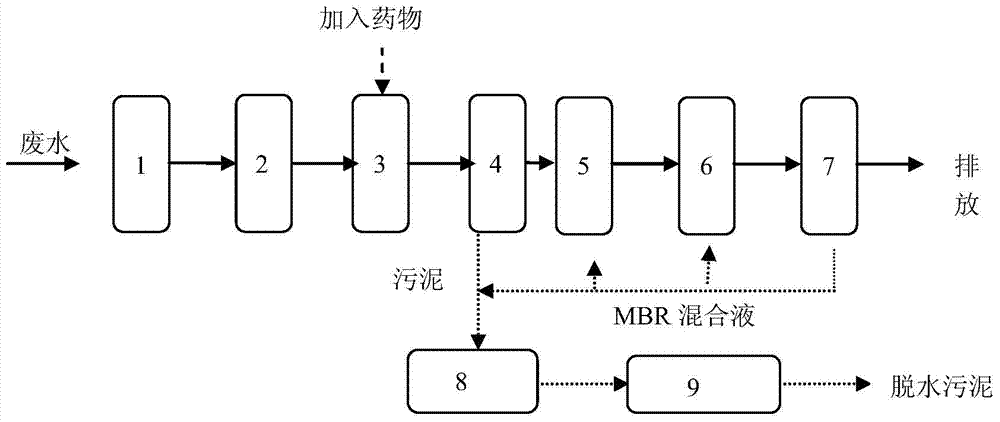

Device and process for treating photovoltaic organic wastewater

A kind of organic wastewater and photovoltaic technology, applied in the direction of water/sewage multi-stage treatment, neutralized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem that the effluent quality is difficult to meet the discharge standard, and achieve the slowdown of membrane pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

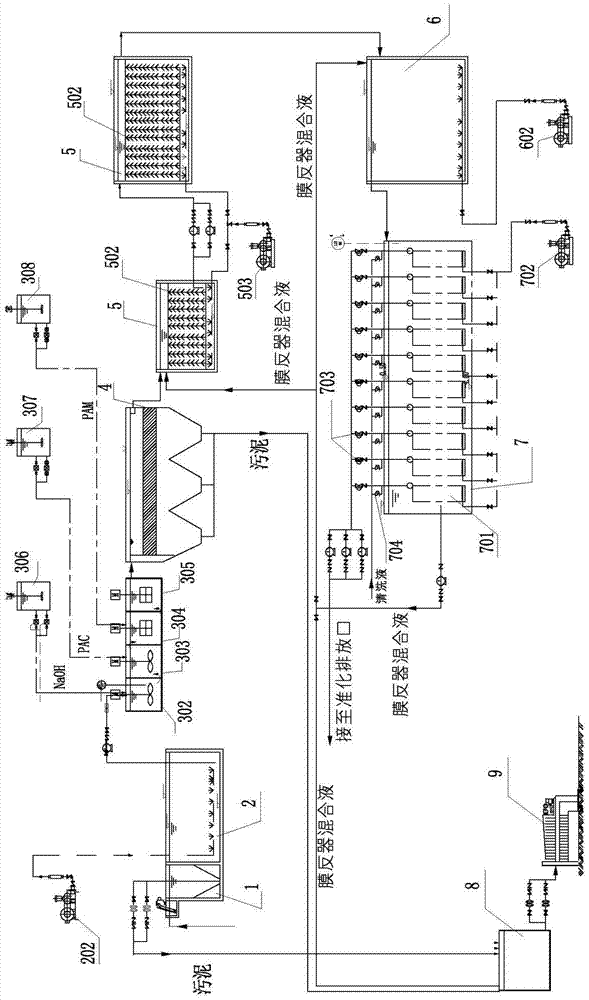

Method used

Image

Examples

Embodiment 1

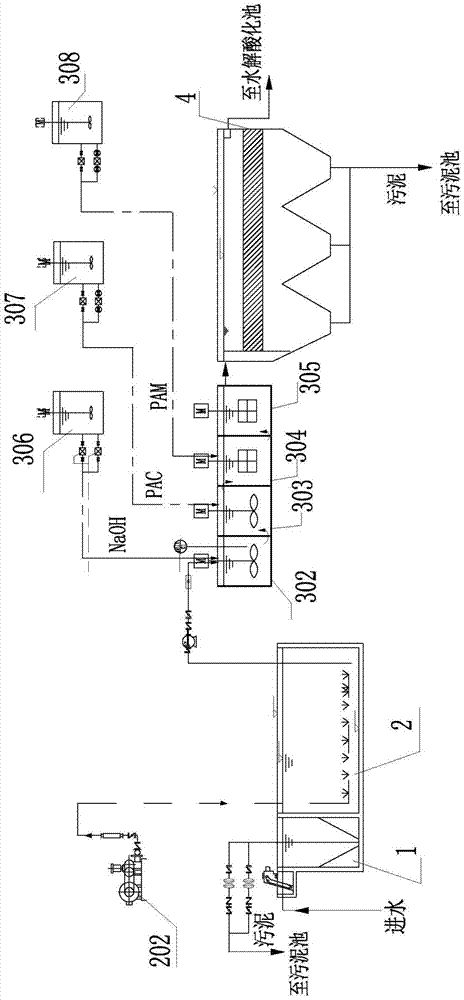

[0041] (1) Photovoltaic organic wastewater enters the grid collection tank 1 for a residence time of 0.5 hours. After preliminary precipitation, the sludge obtained by the precipitation is pumped into the sludge tank 8, and the liquid is lifted into the regulating tank 2 by the pump, and the residence time is 6 hours. , The ventilation equipment ventilates the bottom of the pretreatment tank 203 to homogenize the wastewater;

[0042] (2) The wastewater in the adjustment tank is sent to the reaction tank 3 through a lift pump, and the pH is adjusted in turn, and the coagulation and flocculation reactions are carried out; alkali (NaOH) is added to the pH adjustment tank, and the pH value is adjusted to 8-9. The coagulant PAC is added to the tank, the coagulant PAM is added to the flocculation tank A, and the flocculation reaction is carried out in the flocculation tank B; the ratio of the dosage of the coagulant and the flocculant to the wastewater is 500mg / L; The residence time in...

Embodiment 2

[0060] A photovoltaic cell company 1320t / d photovoltaic organic wastewater treatment, design influent COD cr ≤3000mg / L; SS≤800mg / L, effluent quality COD cr ≤100mg / L; SS≤5mg / L.

[0061] The treatment process is the same as that of Example 1, the difference is that in step (1), the residence time in the grid sump (1) is 1 hour, the residence time in the adjustment tank is 7.5 hours; the sedimentation tank is an inclined plate sedimentation tank.

[0062] Among them, 10 sets of hollow fiber membrane modules of Zhejiang University Qiushi Membrane are used in the membrane reactor pool. After more than 3 years of operation, the effluent COD is stable below 100mg / L, SS is less than 5mg / L, and the membrane modules are cleaned once more than half a year on average. The effluent quality is stable and membrane pollution is effectively controlled. As shown in Table 3.

[0063] table 3

[0064]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com