Device for treating high-concentration ammonia nitrogen sewage and process for treating high-concentration ammonia nitrogen sewage using device

A high-concentration technology for ammonia nitrogen wastewater, which is applied in energy wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

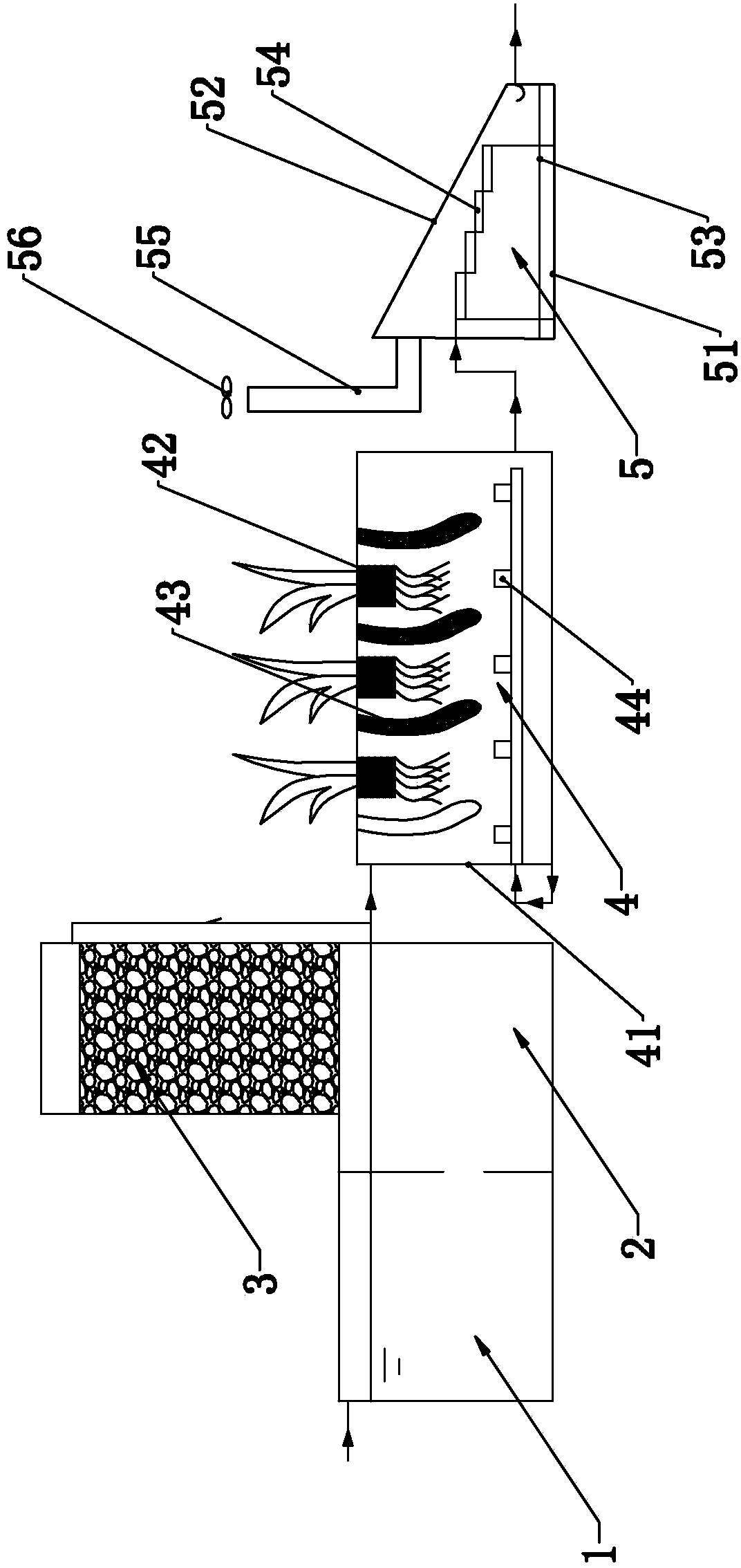

[0016] Such as figure 1As shown, a device for treating high-concentration ammonia nitrogen wastewater includes a sedimentation tank 1, a stabilization tank 2, a biological filter 3, a gasification high-efficiency nitrification reactor 4 and an evaporation crystallization reactor 5, wherein the gasification high-efficiency nitrification reactor 4 It includes an airtight container 41, a planting basket 42, a nitrification bag 43 and an atomizing pump 44, wherein the planting basket 42 is arranged on the top or / and side of the airtight container 41, and the basket body of the planting basket 42 is provided with holes, and the planting basket is planted For plants with well-developed root systems, the nitrification bag 43 is hung in the container 41, and the evaporation crystallization reactor 5 includes a box body 51, a solar heating plate 52, a condensed water collection tank 53, a multi-layer evaporation tray 54, and a ventilation pipe 55 and a wind-force exhaust device 56, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com