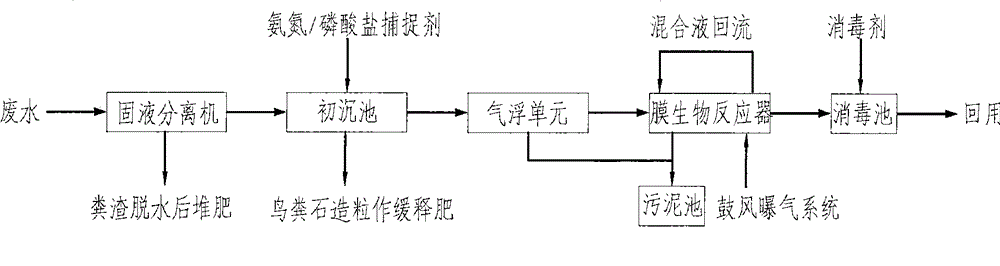

Treatment method cattle farm culture wastewater

ActiveCN104961306AImprove C/N ratioCarbon savingMultistage water/sewage treatmentPhosphateHeifer calf

The invention relates to a treatment method of wastewater, particularly a treatment method of cattle farm culture wastewater, which comprises the following steps: (1) introducing culture wastewater into a solid-liquid separator to remove suspended substances; (2) sending the wastewater subjected to solid-liquid separation into a preliminary sedimentation tank, and adding an ammonia nitrogen and phosphate capturing agent into the preliminary sedimentation tank; (3) pumping effluent water of the preliminary sedimentation tank to a floatation unit, and adding a reagent to remove fine suspended substances; (4) sending effluent water of the floatation unit into a membrane bioreactor to filter out the suspended substances, colloidal substances and bio-unit microbial florae in the wastewater and trap high-molecular organic substances which can not be easily degraded temporarily, wherein the retention time of the reactor is prolonged to maximally decompose the high-molecular organic substances; and (5) sending effluent water of the membrane bioreactor into a disinfection tank, disinfecting, and discharging after reaching the standard or recycling. The treatment method of cattle farm culture wastewater has the advantages of favorable denitrification and dephosphorization effects, high shock load resistance, stable operation, energy saving and favorable effluent water quality, and is convenient for control and maintenance.

Owner:BEIJING JIANYAN ENVIRONMENTAL PROTECTION EQUIP

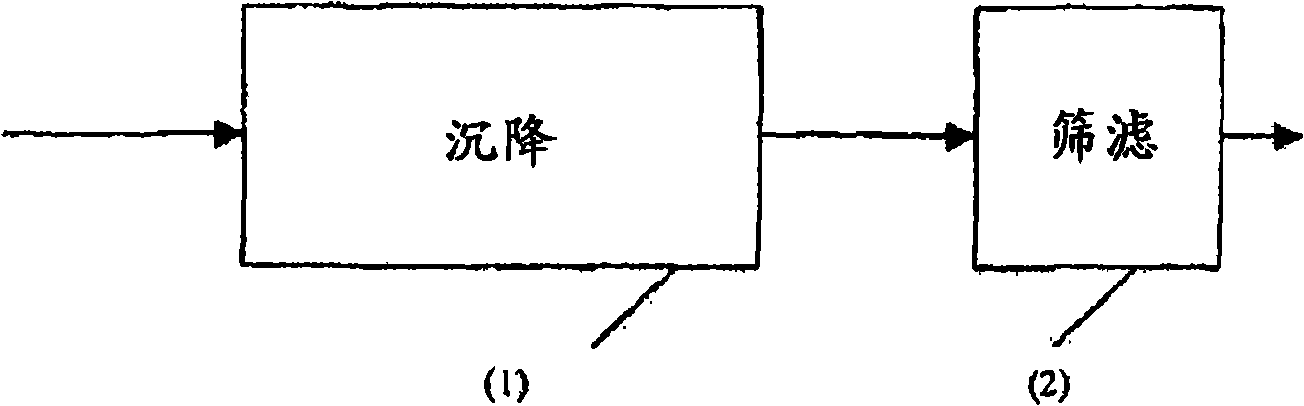

Wastewater treatment method comprising decantation and fine screening stages and device for carrying out said method

InactiveCN101309870AEasy to handleSmall sizeWater treatment parameter controlWater/sewage treatment by irradiationMicrometerWastewater

The invention relates to a wastewater treatment method for reducing the content thereof in suspended materials, in particular in parasites, comprising a decantation stage consisting in transferring said waters to a decanter at a treating rate greater than 10 m / h, wherein said decantation stage is followed by a fine screening stage carried out with the aid of a screen whose mesh size ranges from approximately 5 micrometers to approximately 25 micrometers.

Owner:VEOLIA WATER SOLUTIONS & TECH SUPPORT

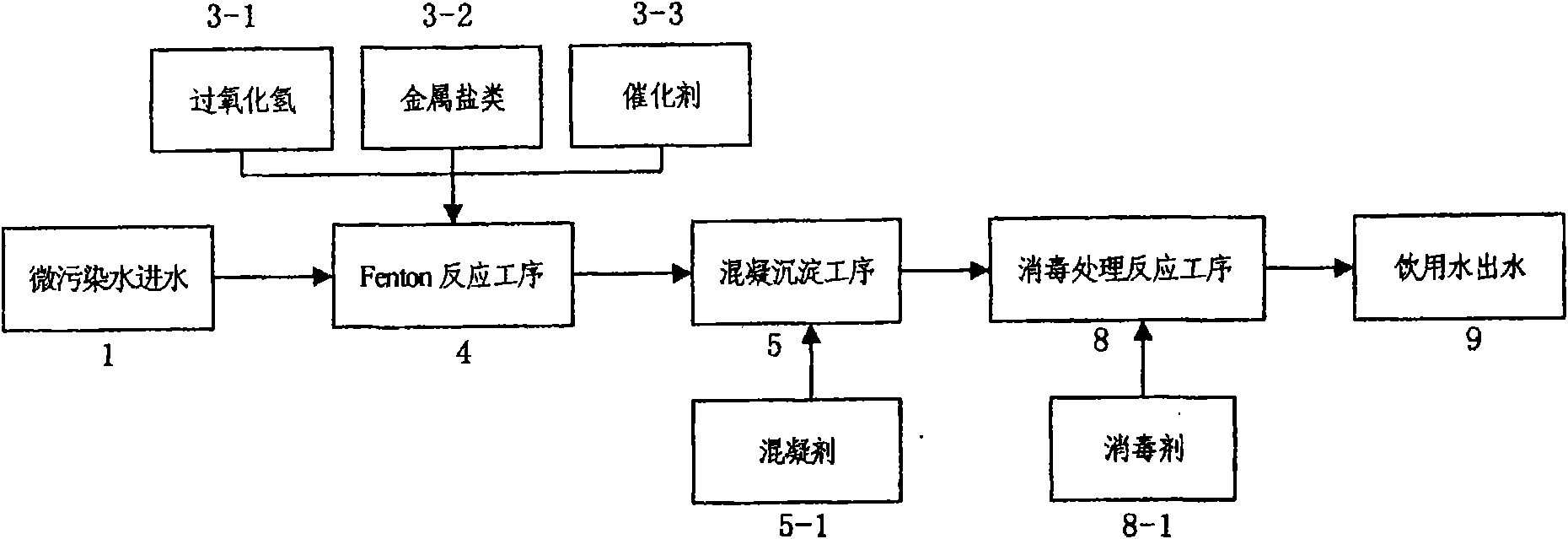

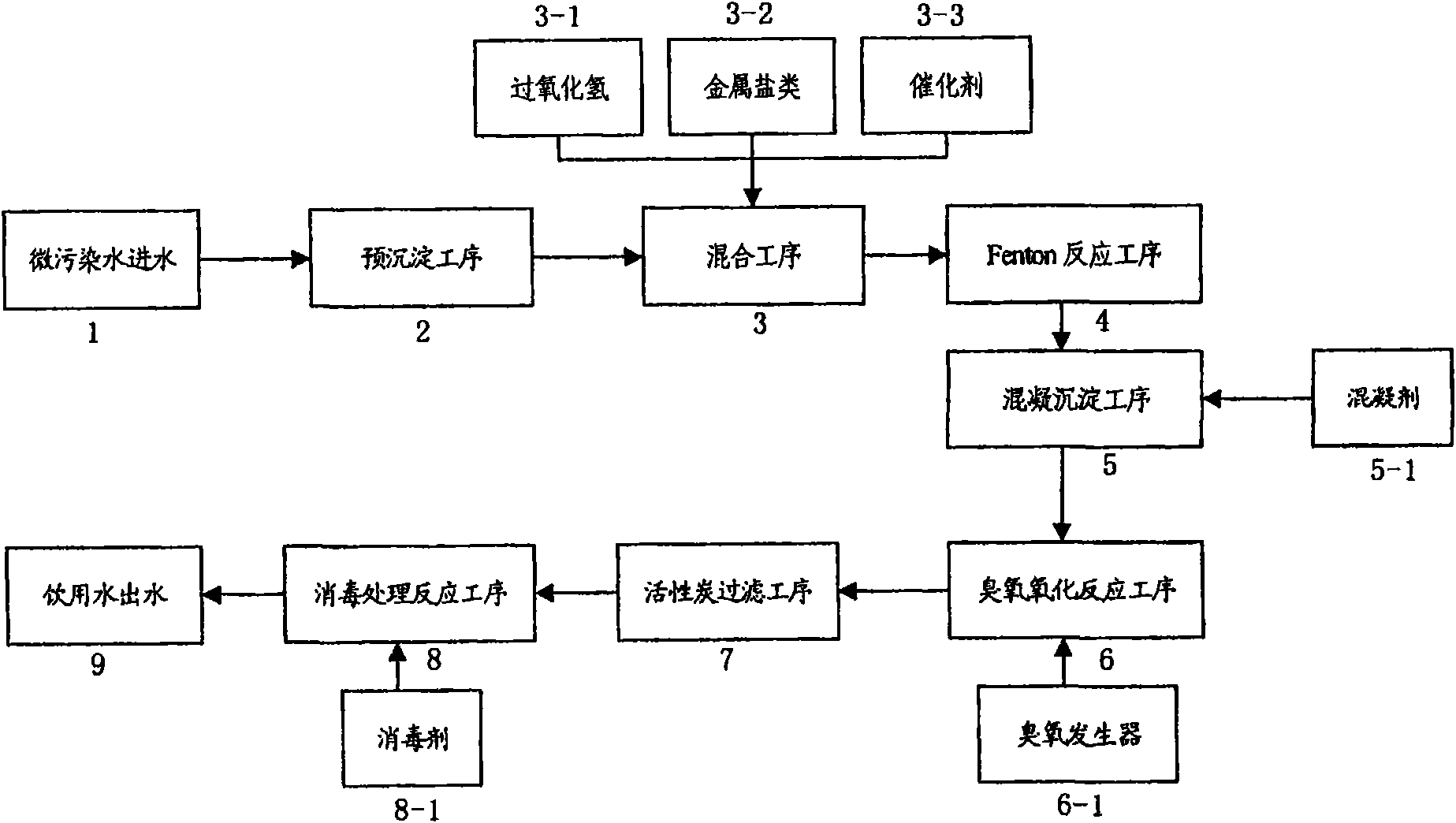

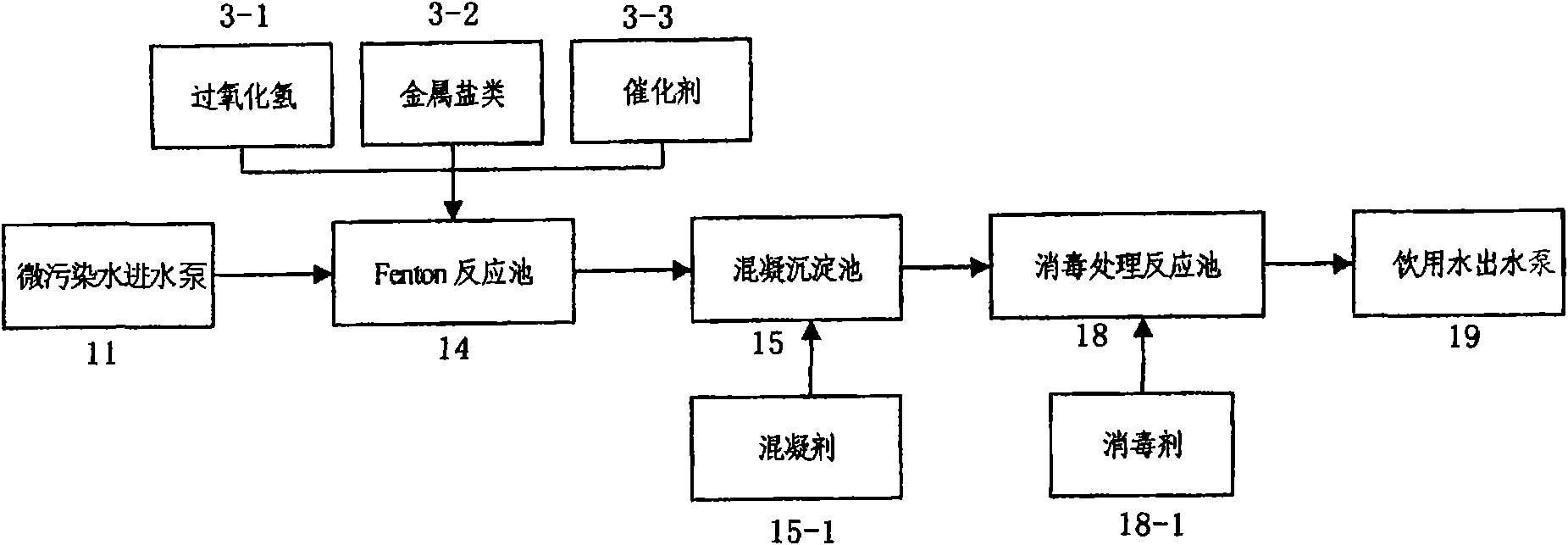

Method and treatment device for purifying water of micro polluted water source

InactiveCN101987764ALow running costImprove processing efficiencyMultistage water/sewage treatmentWater/sewage treatment using germicide/oligodynamic-processWater sourceWater quality

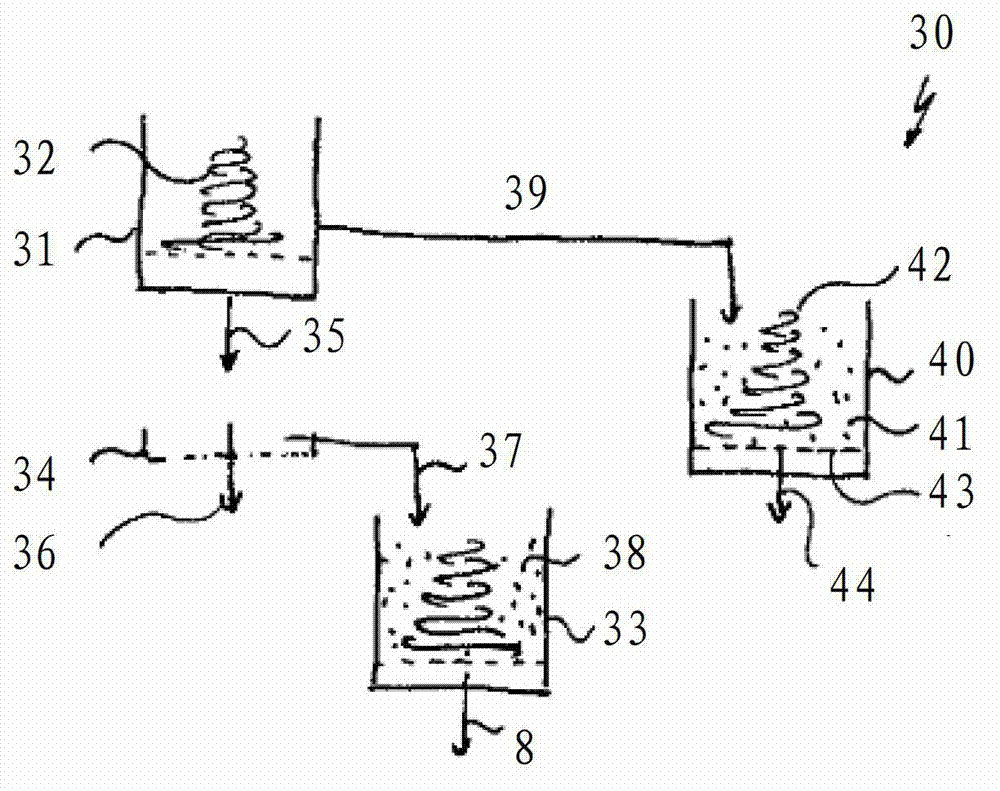

The invention discloses a method for purifying water of a micro polluted water source, which comprises a Fenton reaction process (4), a coagulative precipitation process (5) and an oxidant oxidation and disinfection process (8). The Fenton reaction process (4) means to add oxidant, metal salt and catalyst into the water of the micro polluted water source to be treated with metering respectively so that the oxidant decomposes the organic substances in the sewage and the organic substances are removed from the sewage; the coagulative precipitation process (5) means to add a coagulant into the sewage after the oxidation treatment to precipitate small granular suspension substance, colloidal substance and metal salt in the wastewater; and the oxidant oxidation and disinfection process (8) means to perform further oxidant treatment on the clean water obtained in the previous process to remove residual hydrogen peroxide from the water and disinfect the clean water, wherein the disinfected clean water can be used as drinking water. The invention also provides a treatment device for purifying the water of the micro polluted water source.

Owner:上海凯顿百森建筑材料科技发展有限公司

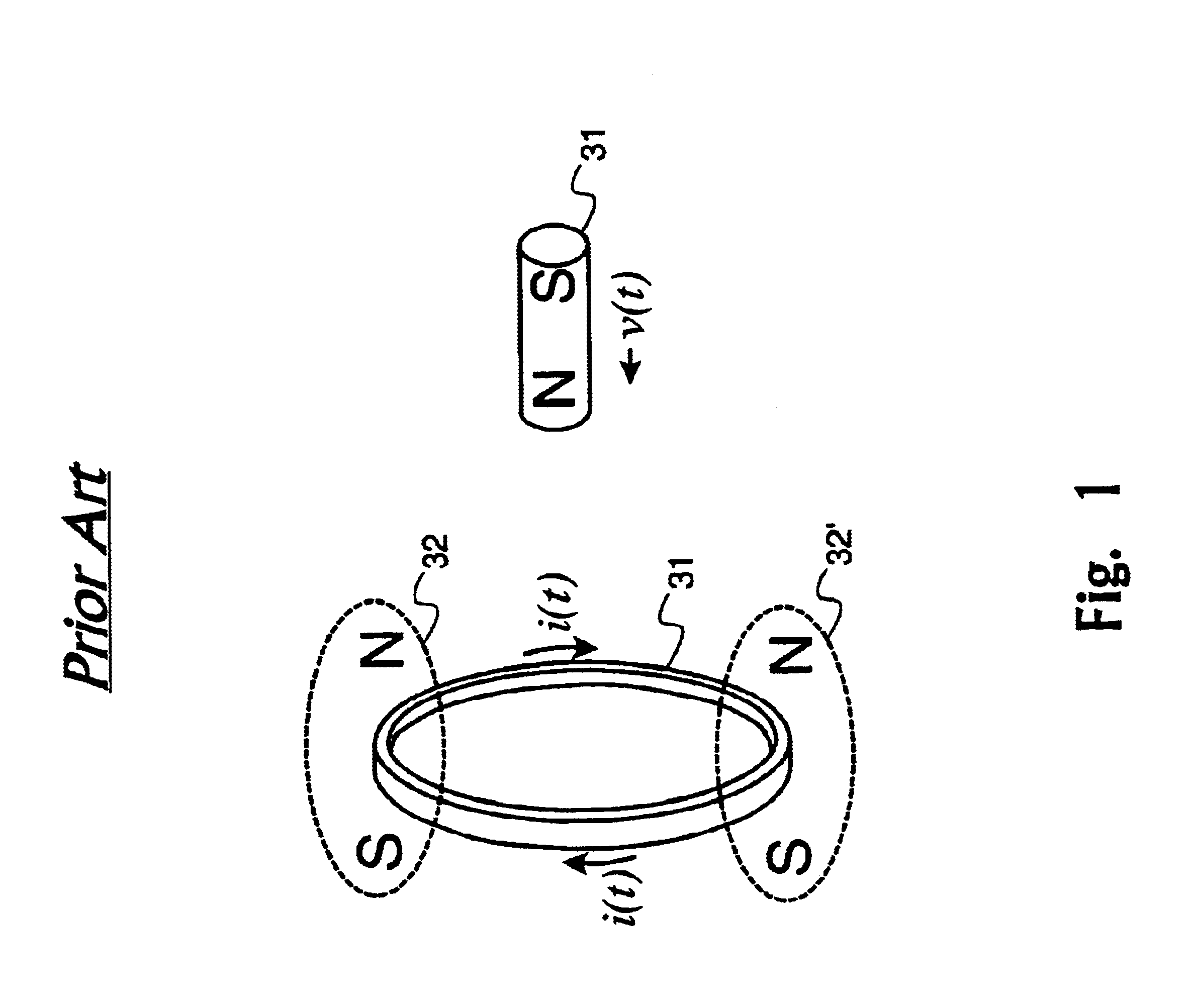

Magnetic separation method and device for treating oil-containing graphite wastewater

InactiveCN106746137APromote energy conservation and emission reductionImprove adsorption capacityWater contaminantsWater/sewage treatment by magnetic/electric fieldsSludgeRetention time

The invention relates to a magnetic separation method for treating oil-containing graphite wastewater, and aims to treat oil and suspended substances in the oil-containing graphite wastewater by using a combined process of air flotation and magnetic separation. The magnetic separation method comprises the following steps: A, firstly, adding wastewater into an air flotation tank so as to enable suspended solids such as a part of oil and graphite in the wastewater to emerge from the water level in an air flotation manner, and scraping the suspended solids into a residue tank, wherein an internal circulation type jet flow pressurization dissolved air flotation method is adopted for air flotation, the dissolved air pressure is 0.25-0.4MPa, the reflux ratio is 10-15%, the separation load is 10-13m<3> / m<2>.h, and the retention time is 20-30 minutes; B, feeding air flotation effluent into a magnetic separation device, performing pre-magnetization by using a pre-magnetization treater in the magnetic separation device, feeding the air flotation effluent into an inclined tube sedimentation tank along with sewage, controlling the flowing speed of the inclined tube sedimentation tank to be 20-35mm / s, subsequently enabling flocculating constituents and suspended solids retained in the water to adhere to a magnetic disc by using a magnetic disc separator, controlling the flowing speed of wastewater flowing through a single magnetic disc separator to be 200-400m<3> / h, scraping the sludge into a sludge discharge device by using a sludge scraper plate, and discharging out treated clean water from a water outlet. The magnetic separation method is free of water treatment agent, and is applicable to treatment on sewage which contains oil and graphite and is not liable to naturally precipitate.

Owner:ANGANG STEEL CO LTD

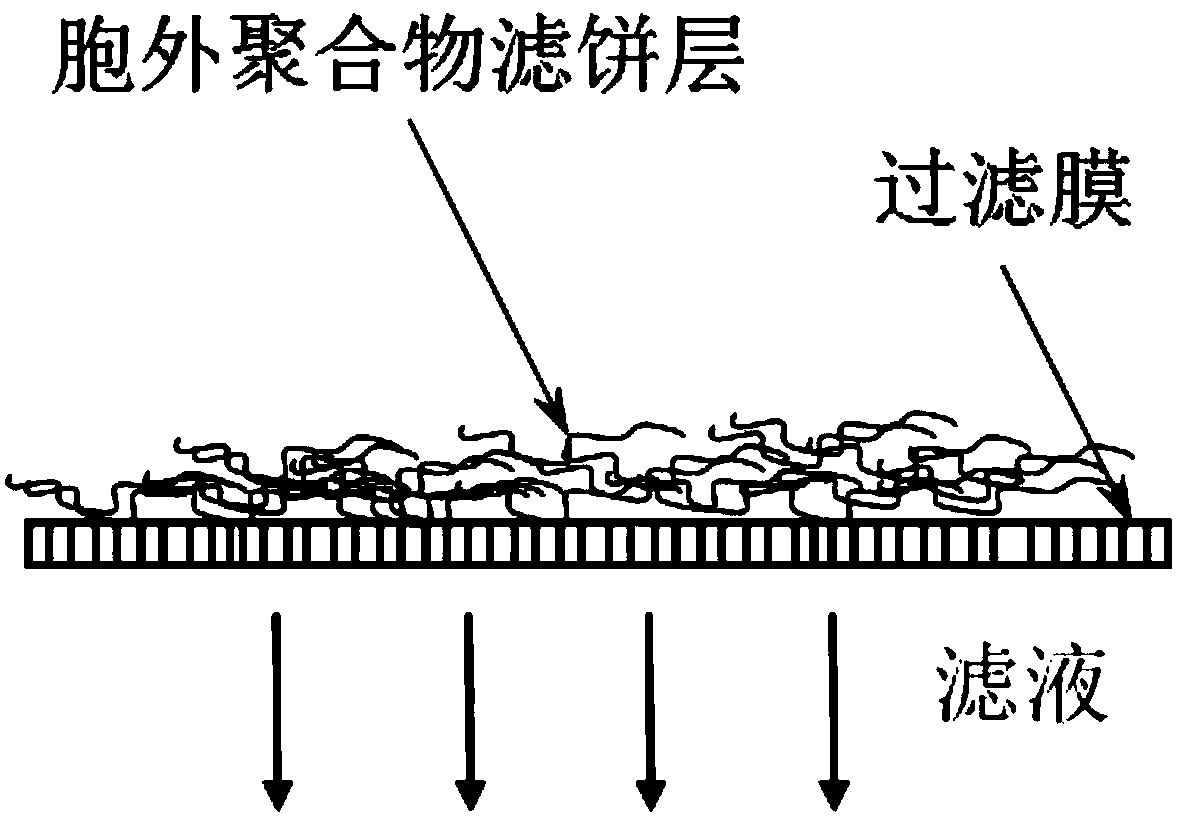

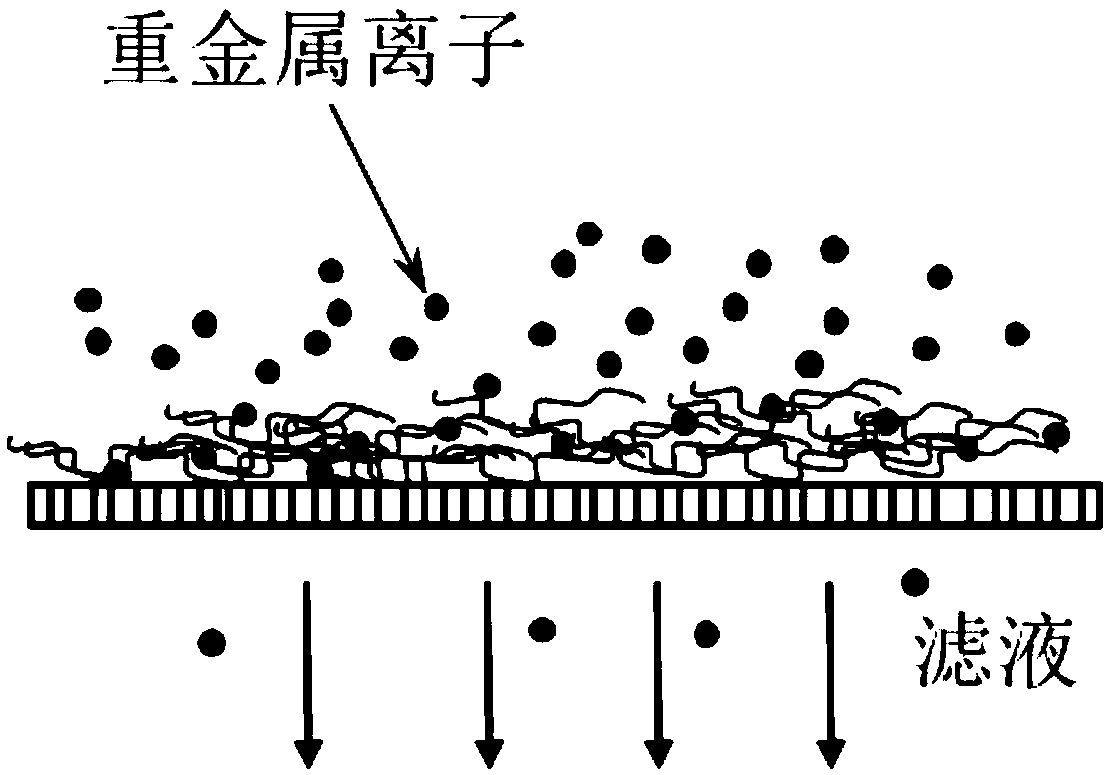

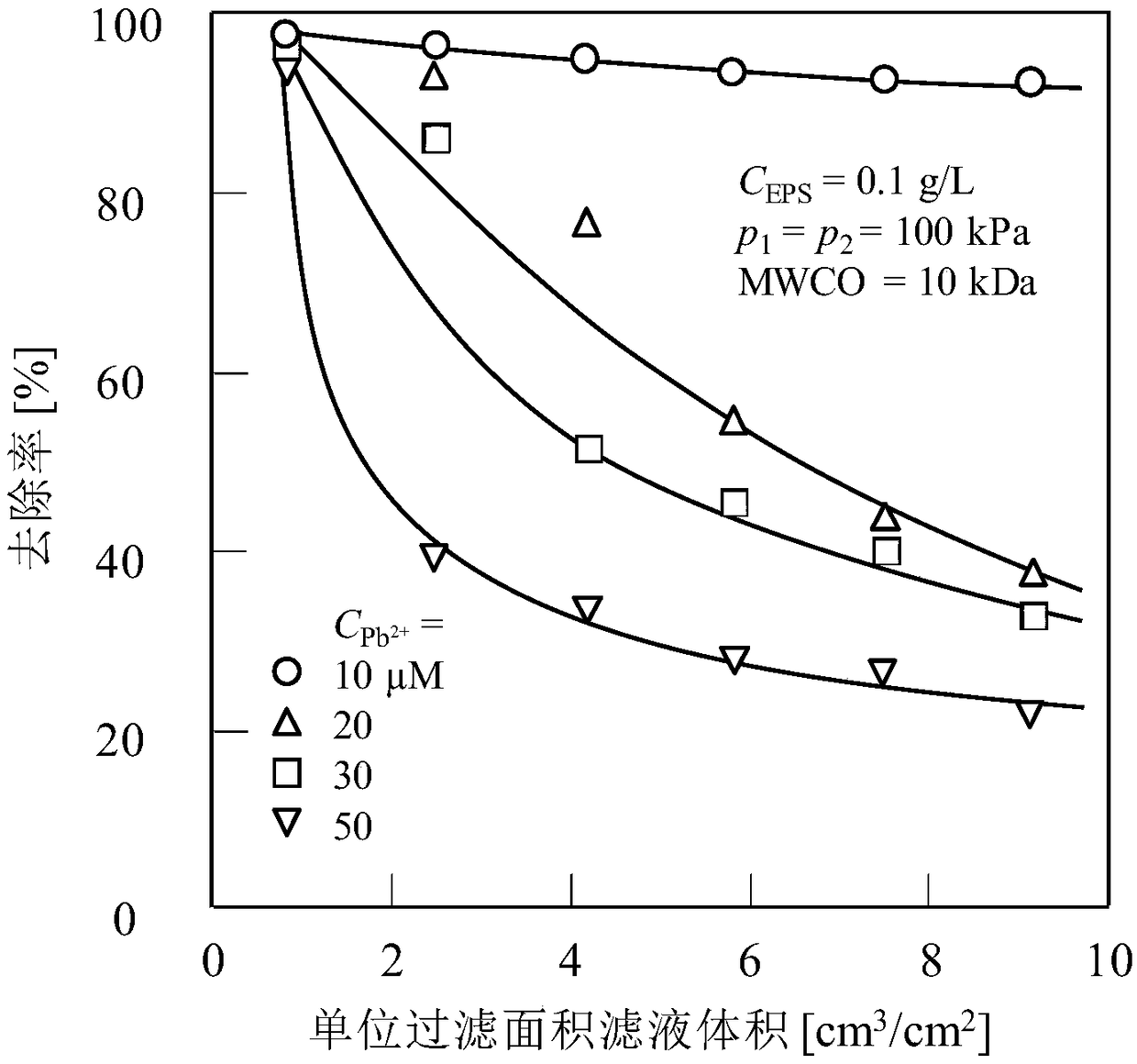

Method for recycling extracellular polymers and removing heavy metal ions from excess sludge

ActiveCN109368742AExtension final outletSolve the separation problemWater contaminantsWater/sewage treatment bu osmosis/dialysisExtracellularFiltration membrane

The invention relates to a method for recycling extracellular polymers and removing heavy metal ions from excess sludge. The method comprises the following steps: S1, desorbing the extracellular polymers on the surfaces of cell bodies in the excess sludge into a water-dissolved state; then, reducing suspended substances after desorption of the extracellular polymers to obtain an extracellular polymer solution; S2, filtering the extracellular polymer solution by using a filtration membrane so as to form an extracellular polymer filter cake layer on the upper surface of the filtration membrane and obtain the filtration membrane with the extracellular polymer filter cake layer; S3, filtering a water solution containing the heavy metal ions by using the filtration membrane with the extracellular polymer filter cake layer. By the method, the operation is simple, and the excess sludge can be reduced by recycling the extracellular polymers in the excess sludge; meanwhile, the two steps of concentrating and recycling the extracellular polymers and removing the heavy metal ions in the excess sludge are coupled, so that the problem that the extracellular polymers adsorbing the heavy metal ions are difficultly separated from water is avoided.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

Flocculating agent for sewage and preparation method thereof

InactiveCN105967292AIncrease in sizeHigh densityWater/sewage treatment by flocculation/precipitationSodium bicarbonateTotal nitrogen

The invention discloses a flocculating agent for sewage and a preparation method thereof. The flocculating agent for the sewage is prepared from the following raw materials in parts by weight: dimethyl diallyl ammonium chloride, sodium silicate, acrylamide, dibenzoyl beroxide, tert-butyl alcohol, ferric chloride, aluminum sulfate octadecahydrate, polyaluminum chloride, ferrous sulfate, polyphosphorus ferric chloride, chitosan, sodium alginate, polyvinyl pyridine salt, a porous adsorbent, sodium bicarbonate, lignin, triethylenetriamide, formaldehyde sodium bisulfite, propionic aldehyde and alums. The capacity and density of the flocculating agent are increased and the flocculating effect is improved; suspension substances in the sewage can be effectively and rapidly flocculated and are gathered into clustered substances which are not easy to disperse and convenient to separate; meanwhile, the corrosion of the flocculating agent to pipeline equipment is lower than that of other similar flocculating agents; the chemical oxygen demand COD, the biochemical oxygen demand BOD and the suspension substances SS of the treated sewage are obviously reduced, and the total nitrogen, ammonia nitrogen and chroma are also reduced.

Owner:张能力

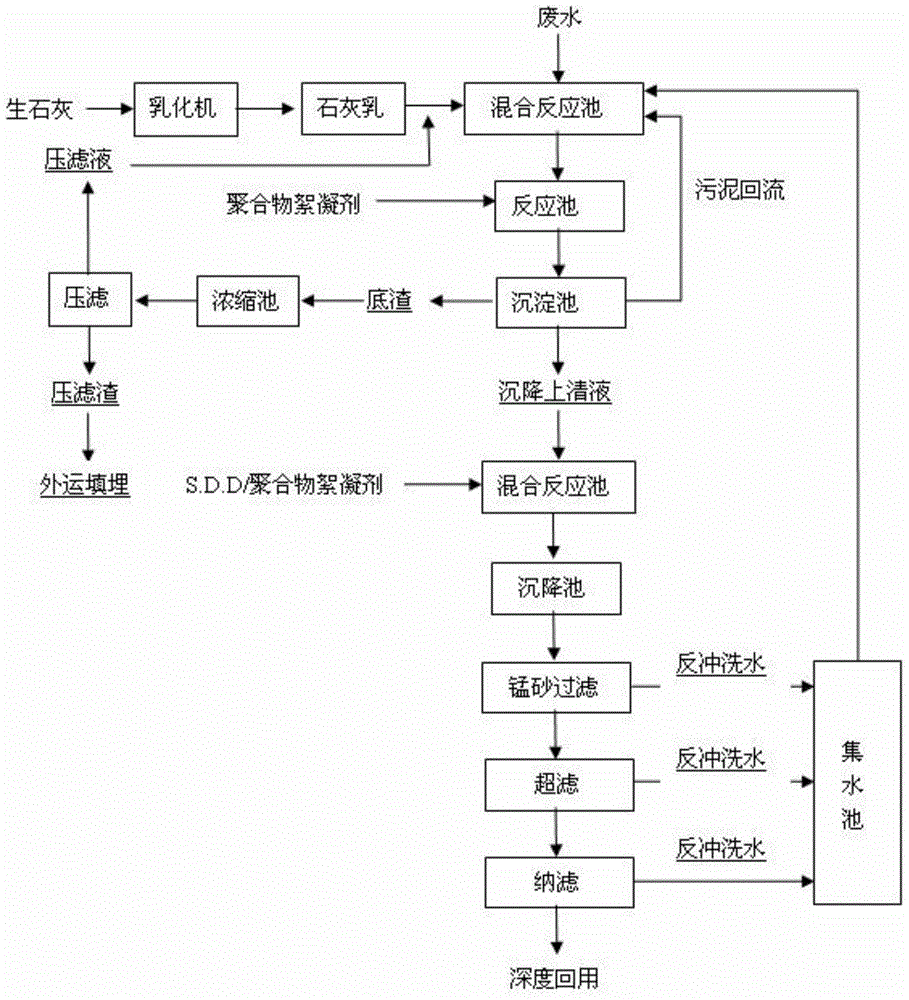

Deep purification and recycling method for waste water containing heavy metal ions

InactiveCN104973714AHigh removal rateImprove water qualityWater contaminantsMultistage water/sewage treatmentUltrafiltrationFiltration

The invention relates to a deep purification and recycling method for waste water containing heavy metal ions. The deep purification and recycling method comprises the following steps: performing chemical neutralization and sedimentation on the waste water containing one or more heavy metal ions to remove most heavy metal ions in water; adding dimethyl carbamodithioic acid or potassium dimethyldithiocarbamate and a polymer flocculating agent, and fundamentally removing the heavy metal ions in the waste water through coagulation sedimentation; adopting sand filtration, ultrafiltration and nanofiltration units to treat effluent water after sedimentation, removing suspended substances, SS, organic matters and partial heavy metal ions in the waste water, wherein the water quality reaches the water quality recycling standard of circulating cooling water after treatment. The waste water containing one or more heavy metal ions at different concentrations can be treated, the application range is large, the operation is simple, and the removal rate is high.

Owner:广西冶金研究院有限公司

Device for treating high-concentration ammonia nitrogen sewage and process for treating high-concentration ammonia nitrogen sewage using device

ActiveCN103864269AGood gas-liquid-solid exchange interfaceImprove mass transfer effectWater/sewage treatmentEnergy based wastewater treatmentHigh concentrationResource utilization

The present invention relates to a device for treating high-concentration ammonia nitrogen sewage and a process for treating high-concentration ammonia nitrogen sewage using the device. The device comprises a sedimentation tank, a stabilization tank, a biofilter, a gasification high-efficient nitrification reactor and an evaporation-crystallization reactor, the treatment process comprises allowing the sewage to flow into the above device, intercepting a majority of suspended materials in the sewage by the precipitation tank, and then enabling the sewage to flow into the stabilization tank, lifting the sewage in the stabilization tank by the pump to the biofilter for treating and enabling the sewage to flow back to the stabilization tank to form an internal circulation, allowing the spillover sewage to enter the gasification high-efficient nitrification reactor for nitrification treatment, enabling the spillover sewage subjected to the nitrification treatment to enter the evaporation-crystallization reactor to generate the final solid product. Through the above-mentioned technical solution, the present invention provides a device for treating high-concentration ammonia nitrogen sewage and a process for treating high-concentration ammonia nitrogen sewage using the device which can improve the treatment effect and realize the resource utilization.

Owner:WENZHOU UNIVERSITY

Method for processing biomass

The invention relates to a method for processing biomass, such as in particular green waste containing wood, and a high density pulper having a spiral, wherein the green waste is treated in a continuously operated, bladed pulper and then the separated fibers are ground in a pulper ball mill.

Owner:汉斯-乔基姆·鲍尔特斯多夫

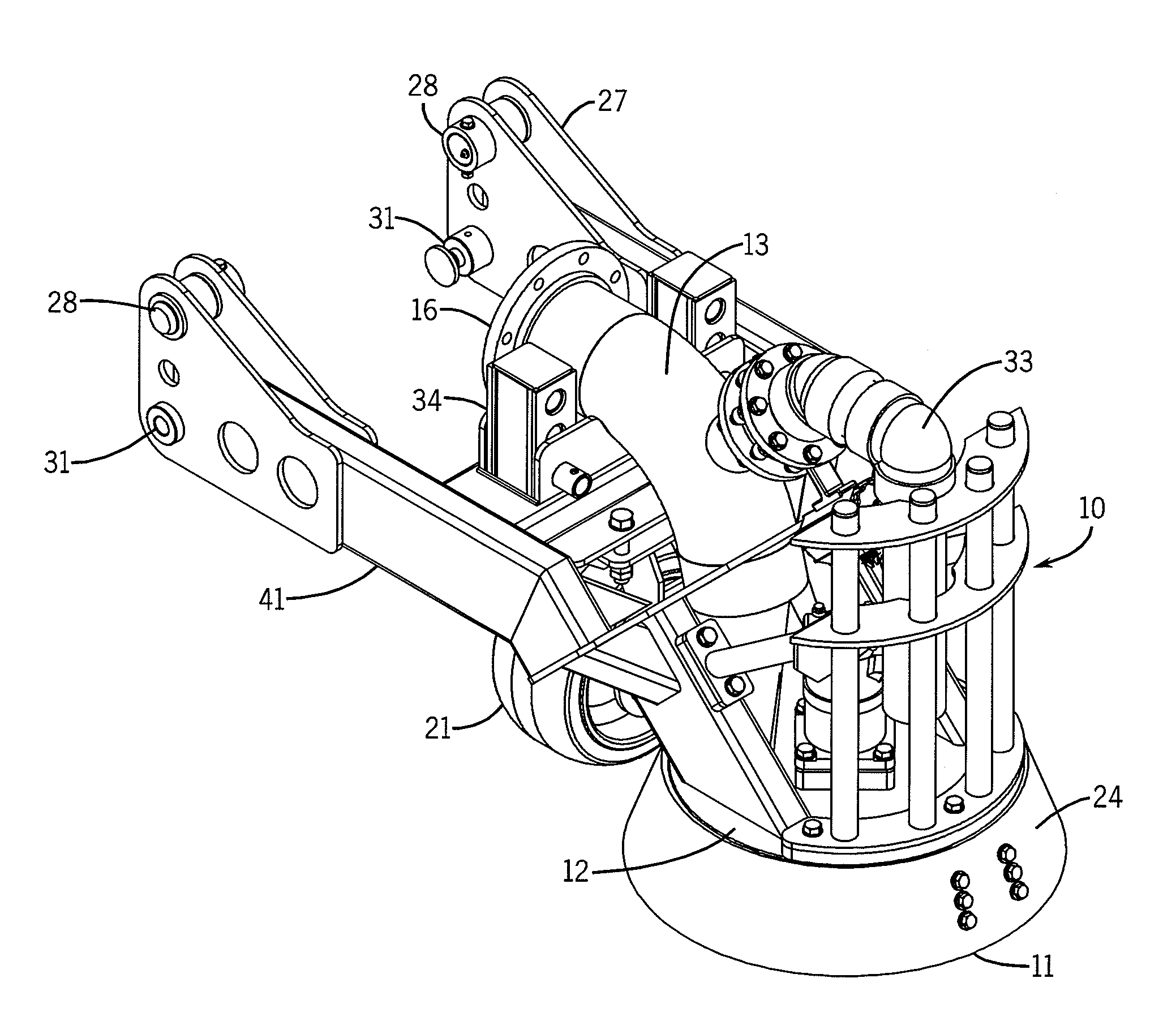

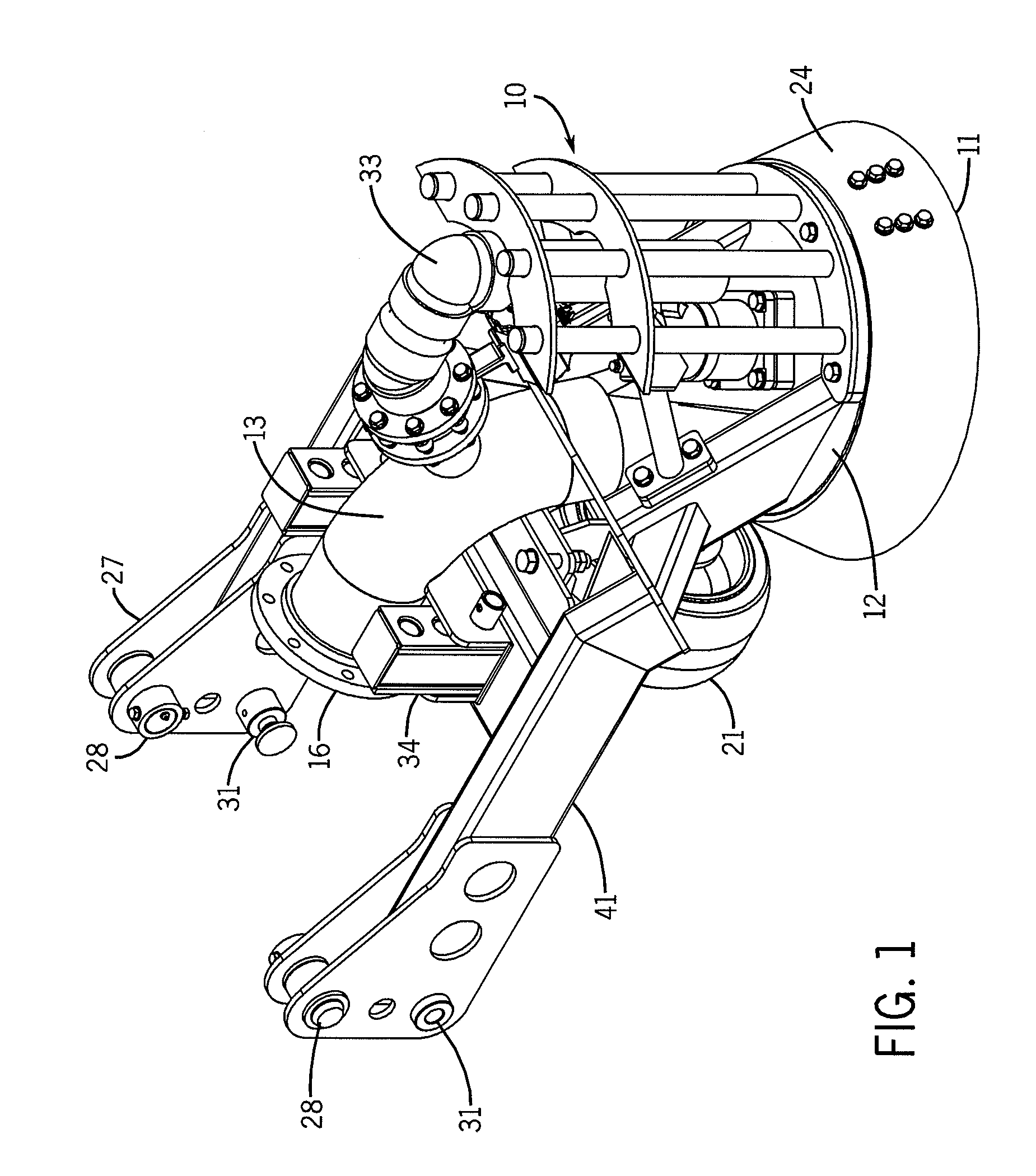

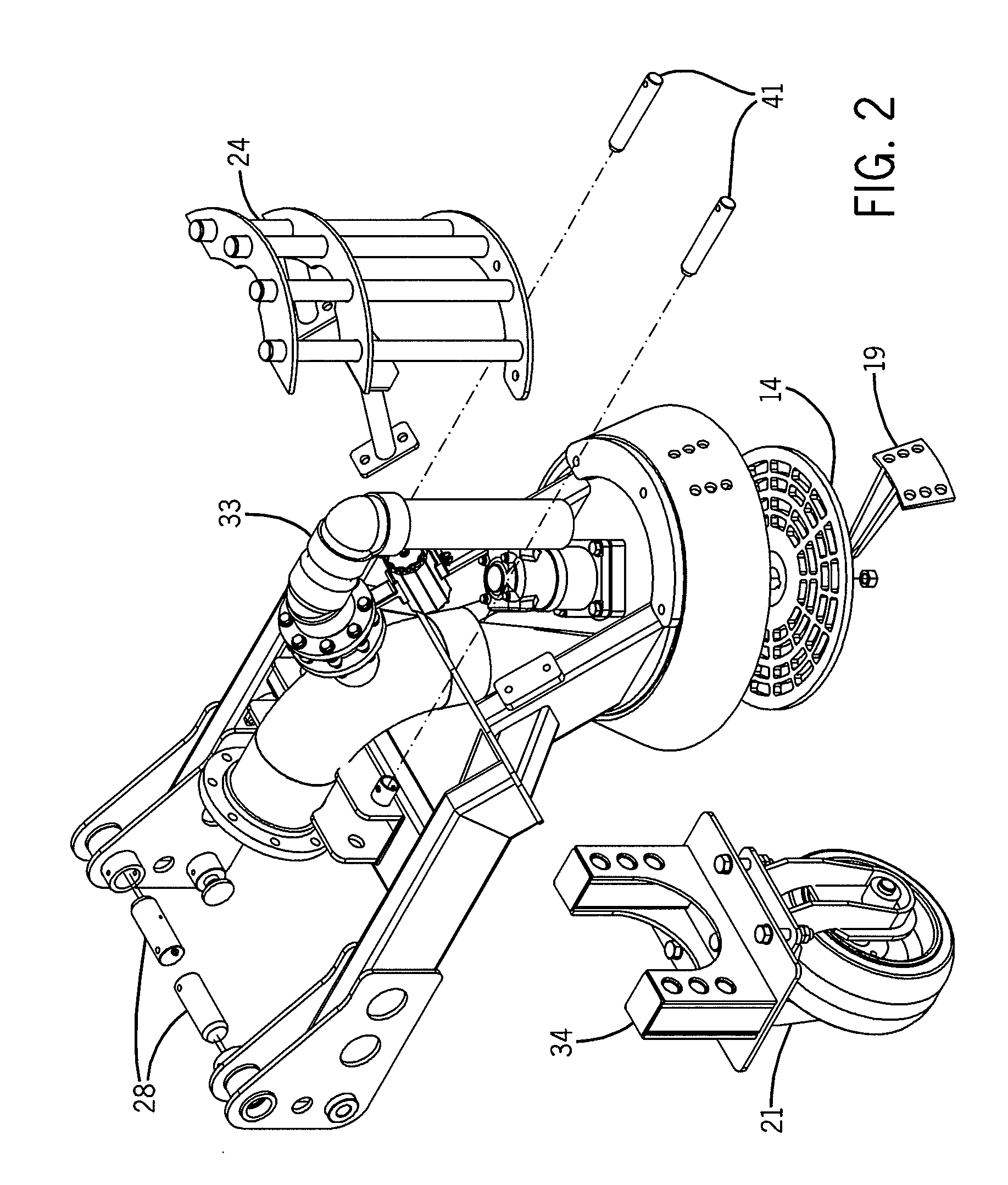

Fine Sediment Removal Attachment for a Dredge

ActiveUS20080172911A1Avoid cavitationMass flow measurement devicesMachines/dredgers working methodsHydraulic motorSolid mass

Contaminated fine sediment is removed from surfaces beneath a body of water by a shrouded, self-cleaning, wheel-guided, open suction attachment for a swinging ladder suction dredge with articulating capabilities. The attachment comprises a wheel-guided, suction assembly in which the slurry is contained in a shroud. The shroud is attached to a head plate, and is designed to both enclose the solid particles suspended as a result of the removal operation, and to direct the suspended material to the mouth of the suction pipe. Inside the area surrounded by the shroud is a gatling plate rotated by a hydraulic motor mounted just above the shroud and head plate.

Owner:J F BRENNAN

Separation device comprising a separation channel and a counter-channel

ActiveUS7442315B2Easy to disassembleEasy to cleanWater/sewage treatment by centrifugal separationComponent separationFractionationBody fluid

The present invention relates to a separation device notably for a flow-force fractionation of suspended substances in a liquid carrier, said separation device comprising a separation channel and a counter-channel.The object of the present invention is mainly the separation of living cells, preferably of human origin, in particular cells which are found in body fluids.

Owner:UNIV DE LIMO

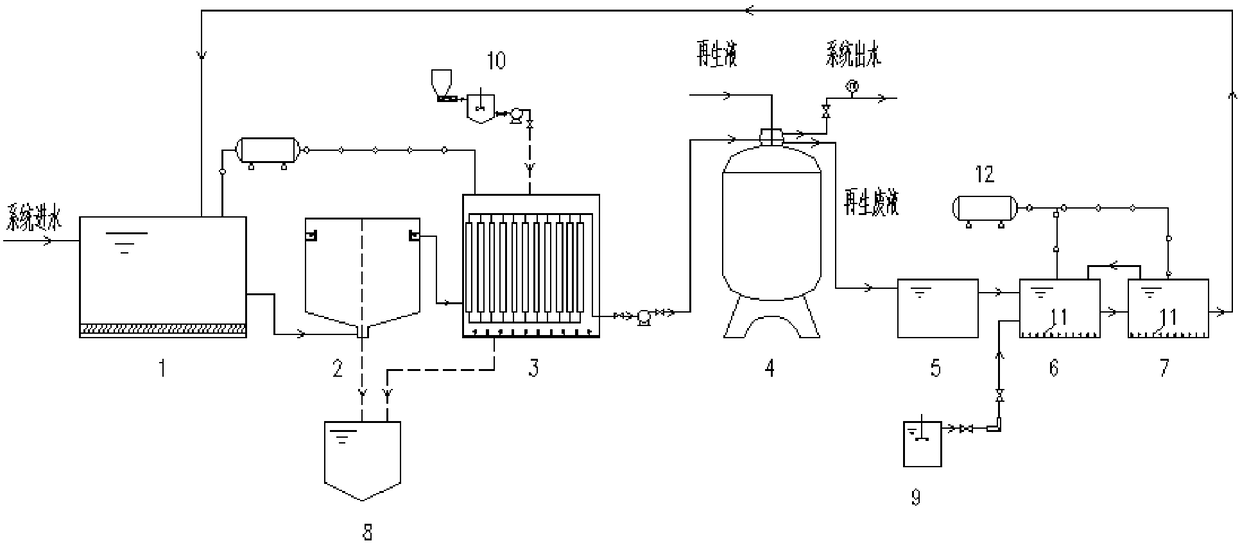

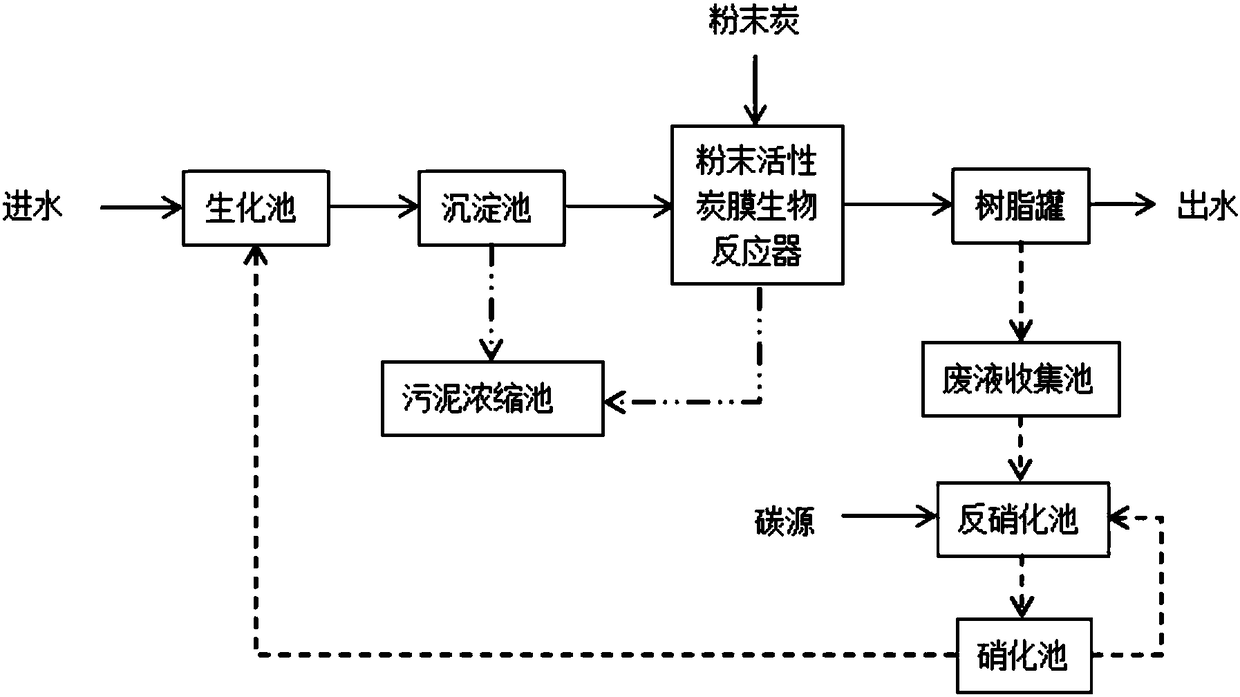

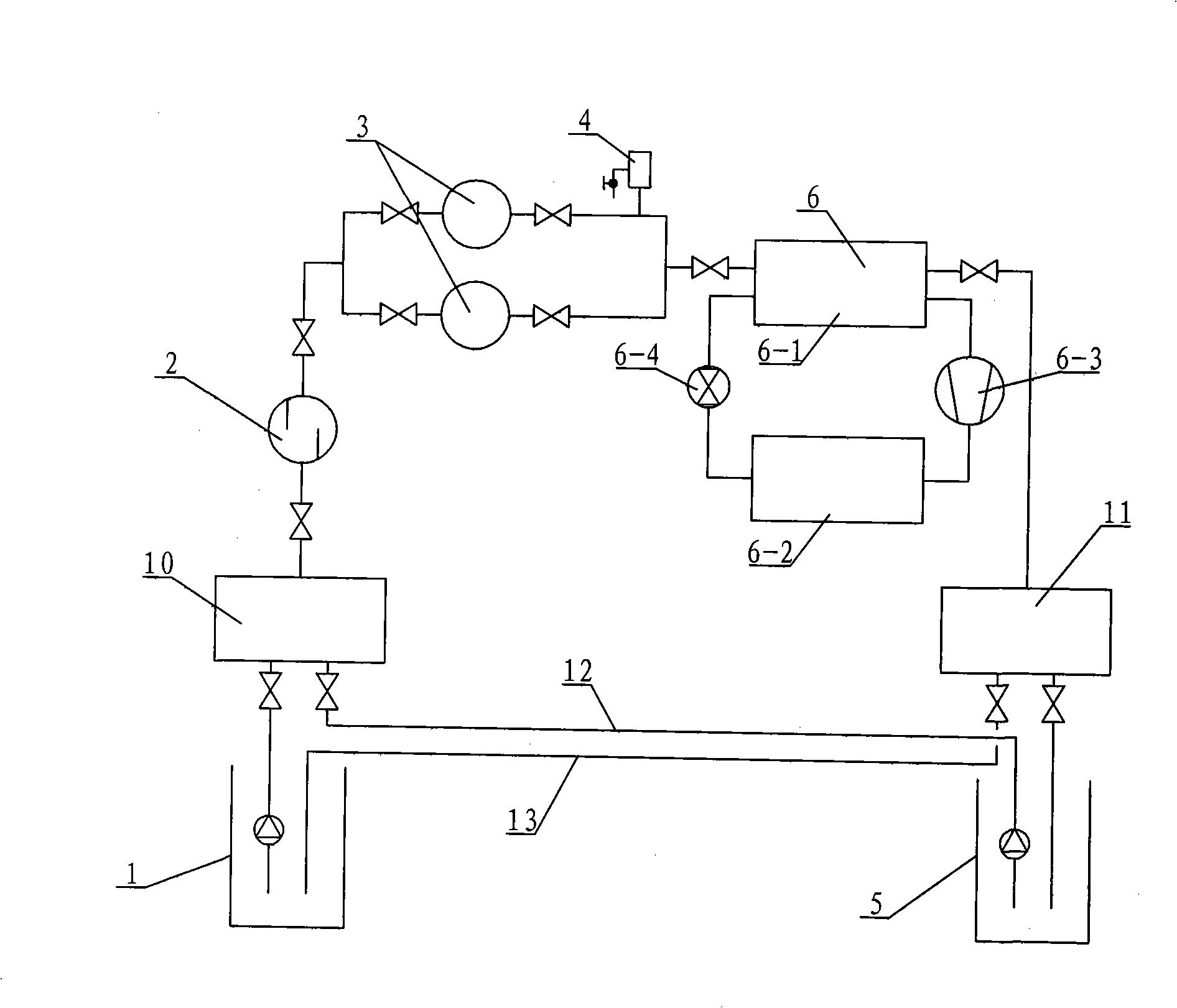

System and method for deeply treating sewage and recycling resin regeneration waste liquid

PendingCN108341556AMature technologySimple technologyWater contaminantsMultistage water/sewage treatmentLiquid wasteActivated sludge

The invention discloses a system and a method for deeply treating sewage and recycling resin regeneration waste liquid. The system comprises a biochemical pool, a settling pond, a powder activated carbon membrane biological reactor, a resin tank, a waste liquid collecting pool, a denitrification pool, a nitration pool and a sludge concentration pool. The method is characterized in that the incoming water of a sewage treatment plant is pre-treated and then enters the biochemical pool, thus the CODcr can be degraded under the effect of activated sludge; supernate flows into the powder activatedcarbon membrane biological reactor after settling, and thus pollutants can be further adsorbed through the powder activated carbon; chroma, suspension substances and CODcr are removed by interceptingthrough a membrane assembly; the water drained by the membrane is fed into the resin tank, and nitrate in the sewage can be removed under the adsorption effect of special nitrate ion exchange resin, and the clean water is directly drained; the resin regeneration waste liquid flows into the waste liquid collecting pool and is then fed into the denitrification pool for denitrification; the water subjected to denitrification flows into the nitration pool for nitration, thus ammonia nitrogen can be reduced, and CODcr can be degraded; the liquid subjected to nitration flows back to the denitrification pool; and the water drained by the nitration pool flows back to the biochemical pool at the front end, thus realizing the recycling of the resin regeneration waste liquid.

Owner:HUBEI JUNJI WATER TREATMENT

Anti-block system of ground water recharging well

InactiveCN101329113AWith non-stop backwashing functionAvoid overfillingOther heat production devicesGeothermal energy generationCycloneAnti jamming

An underground water recharge well anti-jamming system, the invention relates to an underground water recharge well device and aims at solving the problems that once the recharge well is jammed the recharged water quantity into a single well becomes less and less and the water even cannot recharged; the well pipe filtering device is arranged underground and then the cleaning and maintaining are inconvenient as these works obstruct the application of underground water-supply heat pumps. A first well (1) of the invention is connected through pipelines with a first-class cyclone desander (2), two second-class filters (3) are connected in parallel, then one end is connected through the pipeline with the first-class cyclone desander (2) and the other end is connected through pipeline with a water-supply heat pump heat-exchanging mechanism (6) which is connected with pipeline with a second well (5). With the first-class cyclone desander and the second-class filters of the invention, the suspension substances in the first well can be filtered to prevent thin sands, etc. suspension substances from jamming the second well and to avoid the problem that the recharged water quantity into the single well becomes less and less and the water even cannot recharged, so as to lead the underground water-supply heat pump to be applied well.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com