Patents

Literature

52results about How to "Electrical conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

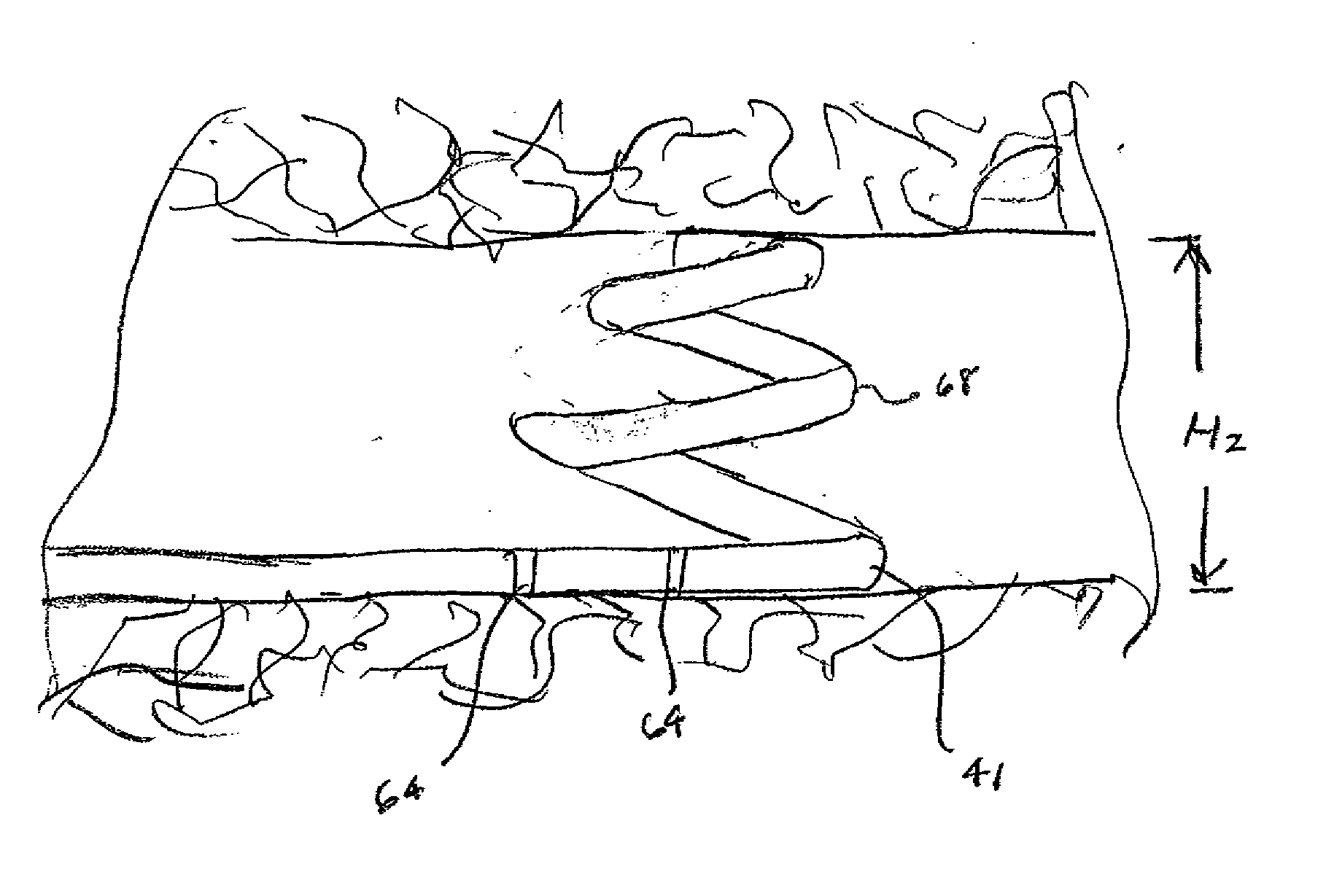

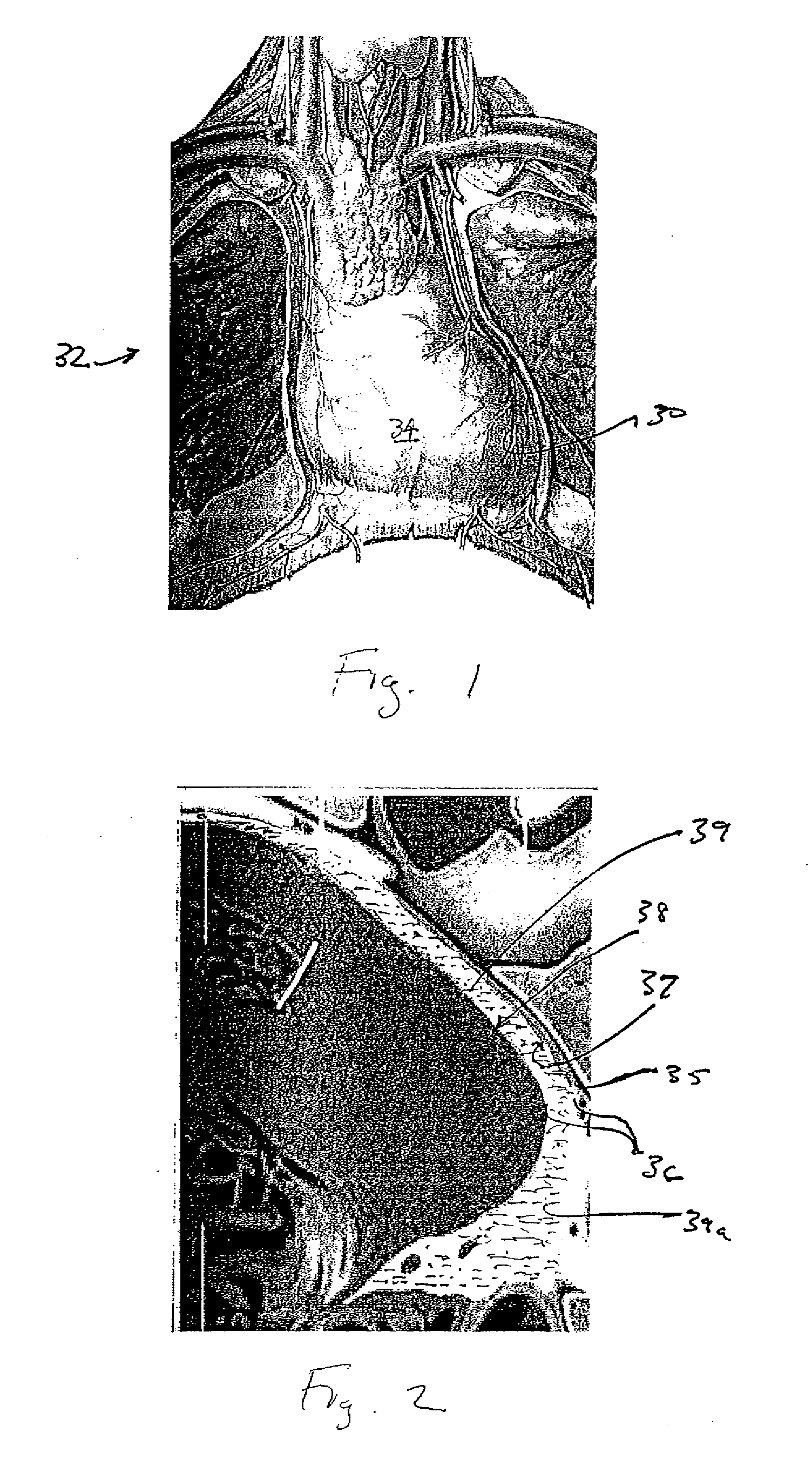

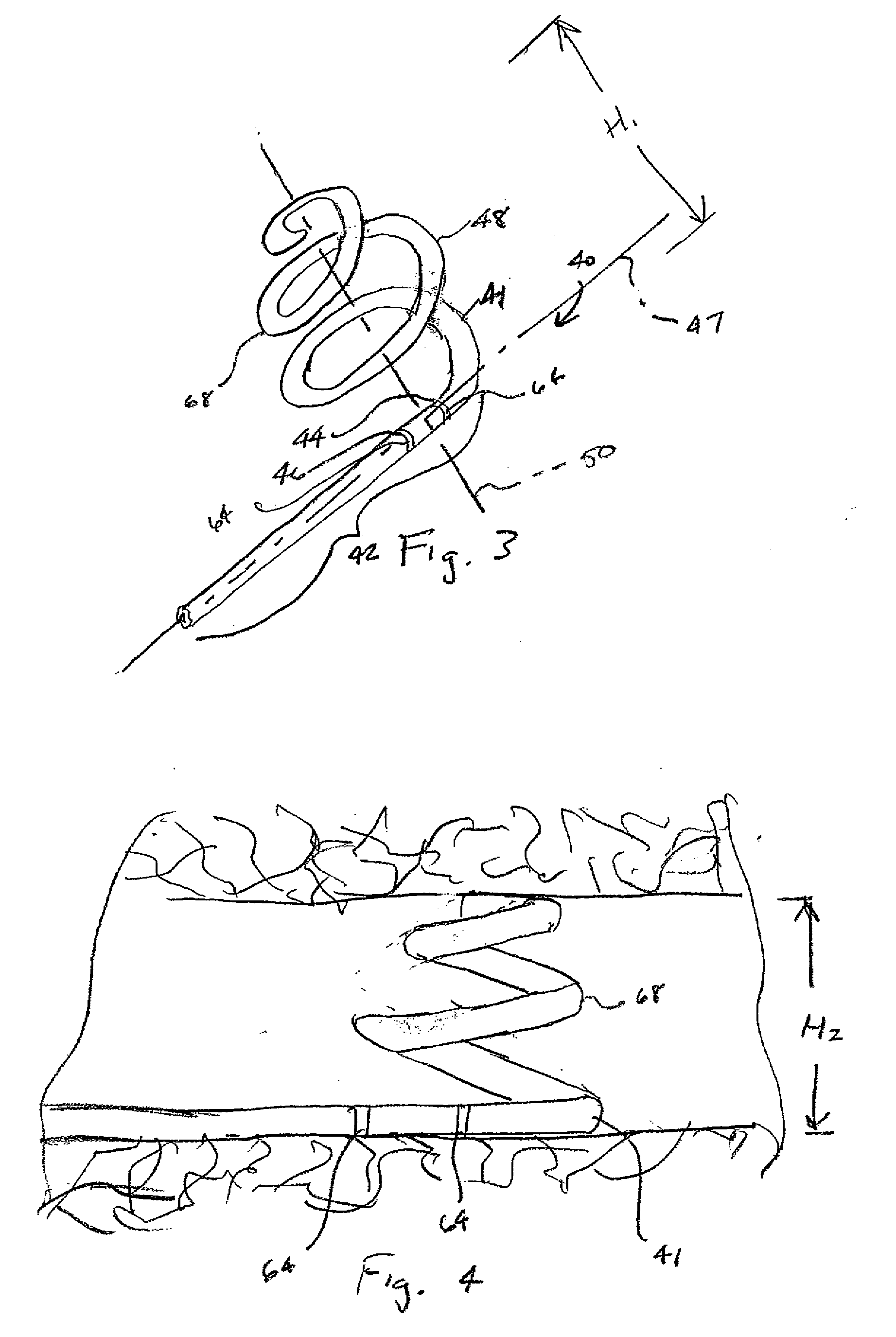

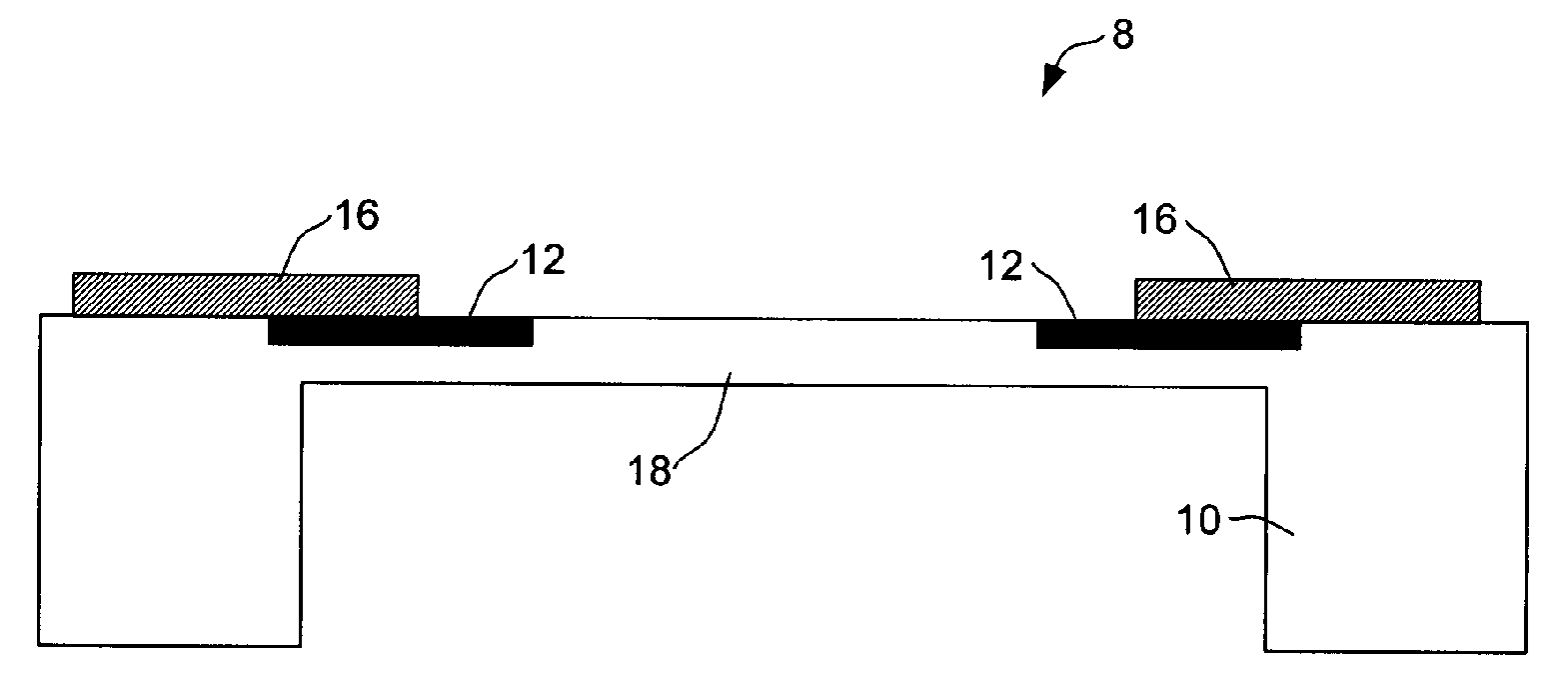

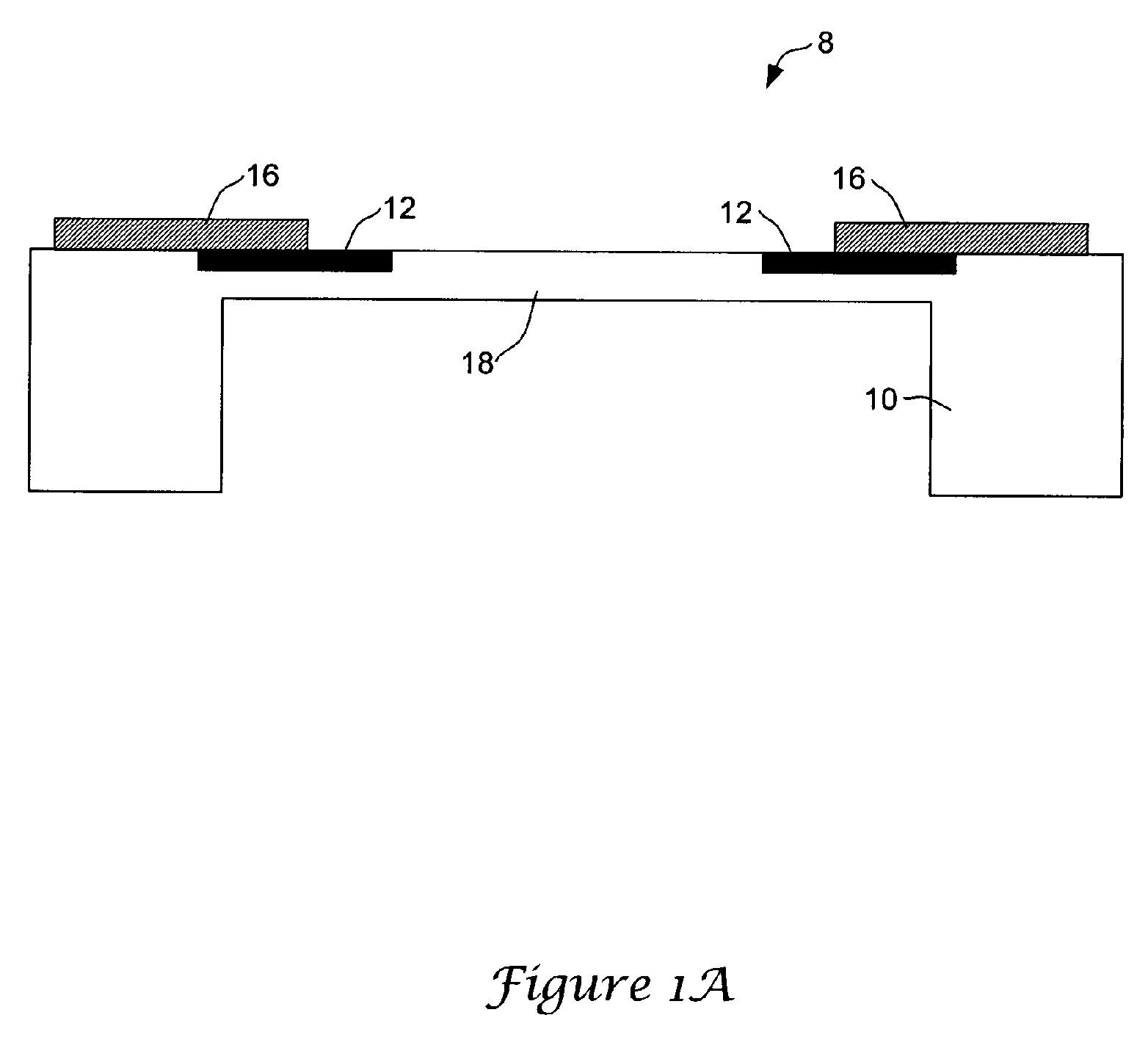

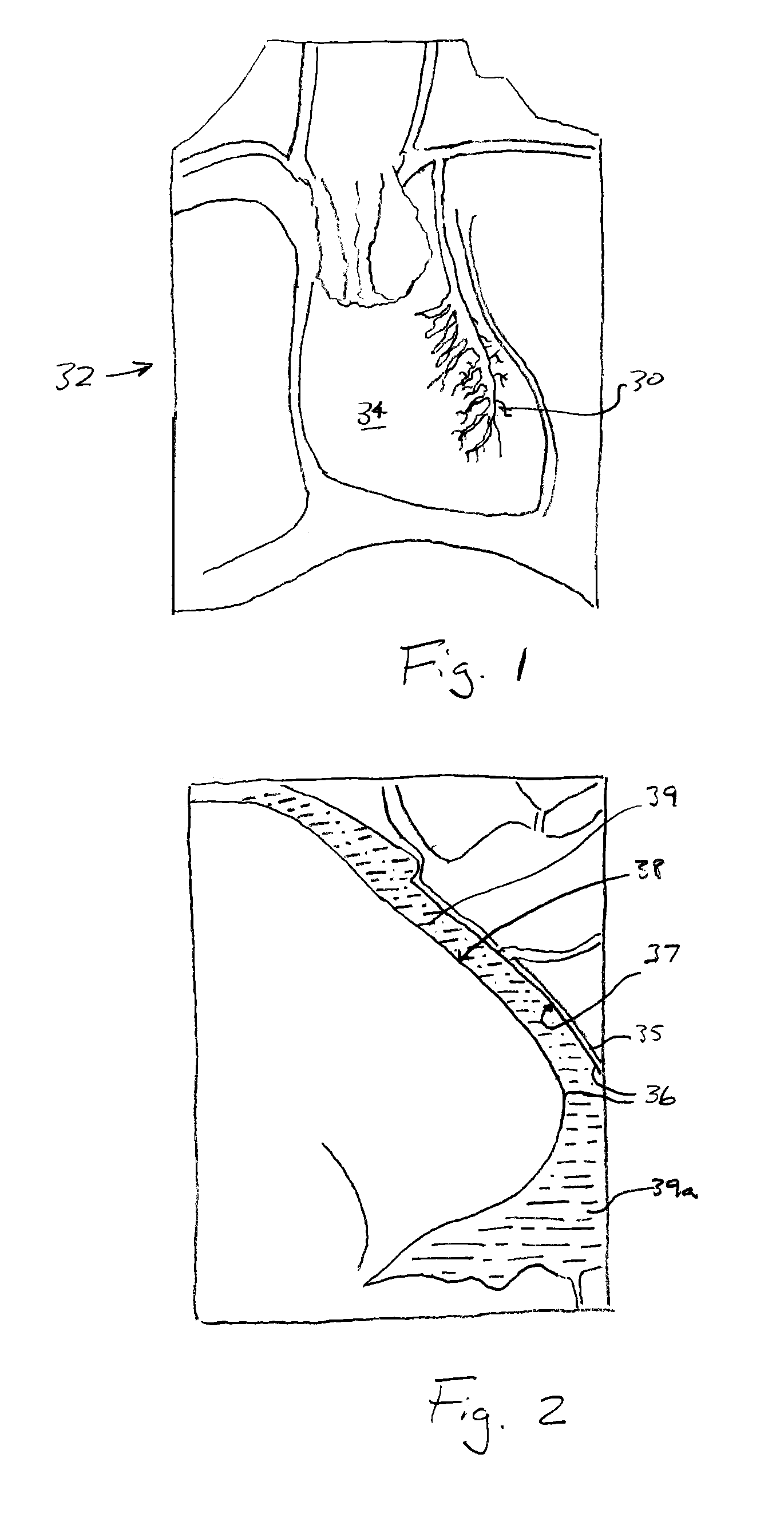

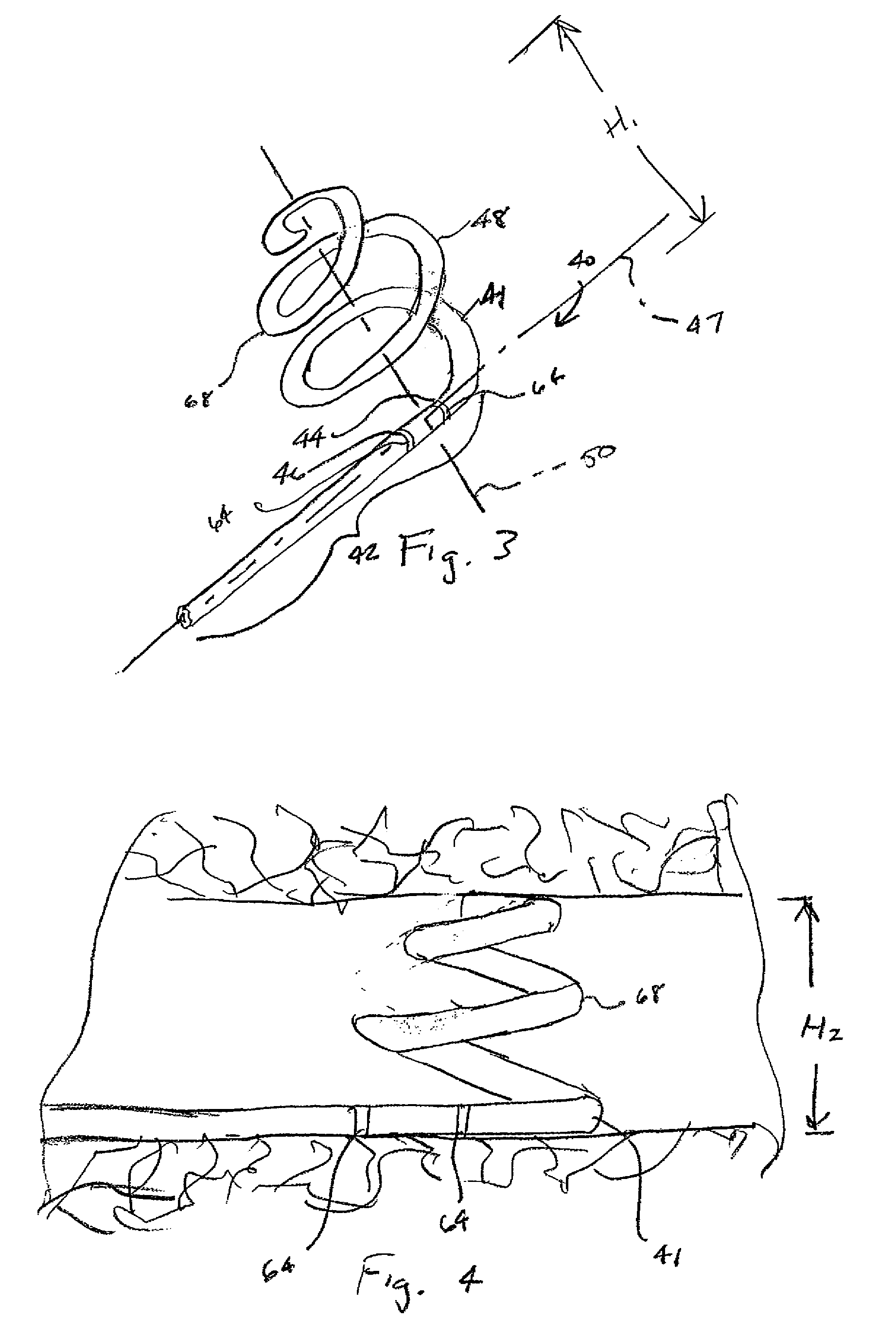

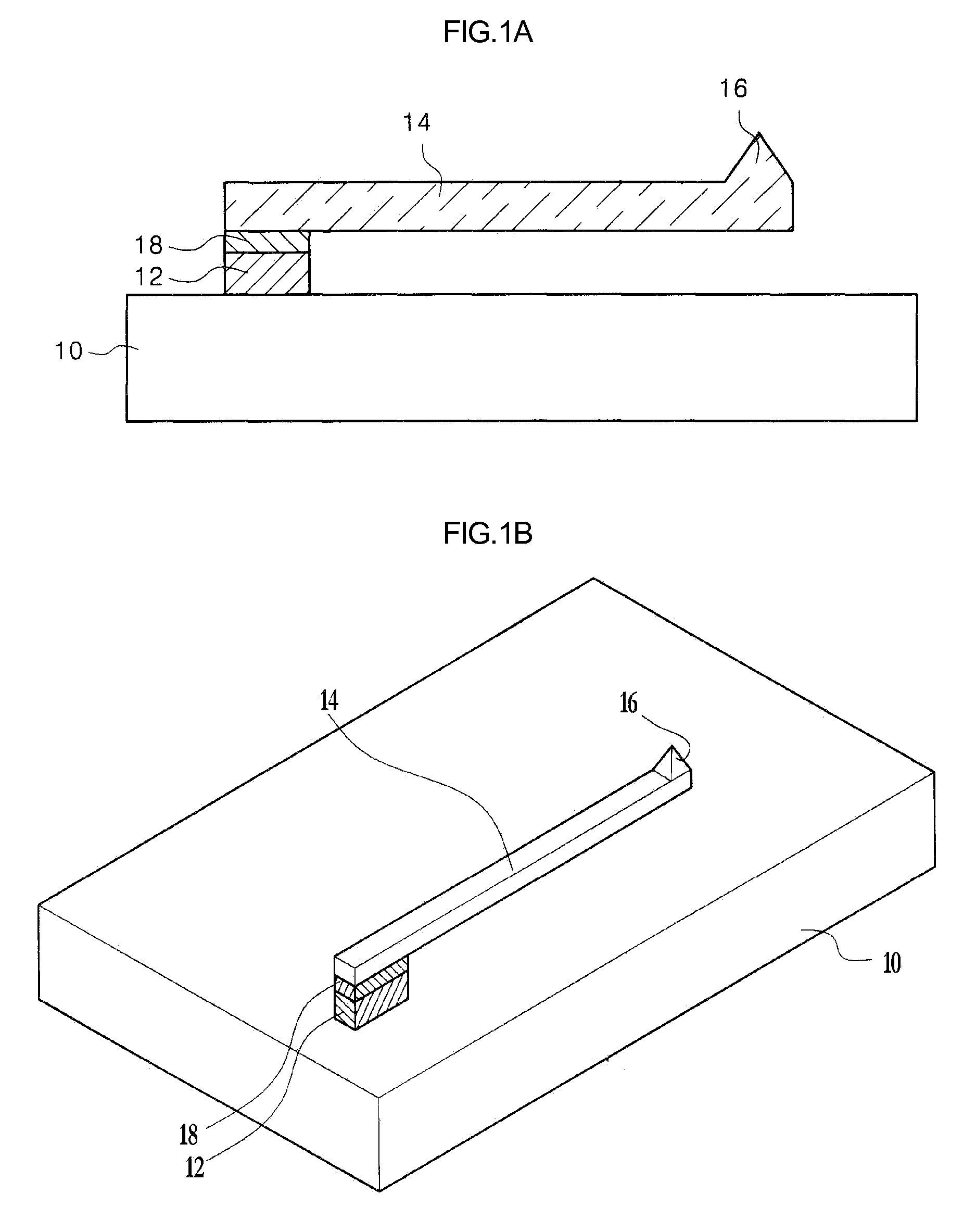

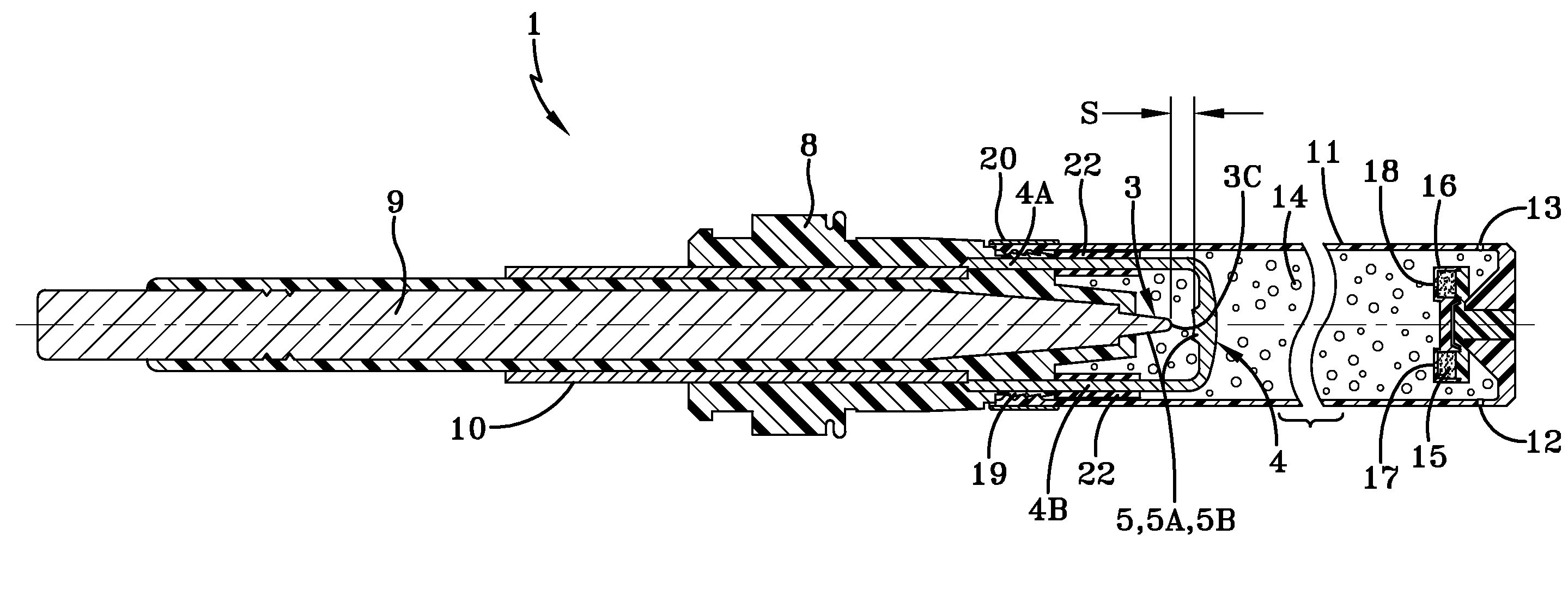

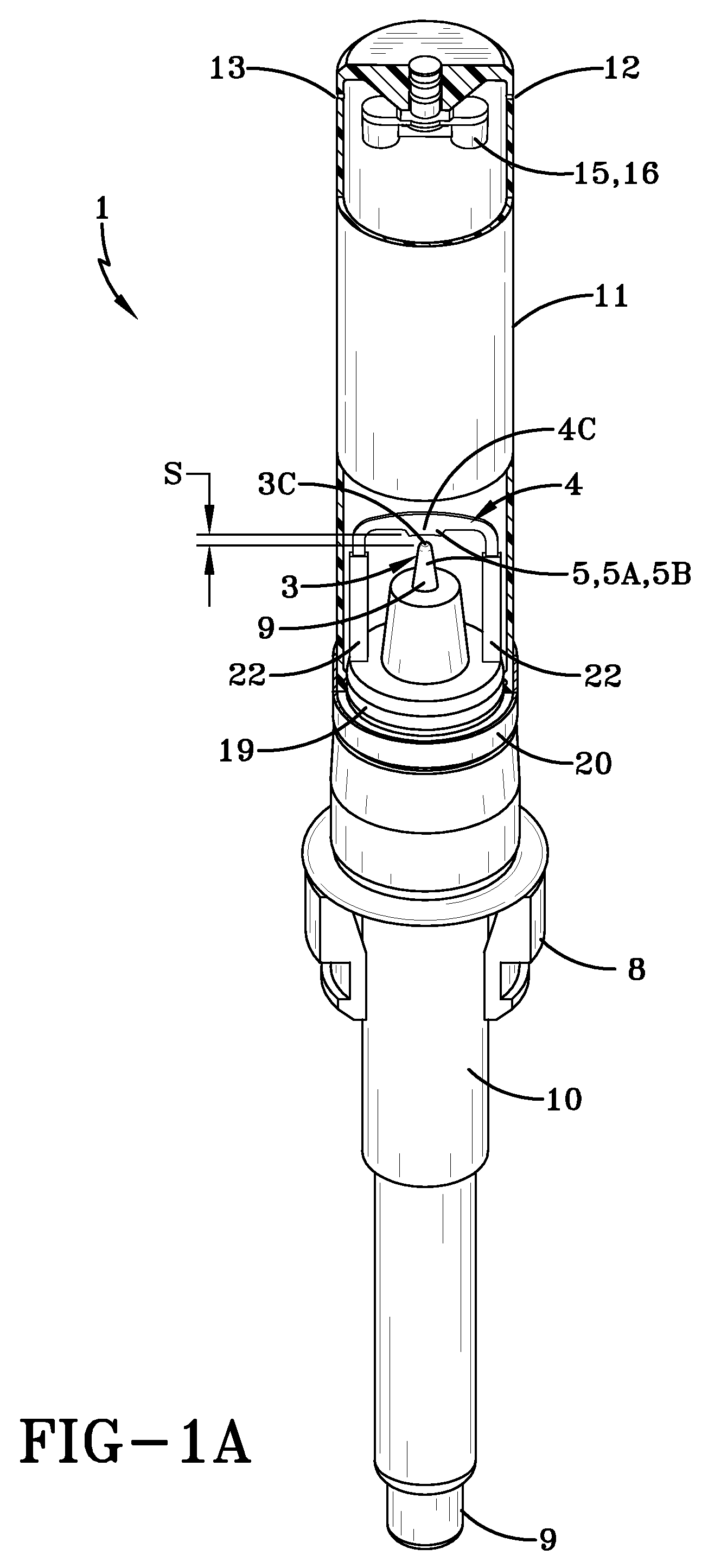

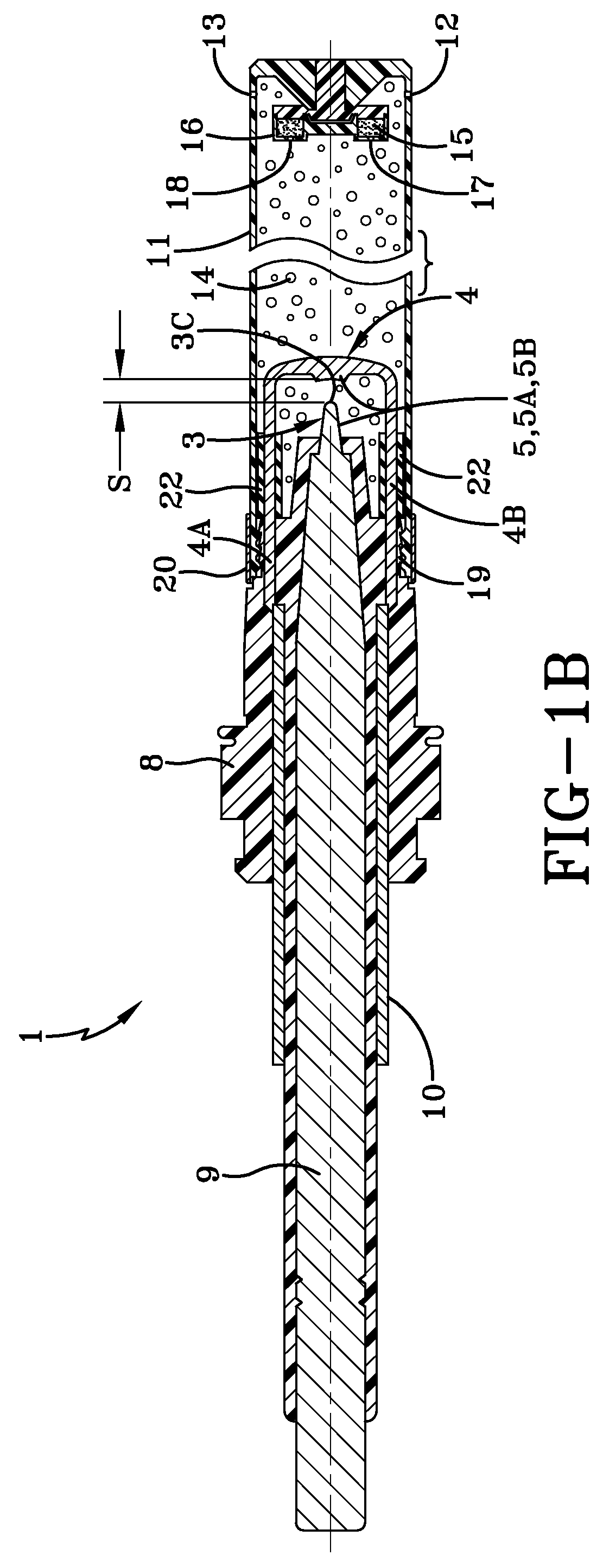

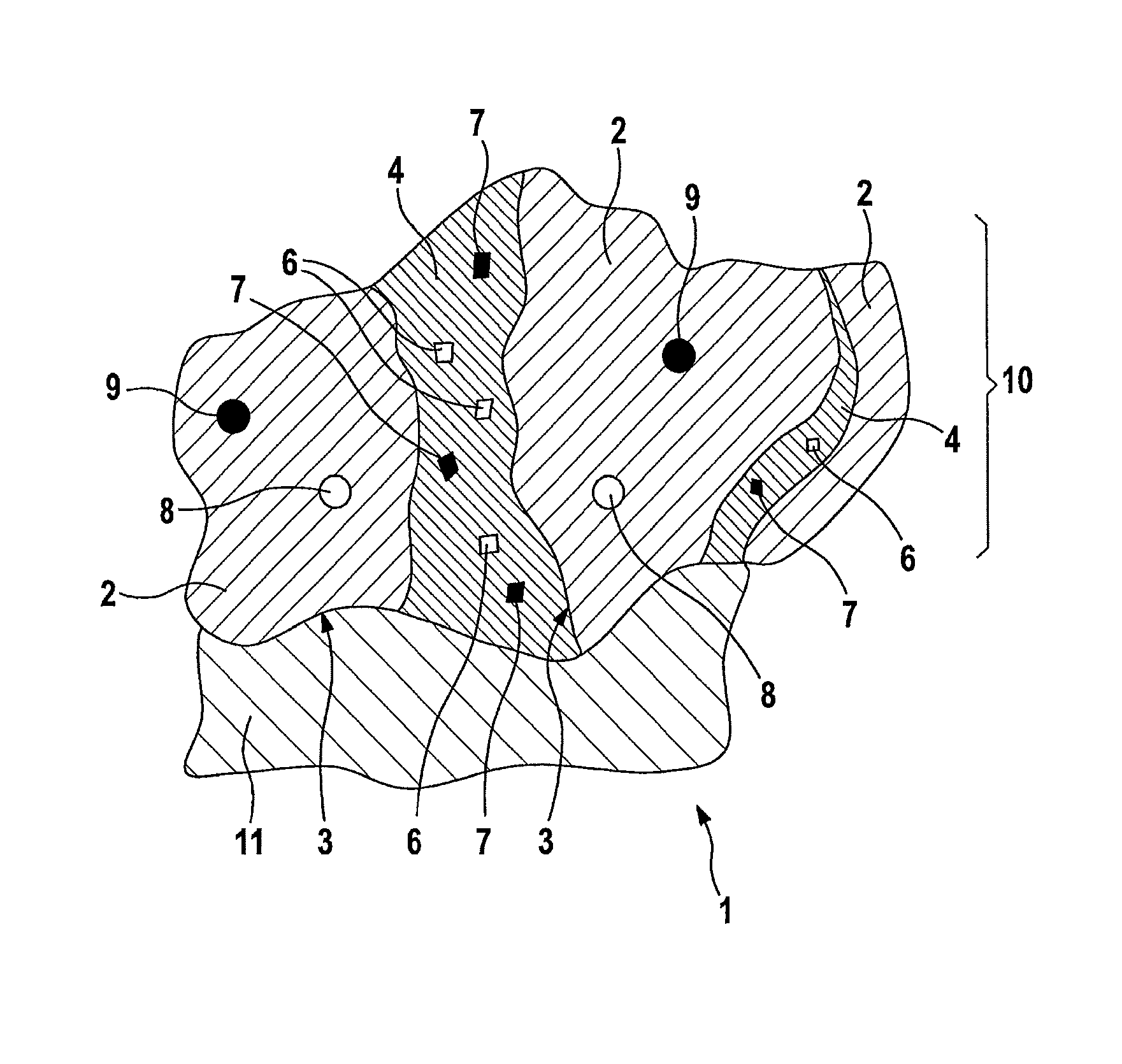

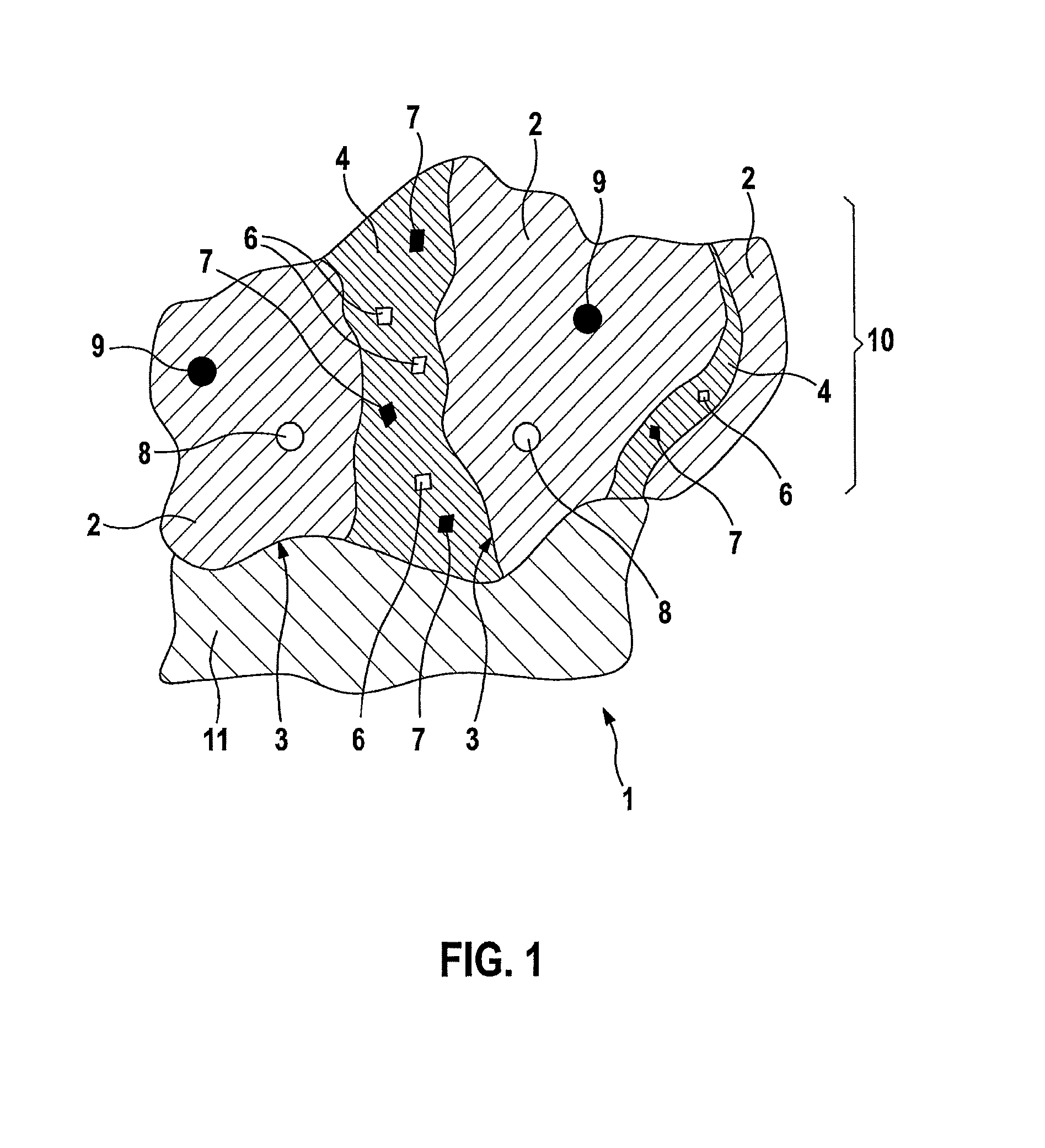

Pacing lead and method for pacing in the pericardial space

InactiveUS20080065185A1Improve electrode stabilityImprove positional stabilityEpicardial electrodesTransvascular endocardial electrodesPericardial spaceAdhesive

A pacing lead for implantation in the pericardial space includes an elongated lead body, a compression fixation element, and at least one electrode on either the lead body or the fixation element. The fixation element defines a resilient structure, and is positioned and dimensioned so that when the lead is disposed in the pericardial space, the resilient fixation element is compressed between the parietal and visceral pericardium, thereby biasing the electrode against the myocardium and providing positional stabilization to the lead. Further positional stability may be provided mechanically with structures enabling the application of adhesive or with fixation screw or tine elements.

Owner:WORLEY SETH

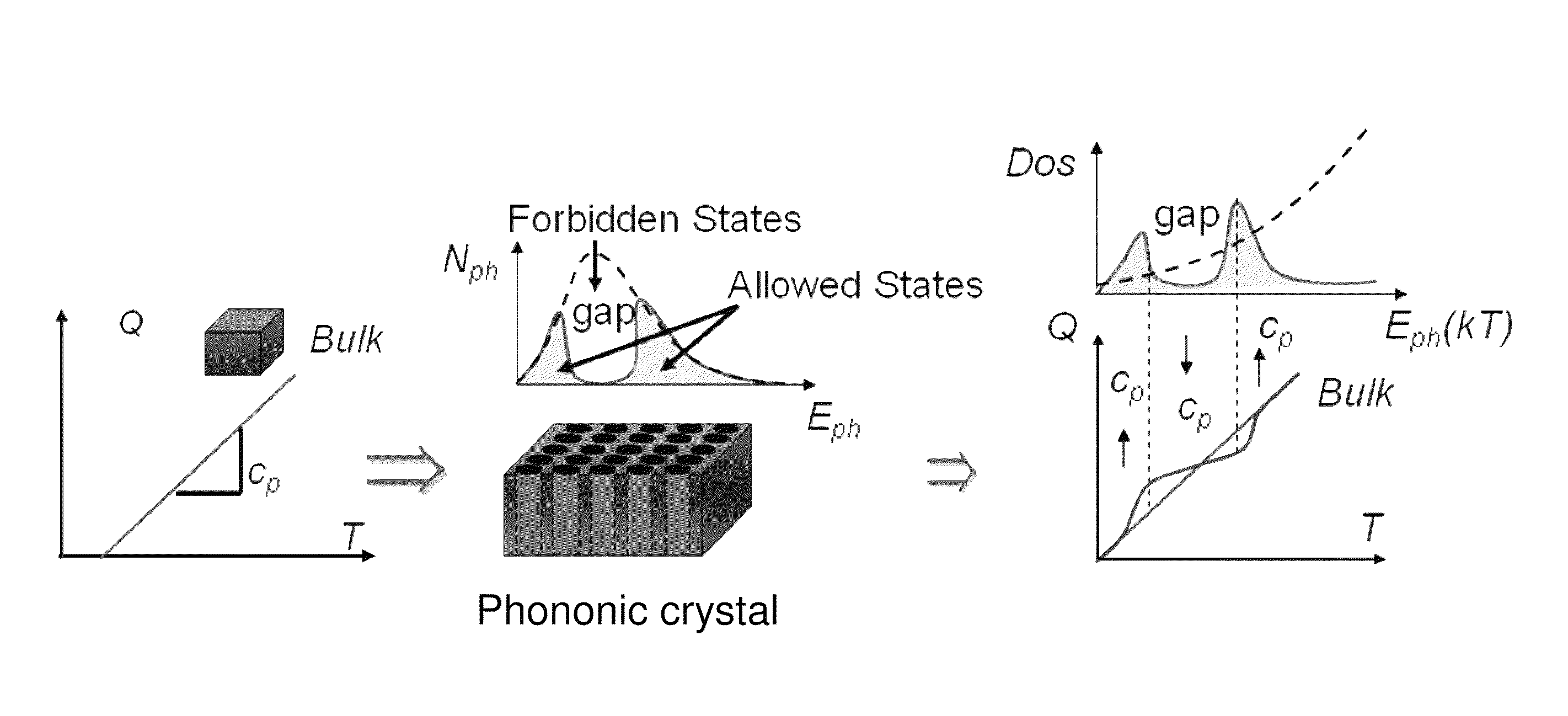

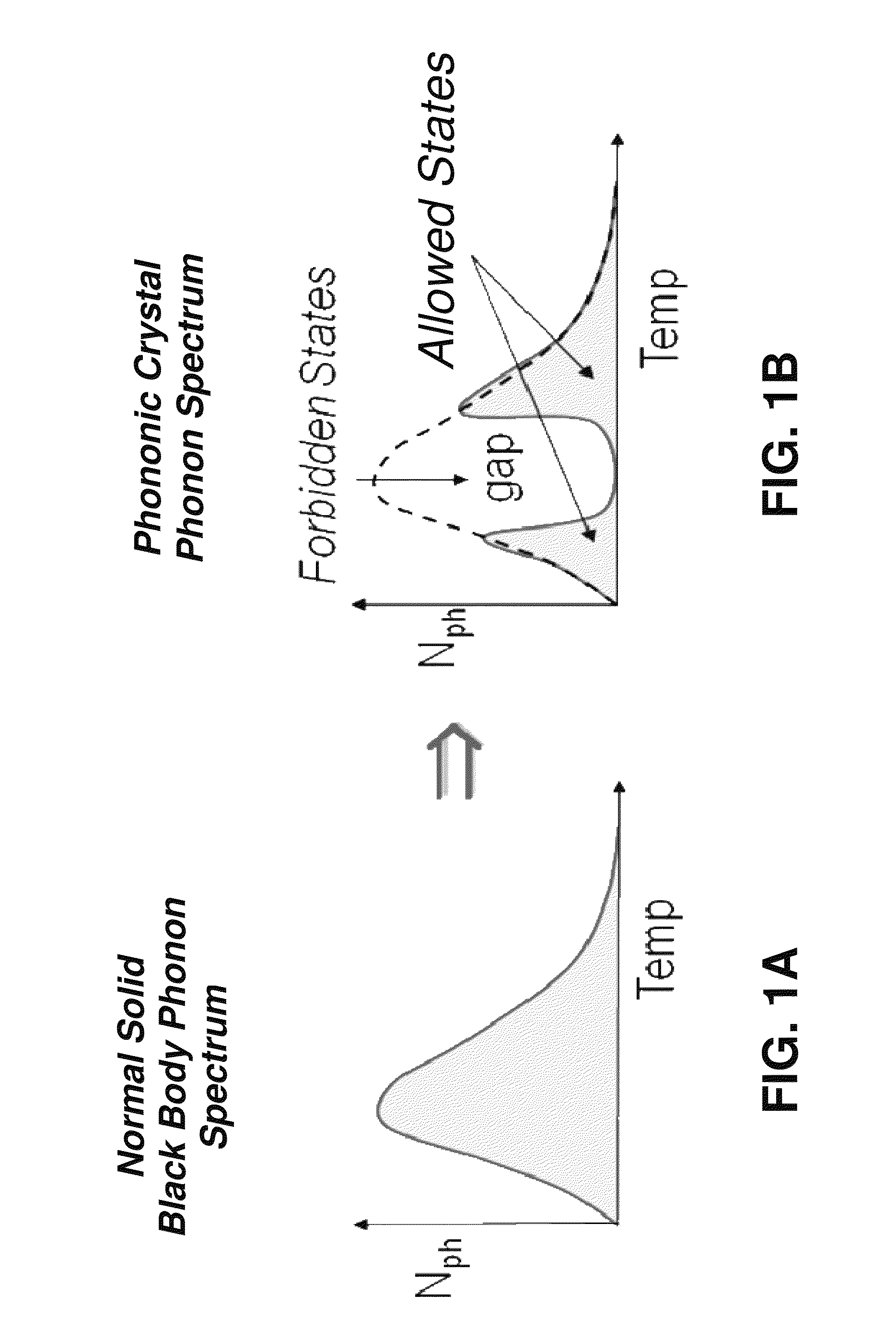

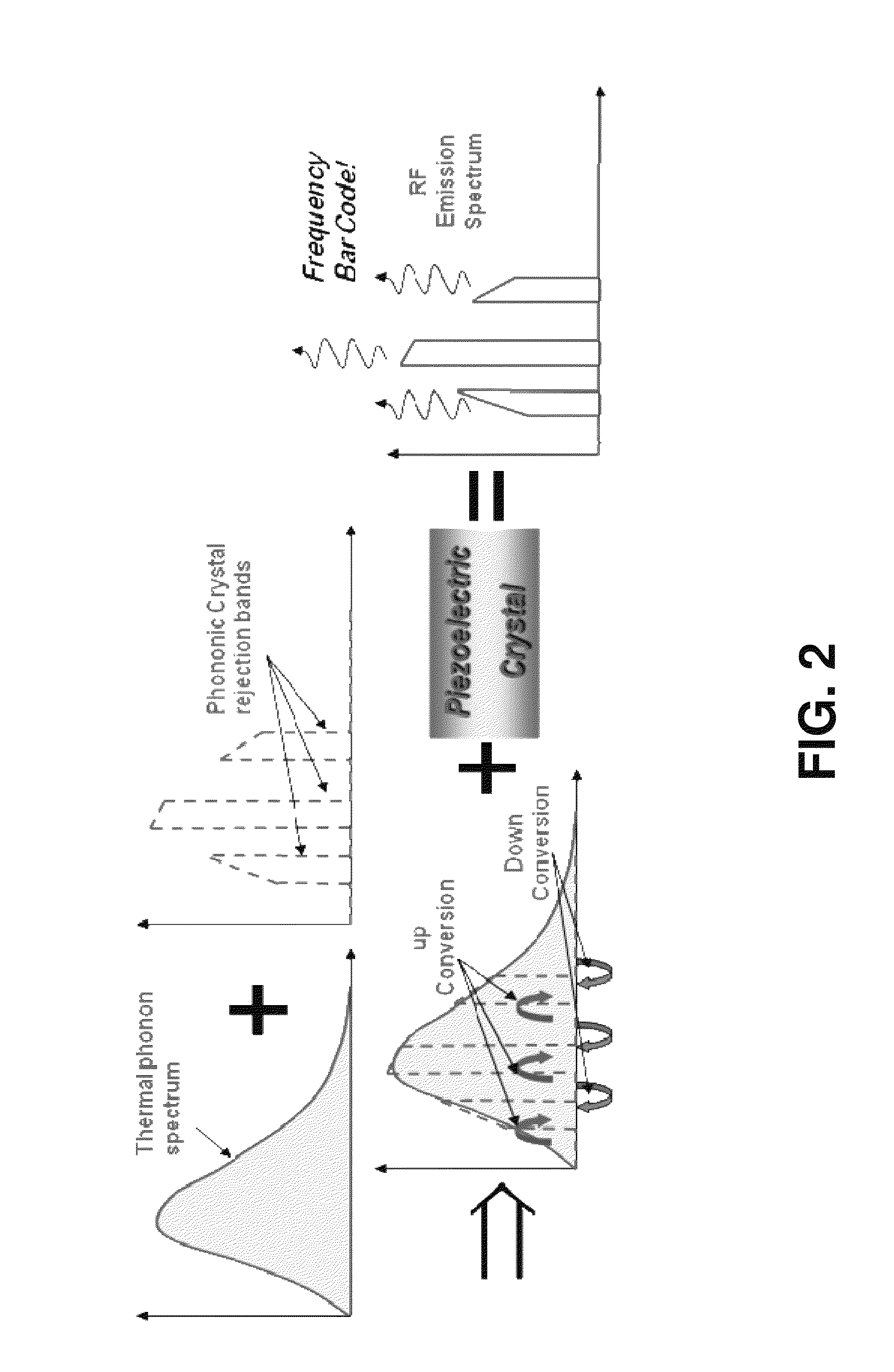

Phononic crystal devices

ActiveUS8094023B1Low thermal conductivityRaise the ratioFire alarmsElectric signalling detailsThermoelectric materialsDielectric

Phononic crystals that have the ability to modify and control the thermal black body phonon distribution and the phonon component of heat transport in a solid. In particular, the thermal conductivity and heat capacity can be modified by altering the phonon density of states in a phononic crystal. The present invention is directed to phononic crystal devices and materials such as radio frequency (RF) tags powered from ambient heat, dielectrics with extremely low thermal conductivity, thermoelectric materials with a higher ratio of electrical-to-thermal conductivity, materials with phononically engineered heat capacity, phononic crystal waveguides that enable accelerated cooling, and a variety of low temperature application devices.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

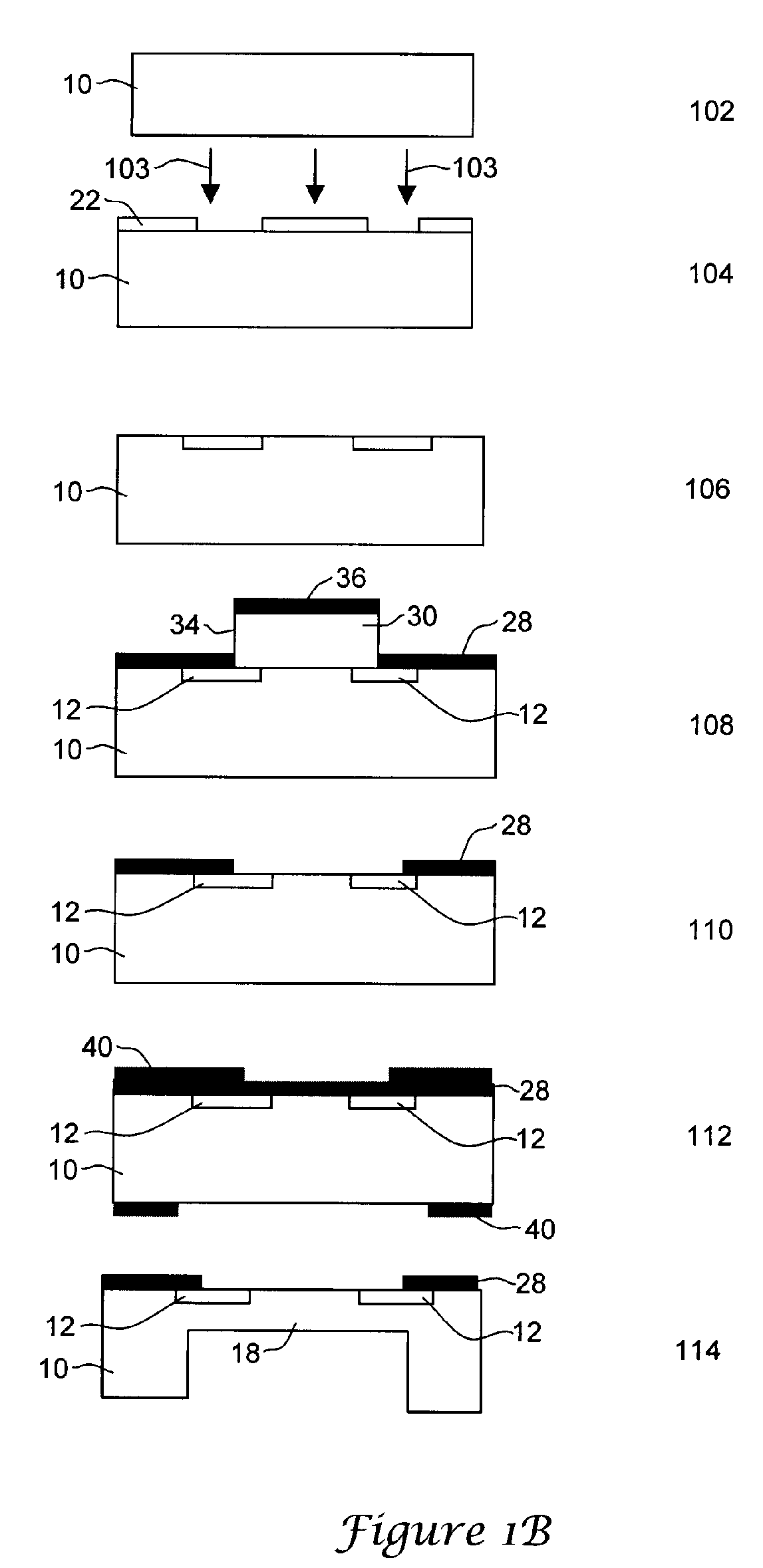

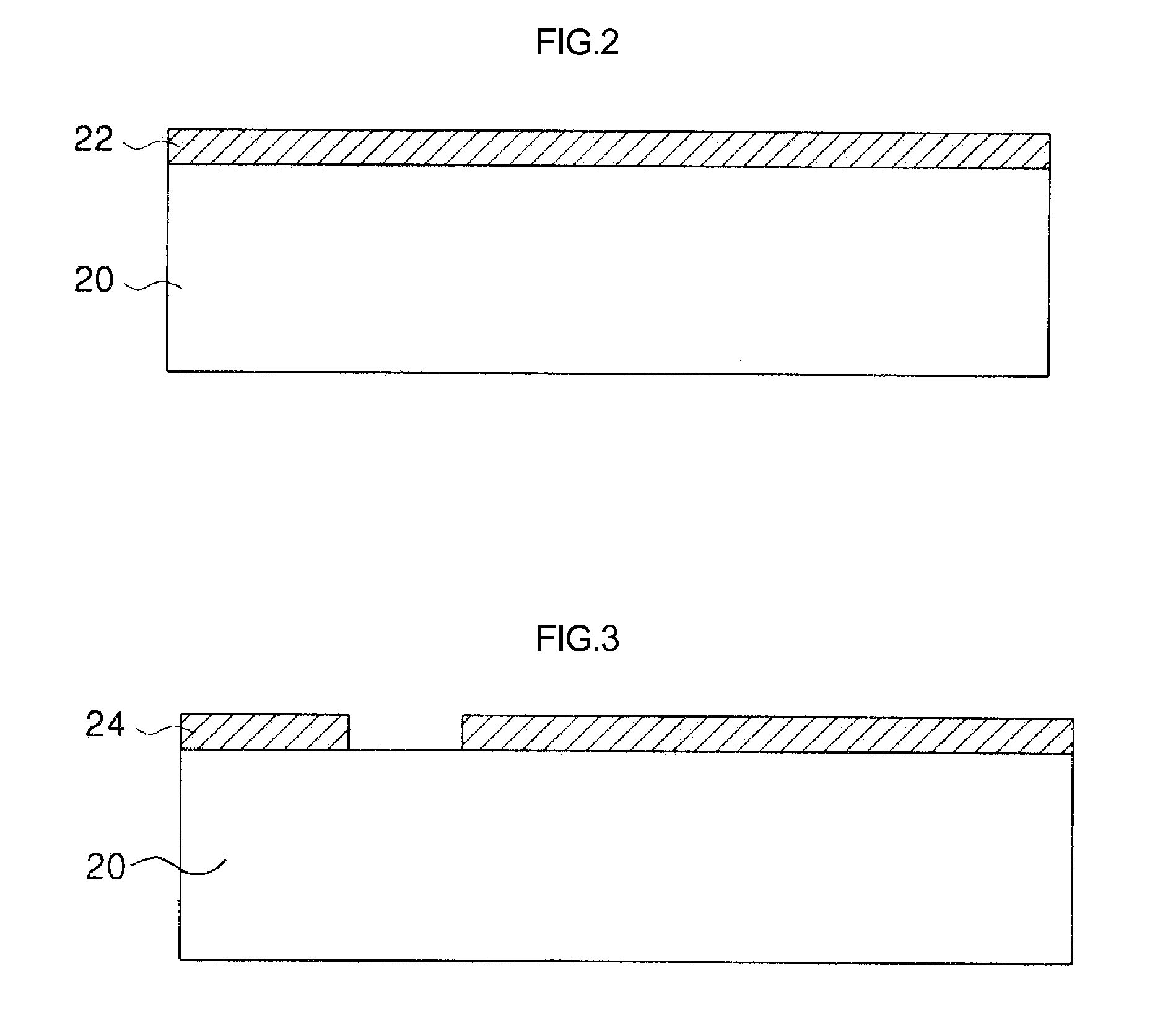

Micro-machined pressure sensor with polymer diaphragm

ActiveUS20060213275A1Easy to understandElectrical conductivityFluid pressure measurement by electric/magnetic elementsSemiconductor/solid-state device manufacturingPolymer substrateNitrogen

A piezoresistive pressure and / or strain sensor micro-machined primarily from plastic and / or glass. In one illustrative embodiment, the piezoresistive pressure sensor is formed on a polymer substrate. A first selectively implanted region is provided in the polymer substrate to create a piezoresistive region in the polymer substrate. A second selectively implanted region is then provided in at least part of the first selectively implanted region to modulate the electrical conductivity of the first selectively implanted region. The illustrative sensor may be selectively implanted with, for example, nitrogen to create the piezoresistive region, and boron to modulate the electrical conductivity of the piezoresistive region. Phosphorus or any other suitable material may also be used to modulate the electrical conductivity of the piezoresistive region, as desired. The piezoresistive pressure / strain sensor may be formed from a single substrate, or two or more substrates, and the resulting pressure / strain sensor may be mounted in a plastic package, if desired.

Owner:HONEYWELL INT INC

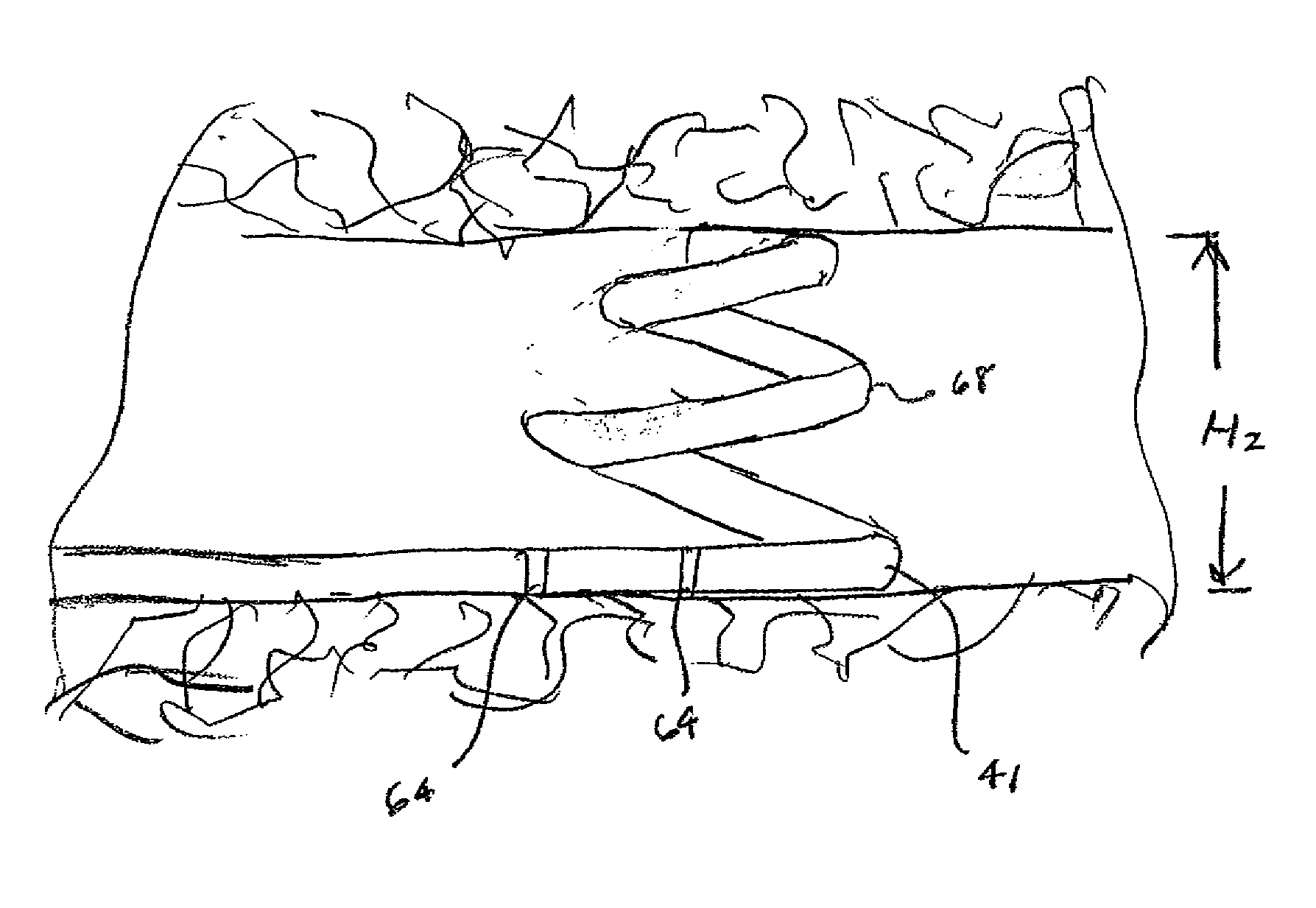

Pacing lead and method for pacing in the pericardial space

InactiveUS8036757B2Improve conductivityReduce voltageEpicardial electrodesTransvascular endocardial electrodesPericardial spaceAdhesive

A pacing lead for implantation in the pericardial space includes an elongated lead body, a compression fixation element, and at least one electrode on either the lead body or the fixation element. The fixation element defines a resilient structure, and is positioned and dimensioned so that when the lead is disposed in the pericardial space, the resilient fixation element is compressed between the parietal and visceral pericardium, thereby biasing the electrode against the myocardium and providing positional stabilization to the lead. Further positional stability may be provided mechanically with structures enabling the application of adhesive or with fixation screw or tine elements.

Owner:WORLEY SETH

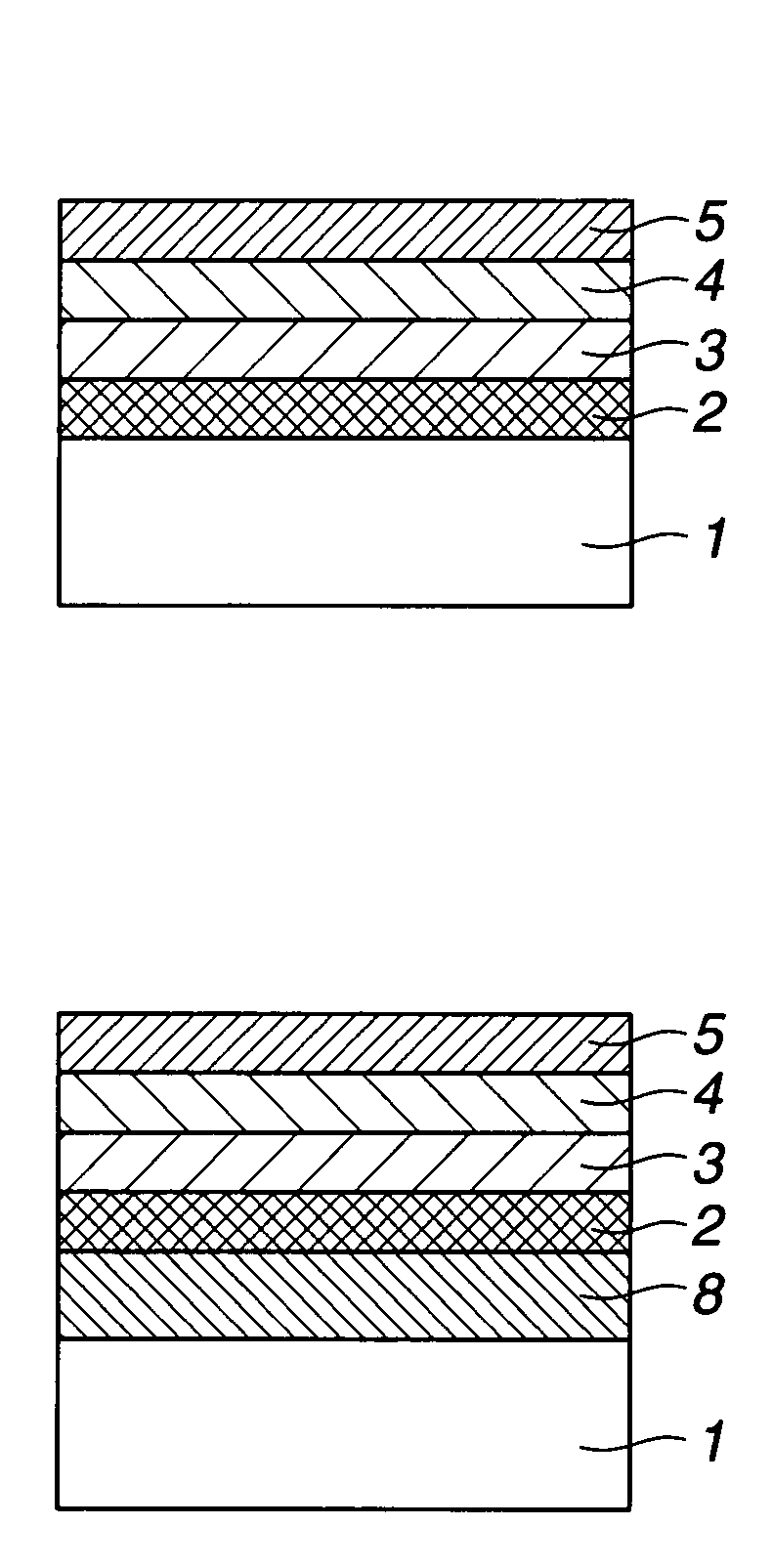

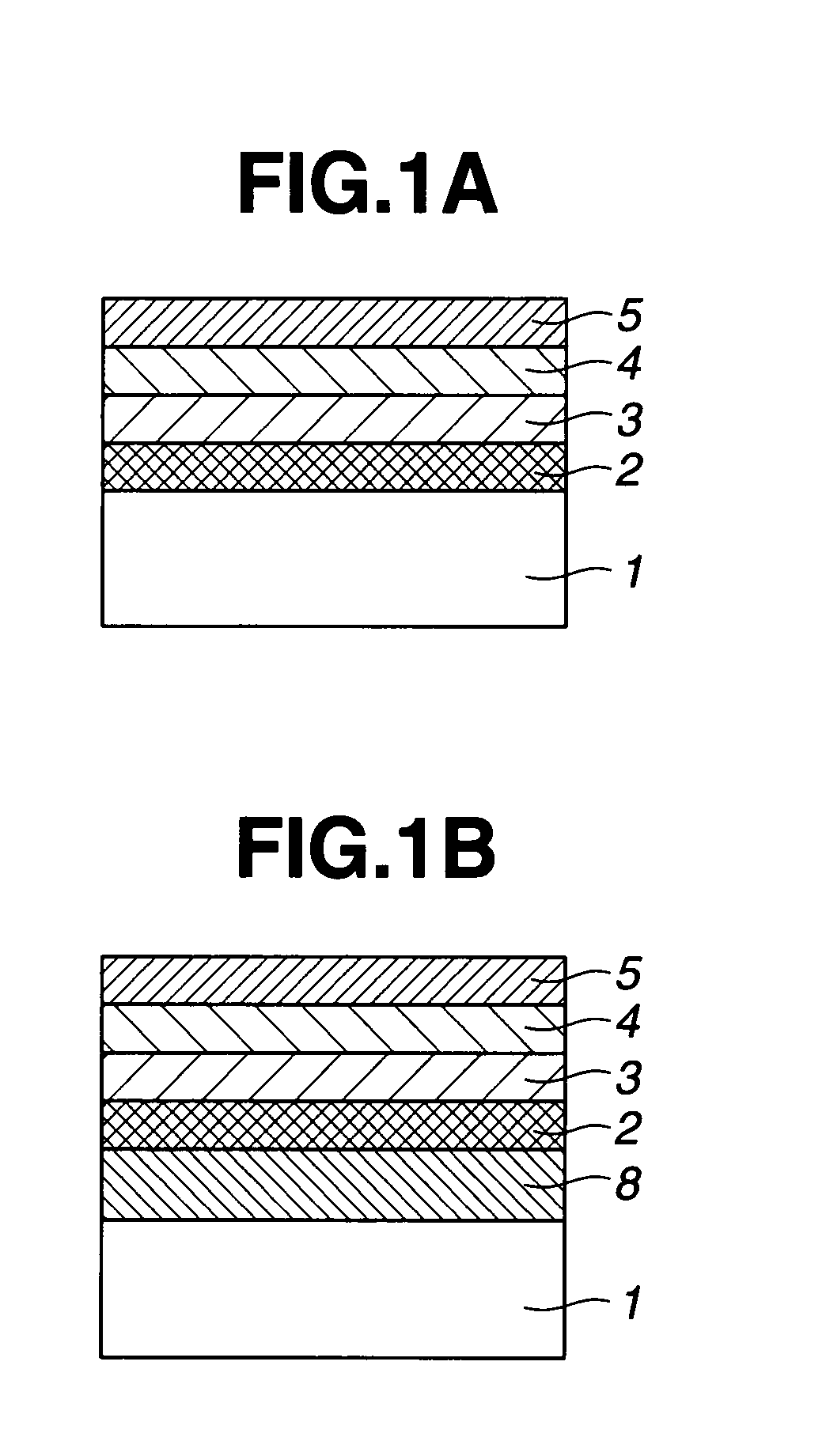

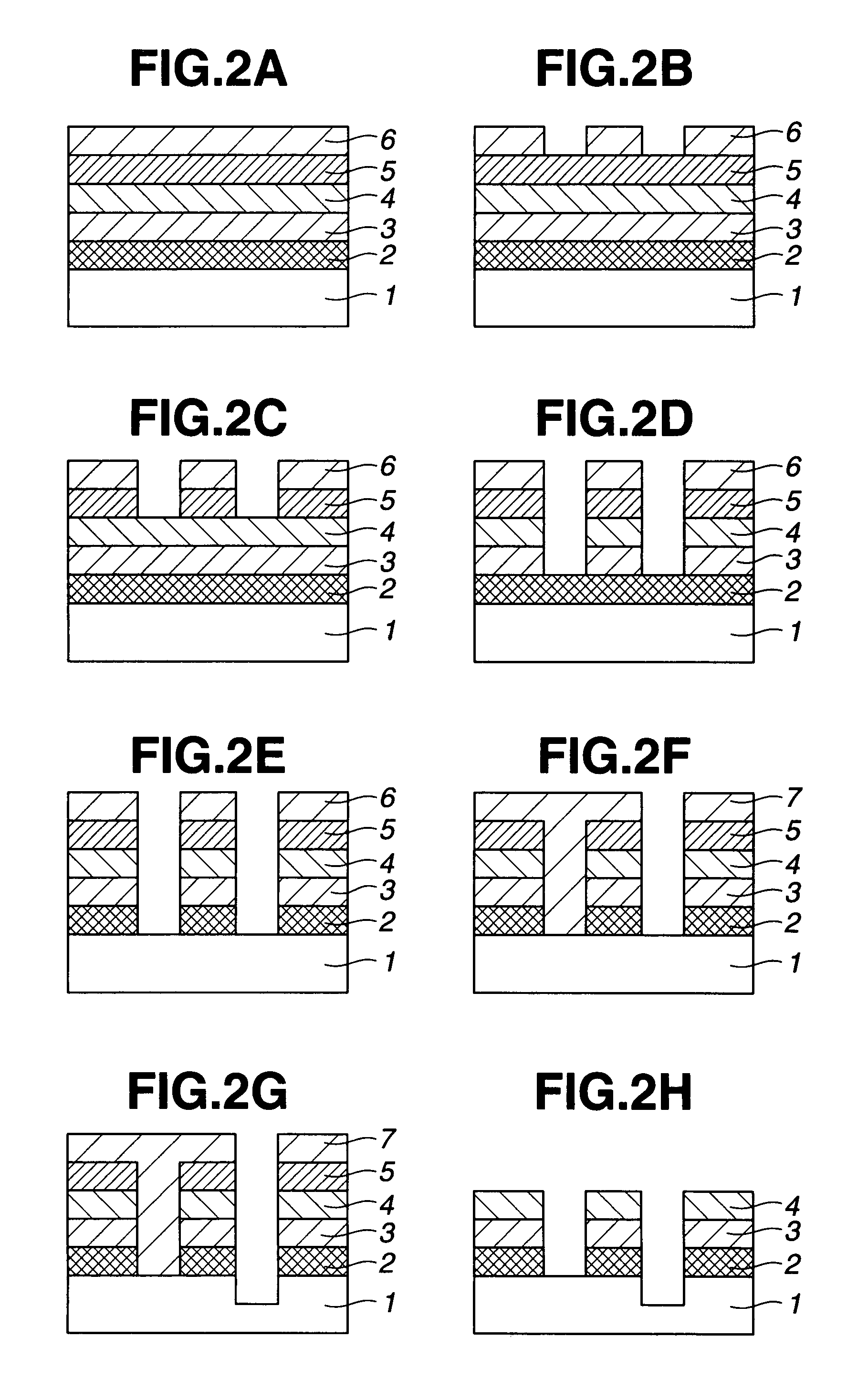

Photomask blank

ActiveUS20070248897A1Improve conductivityEnsure stabilityVacuum evaporation coatingSputtering coatingNitrogenOxygen

A photomask blank has a light-shielding film composed of a single layer of a material containing a transition metal, silicon and nitrogen or a plurality of layers that include at least one layer made of a material containing a transition metal, silicon and nitrogen, and has one or more chrome-based material film. The high transition metal content ensures electrical conductivity, preventing charge-up in the photomask production process, and also provides sufficient chemical stability to cleaning in photomask production. The light-shielding film has a good resistance to dry etching of the chrome-based material film in the presence of chlorine and oxygen, thus ensuring a high processing accuracy.

Owner:SHIN ETSU CHEM IND CO LTD +1

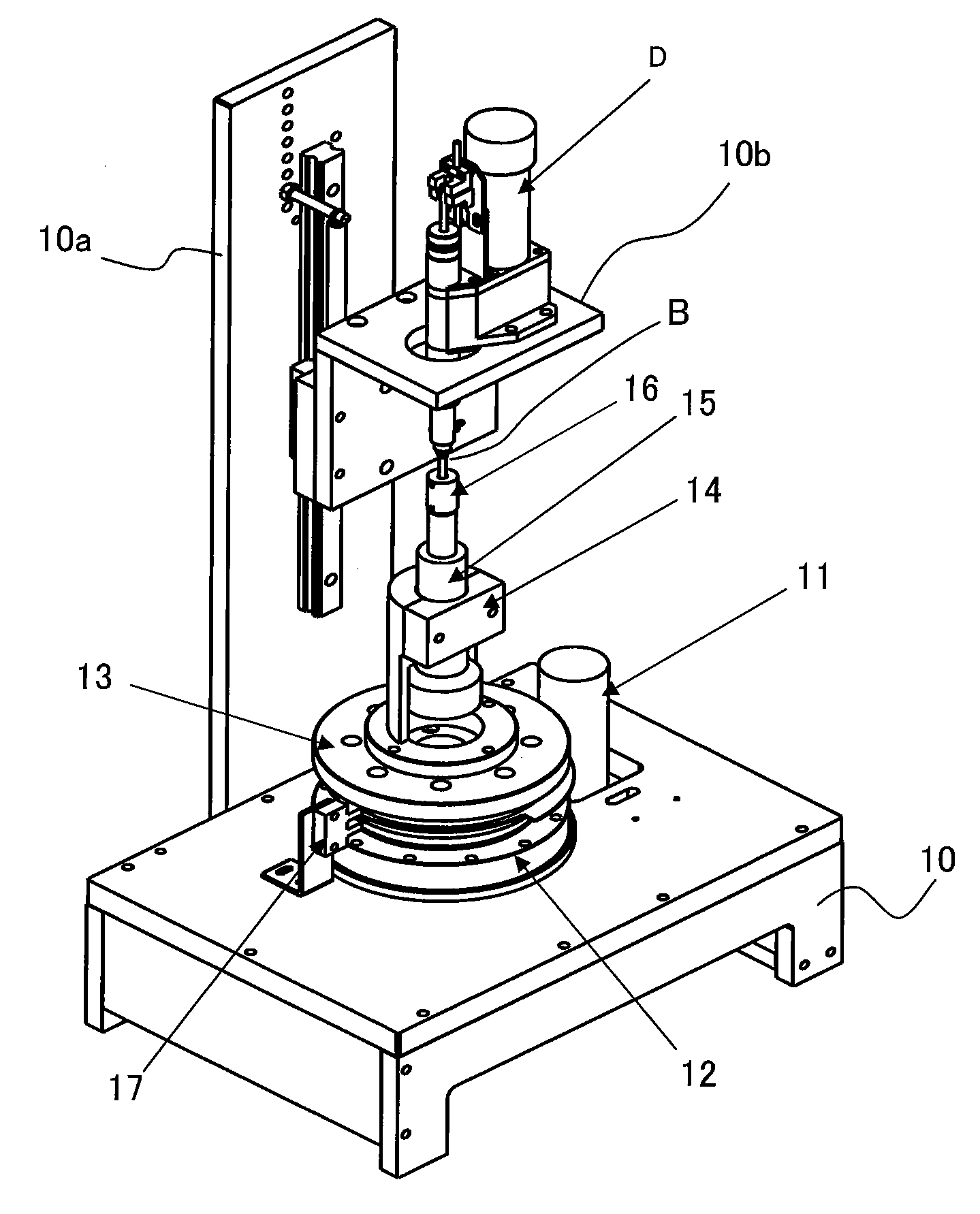

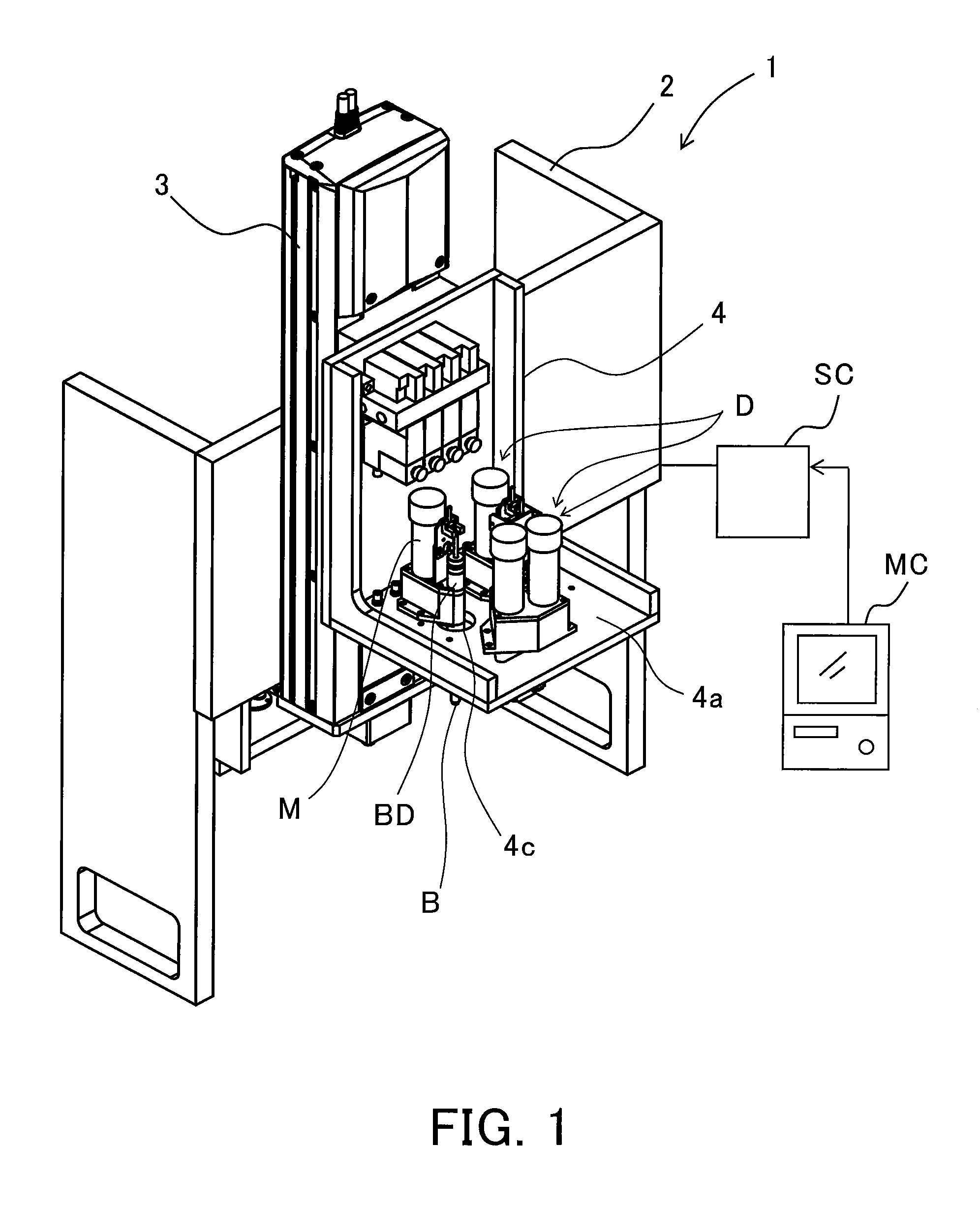

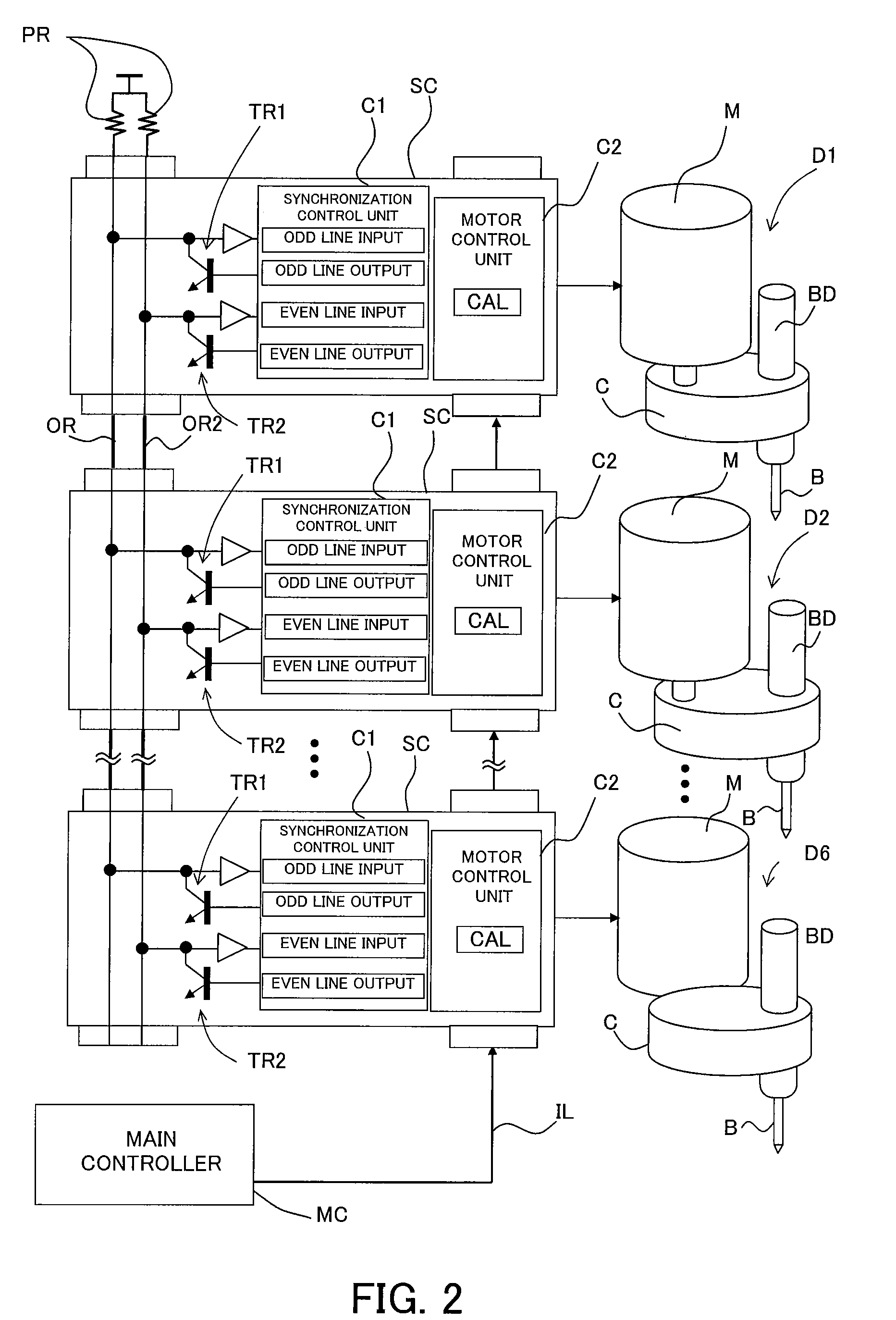

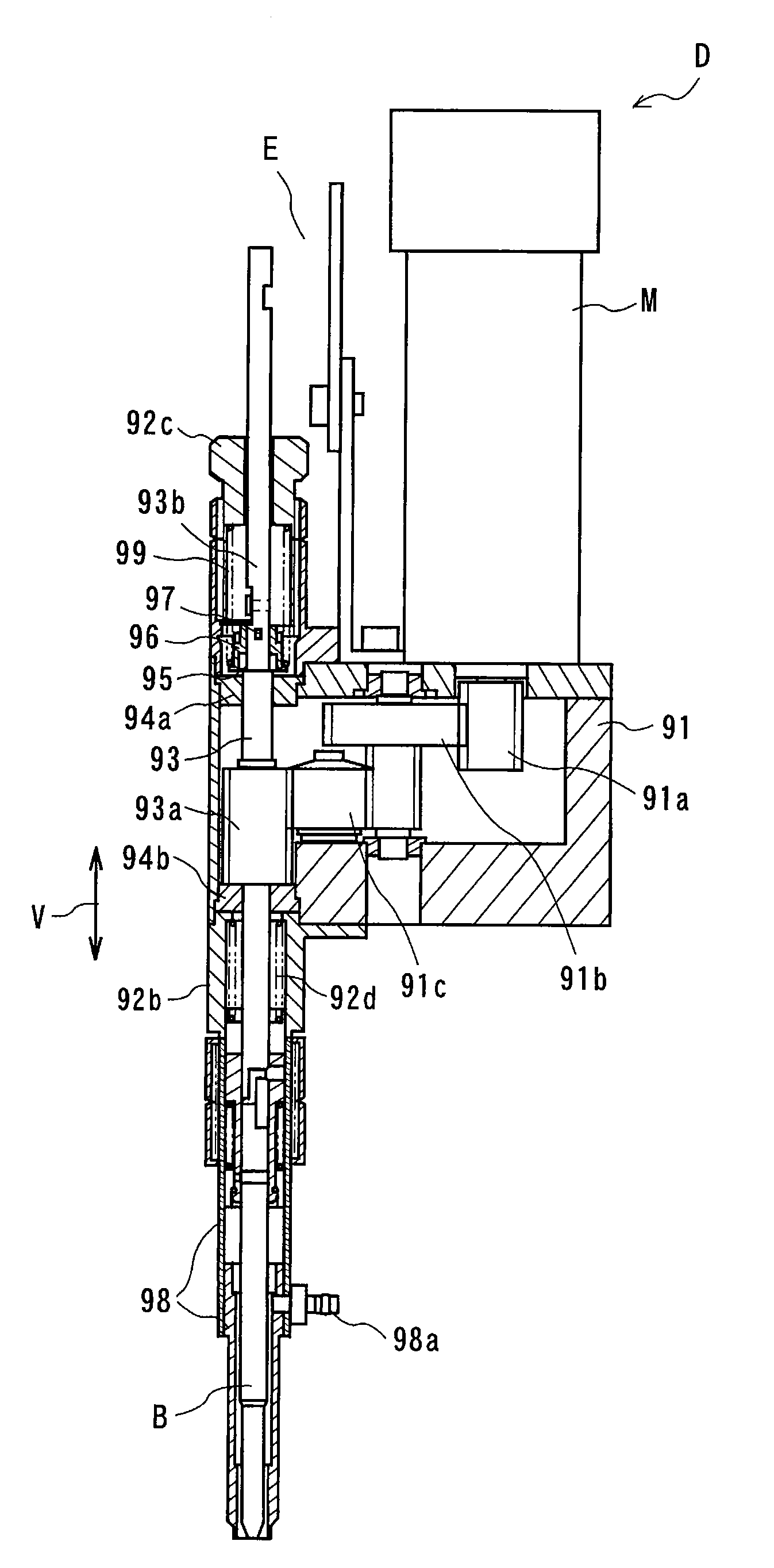

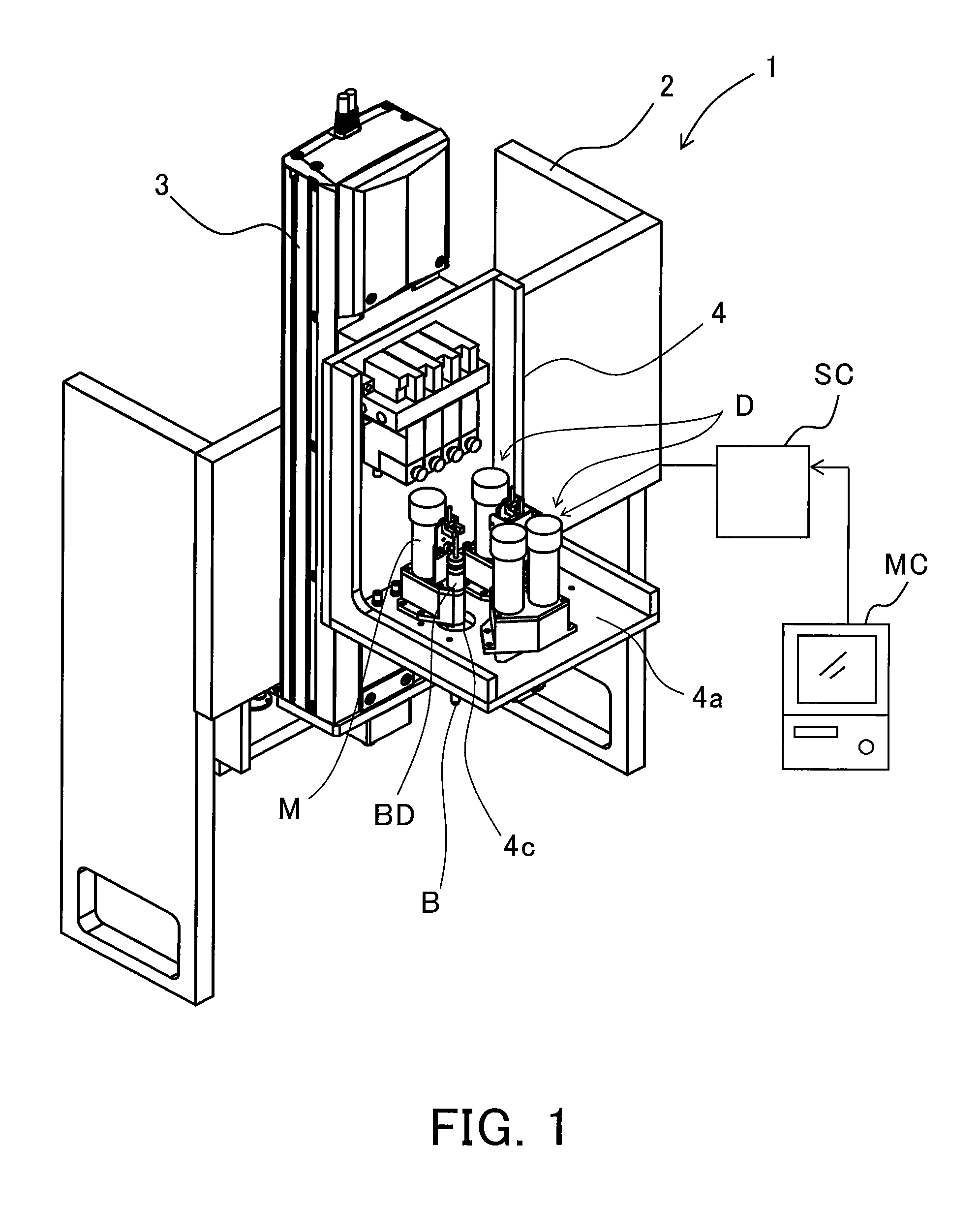

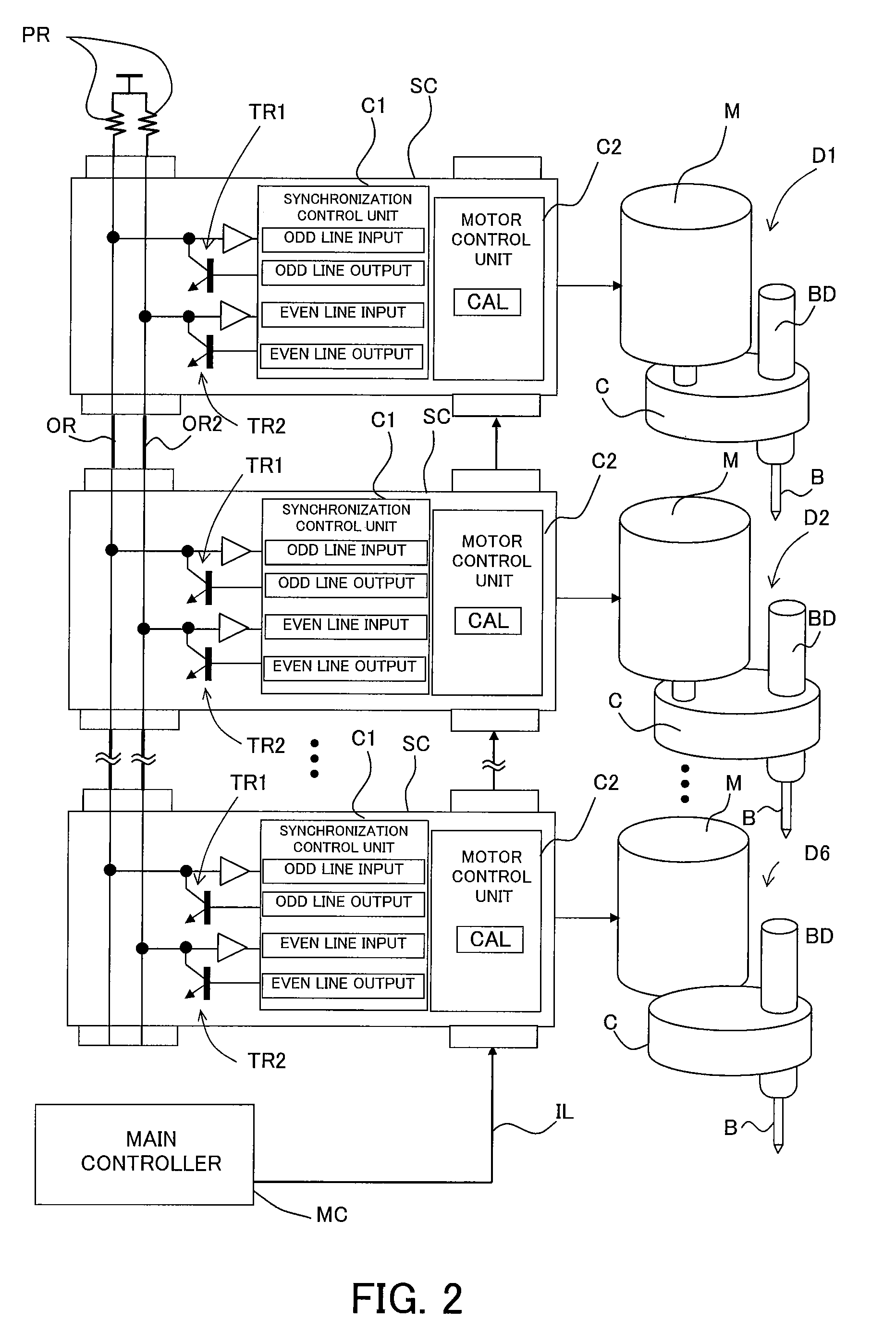

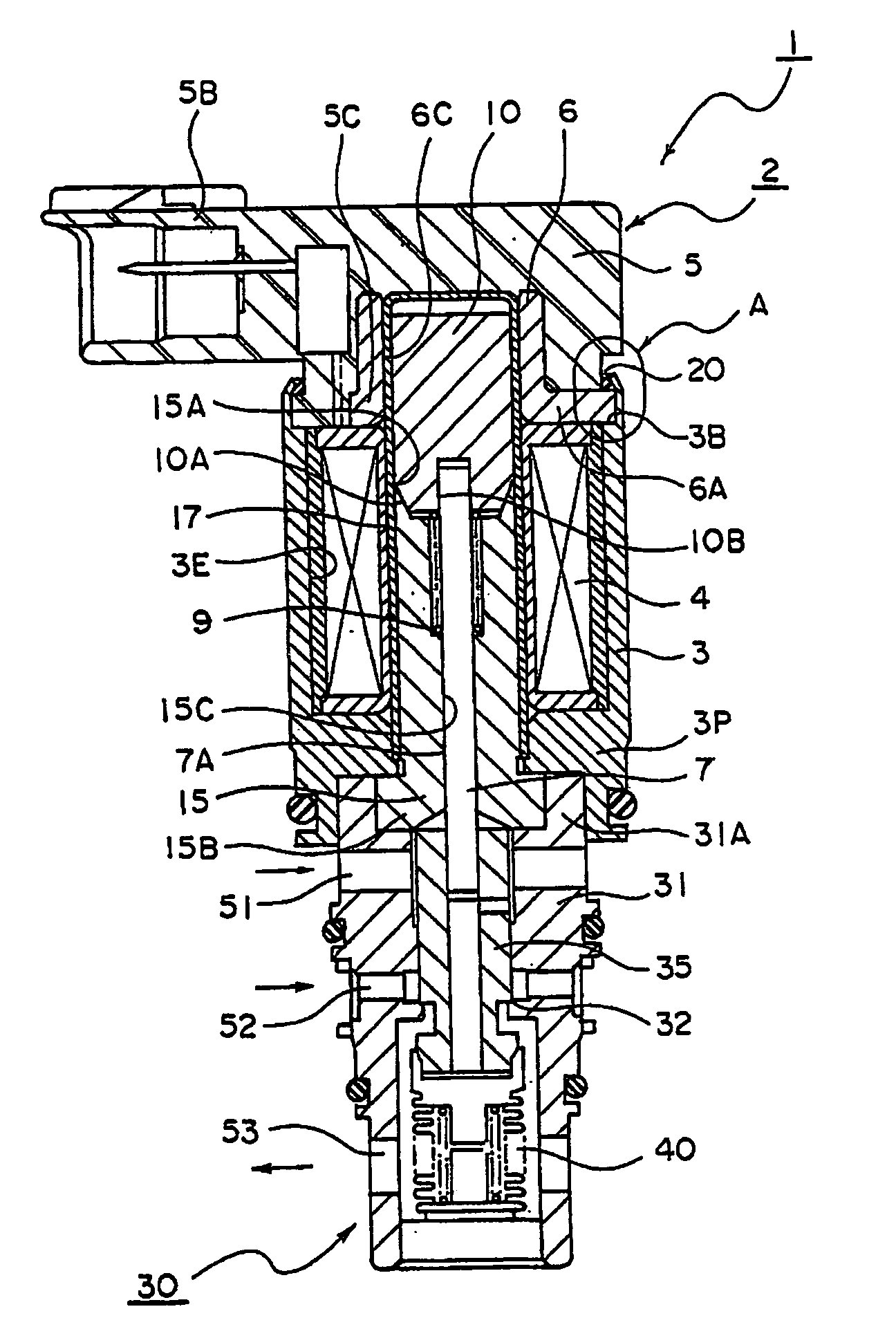

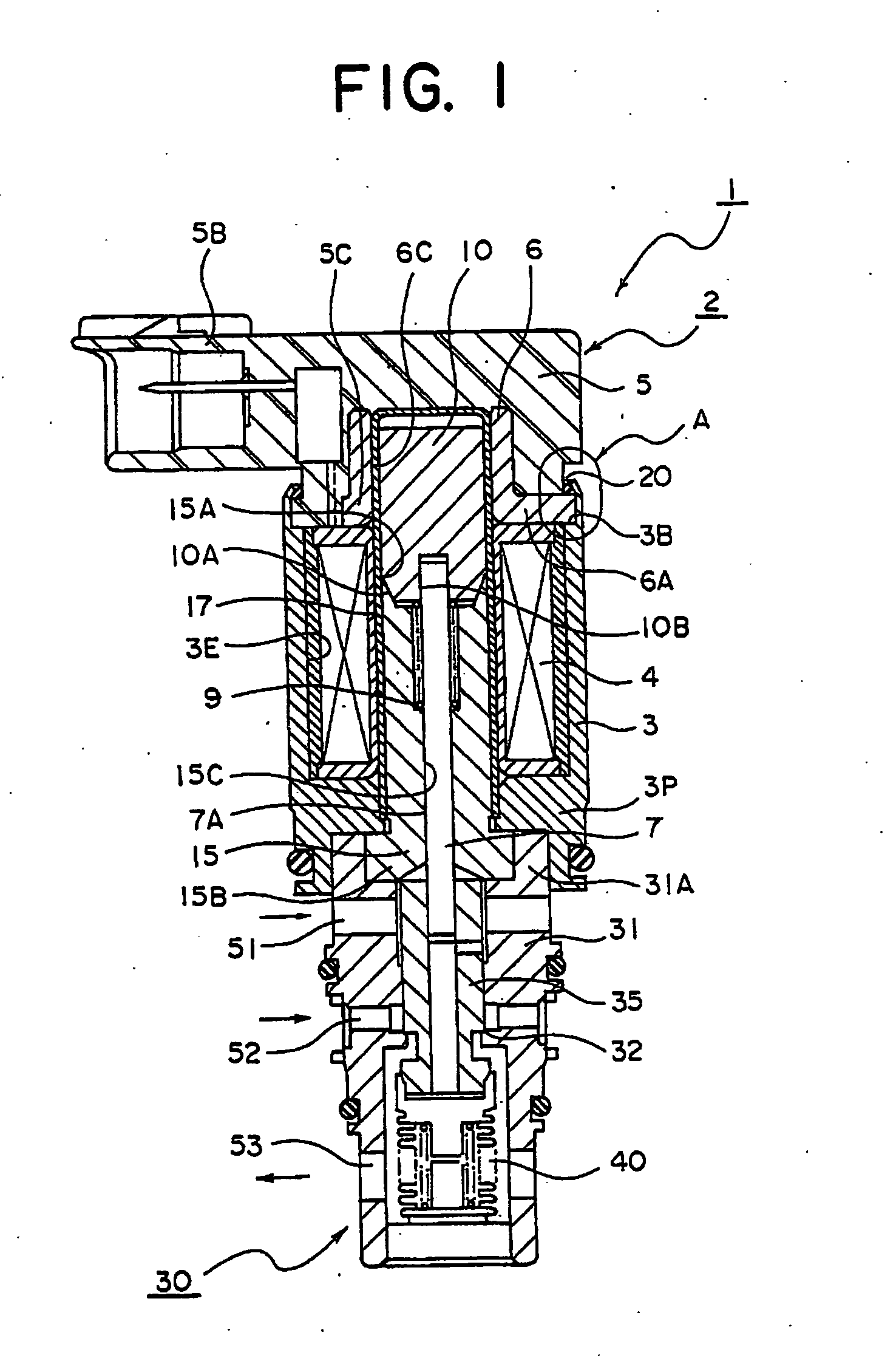

Screw tightening apparatus

InactiveUS20080314204A1Easy to processImprove conductivityMeasurement of torque/twisting force while tighteningSpannersEngineeringDrill bit

The screw tightening apparatus includes a motor, an output shaft to which a bit for screw tightening is connected so as to be rotatable integrally with the output shaft and which is axially movable, the output shaft being driven to be rotated by the motor, a spring whose one end contacts a member constituting a main body of the screw tightening apparatus, and a spring receiving member which the other end of the spring contacts and transmits a biasing force of the spring to the output shaft. The screw tightening apparatus further includes a conductive member which contacts the output shaft and the spring receiving member. This configuration enables static electricity generated on the bit to certainly flow into the main body of the apparatus (ground) via the output shaft, the conductive member, the spring receiving member, and the spring.

Owner:FUJITSU LTD

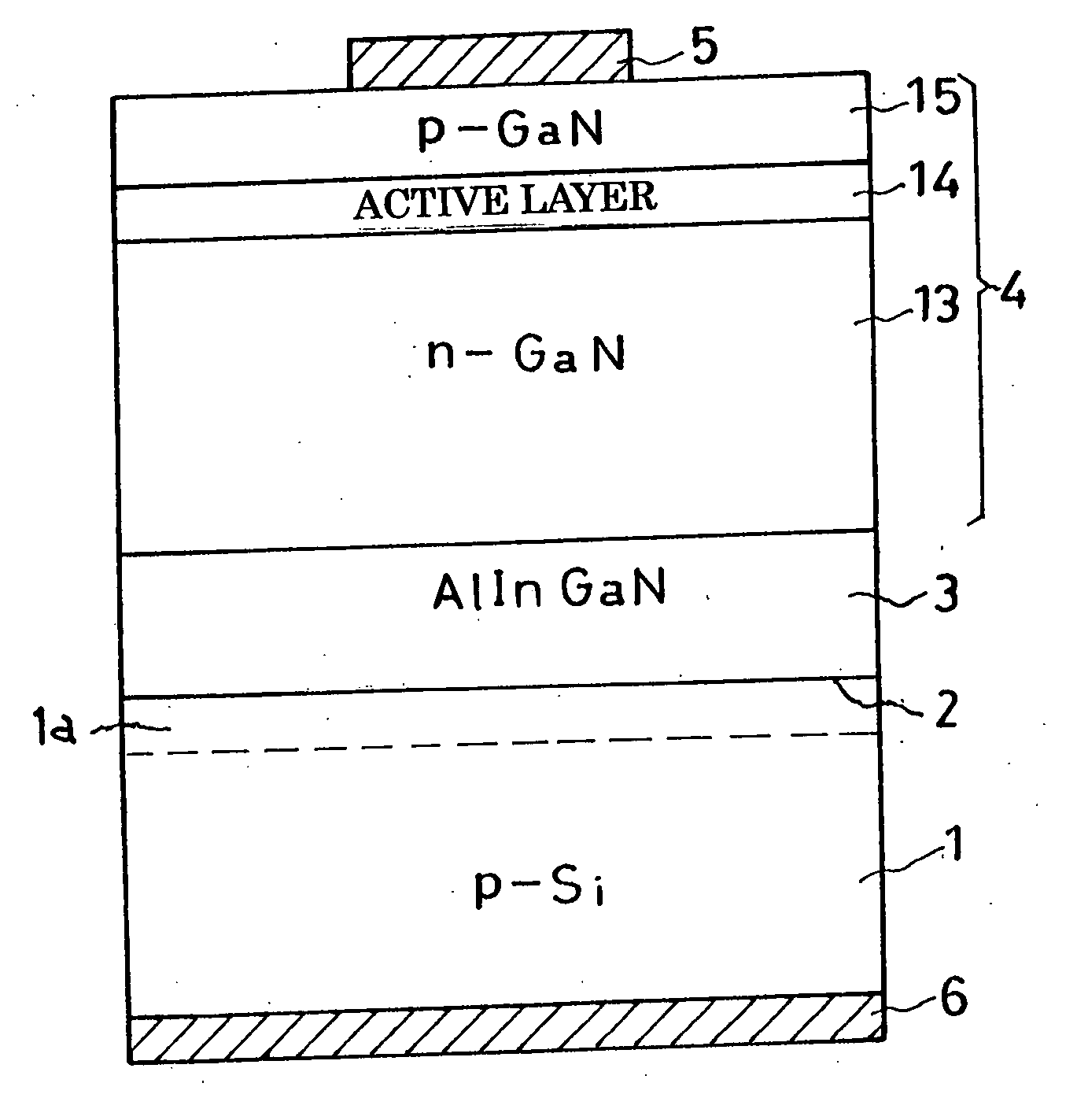

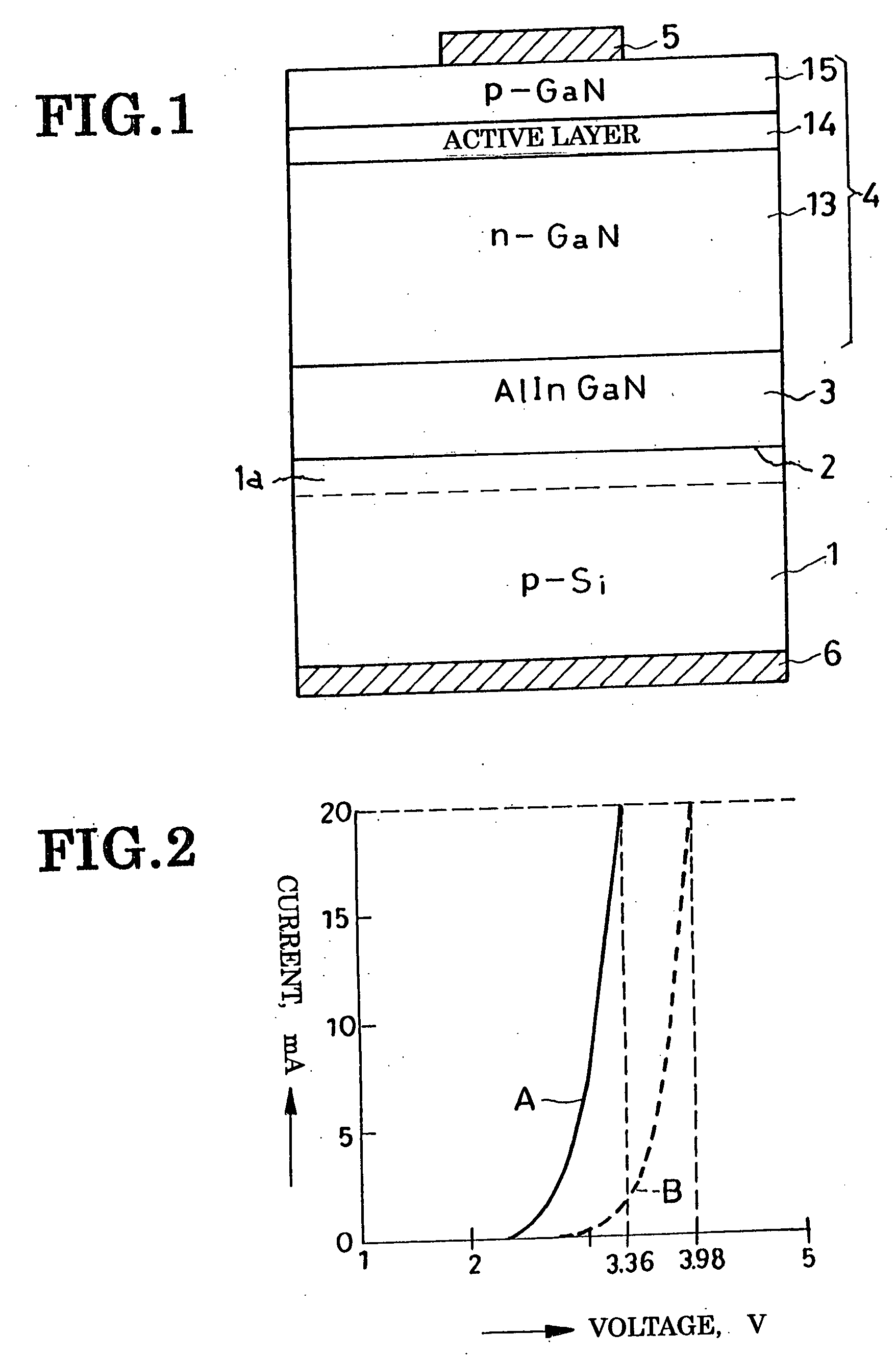

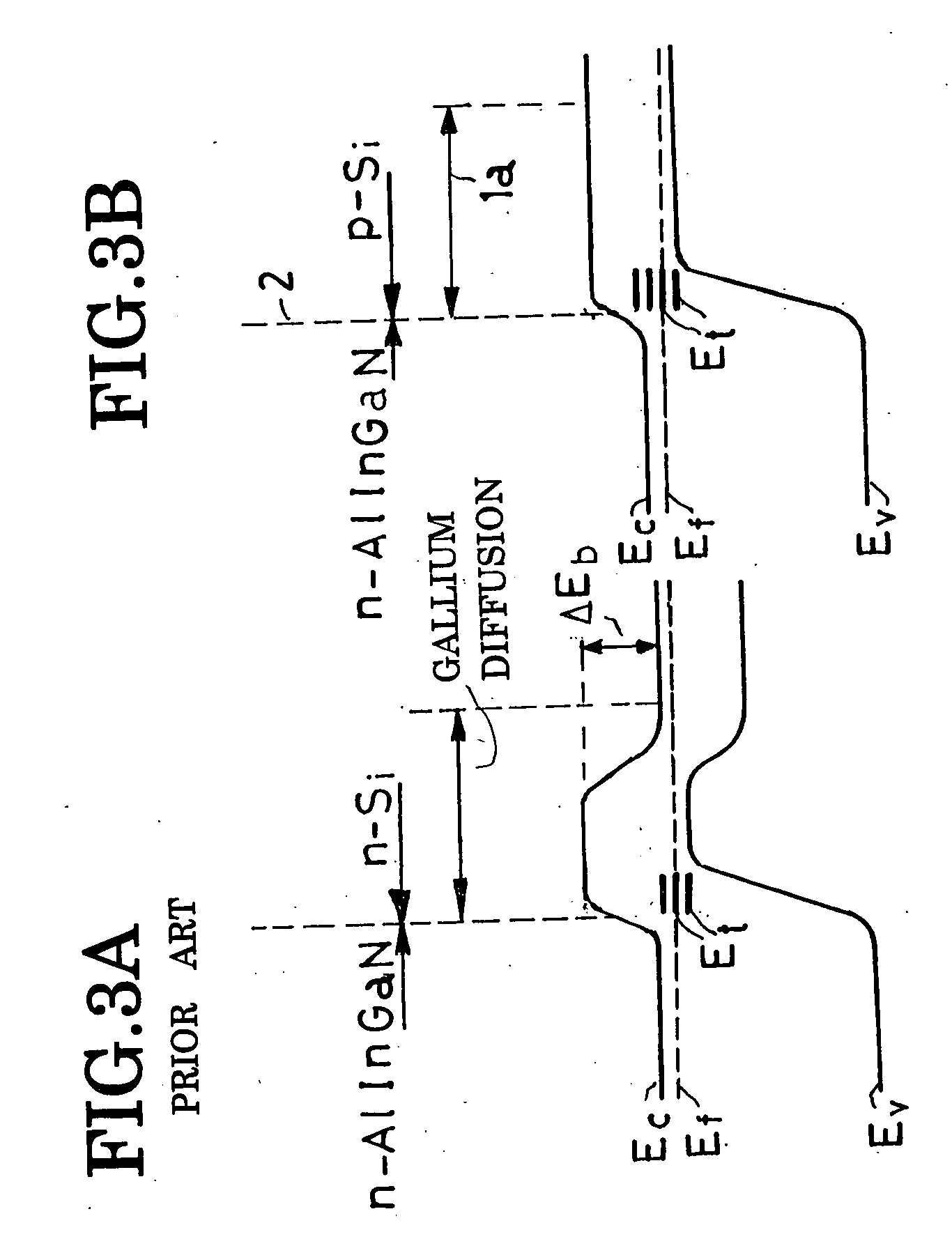

Nitride-based semiconductor device of reduced voltage drop, and method of fabrication

ActiveUS20060175628A1Minimize voltage dropLess driving voltageSemiconductor/solid-state device manufacturingSemiconductor devicesHeterojunctionDevice material

A light-emitting diode is built on a silicon substrate which has been doped with a p-type impurity to possess sufficient conductivity to provide part of the current path through the LED. The p-type silicon substrate has epitaxially grown thereon a buffer region of n-type AlInGaN. Further grown epitaxially on the buffer region is the main semiconductor region of the LED which comprises a lower confining layer of n-type GaN, an active layer for generating light, and an upper confining layer of p-type GaN. In the course of the growth of the buffer region and main semiconductor region there occurs a thermal diffusion of gallium and other Group III elements from the buffer region into the p-type silicon substrate, with the consequent creation of a p-type low-resistance region in the substrate. Interface levels are created across the heterojunction between p-type silicon substrate and n-type buffer region. The interface levels expedite carrier transport from substrate to buffer region, contributing to reduction of the drive voltage requirement of the LED.

Owner:SANKEN ELECTRIC CO LTD

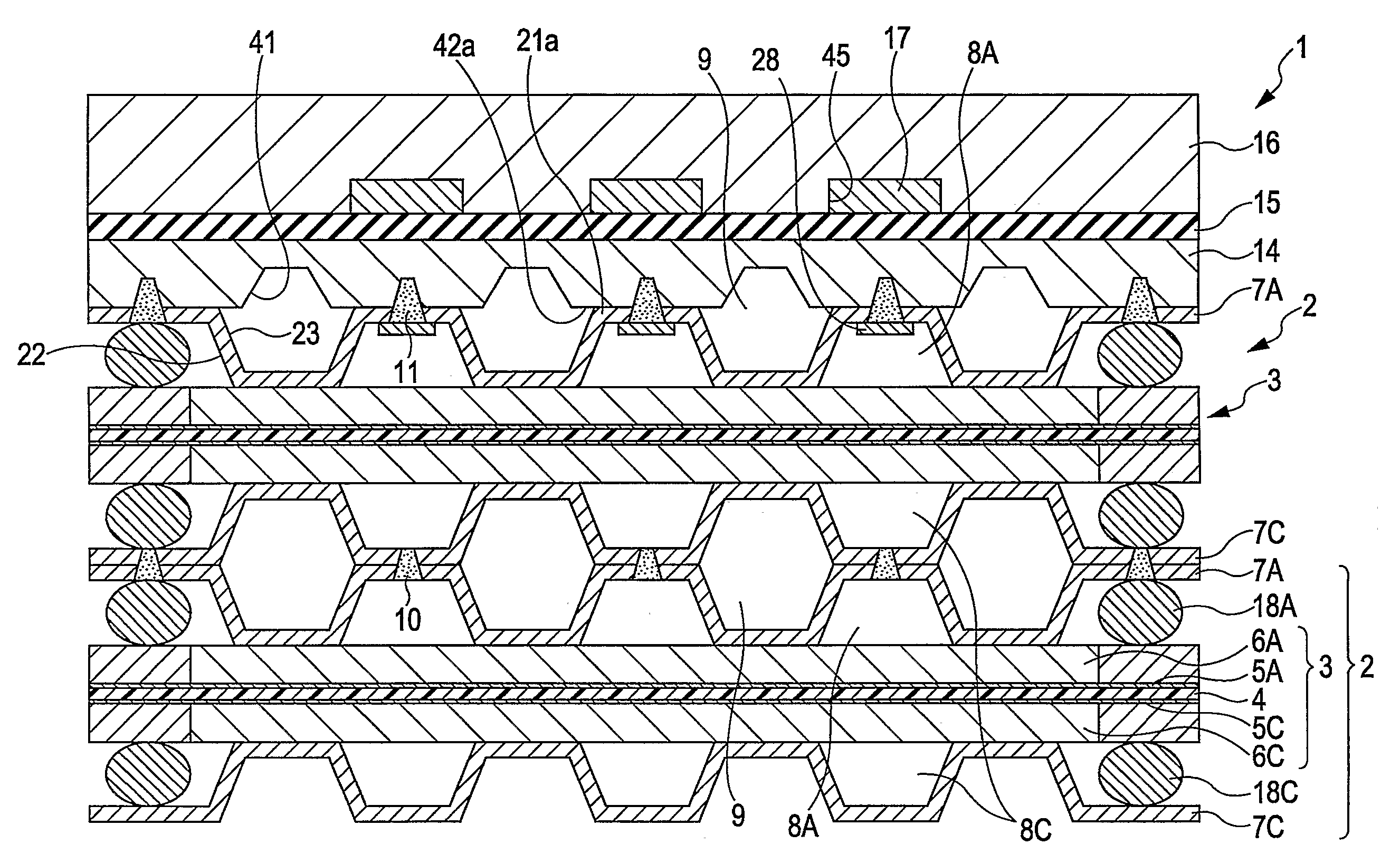

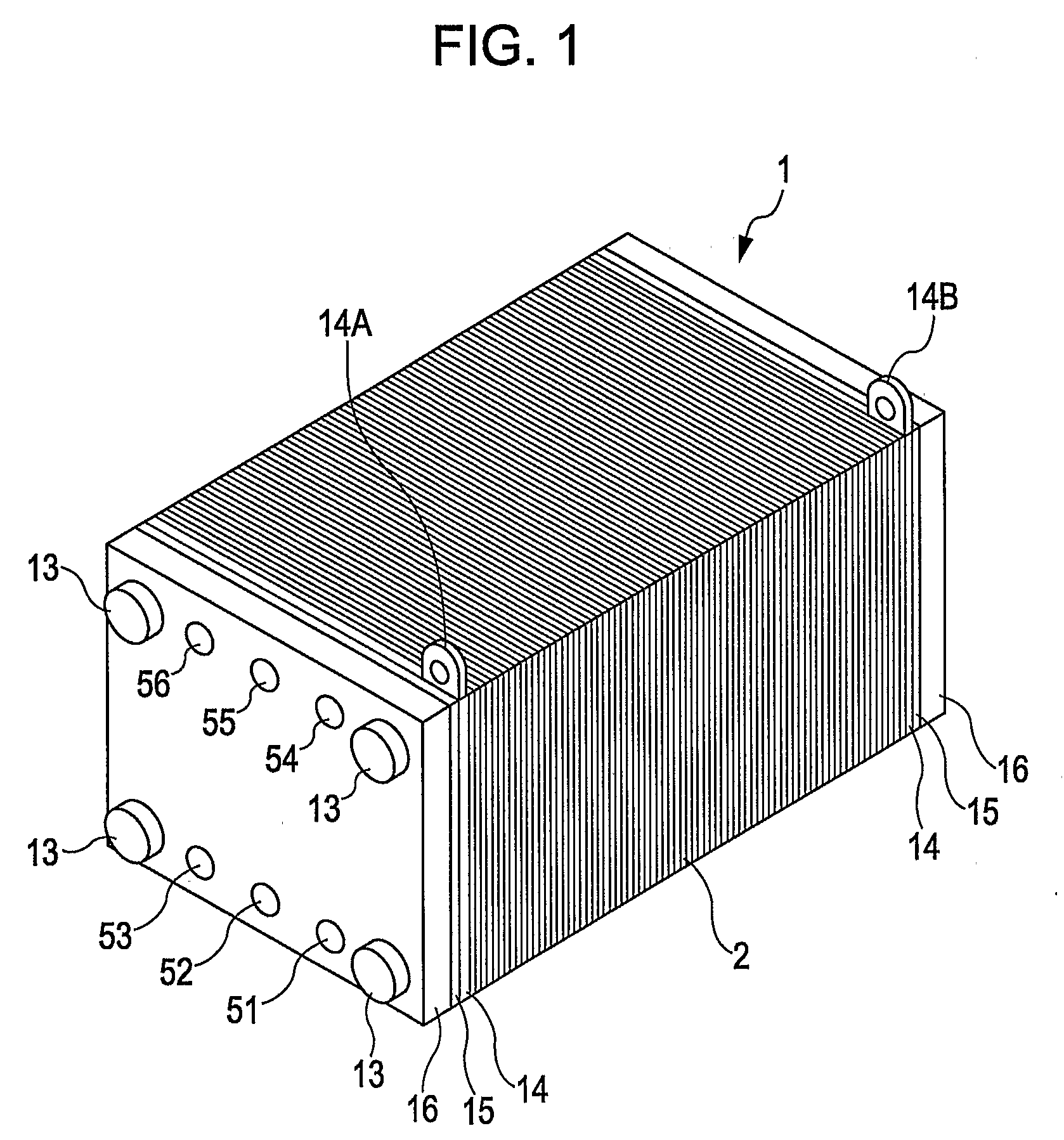

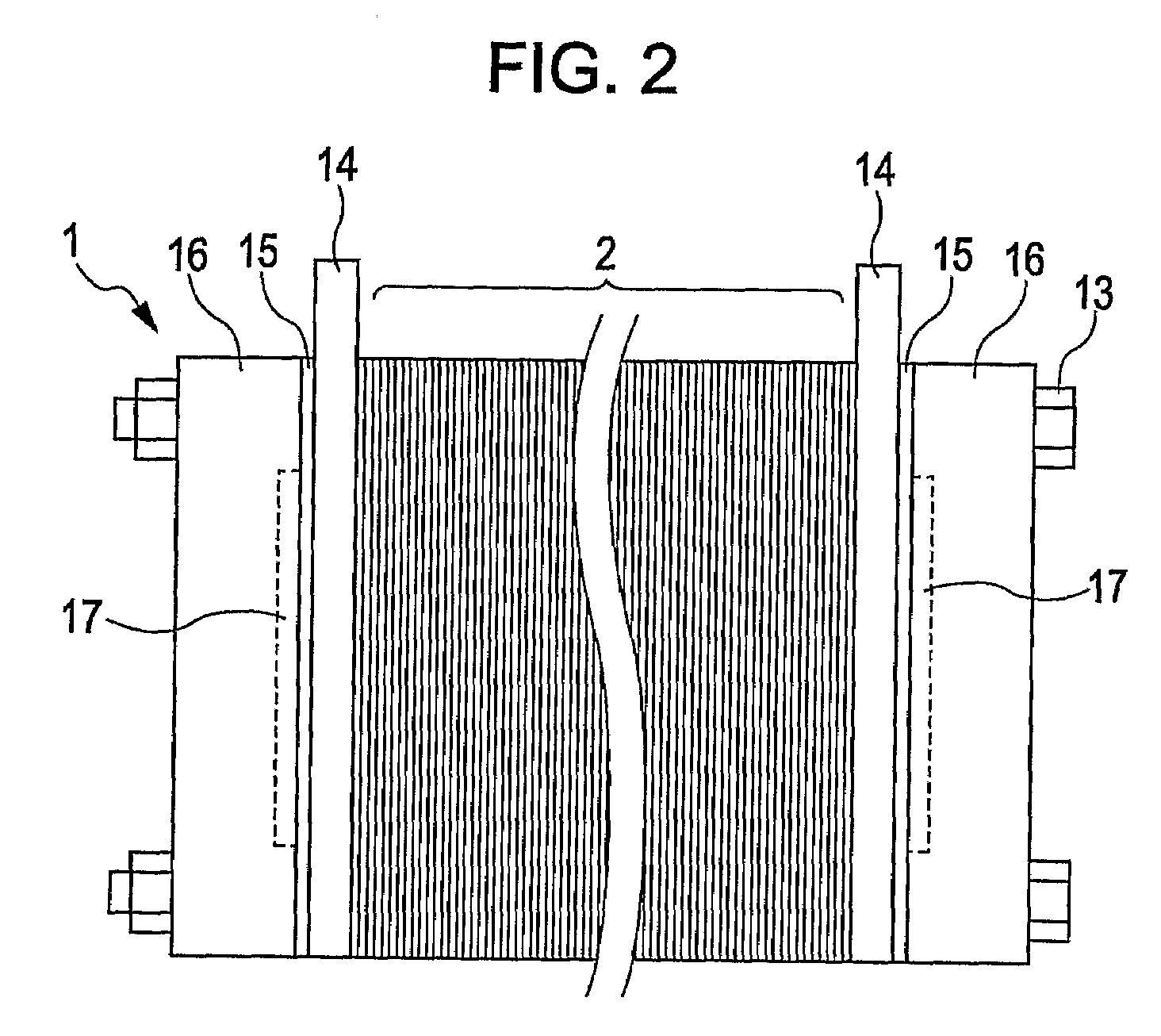

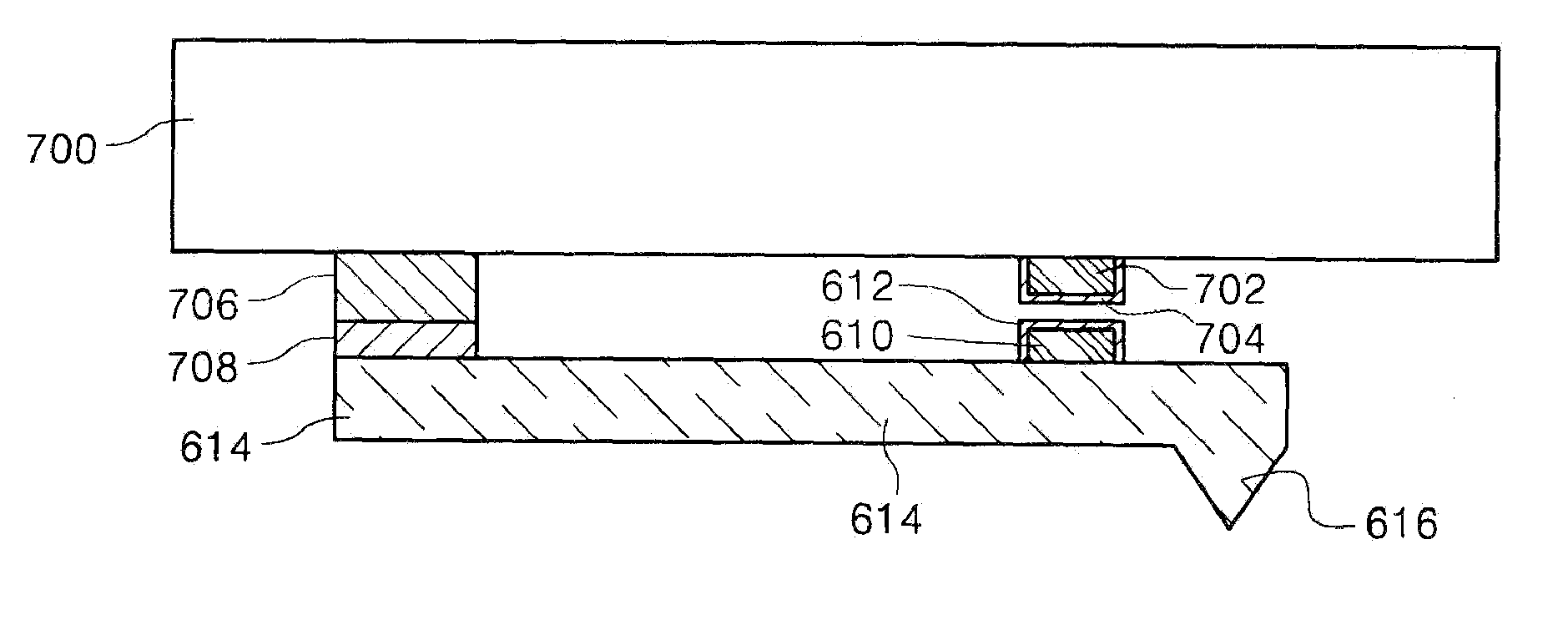

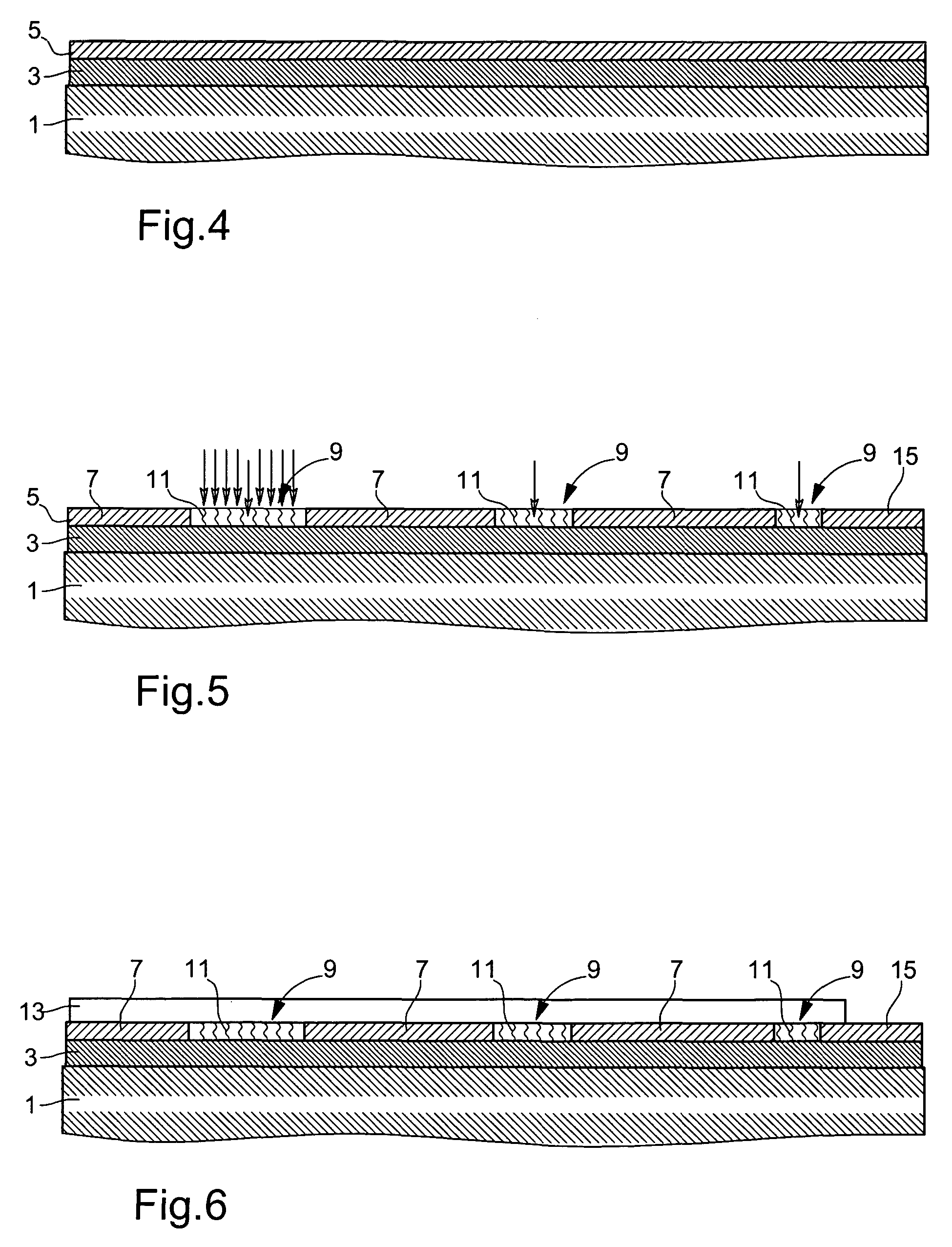

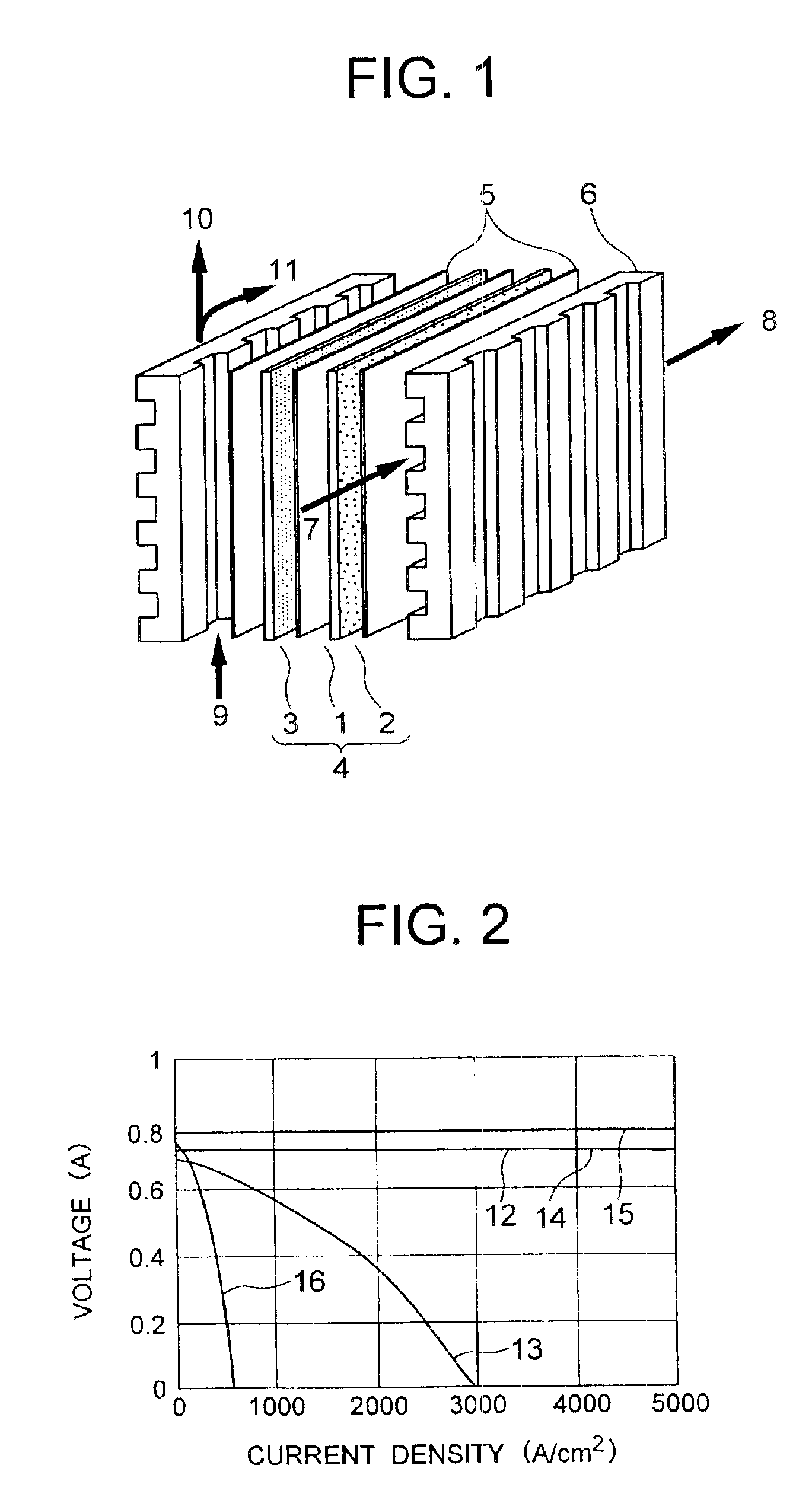

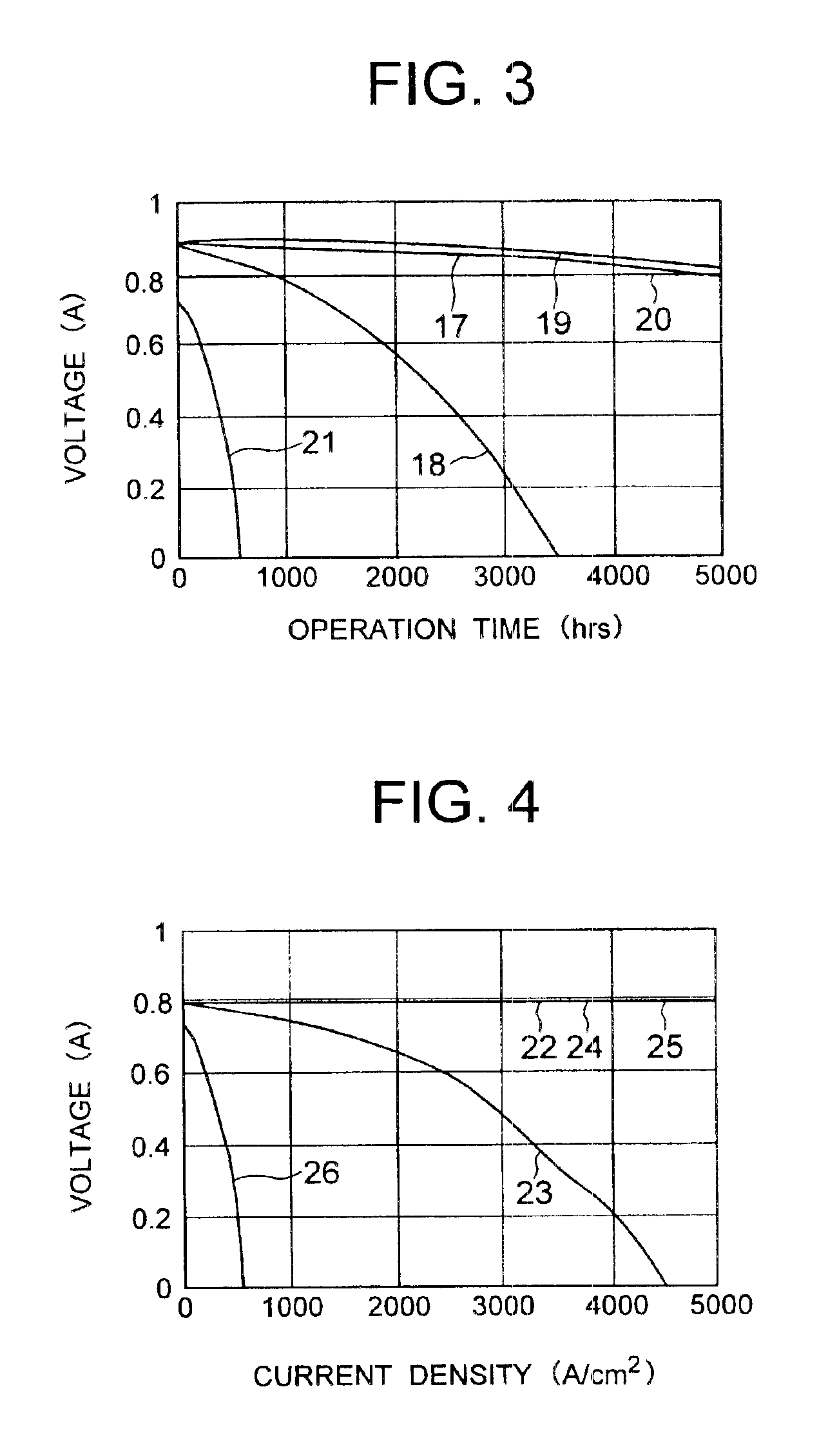

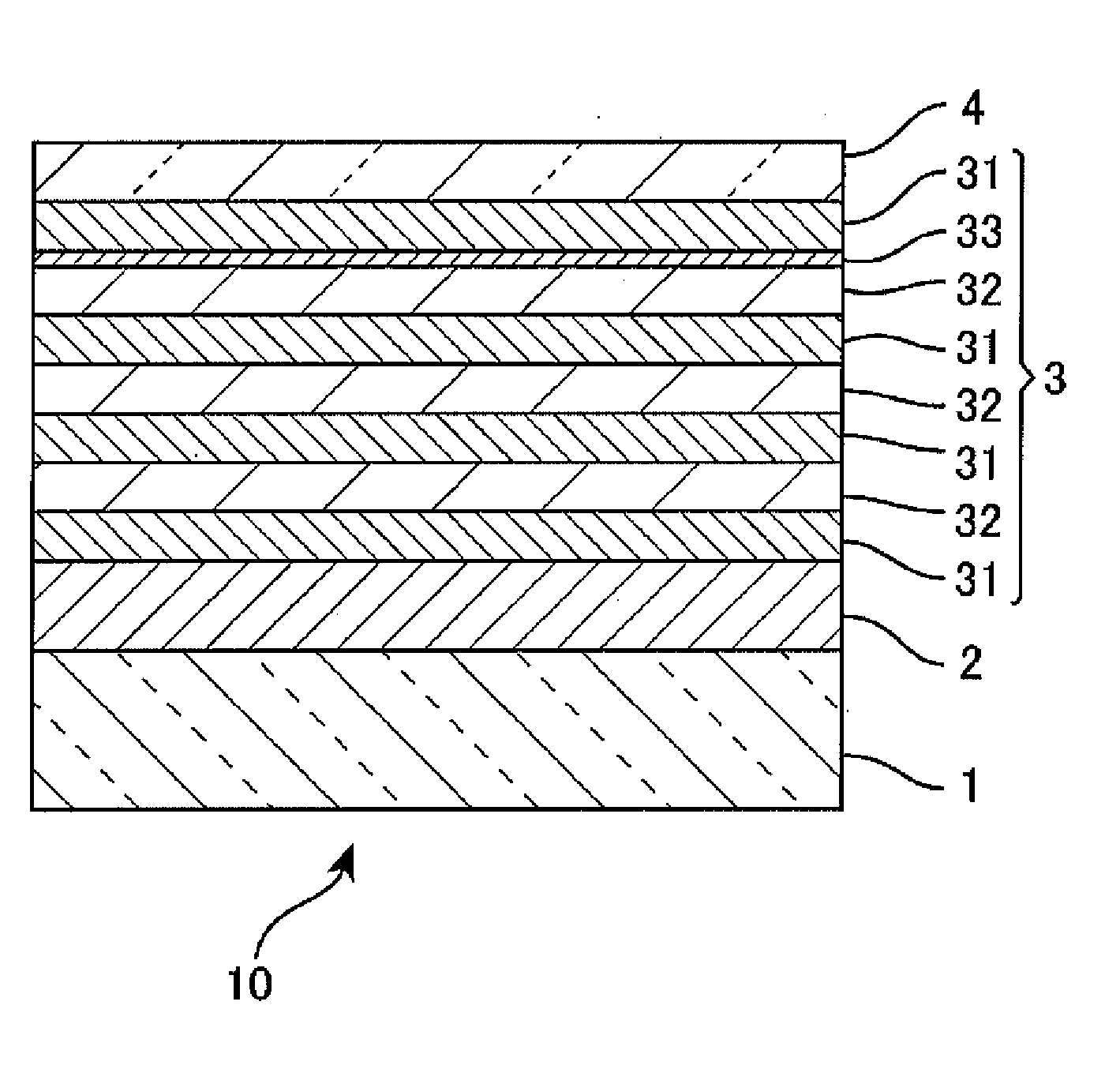

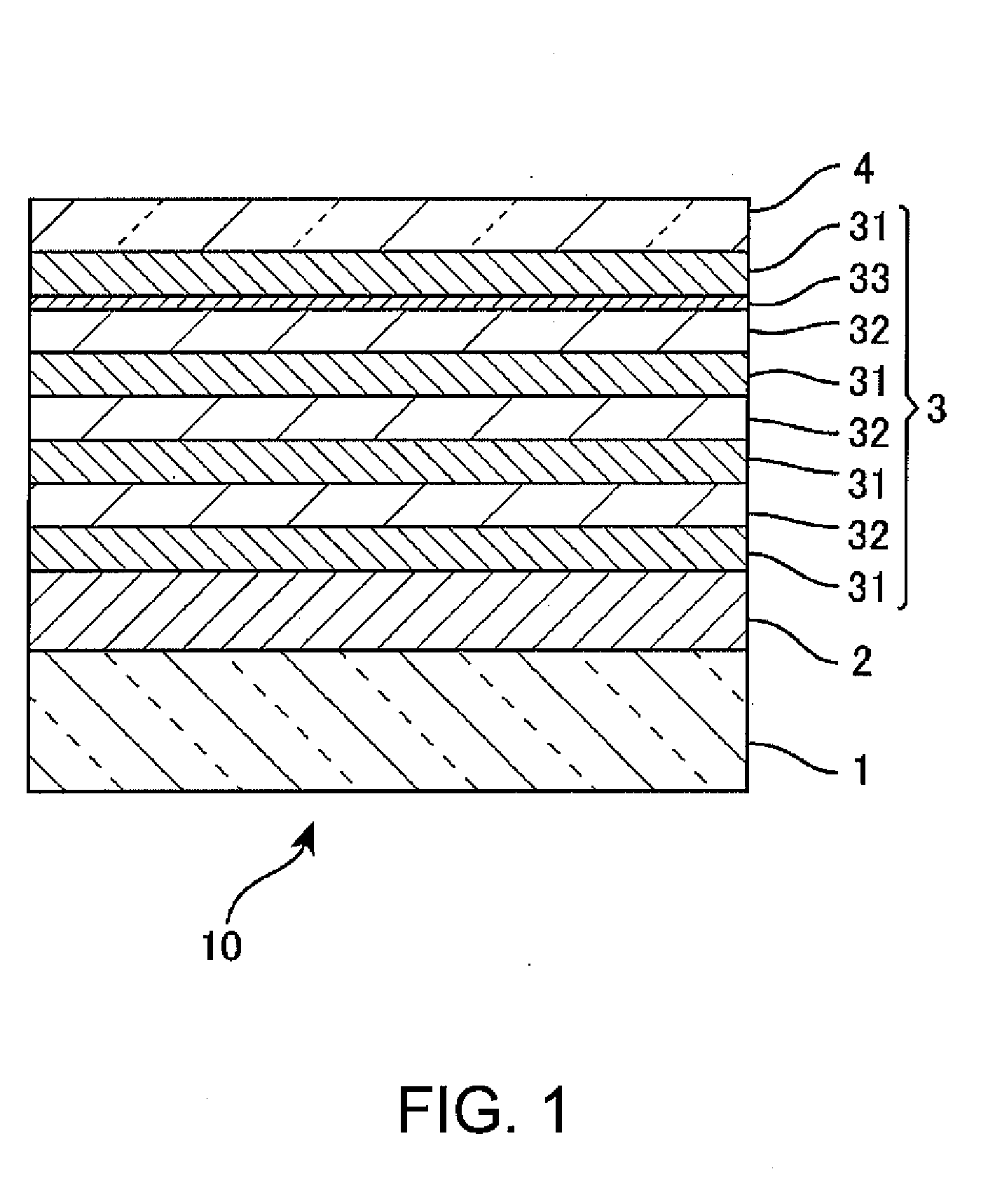

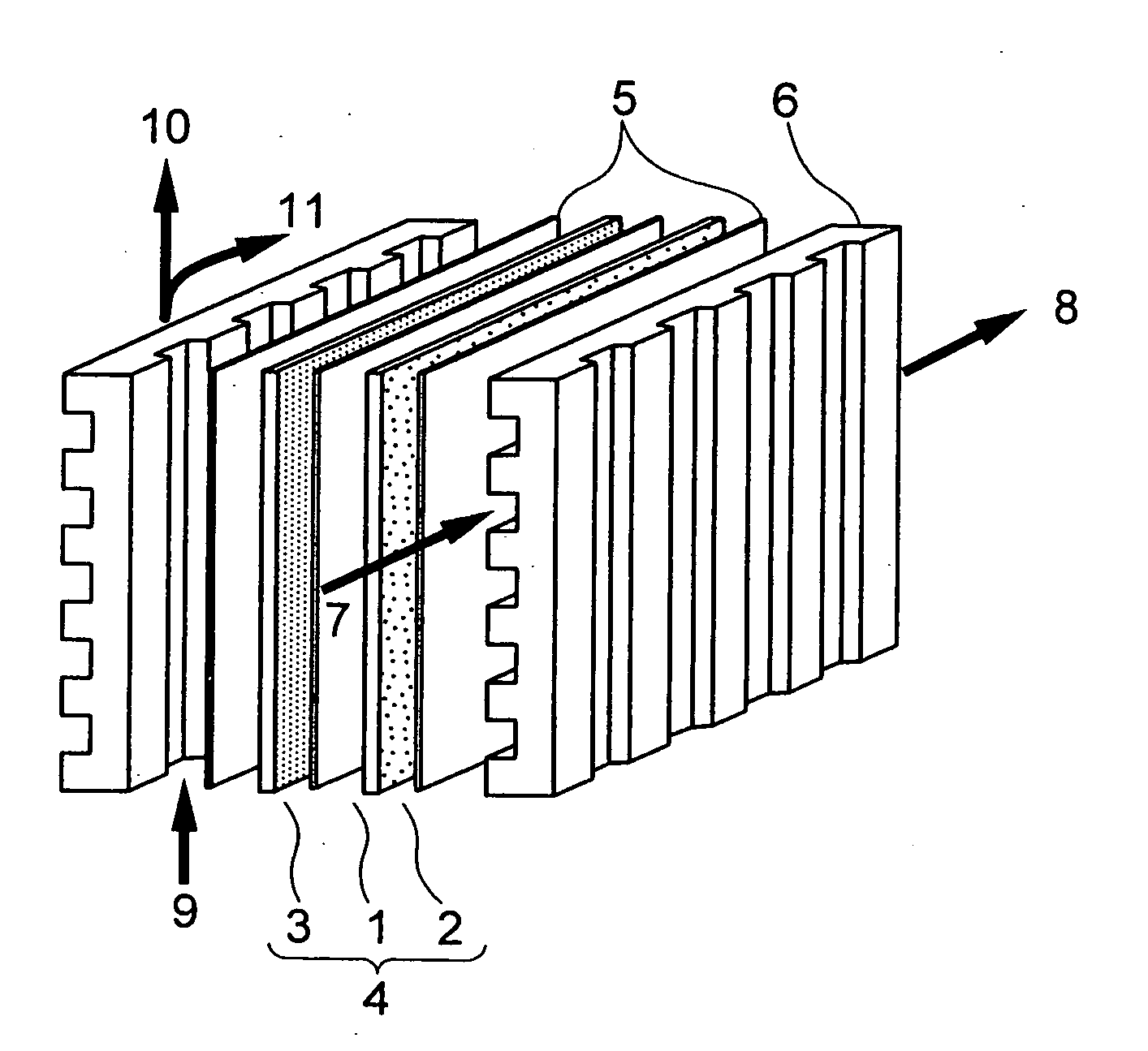

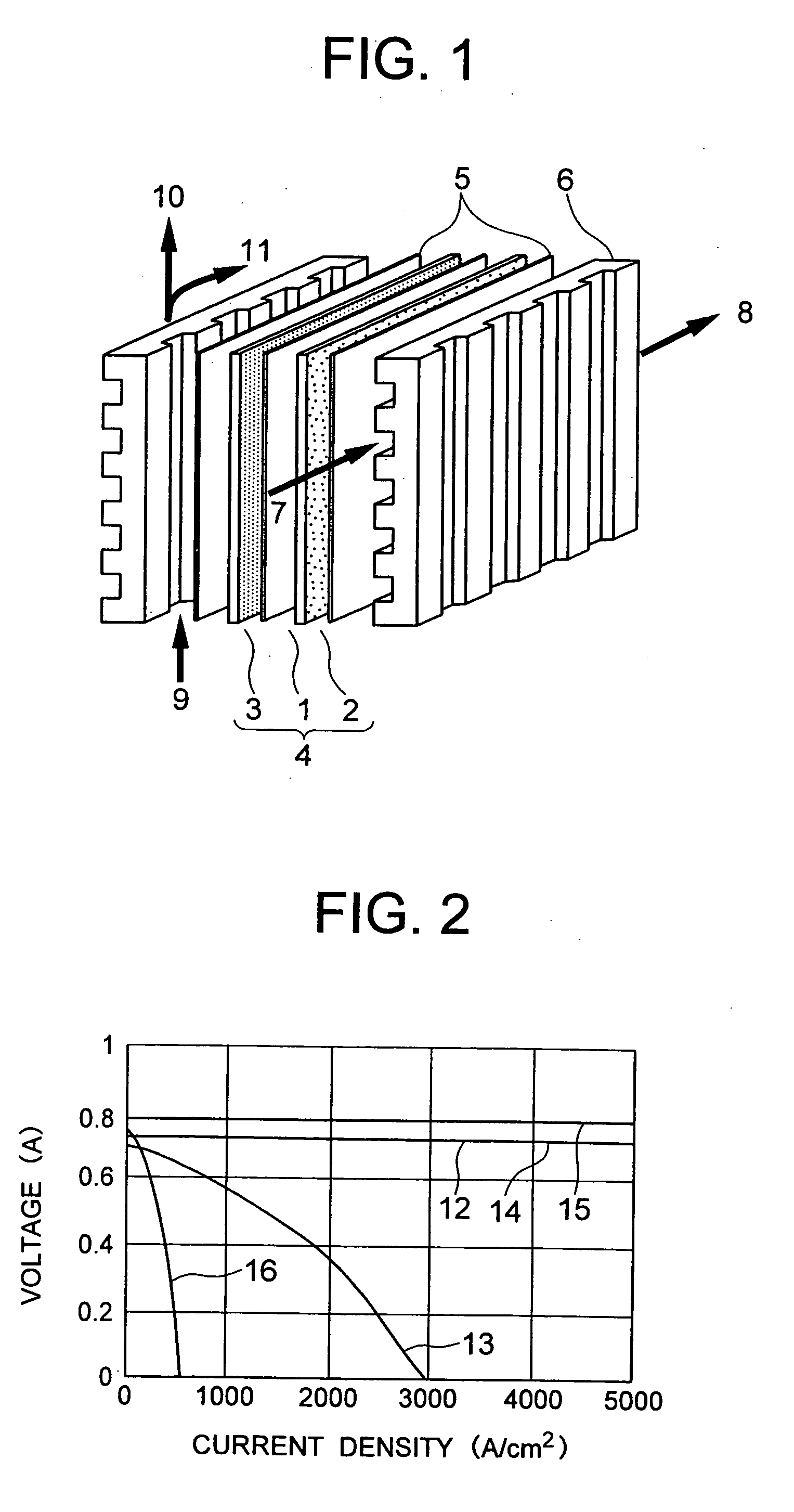

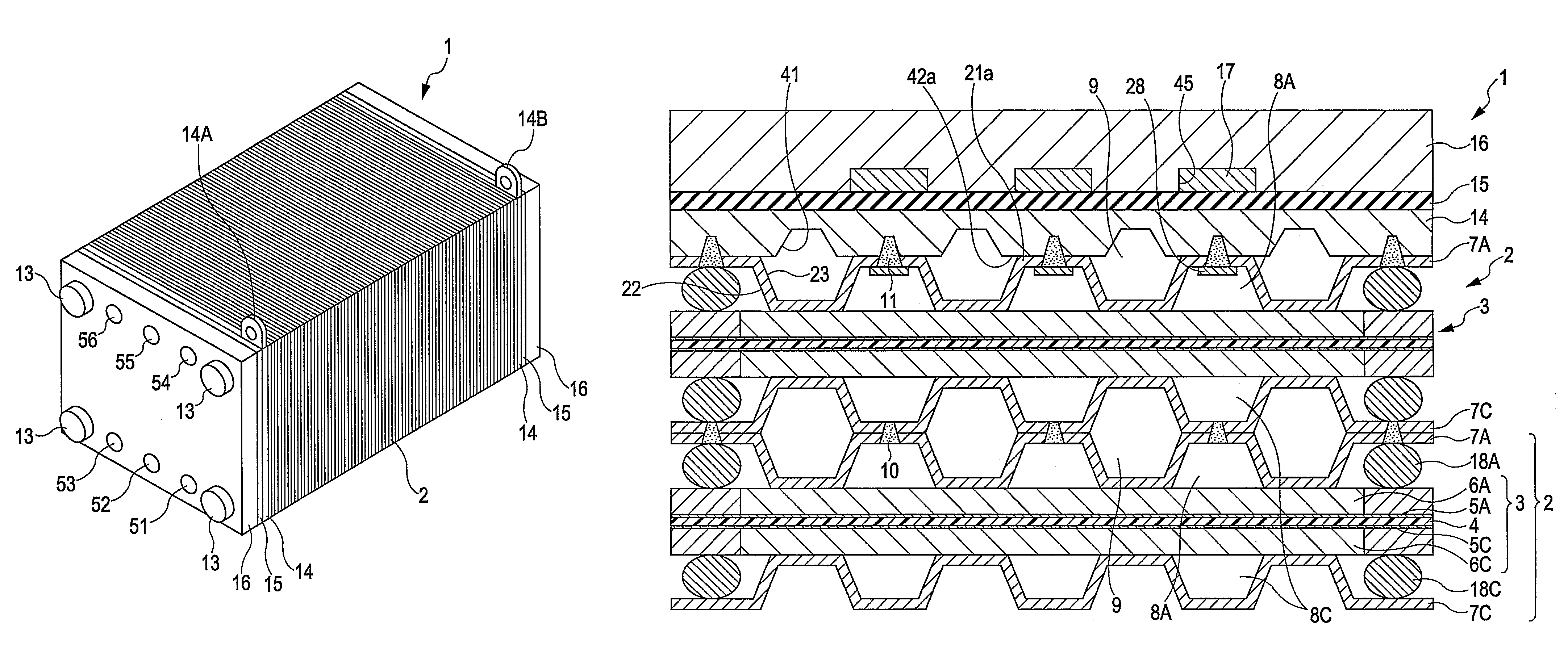

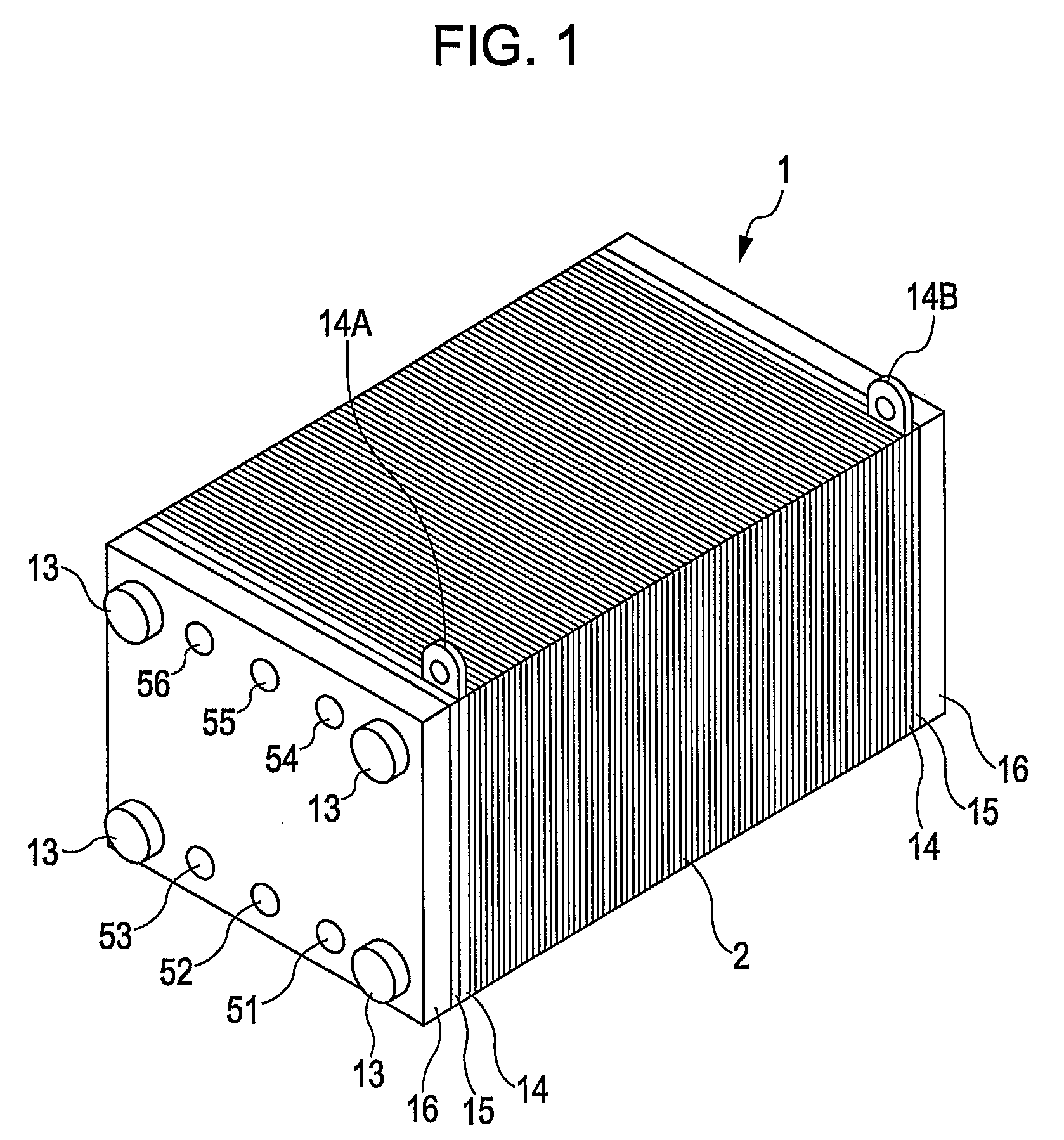

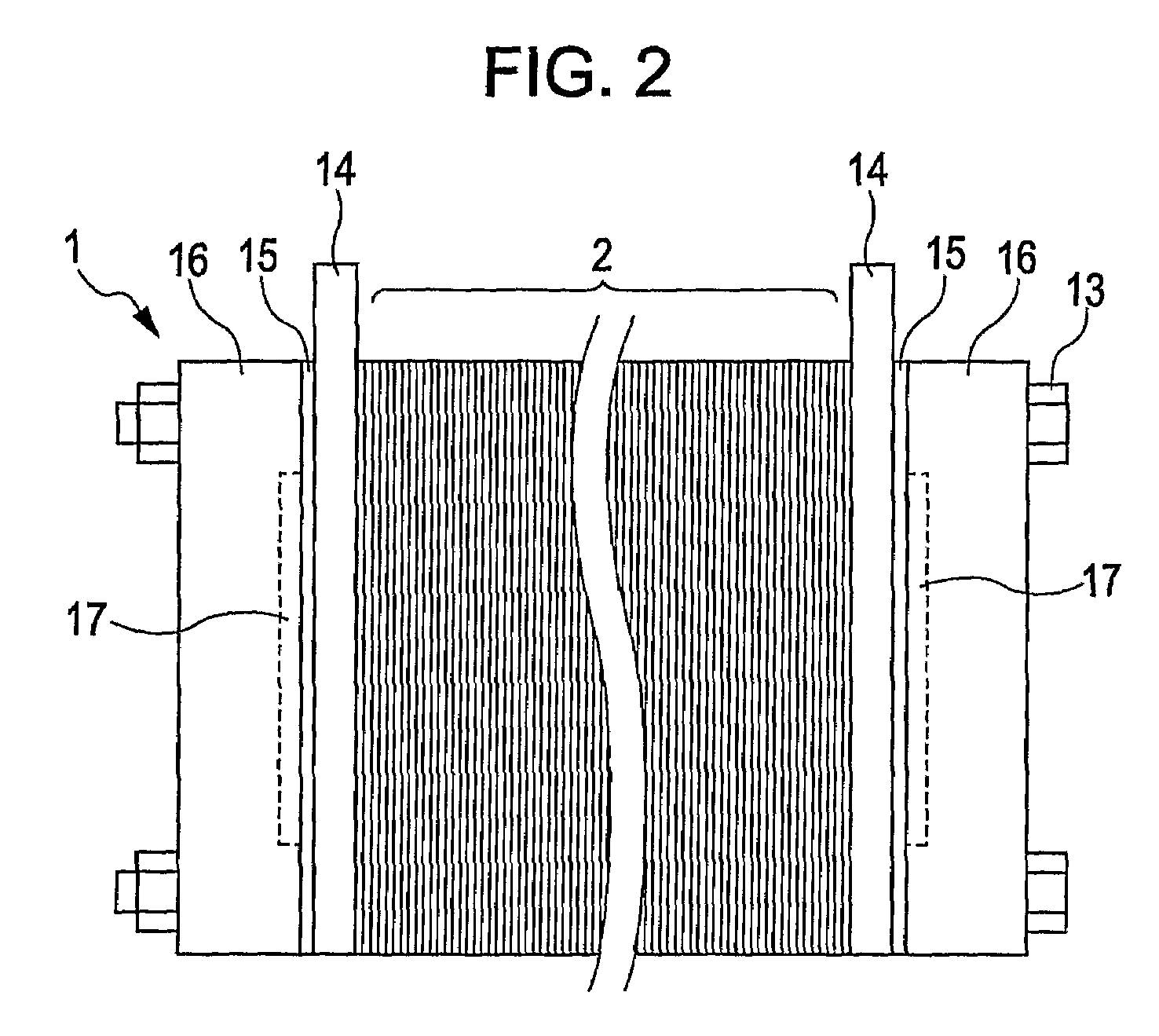

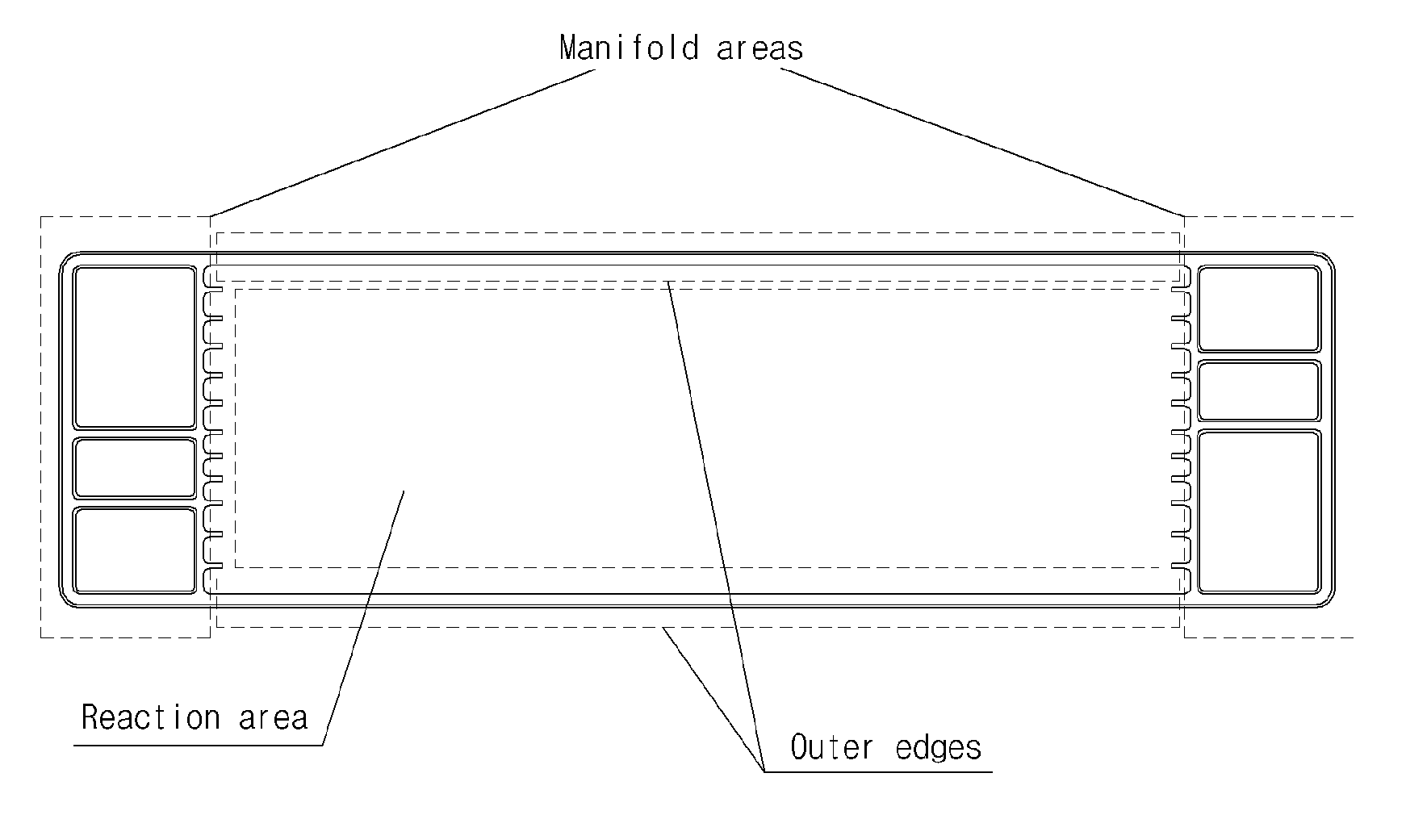

Fuel cell stack and method for making the same

ActiveUS20090053571A1Improve fuel cell performanceReduce resistanceFuel cells groupingFinal product manufactureFuel cellsElectromotive force

A fuel cell stack includes a membrane electrode assembly including an electrolyte membrane and electrode catalyst layers sandwiching the electrolyte membrane; metal separators that define gas channels, the metal separators being respectively disposed at both surfaces of the membrane electrode assembly; a current collector from which electromotive force is derived, the current collector being in contact with at least one of the metal separators; and joining parts that join the metal separator to the current collector at portions where the metal separator contacts the current collector.

Owner:NISSAN MOTOR CO LTD

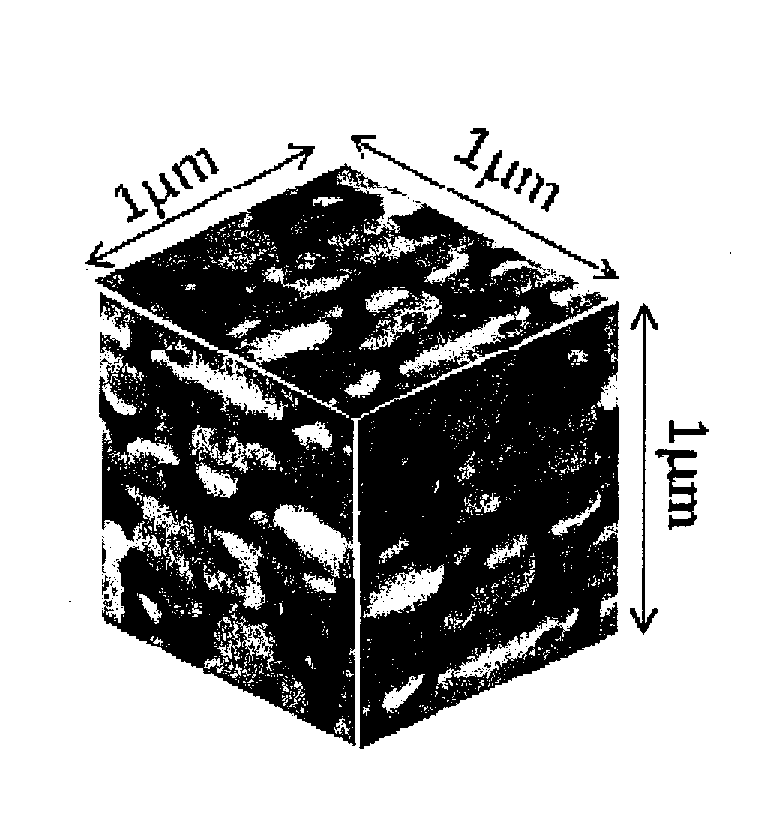

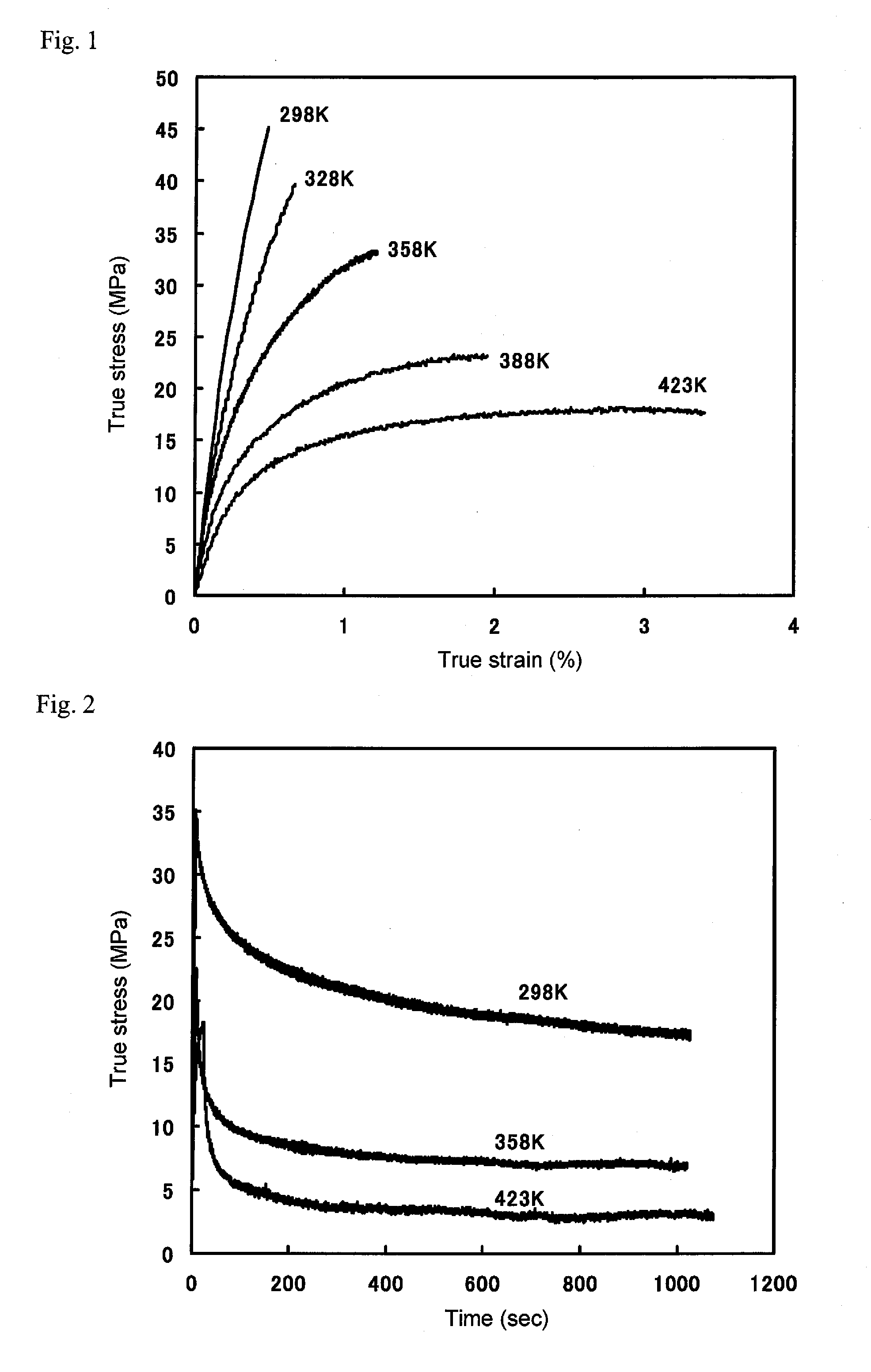

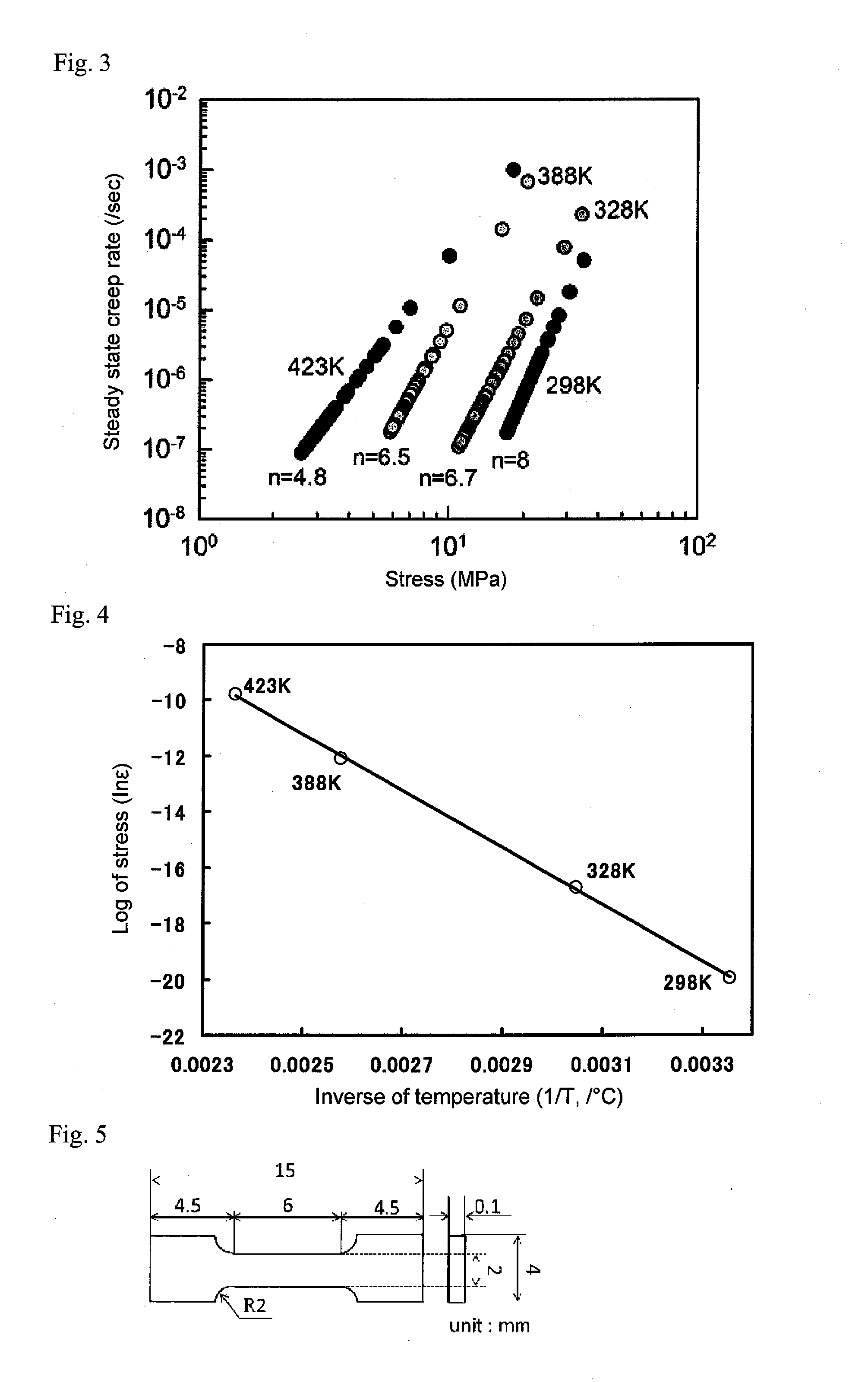

Sintered body of silver fine particle

ActiveUS20150041974A1Relieve pressureCrack suppressionMaterial nanotechnologyTransportation and packagingActivation energyMicroparticle

A sintered body of silver fine particles for a bonding member to bond components of a semiconductor device, wherein an activation energy for creep of the sintered body of the silver fine particles is from 0.4 to 0.75 times that of an activation energy for a lattice diffusion of bulk silver.

Owner:NAMICS CORPORATION

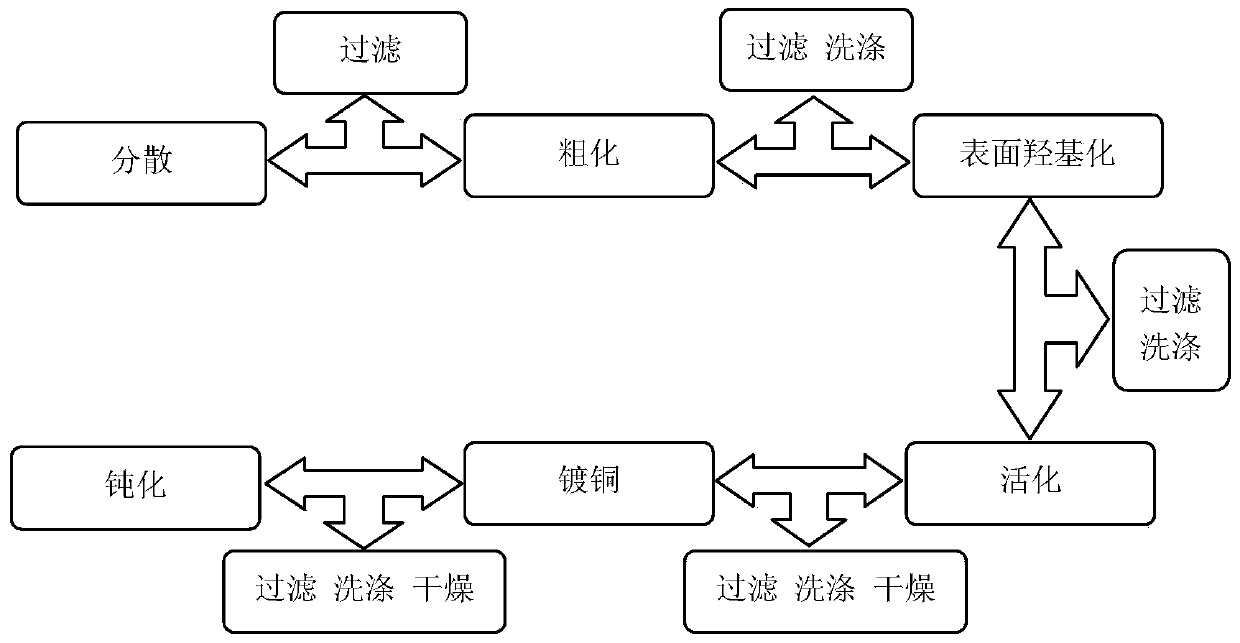

Palladium-free chemical copper-plating method on graphite nanosheet surface

ActiveCN103469182AImprove conductivityElectrical conductivityLiquid/solution decomposition chemical coatingIonCopper plating

The invention discloses a palladium-free chemical copper-plating method on a graphite nanosheet surface. The palladium-free chemical copper-plating method is characterized in that a graphite nanosheet which is coated with a complete and compact metal copper housing on the surface is finally obtained through dispersing, coarsening, surface hydroxylation, activating, copper plating and passivating in sequence. The graphite nanosheet has a plurality of hydroxyls after surface hydroxylation treatment, and is activated, so that active ions and the graphite nanosheet are combined by chemical bonds, and binding force between a coating and the graphite nanosheet is strong; moreover, a problem that stannous chloride and palladium chloride which are dear and not environment-friendly are used in conventional graphite surface treatment is overcome. Besides, a complexing agent used by copper plating liquid provided by the invention is a composite complexing agent of sodium ethylene diamine tetracetate and citrate, wherein addition of the citrate is 100-400 times the sodium ethylene diamine tetracetate, hardness of the coating is regulated by regulating a proportion of the citrate and the sodium ethylene diamine tetracetate, thereby avoiding only using dear sodium ethylene diamine tetracetate as the complexing agent. The palladium-free chemical copper-plating method disclosed by the invention has environment-friendly effect, is economical and practical, and has good application prospect.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

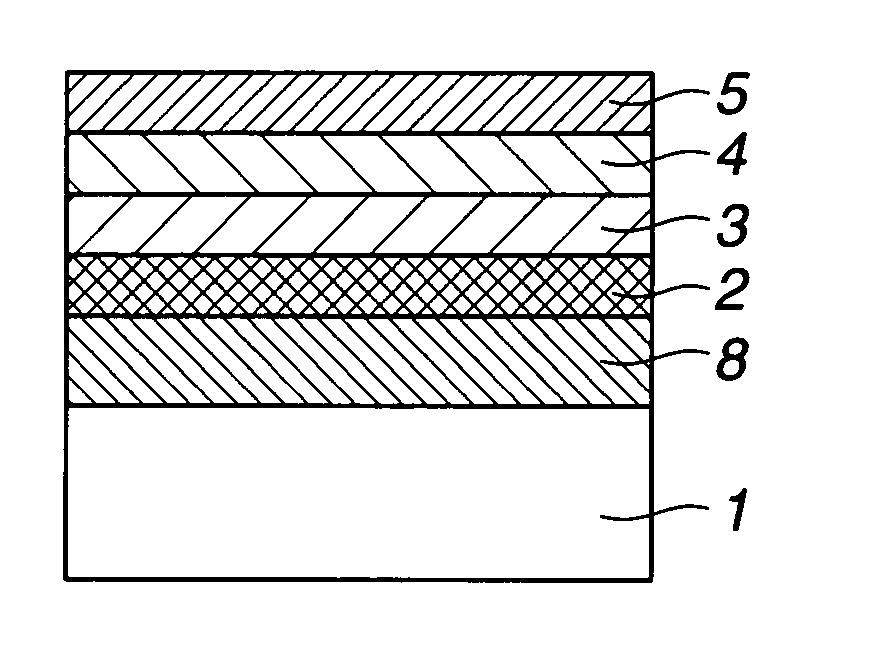

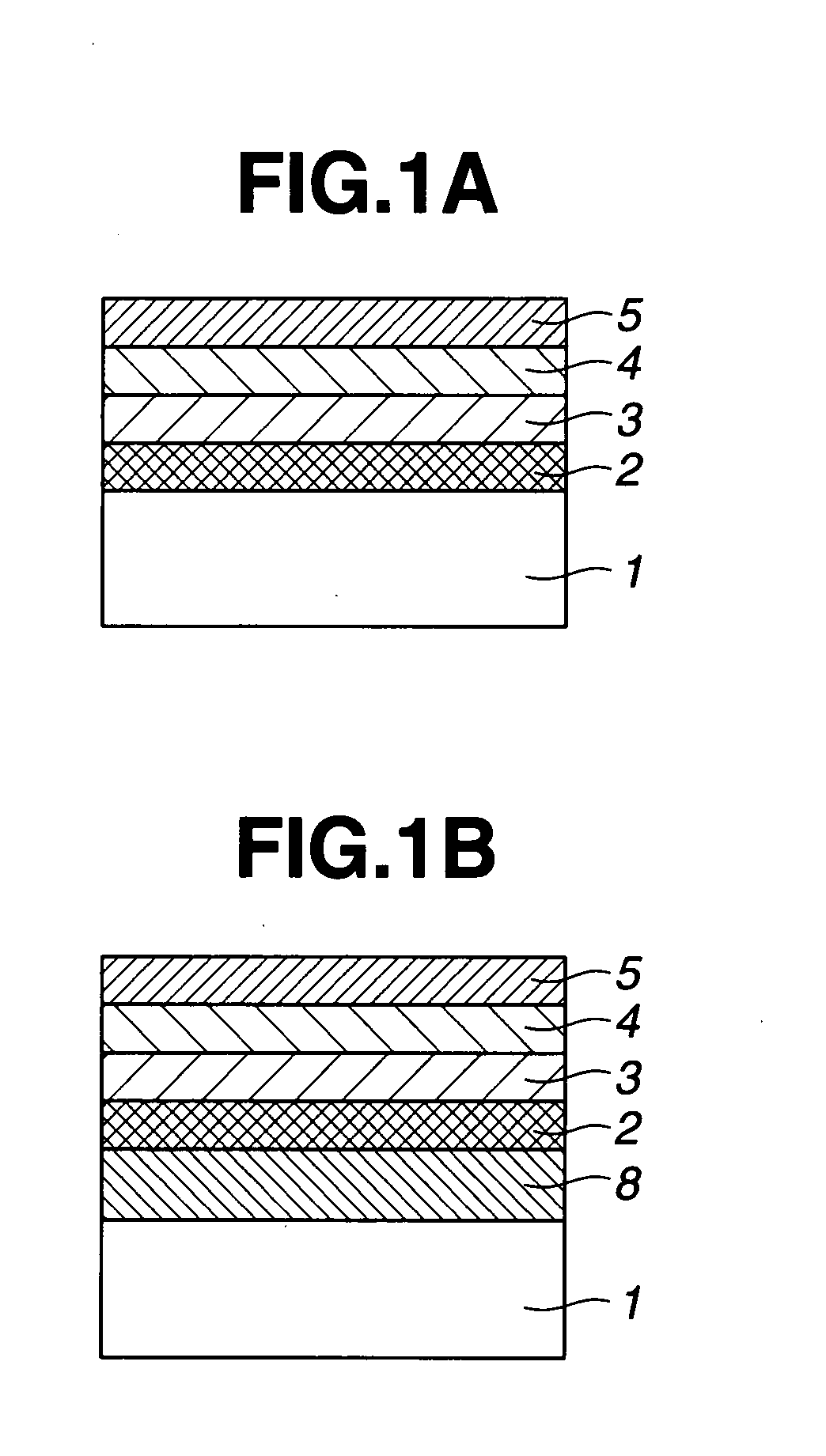

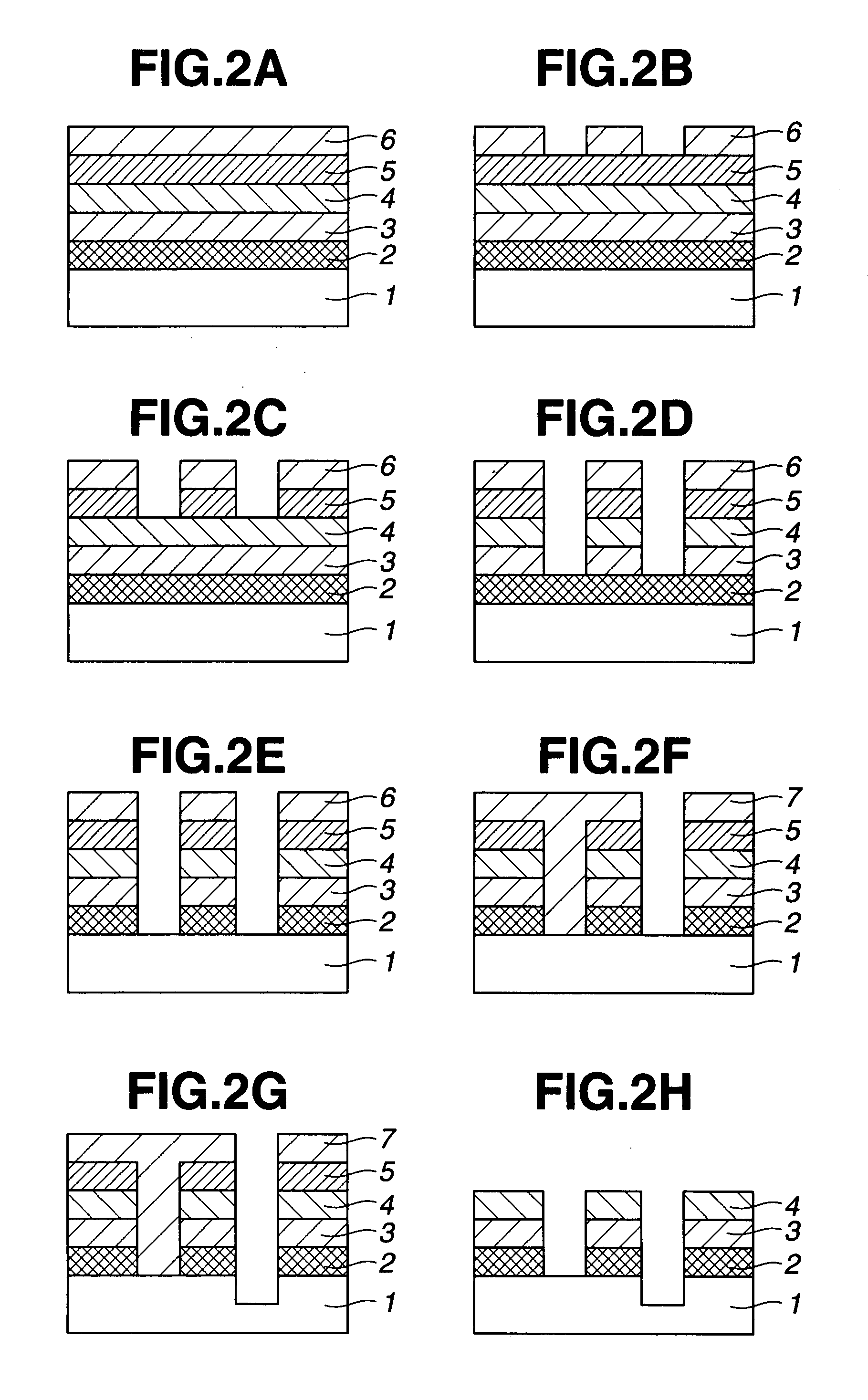

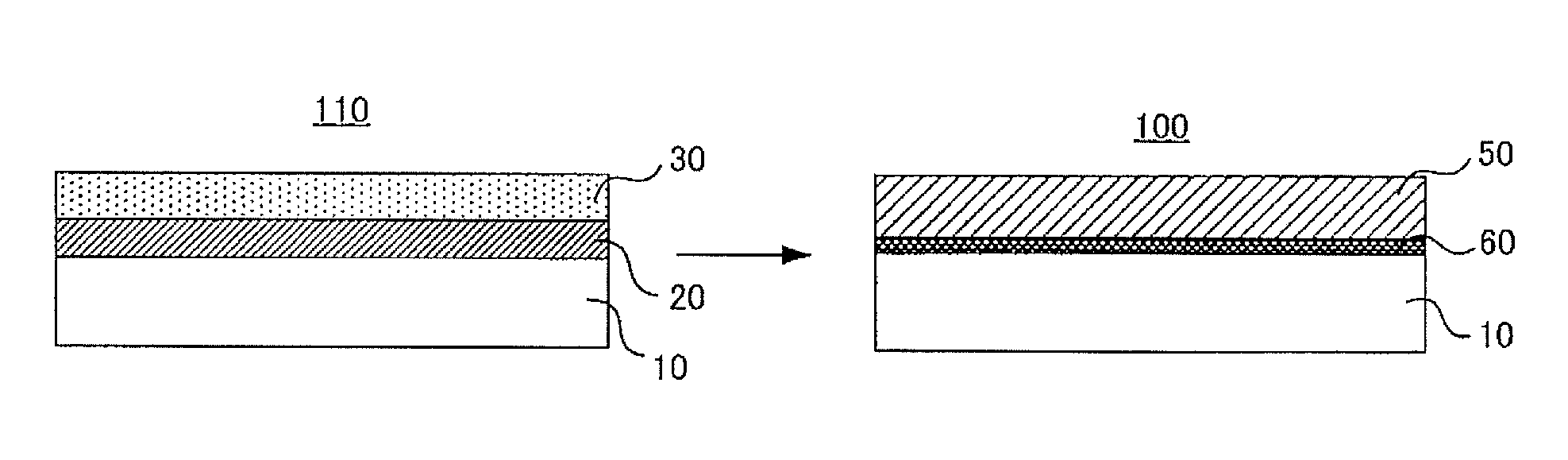

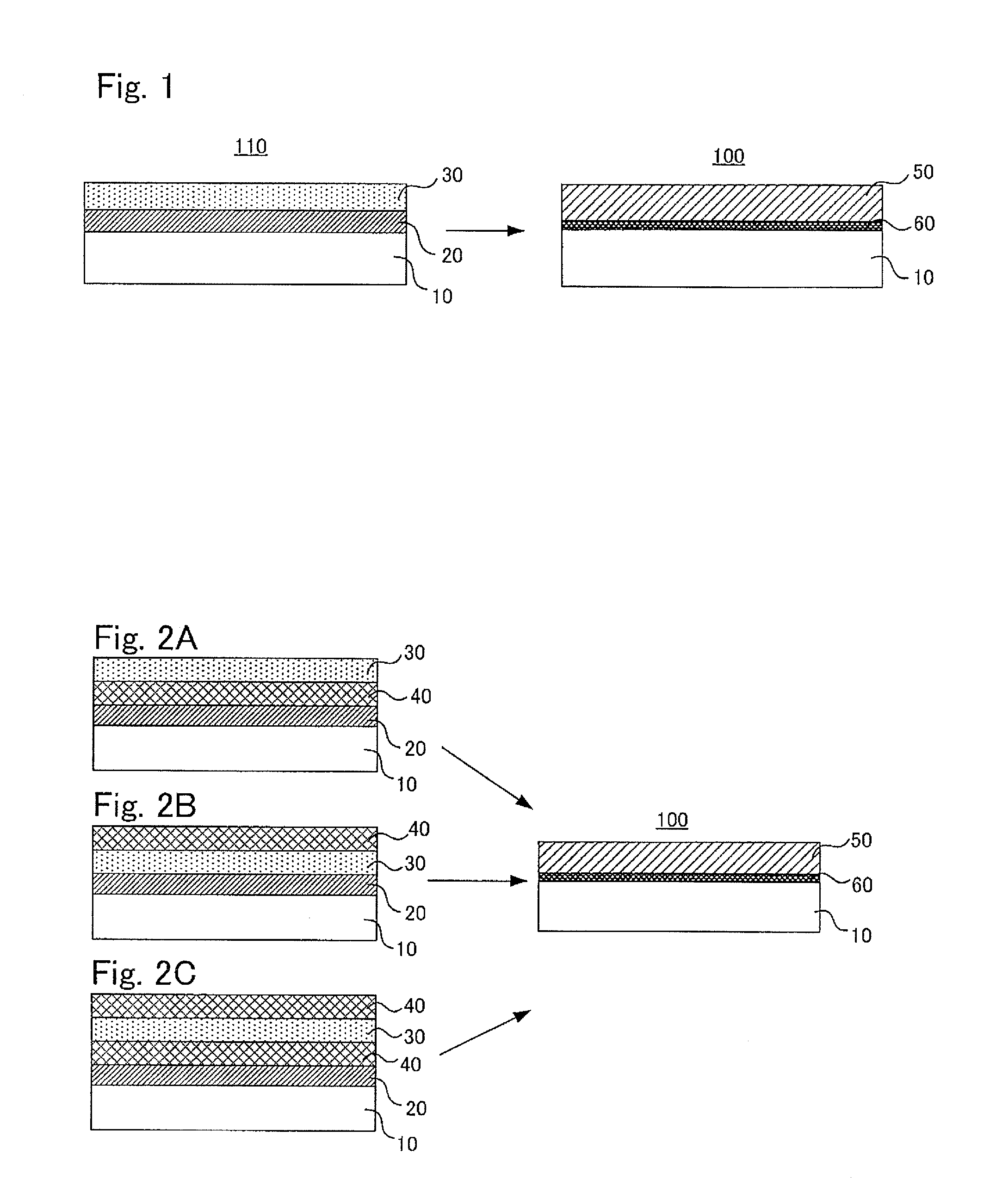

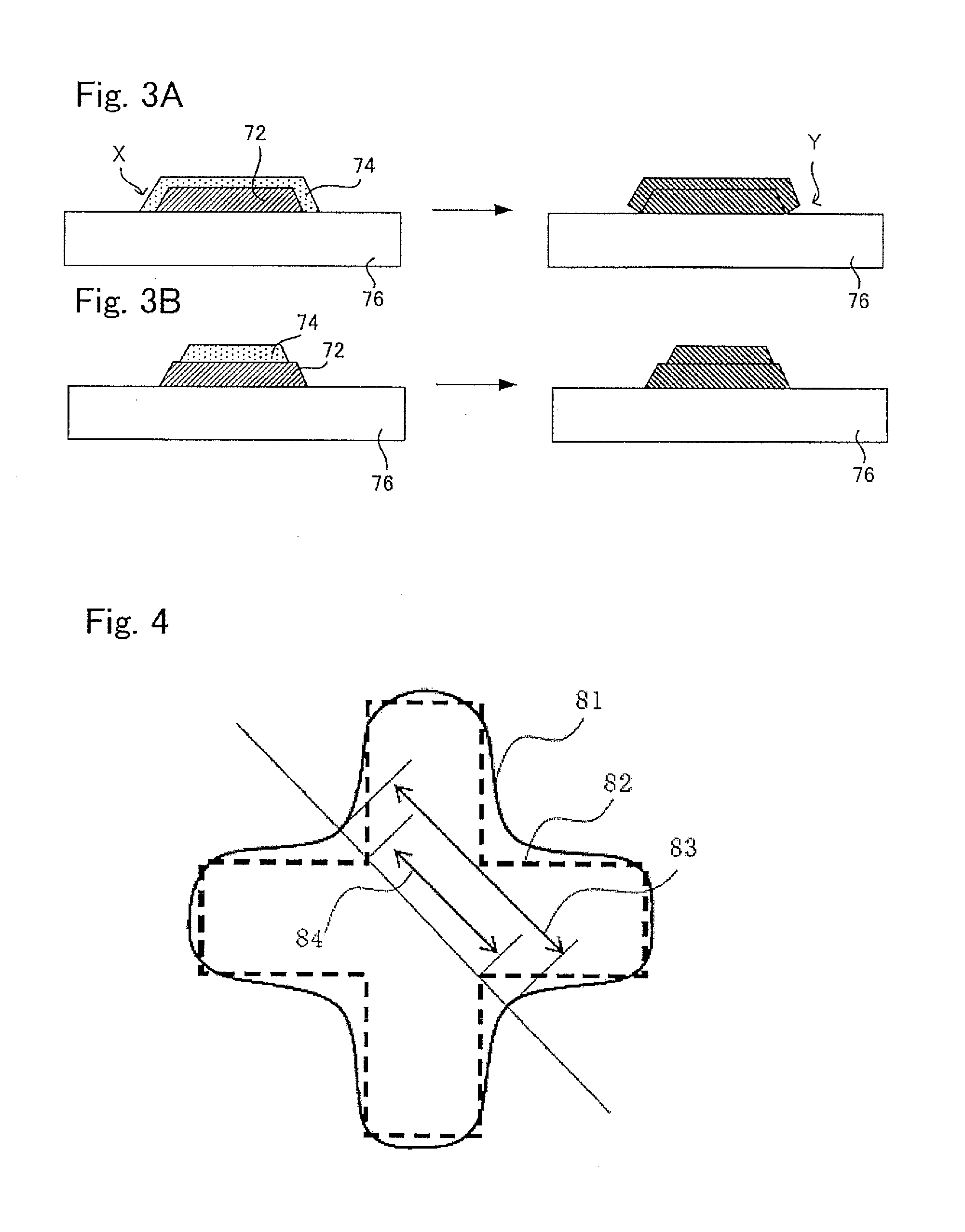

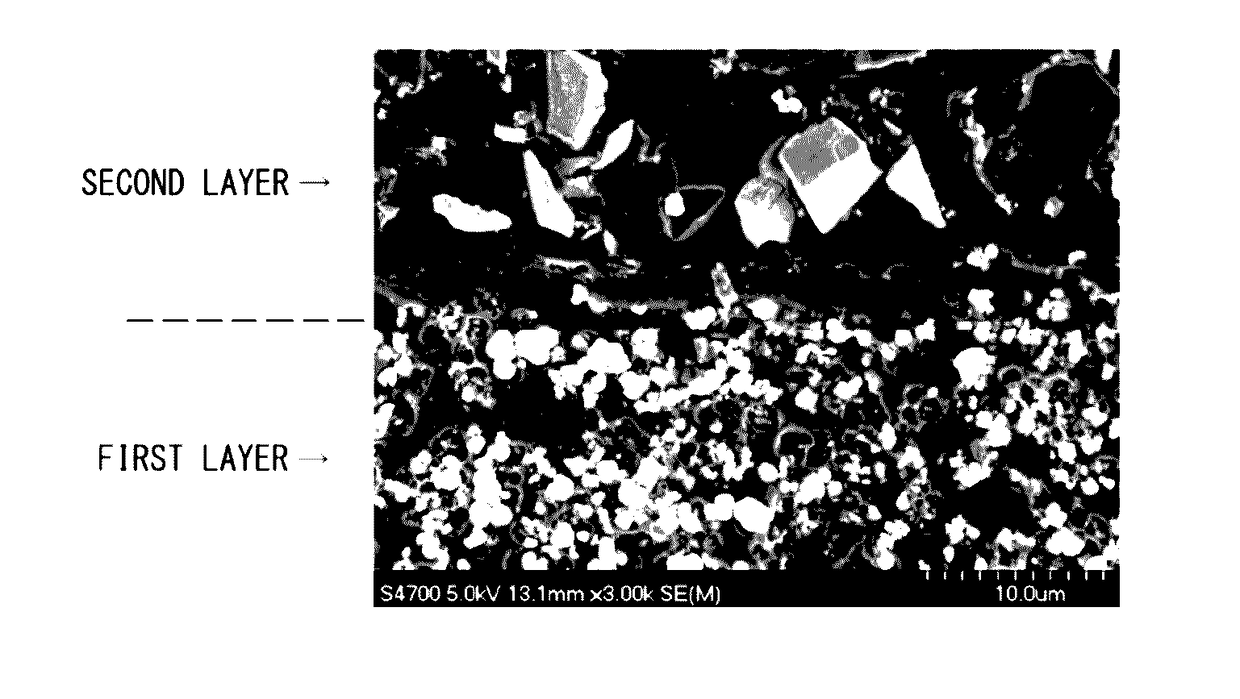

Production method of metallized substrate

ActiveUS20120321805A1Inhibit migrationImprove conductivityConductive materialPretreated surfacesTitanium nitrideSilver copper

A production method for a metallized substrate to produce a metallized substrate which comprises: a sintered nitride ceramic substrate; a titanium nitride layer formed on the sintered substrate; and a metal layer containing copper, silver and titanium formed on the titanium nitride layer. The method comprises: a step of layering a first paste layer containing copper powder and titanium hydride powder on the sintered nitride ceramic substrate, to produce a first layered body; a step of layering a second paste layer containing silver-copper alloy powder on the first paste layer of the first layered body, to produce a second layered body; and a step of firing the second layered body, to thereby form the titanium nitride layer and the metal layer on the sintered nitride ceramic substrate.

Owner:TOKUYAMA CORP

Method for manufacturing electrical contact element for testing electro device and electrical contact element thereby

InactiveUS20060192581A1Electrical conductivitySemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsElectricityBiomedical engineering

Disclosed is an electrical contact element used to test an electronic device. The electrical contact element has a beam portion and a tip portion attached to an end of the beam portion. In representative embodiments, a part of the beam portion is bent, e.g., such that the beam portion is zigzagged one or more times. A projection may be formed around a proximal end of the tip portion.

Owner:PHICOM CORP

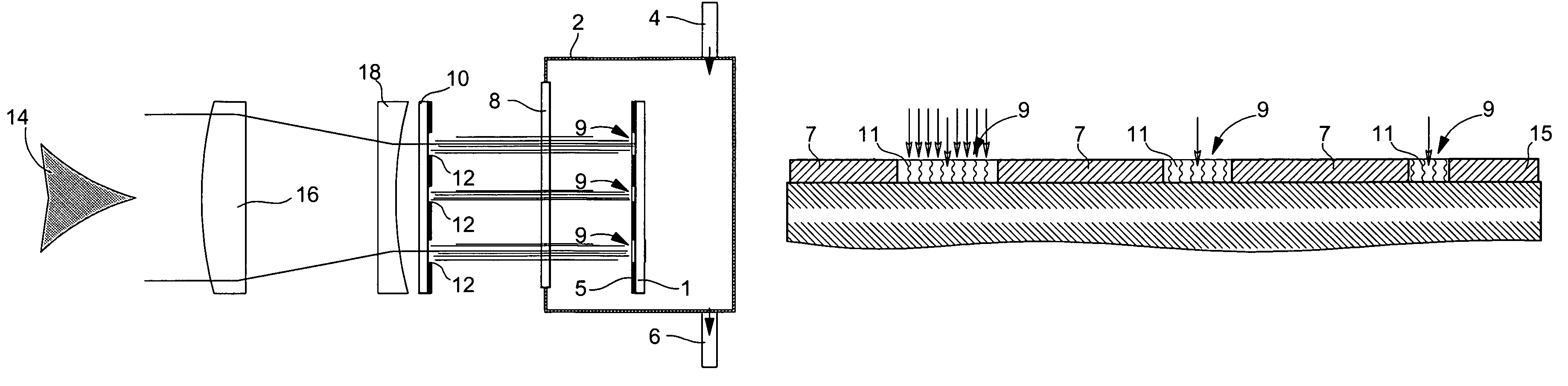

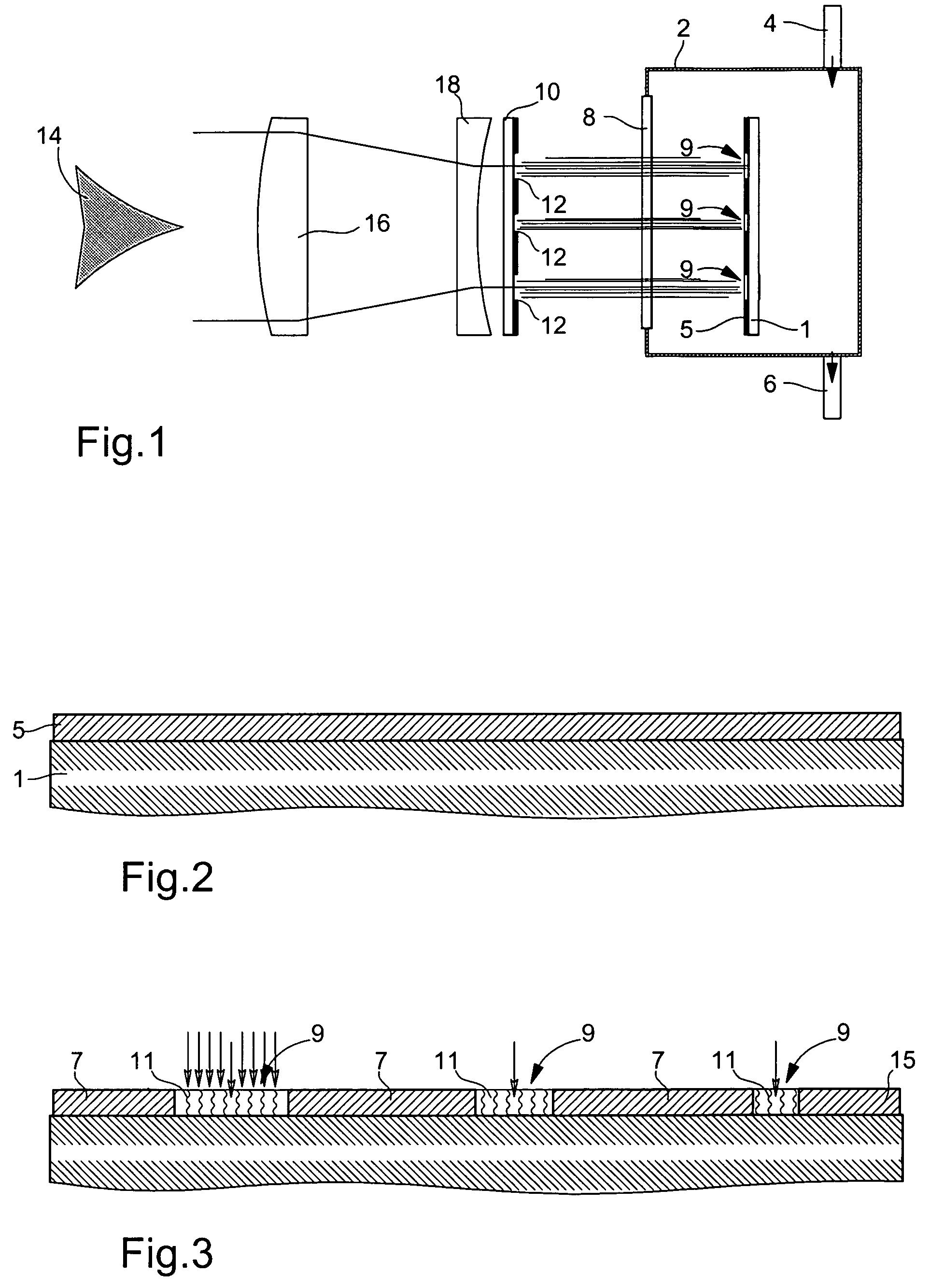

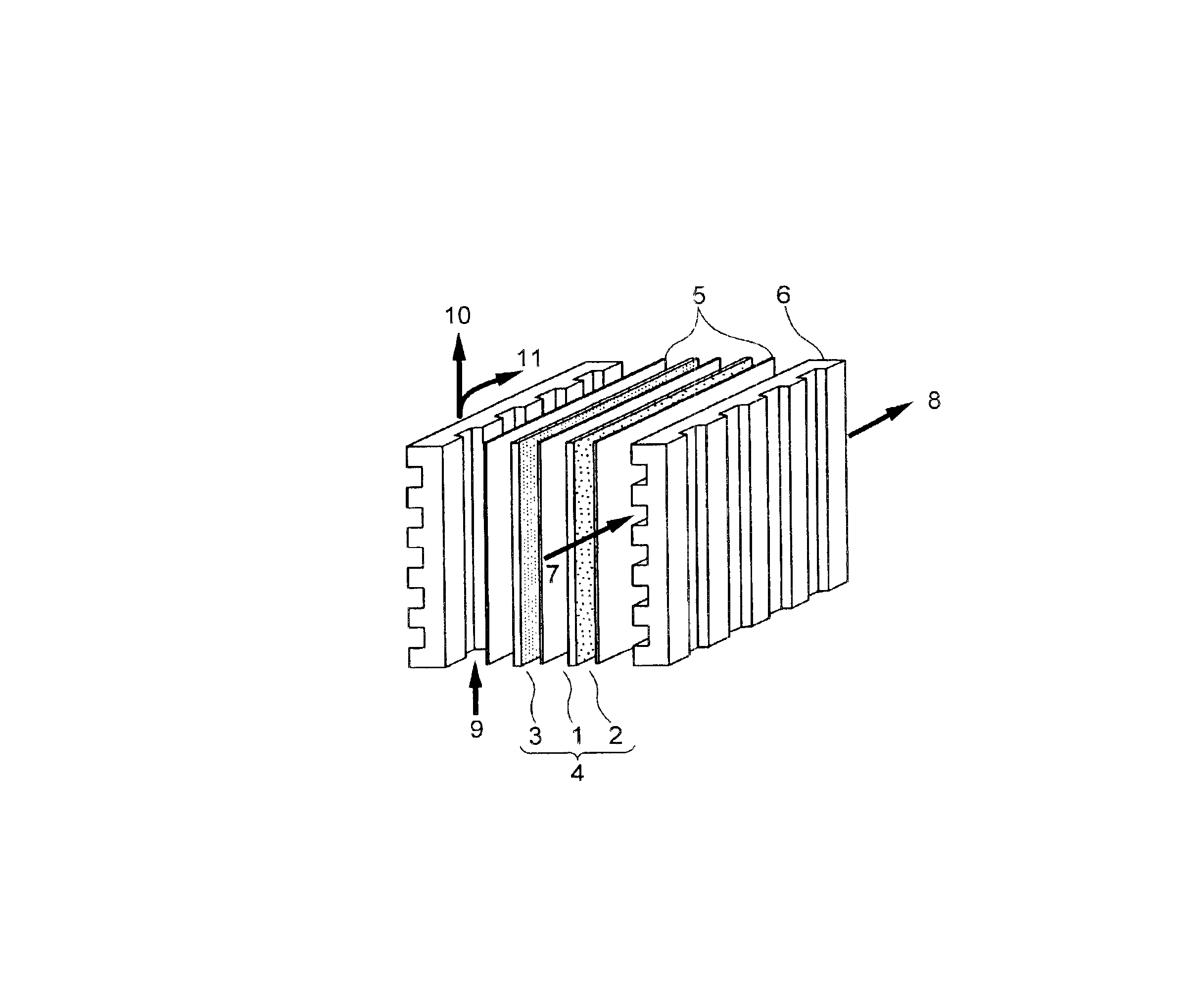

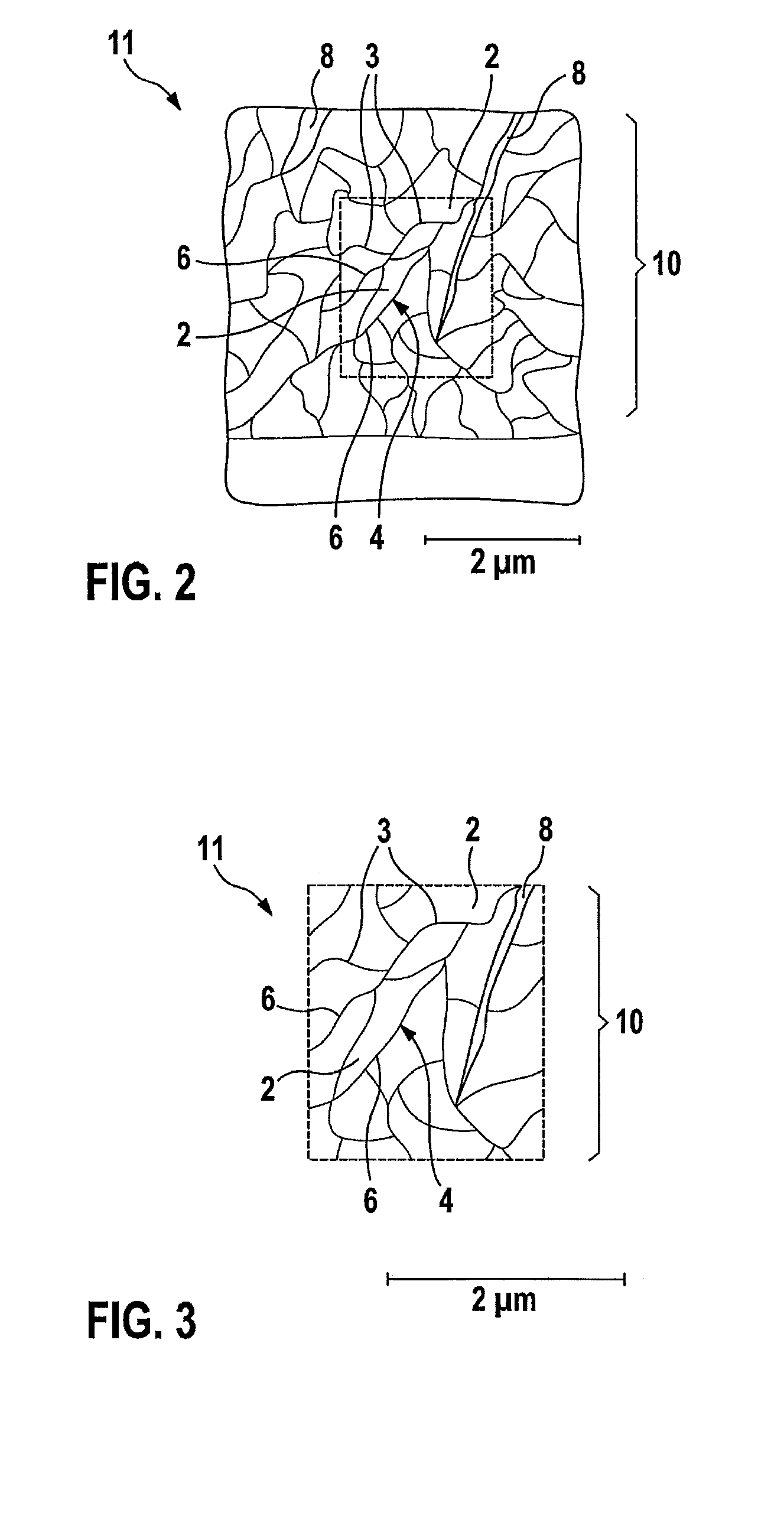

Transparent substrate with invisible electrodes and device incorporating the same

ActiveUS7843061B2Electrical conductivitySatisfy Compensation RequirementsNanotechConductive layers on insulating-supportsDielectricNanometre

The electrodes (7) and the contact zones (15) are structured in a film of a transparent conductive oxide (TCO), deposited on a transparent support (1) possibly coated with an intermediate film (3), while being separated by dielectric spaces (9) formed by nano fissures (11) obtained by UV radiation and passing through the TCO film. A protective film (13) can coat the electrodes (7) and the dielectric spaces (9).

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

Aqueous Primer Composition and a Process for the Application of the Same

InactiveUS20090130322A1Improve water resistanceImprove adhesionConductive materialSpecial tyresPolymer sciencePolyolefin

This invention provides an aqueous primer composition which comprises (A) an aqueous dispersion of modified polyolefin which comprises an unsaturated carboxylic acid- or acid anhydride-modified polyolefin (a) having a melting point of 120° C. or lower and a weight average molecular weight of 30,000 to 180,000, dispersed in an aqueous medium, (B) an ionic functional group-containing acrylic resin, and (C) a conductive carbon-containing pigment, and which forms a coating film with an L value of 35 or more and a surface resistivity of 1×108Ω / □ or less.

Owner:KANSAI PAINT CO LTD

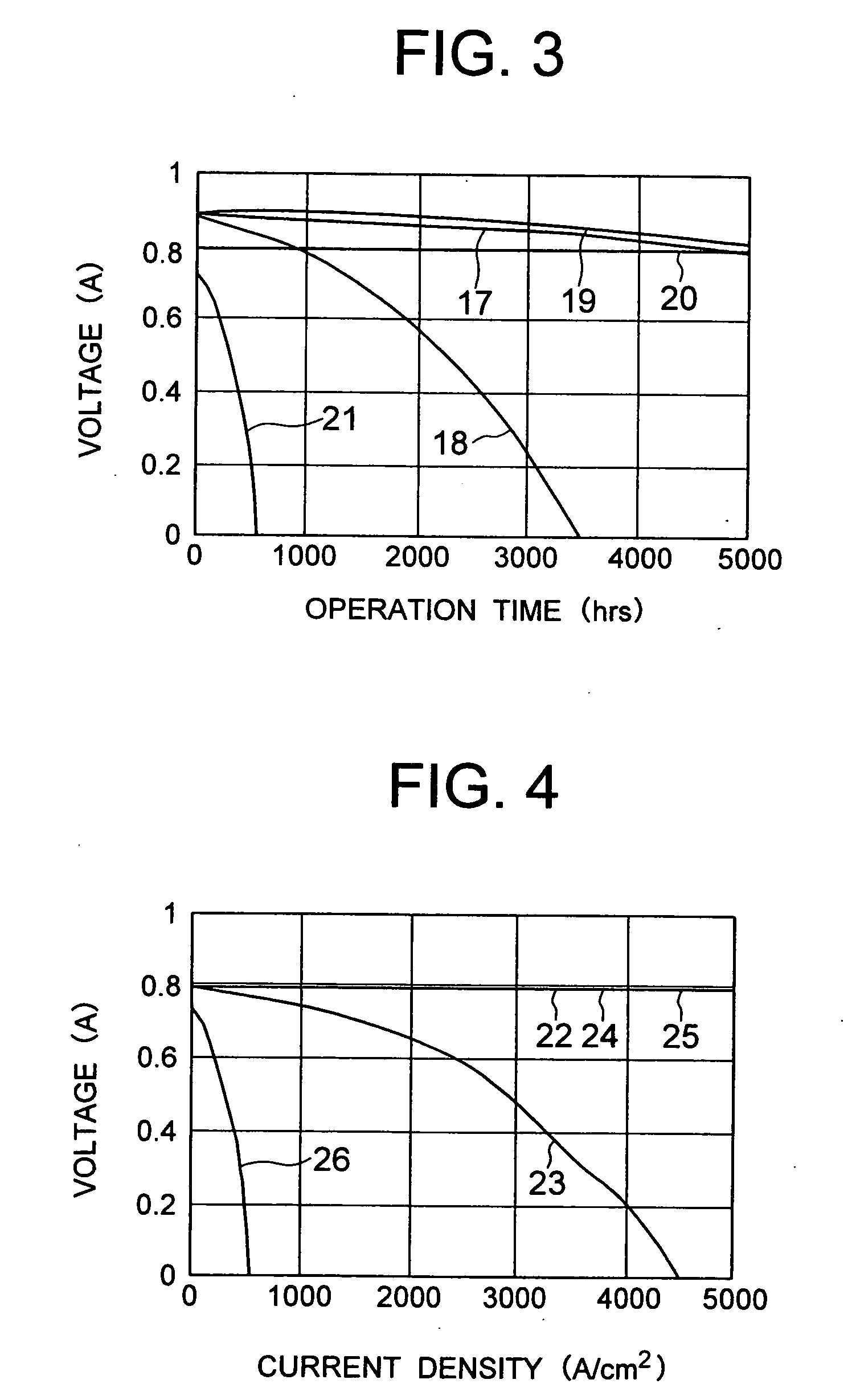

Solid polyelectrolyte, assembly of membrane and electrodes, and fuel cell

InactiveUS6893764B2Low costIncreased durabilityNon-metal conductorsSolid electrolytesPolymer electrolytesPolyelectrolyte

An object of the present invention is to provide a highly durable solid polymer electrolyte that has a deterioration resistance equal to or higher than that of the fluorine-containing solid polymer electrolytes or a deterioration resistance sufficient for practical purposes, and can be produced at a low cost. According to the present invention, there is provided a solid polymer electrolyte comprising a polyether ether sulfone that is used as a electrolyte and has sulfoalkyl groups bonded to its aromatic rings and represented by the general formula —(CH2)n—SO3H.

Owner:HITACHI LTD

Optical Article and Process for Producing the Same

InactiveUS20100225882A1Reduce sheet resistanceElectrical conductivitySpectales/gogglesMirrorsOptoelectronicsReflective layer

A process for producing an optical article having an antireflection layer formed directly or via another layer on an optical base material, includes: forming a primary layer contained in the antireflection layer; and forming a light transmissive conductive layer containing a metal containing germanium as a main component and / or a compound of germanium and a transition metal on a surface of the primary layer.

Owner:HOYA LENS MFG PHILIPPINES

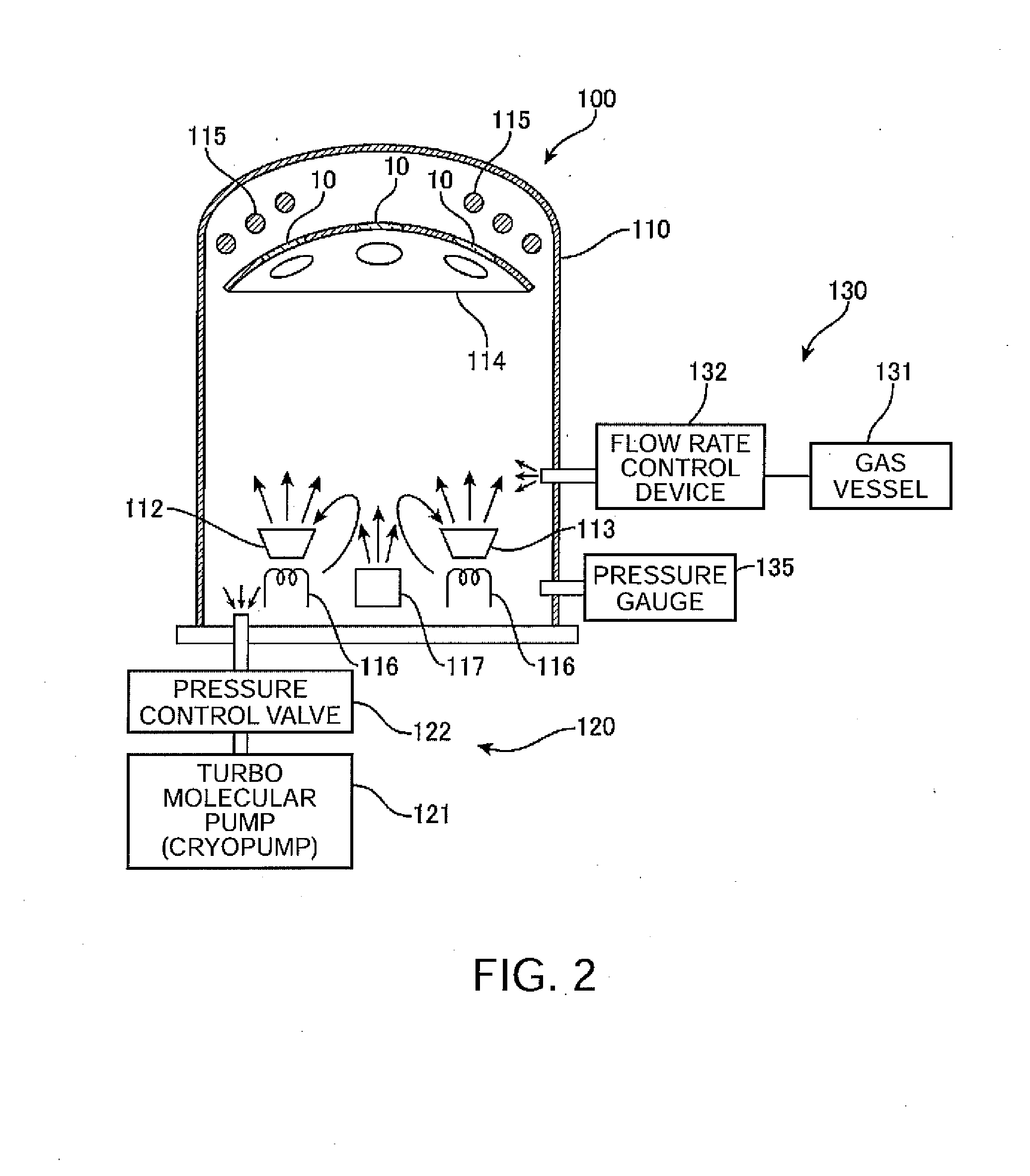

Device for producing electrical discharges in an aqueous medium

InactiveUS20080191596A1Improve conductivityImprove ductilityElectric discharge tubesSurgeryPlatinumMetal alloy

A device for producing electrical discharges in an aqueous medium, the device has a first electrode 3 and a second electrode 4, where each electrode 3, 4 is made of a metal alloy 5 and each has an electrode tip 3C, 4C integral or otherwise affixed to said electrode 3, 4. Each tip 3C, 4C is made of a metal alloy and at least the outer surface of such tips includes a percentage of gold or platinum. Preferably the entire tip 3C, 4C portion is made of an alloy 5 having between 0.02 to 20 percent weight percent gold or platinum. The tip metal alloy 5 preferably has a base composition of steel, more preferably a base composition having either at least 4 percent cobalt or at least 4 percent nickel in combination with the small amount of gold or platinum. The use of gold or platinum provides exceptional electrical conductivity, but improves the ductility of the tip material such that the explosive and corrosive effects of the high voltage plasma discharges in the acoustic shock waves are greatly diminished.

Owner:TISSUE REGENERATION TECH

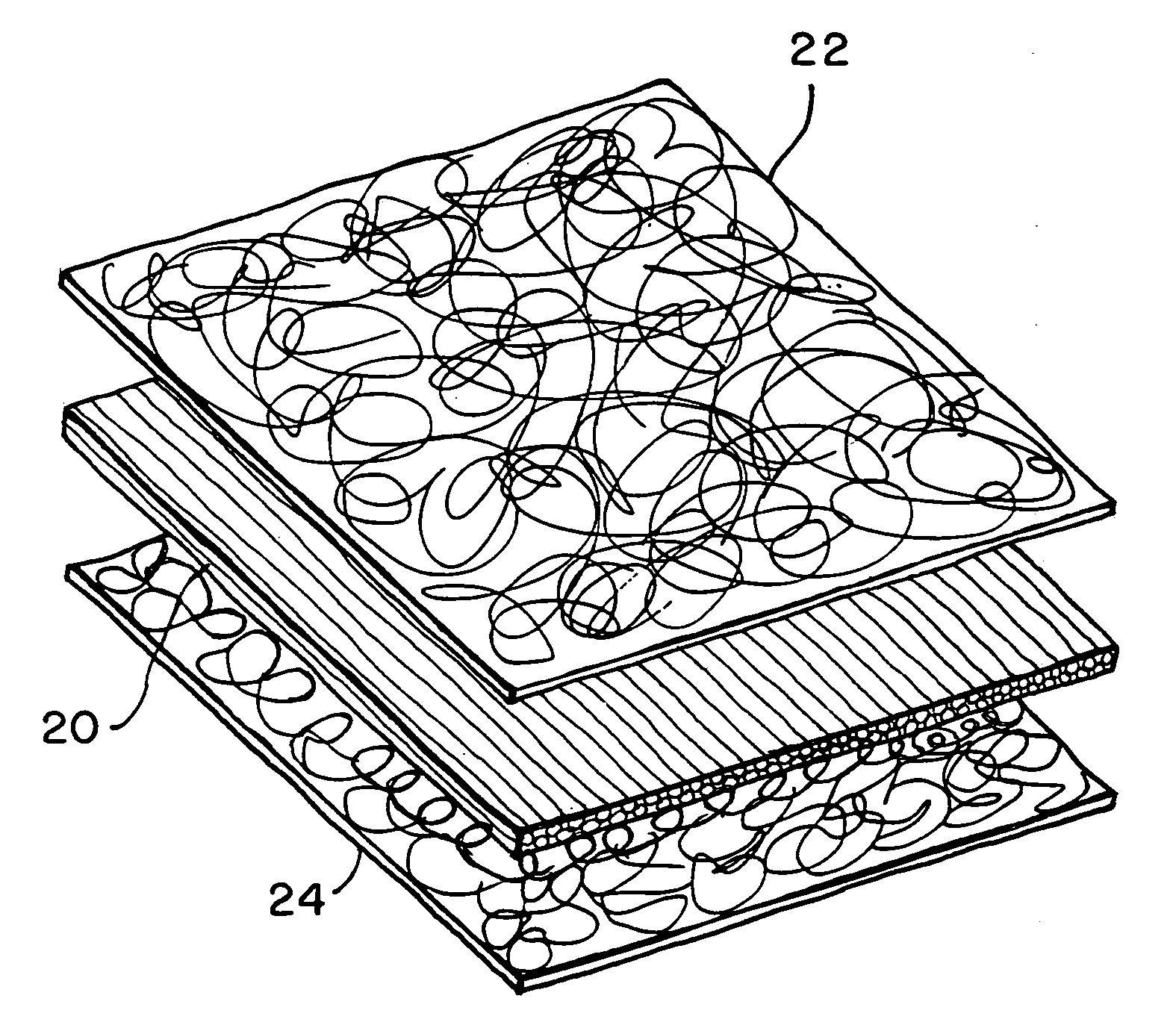

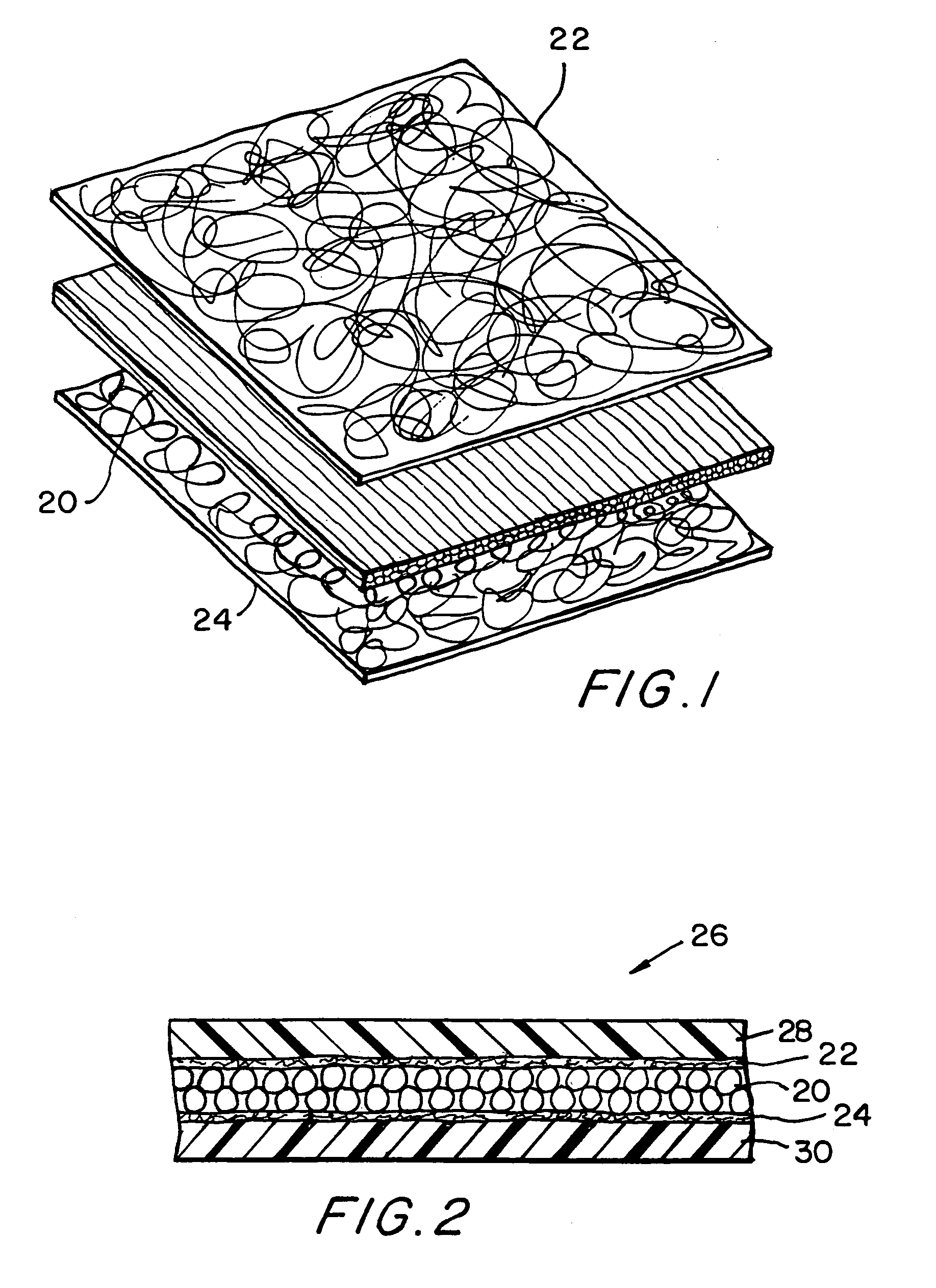

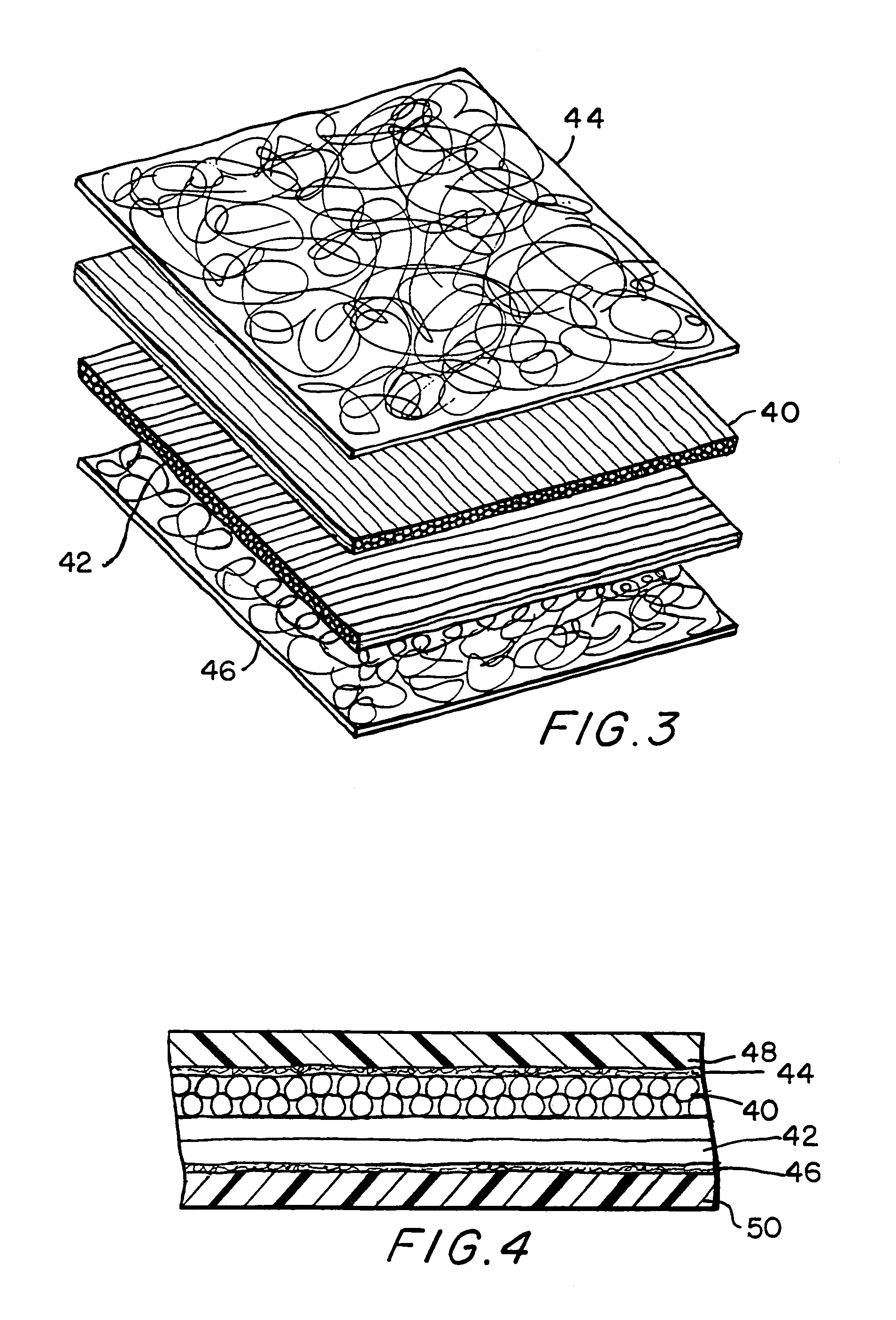

Composite carbon fiber material and method of making same

InactiveUS7041192B2Small thicknessImprove conductivityAdhesive processes with surface pretreatmentLaminationThermoplasticPower flow

A composite carbon fiber material is formed of one or more layers of carbon fiber material in which the carbon fibers are aligned all in the same direction and a mat of nonwoven, woven, or off-axis unidirectional carbon fibers are laminated together. Layers may be used individually or as a hybrid. The layers can be preimpregnated or impregnated during processing using thermoplastic or thermosetting resins. A layer of thermoplastic resin is applied either over the surface or within the composite structure, and the resin permeates the material so as to provide a more stable mechanical structure once the resin is processed. The material combines good mechanical strength with improved electrical current carrying properties when compared with the aligned carbon fiber layer alone. The layering sequence, layer type, and resin type can be specified to tailor electrical properties, mechanical properties, durability, and wear resistance. The resultant material achieves these results in substantially smaller material thickness than previously available.

Owner:MICRO CONTACTS

Solid polyelectrolyte, assembly of membrane and electrodes, amd fuel cell

InactiveUS20050031930A1Low costIncreased durabilityNon-metal conductorsSolid electrolytesPolyelectrolytePolymer electrolytes

An object of the present invention is to provide a highly durable solid polymer electrolyte that has a deterioration resistance equal to or higher than that of the fluorine-containing solid polymer electrolytes or a deterioration resistance sufficient for practical purposes, and can be produced at a low cost. According to the present invention, there is provided a solid polymer electrolyte comprising a polyether ether sulfone that is used as an electrolyte and has sulfoalkyl groups bonded to its aromatic rings and represented by the general formula —(CH2)n—SO3H.

Owner:HITACHI LTD

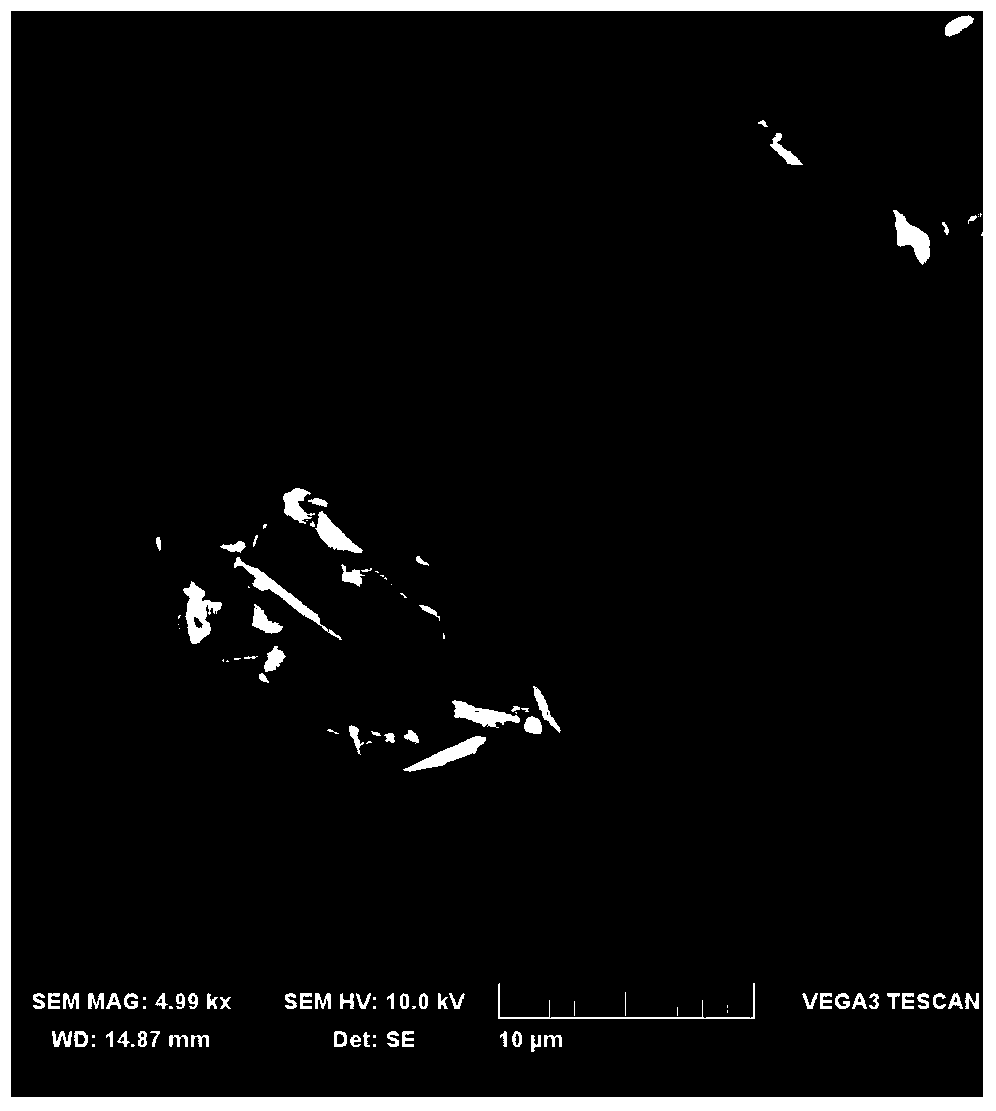

Cu-ni-si-co copper alloy for electronic materials and method for manufacturing same

ActiveUS20090301614A1Maintain good propertiesImprove conductivityConductive materialMetal/alloy conductorsPunchingUltimate tensile strength

The invention provides Cu—Ni—Si—Co alloys having excellent strength, electrical conductivity, and press-punching properties. In one aspect, the invention is a copper alloy for electronic materials, containing 1.0 to 2.5 mass % of Ni, 0.5 to 2.5 mass % of Co, and 0.30 to 1.2 mass % of Si, the balance being Cu and unavoidable impurities, wherein the copper alloy for electronic material has a [Ni+Co+Si] content in which the median value ρ (mass %) satisfies the formula 20 (mass %)≦ρ≦60 (mass %), the standard deviation σ (Ni+Co+Si) satisfies the formula σ (Ni+Co+Si)≦30 (mass %), and the surface area ratio S (%) satisfies the formula 1%≦S≦10%, in relation to the compositional variation and the surface area ratio of second-phase particles size of 0.1 μm or greater and 1 μm or less when observed in a cross section parallel to a rolling direction.

Owner:JX NIPPON MINING& METALS CORP

Screw tightening apparatus

InactiveUS7661335B2Easy to processImprove conductivityMeasurement of torque/twisting force while tighteningSpannersDrill bitStatic electricity

The screw tightening apparatus includes a motor, an output shaft to which a bit for screw tightening is connected so as to be rotatable integrally with the output shaft and which is axially movable, the output shaft being driven to be rotated by the motor, a spring whose one end contacts a member constituting a main body of the screw tightening apparatus, and a spring receiving member which the other end of the spring contacts and transmits a biasing force of the spring to the output shaft. The screw tightening apparatus further includes a conductive member which contacts the output shaft and the spring receiving member. This configuration enables static electricity generated on the bit to certainly flow into the main body of the apparatus (ground) via the output shaft, the conductive member, the spring receiving member, and the spring.

Owner:FUJITSU LTD

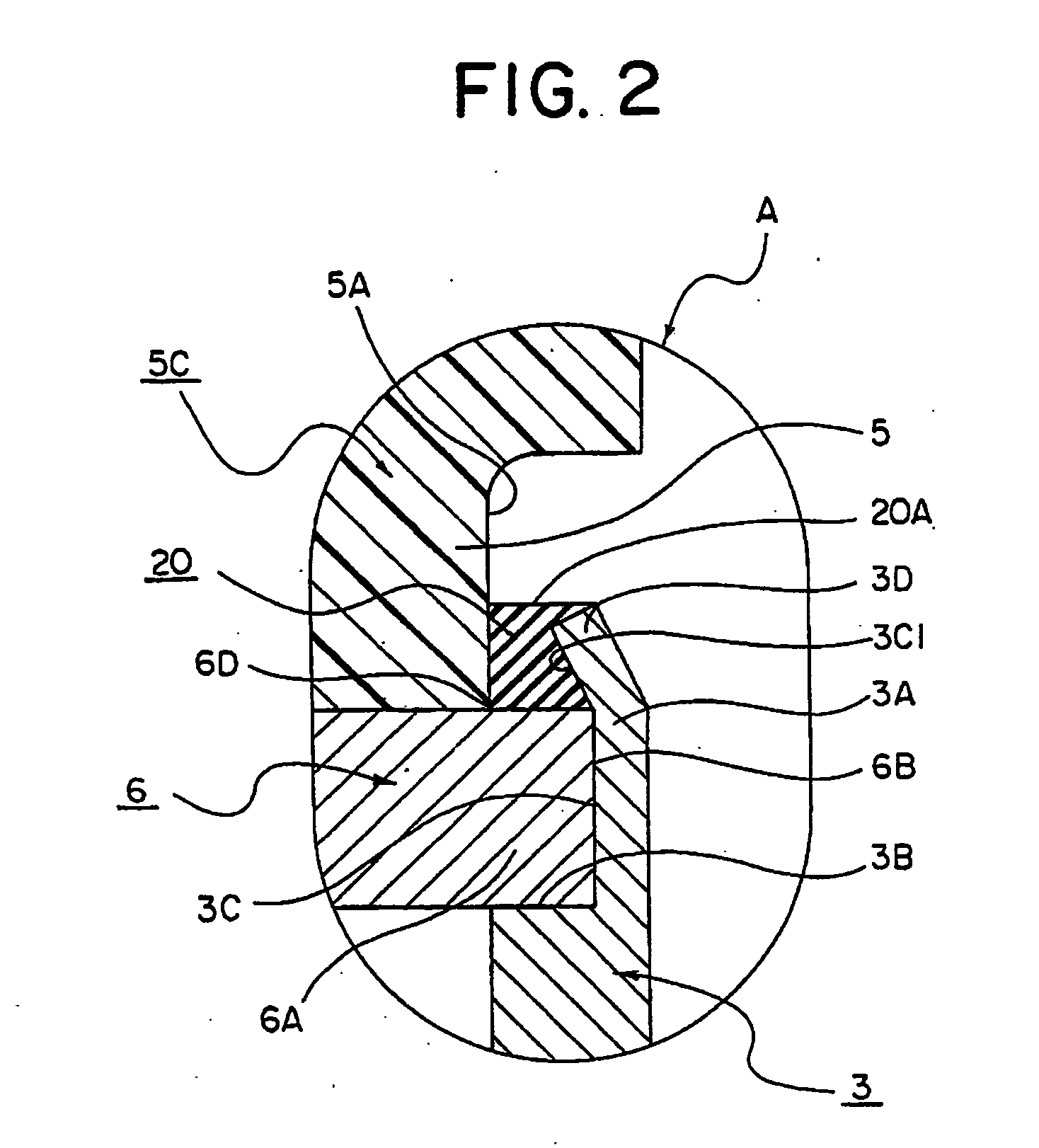

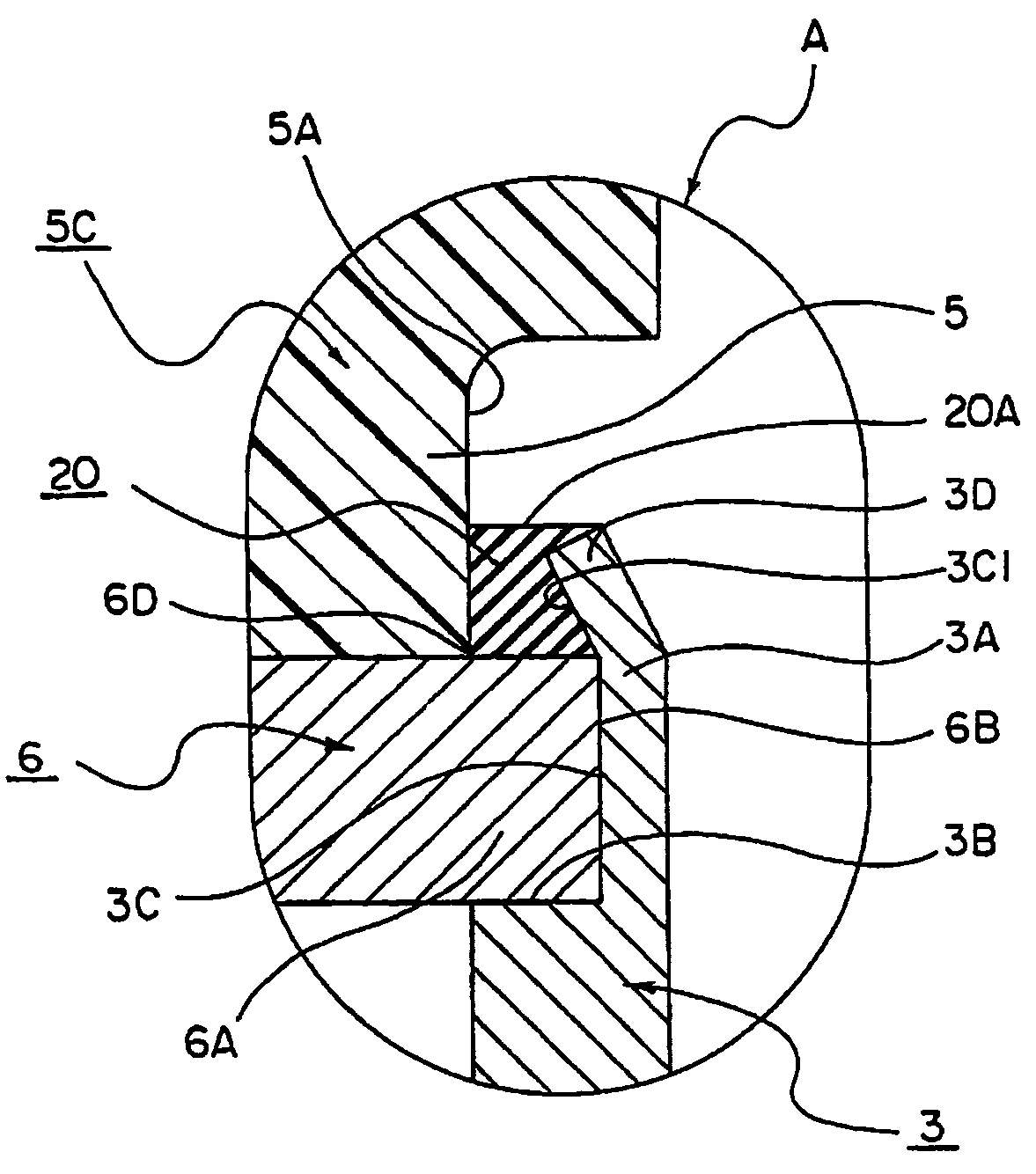

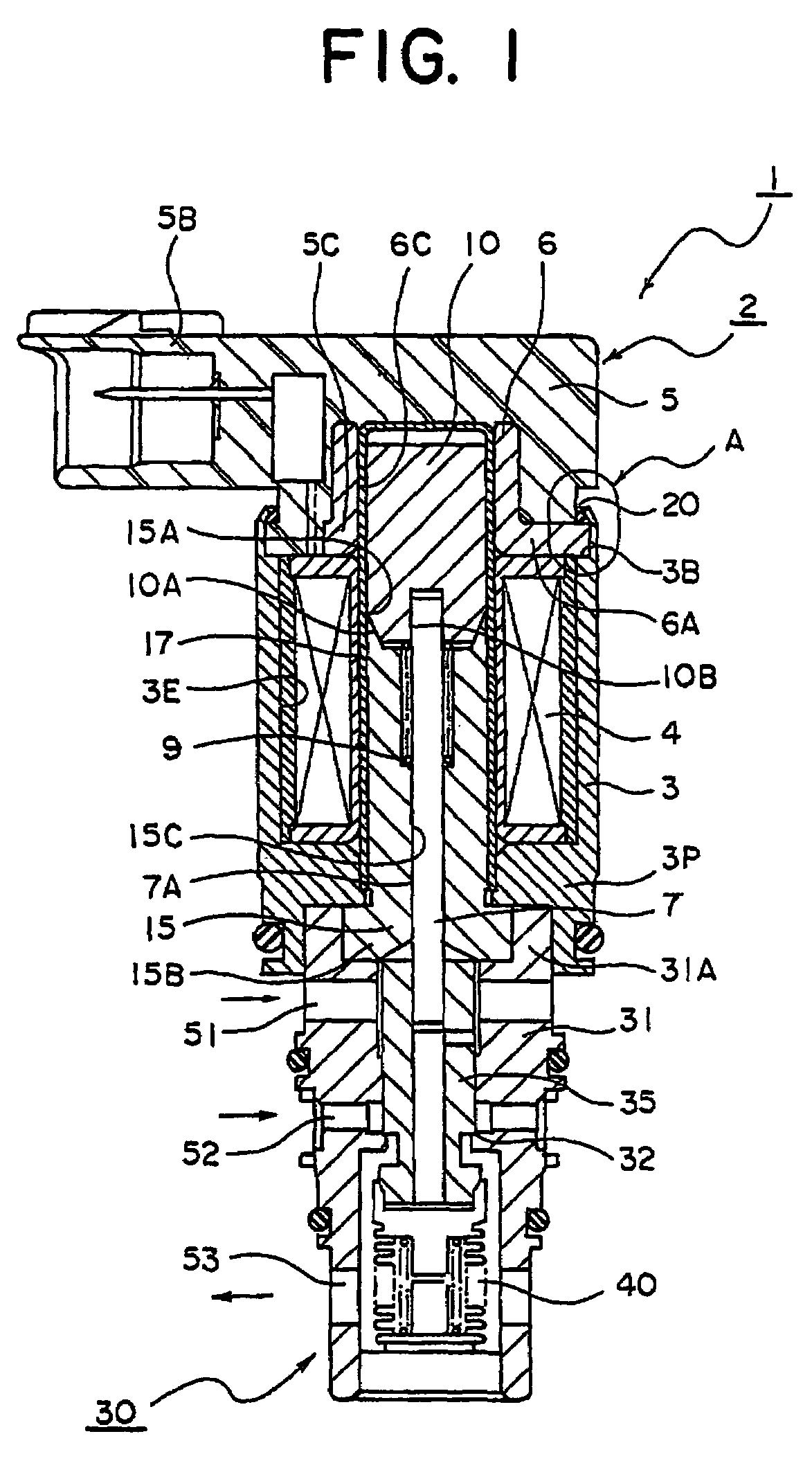

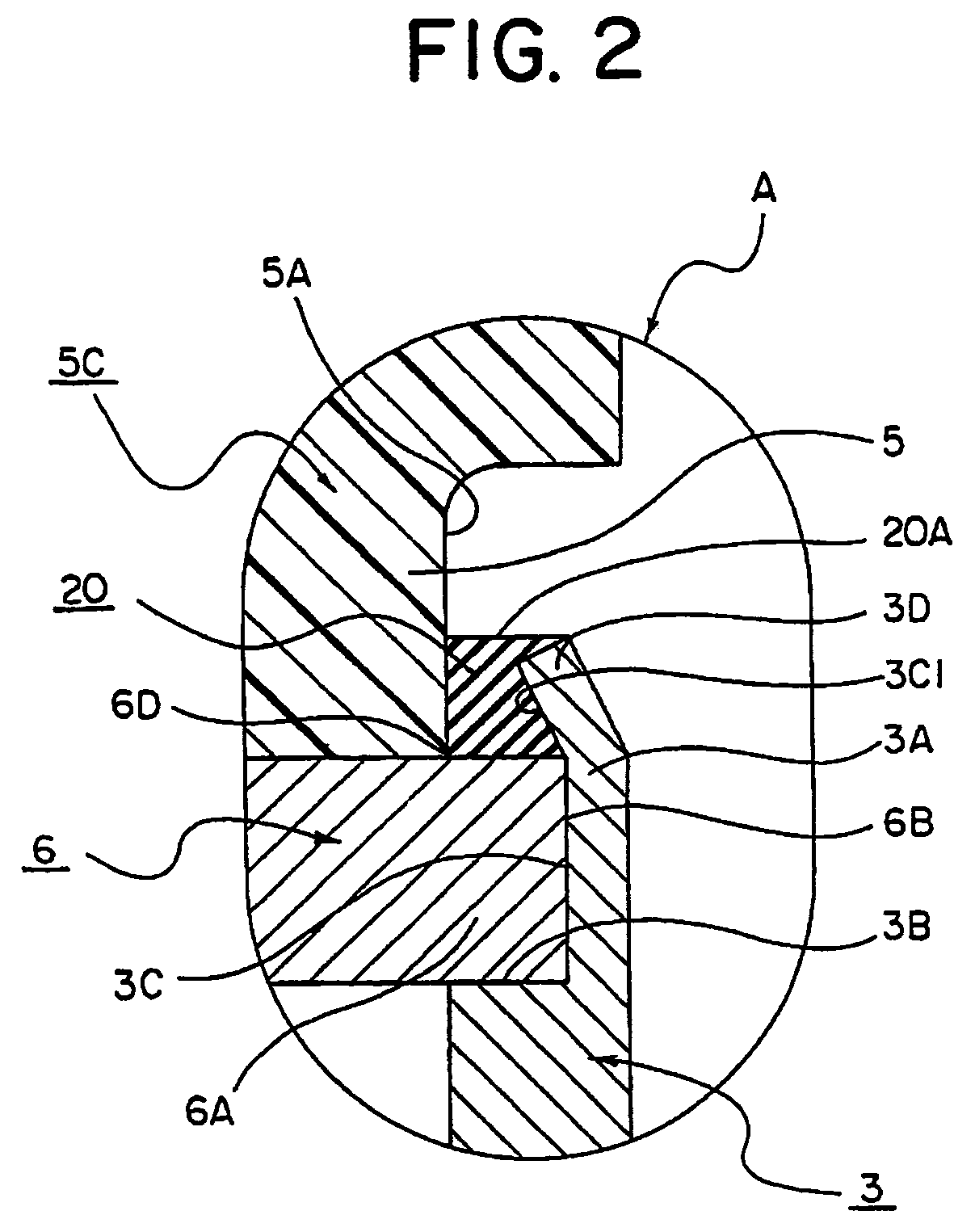

Solenoid Control Device

ActiveUS20080164434A1No peeling of anti-corrosionSmall inclinationEngine sealsOperating means/releasing devices for valvesControl valvesMagnetic circuit

A case main body and an upper plate are reliably fitted together, a seal is formed between the fitting surfaces, and a magnetic circuit is prevented from malfunctioning. A solenoid-controlled valve, which connects a solenoid section (2) and a valve section (30), comprises a cylindrical case main body (3) having a solenoid coil (4) housed therein and having a connecting section (3A) at one end, an upper plate (6) having a locking surface (6B) adapted to be fitted to the connecting section (3A), and a connector (5) integrally provided with the upper plate (6). A seal section (20) is joined to an outer surface between the fitting surfaces of the connecting section (3A) and the upper plate (6).

Owner:EAGLE INDS

Fuel cell stack and method for making the same

ActiveUS8173320B2Electrical conductivityLower performance requirementsFuel cells groupingFinal product manufactureFuel cellsElectromotive force

A fuel cell stack includes a membrane electrode assembly including an electrolyte membrane and electrode catalyst layers sandwiching the electrolyte membrane; metal separators that define gas channels, the metal separators being respectively disposed at both surfaces of the membrane electrode assembly; a current collector from which electromotive force is derived, the current collector being in contact with at least one of the metal separators; and joining parts that join the metal separator to the current collector at portions where the metal separator contacts the current collector.

Owner:NISSAN MOTOR CO LTD

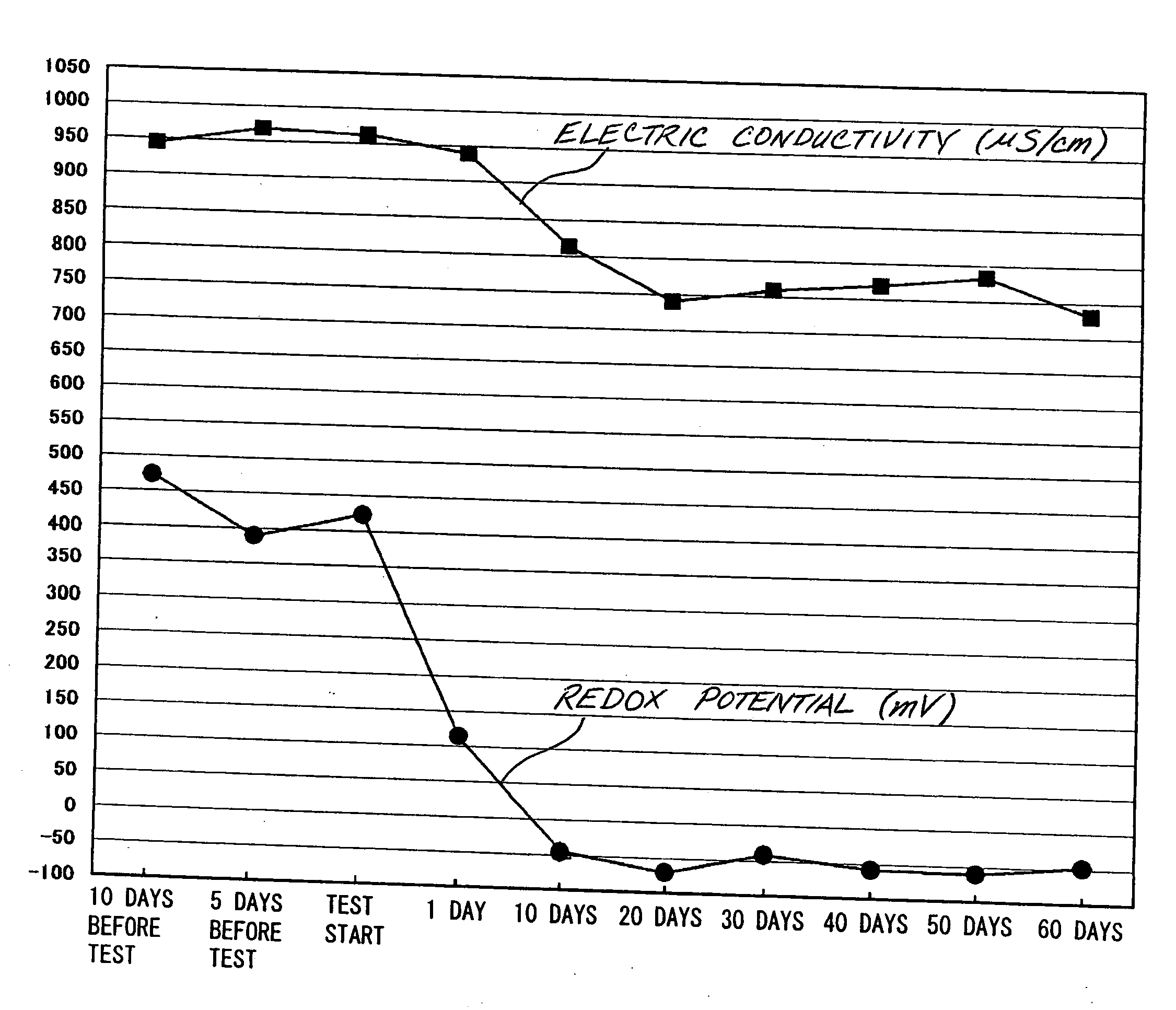

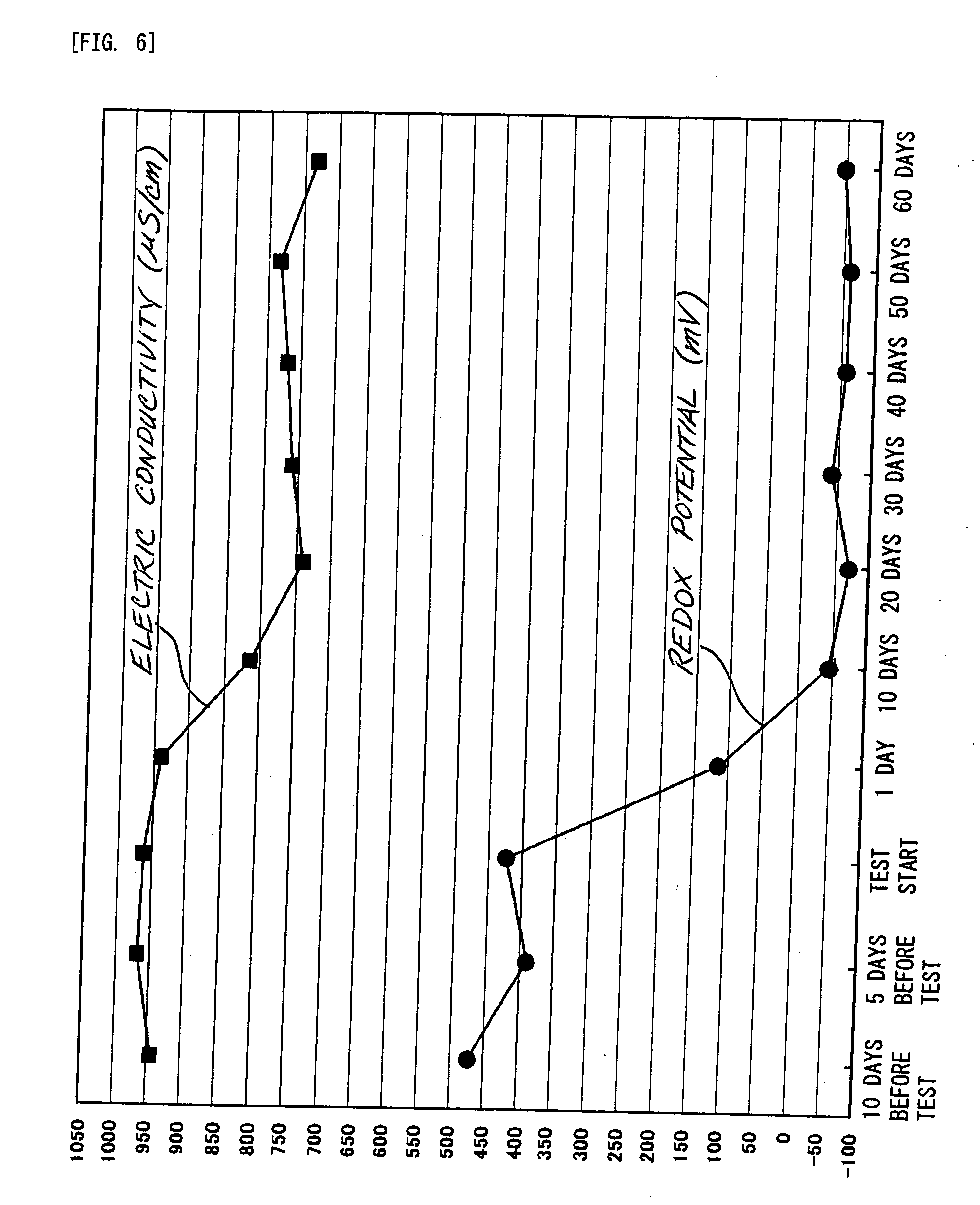

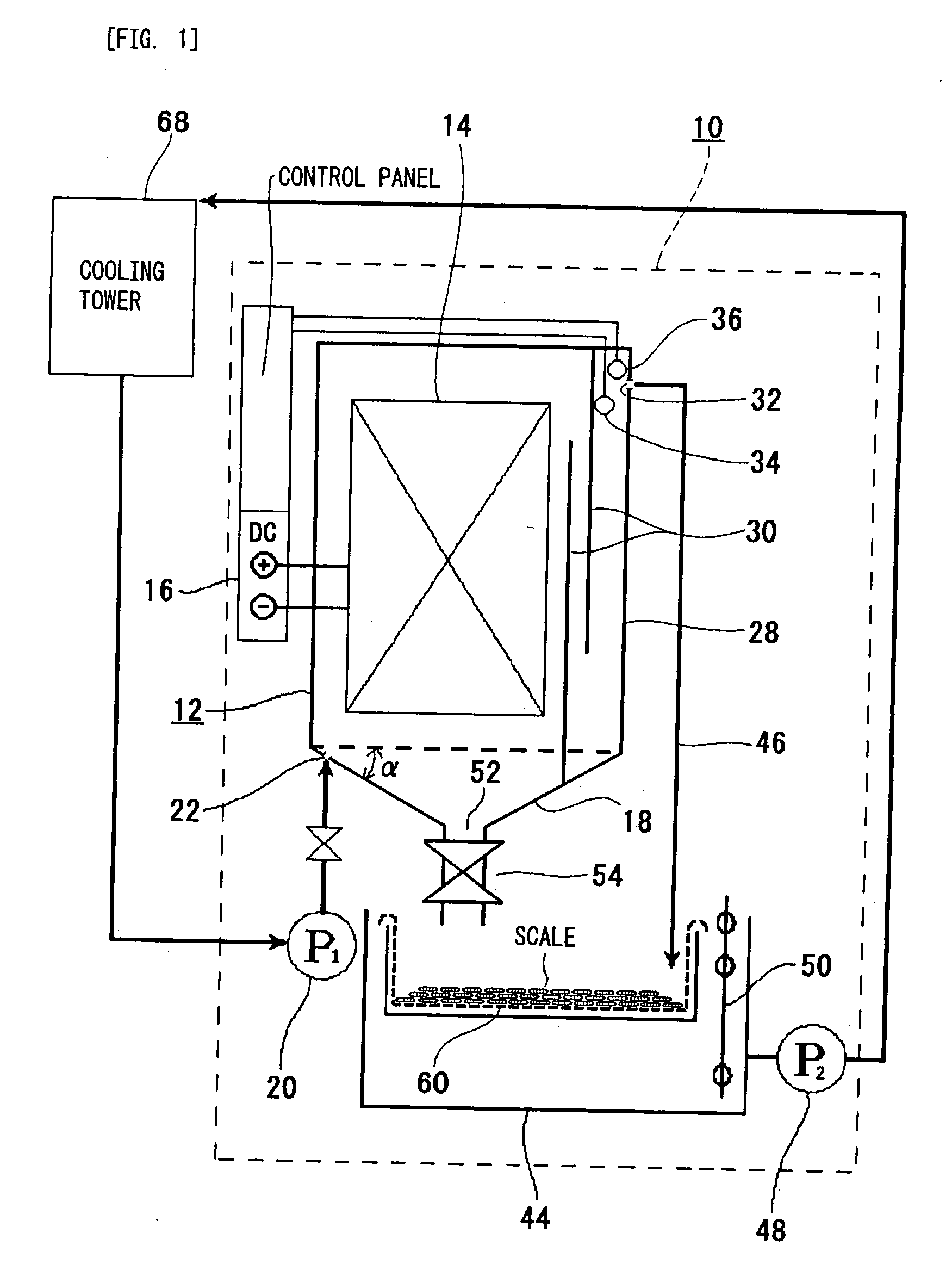

Method and Device for Cleaning Circulation Water

InactiveUS20080272060A1Efficient removalElectrical conductivityWater treatment parameter controlWater/sewage treatment by irradiationPower flowElectrolysis

The object of the invention is to provide a method for cleaning circulation water, which reduces the cost of operation and maintenance as much as possible, without a cumbersome cleaning operation such as by detaching electrode plates from an electrolysis cleaning tank and removing scale from inside the tank, and to provide a device used in this method. Accordingly, the present invention provides a method for cleaning circulation water, comprising the steps of flowing circulation water to be cleaned between electrode plates placed in a face-to-face manner between one another; and applying DC voltage between the electrode plates, allowing one or more metal ions contained in the circulation water to be precipitated onto the negative electrode plates by electrolysis, to clean the circulation water, wherein the electrode plates used are made of titanium plates, and wherein a desired amount of current flows, while an anodized oxide coating formed on the surface of the positive electrode plates is compulsively subject to dielectric breakdown by increasing the voltage applied to the anodized oxide coating. FIG. 1 is a representative drawing.

Owner:KOGANEI

Photomask blank

ActiveUS7790339B2Improve conductivityEnsure stabilityVacuum evaporation coatingSputtering coatingNitrogenOxygen

A photomask blank has a light-shielding film composed of a single layer of a material containing a transition metal, silicon and nitrogen or a plurality of layers that include at least one layer made of a material containing a transition metal, silicon and nitrogen, and has one or more chrome-based material film. The high transition metal content ensures electrical conductivity, preventing charge-up in the photomask production process, and also provides sufficient chemical stability to cleaning in photomask production. The light-shielding film has a good resistance to dry etching of the chrome-based material film in the presence of chlorine and oxygen, thus ensuring a high processing accuracy.

Owner:SHIN ETSU CHEM IND CO LTD +1

Spark plug electrode material and spark plug

InactiveUS9166380B2Improve conductivityReduces corrosion and erosionSparking plugs manufactureSilicon oxideGrain boundary

A spark plug electrode material containing nickel, silicon, and copper, the electrode material, in the case of proper use, forming a nickel oxide layer made of nickel oxide grains on at least a part of its surface, the grain boundary phase of the nickel oxide grains including silicon and / or silicon oxide.

Owner:ROBERT BOSCH GMBH

Solenoid control device

ActiveUS7611121B2Avoid breakingEasy to provideEngine sealsOperating means/releasing devices for valvesEngineeringControl valves

A case main body and an upper plate are reliably fitted together, a seal is formed between the fitting surfaces, and a magnetic circuit is prevented from malfunctioning. A solenoid-controlled valve, which connects a solenoid section (2) and a valve section (30), comprises a cylindrical case main body (3) having a solenoid coil (4) housed therein and having a connecting section (3A) at one end, an upper plate (6) having a locking surface (6B) adapted to be fitted to the connecting section (3A), and a connector (5) integrally provided with the upper plate (6). A seal section (20) is joined to an outer surface between the fitting surfaces of the connecting section (3A) and the upper plate (6).

Owner:EAGLE INDS

Electroconductive polyethylene resin composition, and molded article and laminate using the same

ActiveUS20160284435A1Increase stickinessProduction is possibleSynthetic resin layered productsNon-conductive material with dispersed conductive materialSurface resistivityChemistry

An electroconductive polyethylene resin composition comprises: a resin component comprising a polar-group-containing polyethylene resin (A) and a polyethylene resin (B); and an electroconductive filler (E) incorporated into the resin component, wherein each of the proportions of the polar-group-containing polyethylene resin (A) and the polyethylene resin (B) in the resin component is the polar-group-containing polyethylene resin (A): 0.5 wt %-80 wt % and the polyethylene resin (B): 99.5 wt %-20 wt %, and the electroconductive polyethylene resin composition satisfies the following requirement (1): (1) surface resistivity: 10Ω / □-1010Ω / □.

Owner:JAPAN POLYETHYLENE CORP

Carbon-based acoustic matching layer and method for producing same

ActiveUS20170125005A1High mechanical strengthAvoid lostLayered productsPiezoelectric/electrostrictive transducersCarbonizationPhenol

Provided are: a carbonaceous acoustic matching layer which exhibits satisfactory mechanical strength, in which losses at a layer interface are suppressed as far as possible and in which the degree of variation in acoustic impedance in the thickness direction can be increased; and a method for producing same. The carbonaceous acoustic matching layer is obtained by dispersing filler particles, which are selected on the basis of the desired acoustic impedance of each layer, in a resin such as a furan resin, a phenol resin or a vinyl chloride resin, curing, laminating, and then carbonizing the resin by heating in a non-oxidizing atmosphere, amorphous carbon, which is obtained by the resin carbonization, is integrated across all the layers. The blending proportion of the filler particles is decided so that the difference in coefficient of linear contraction caused by the carbonization is at a minimum between adjacent layers.

Owner:MITSUBISHI PENCIL CO LTD

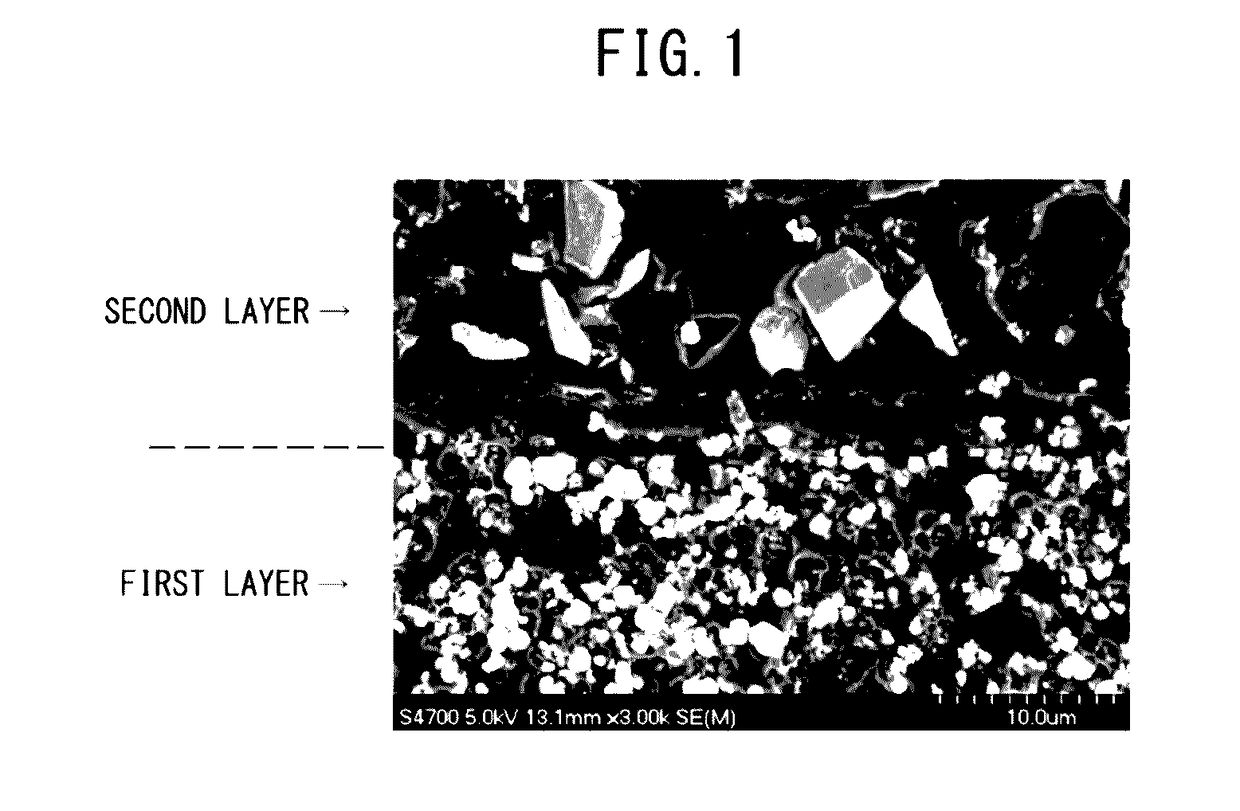

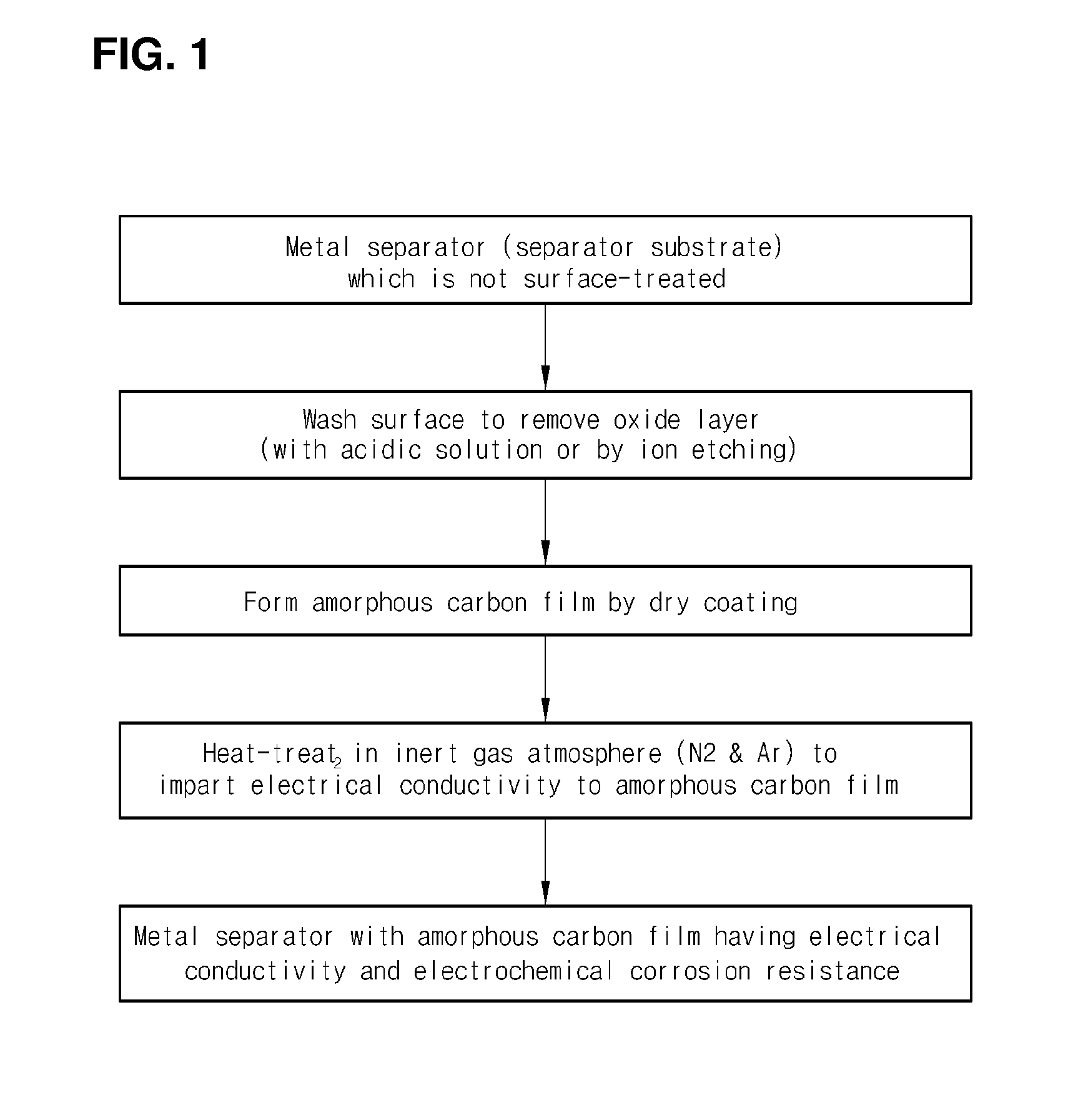

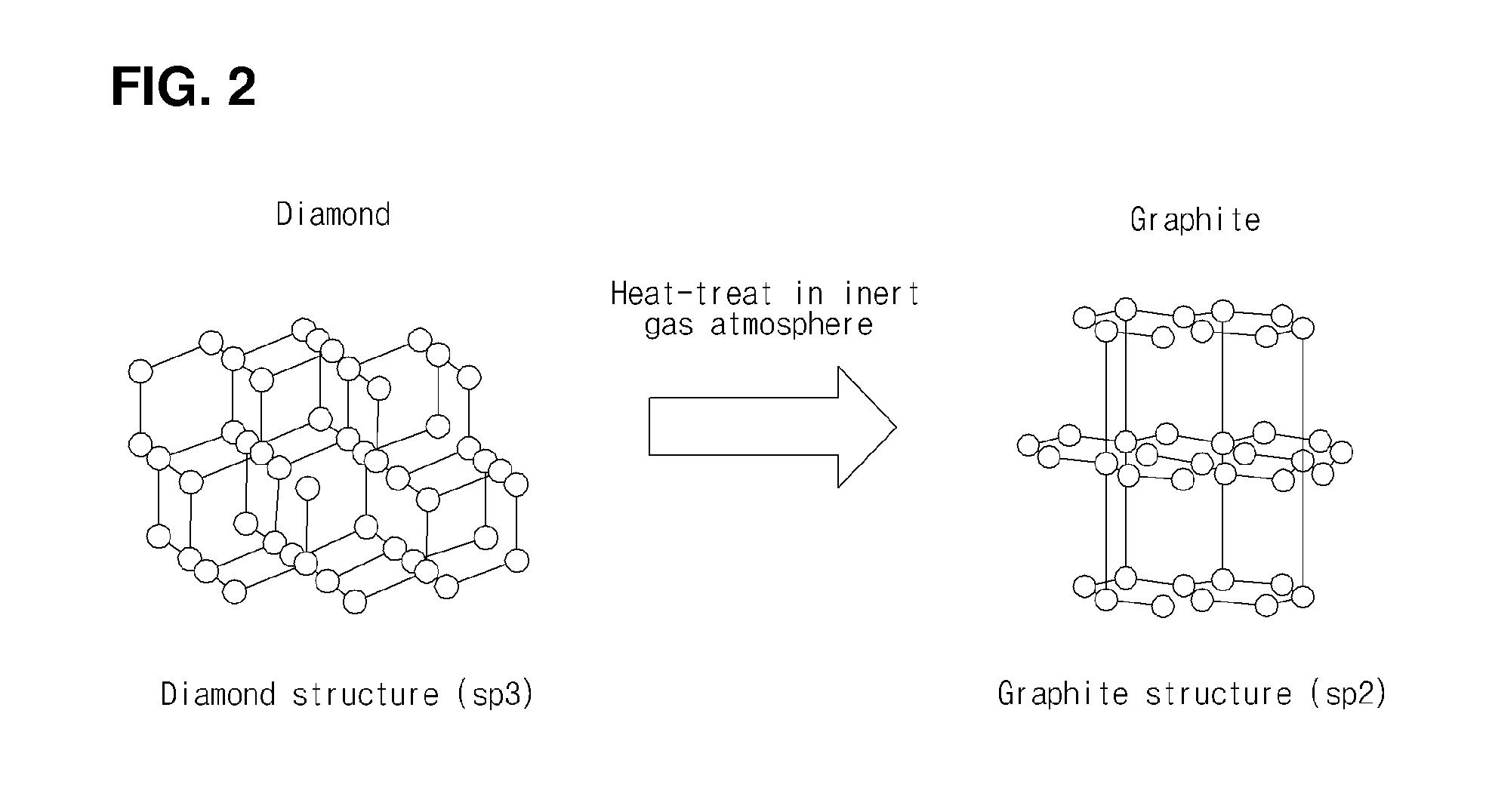

Metal separator for fuel cell and method for treating surface of the same

InactiveUS20110135812A1Increase the proportion of spElectrical conductivityFinal product manufactureCoatingsFuel cellsElectrochemical corrosion

The present invention provides a metal separator for a fuel cell, which is surface-treated to have high electrical conductivity and electrochemical corrosion resistance, and a method for treating the surface of the same. The metal separator may include an amorphous carbon film formed on the surface of a separator substrate, the amorphous carbon film being carbonized by heat treatment to increase the proportion of sp2. The surface treatment method may include: forming an amorphous carbon film on the surface of a separator substrate; and carbonizing the amorphous carbon film by heat treatment. Fuel cells having the metal separator can show excellent performance.

Owner:HYUNDAI MOTOR CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com