Patents

Literature

110results about How to "Eliminate scaling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

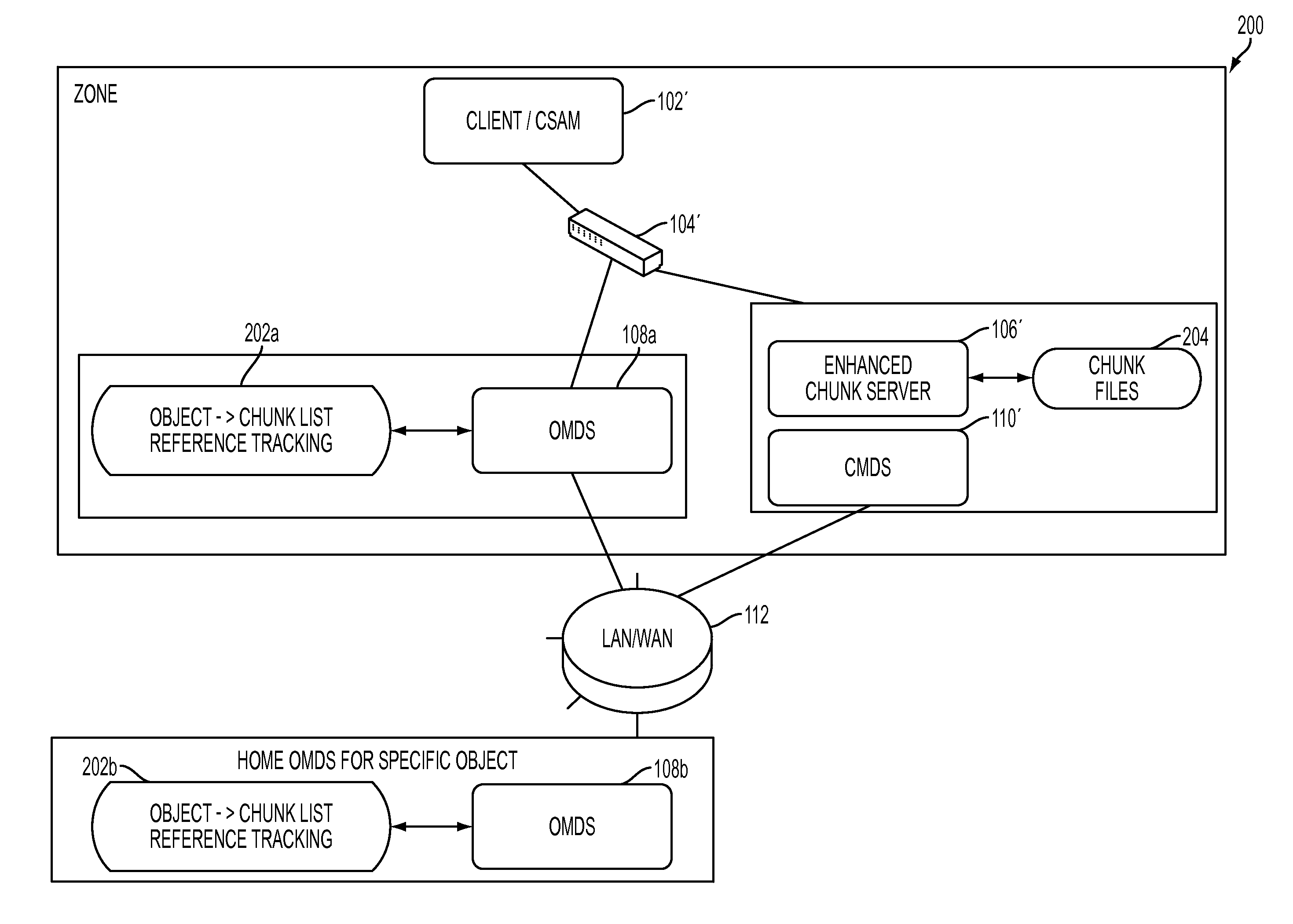

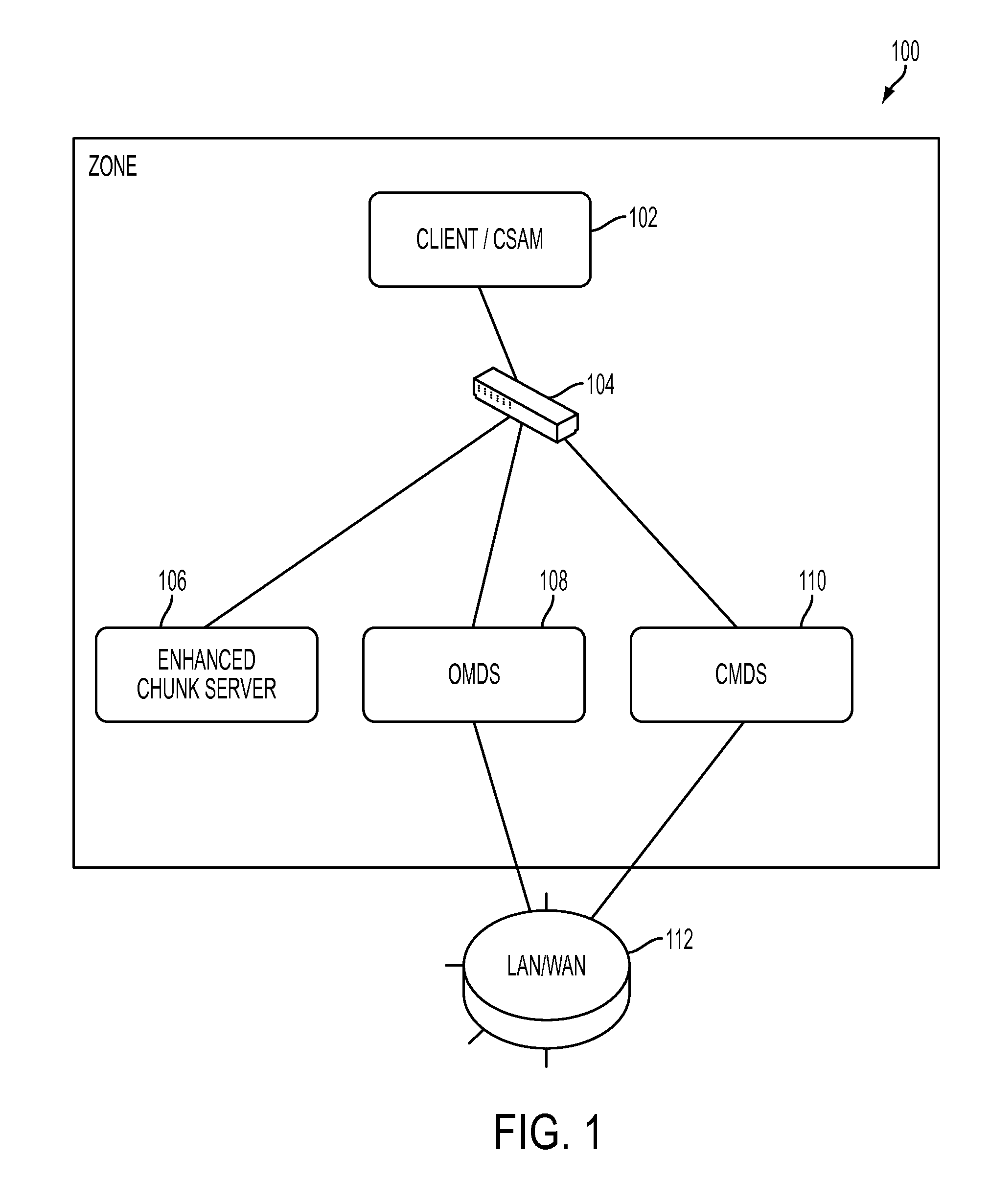

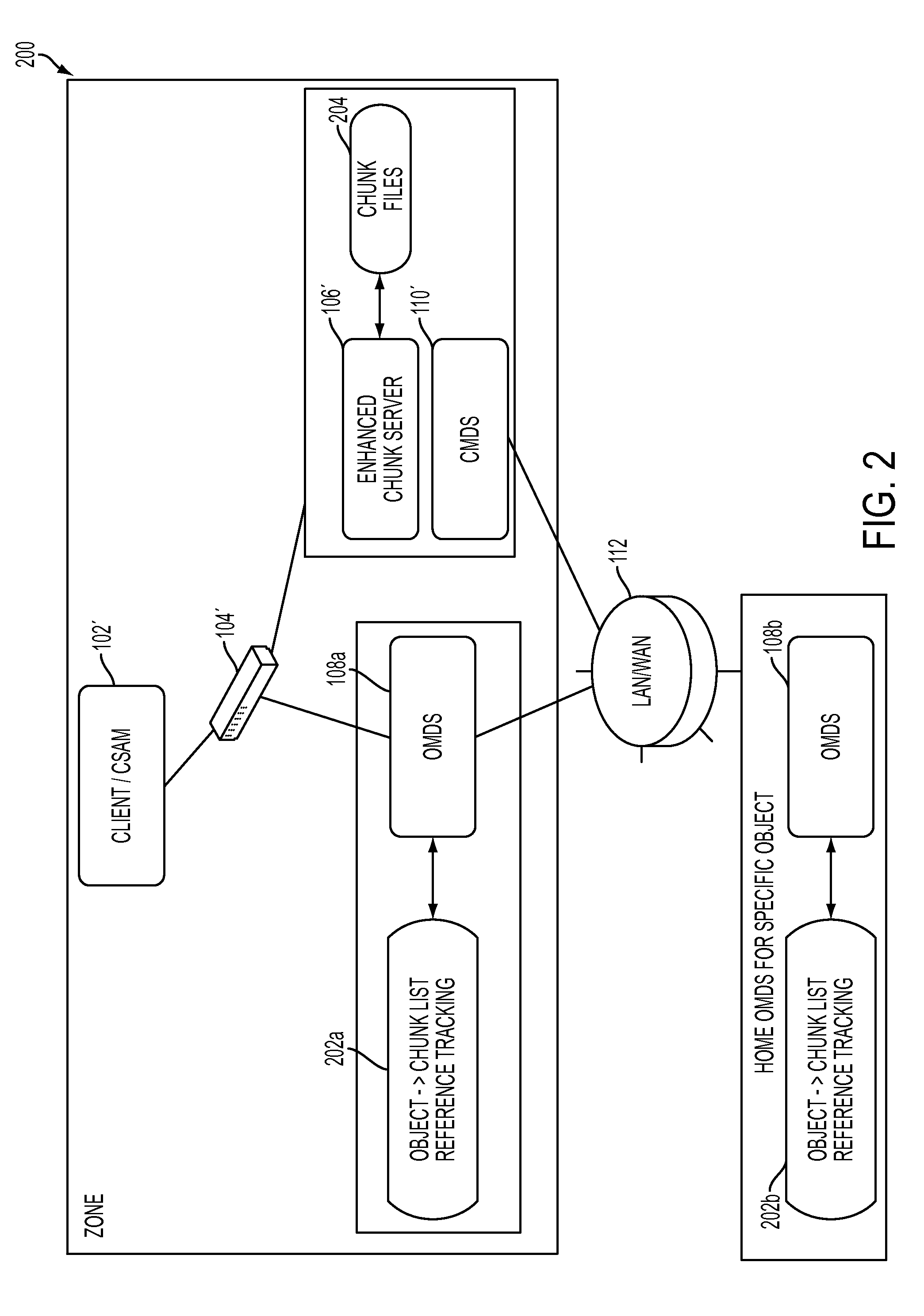

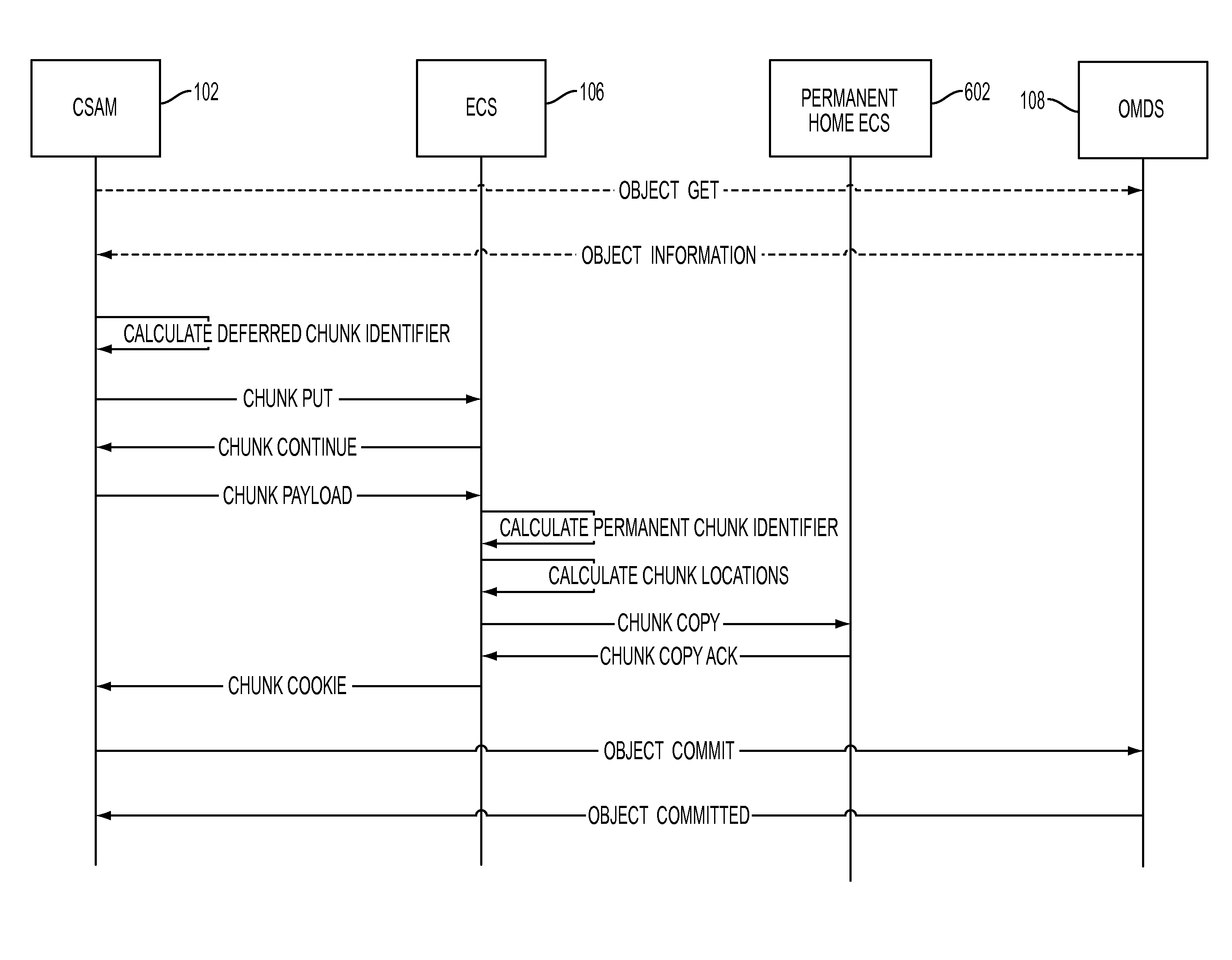

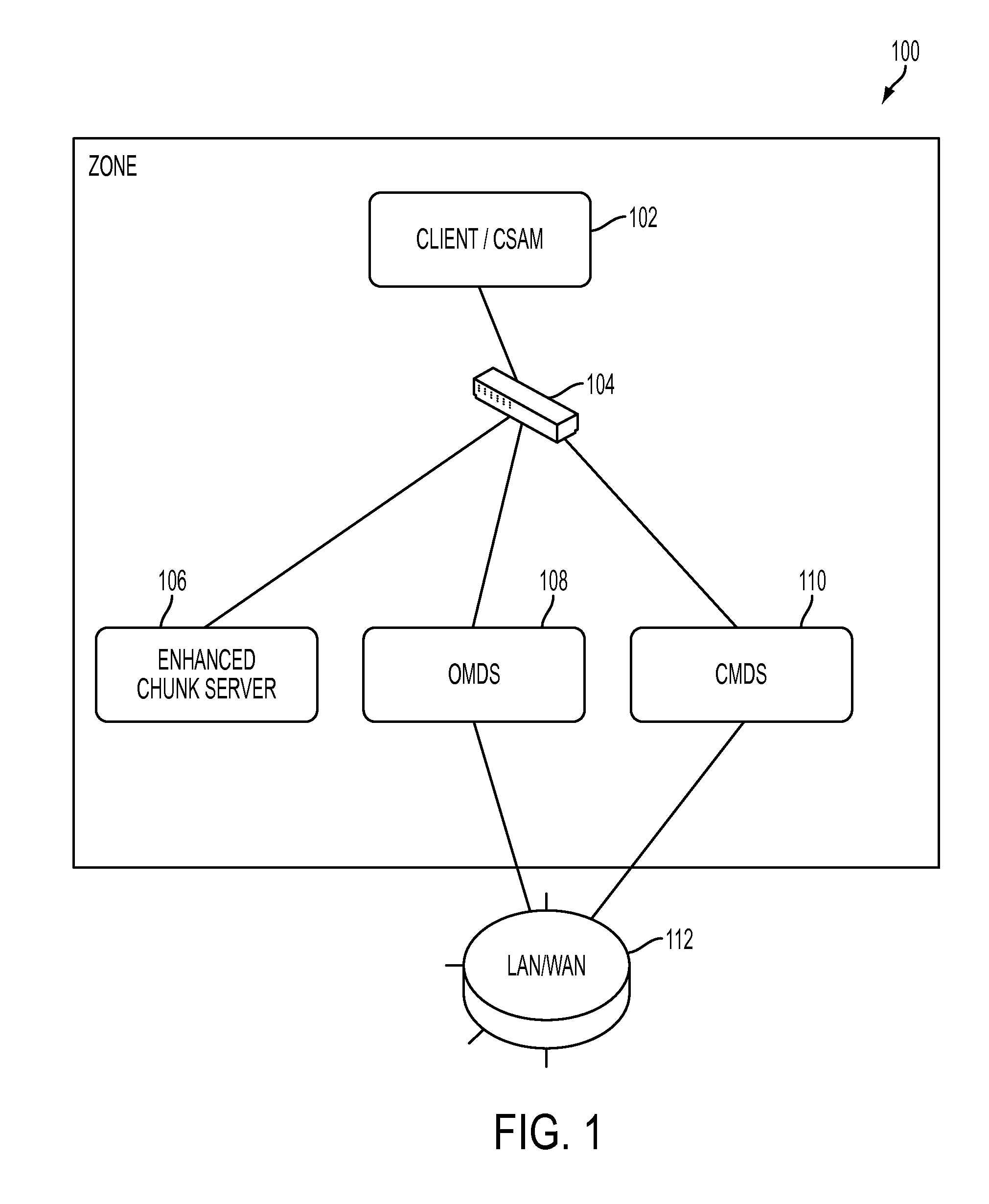

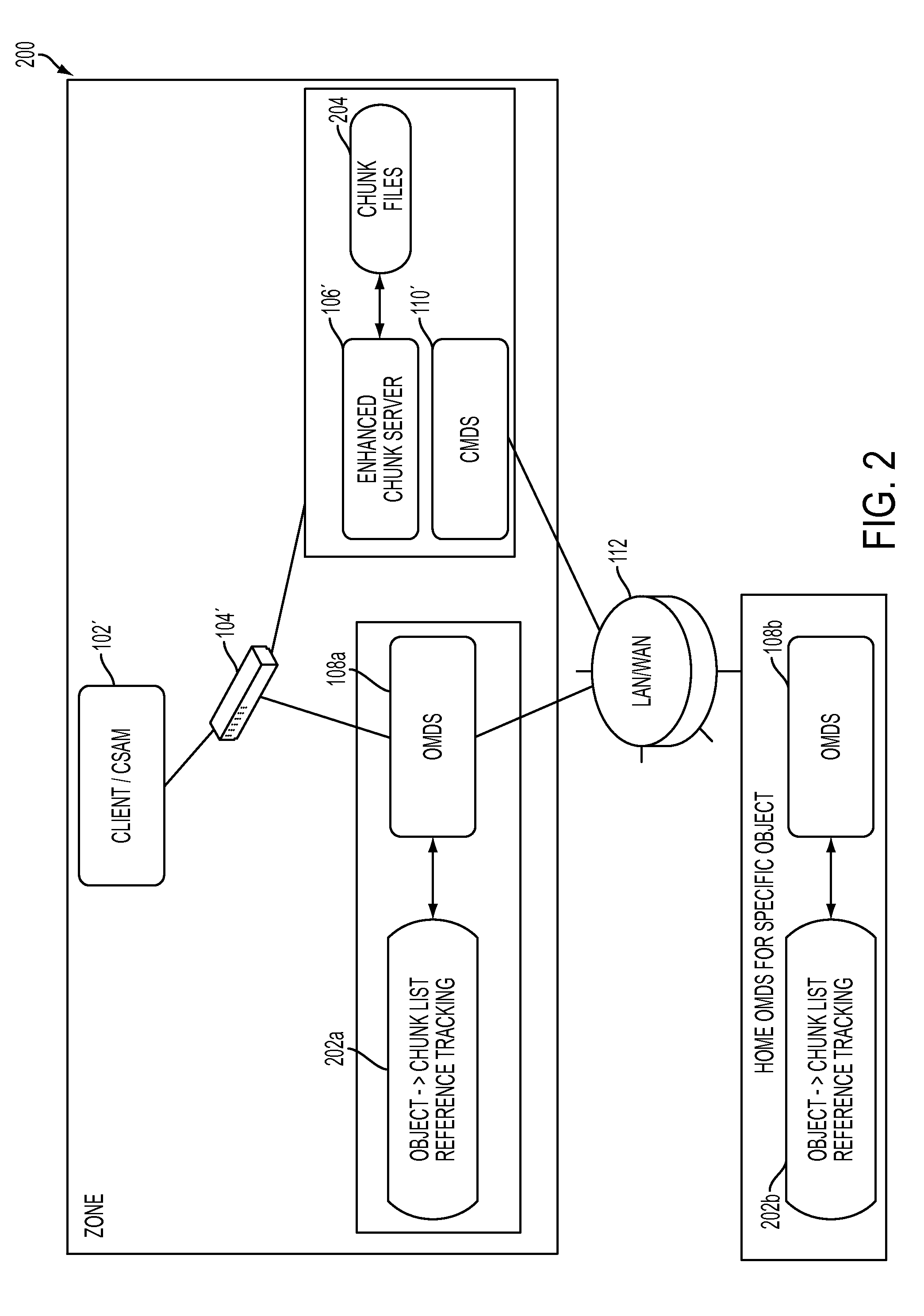

Cloud storage system with distributed metadata

ActiveUS20130041872A1Scale wellEfficient storageDigital data information retrievalDigital data processing detailsClient-sideLocation aware

A method and system is disclosed for providing a cloud storage system supporting existing APIs and protocols. The method of storing cloud storage system (CSS) object metadata separates object metadata that describes each CSS object as a collection of named chunks with chunk locations specified as a separate part of the metadata. Chunks are identified using globally unique permanent identifiers that are never re-used to identify different chunk payload. While avoiding the bottleneck of a single metadata server, the disclosed system provides ordering guarantees to clients such as guaranteeing access to the most recent version of an object. The disclosed system also provides end-to-end data integrity protection, inline data deduplication, configurable replication, hierarchical storage management and location-aware optimization of chunk storage.

Owner:NEXENTA BY DDN INC

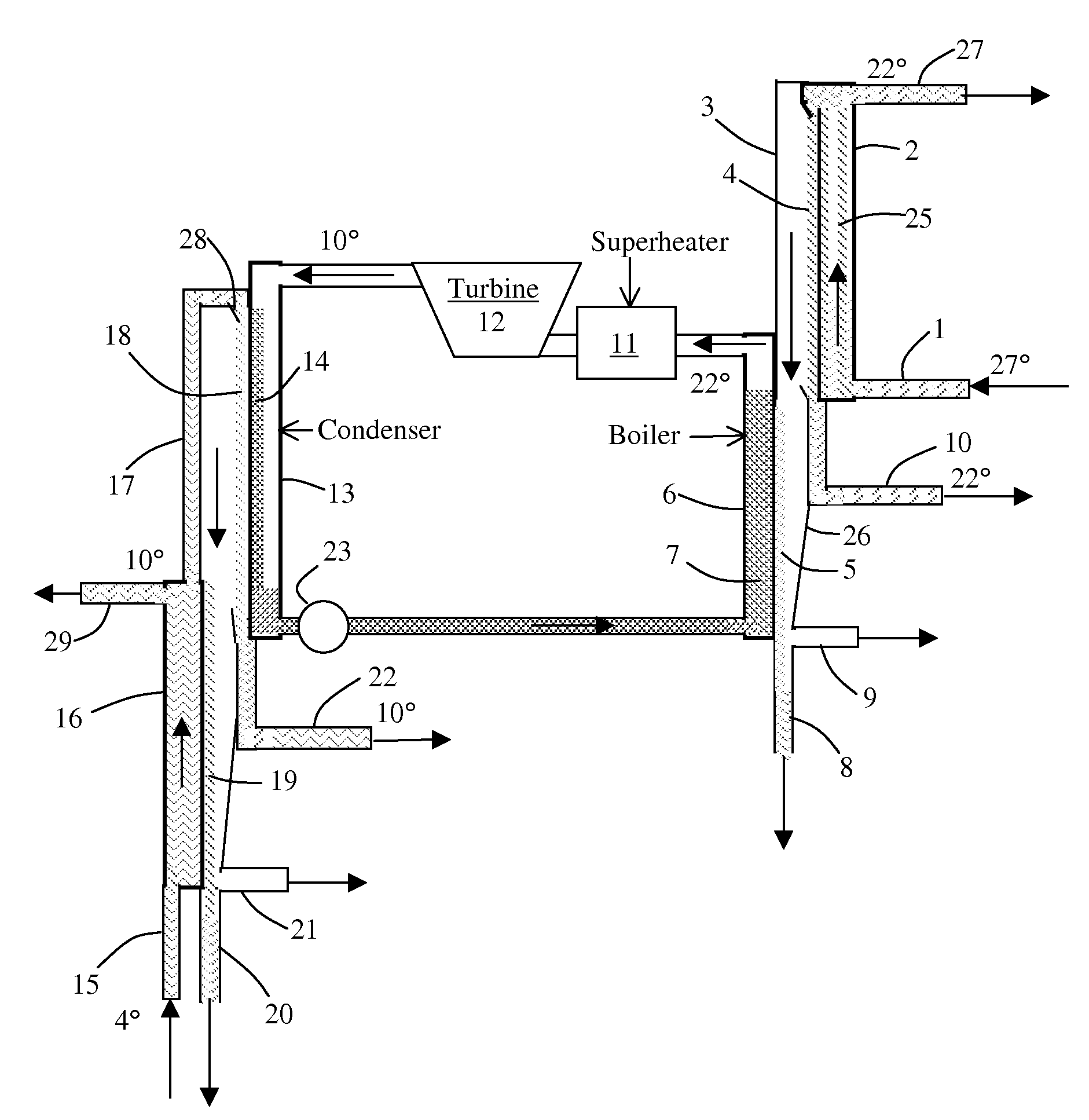

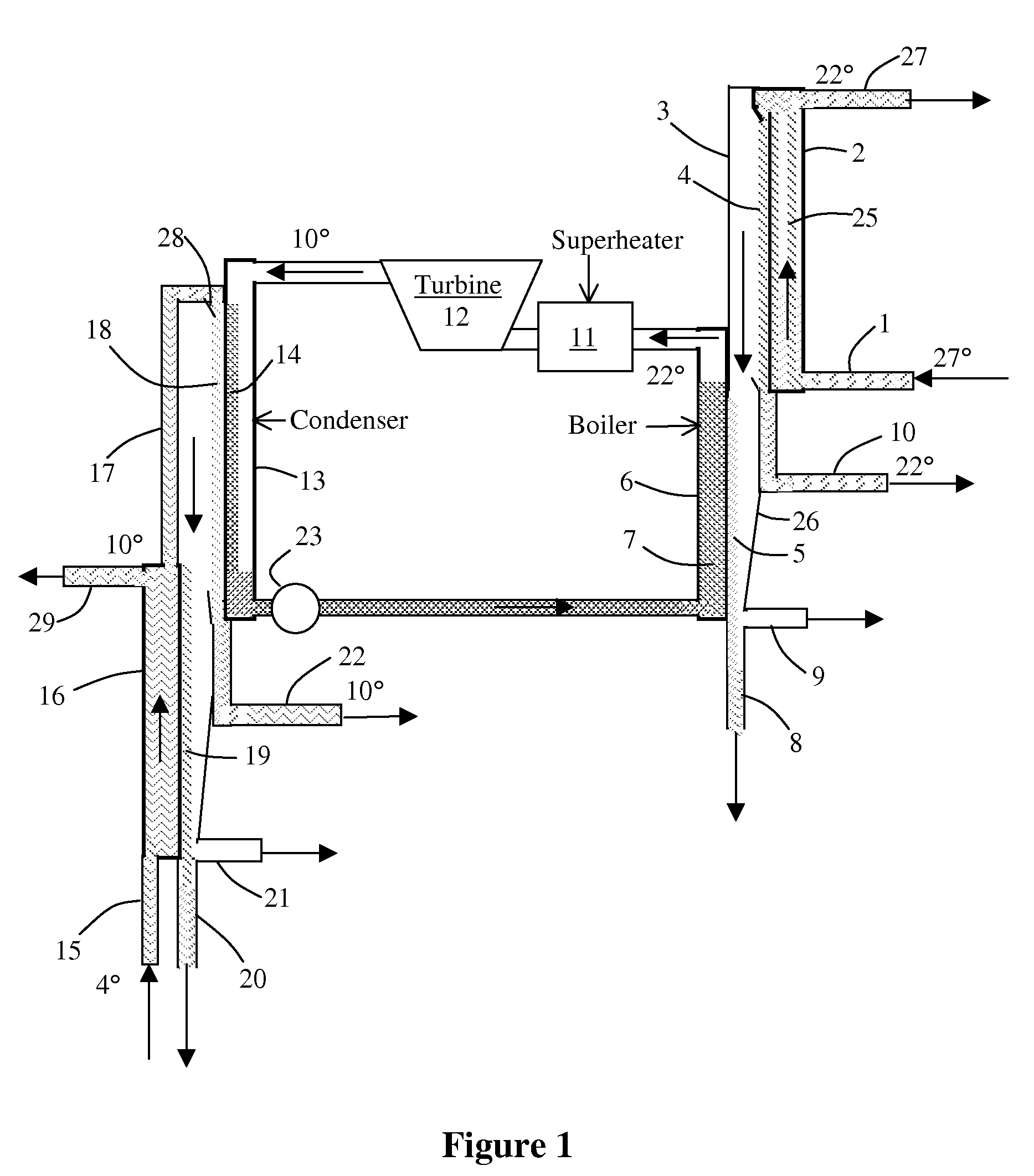

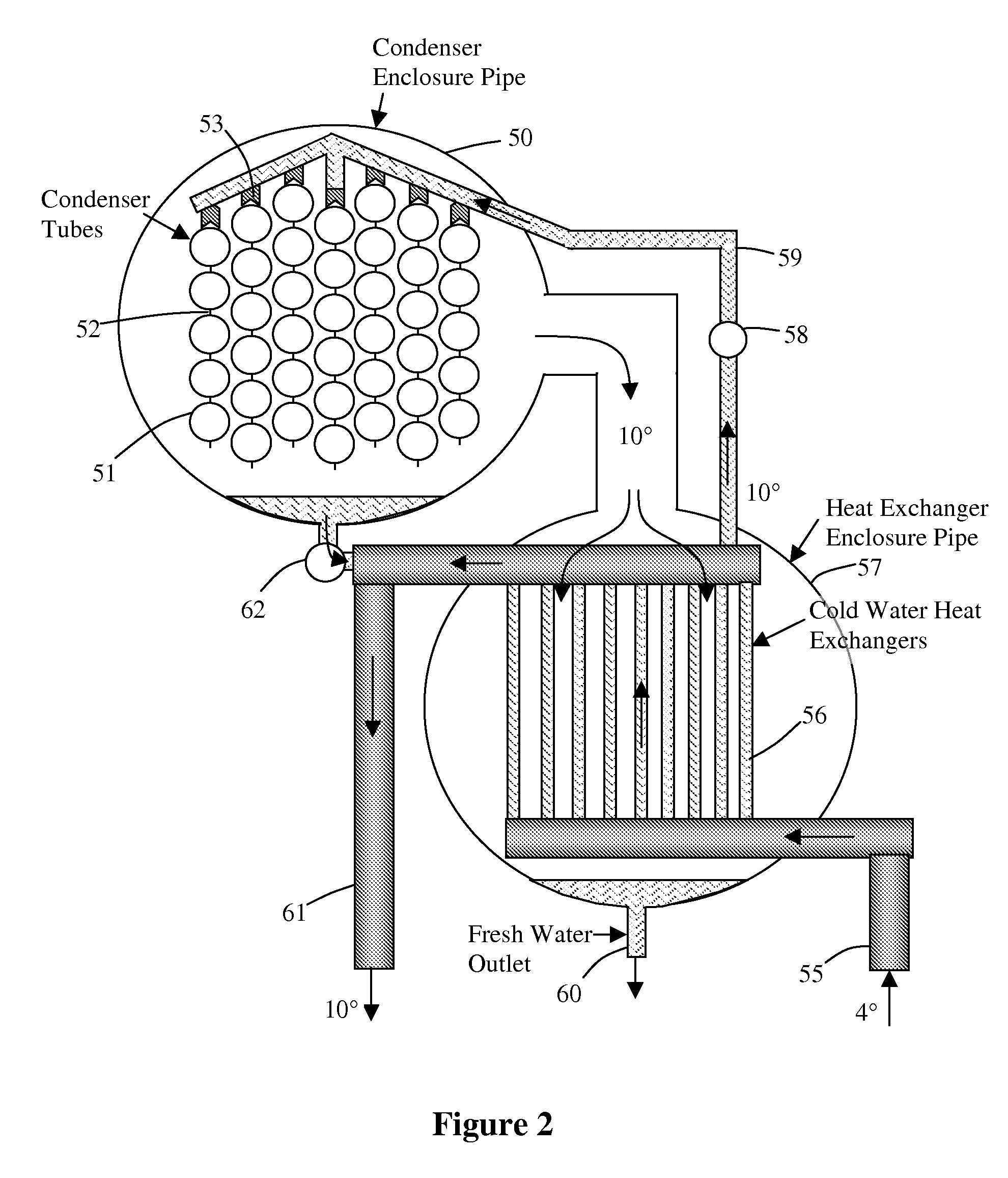

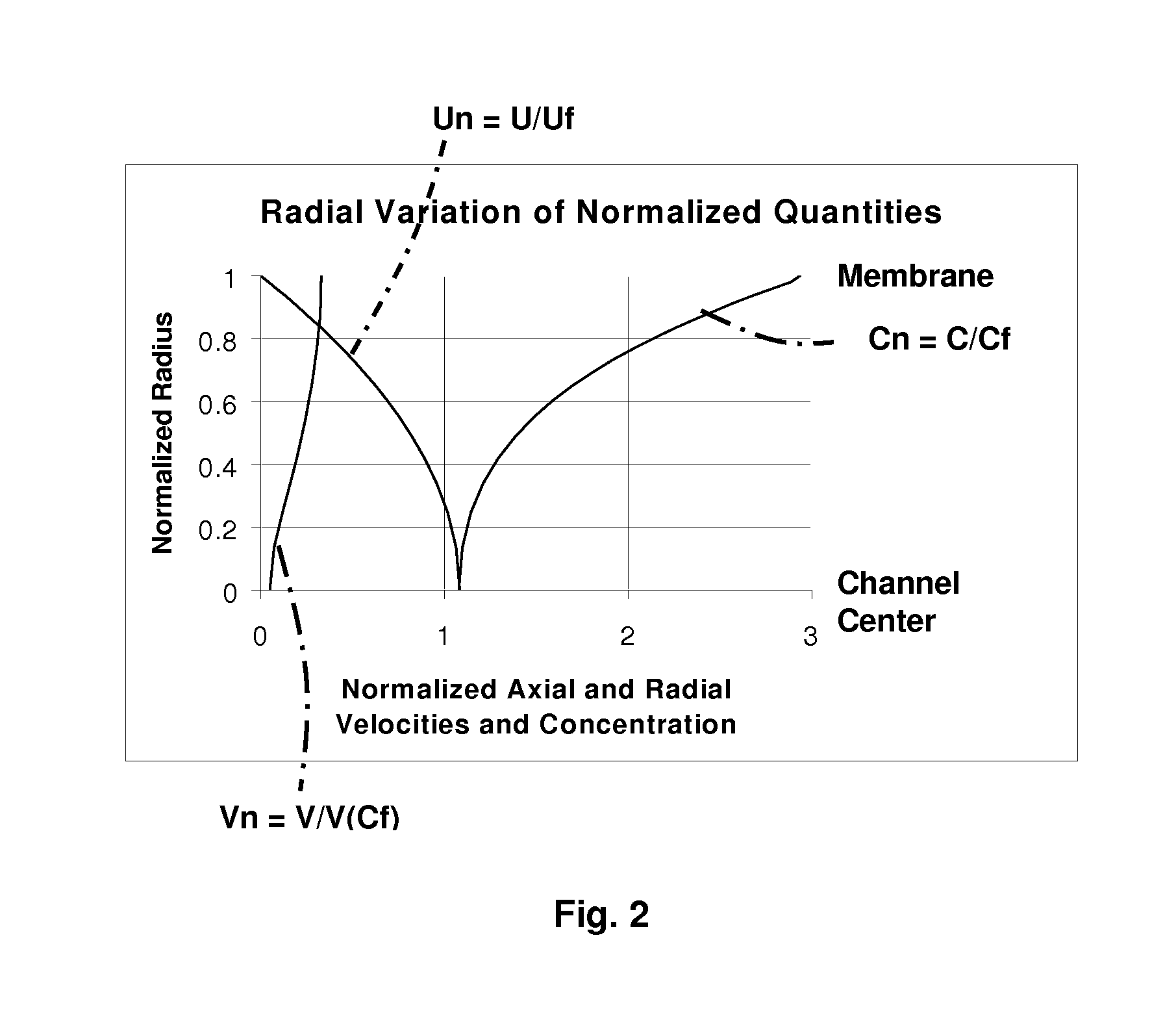

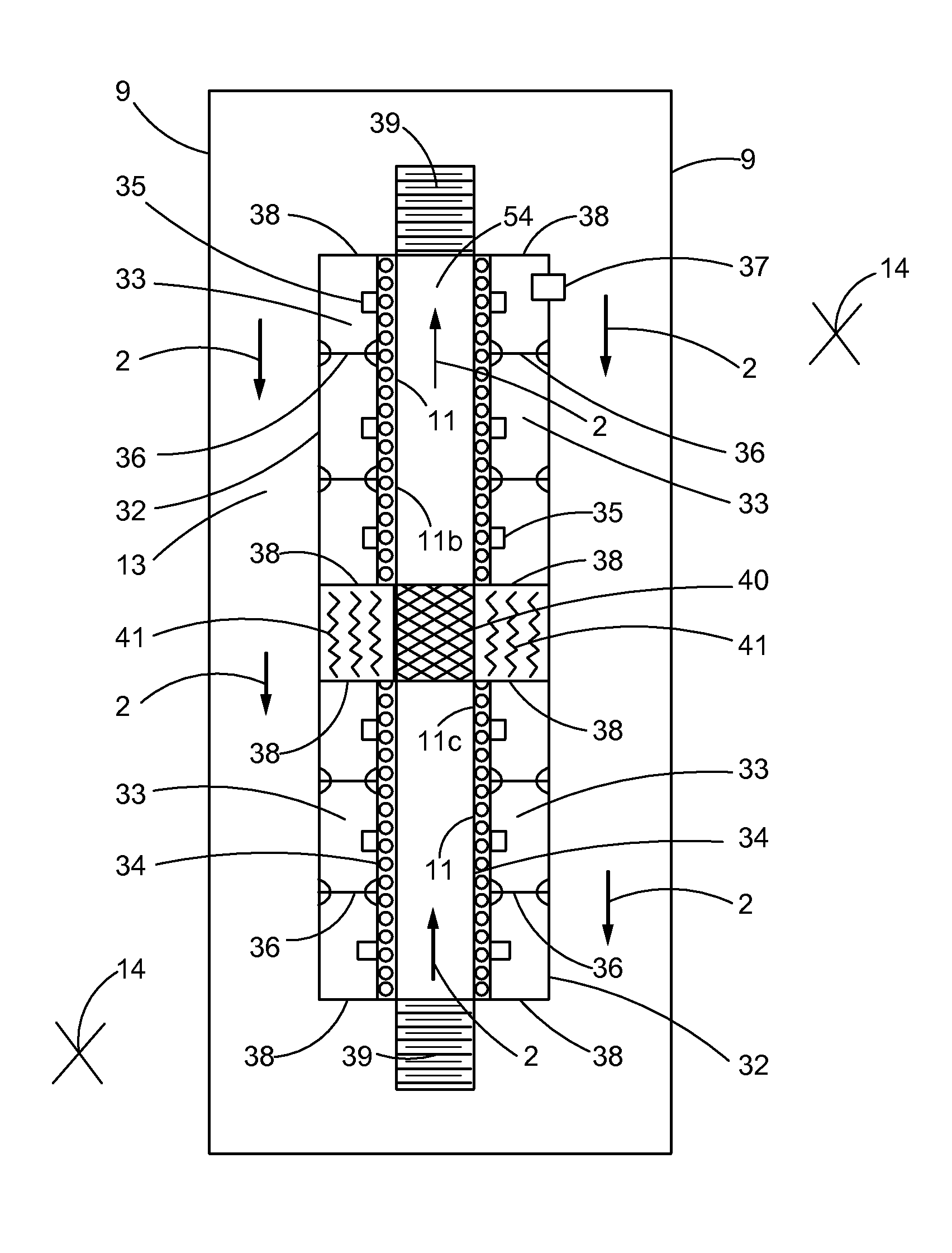

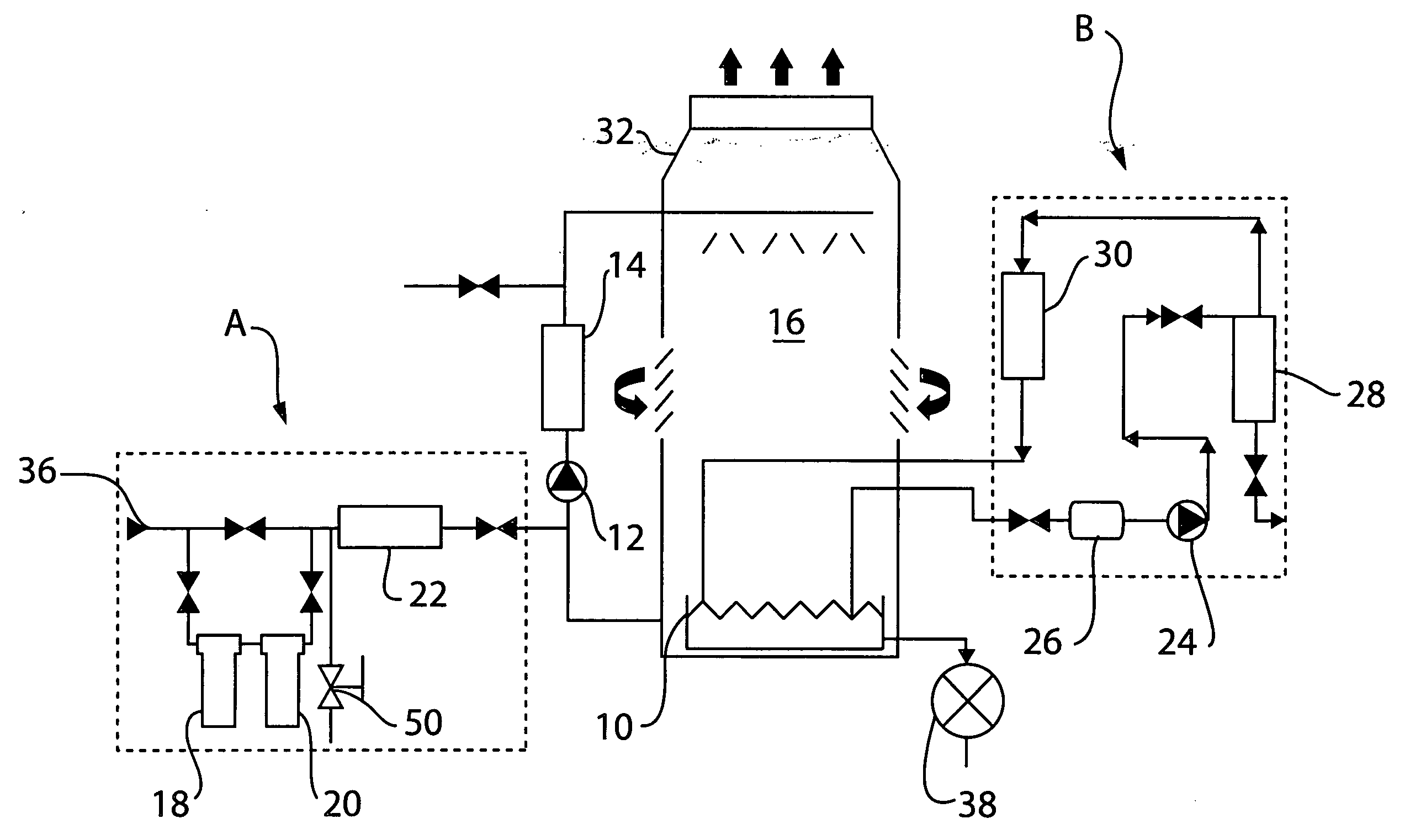

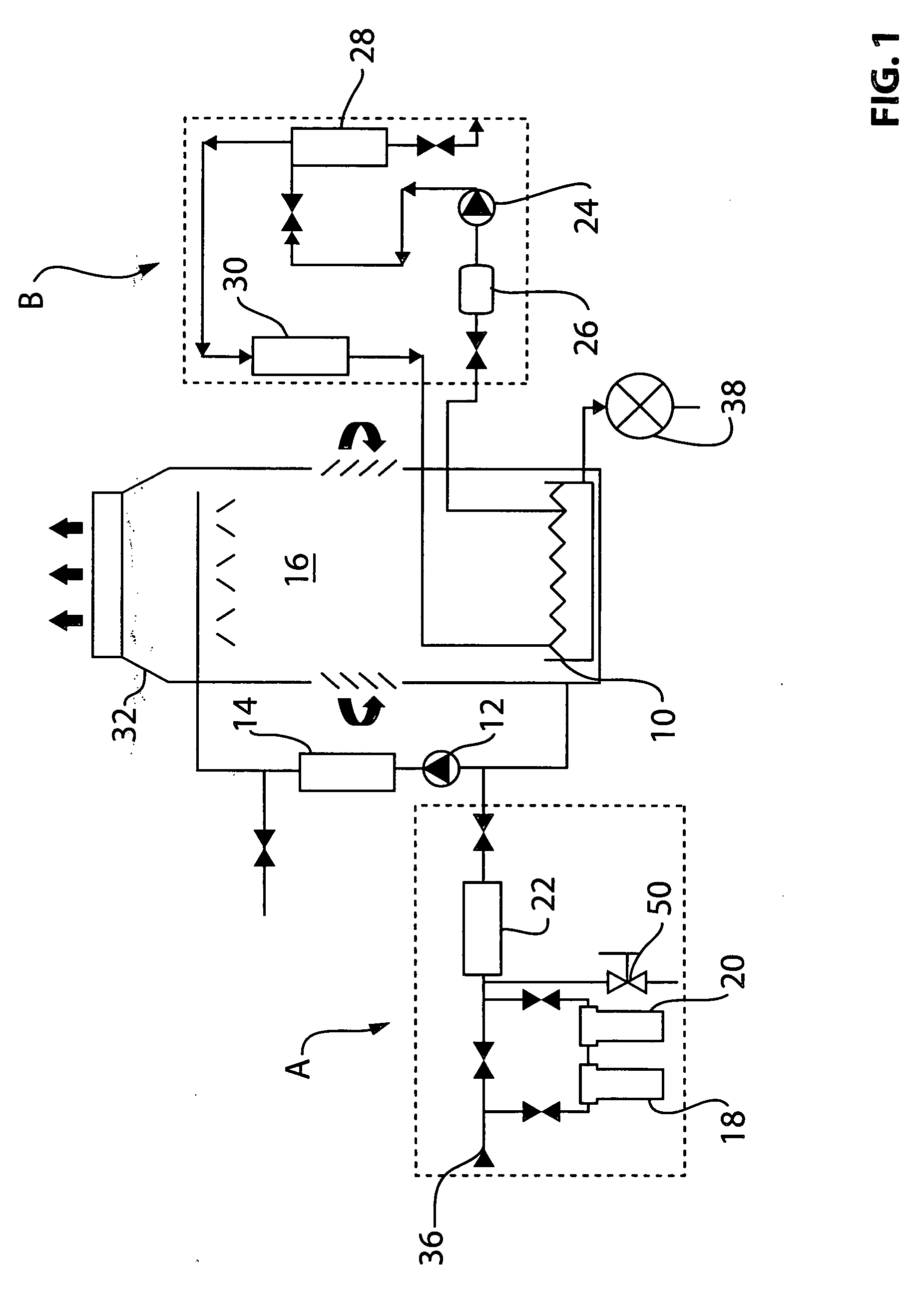

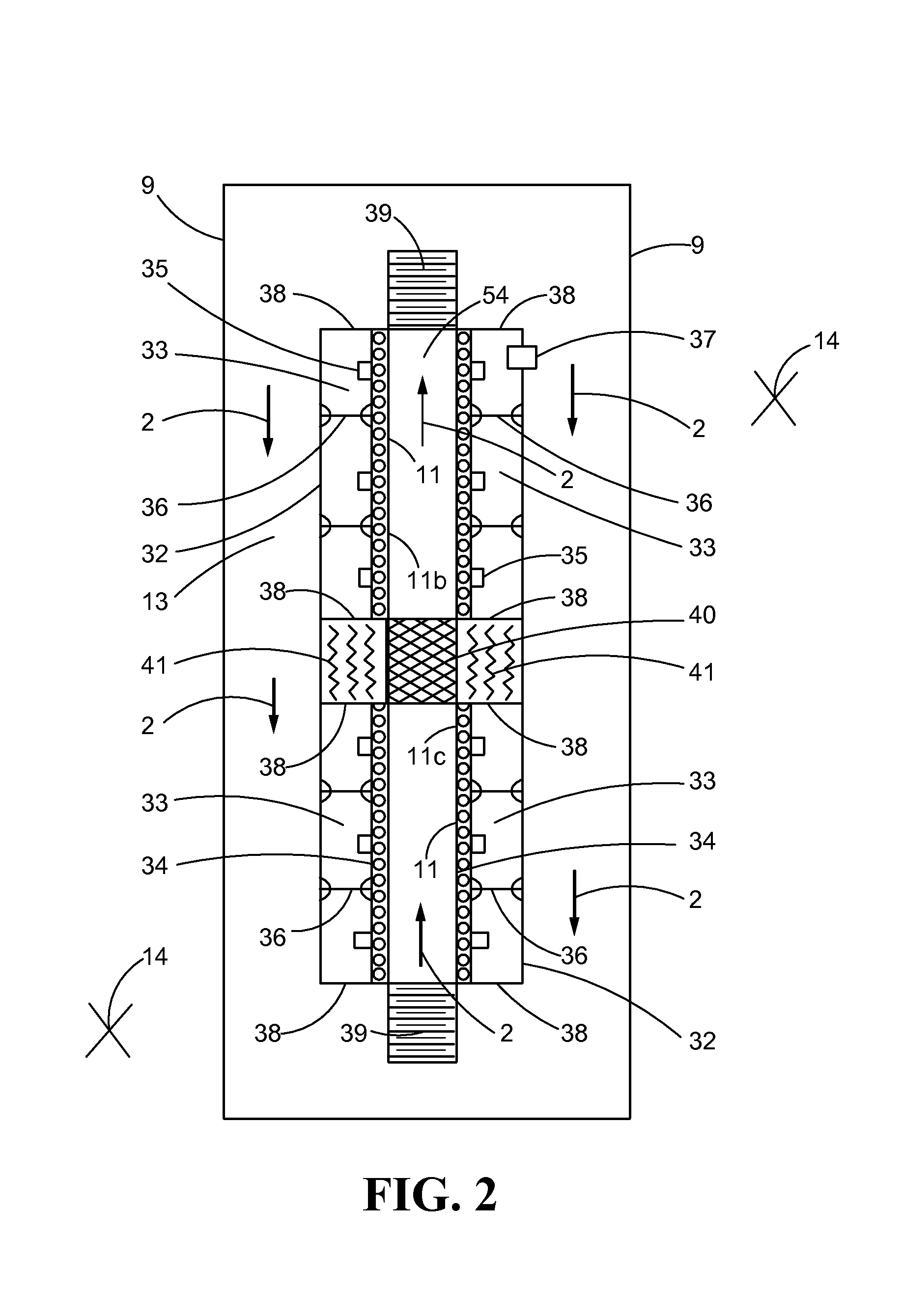

Heat Transfer Methods for Ocean Thermal Energy Conversion and Desalination

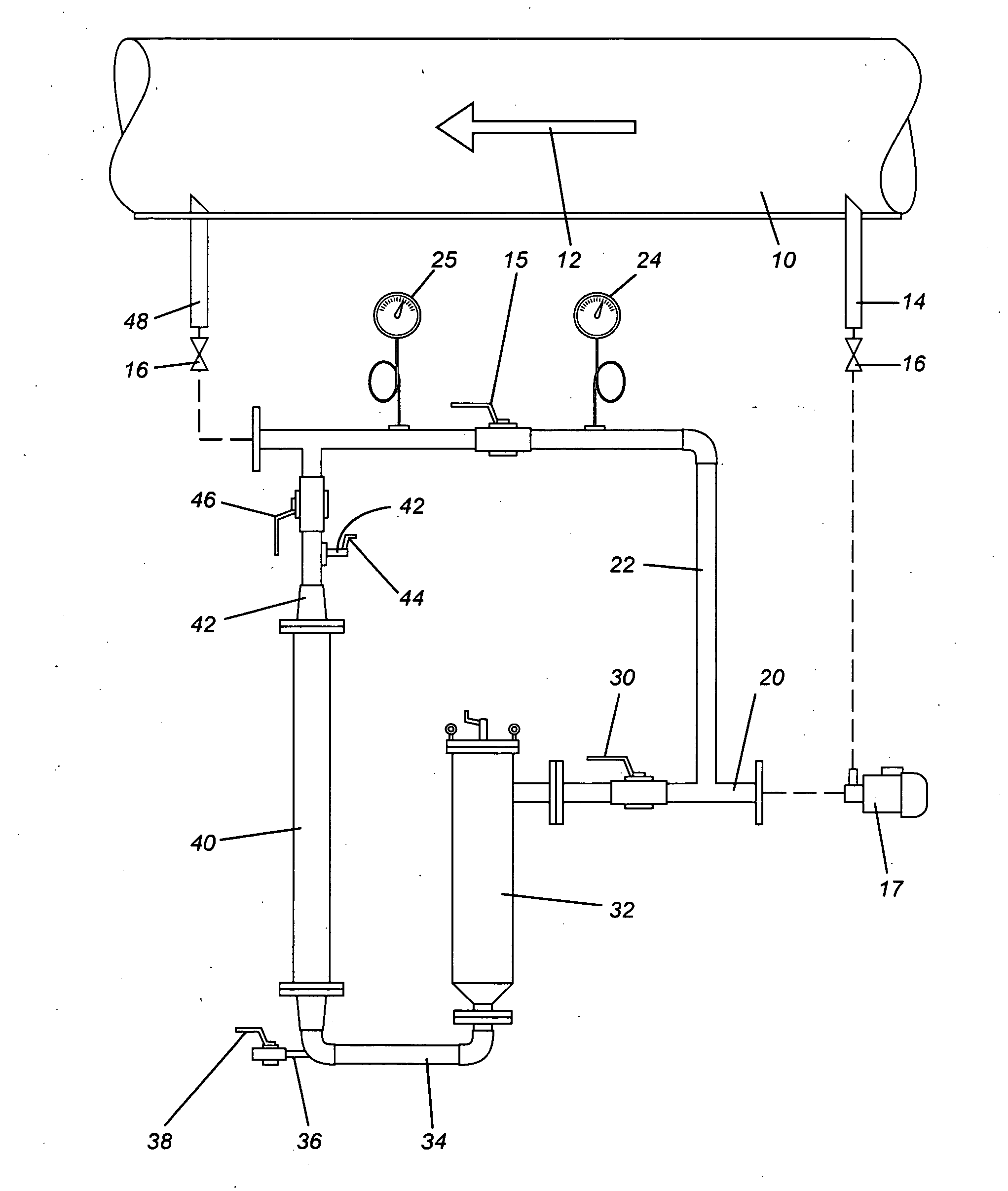

InactiveUS20090077969A1Eliminate scalingPrevent buildupGeneral water supply conservationBarometric condensationOcean thermal energy conversionWater discharge

A means is provided to produce fresh water from seawater on both the boiler side and the condenser side of an OTEC power plant. Part of the warm ocean surface water is evaporated, and its vapor transfers heat to the working-fluid boiler as the vapor condenses. The condensation of the vapor provides fresh water. On the condenser side, the condensation of the working-fluid vapor from the turbine in the condenser releases heat that evaporates seawater that runs down the outside of the condenser surfaces. The vapor from the seawater is condensed by a heat exchanger that uses input from colder seawater. As the cold seawater accepts heat from the condensing vapor, it becomes slightly warmer and provides the source of seawater that accepts heat from the condenser. The condensing vapor on the heat exchanger becomes fresh water that is drawn out as potable water. To provide additional fresh water, a multi-stage desalination unit uses the warm water discharge and the cold-water discharge from the OTEC plant to provide a temperature gradient that causes evaporation and condensation in each stage of the unit.

Owner:PRUEITT MELVIN L

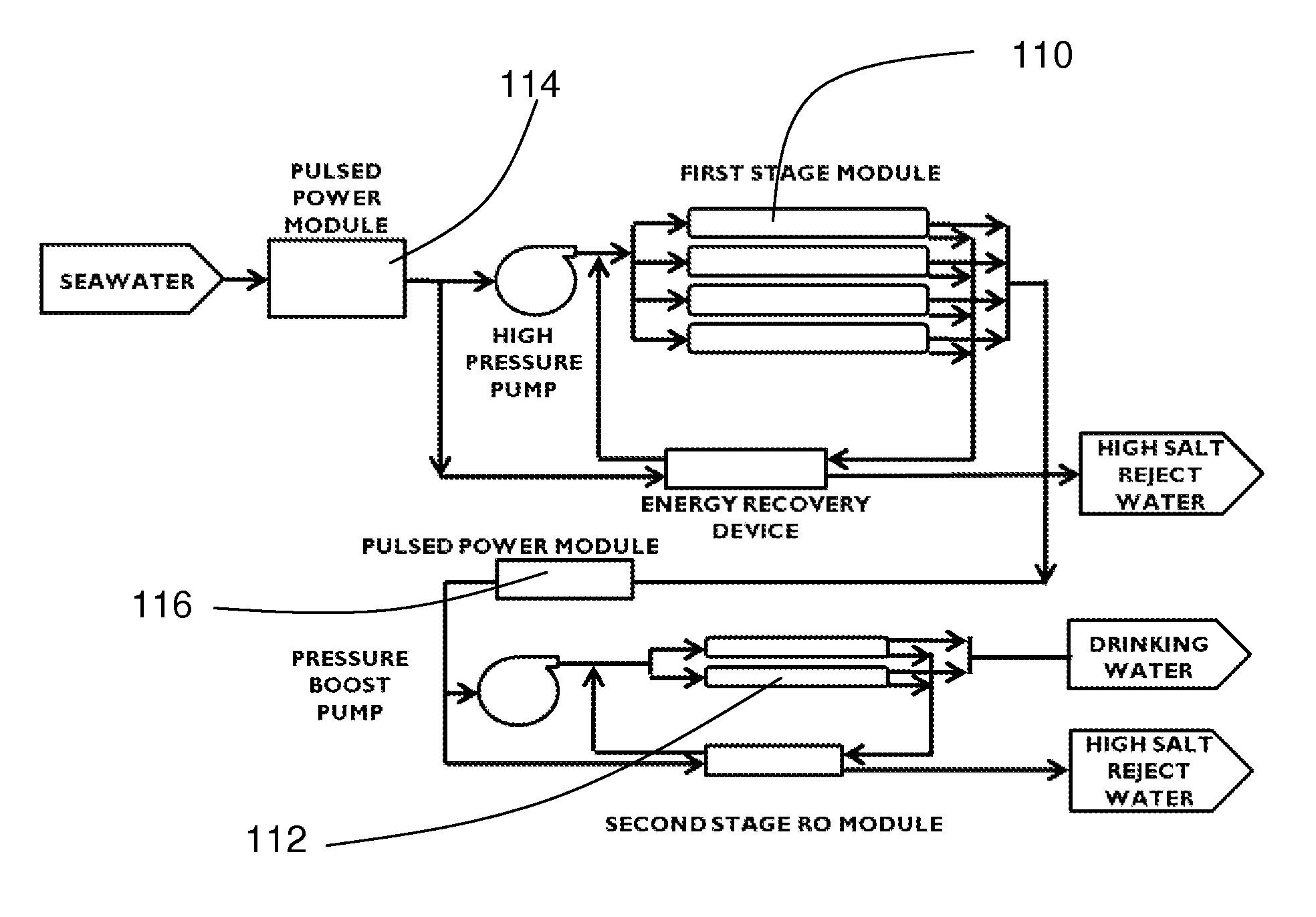

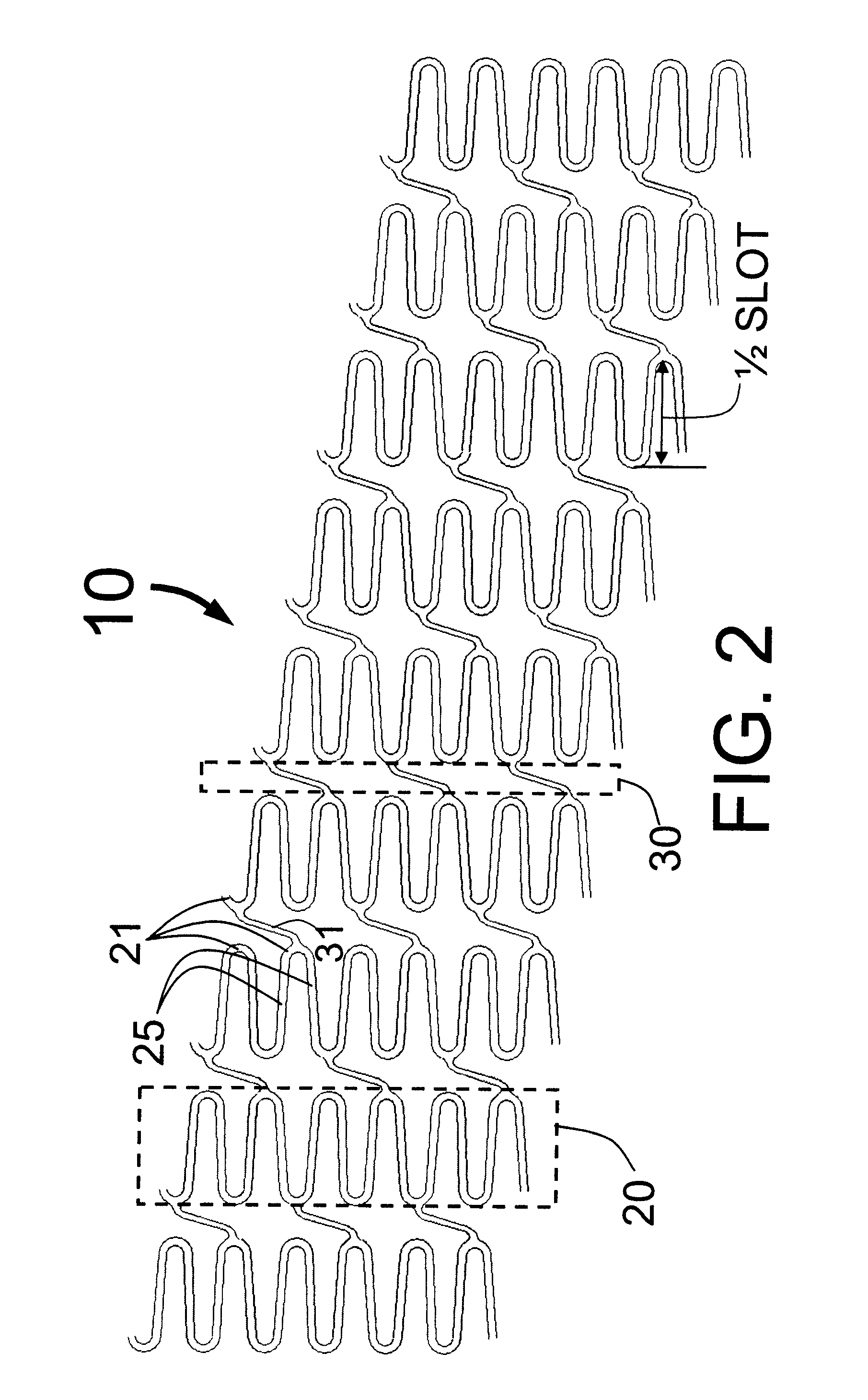

Systems and methods for filtration

InactiveUS20120298578A1Reduce foulingImprove water qualityMaterial nanotechnologyGeneral water supply conservationMicroorganismFiltration membrane

Filtration systems (40) utilize a pre-treatment method to cause scale formation to occur on particles (94) in the fluid stream (96) rather than on the filter surface and may also destroy microorganisms in the fluid stream. More specifically, but not limited to, a filtration device can be a filtration membrane, such as spiral wound filtration membrane (60), that utilizes an open feed spacer (80), such for example an embossed or printed pattern on the membrane, to create a thin feed spacer channel which replaces a conventional feed spacer mesh material. System (40) further utilizes a treatment device (54) to enable a pulsed power, magnetic, electro-magnetic, electro-static, or hydrodynamic fluid treatment scheme to condition particles in the fluid stream (96) such that scale forming elements precipitate (94) on to the particles in the fluid stream rather than on the filtration surfaces.

Owner:AQUA MEMBRANES +1

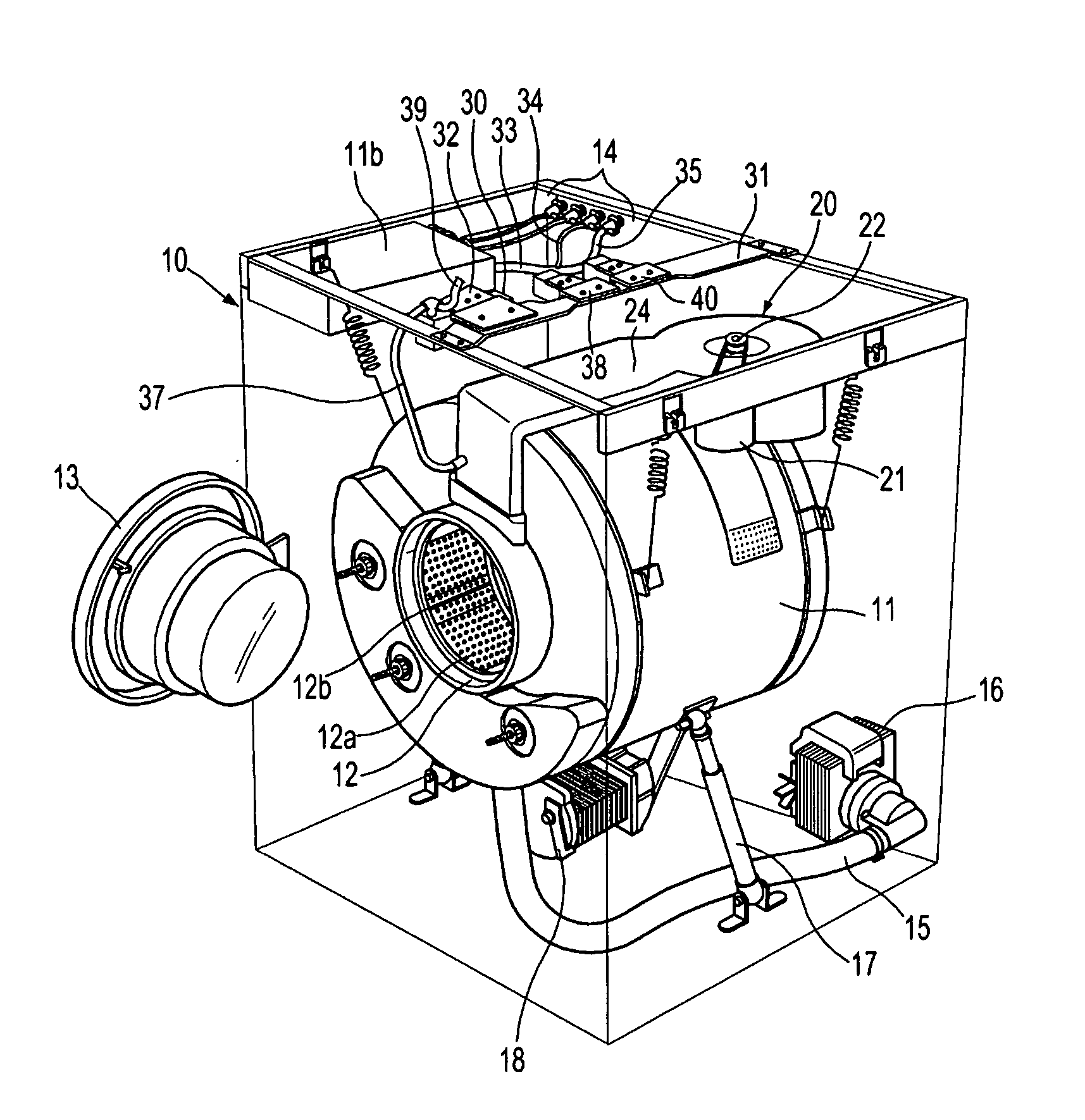

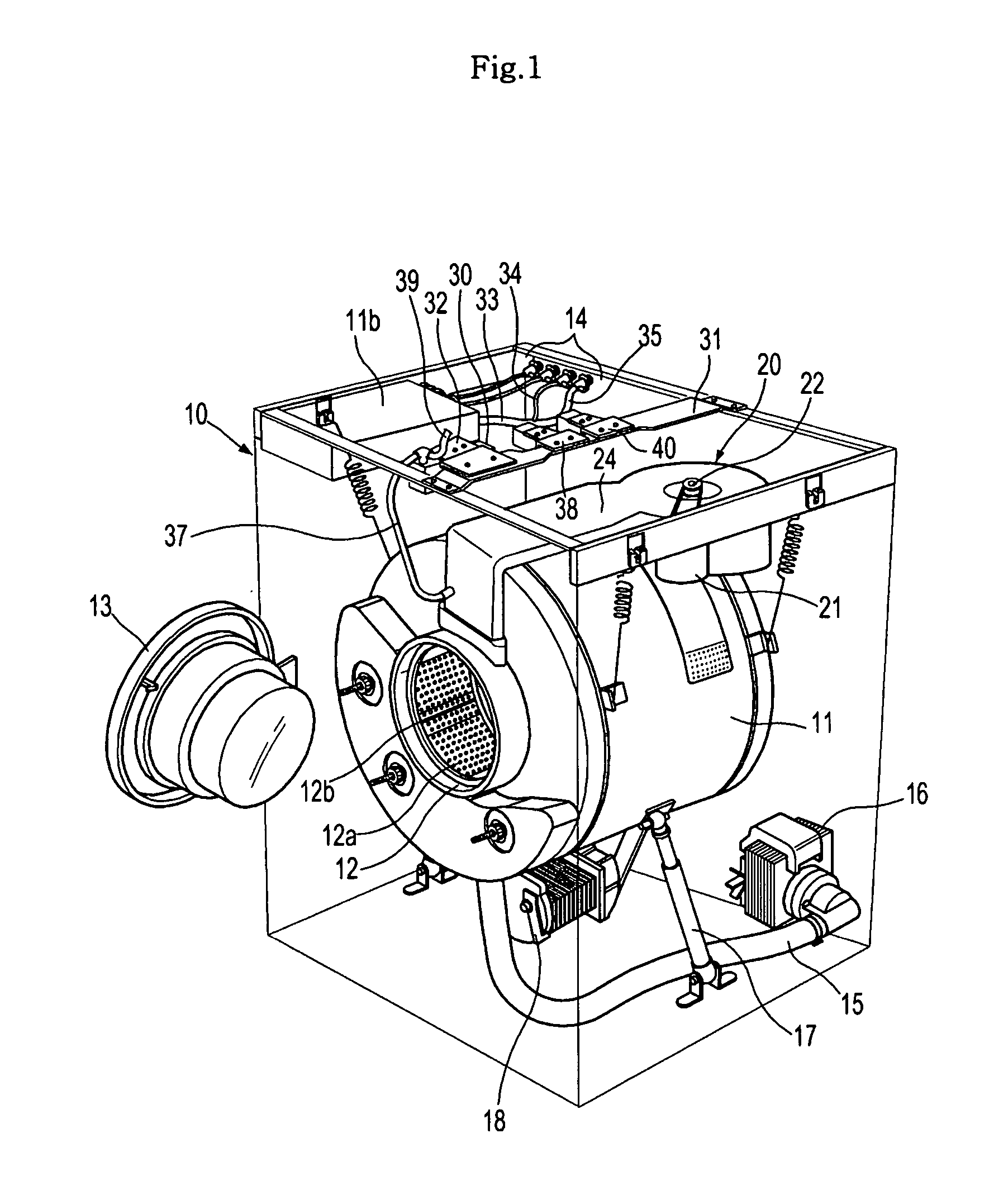

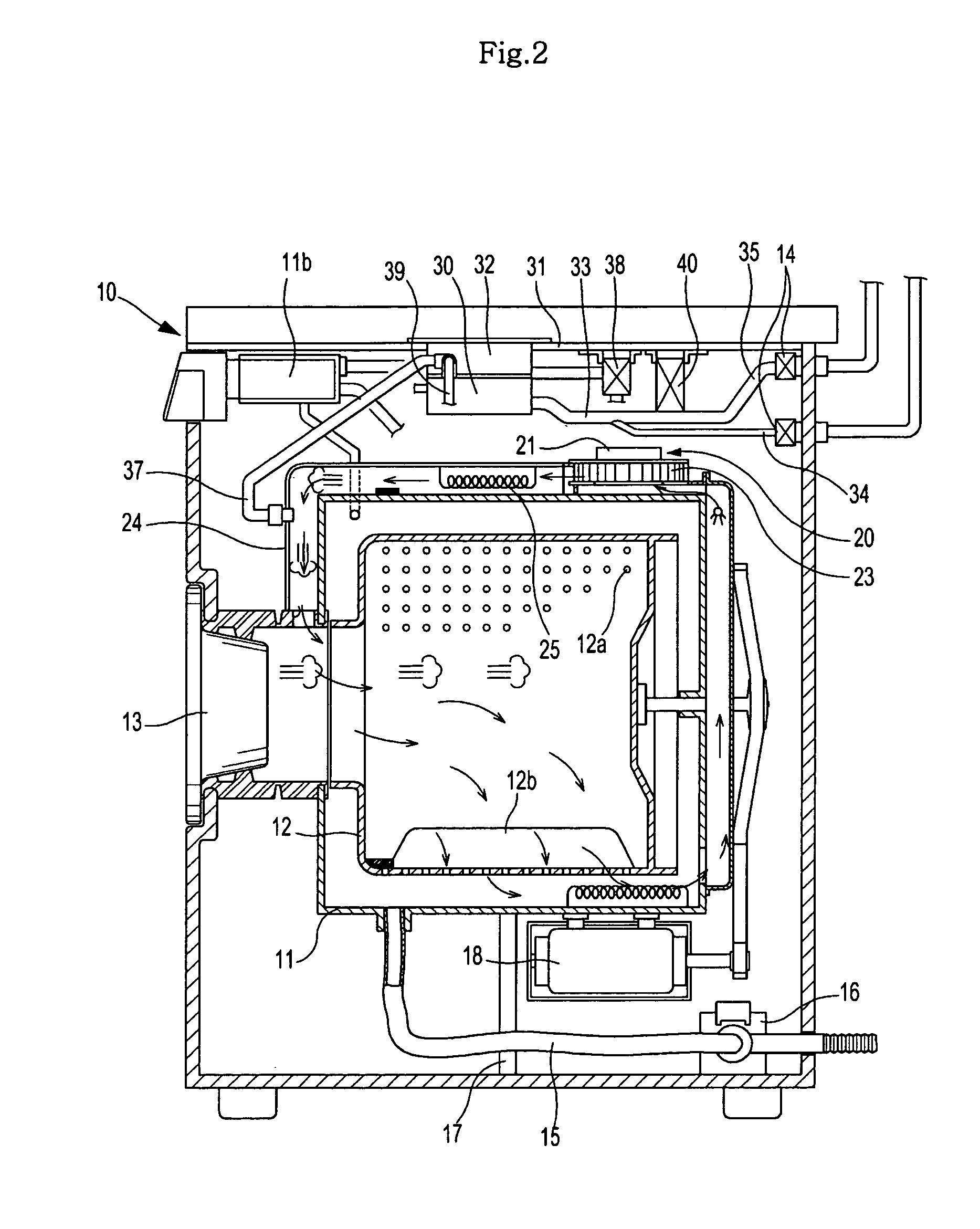

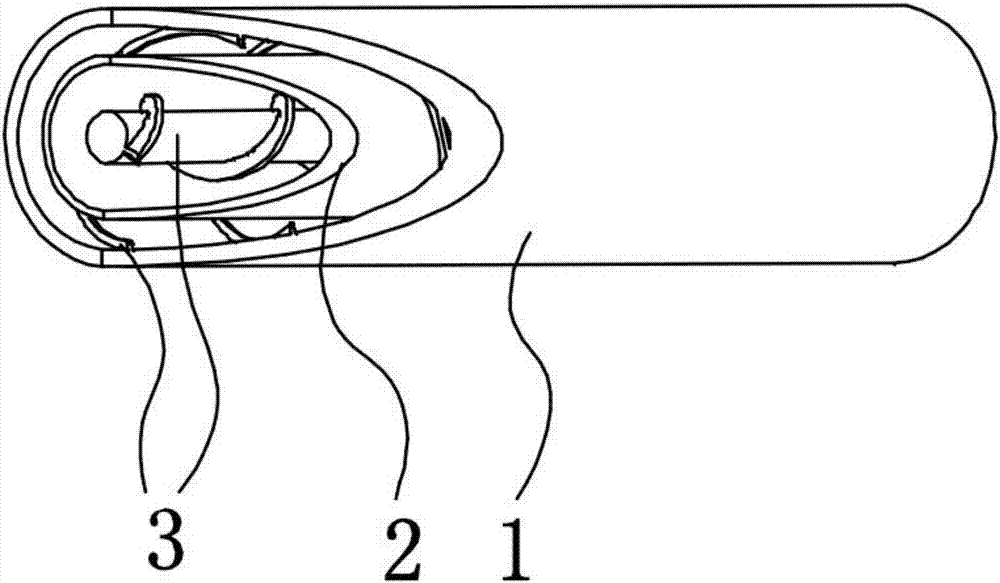

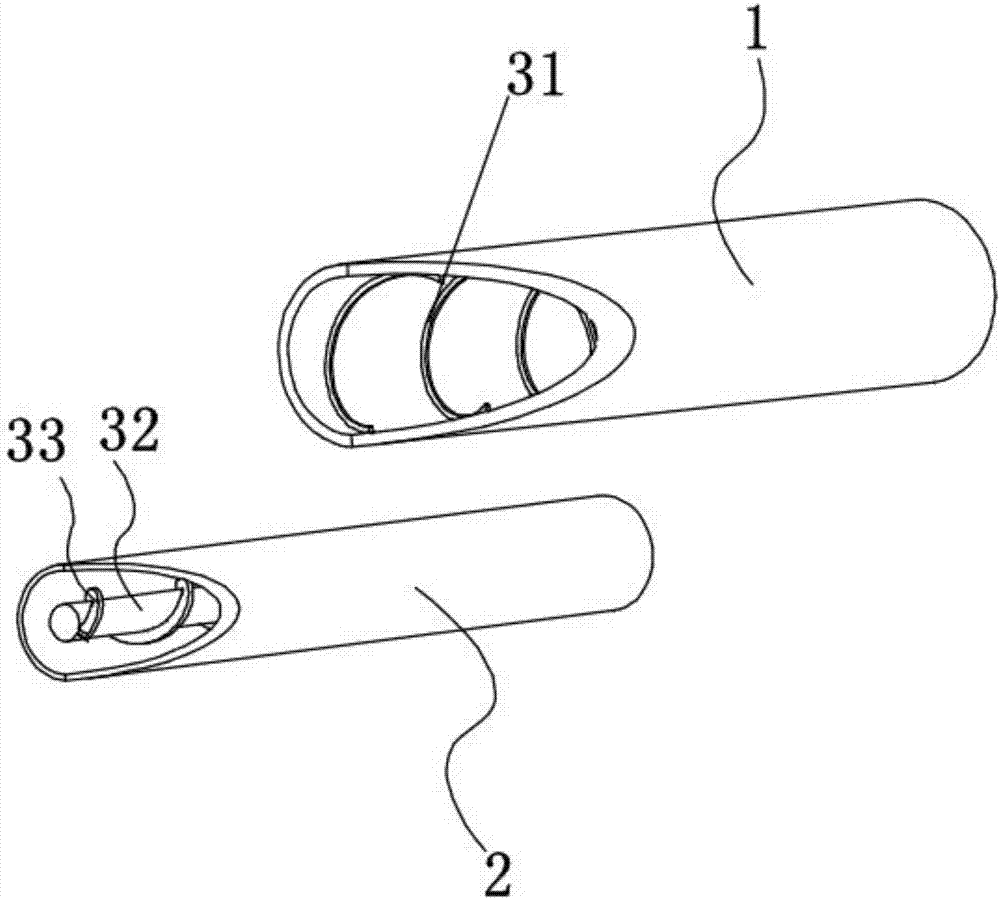

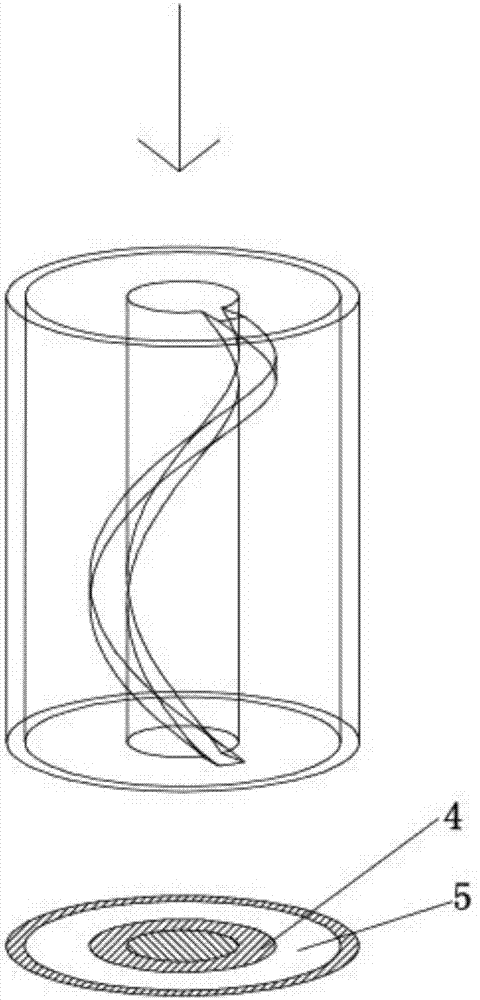

Drum washing machine

InactiveUS20070101773A1Eliminate scalingTextile treatment machine partsHollow article cleaningProcess engineeringVALVE PORT

A drum washing machine, in which scale deposited in a steam generating device installed for improving sterilizing and washing capacities is efficiently eliminated. The drum washing machine includes a housing; a tub for containing washing water; a drum rotatably installed in the tub; and a steam generating device installed in the housing for supplying steam for sterilizing laundry to the drum, wherein a scale eliminating unit is installed in a water supply channel of the steam generating device, and includes at least one protrusion formed on the inner circumferential surface of the water supply channel or a water supply valve and a pulsation circuit for controlling the flow rate and amount of the water. The scale eliminating unit forms turbulence in the steam generating device or supplies water having varied flow rate and amount to the steam generating device, thereby efficiently eliminating scale deposited in the steam generating device.

Owner:SAMSUNG ELECTRONICS CO LTD

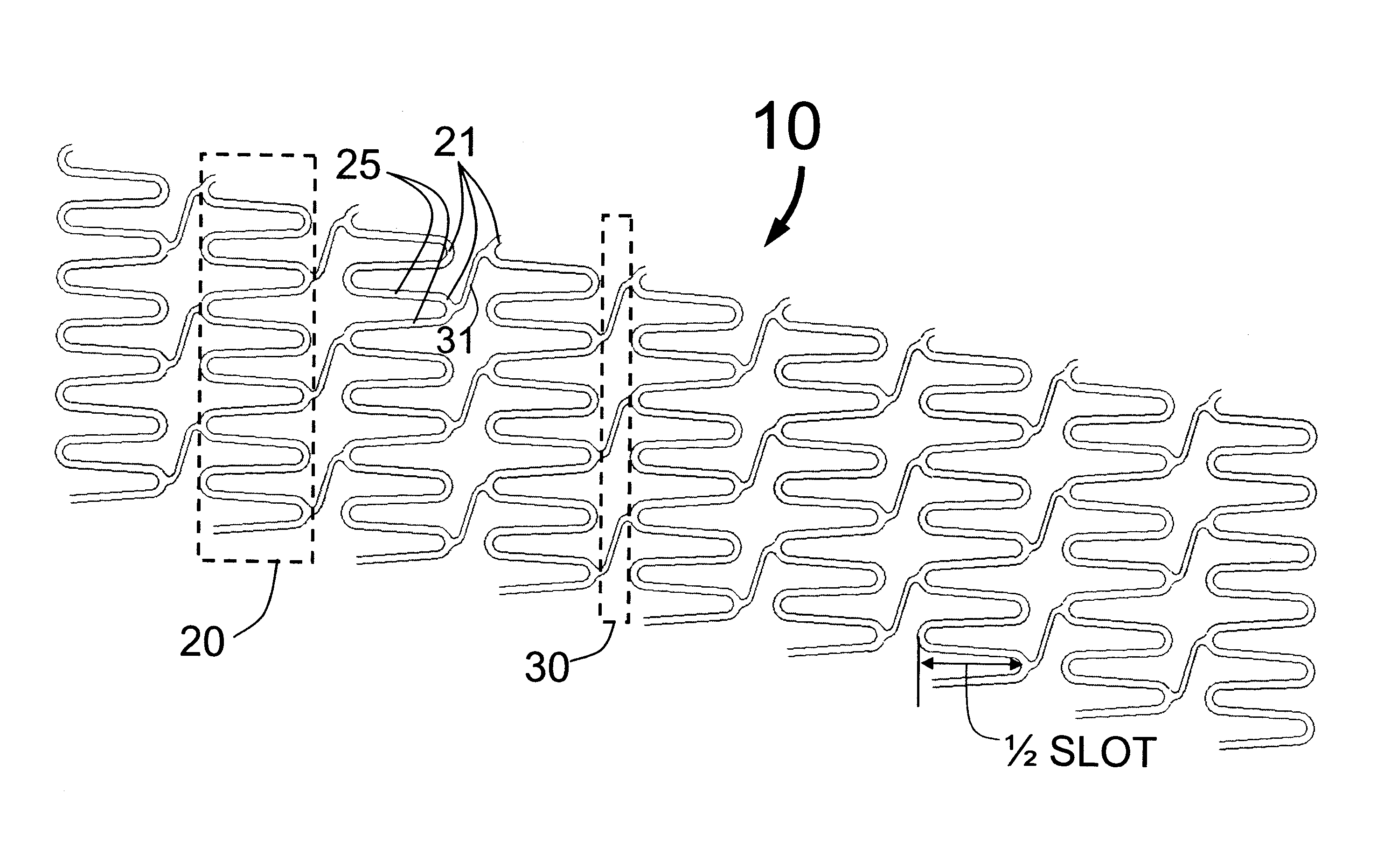

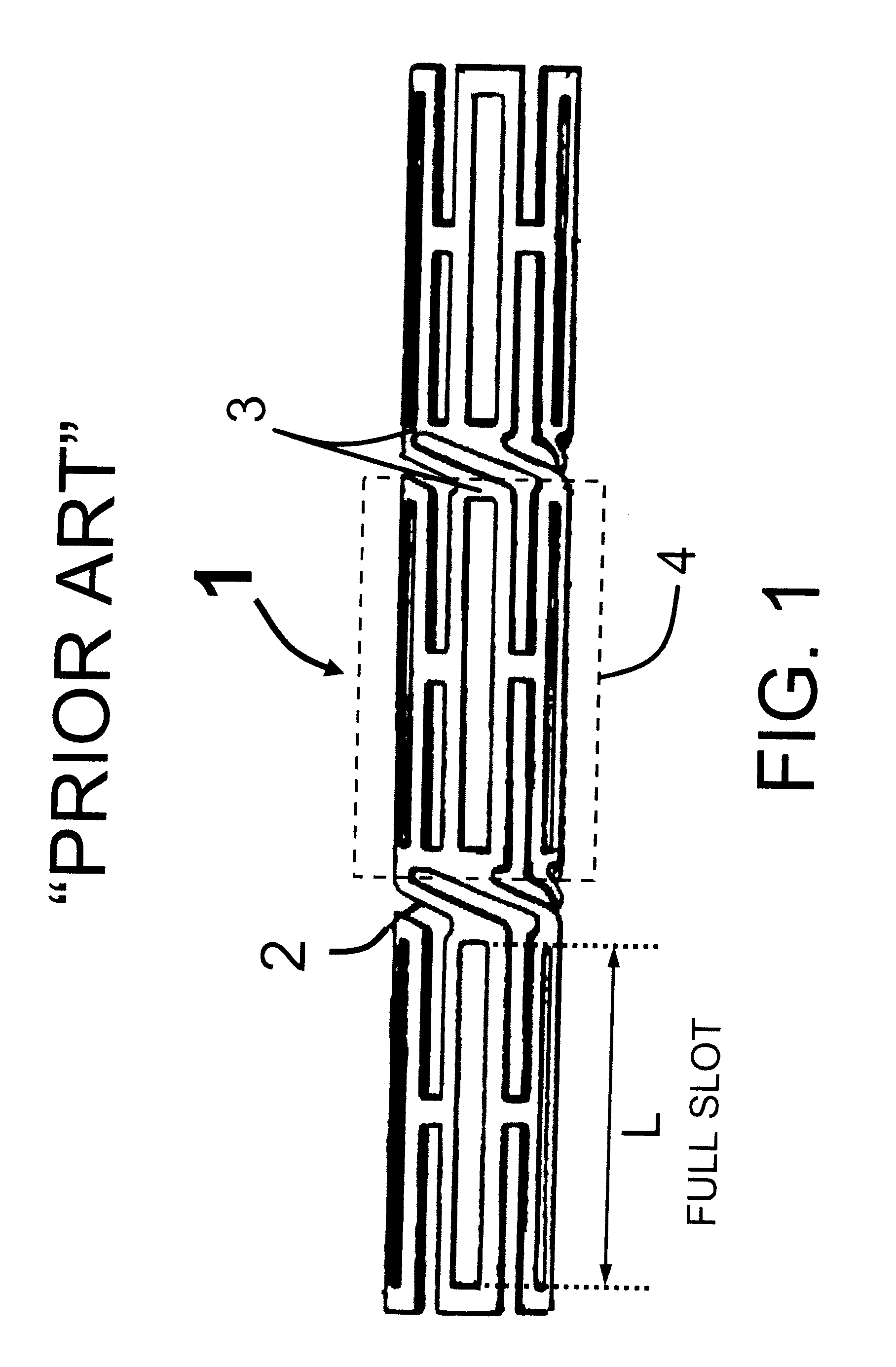

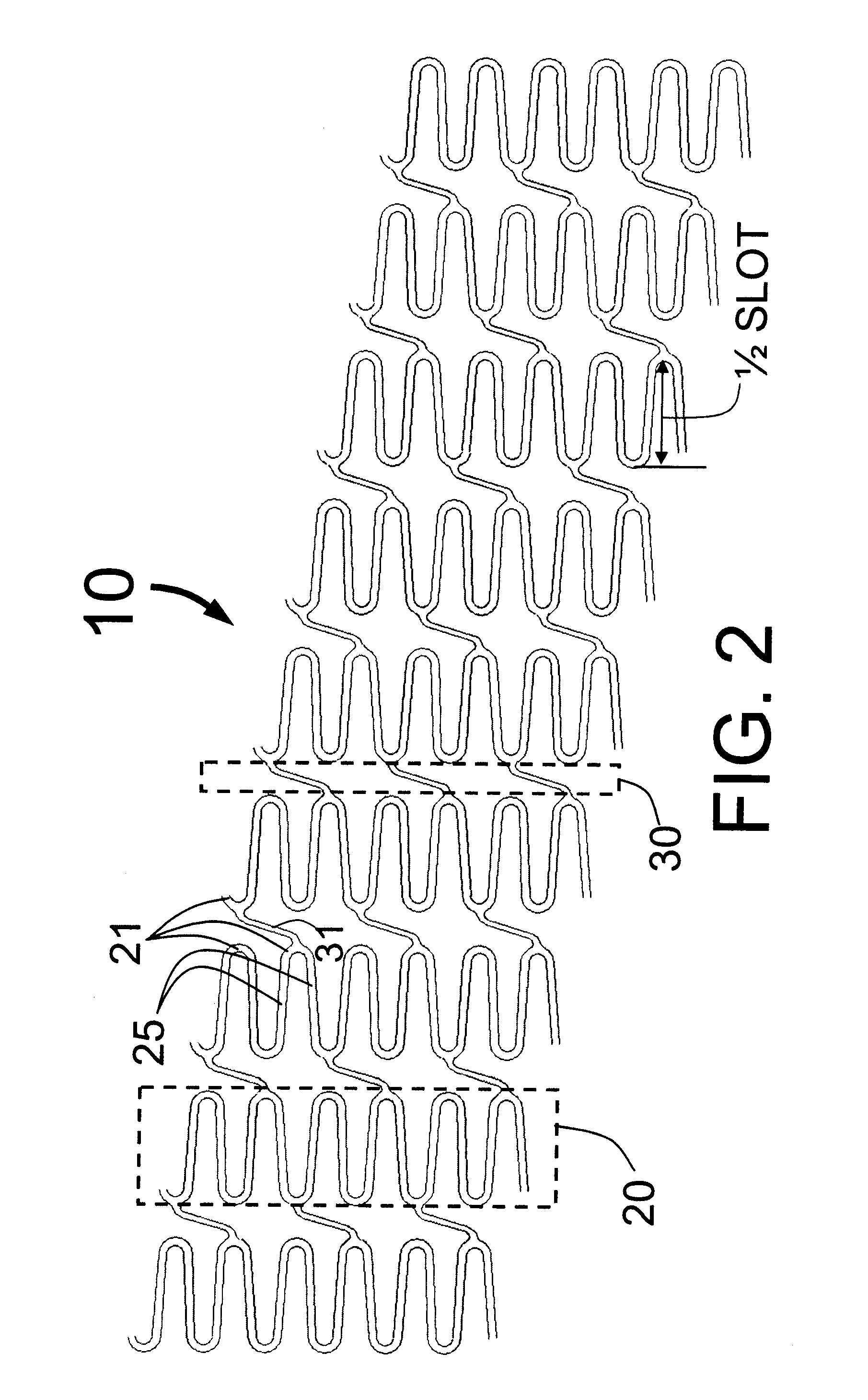

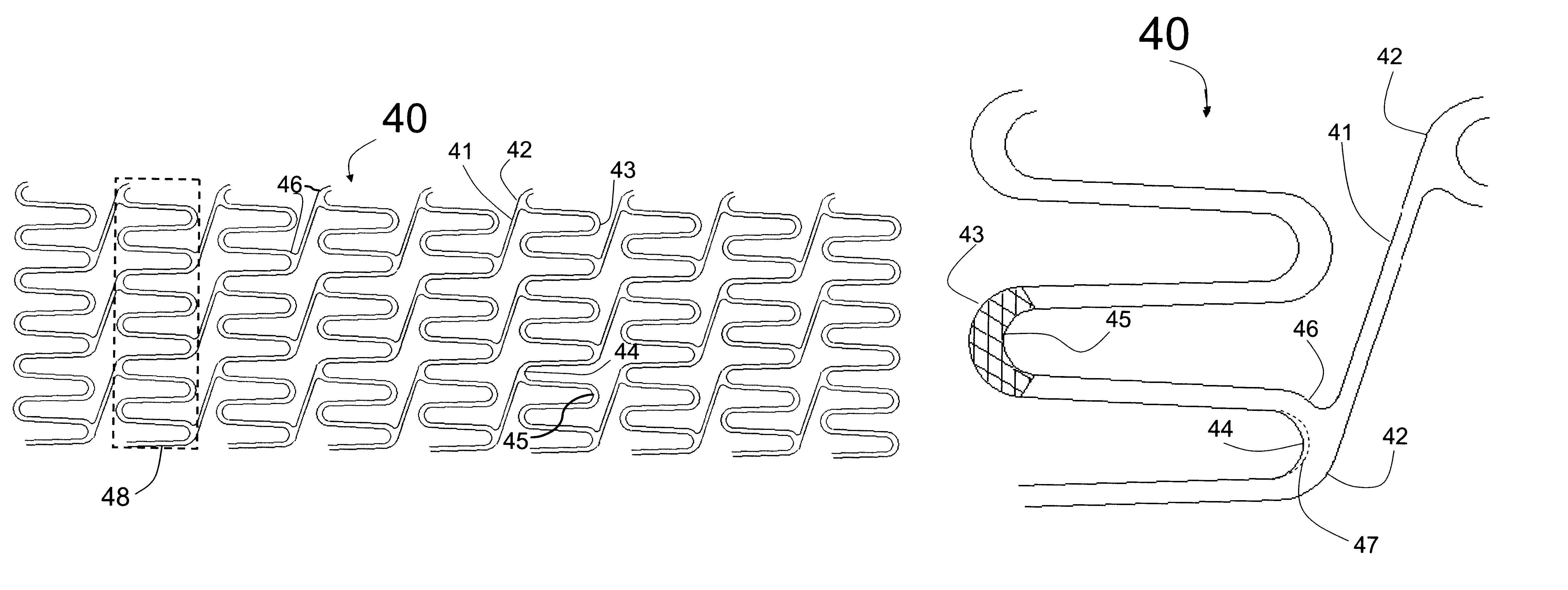

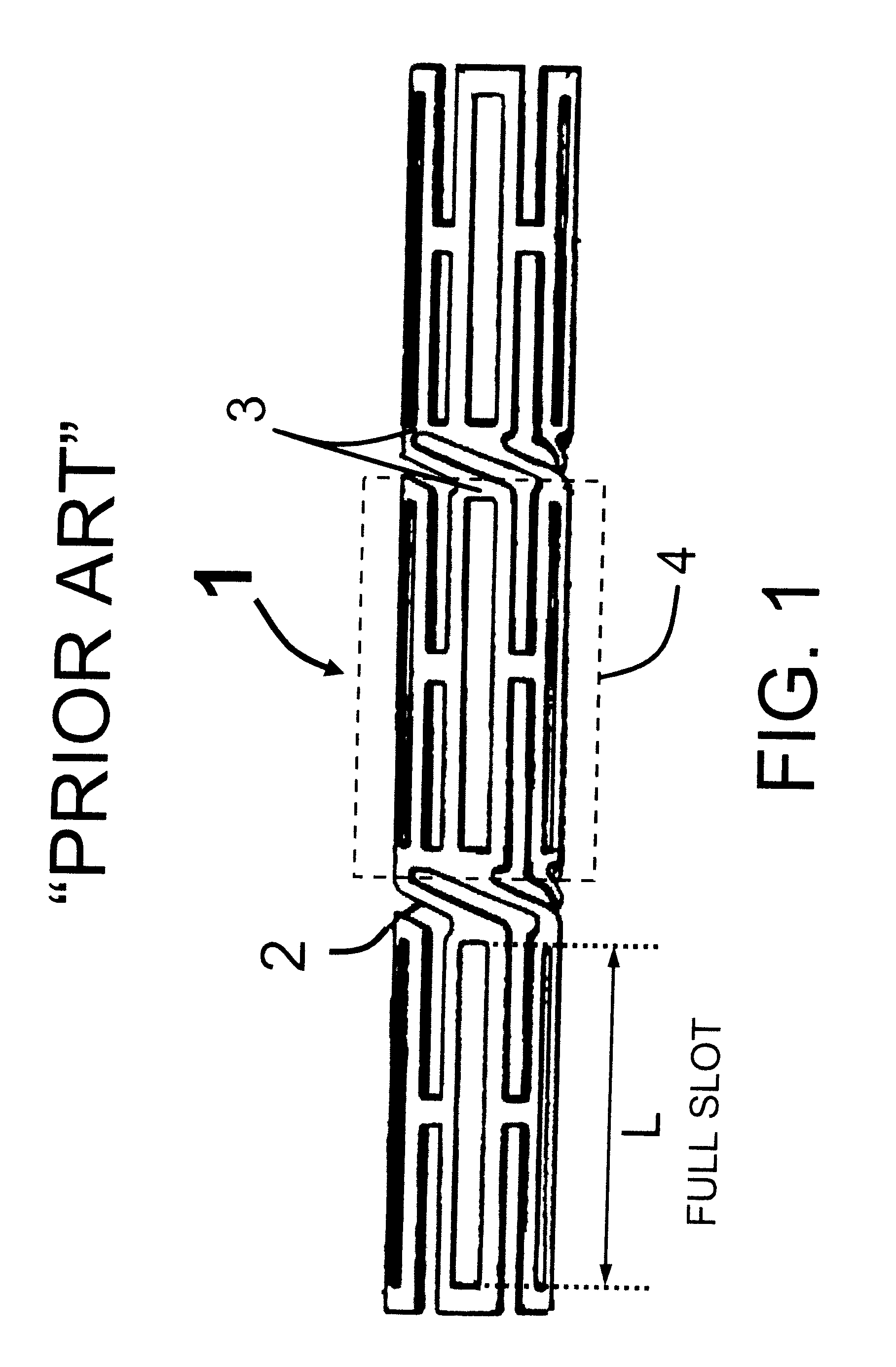

Hybrid stent with helical connectors

ActiveUS20110093059A1Minimal fish scalingIncrease flexibilityStentsBlood vesselsInsertion stentMaximum diameter

The present invention is a hybrid stent design using half-slot circumferential sets of strut members with short (<1.5 mm) slot length that has minimal fish scaling and excellent stent retention and flexibility. These half-slot circumferential sets of strut members are connected one to the other with helical connectors similar to those of the Palmaz stent. One important difference in the design of the stent of the present invention is that the helical connectors are attached to every other crown (rather than connected to every crown) to further improve stent flexibility. By appropriately varying the strut width of both the connected and unconnected curved crowns to be greater at the center than at their ends, an increased radial strength can be provided for a given maximum strain that is imparted to the stent when it is expanded to its maximum diameter.

Owner:SVELTE MEDICAL SYST

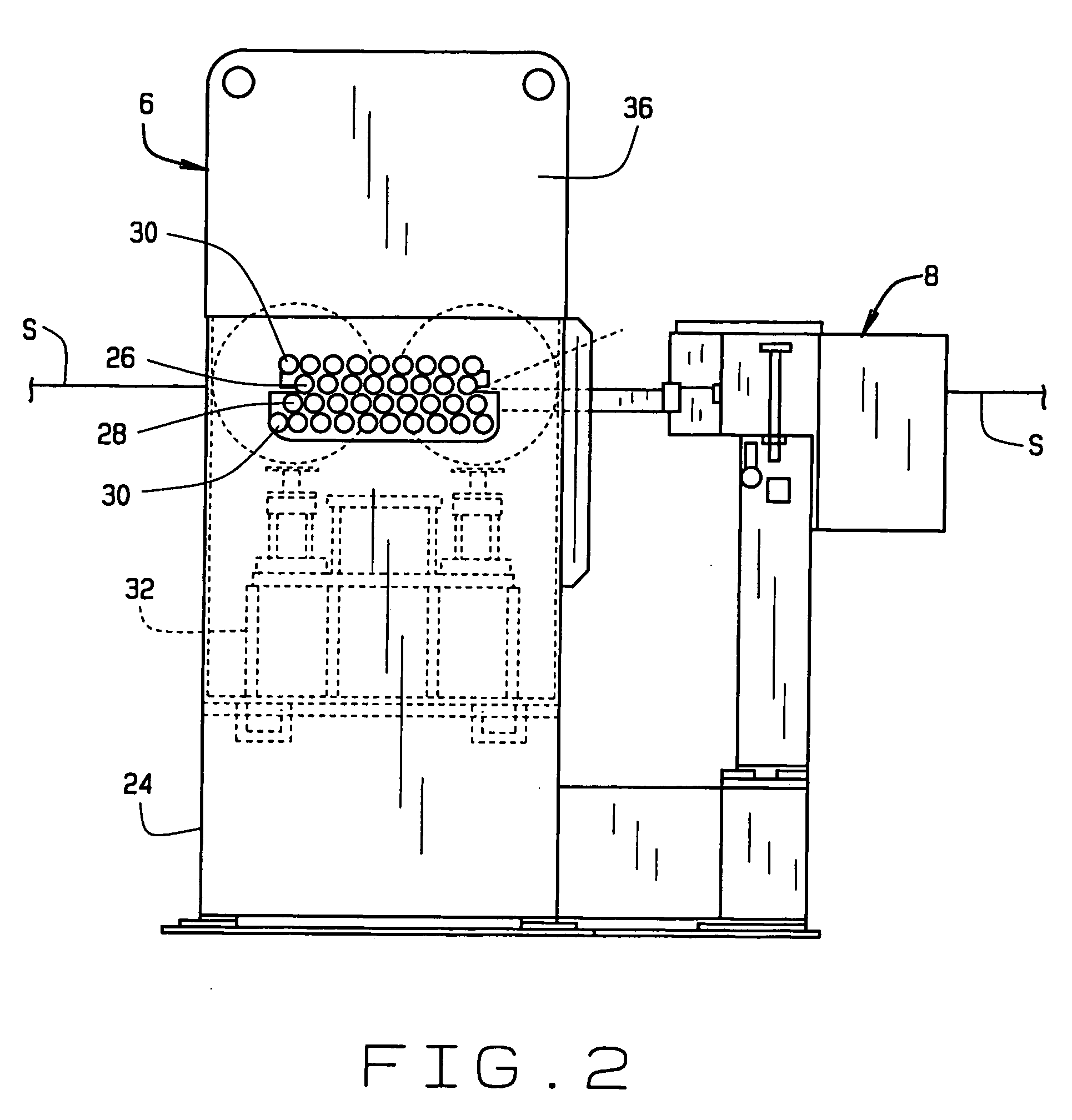

Sheet metal scale removing water jet process

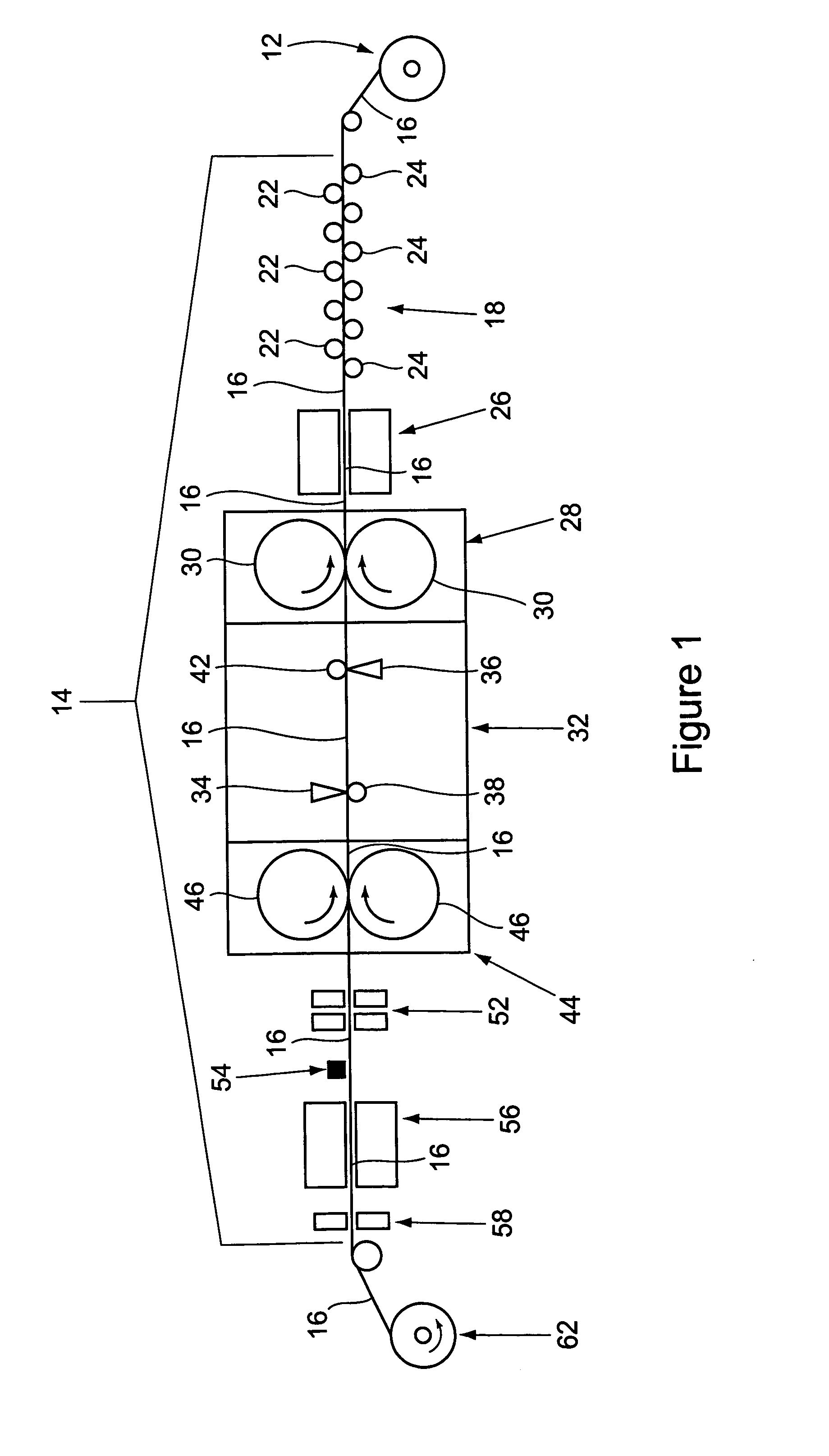

InactiveUS7077724B1Less complexEliminate scalingElectrostatic cleaningWork treatment devicesEngineeringHigh pressure

An apparatus and method of removing scale from the surfaces of processed sheet metal employs high pressure jets of water directed from nozzles positioned in close proximity to the sheet metal surfaces.

Owner:THE MATERIAL WORKS

Cloud storage system with distributed metadata

ActiveUS8533231B2Efficient storageEasy to scaleDigital data information retrievalDigital data processing detailsData integrityCloud storage system

Owner:NEXENTA BY DDN INC

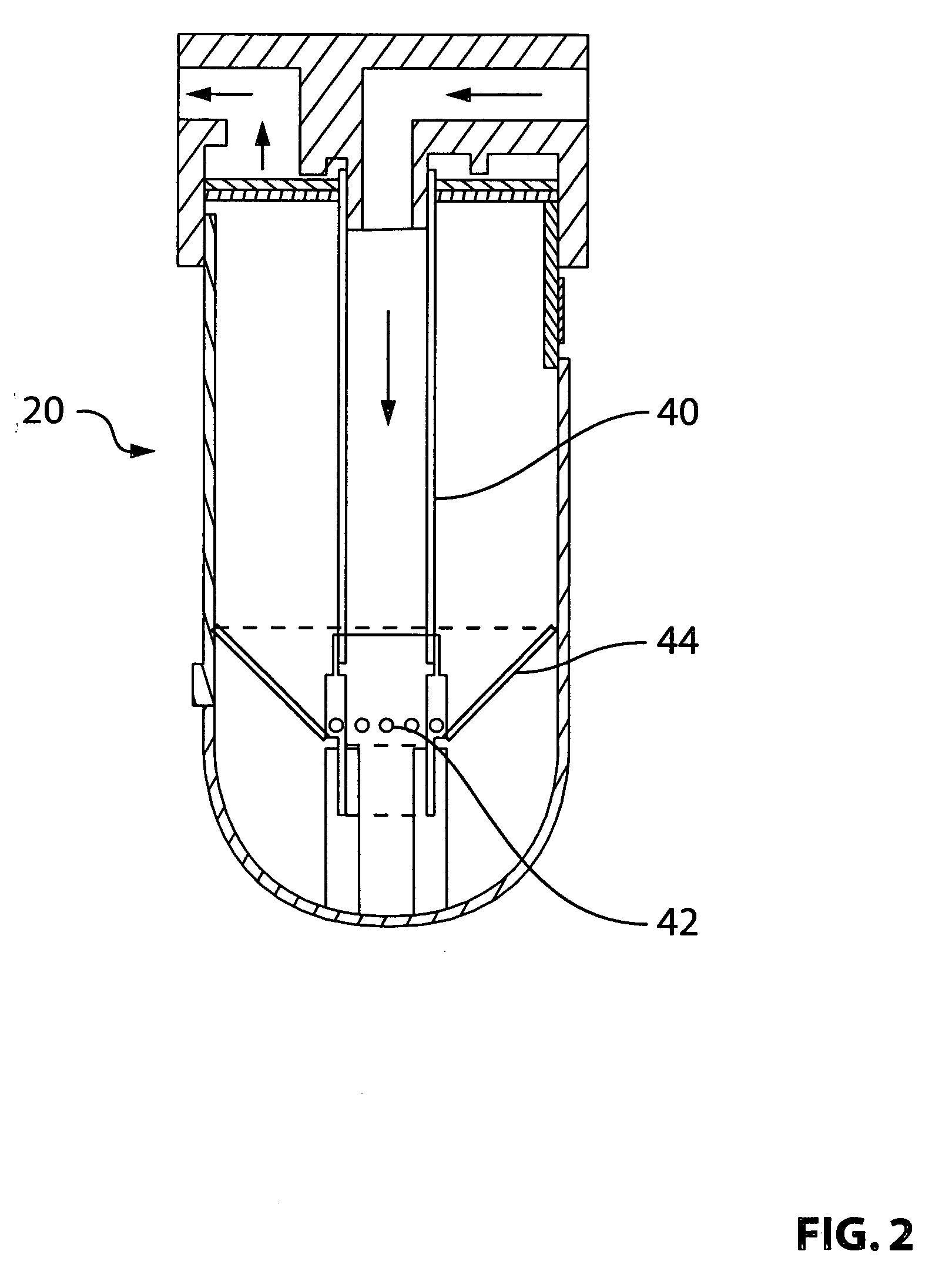

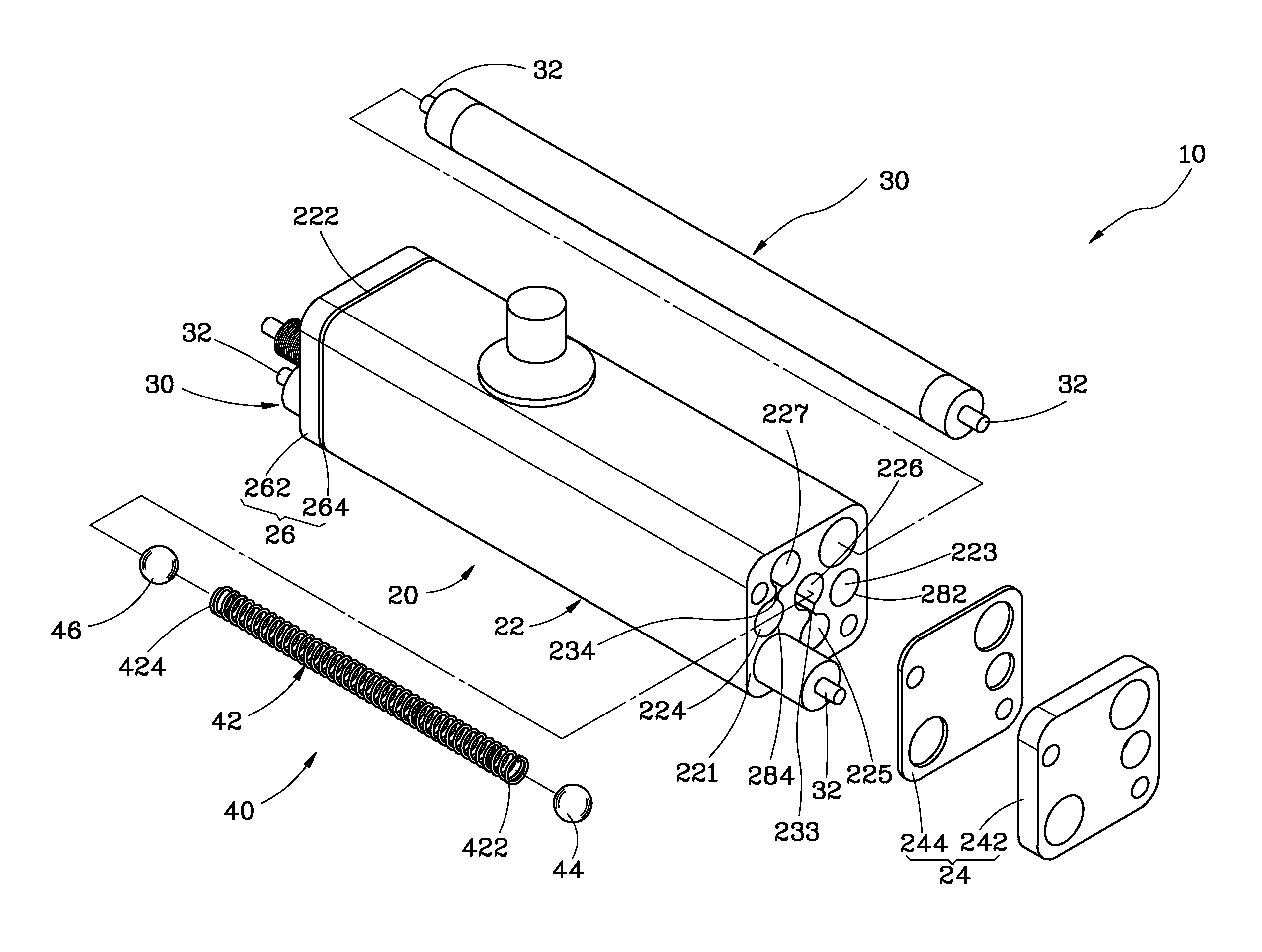

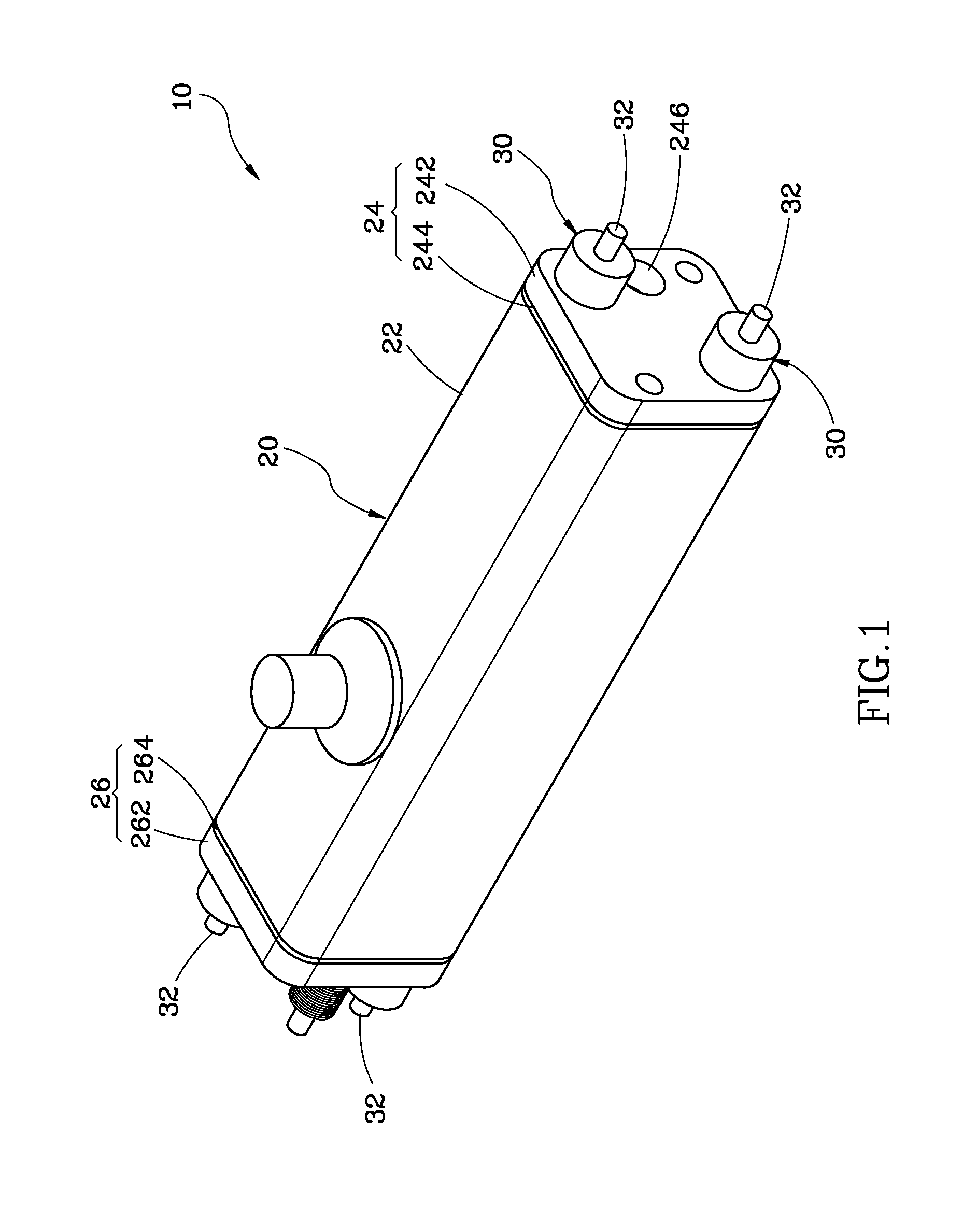

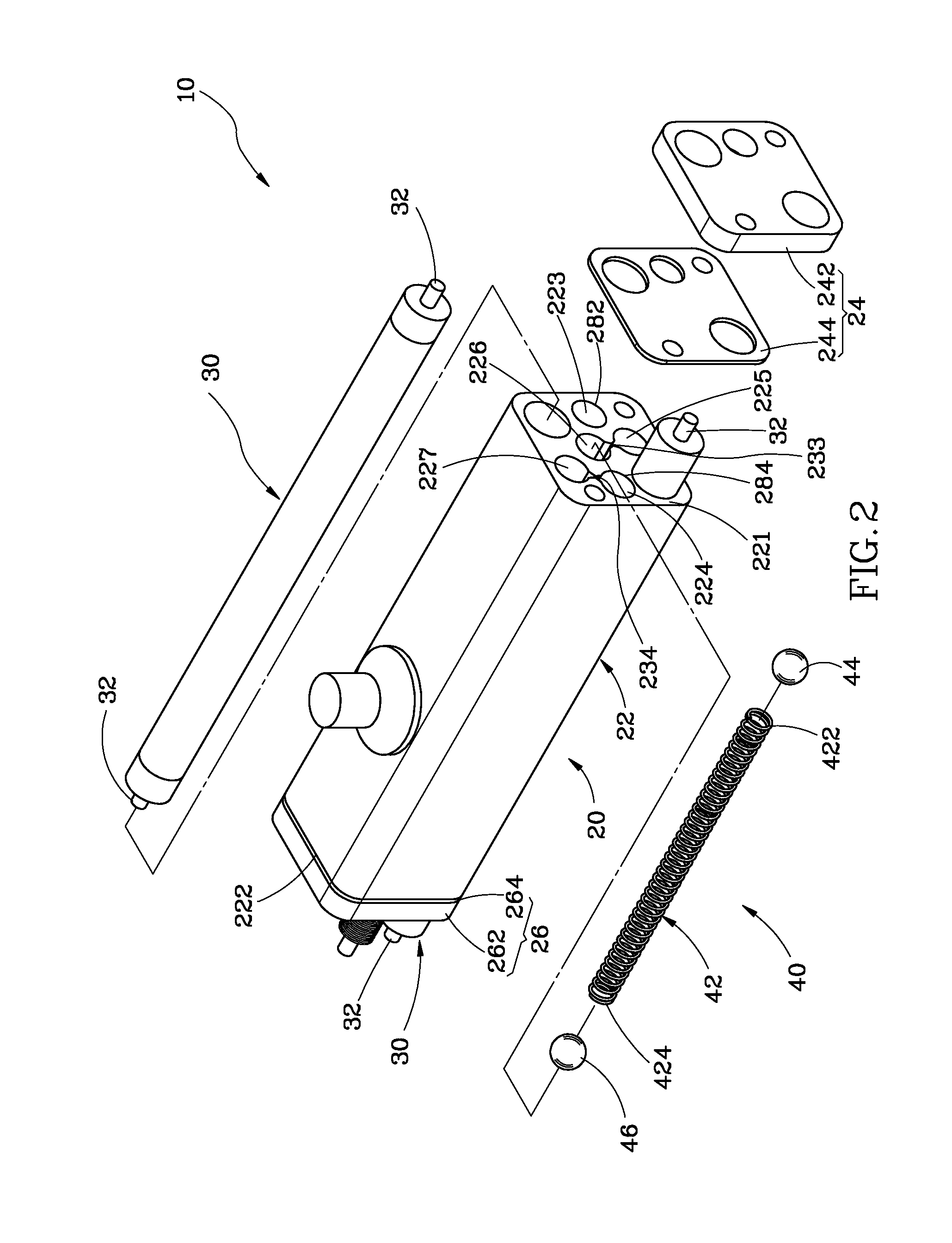

Methods and apparatus for negating mineral scale buildup in flapper valves

ActiveUS7896082B2Prevent scalingEliminate buildupConstructionsCleaning apparatusSleeve valveEngineering

Methods and devices for negating scale buildups on interior surfaces of a sliding sleeve valve housing above the flow tube. In some aspects, a wiper member provides additional clearance between the flow tube and housing to compensate for scale buildup. In other aspects, the interior surface of the valve housing is provided with a sleeve that is disposed between the interior surface of the valve housing and the general flowbore passing through the valve housing to protect the interior surface against scale buildup.

Owner:BAKER HUGHES INC

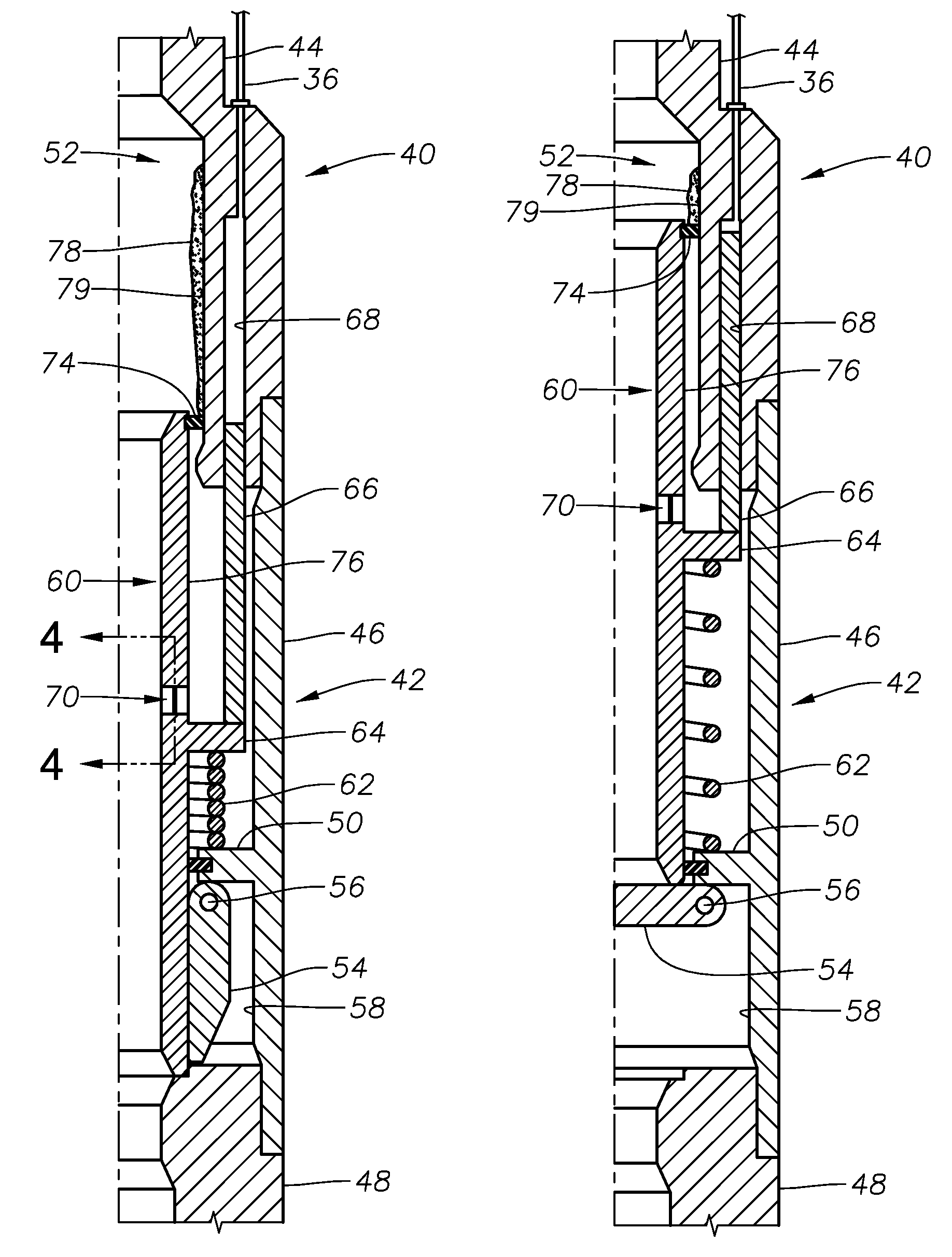

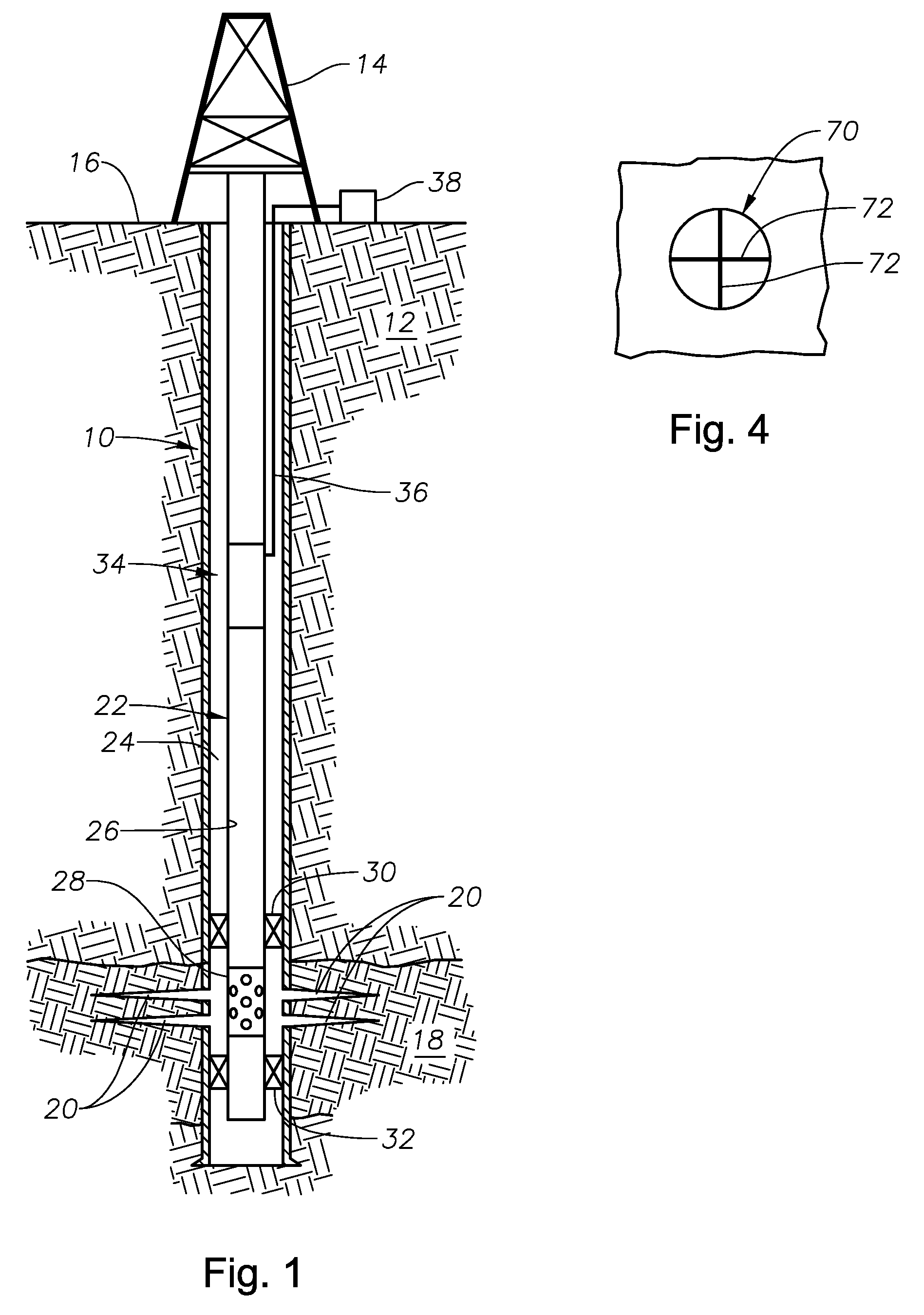

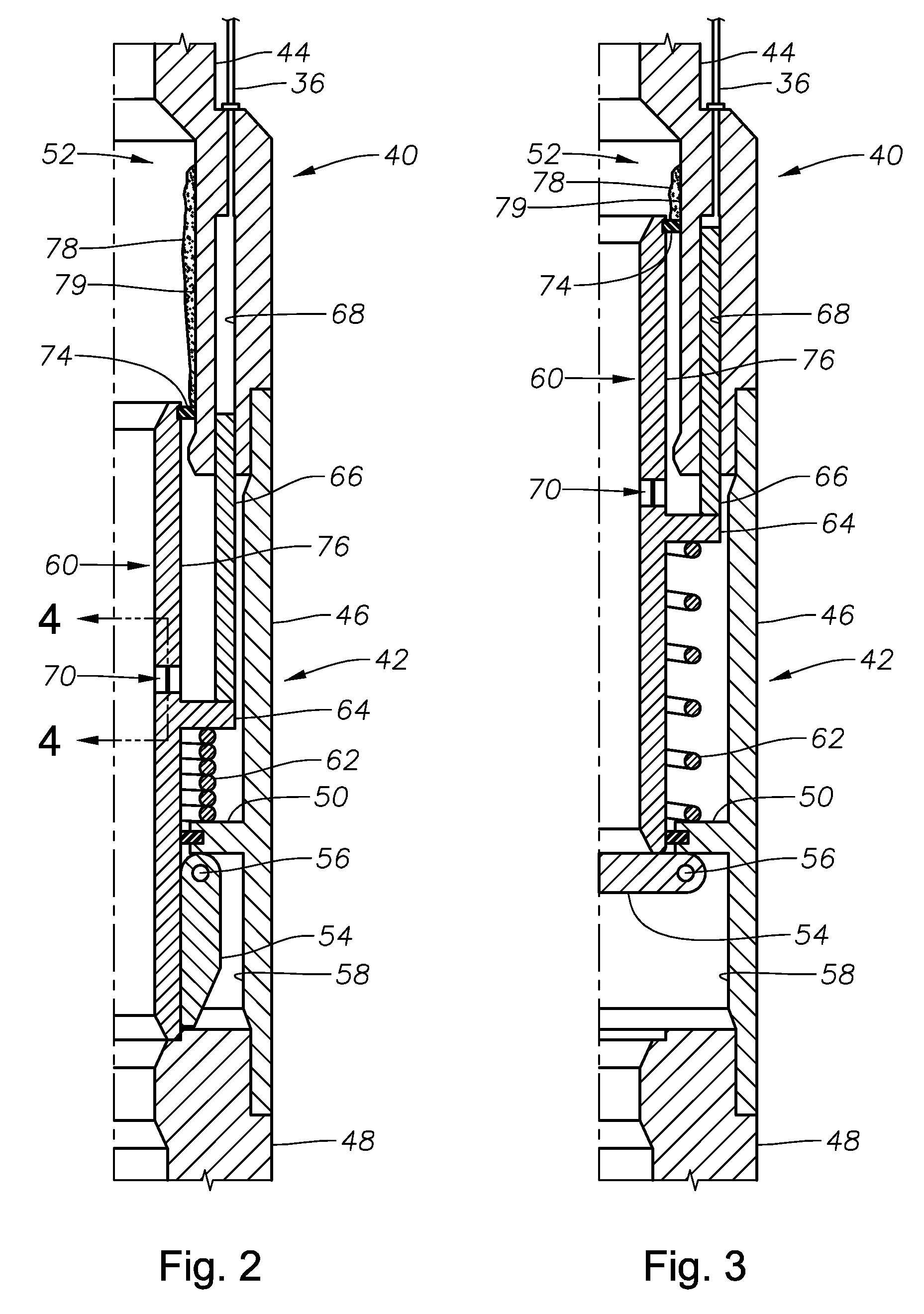

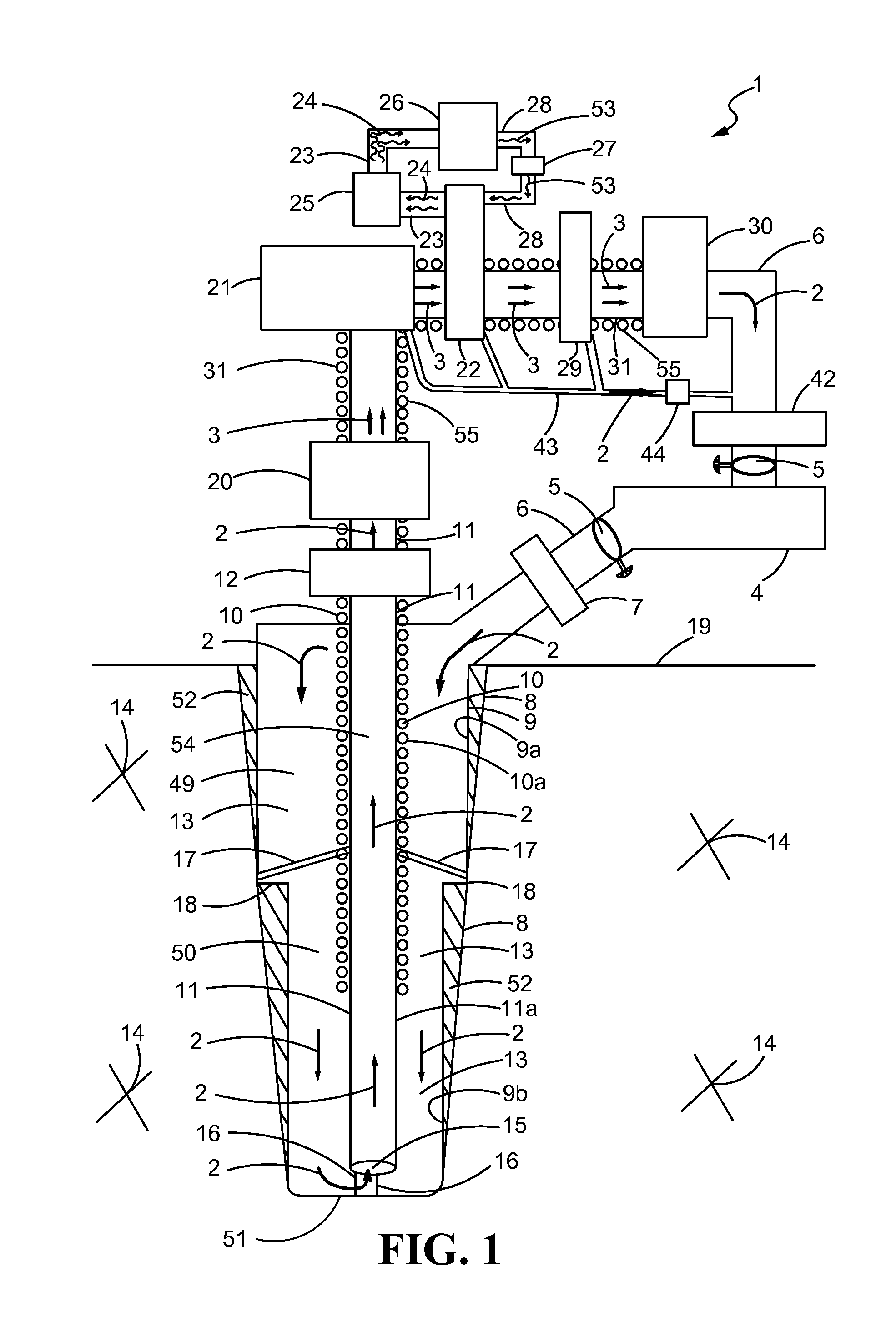

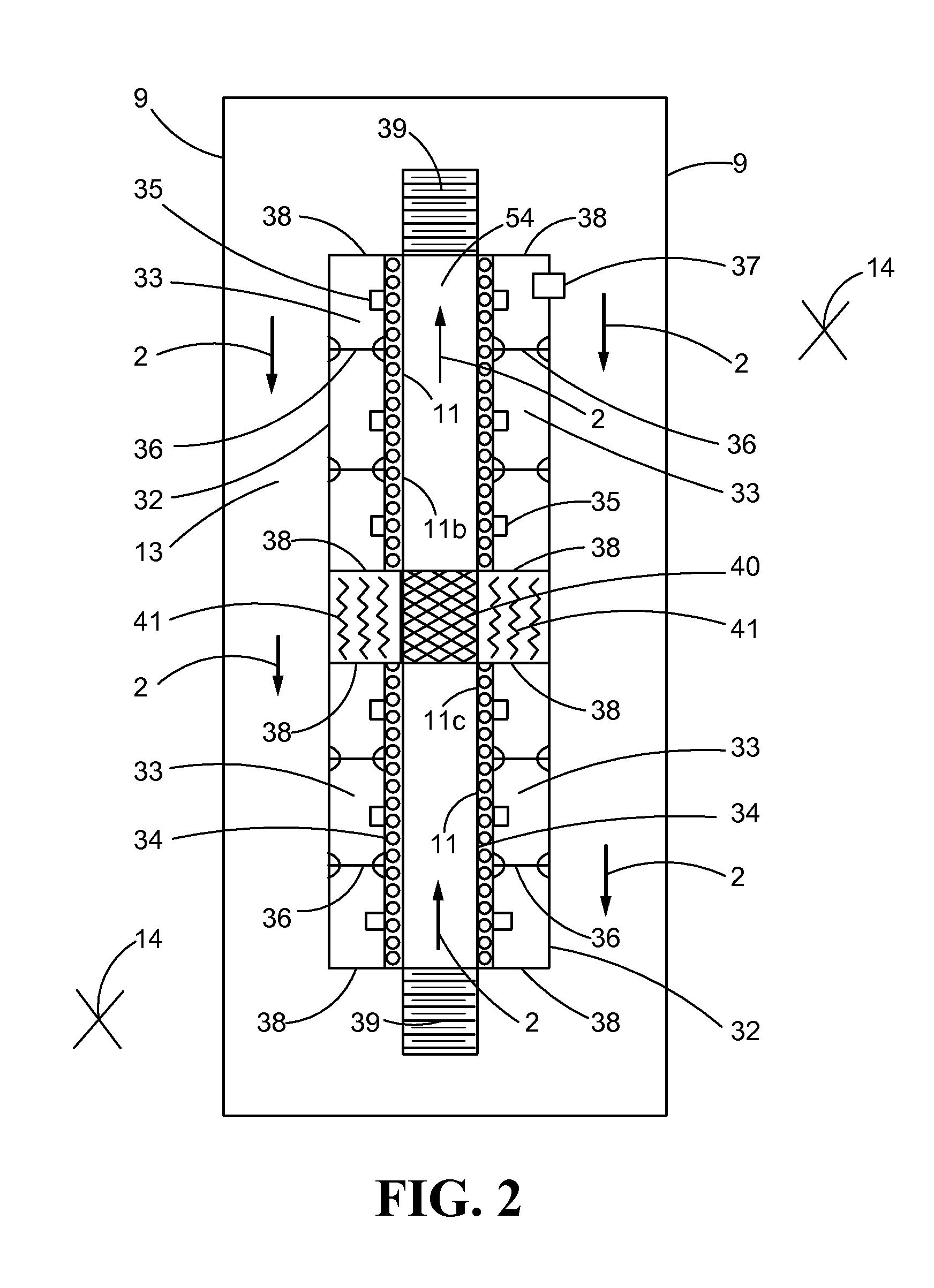

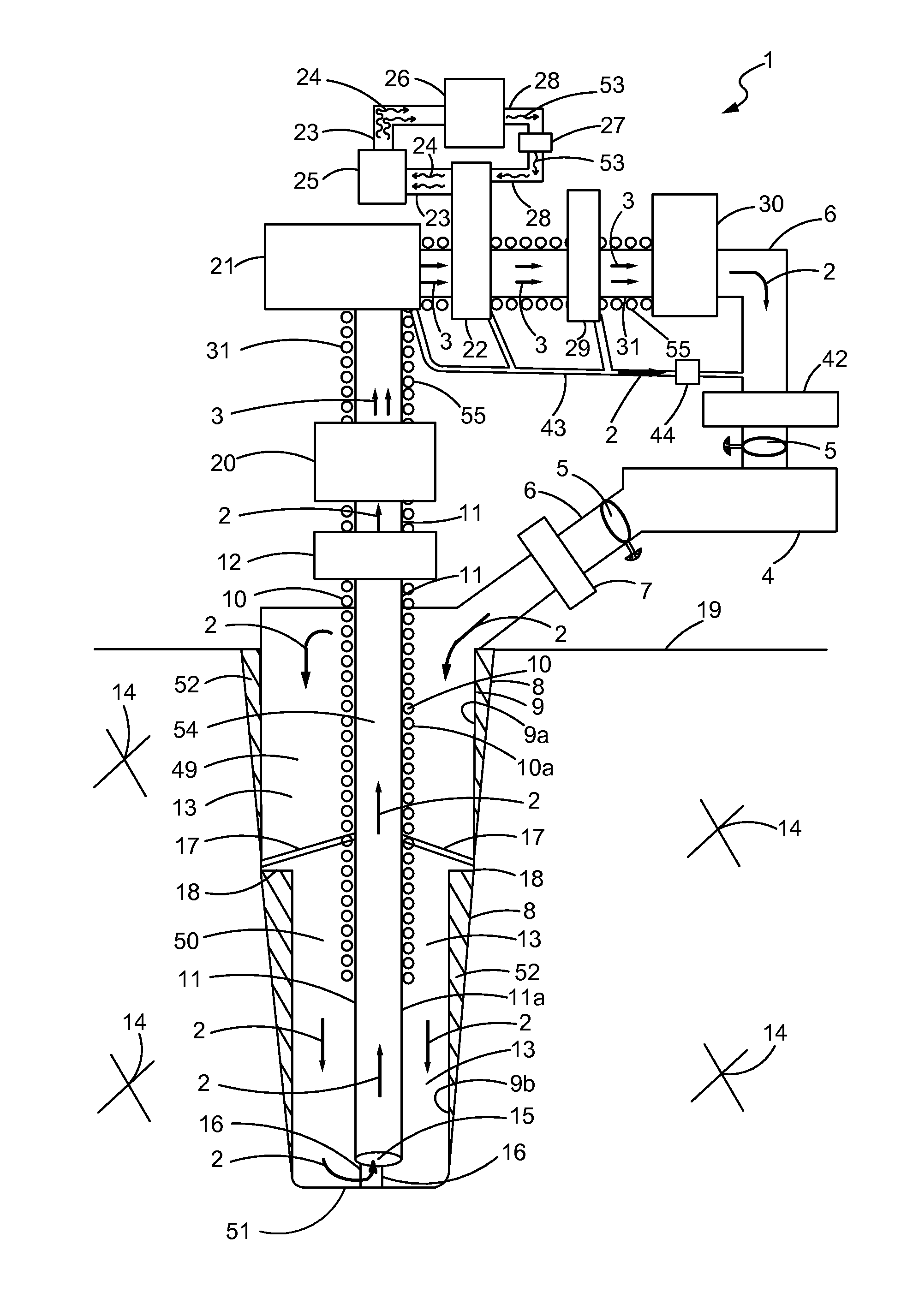

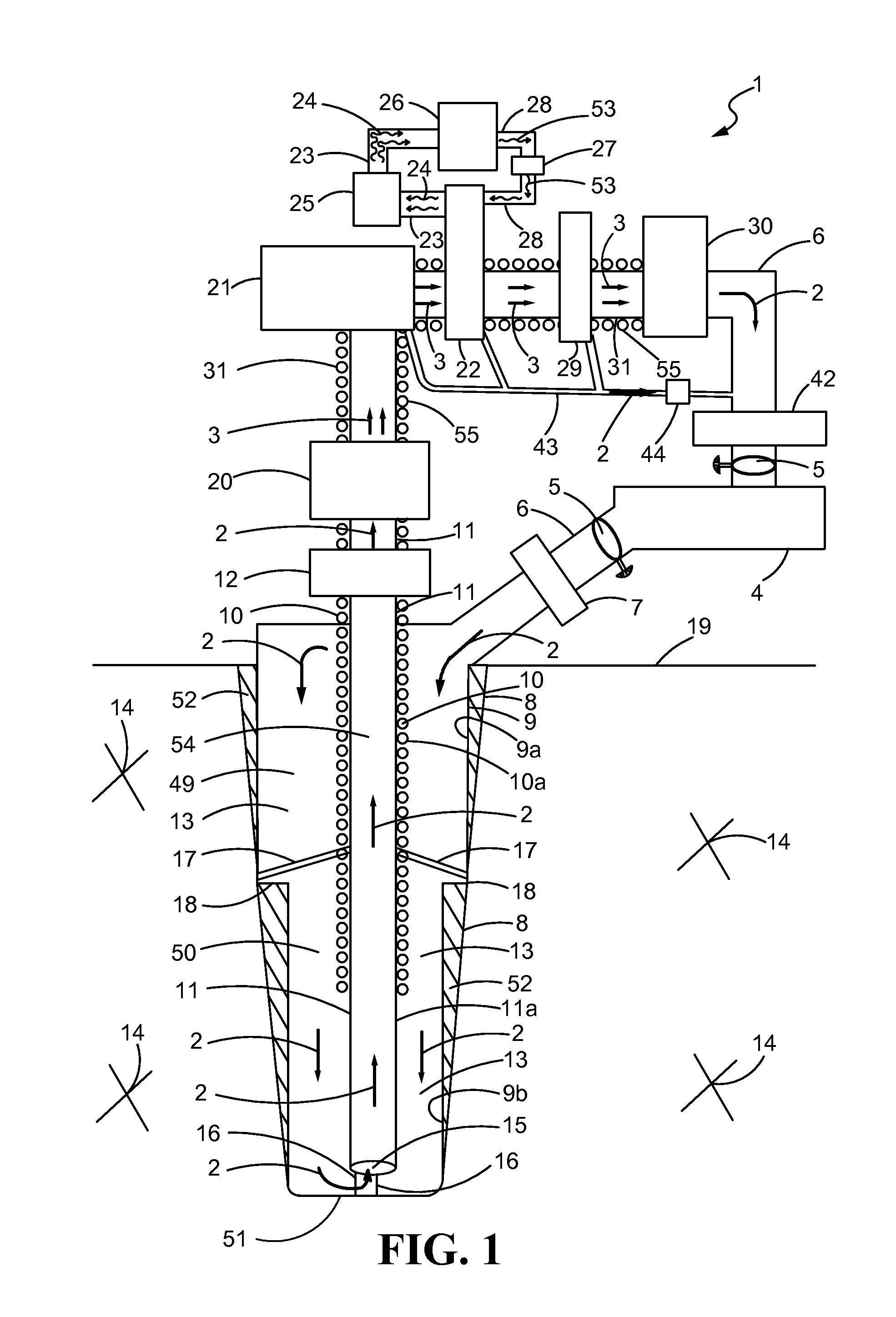

Single well, self-flowing, geothermal system for energy extraction

ActiveUS9394771B2Reduce and eliminate parasitic power drawImproving overall environmental impact and economic feasibilityCollector components/accessoriesOther heat production devicesWorking fluidEngineering

A renewable energy, single well, primarily self-flow, geothermal heat / power production system that acquires naturally occurring sub-surface geothermal heat to heat water and / or produce mechanical / electrical power using a heat exchangers or a turbine / generator. The sub-surface structures defining a working fluid flow path may be insulated, such as with vacuum insulation, to increase system efficiency and ensure a substantially self-generating working fluid flow.

Owner:DEEP WELL POWER

Water treatment apparatus and method

ActiveUS20050011839A1Eliminate scalingSuppress bio-organic contaminationSolid sorbent liquid separationWater softeningEvaporationWater cycling

An automatic, self-regulating method of water treatment for use in water circulating towers in which water is evaporated, and make up water is added, with components which synergistically function to cut chemical, energy, water, corrosion, pollution, and maintenance costs, by passing the water through a Water Conditioning unit to prevent adhering evaporation scale deposits along with their content of concentrated biofouling nutrients from forming on the flooded surfaces of the tower and its associated water flow circuit, adding. a trace level of iodine to the input make-up water to enhance the further disinfection of nutrient-deprived surfaces from any residual biofilm and chance pathogen contaminations, and adding a trace level addition of zinc ions in the water such as by an assured treatment feeder to the input make-up flow for inhibiting residual iodine-resistant algal and bacterial organisms of hazard for restoring bionutrient tower conditions, such as within sun-lit environments, and apparatus for carrying out the foregoing method.

Owner:EVANDTEC

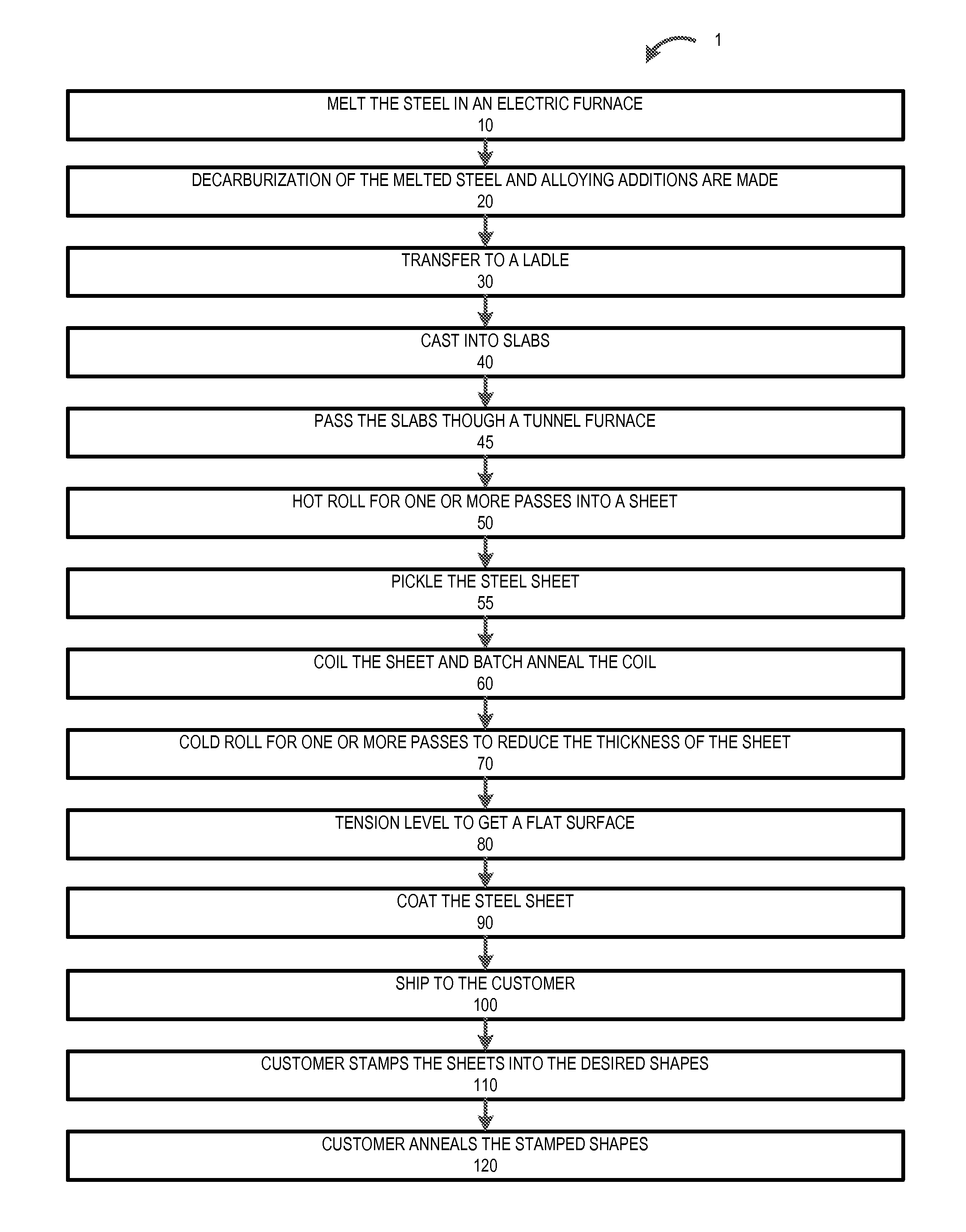

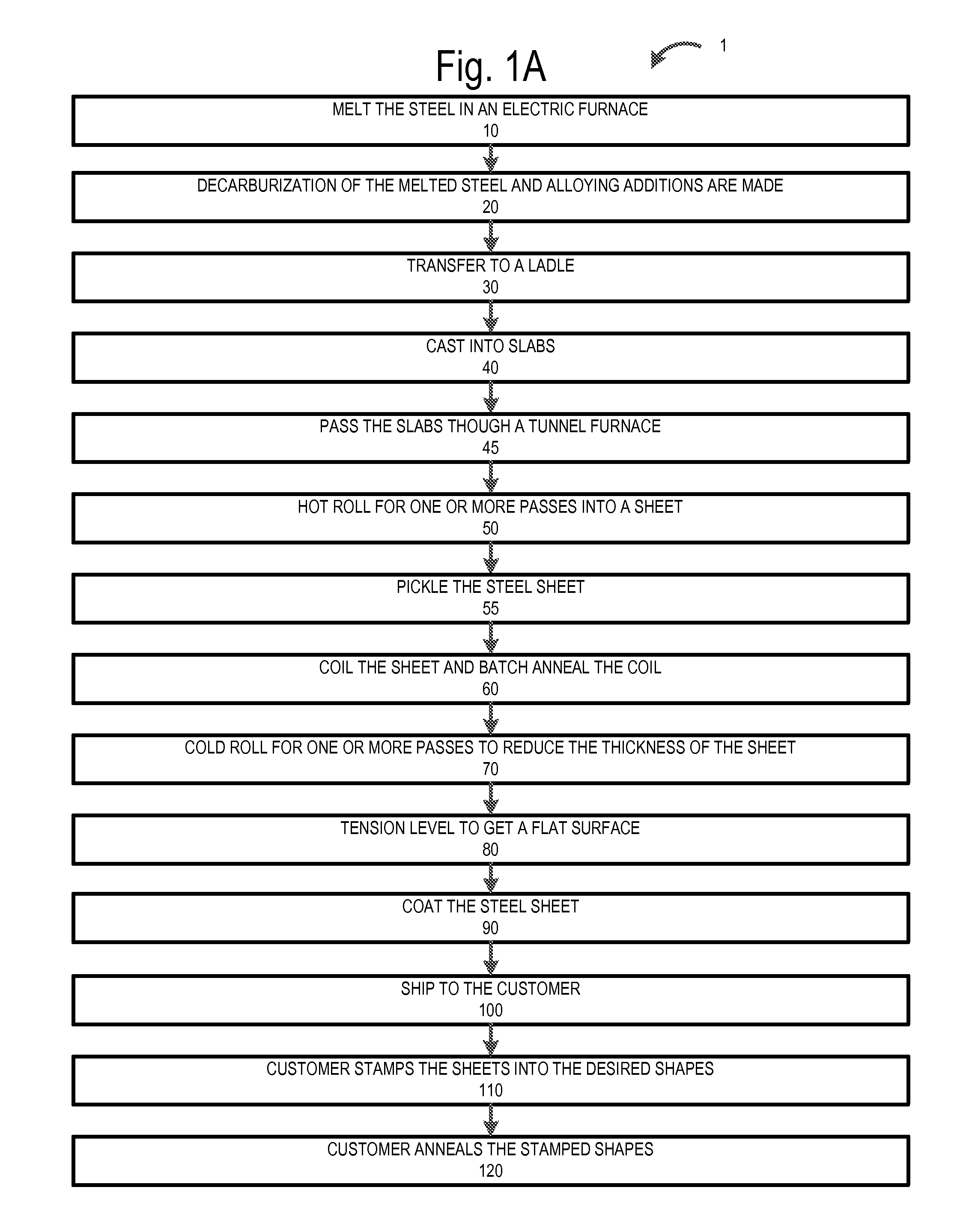

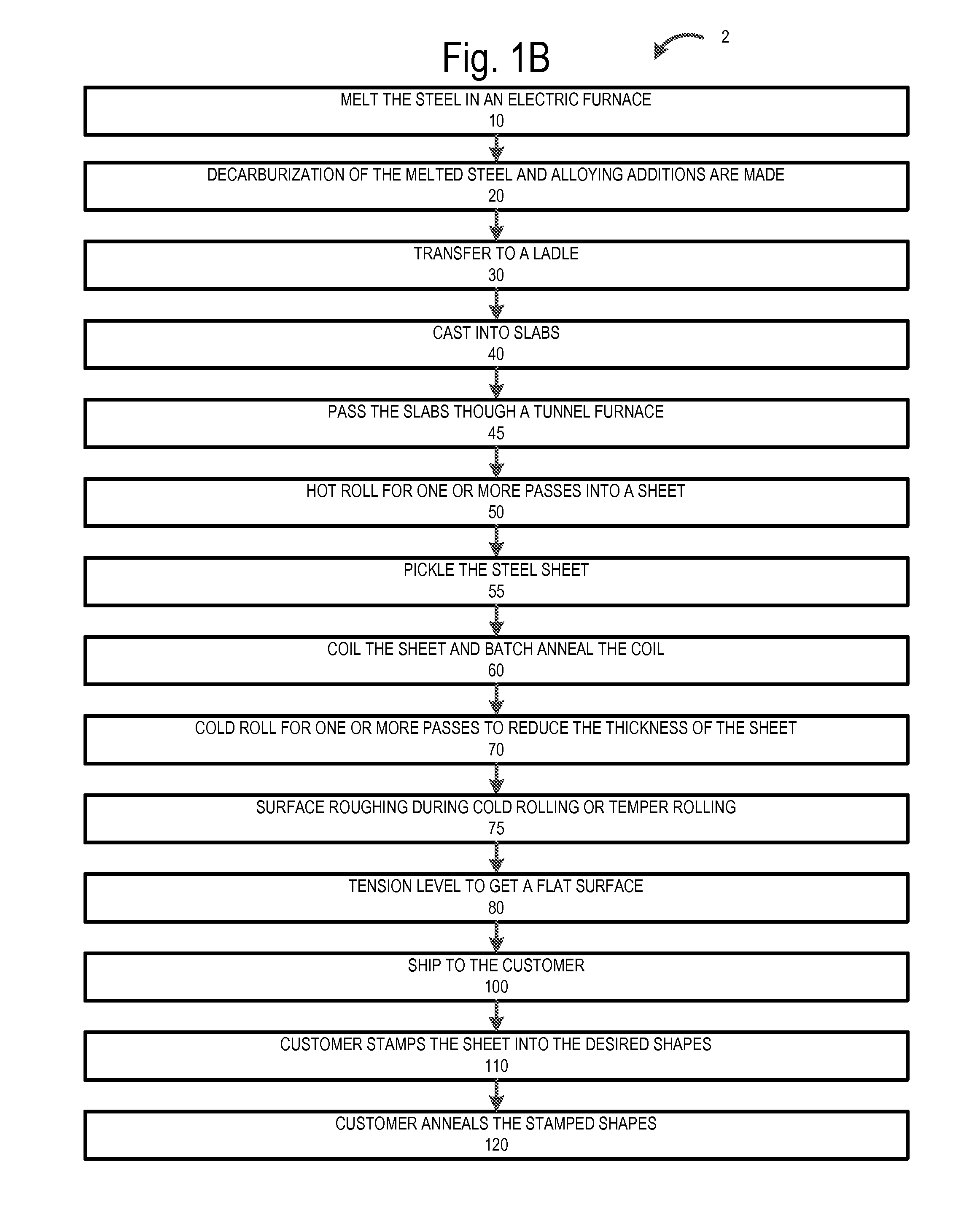

Electrical steel processing without a post cold-rolling intermediate anneal

InactiveUS20150318093A1Promotes an increase in inductionImprove permeabilityInorganic material magnetismFurnace typesElectrical steelStrip steel

Embodiments of the present invention comprise; annealing steel sheets (e.g., hot rolled steel sheets or thin cast strip steel); cold rolling the sheets in one or more cold rolling steps (e.g., with annealing steps between multiple cold rolling steps); and performing one or more of tension leveling, a rough rolling, or a coating process on the sheets after cold rolling, without an intermediate annealing step between the final cold rolling step and the tension leveling, the rough rolling, or the coating process, or the customer stamping or final customer annealing. In order to achieve the desired properties for the steel sheet, stamping and final annealing is performed by the customer. The new process provides an electrical steel with the similar, same, or better magnetic properties than an electrical steel manufactured using the traditional processing that utilizes an intermediate annealing step after cold rolling and before the stamping and final annealing.

Owner:NUCOR CORP

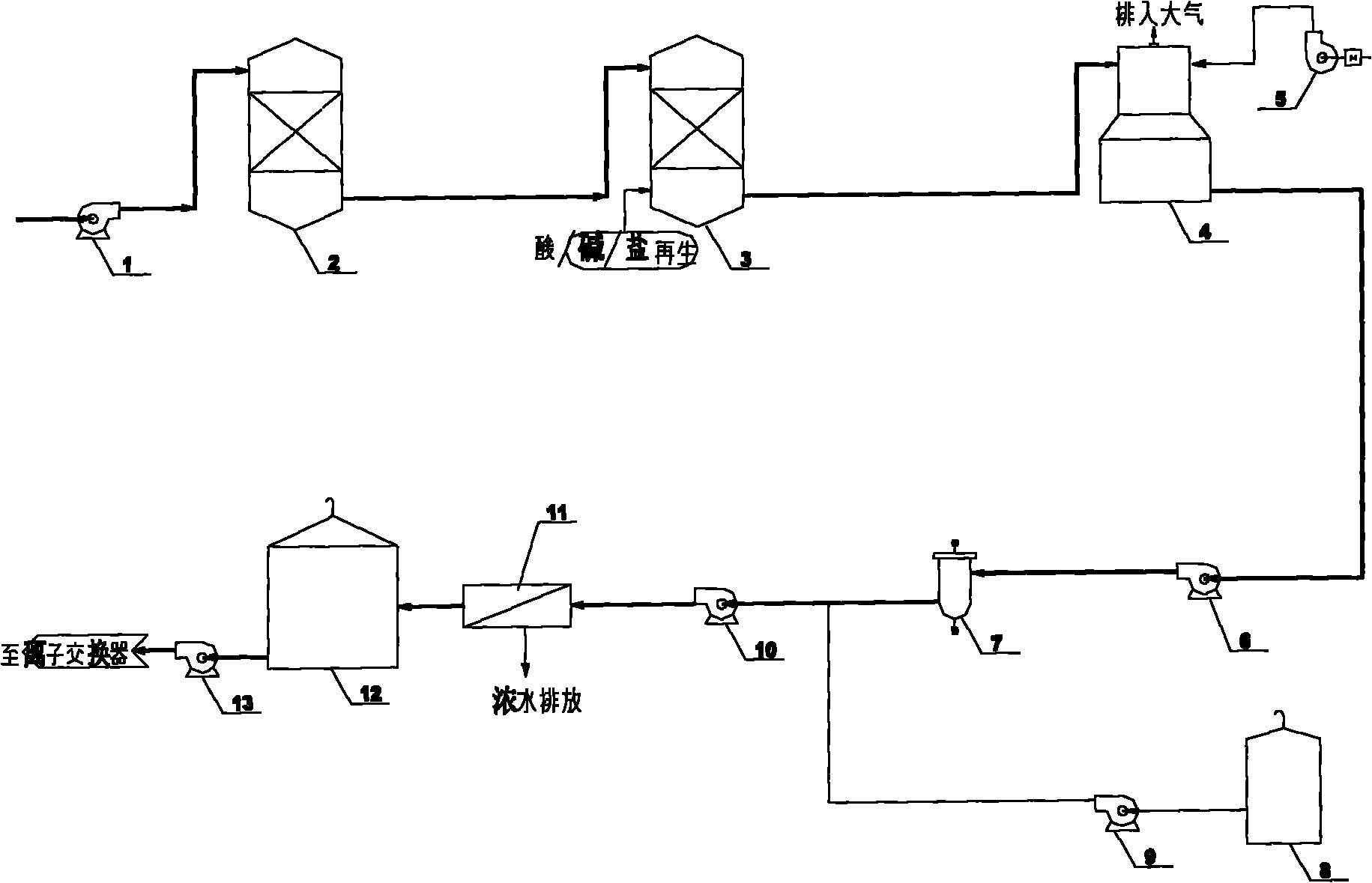

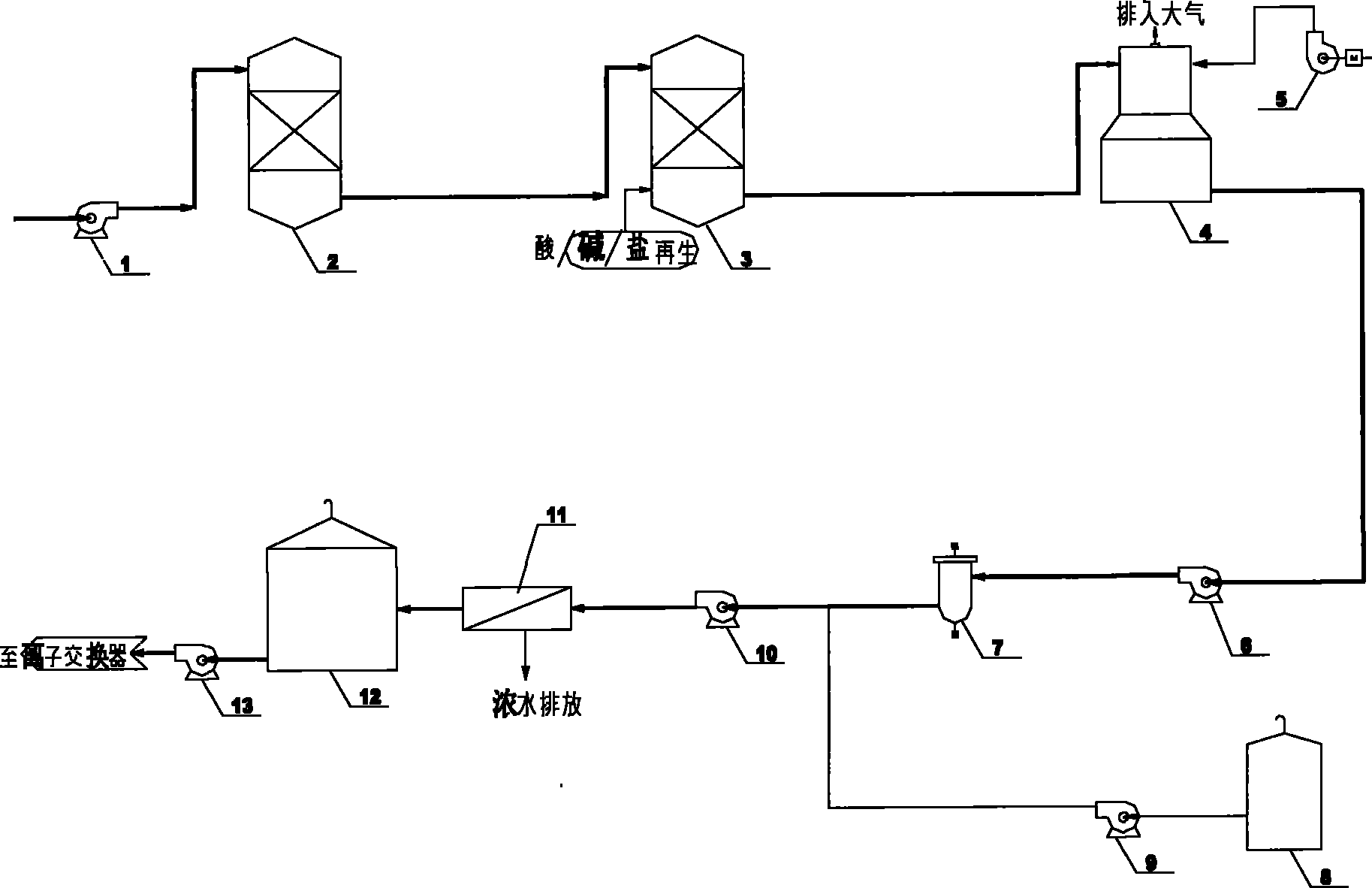

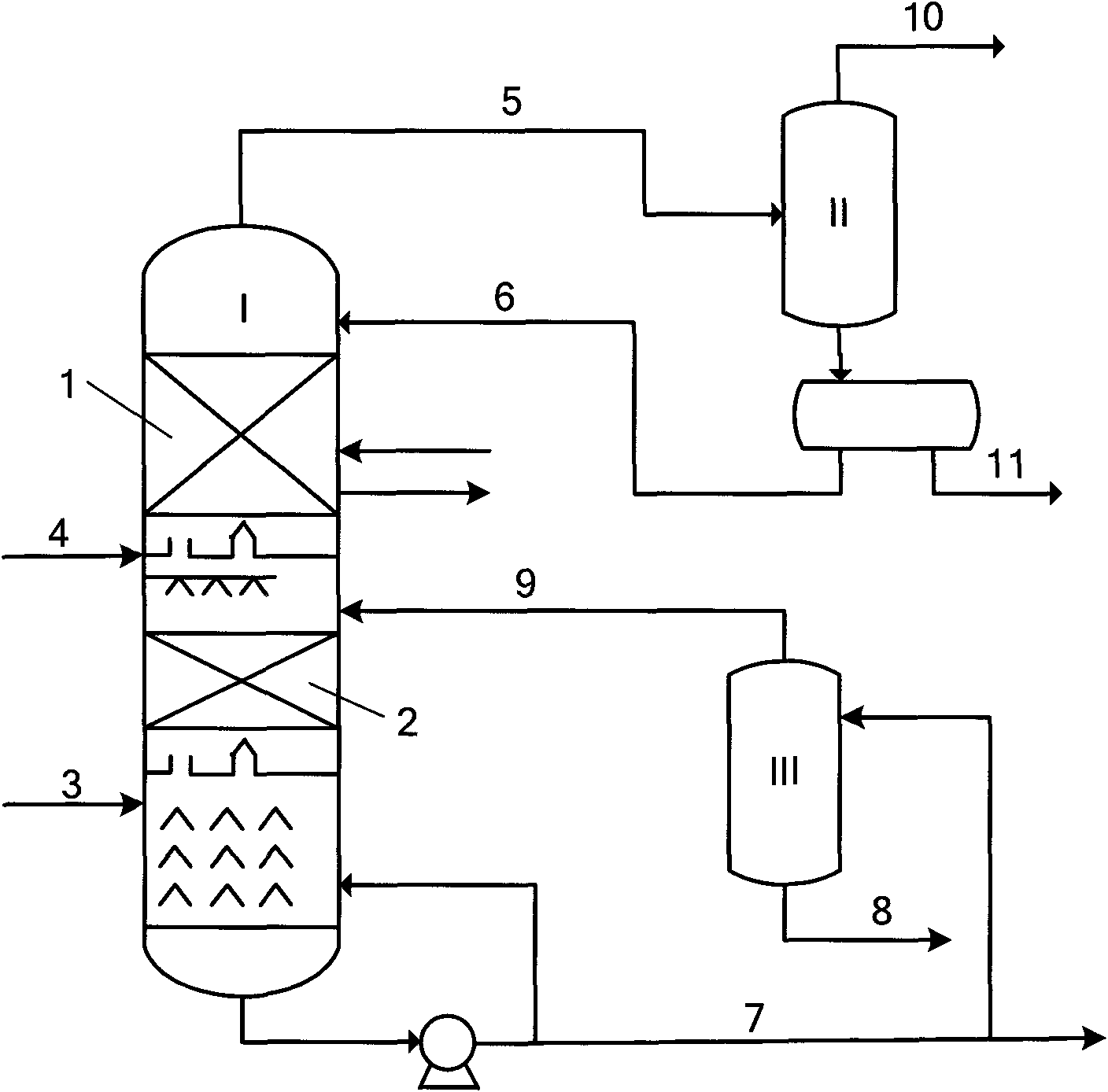

Wastewater recycling treatment process

InactiveCN101767888AImprove throughputEliminate scalingWater/sewage treatment by ion-exchangeWater/sewage treatment bu osmosis/dialysisFiltration membraneReverse osmosis

The invention discloses a wastewater recycling treatment process, which comprises the following steps: leading raw water to pass through a filter for removing suspended matters and solid particles in the raw water, leading outlet water of the filter to enter into an ion exchanger, removing calcium and magnesium ions in the raw water through ion exchange, further removing the hardness in the water, leading the outlet water of the ion exchanger to enter into a decarbonizing tower, and removing the alkalinity of the raw water under the air stripping action of a rotary fan; leading the raw water out of the decarbonizing tower to enter into a precision filter under the action of a lifting pump, lifting the outlet water of the precision filter to a nano-filtration / reverse osmosis system which is mainly formed by parallel connection and / or series connection of a nano-filtration membrane and a reverse osmosis membrane under the action of a high pressure pump, leading the nano-filtration / reverse osmosis system to discharge concentrated water, leading the nano-filtration / reverse osmosis system to drain produced water into a produced water tank, and becoming the final outlet water. The process can effectively avoid the membrane pollution, improve the recycling rate, further greatly reduce the discharge amount of wastewater, simultaneously reduce the using amount of membranes due to the improvement of running conditions of a membrane system and further reduce the investment and the running cost.

Owner:郑理慎

Single Well, Self-Flowing, Geothermal System for Energy Extraction

ActiveUS20130192816A1Improve sealingReduce and eliminate parasitic power drawCollector components/accessoriesOther heat production devicesWorking fluidEngineering

A renewable energy, single well, primarily self-flow, geothermal heat / power production system that acquires naturally occurring sub-surface geothermal heat to heat water and / or produce mechanical / electrical power using a heat exchangers or a turbine / generator. The sub-surface structures defining a working fluid flow path may be insulated, such as with vacuum insulation, to increase system efficiency and ensure a substantially self-generating working fluid flow.

Owner:DEEP WELL POWER

Steam generator

InactiveUS20110274416A1Prolonging steam generator lifespanExtend your lifeSteam generation heating methodsBoiler controlEngineering

Owner:CHEN HSI FU

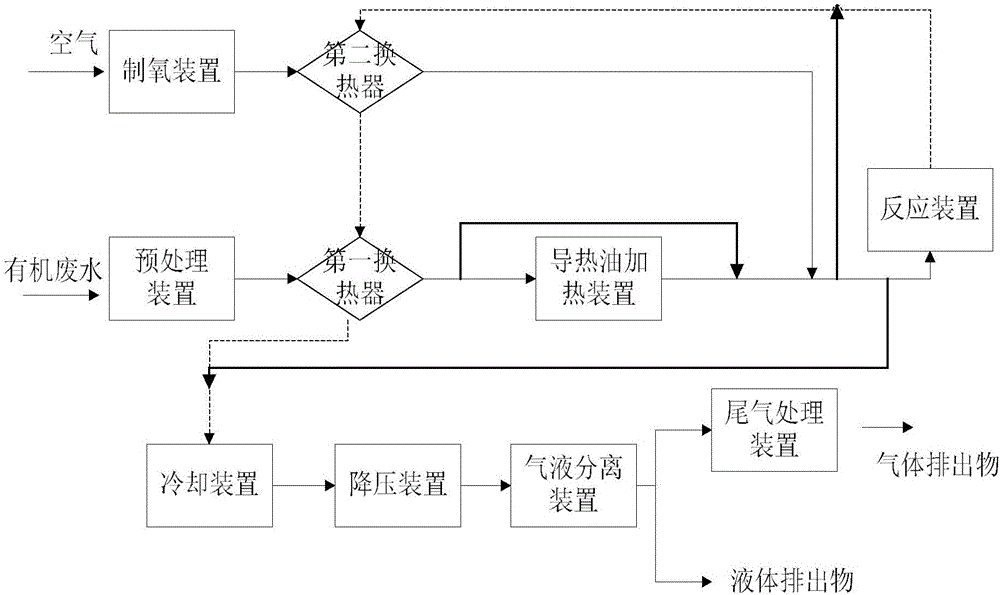

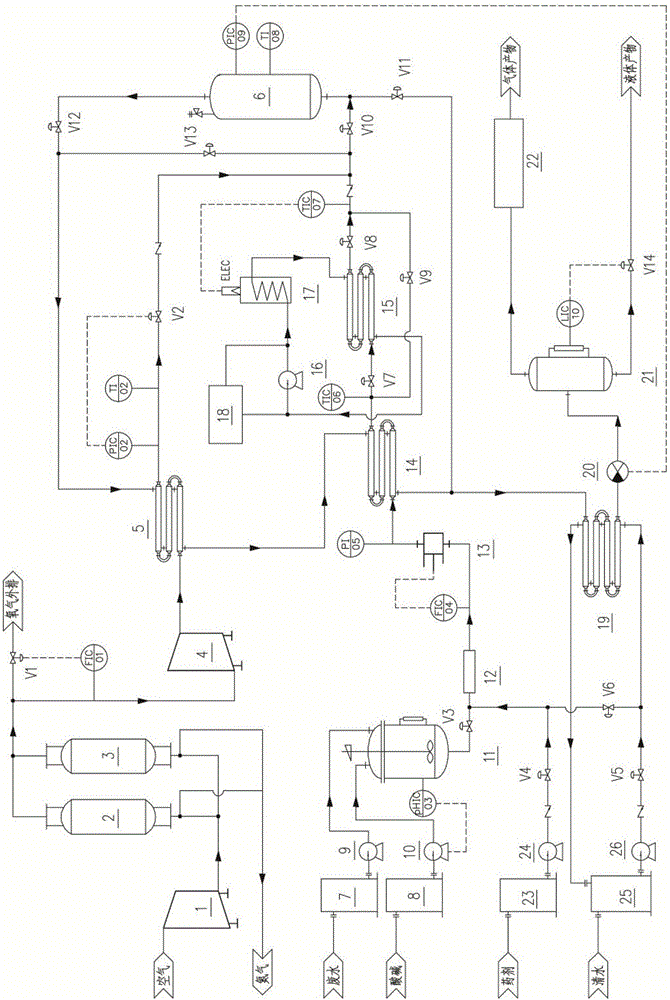

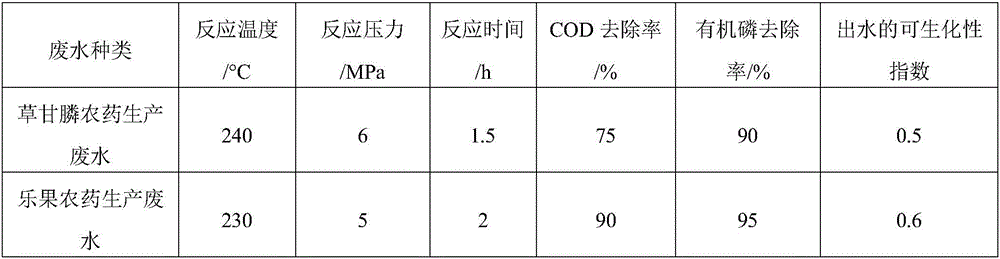

High-concentration organic wastewater wet oxidation treatment system and method

PendingCN106380021AAchieve homogeneityRealize the adjustment functionDispersed particle separationTreatment involving filtrationHigh concentrationSlag

The invention discloses a high-concentration organic wastewater wet oxidation treatment system, which is integrated by an oxygen generating device, a pretreatment device, a heat conducing oil heating device, a wet oxidation treatment device, a cooling pressure reduction device, a gas-liquid separation device, a tail gas treatment device and the like. The invention also discloses a method for treating high-concentration organic wastewater by the system. Compared with the prior art, the system has the advantages that the transportation and the installation are convenient; the integration performance is good; the system fully recovers and utilizes heat after reaction through a multistage heat exchanger for preheating waste water and oxygen, so that the operation cost can be reduced; through the oxygen generating device, air is used as raw materials for preparing high-purity oxygen on site for wet oxidation reaction, so that the contaminant removing efficiency can be improved; the wet oxidation reaction device made of duplex metal composite materials is used, and a catalyst box is arranged inside the reaction device, so that the corrosion resistant capability of the reaction device is favorably improved, and the reaction conditions are reduced. The system can realize reaction device slag discharging in the operation process, so that the risk of system scale formation and blockage is favorably reduced, and the system can be widely applied to the treatment of high-concentration difficult-to-degrade organic wastewater.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI +1

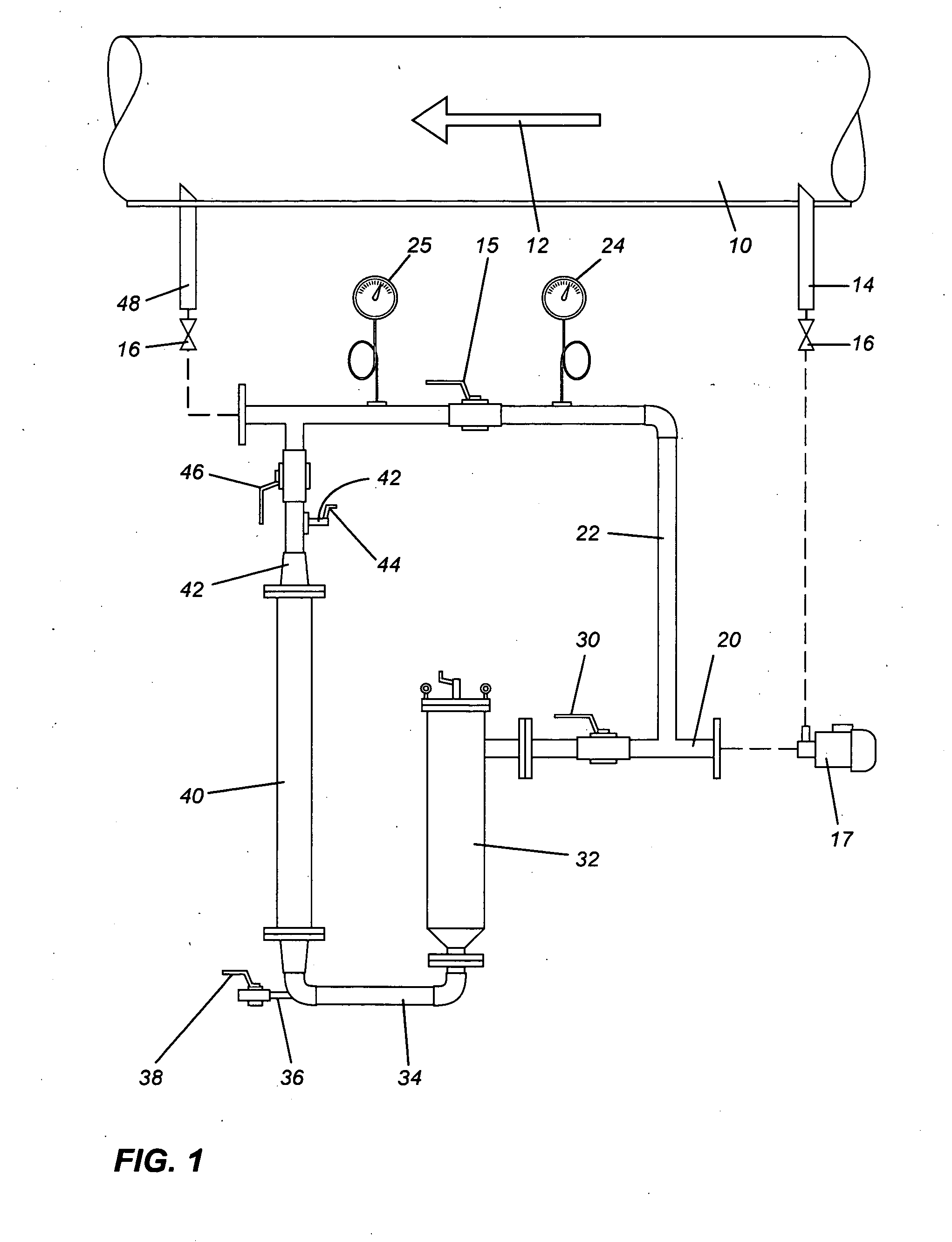

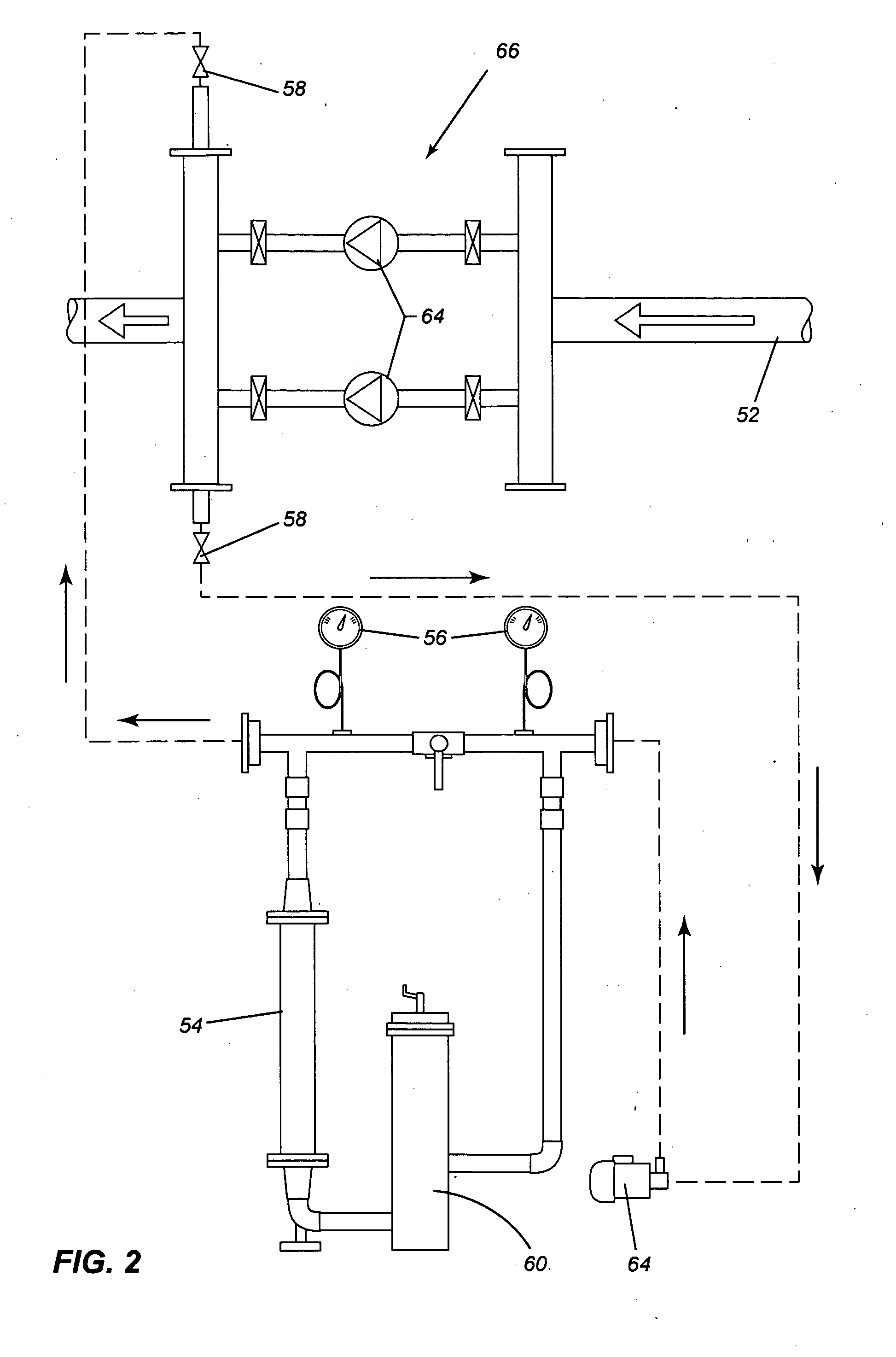

Water treatment

InactiveUS20080264607A1Prevent scalingEliminate scalingSpecific water treatment objectivesTreatment involving filtrationChillerBiomedical engineering

A method and device for removing scaling from the interior of a conduit used in a heat transfer device, the method comprising the steps of diverting a portion of the fluid from the conduit, passing the diverted portion through a filter, passing the filtered portion through a magnetic field, and reintroducing the fluid into the conduit. The method of the present invention can also be used with chillers to control bacterial growth therein.

Owner:HEBERT CLAUDE L

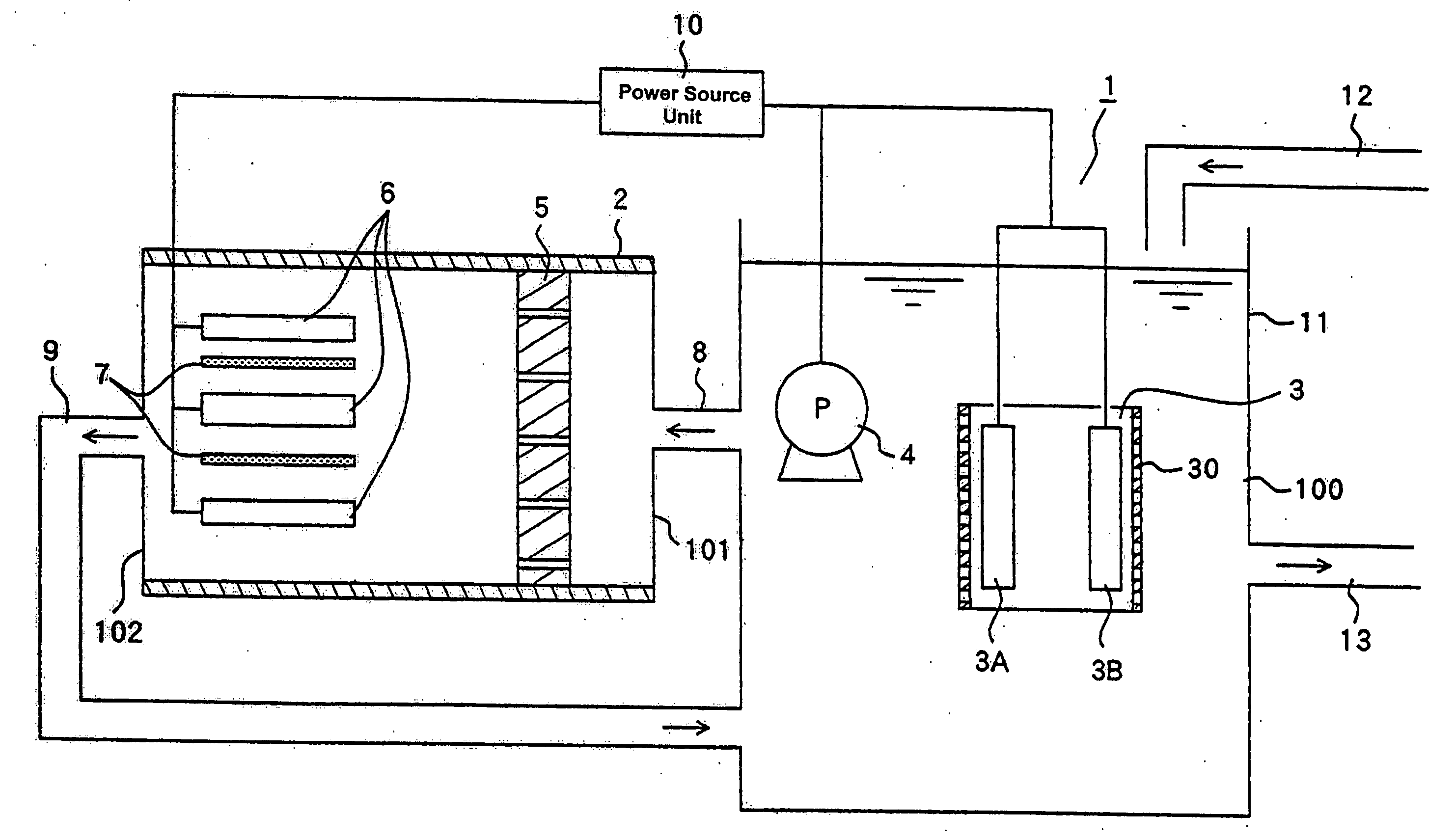

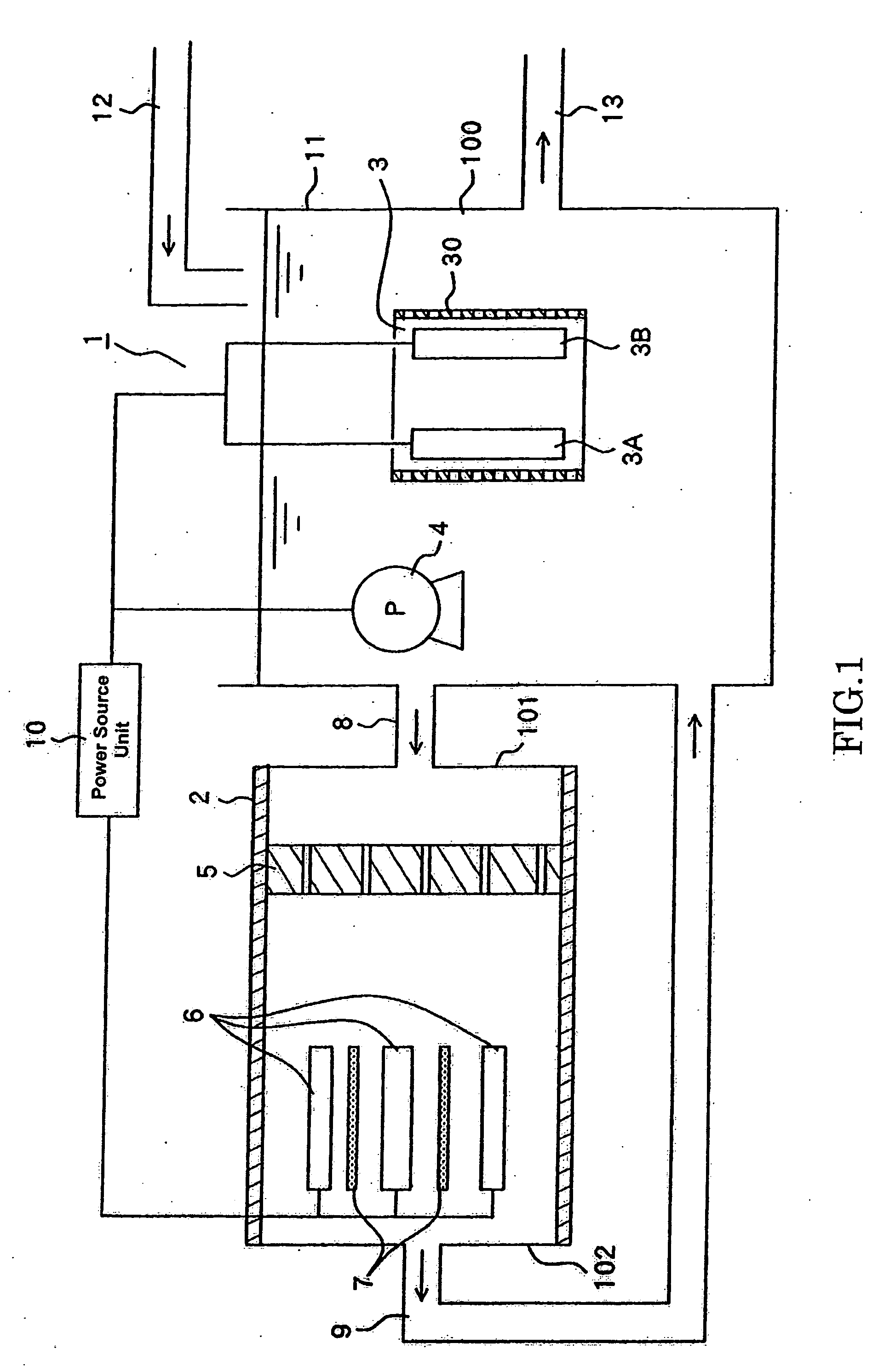

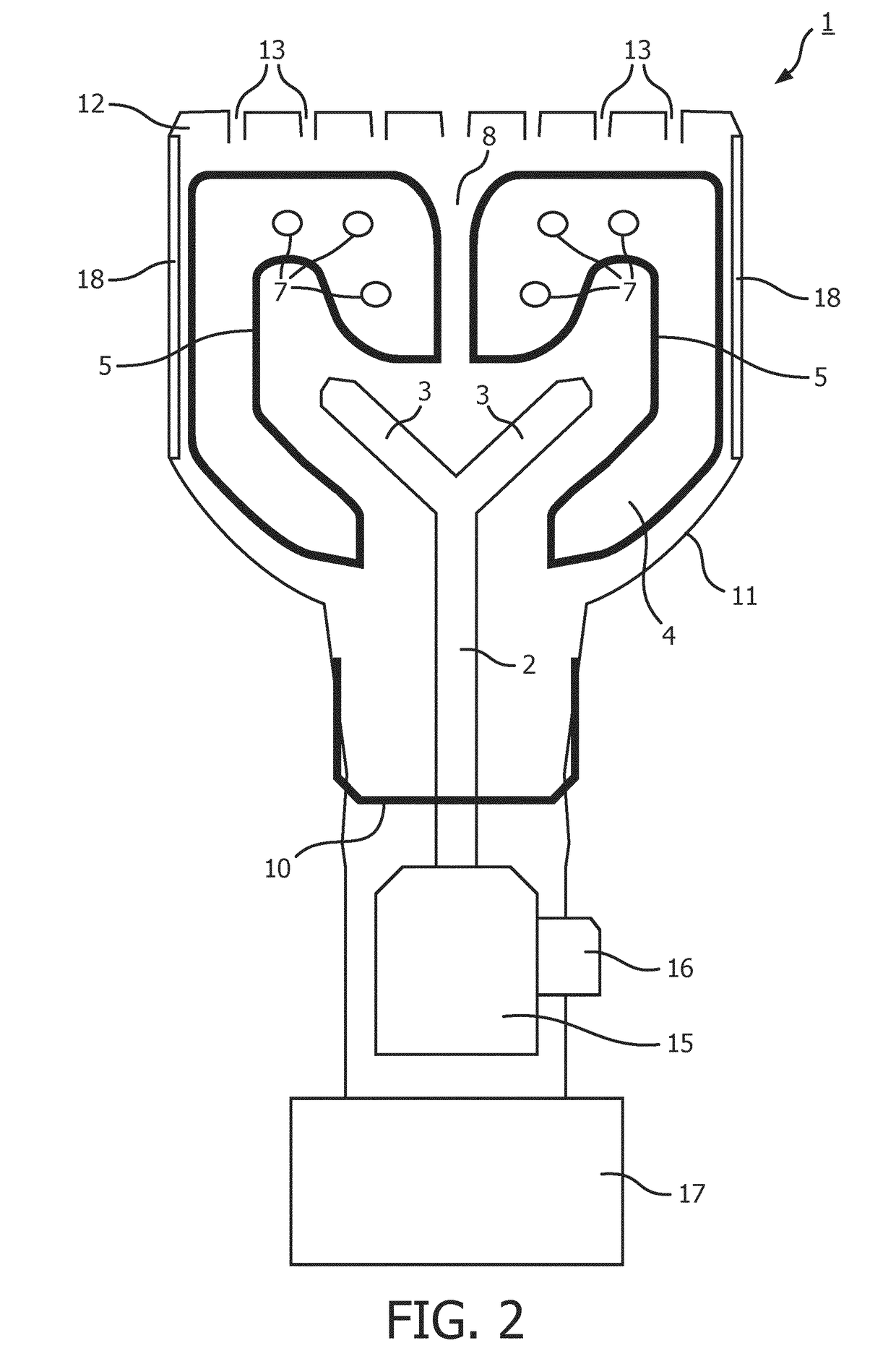

Photocatalyst water treating apparatus

InactiveUS20070020158A1Prevents the deposition of scaleAvoid depositionScale removal and water softeningTreatment involving filtrationCompound (substance)Inorganic compound

An object is to dissolve and remove rust and scale deposits of inorganic compounds formed in a reservoir, in which to store water that requires processing, or in piping, or on a jacket of a UV-lamp without using any chemicals. A photocatalytic water-processing system utilizes a reservoir 11 in which organic and inorganic materials present in water 100 that requires processing the water are decomposed. The system comprises: a circulation path including: a main unit 2 arranged outside the reservoir 11; an inlet pipe 8 connecting to an inlet of the main unit 2; and an outlet pipe 9 connecting to an outlet of the main unit 2; a pump 4 for circulating the water; a filter 5 arranged within the main unit 2; photocatalytic processing means arranged downstream of the filter 5 and including a photocatalyst carrier 7 and a UV-lamp 6; and an electrode unit 3 arranged within the reservoir 11. The water 100 is electrolyzed as a current is applied to the electrode unit 3.

Owner:REIKEN

Hybrid stent with helical connectors

ActiveUS8114149B2Minimal fish scalingIncrease flexibilityStentsBlood vesselsInsertion stentMaximum diameter

The present invention is a hybrid stent design using half-slot circumferential sets of strut members with short (<1.5 mm) slot length that has minimal fish scaling and excellent stent retention and flexibility. These half-slot circumferential sets of strut members are connected one to the other with helical connectors similar to those of the Palmaz stent. One important difference in the design of the stent of the present invention is that the helical connectors are attached to every other crown (rather than connected to every crown) to further improve stent flexibility. By appropriately varying the strut width of both the connected and unconnected curved crowns to be greater at the center than at their ends, an increased radial strength can be provided for a given maximum strain that is imparted to the stent when it is expanded to its maximum diameter.

Owner:SVELTE MEDICAL SYST

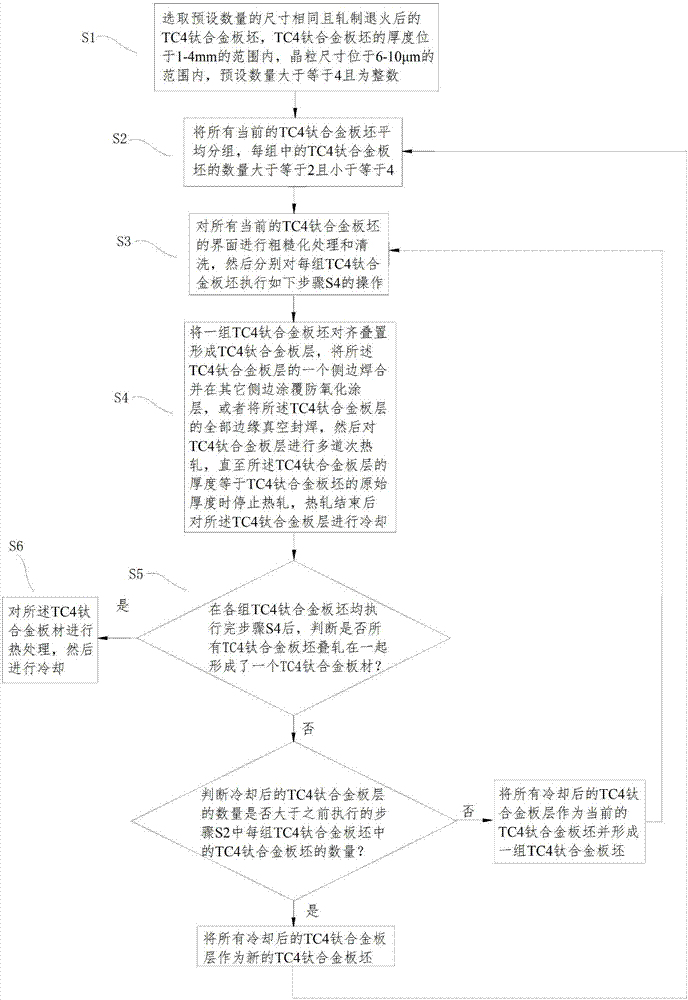

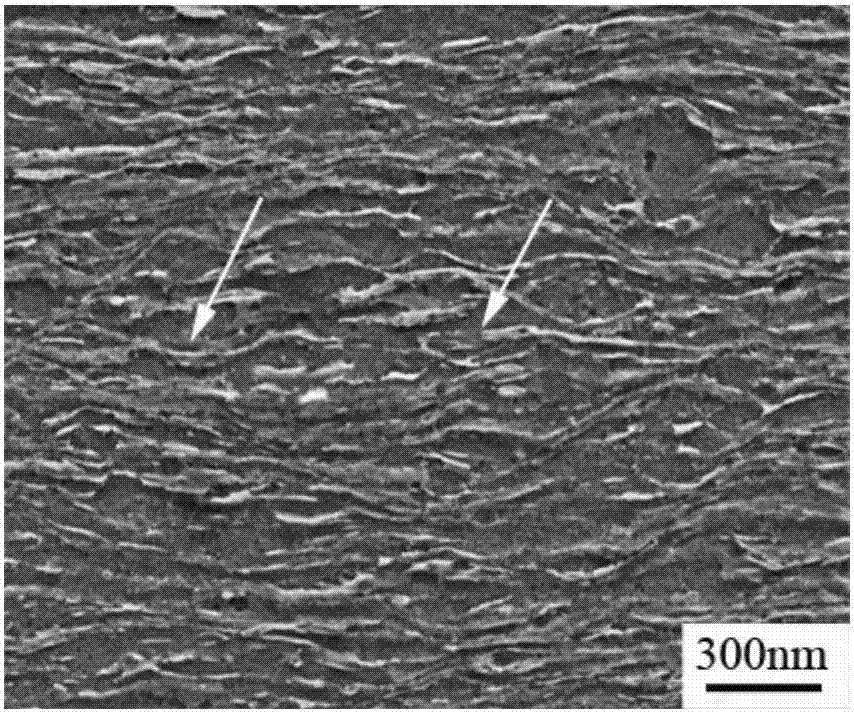

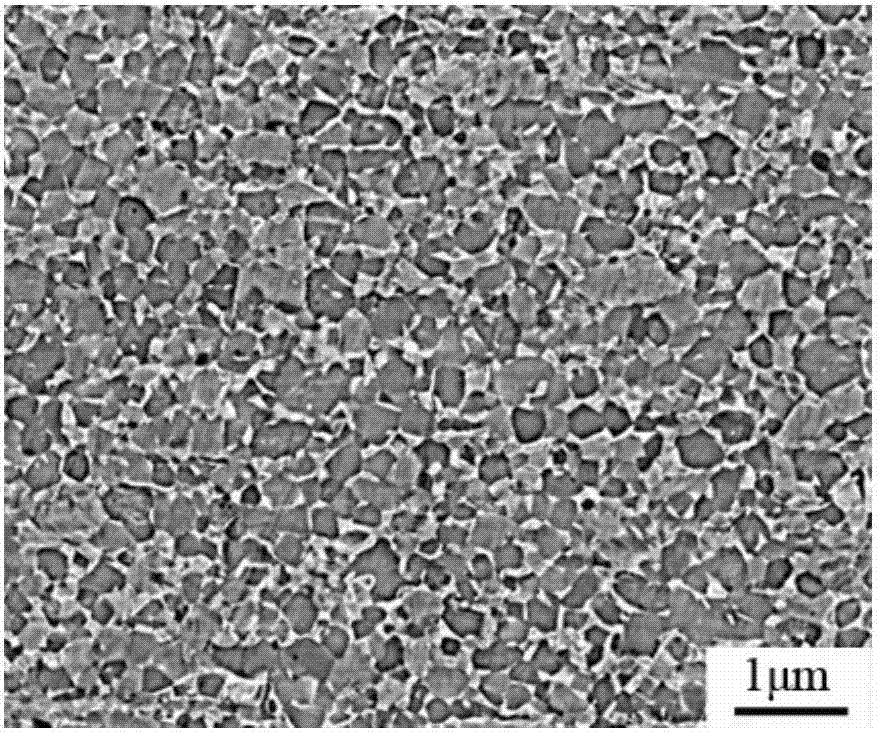

Preparation method of equal-thickness ultrafine grain TC4 titanium alloy plate

InactiveCN107030111AFacilitated DiffusionNo separationWelding/cutting auxillary devicesAuxillary welding devicesTitanium alloyHeat treating

The invention relates to the technical field of metallurgy, in particular to a preparation method of an equal-thickness ultrafine grain TC4 titanium alloy plate. The preparation method comprises the steps that S1, plate blanks obtained after rolling and annealing are taken; S2, the plate blanks are grouped; S3, interfaces of the plate blanks are subjected to roughening treatment and cleaning, and then the following operation of S4 is executed on each group; S4, the plate blanks in each group are stacked into a plate layer, one side edge of each plate layer is welded, the other side edges of each plate layer are coated with anti-oxidation coatings, or all edges of the plate layers are subjected to vacuum seal welding, the hot rolling process is adopted for ply rolling and welding, final hot rolling is carried out till the thickness of the plate layers is equal to the original thickness of the plate blanks, and then air cooling is carried out; S5, if the plate layers need to be grouped again, the plate layers serve as new plate blanks to return to the step S2, and otherwise all the plate layers form a plate blank group to return to the step S3 till all the plate blanks are subjected to ply rolling into the plate; S6, the plate is subjected to heat treatment and then cooled. According to the method, the defects of the insufficient hot rolling deformation and deformation cracking and incomplete welding in the ply rolling process can be overcome, and the equal-thickness ultrafine grain plate can be prepared.

Owner:NORTHEASTERN UNIV

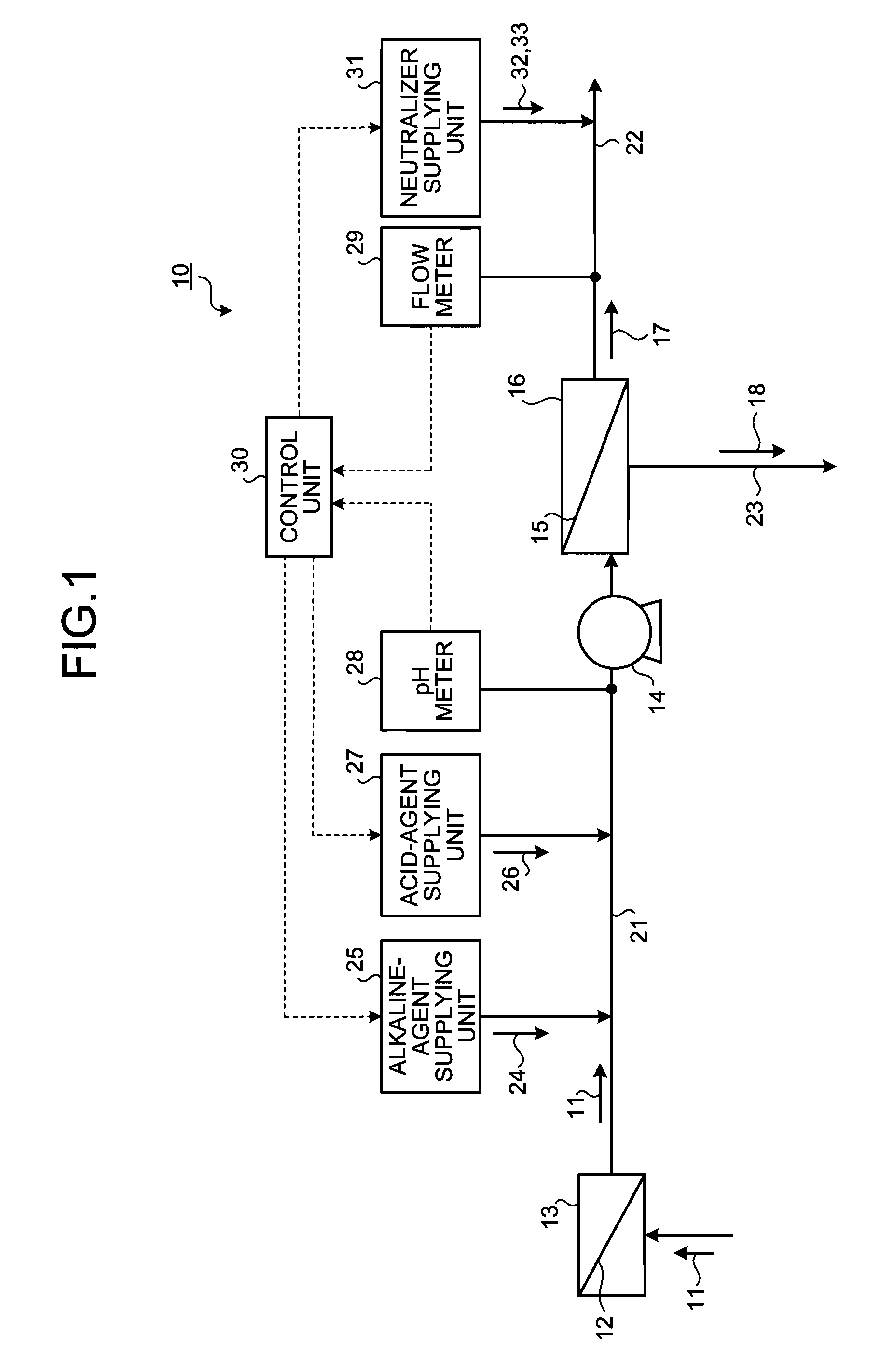

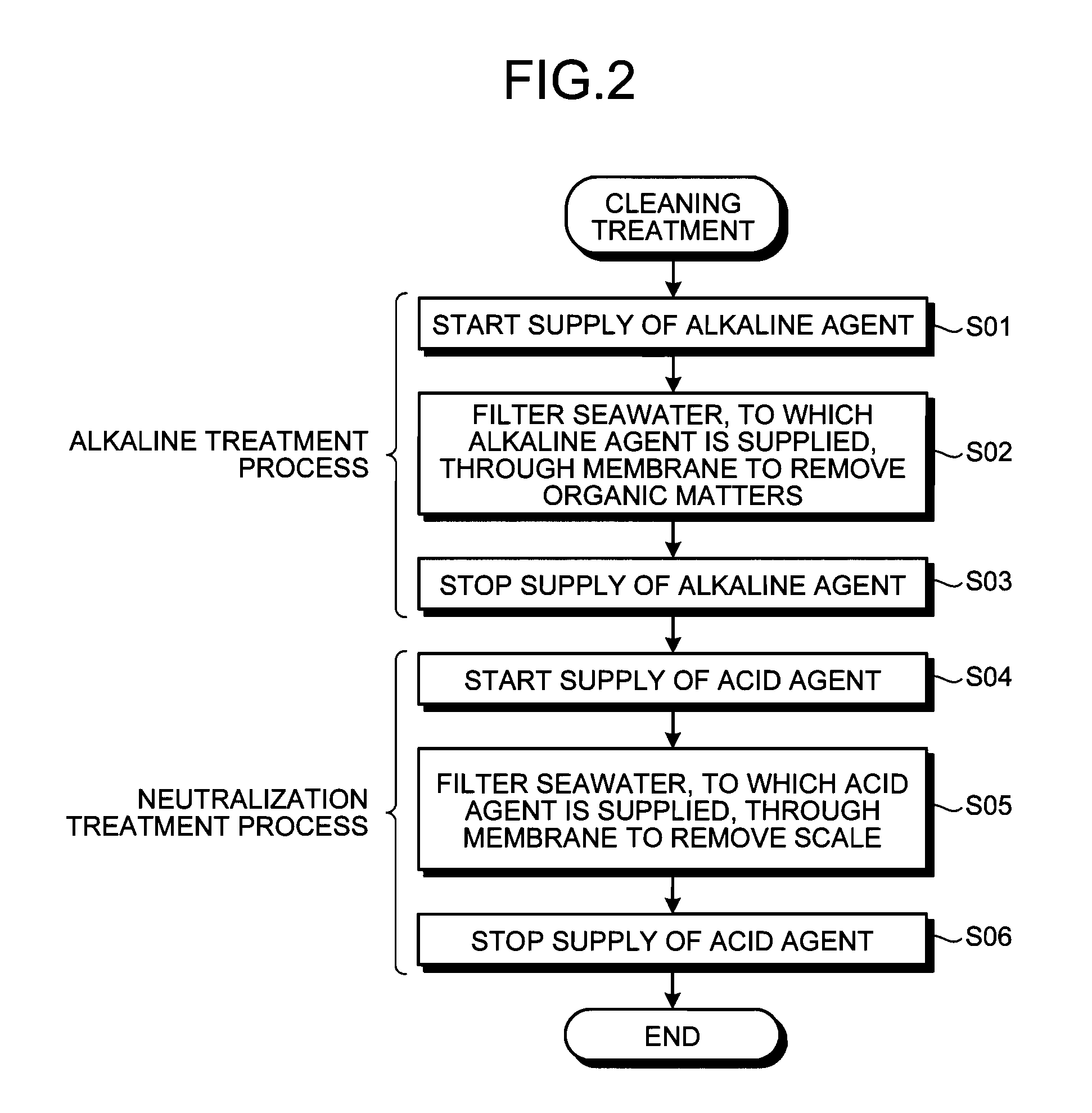

Method of cleaning filtration membrane

Owner:MITSUBISHI HEAVY IND LTD

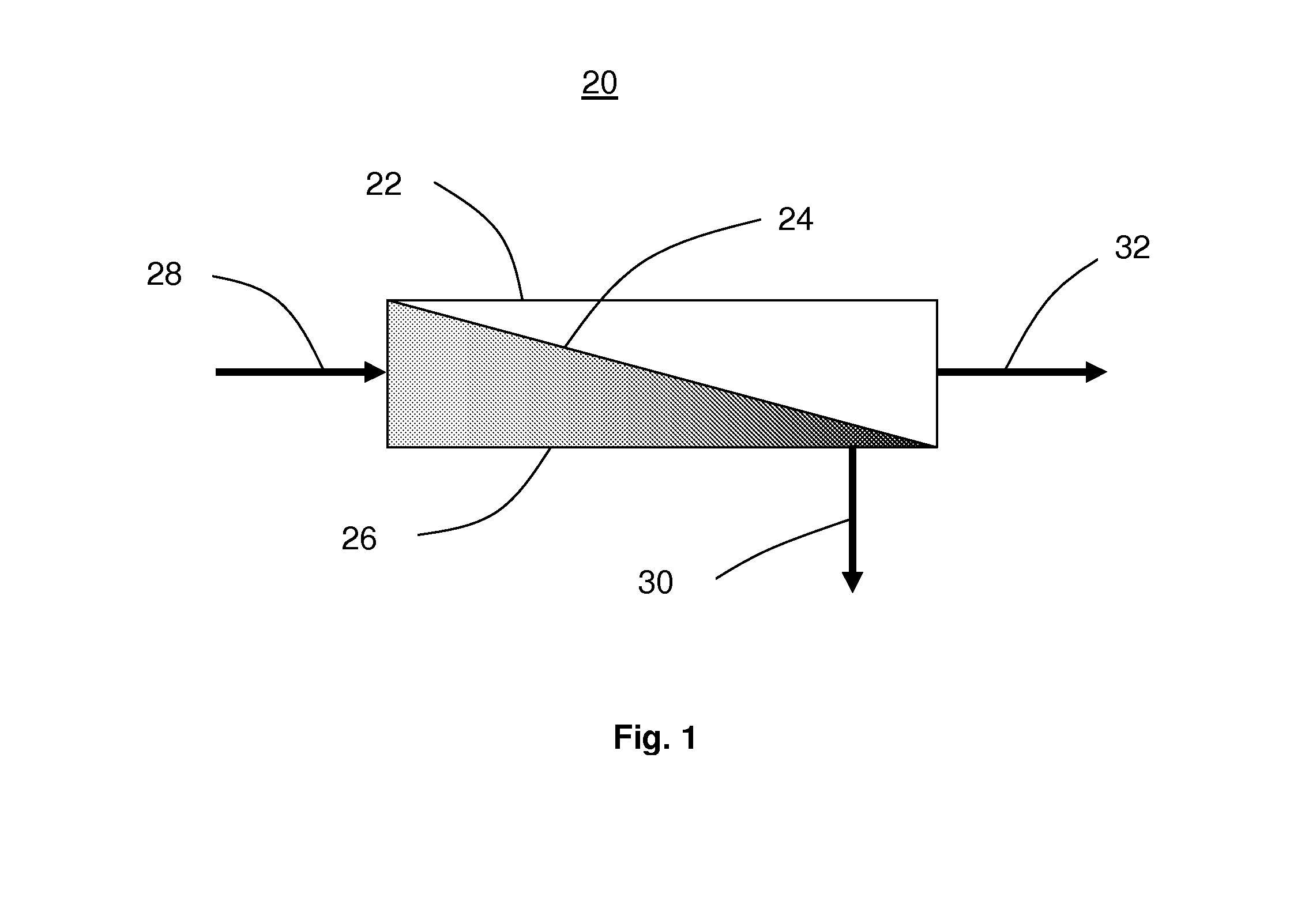

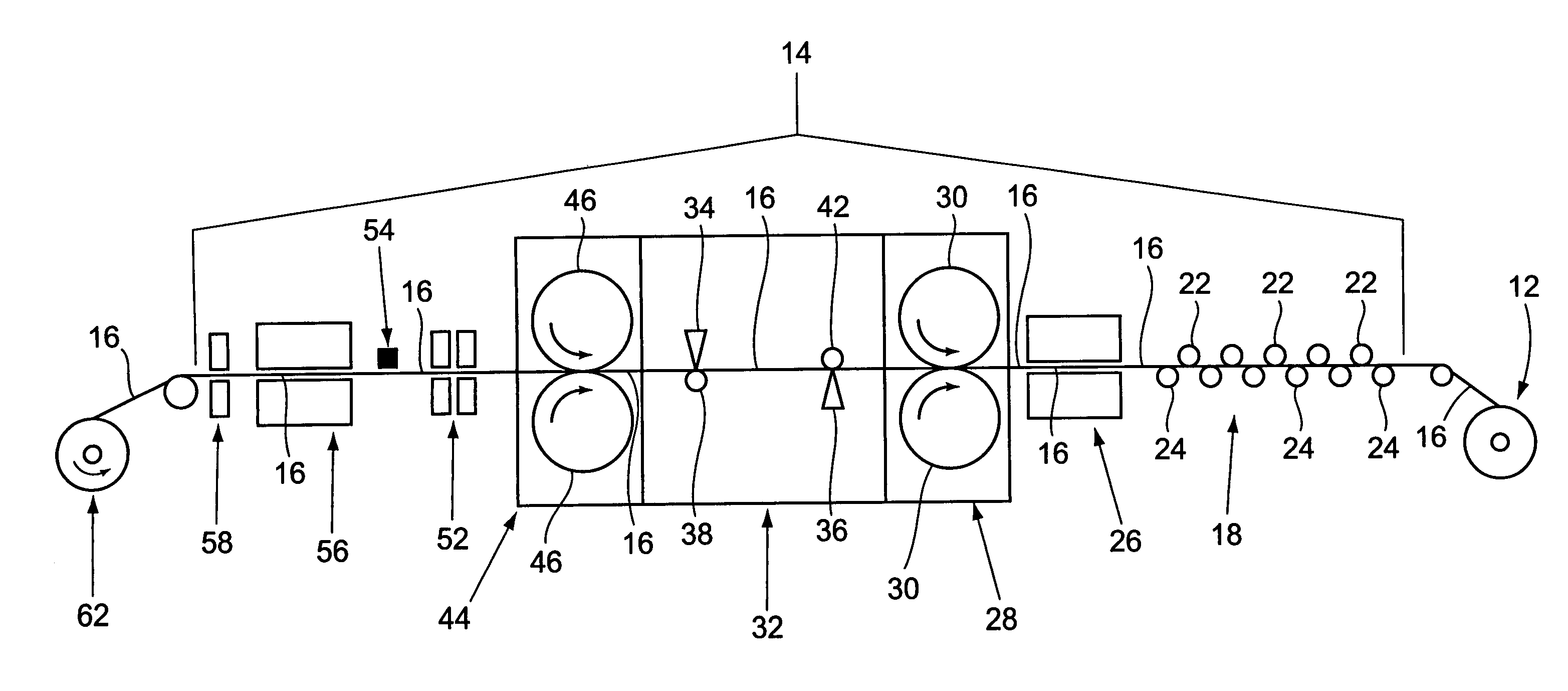

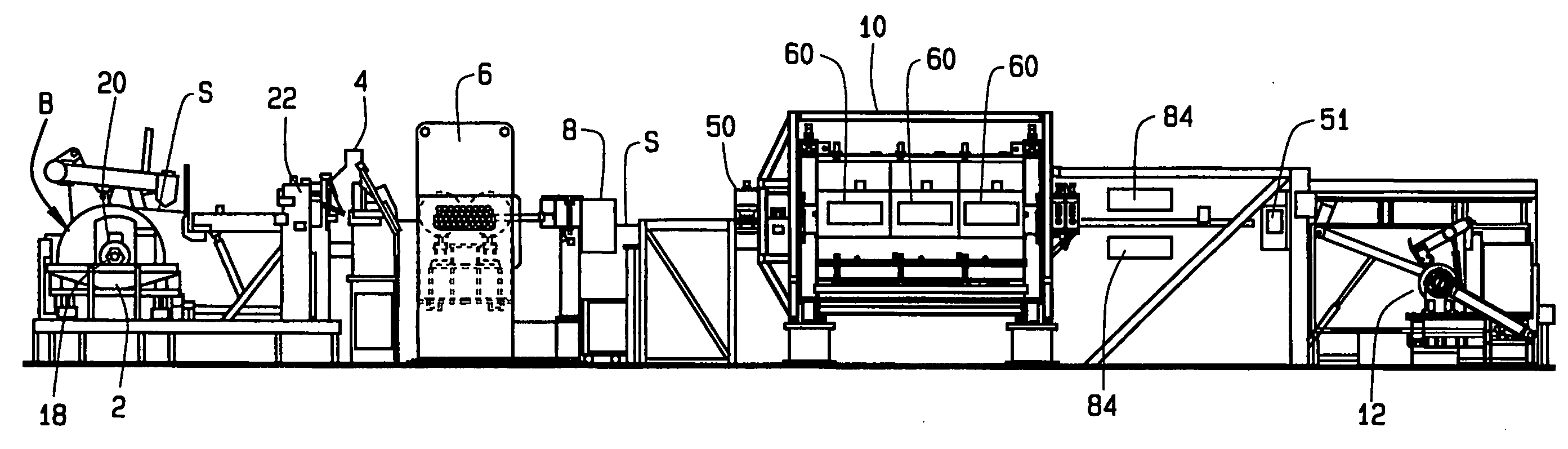

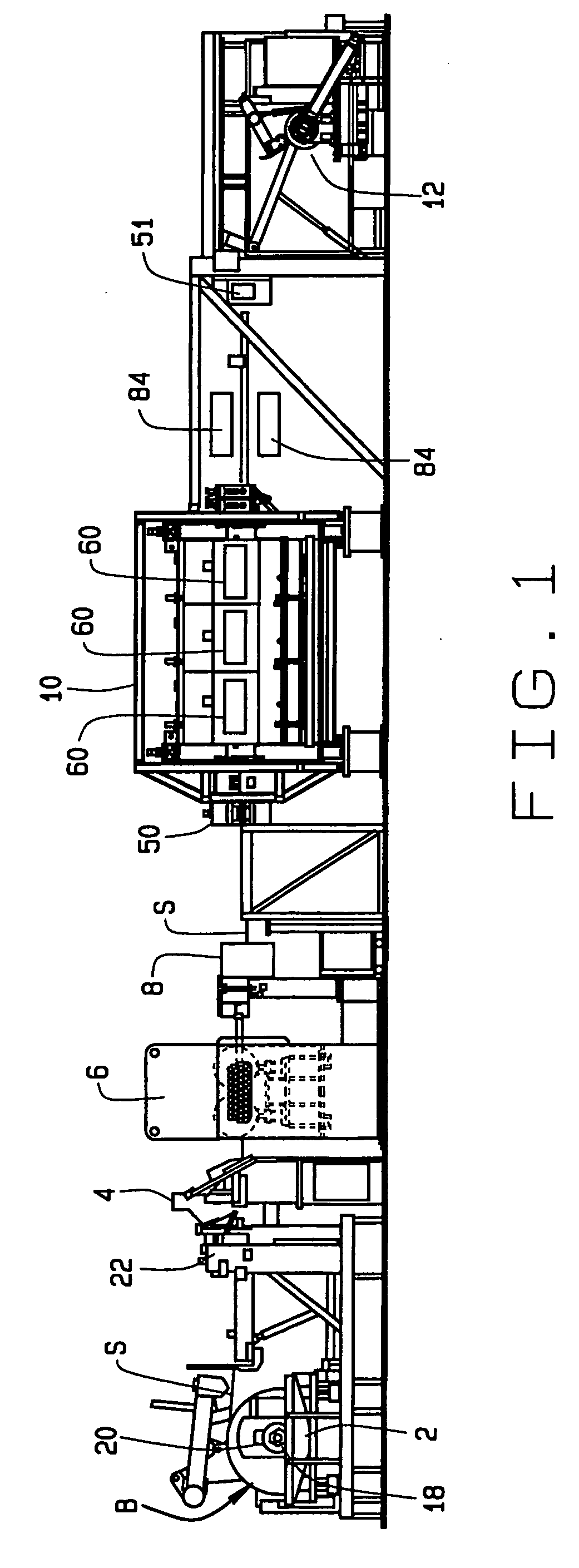

Method and apparatus for conditioning sheet metal

A metal processing apparatus, comprising a pay-off reel for supporting and uncoiling a coil of metal, a roller-leveler apparatus adapted to receive a strip of sheet metal from the pay-off reel for conditioning the strip of steel, a recoiler for re-coiling the coil of metal, and whereby the apparatus generates enough tension on the strip of metal to improve flatness and remove coil breaks from the strip of metal as it advances through the roller-leveler.

Owner:RED BUD IND

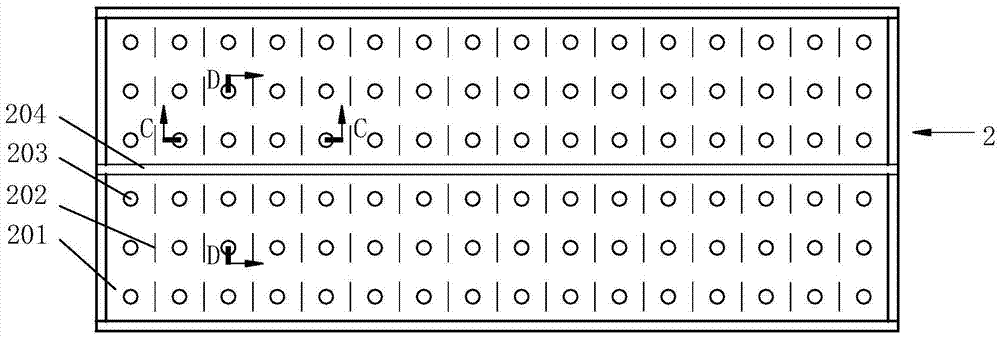

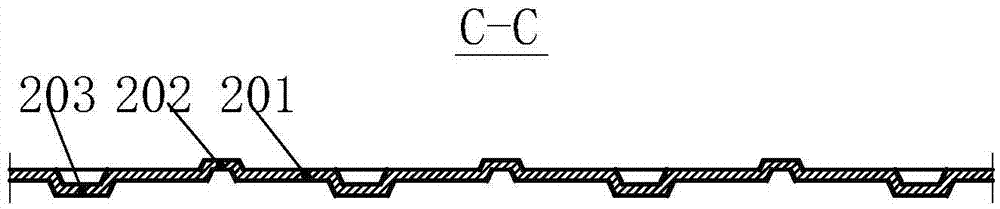

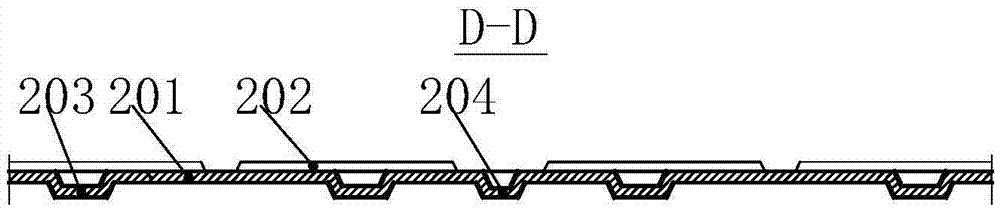

Corrugated plate beam of single-side contact-free through flow way

ActiveCN107024124AEliminate cloggingEliminate scalingLaminated elementsStationary plate conduit assembliesPlate heat exchangerMechanical engineering

The invention relates to the technical field of plate type heat exchangers, in particular to a corrugated plate beam of a single-side contact-free through flow way. The corrugated plate beam comprises a plurality of plate pieces, and each plate piece comprises a main heat transfer face, turbulent flow ripples evenly distributed on the main heat transfer face, pressure bearing ripples and ranging ripples extending from one end to the other end in the direction of the length of the corresponding plate piece. According to the plate beam, the problems that in the prior art, a flow way of a plate type heat exchanger is blocked, fouling corrosion happens, and the cold and heat medium temperature is crossed are solved.

Owner:TIANJIN HUASAIER HEAT TRANSFER EQUIP

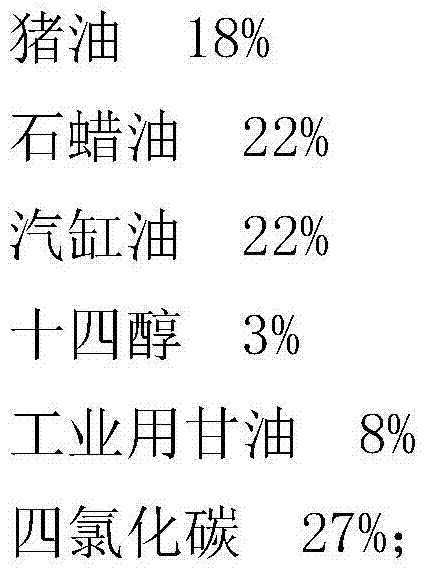

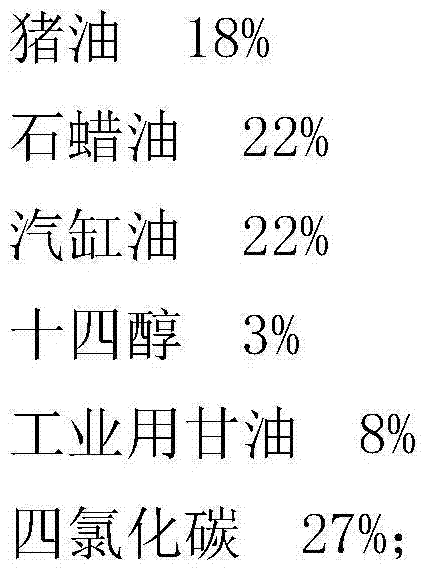

Lubricating liquid for lubricating surface of aluminum alloy material and preparation method thereof

InactiveCN104119995AEliminate surface defectsEliminates oil and scaleBase-materialsParaffin oilsOxide

The invention discloses a lubricating liquid for lubricating the surface of an aluminum alloy material and a preparation method thereof, and relates to the technical field of lubricating liquids. The lubricating liquid is composed of the following components: lard, paraffin oil, steam cylinder oil, tetradecyl alcohol, industrial glycerin, and carbon tetrachloride. The lubricating liquid can eliminate the surface defects of an aluminum alloy material, oil stains and oxide scales, so the lubricating effect is better, the fluidity and lubricity of aluminum alloy products are better during the extrusion process, and the part quality is improved.

Owner:ANHUI CHENGYOU AUTO PARTS MFG

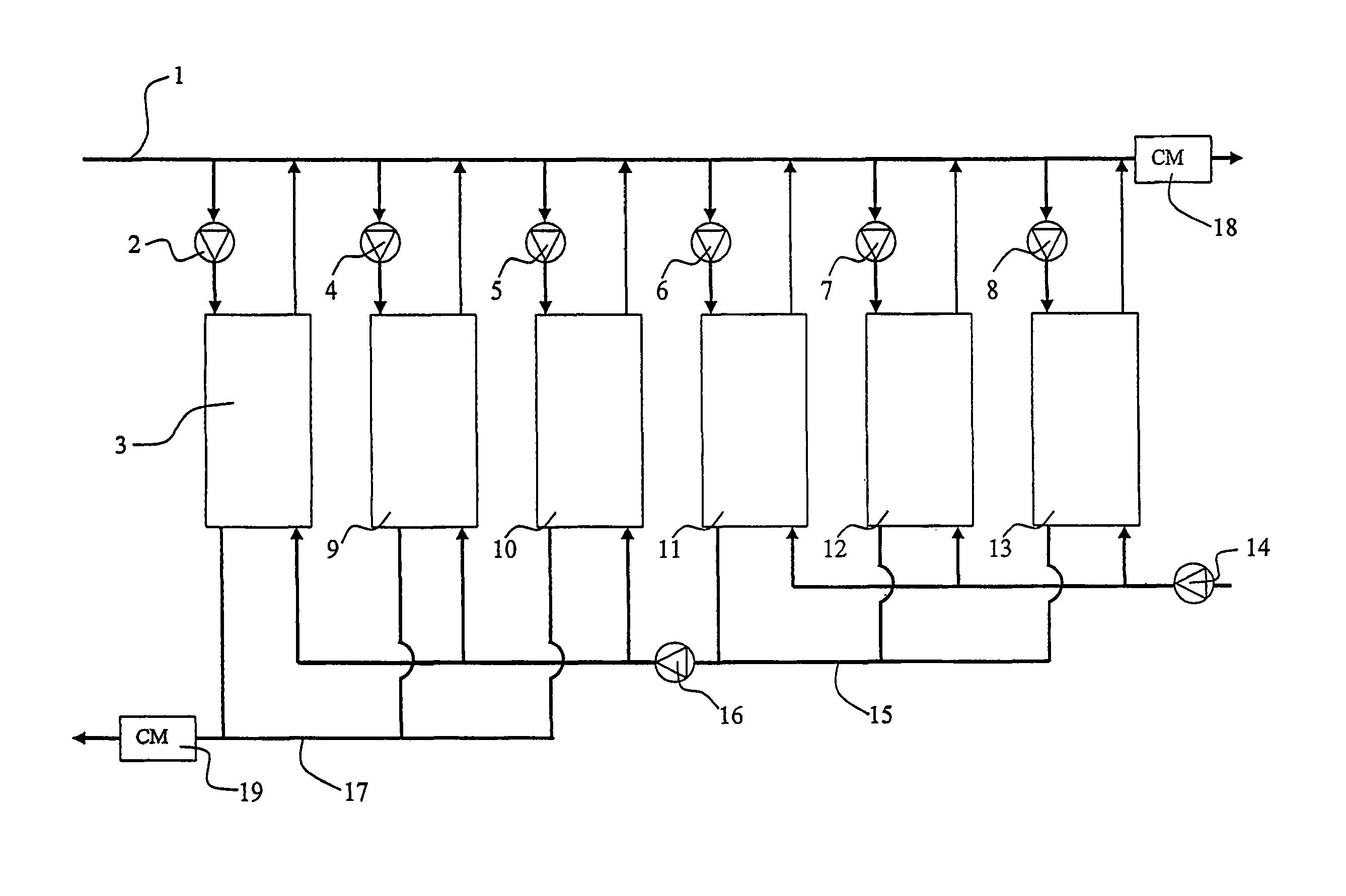

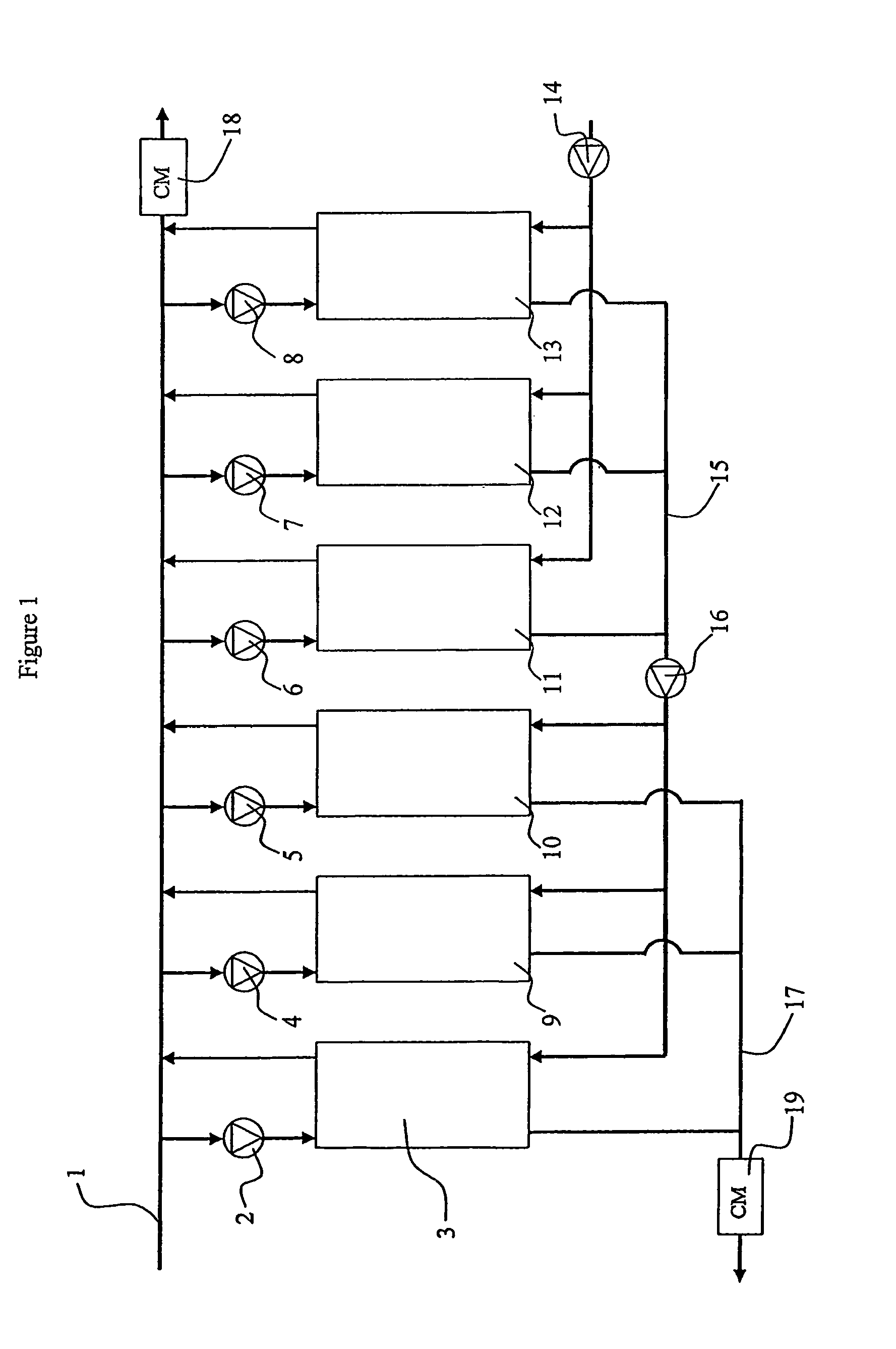

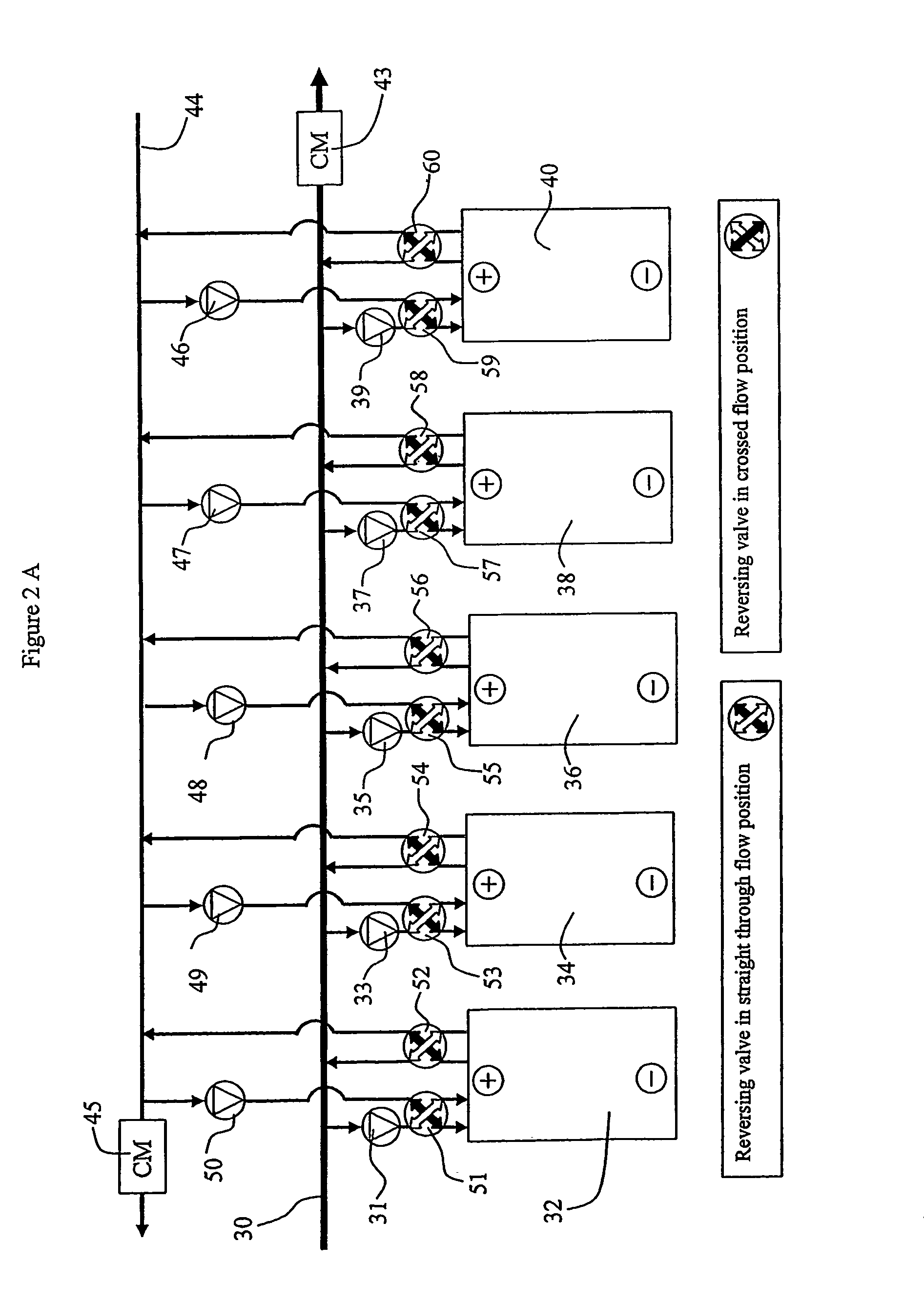

Electrodialysis system and process

ActiveUS8142633B2Improve matchReduced back-diffusionSludge treatmentVolume/mass flow measurementElectricityPower flow

A treatment system and method for continuous deionization of a biologically derived feed stream includes a plurality of electrodialysis units (3, 9, 10, 11, 12, 13) arranged in stages along a treatment line, and stages are controlled such that the feed stream attains a certain quality before entering the next stage. The feed and concentrate streams move in generally opposite sense along the line, matching fluid characteristics of dilute and concentrate cells. The treatment line has two or more stages. Systems may have phased staging operations, and cell constructions may adapt the electrodialysis units for enhanced processing of difficult process fluids. A controller sets operating potentials in different electrical stages, and simple control parameters optimize ion removal and current efficiency without polarization of the fluid. The invention also includes phased staging of reversal operation, and cell constructions or fillings that adapt the treatment cells for enhanced processing.

Owner:BL TECH INC

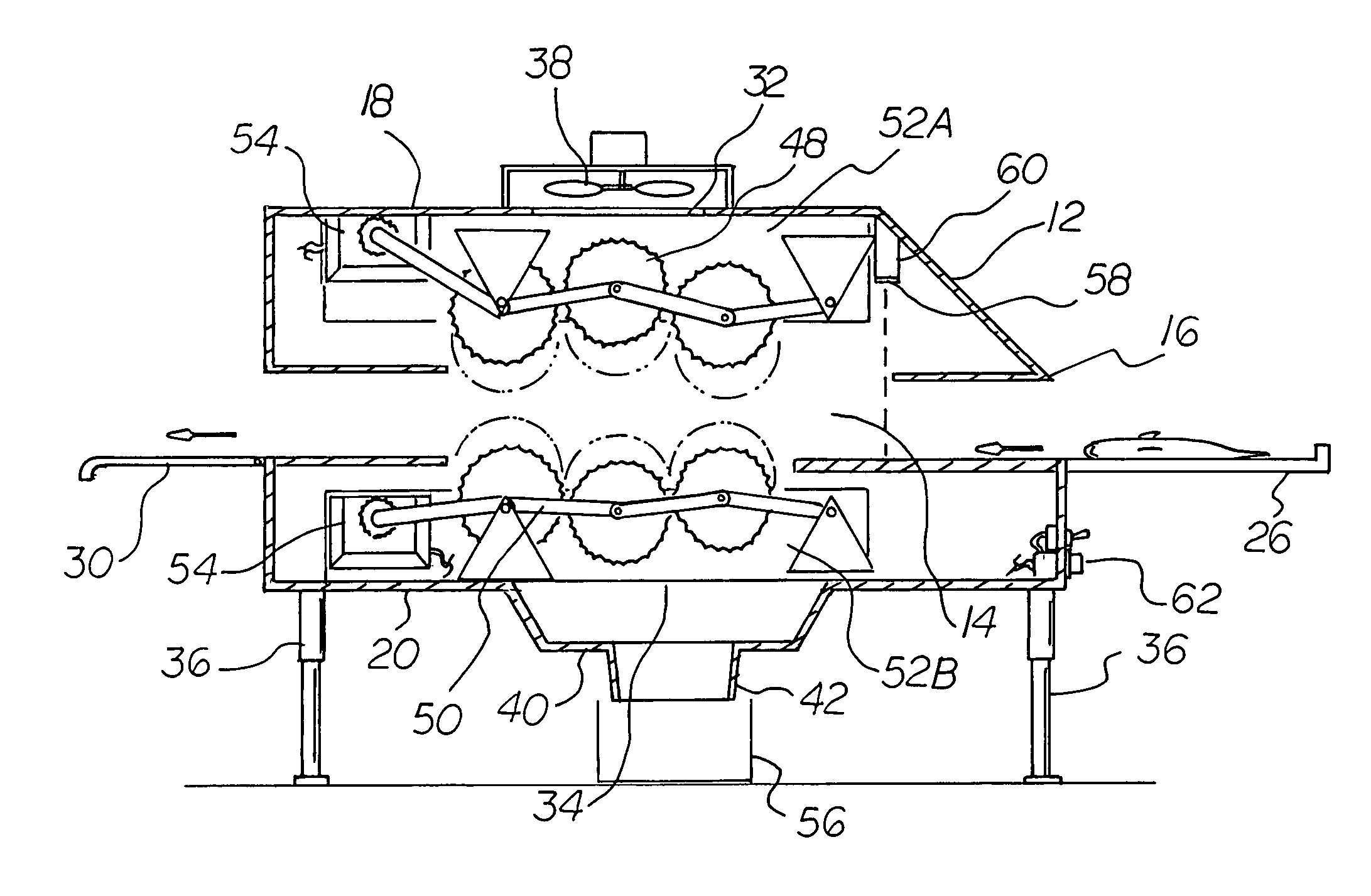

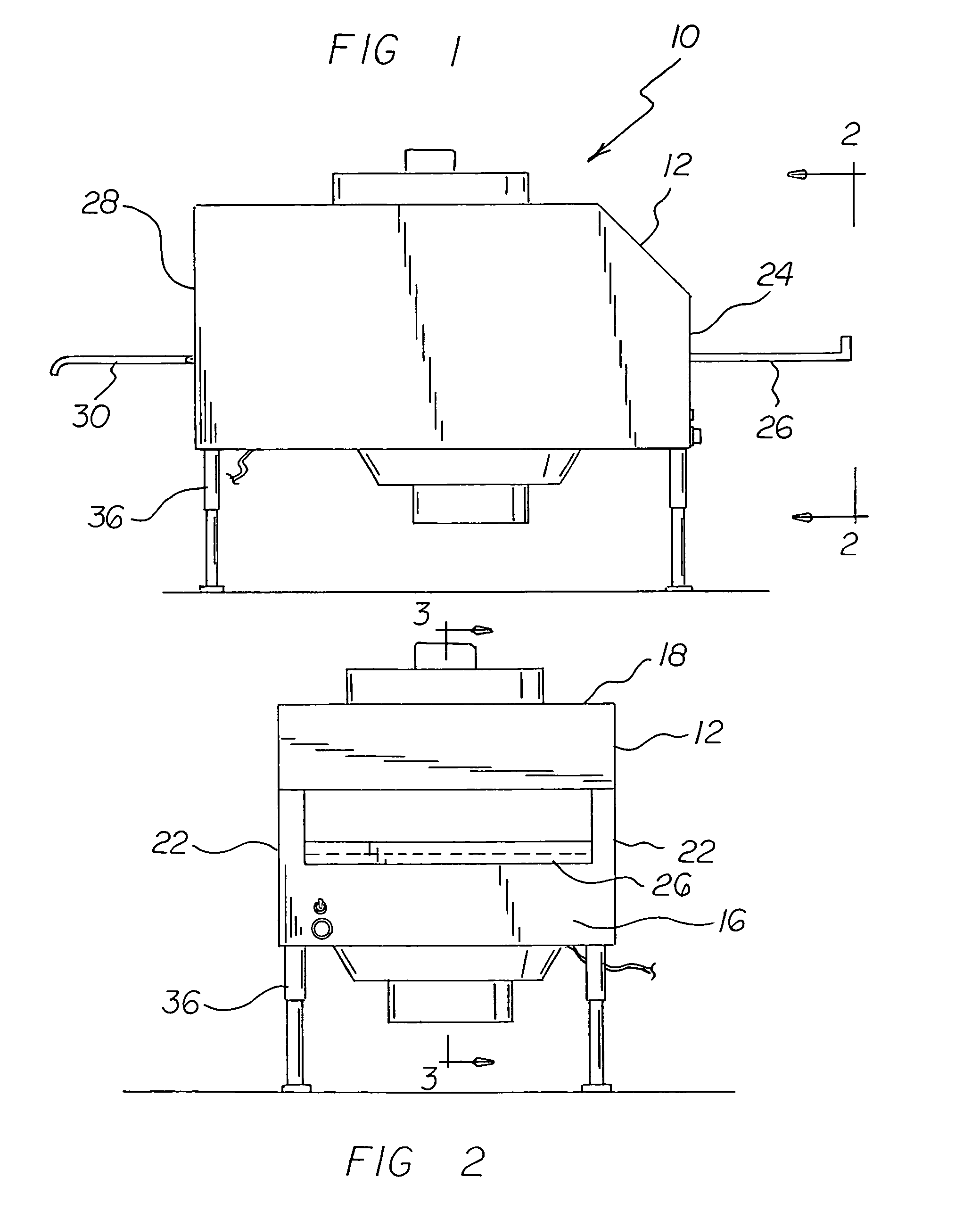

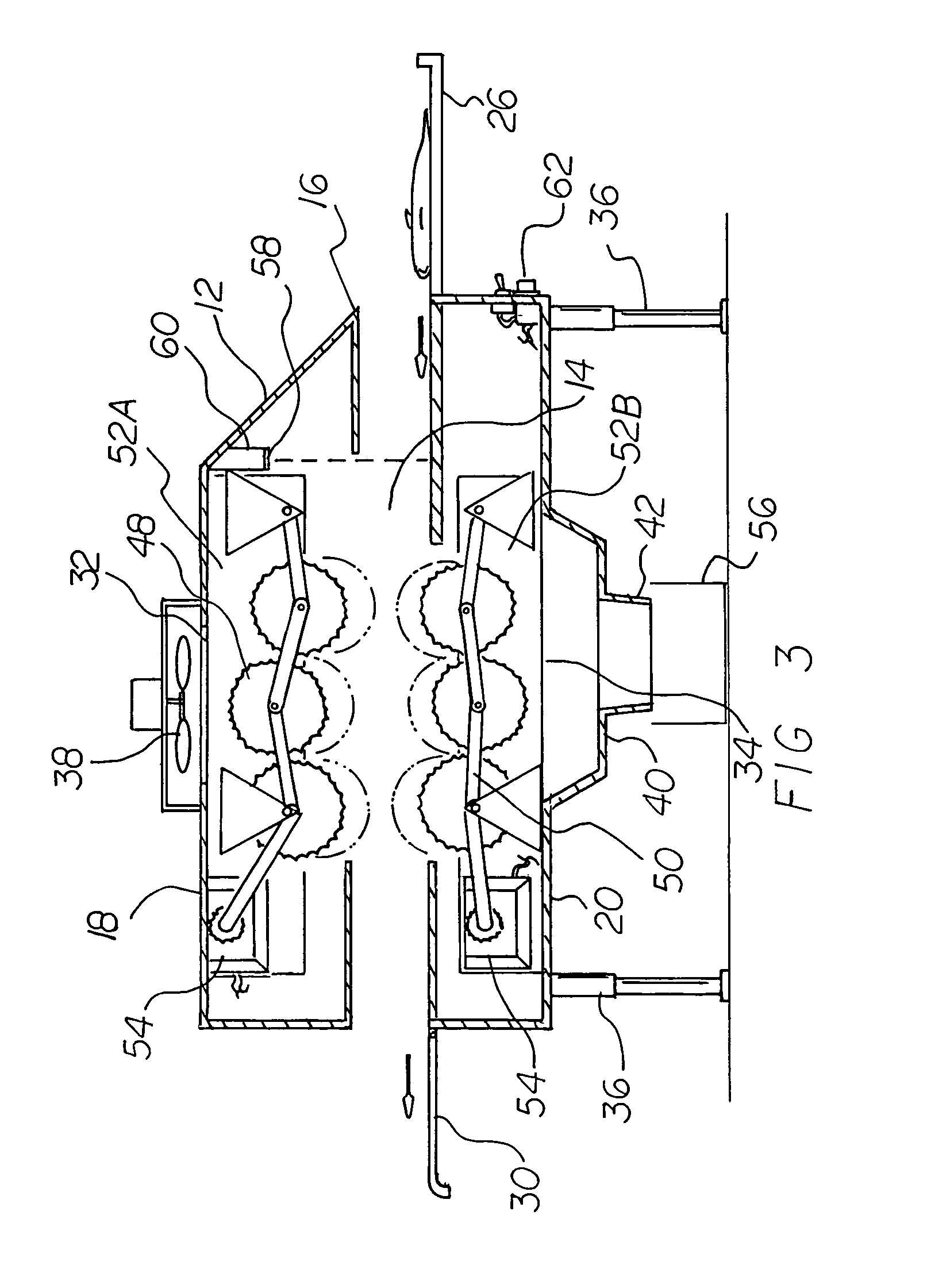

Fish scaling system

InactiveUS7037185B1Easily and efficiently manufacture and marketDurable and reliable constructionFish washing/descalingAirflowControl switch

A housing has an interior with first and second ends and top and bottom faces. The housing has an air flow aperture in the top face. The housing has a debris aperture in the bottom face. The bottom face rests upon adjustable legs. Blades with cutting edges are provided in the housing in a cylindrical configuration. A first set of blades is adjacent to the top face. A second set of blades is adjacent to the bottom face. The sets of blades are independently rotatably coupled on a belt driven mount support subsystem each powered by a motor. A plurality of sensors is provided within the interior of the housing. A plurality of control switches controls the operation of the system.

Owner:SPENCE ROY

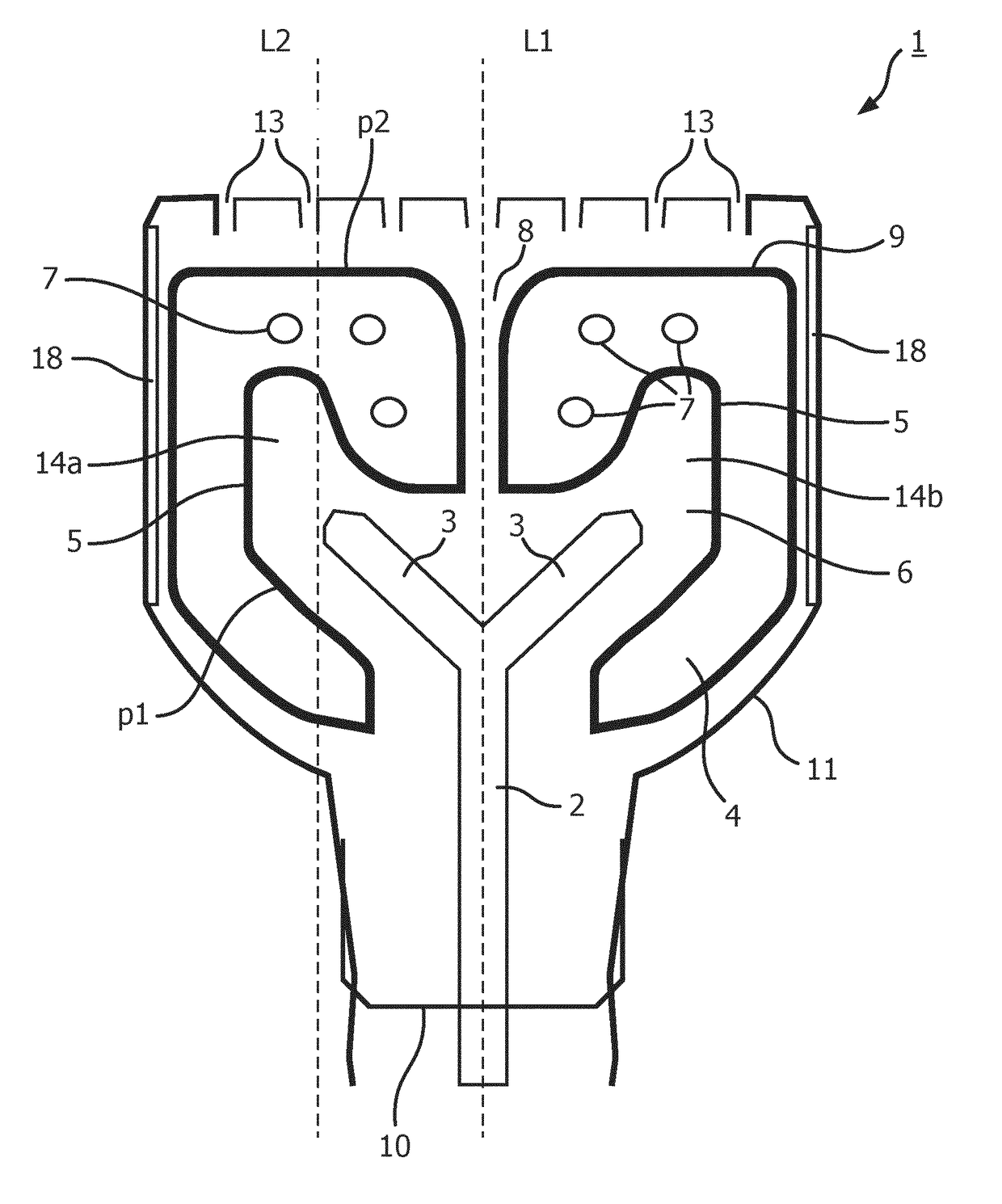

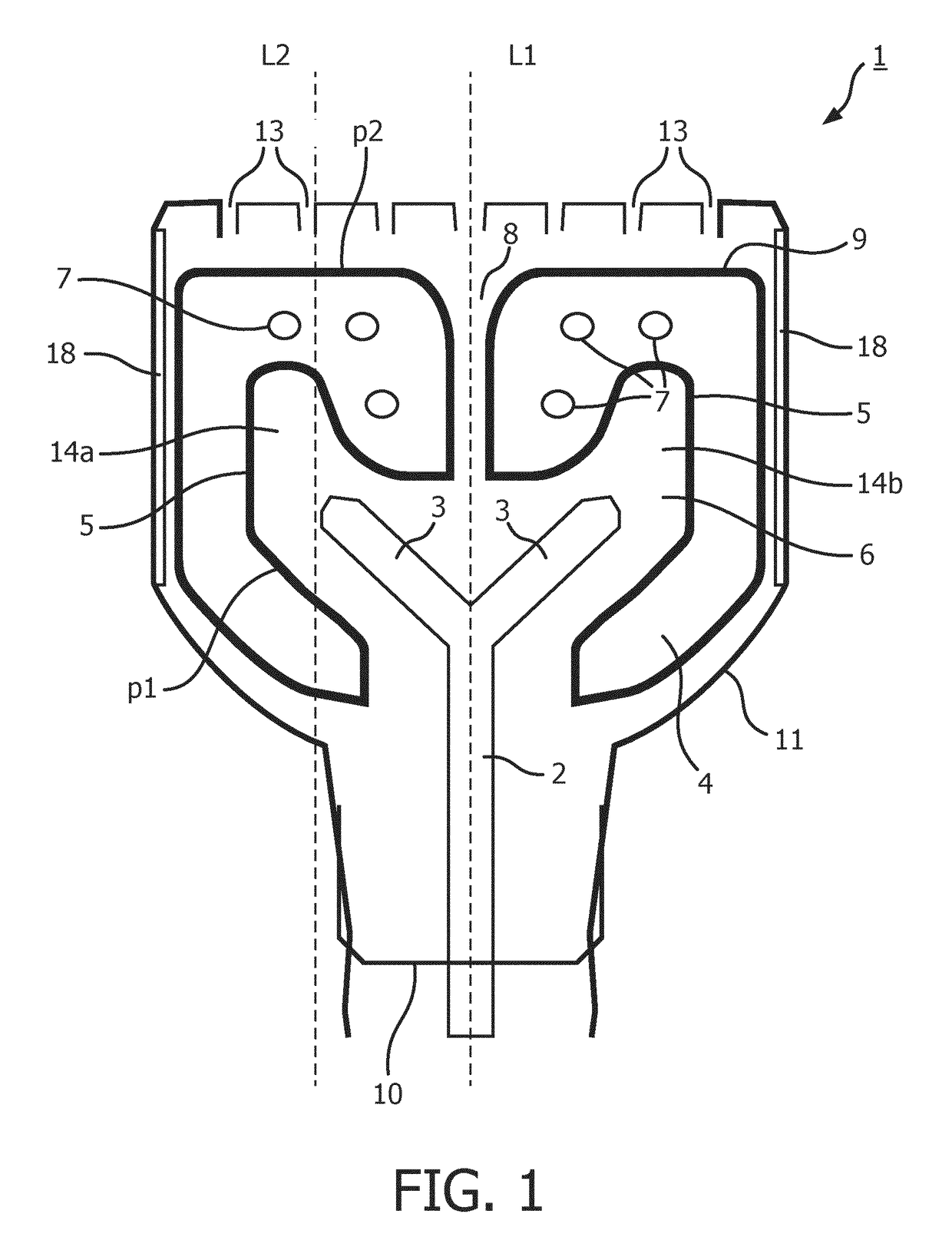

Device and method for generating steam

ActiveUS20180142883A1Evenly distributedEfficient heatingSteam generation heating methodsFlash steam boilersSpray nozzleEngineering

The invention relates to a device (1) for generating steam. The device (1) comprises a water outlet arrangement (2) having an open end (3) to spray water onto a water receiving arrangement (4). The water receiving arrangement (4) comprises an interior surface (5) defining a chamber (6) in which the open end (3) is arranged so that water sprayed from the open end (3) is sprayed onto the interior surface (5). The device further comprises a heating element (7) for heating the interior surface (5) up to a temperature for generating steam from water sprayed on the interior surface (5). The interior surface (5) is formed by two separate cavities (14a, 14b), the open end (3) comprising a spray nozzle (2) received within each cavity (14a, 14b) so that each spray nozzle (2) sprays water onto a region of the interior surface (5), each region being defined by the cavity (14a,14b) in which a respective spray nozzle (2) is received. This allows the water sprayed by the water outlet arrangement (4) be more uniformly spread on the interior surface (5), leading to more effective heating and more steam may be generated per unit time.

Owner:VERSUNI HLDG BV

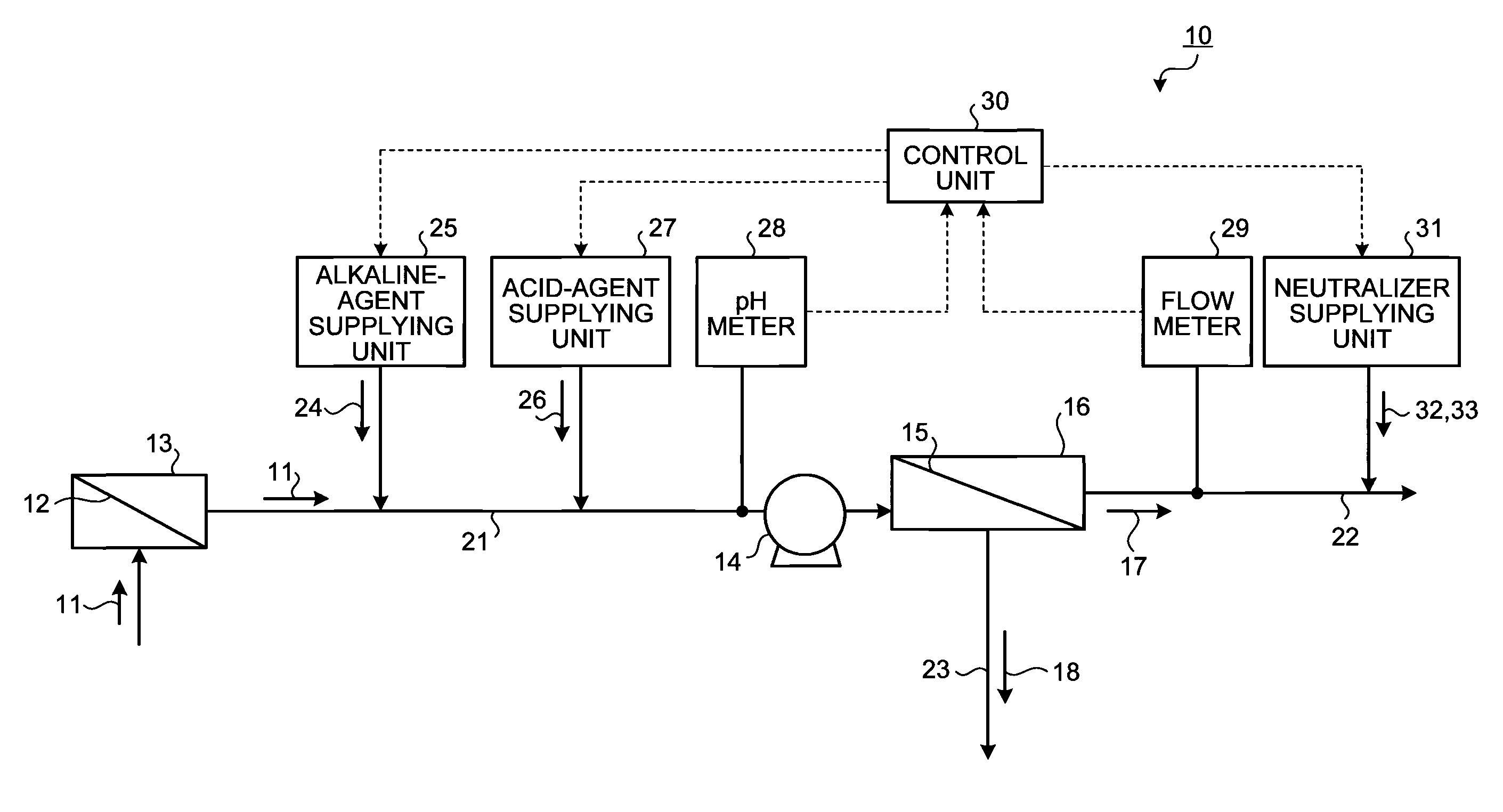

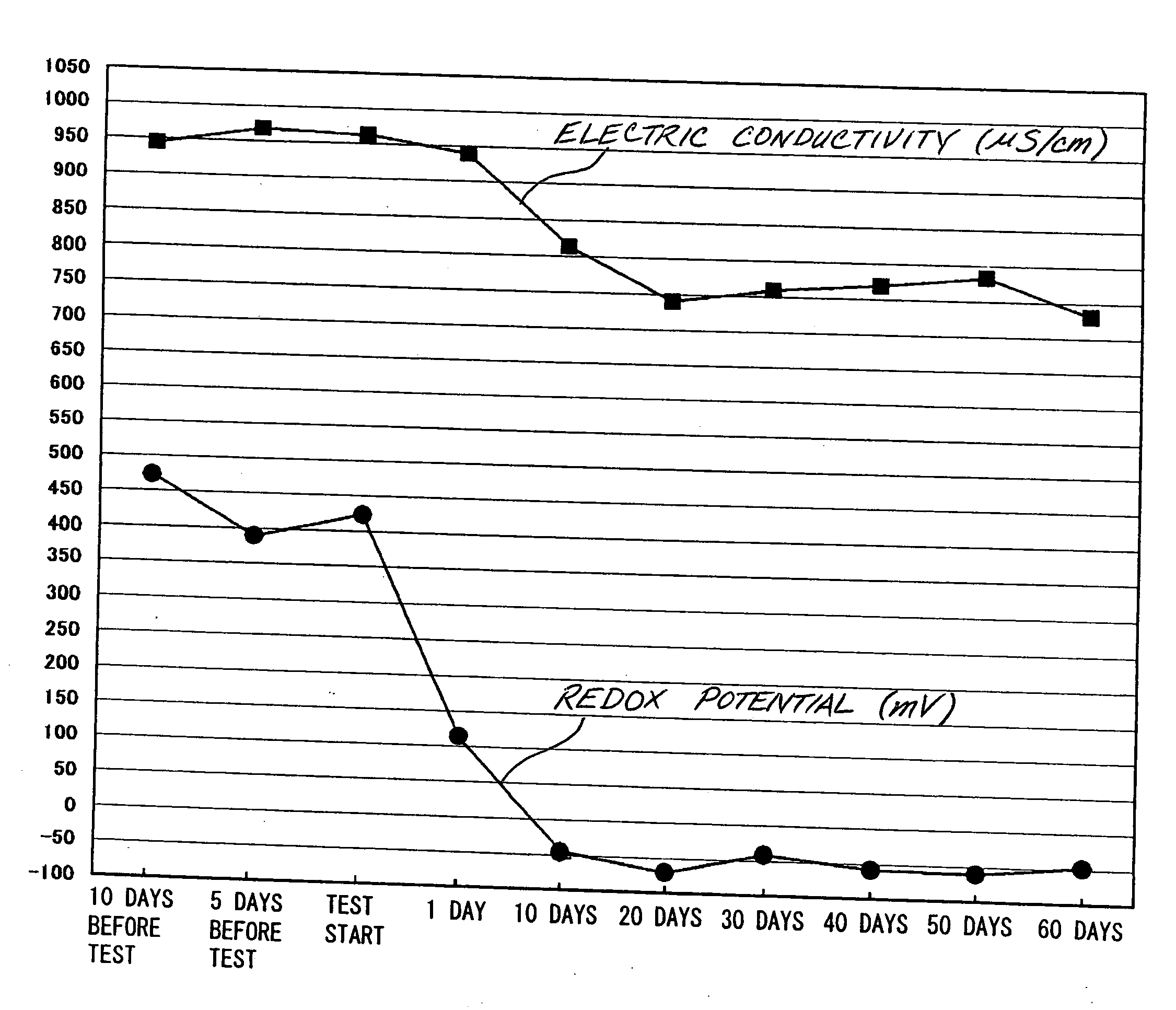

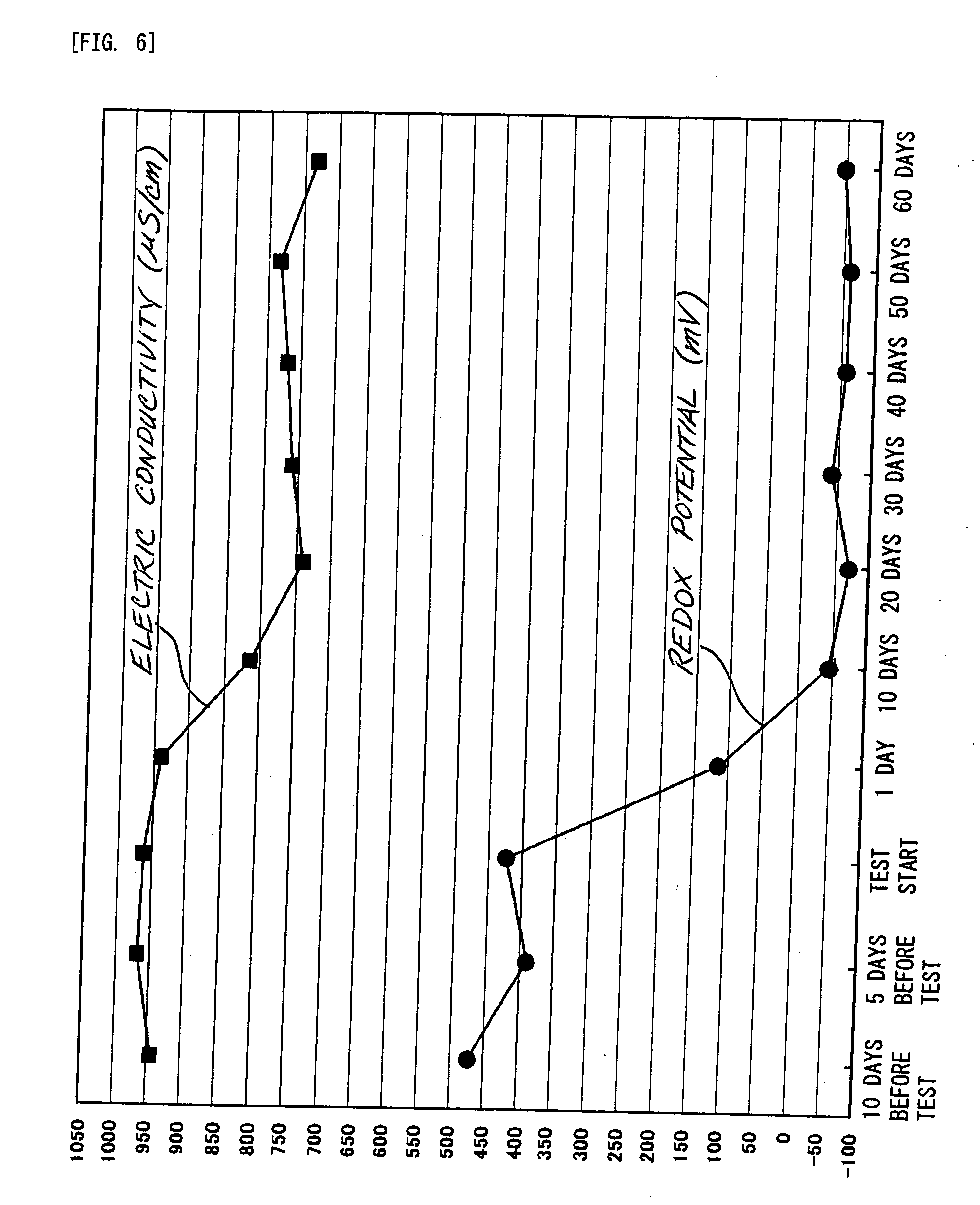

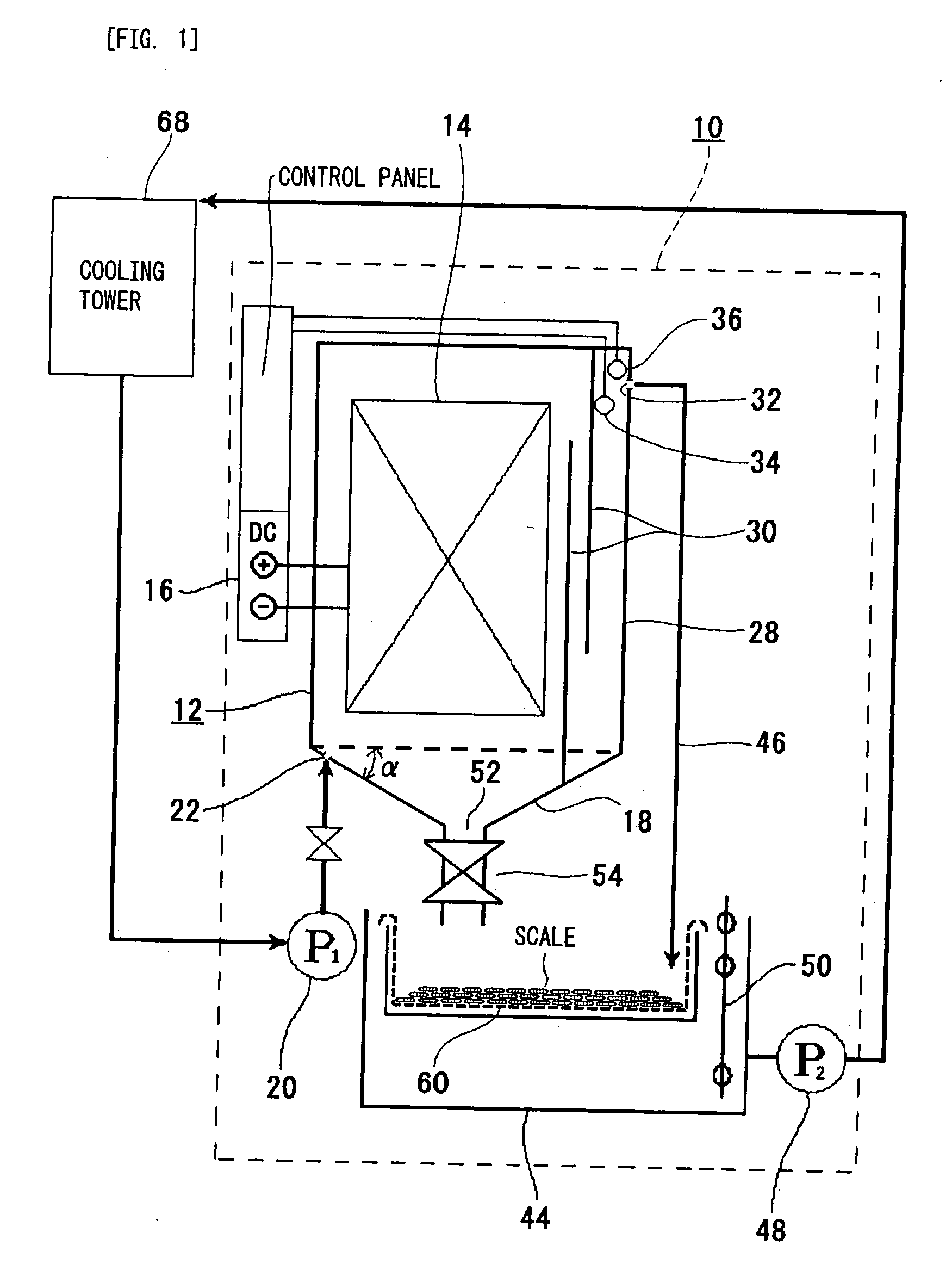

Method and Device for Cleaning Circulation Water

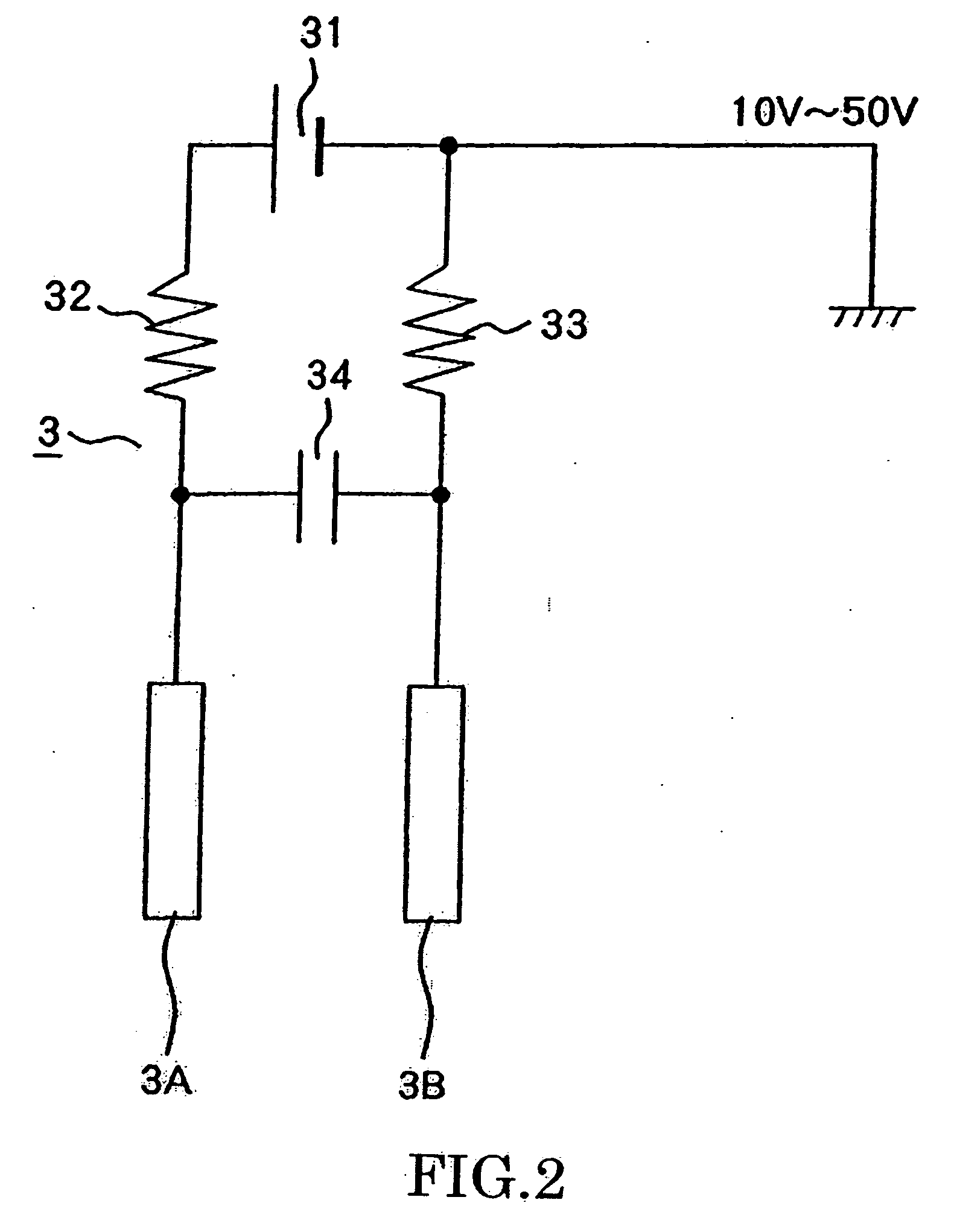

InactiveUS20080272060A1Efficient removalElectrical conductivityWater treatment parameter controlWater/sewage treatment by irradiationPower flowElectrolysis

The object of the invention is to provide a method for cleaning circulation water, which reduces the cost of operation and maintenance as much as possible, without a cumbersome cleaning operation such as by detaching electrode plates from an electrolysis cleaning tank and removing scale from inside the tank, and to provide a device used in this method. Accordingly, the present invention provides a method for cleaning circulation water, comprising the steps of flowing circulation water to be cleaned between electrode plates placed in a face-to-face manner between one another; and applying DC voltage between the electrode plates, allowing one or more metal ions contained in the circulation water to be precipitated onto the negative electrode plates by electrolysis, to clean the circulation water, wherein the electrode plates used are made of titanium plates, and wherein a desired amount of current flows, while an anodized oxide coating formed on the surface of the positive electrode plates is compulsively subject to dielectric breakdown by increasing the voltage applied to the anodized oxide coating. FIG. 1 is a representative drawing.

Owner:KOGANEI

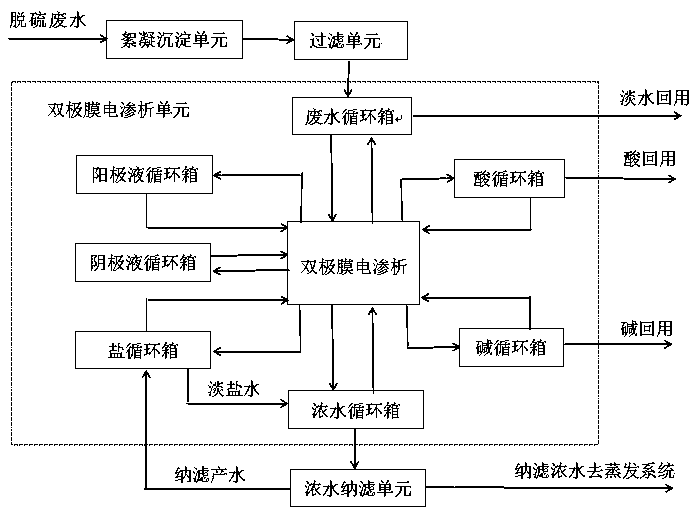

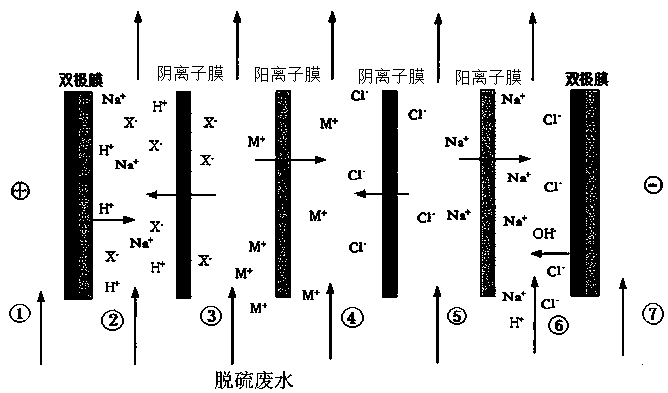

Thermal power plant desulfurization wastewater resource utilization system and method with low reagent consumption

InactiveCN111517533AEliminates fouling tendencyRealize resourcesDispersed particle separationTreatment involving filtrationWastewaterFresh water

The invention provides a thermal power plant desulfurization wastewater resource utilization system and method with low reagent consumption. The system comprises a flocculent precipitation unit, a filtering unit, a bipolar membrane electrodialysis unit and a concentrated water nanofiltration unit which are sequentially connected in series. The bipolar membrane electrodialysis unit adopts a seven-chamber bipolar membrane electrodialysis assembly unit; the bipolar membrane electrodialysis unit is divided into seven different chambers by a bipolar membrane, an anionic membrane, a cationic membrane, an anionic membrane, a cationic membrane and a bipolar membrane which are arranged in sequence; each chamber is respectively connected with an anolyte circulating box, an acid circulating box, a desulfurization wastewater circulating box, a concentrated water circulating box, a salt circulating box, an alkali circulating box and a catholyte circulating box; the filtering unit is connected withthe desulfurization wastewater circulating tank, the concentrated water circulating tank is connected with the concentrated water nanofiltration unit, the wastewater circulating tank is connected withthe fresh water recycling pipeline, the acid circulating tank is connected with the acid recycling pipeline, and the alkali circulating tank is connected with the alkali recycling pipeline. The system has extremely important significance for realizing zero discharge of desulfurization wastewater, reducing discharge of solid wastes and practically protecting the water ecological environment.

Owner:国能安徽综合能源有限责任公司

Efficient heat exchanger and application thereof

PendingCN107166995AReduce material usageReduce consumptionStationary tubular conduit assembliesHeat transfer modificationCentrifugal forceThermal efficiency

The invention discloses an efficient heat exchanger and application thereof. The efficient heat exchanger comprises at least one set of heat exchange assemblies arranged in the heat exchanger and is characterized in that each heat exchange assembly comprises an outer pipe and an inner pipe arranged inside the outer pipe; the position between inner pipes as well as the position between each inner pipe and the corresponding outer pipe are each provided with a runner for allowing a medium to flow; each runner is internally provided with a swirling flow field device for enabling the medium in the runner to generate swirling flow; and at least one of the swirling flow field devices can make swirling flow centrifugal force or swirling flow centripetal force generated by the medium in the runners directly act on the heat exchange surfaces inside the runners. The efficient heat exchanger is reasonable in design, simple in structure, small in flowing resistance, high in heat exchange efficiency, economical, practical and suitable for industrialized popularization.

Owner:FUJIAN DEXING ENERGY CONSERVATION TECH

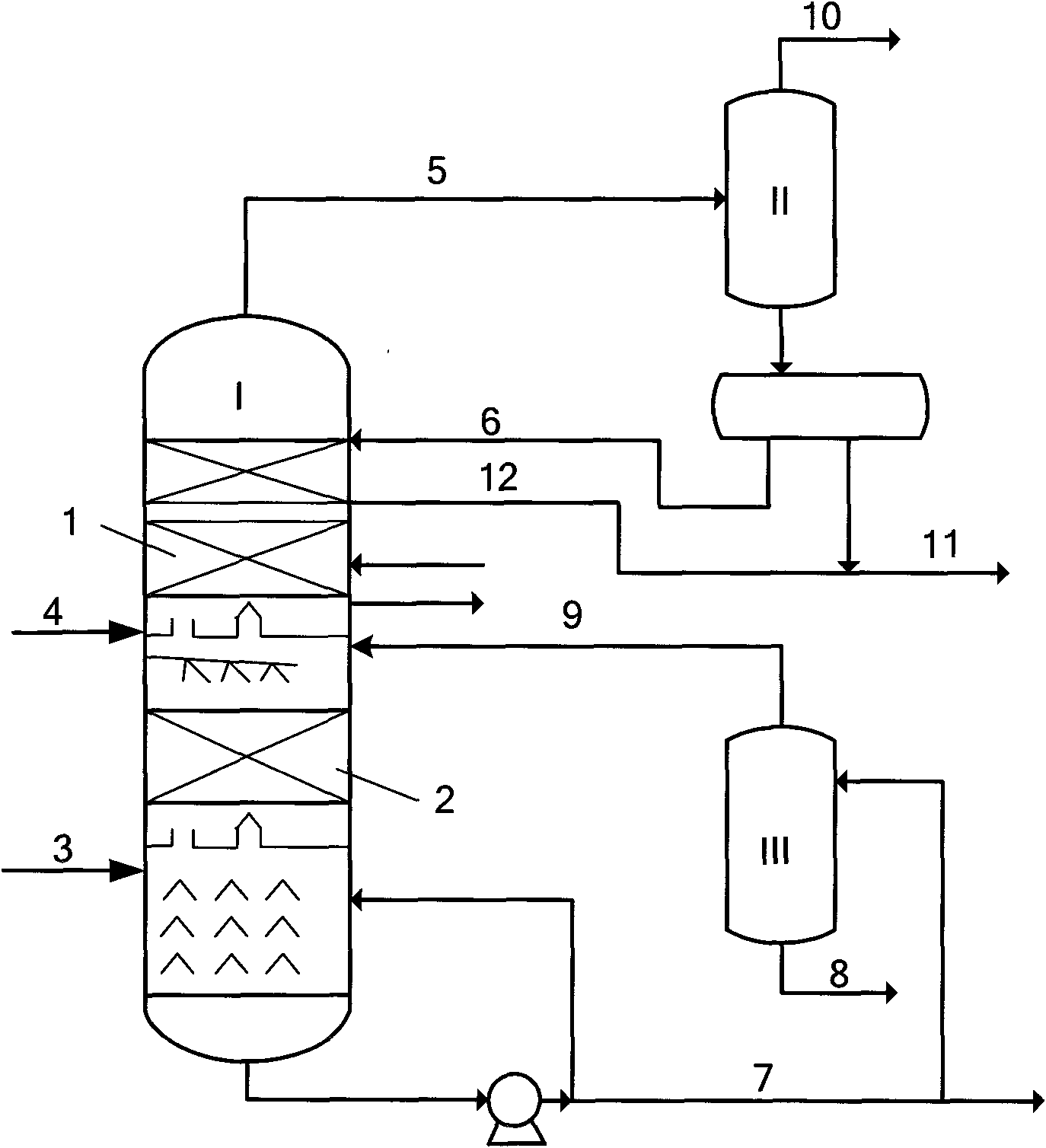

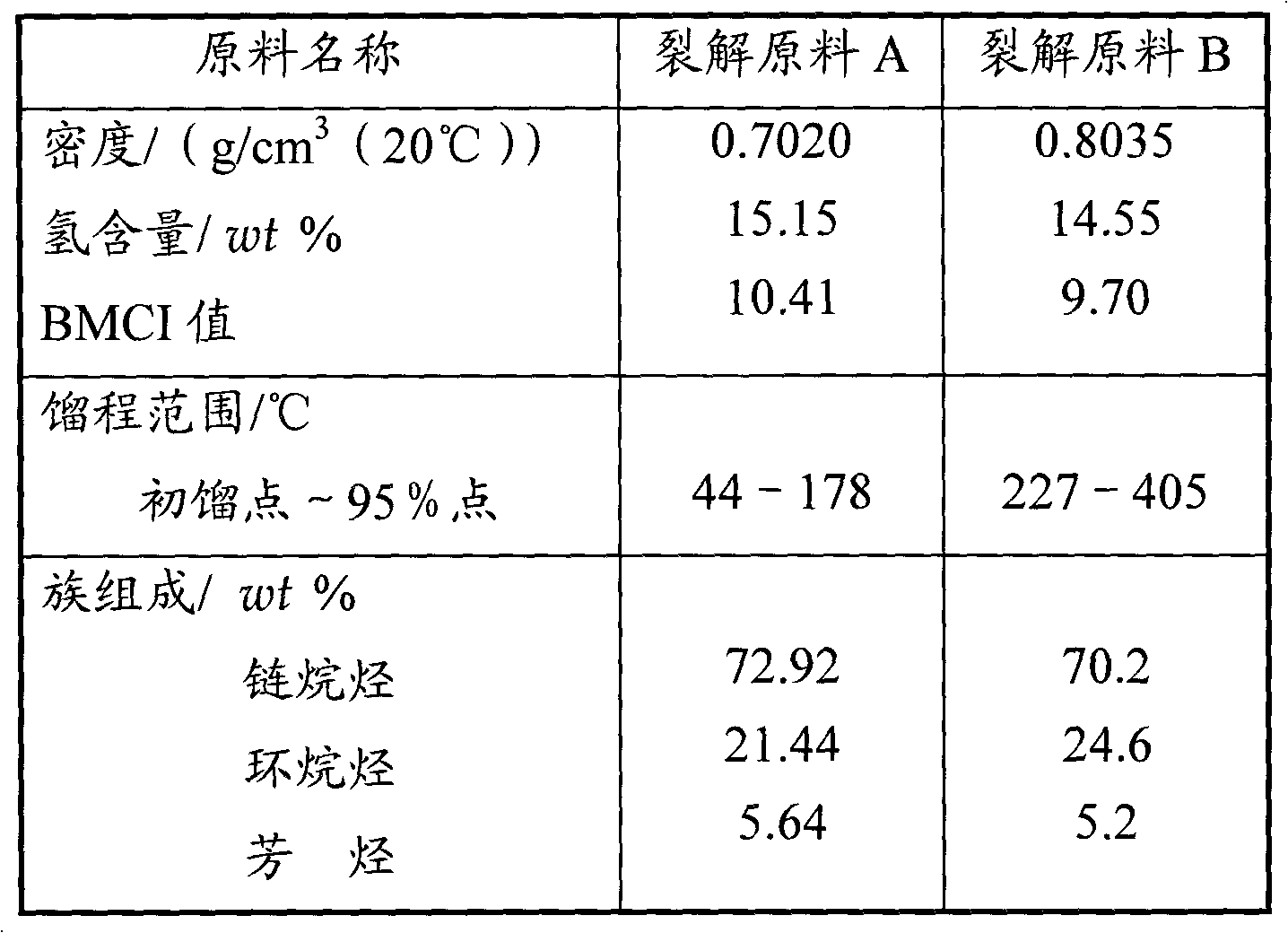

Method for preventing ethylene device gasoline fractionating tower from scale formation and blockage

ActiveCN101962564AExtended operating cycleIncrease throughputGasoline stabilisationTreatment apparatus corrosion/fouling inhibitionRefluxDistillation

The invention relates to a method for preventing an ethylene device gasoline fractionating tower from scale formation and blockage. The method comprises the following steps of: introducing cracked gas into the gasoline fractionating tower; separating materials discharged from the top of the gasoline fractionating tower into the cracked gas, water and cracked gasoline light fraction through a water wash tower; leading out cracked gasoline heavy fraction from the middle part of a rectifying section of the gasoline fractionating tower; performing steam stripping on the material flow at the bottom of the gasoline fractionating tower to obtain cracked tar; returning one part of the cracked gasoline light fraction serving as top reflux to a gasoline distillation tower; and mixing the other partof the cracked gasoline light fraction and the cracked gasoline heavy fraction and then introducing the mixture into a cracked gasoline hydrogenation device. The method provided by the invention has the advantages of preventing the gasoline fractionating tower from scale formation and blockage, effectively prolonging the operating cycle of the gasoline fractionating tower and saving production cost on the basis of not changing the functions of the original gasoline fractionating tower.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com