Patents

Literature

33results about How to "Satisfy Compensation Requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

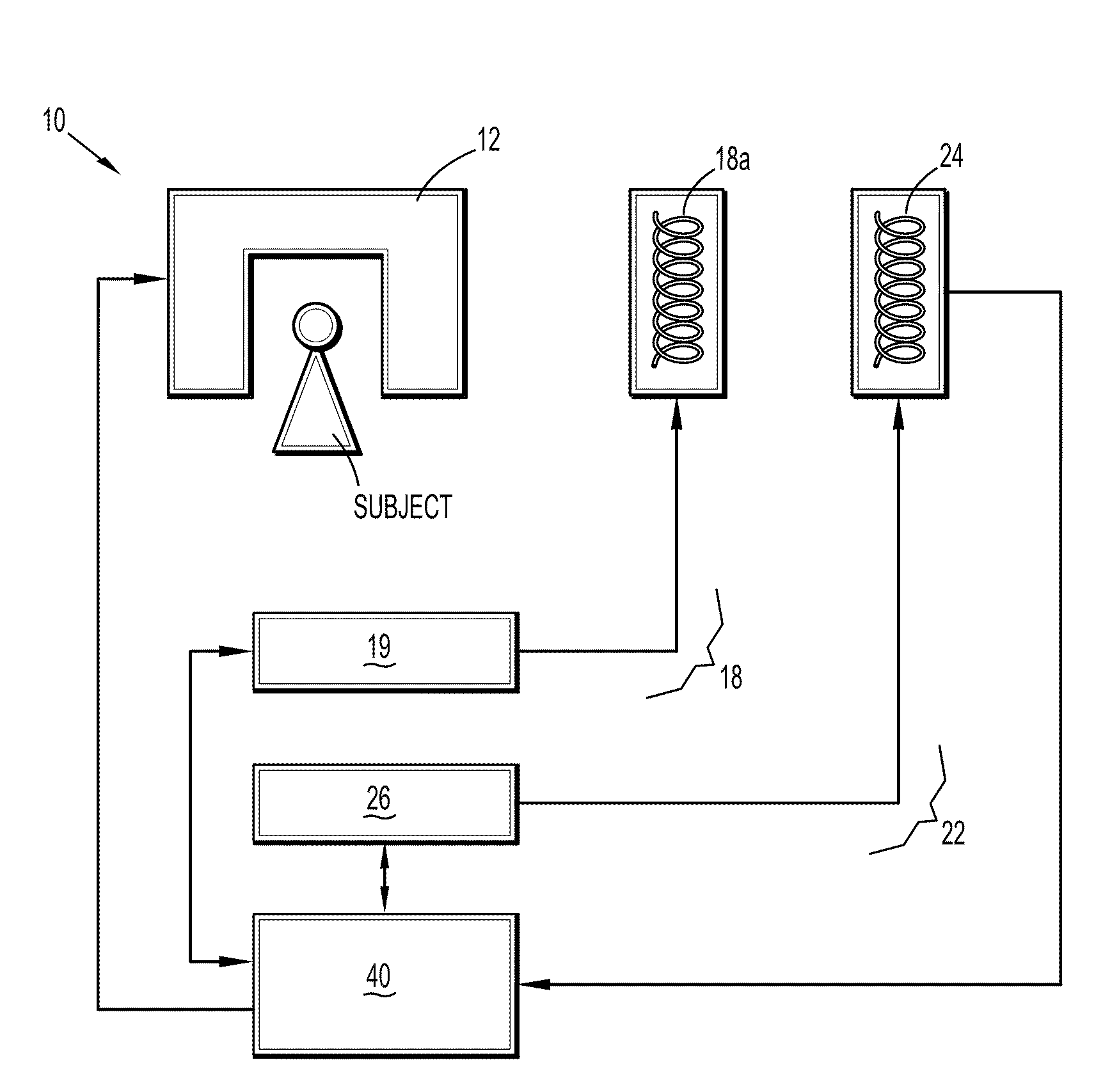

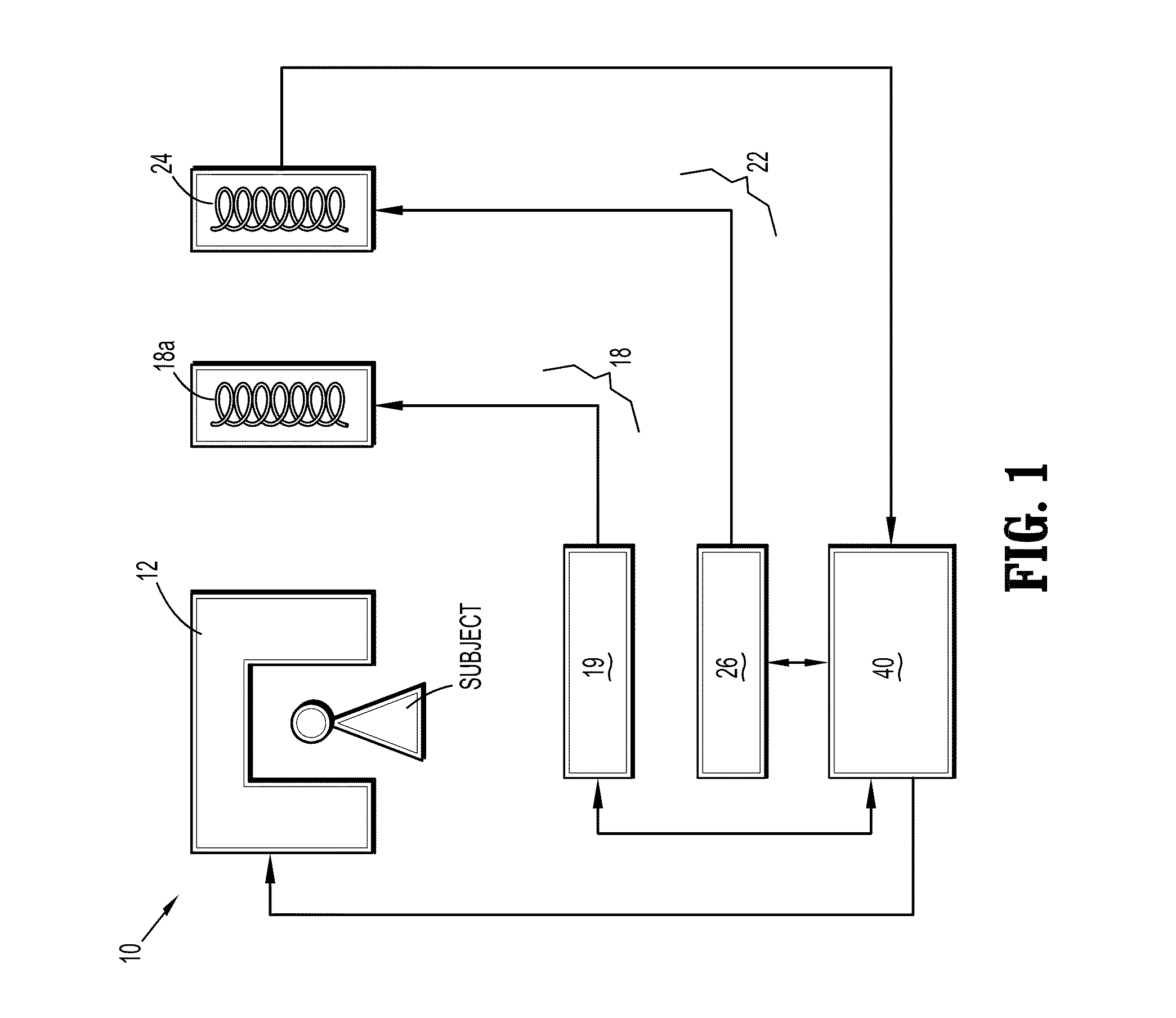

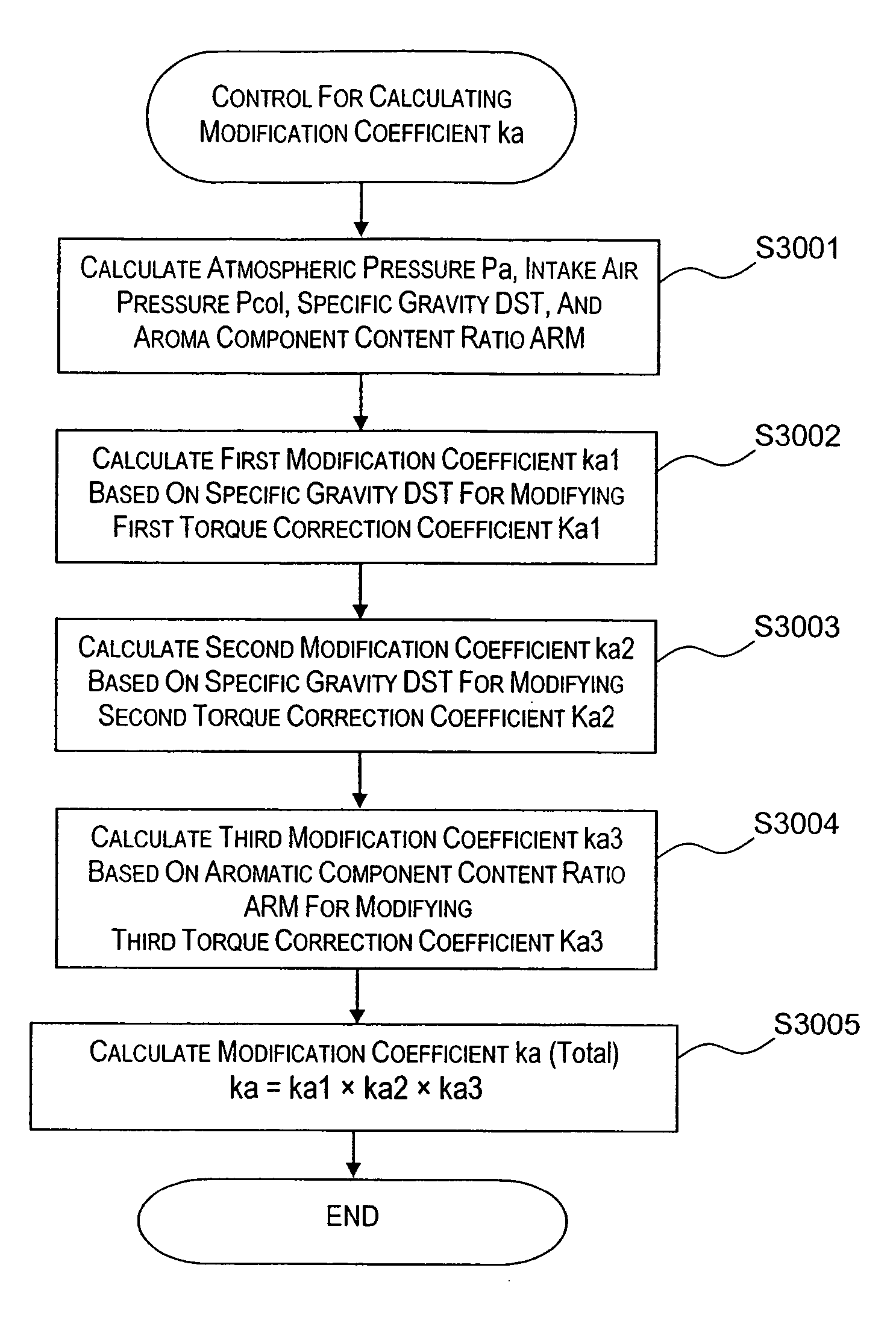

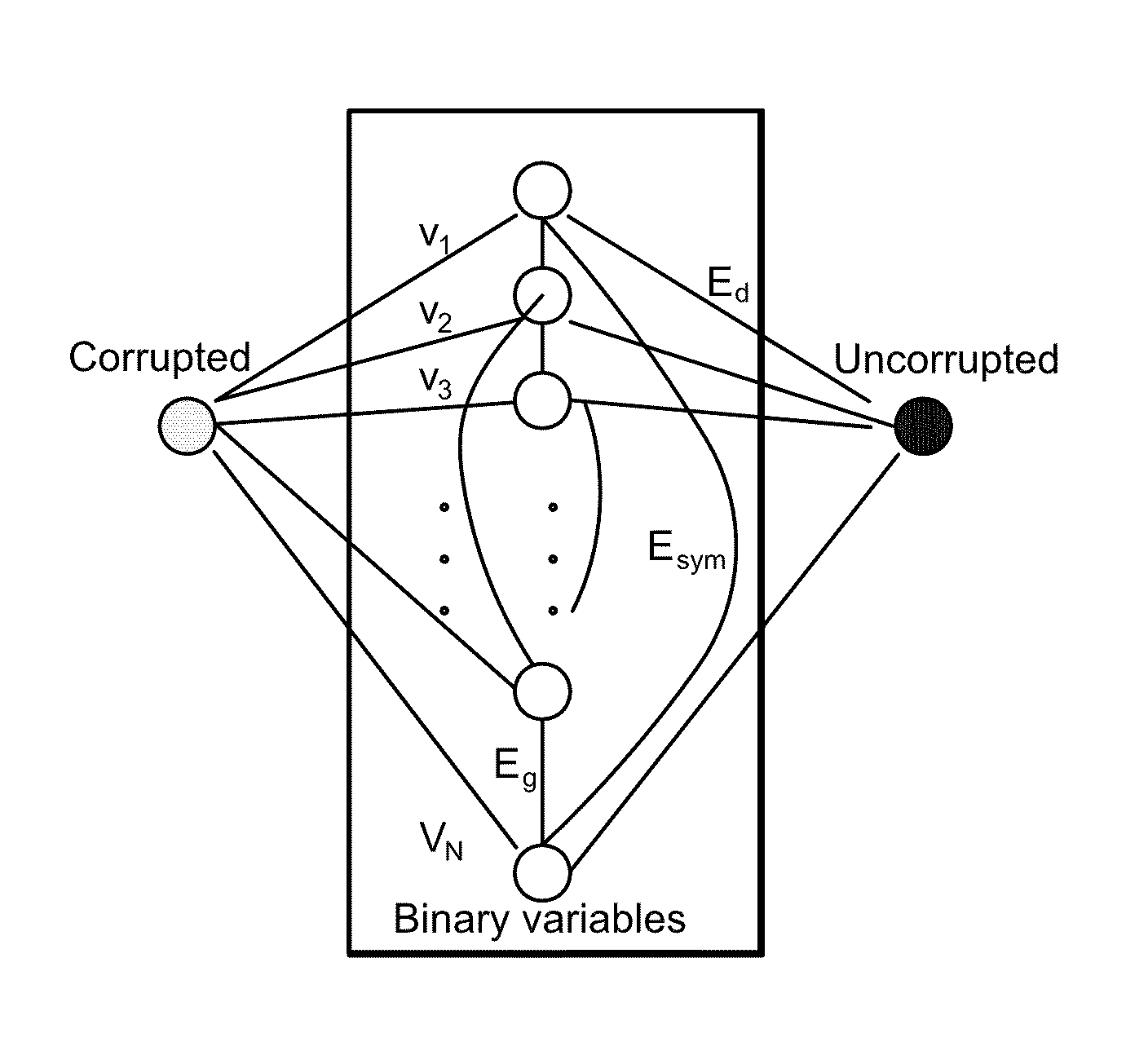

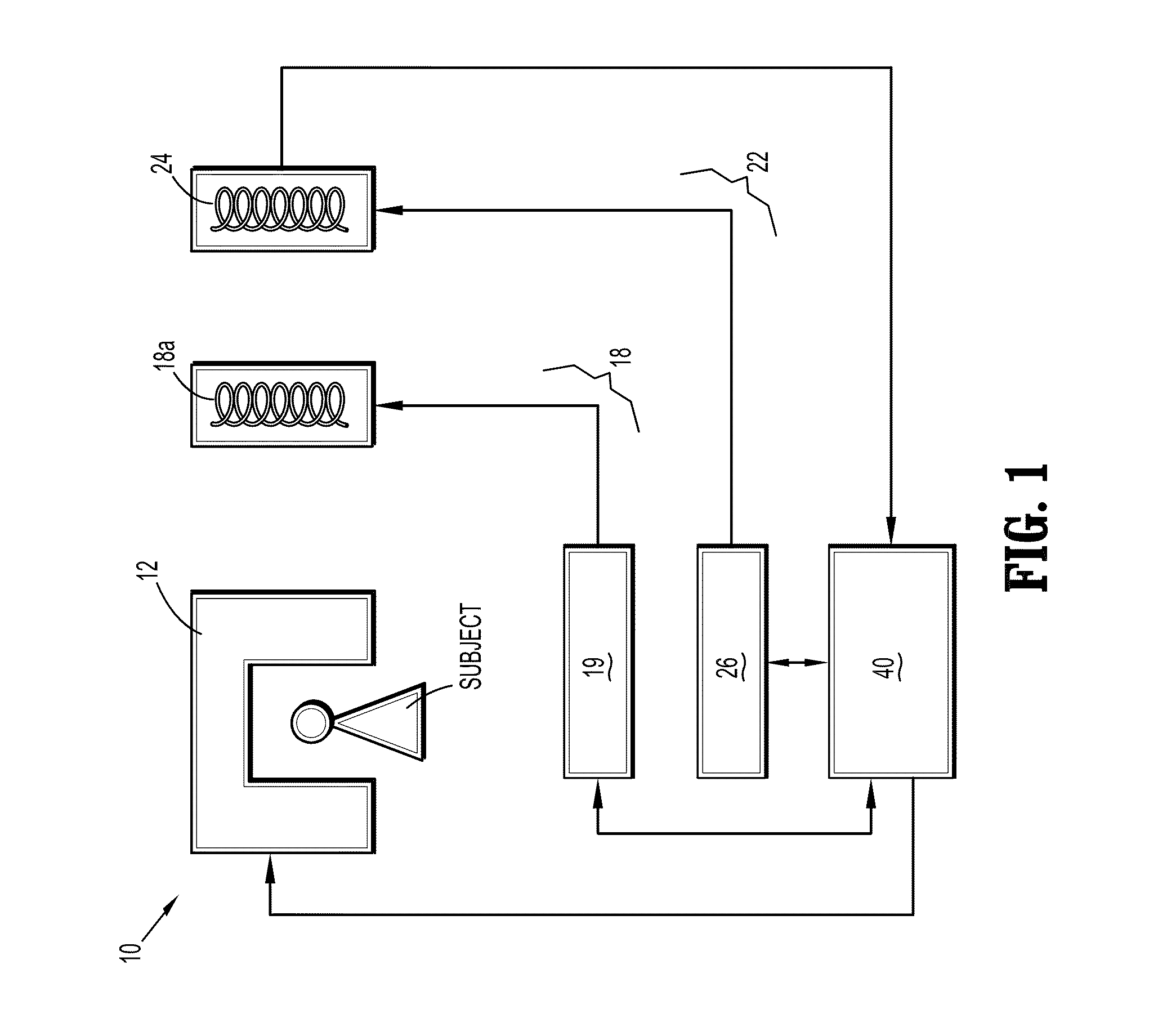

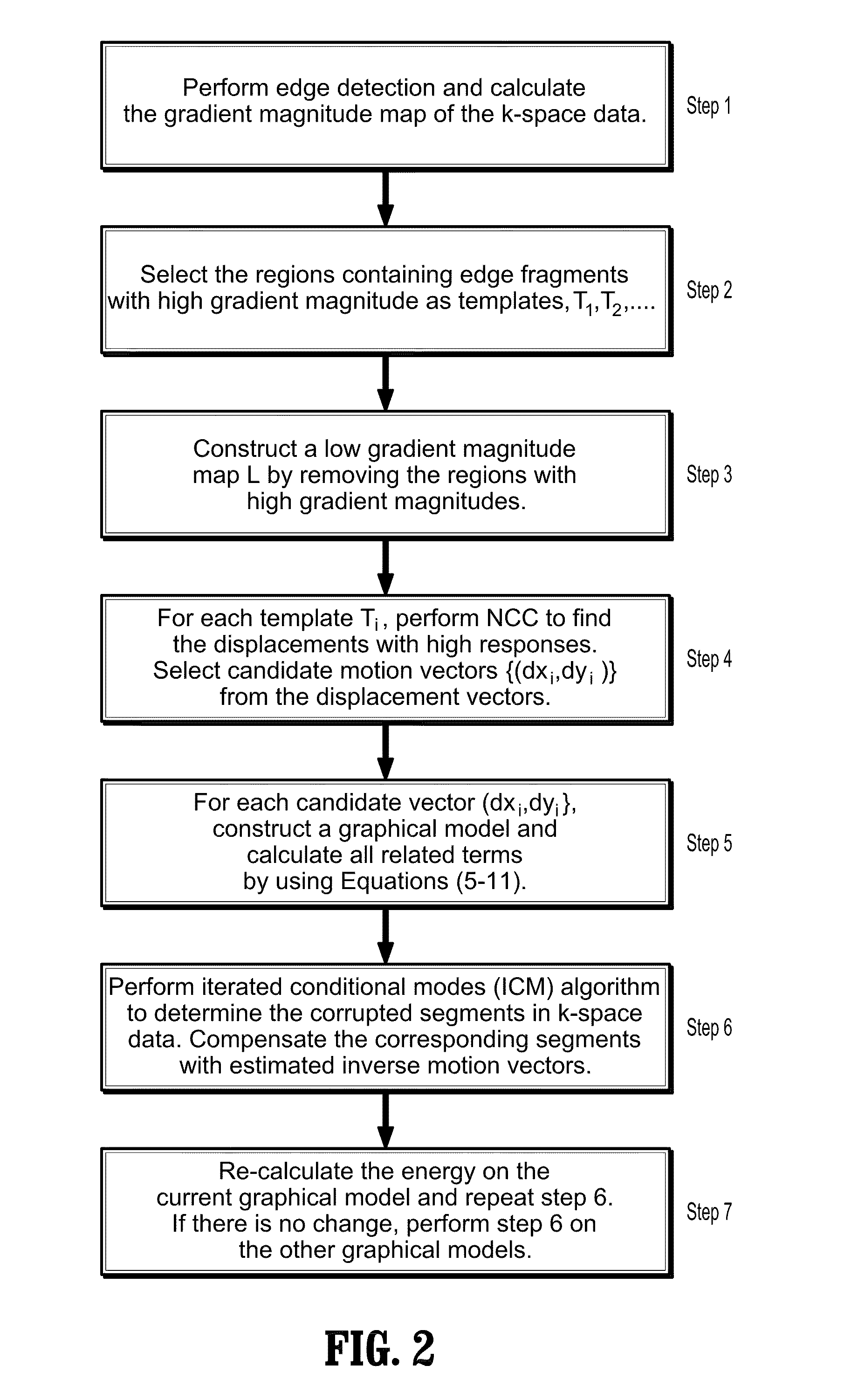

Method for correcting motion artifacts in magnetic resonance images

ActiveUS20100142789A1Satisfy Compensation RequirementsMinimizing energyMagnetic measurementsCharacter and pattern recognitionGraphicsMotion vector

For resonance image data of an imaged subject, a method that first detects and estimates the dominant motions of k-space data (i.e., the motion vectors) and then constructs a graphical model for each estimated motion vector. The segments of the k-space that are determined to be corrupted by motion are restored by minimizing the energy associated with the corresponding graphical model. Consequently, the MR image of the imaged subject becomes free of motion artifacts.

Owner:SIEMENS HEALTHCARE GMBH

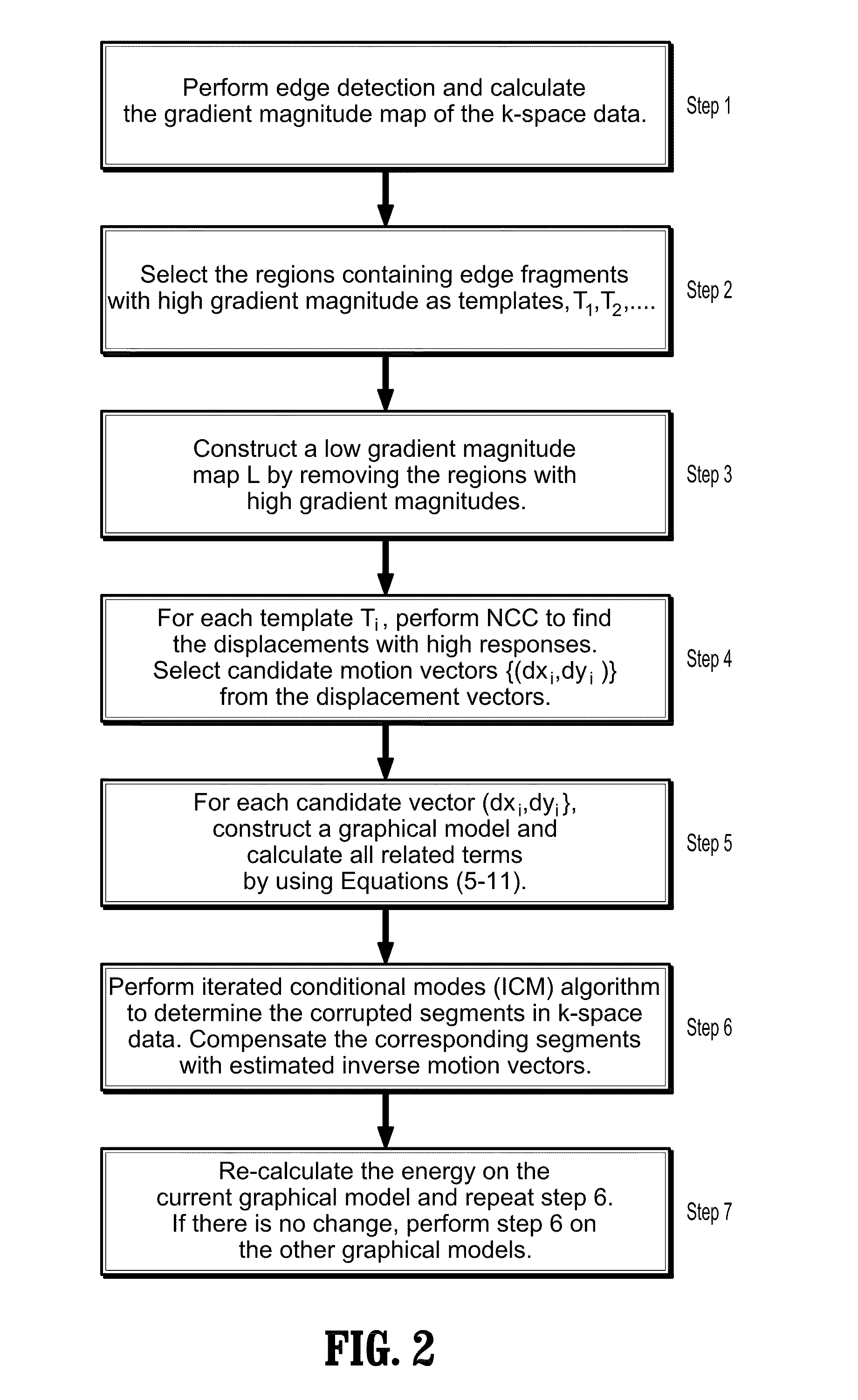

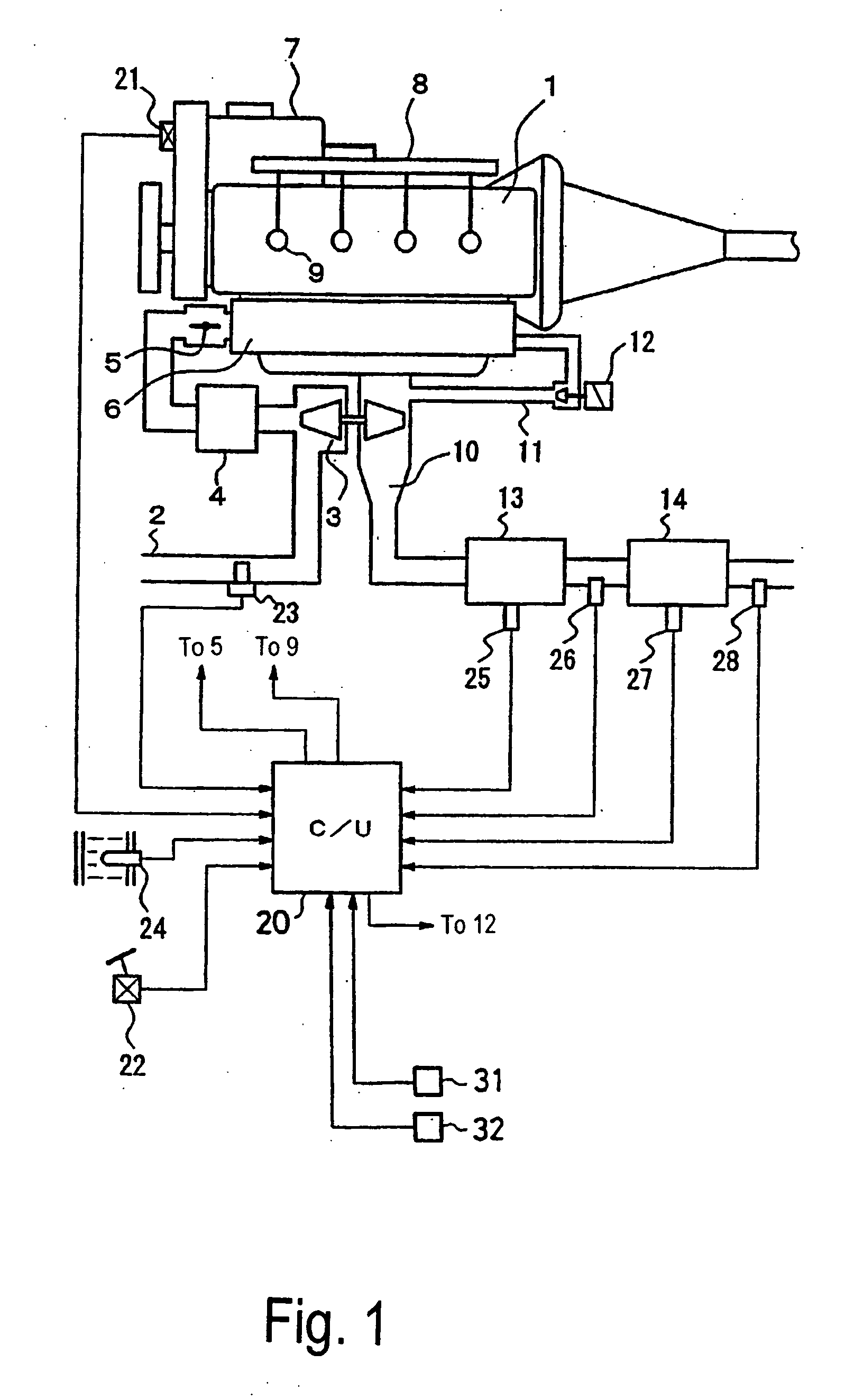

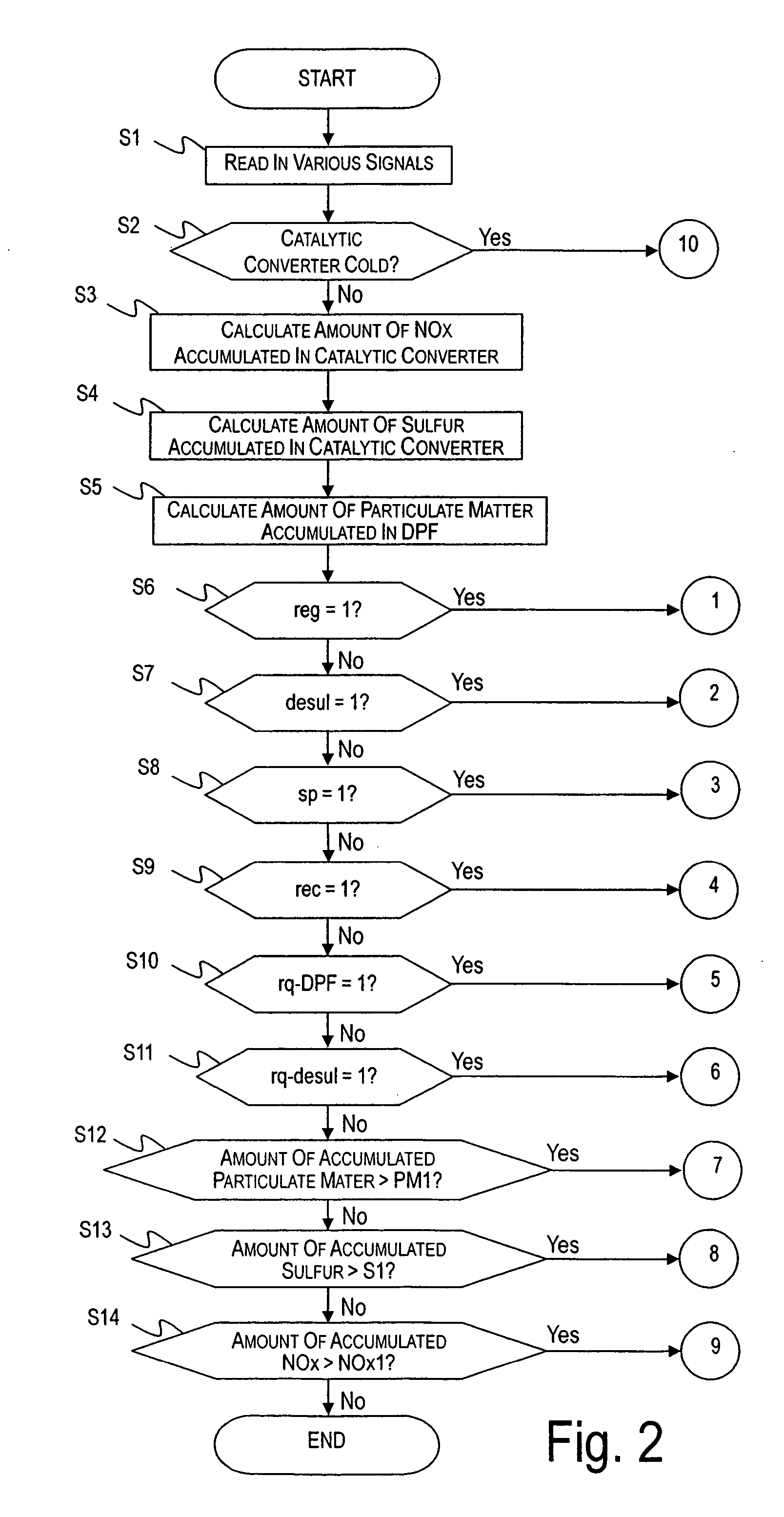

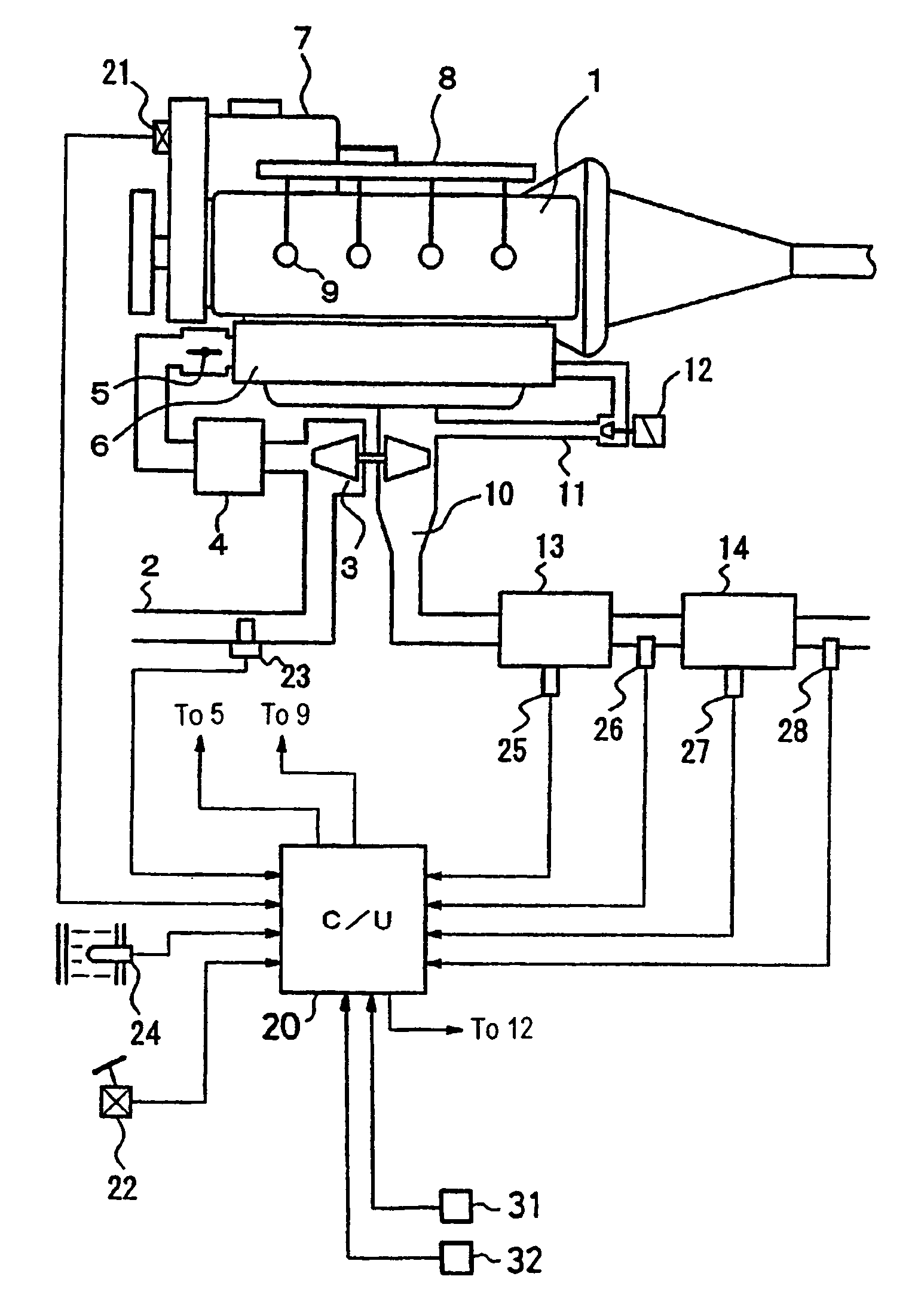

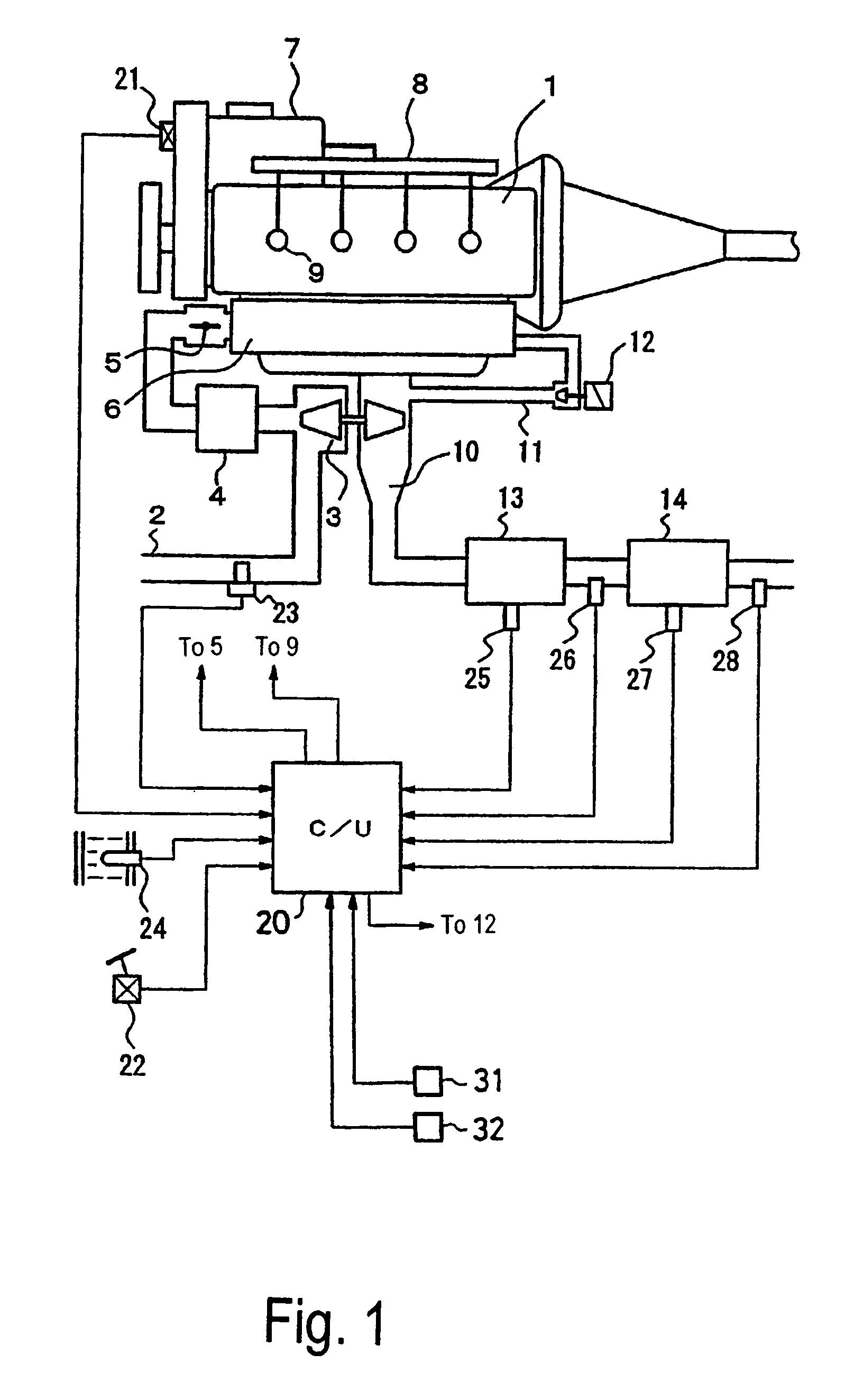

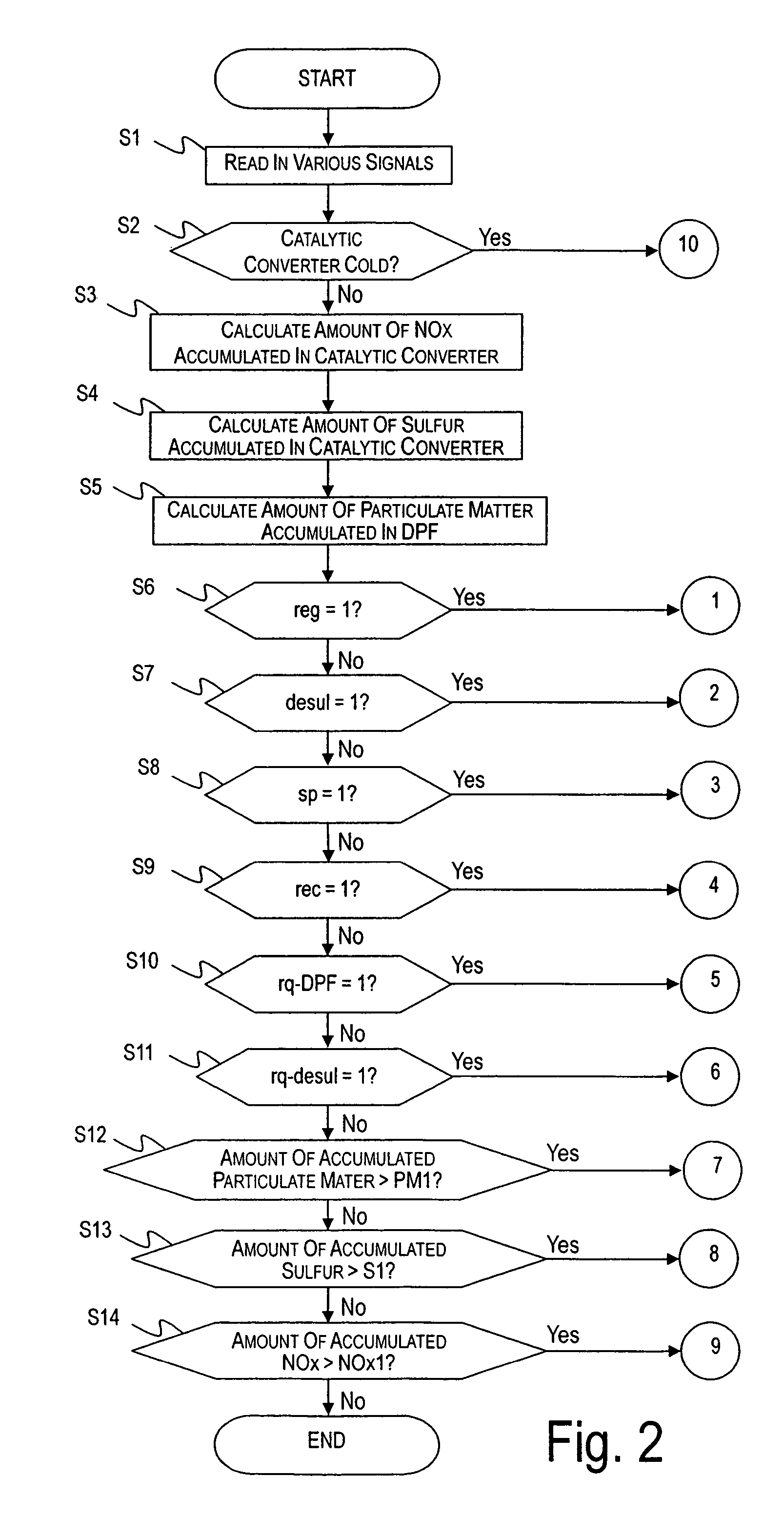

Internal combustion engine control device

InactiveUS20050188948A1Satisfactory torque compensationGuaranteed uptimeElectrical controlInternal combustion piston enginesControl modeAir–fuel ratio

An internal combustion engine control device is configured to take a fuel property into account when compensating for torque decline that occurs when a prescribed combustion control mode is executed. The internal combustion engine control device is configured to calculate a first modification coefficient designed to modify a first torque correction coefficient corresponding to a air-fuel ratio based on the specific gravity of the fuel, a second modification coefficient designed to modify a second torque correction coefficient corresponding to a working gas quantity based on the specific gravity of the fuel, and a third modification coefficient designed to modify a third torque correction coefficient corresponding to a fuel injection timing based on an aromatic component content ratio of the fuel. The internal combustion engine control device is then configured to multiply the first, second and third modification coefficients together to calculate a modification coefficient for modifying a torque correction value.

Owner:NISSAN MOTOR CO LTD

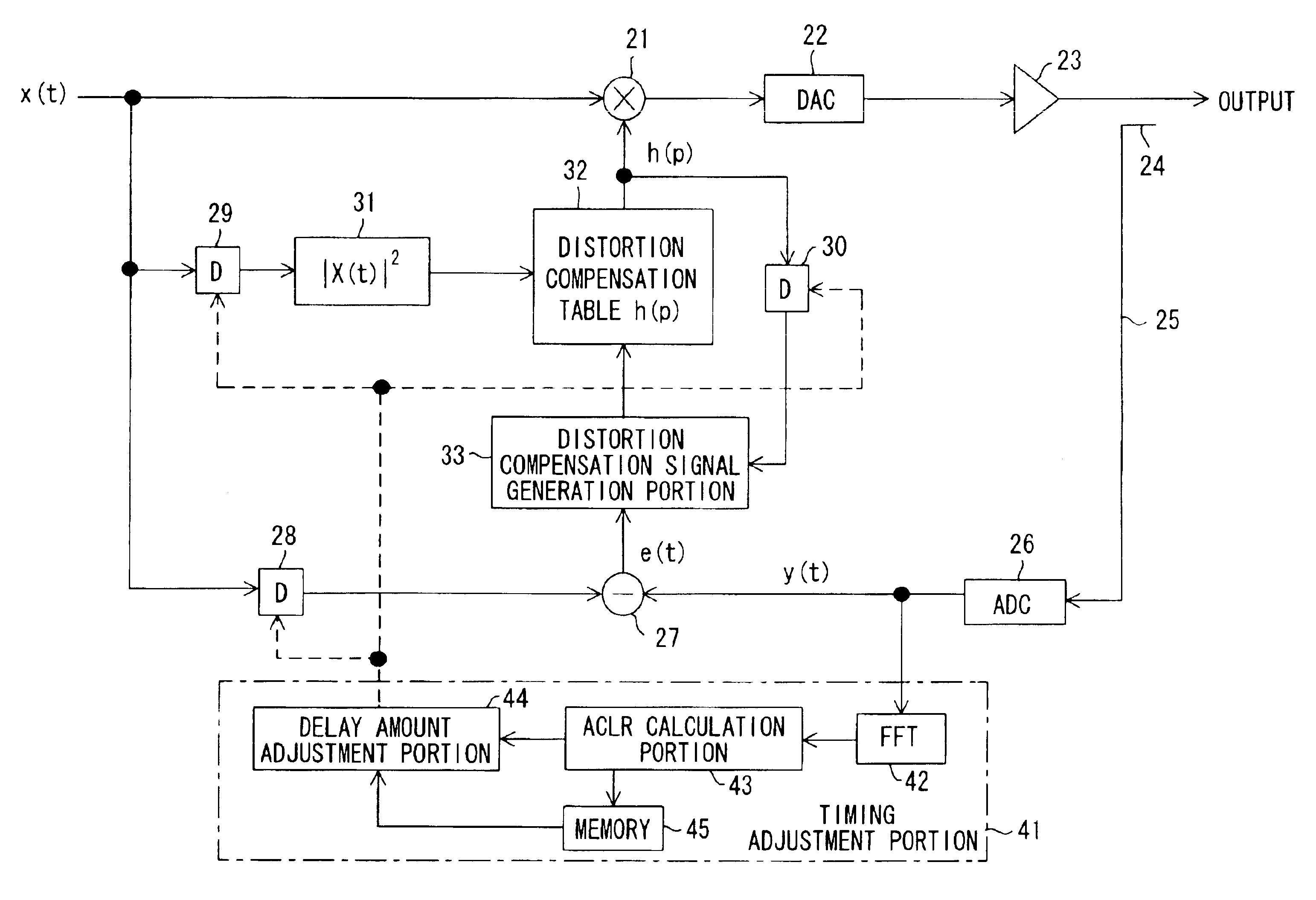

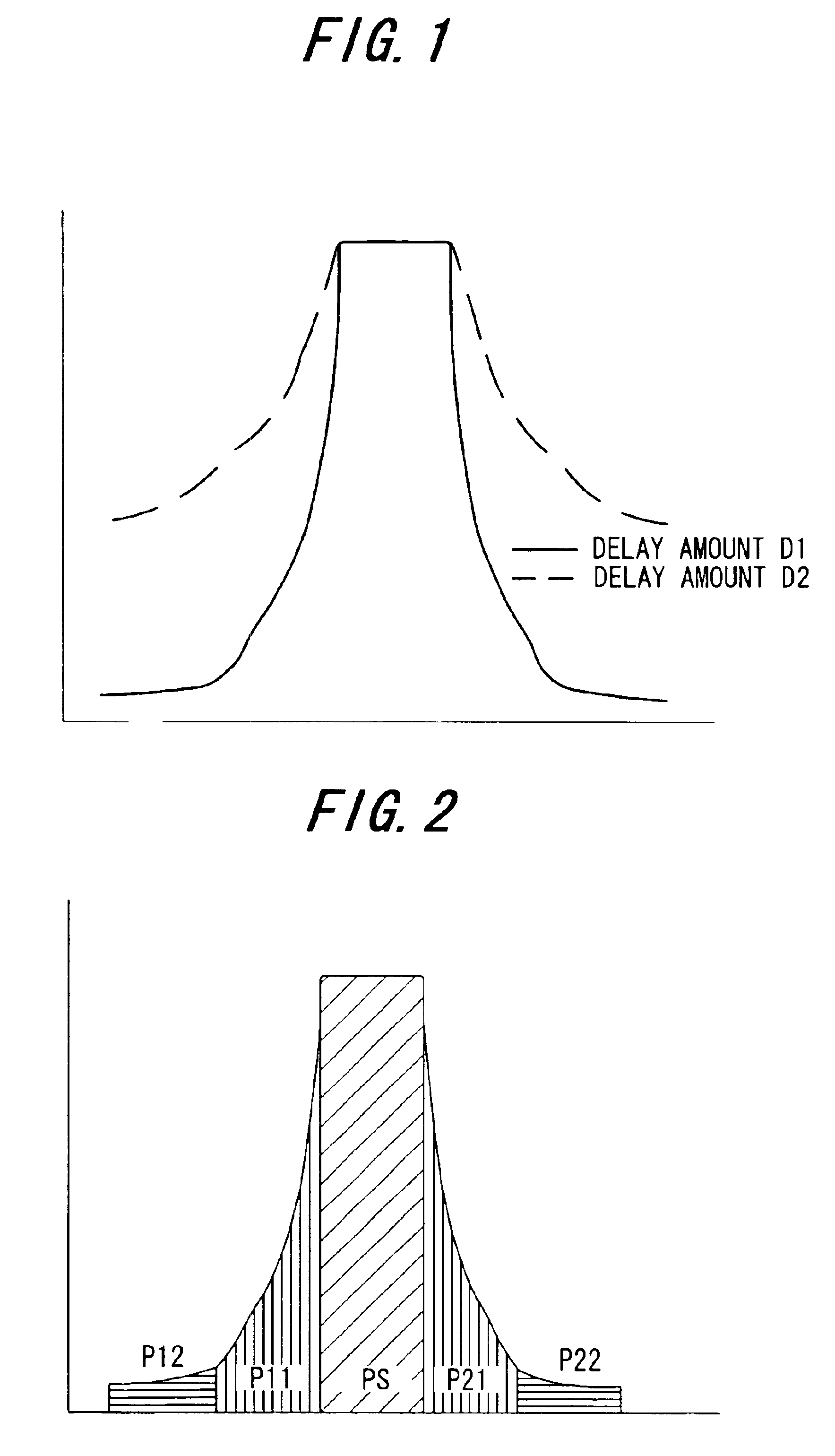

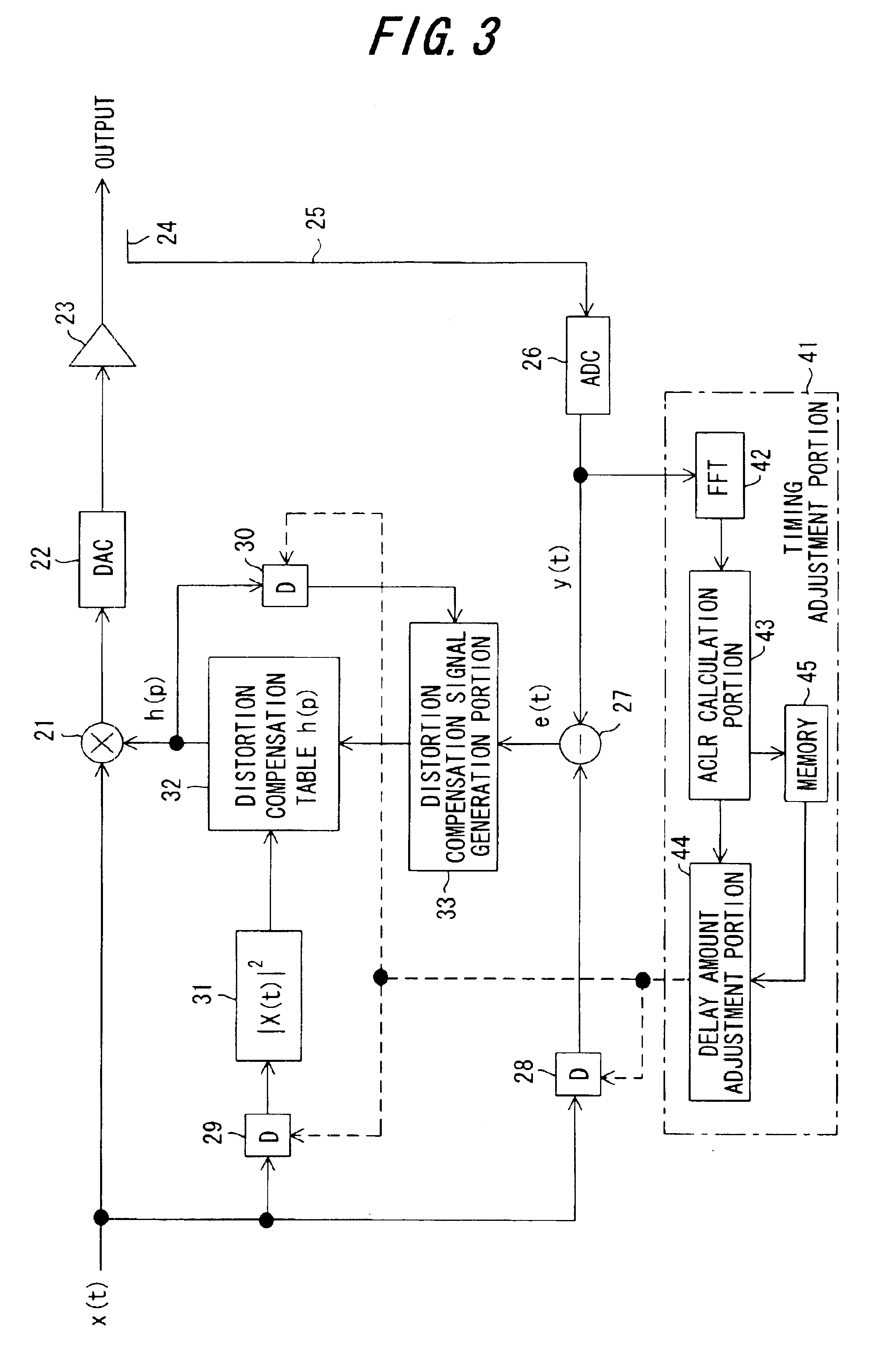

Distortion compensation device

InactiveUS6864745B2Guaranteed uptimeHigh precisionAmplifier modifications to reduce non-linear distortionAmplifier modifications to reduce noise influenceFast Fourier transformSignal-to-noise ratio (imaging)

In a distortion compensation device which uses distortion compensation coefficients to subject distortion compensation processing to an input signal and supply the result of the distortion compensation processing to a distorting device, calculates the distortion compensation coefficients based on the input signal before distortion compensation and the feedback signal fed back from the output side of the distorting device, and stores the calculated distortion compensation coefficients in association with the input signal, (1) the feedback signal is AD-converted; (2) the AD-converted output is subjected to fast Fourier transform (FFT) processing; (3) the FFT calculation result is used to calculate the value of either the signal-to-noise ratio SNR, or the adjacent channel leakage power ratio ACLR, or the noise level; (4) the delay time occurring in the distorting device and feedback loop is adjusted such that the difference between the above calculated value at the current time and the above calculated value at the immediately preceding time is either zero, or is equal to or less than a threshold value; and, (5) this adjustment processing is repeated to determine the accurate delay time, and based on this delay time the timing of each of the portions of the distortion compensation device is adjusted.

Owner:FUJITSU LTD

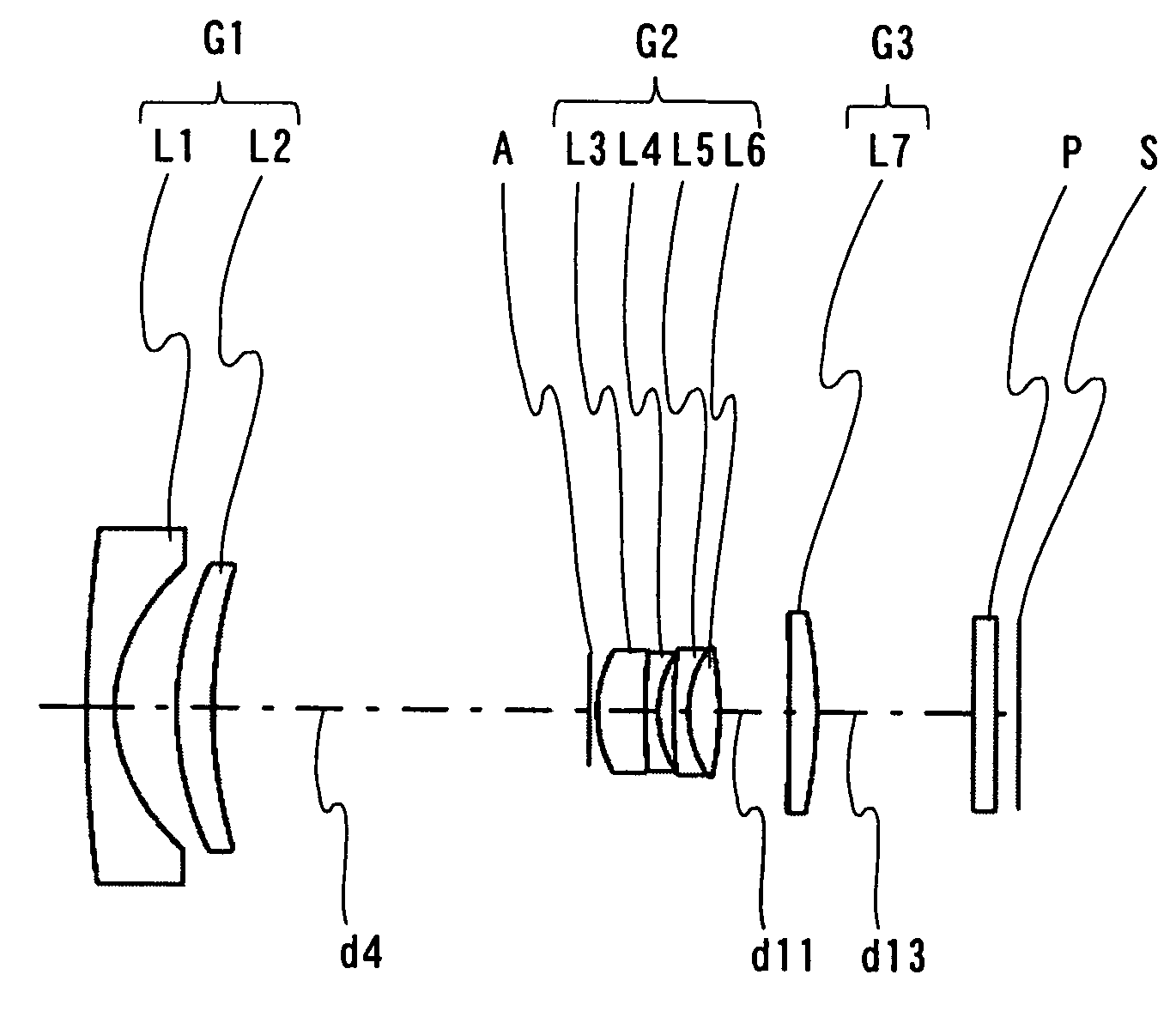

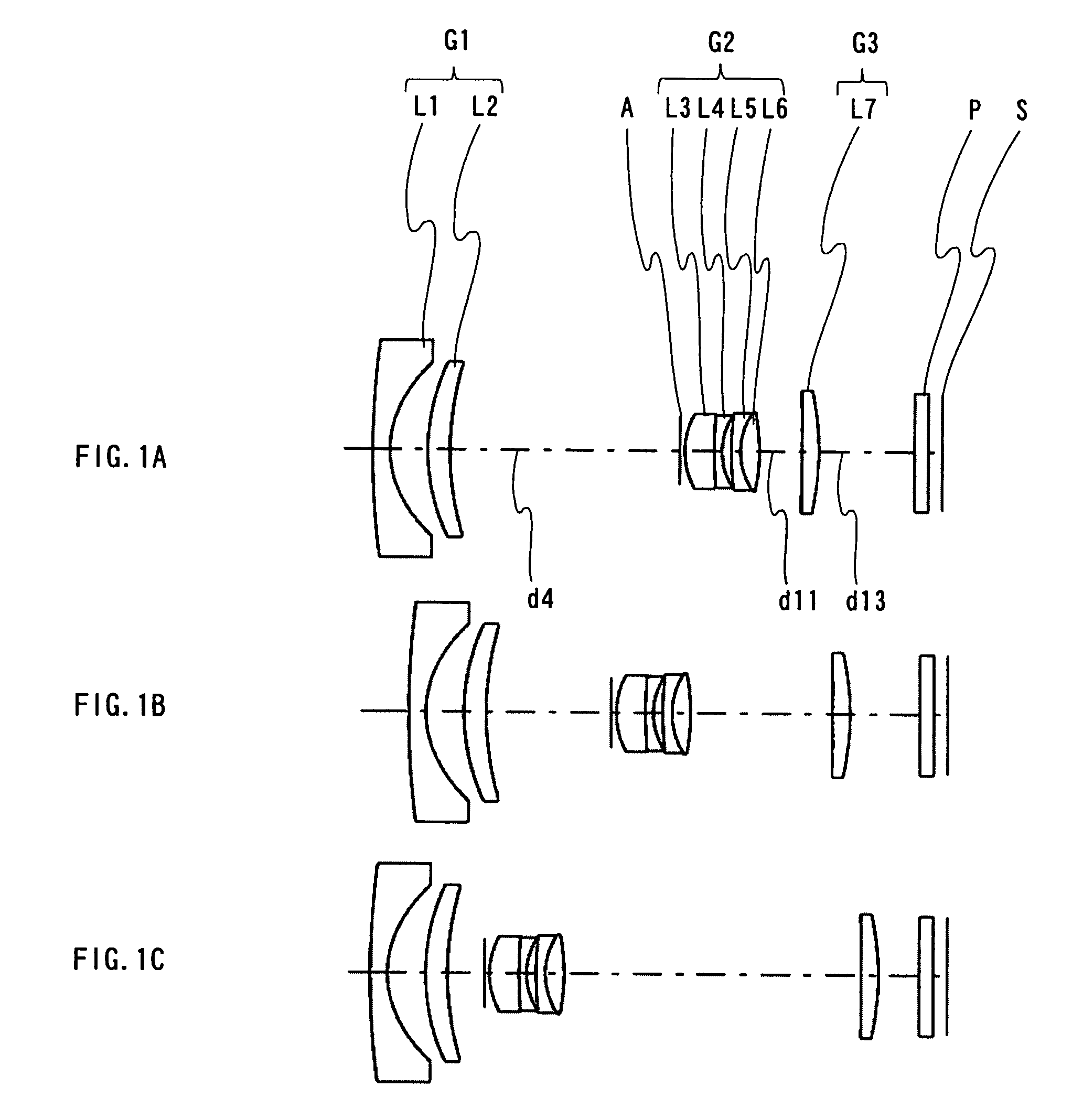

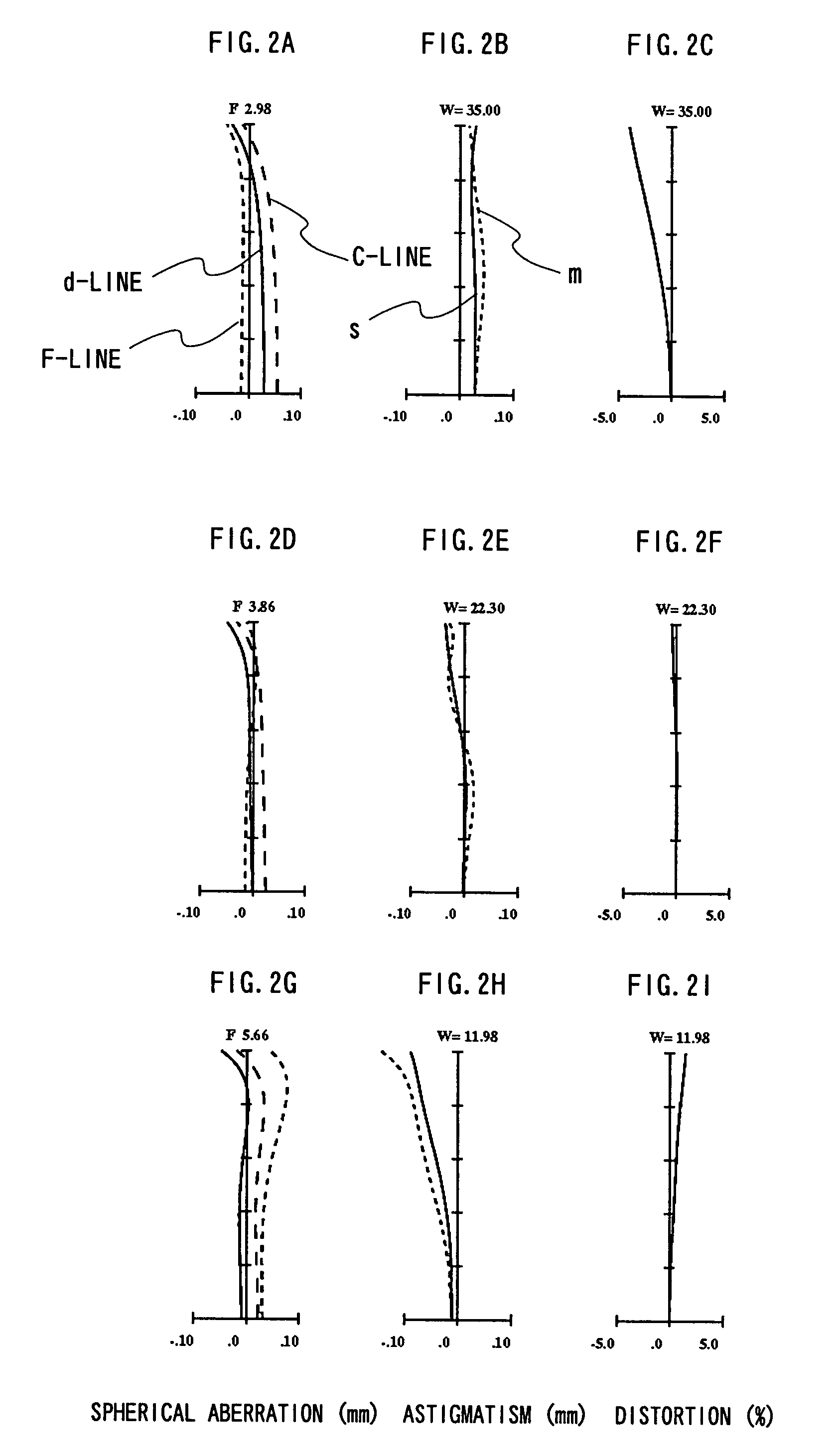

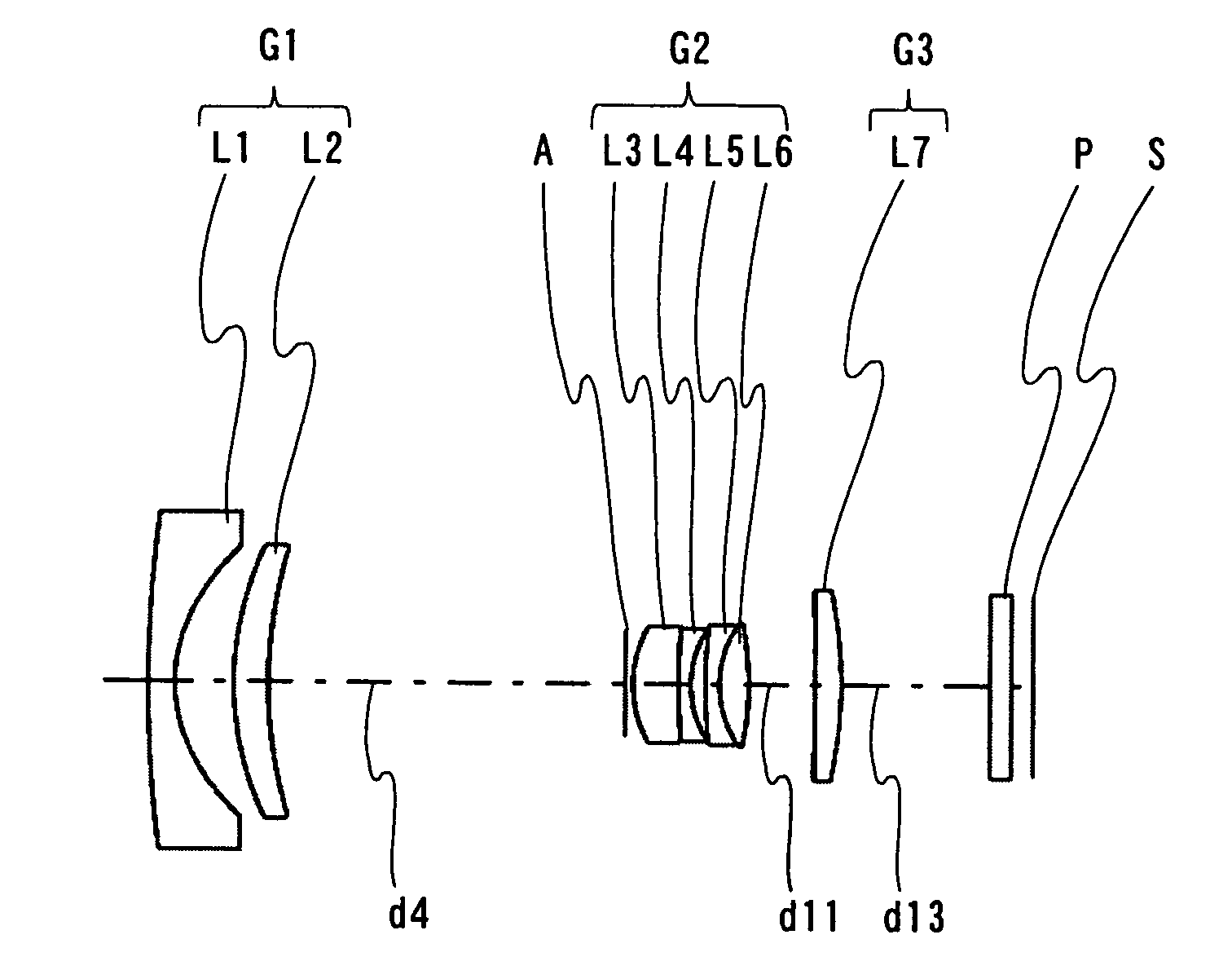

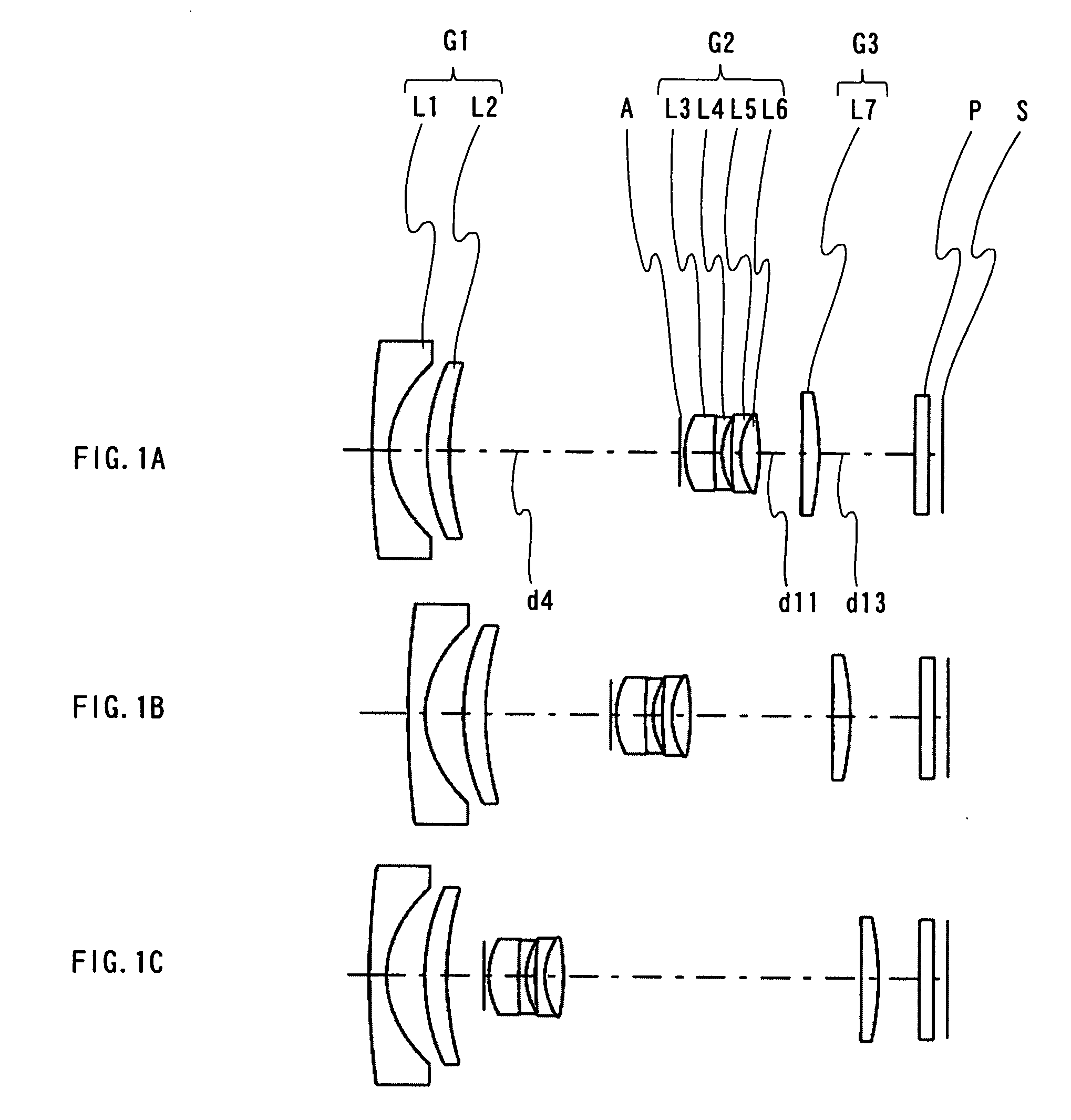

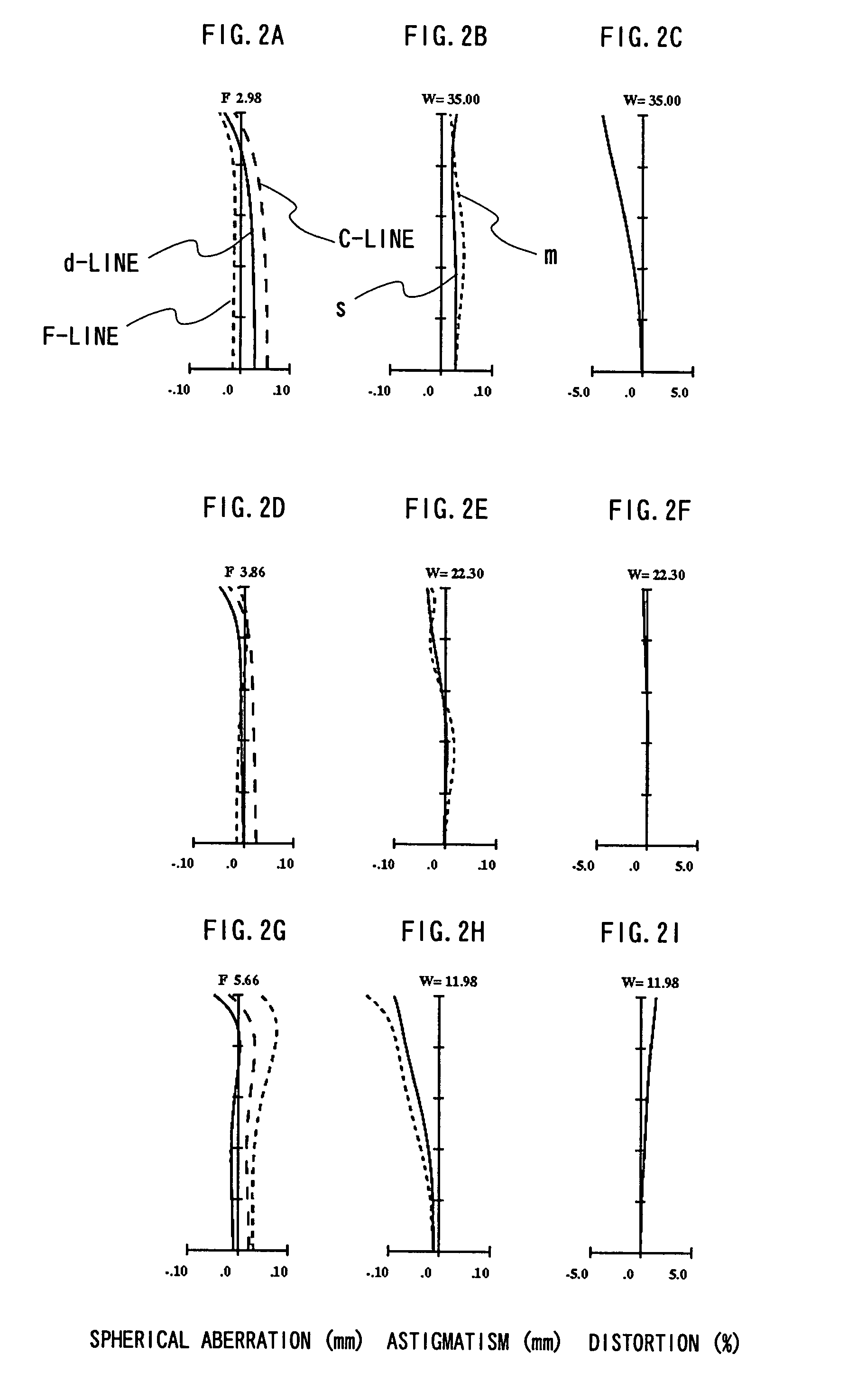

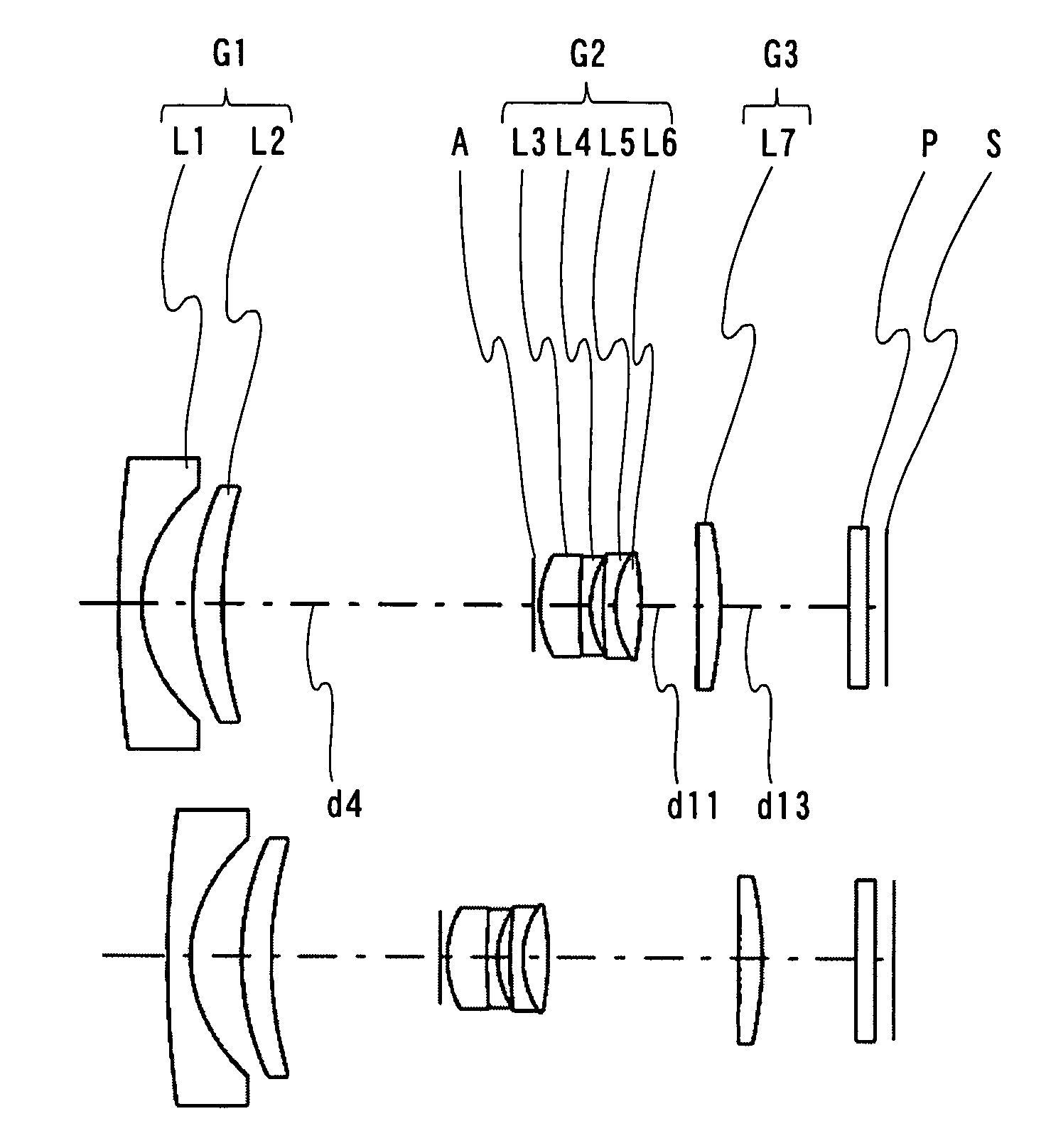

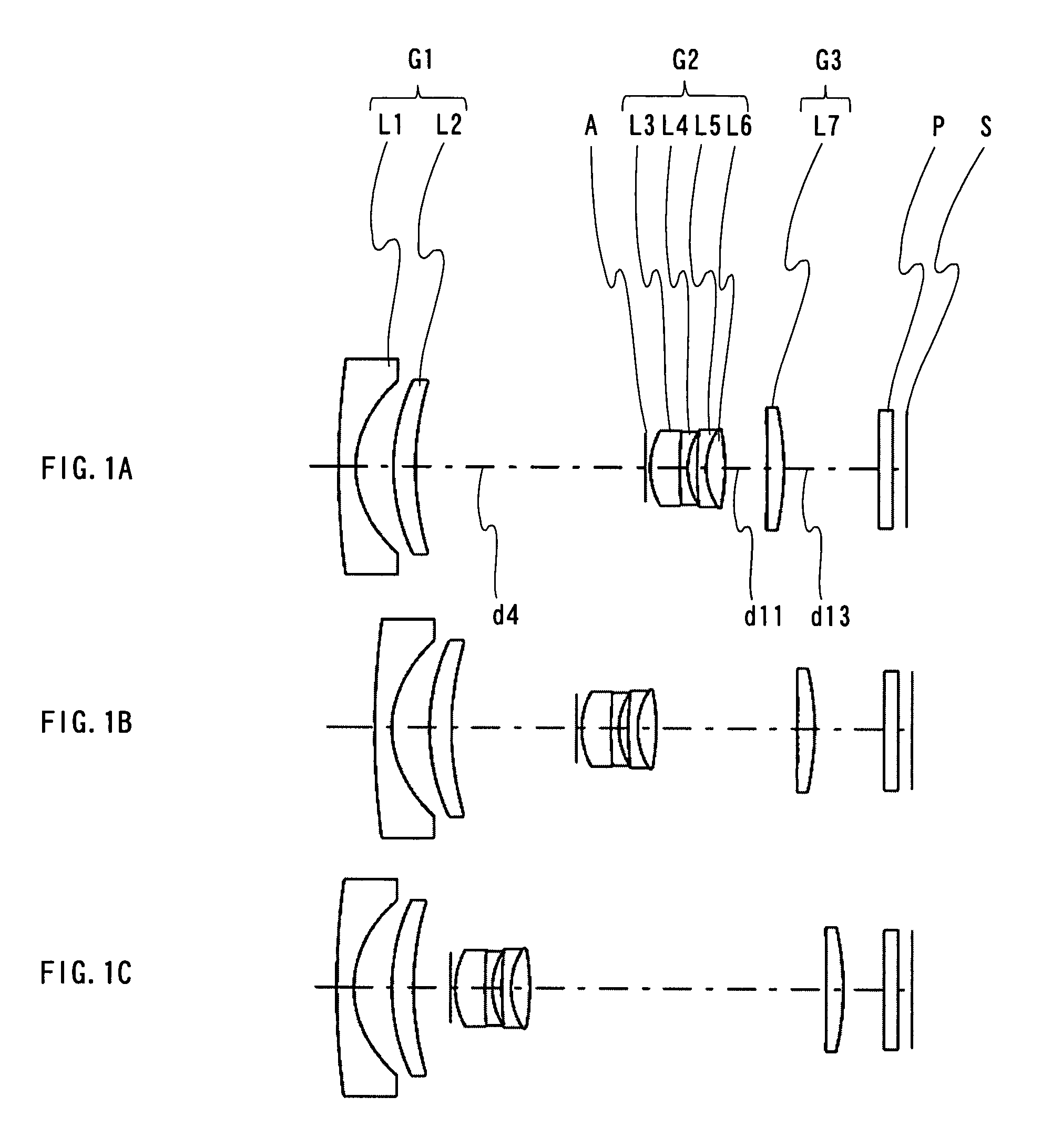

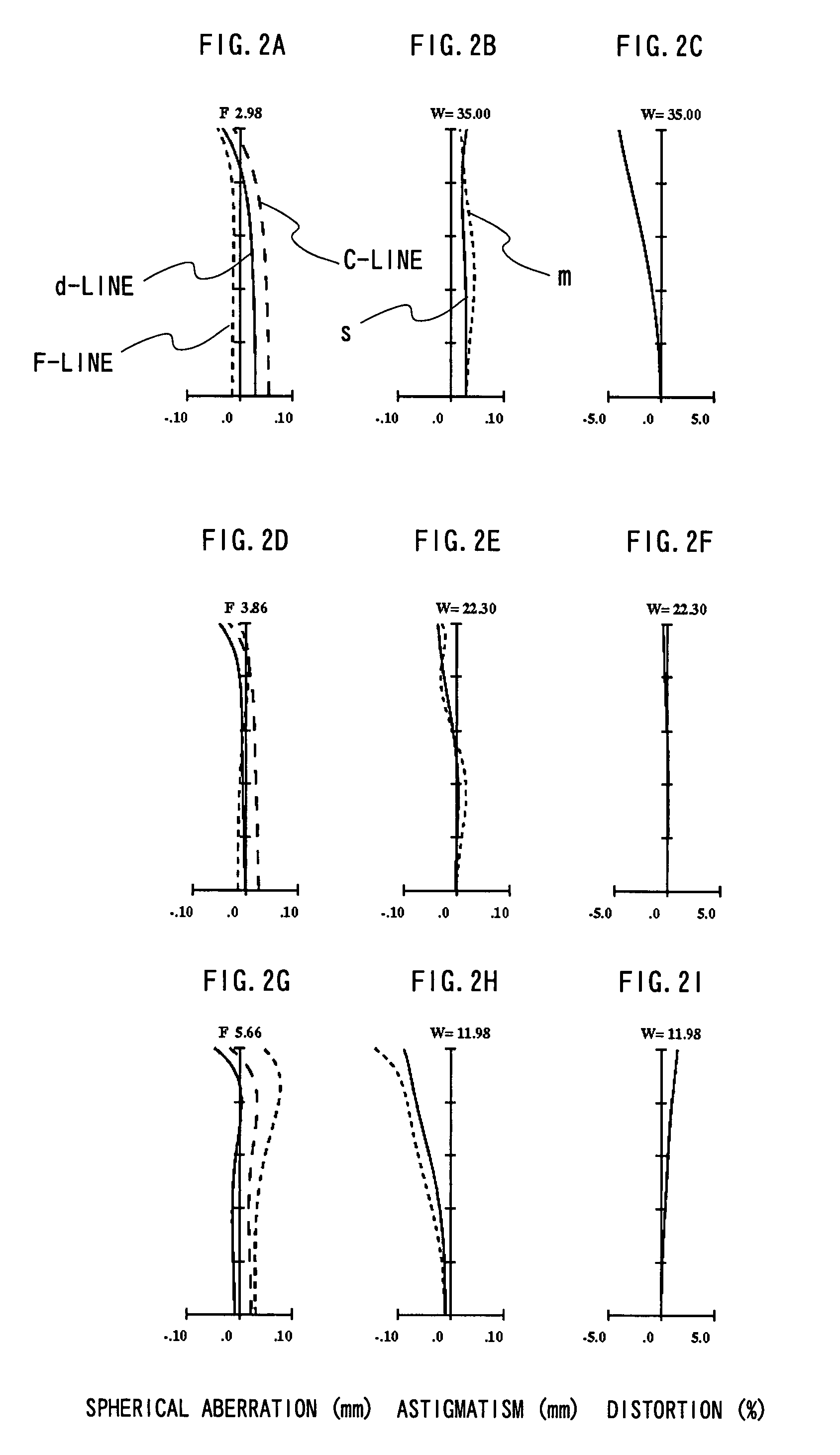

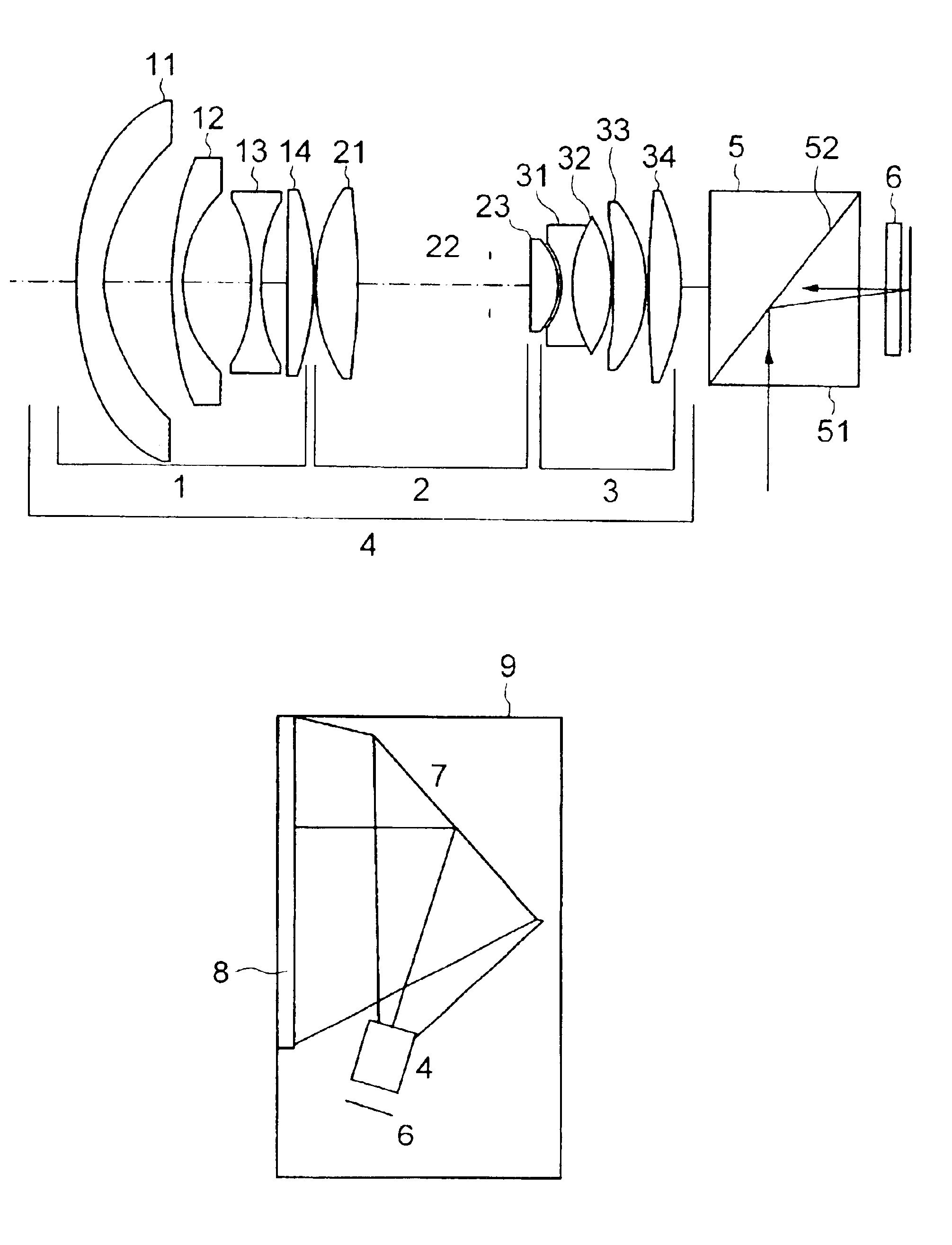

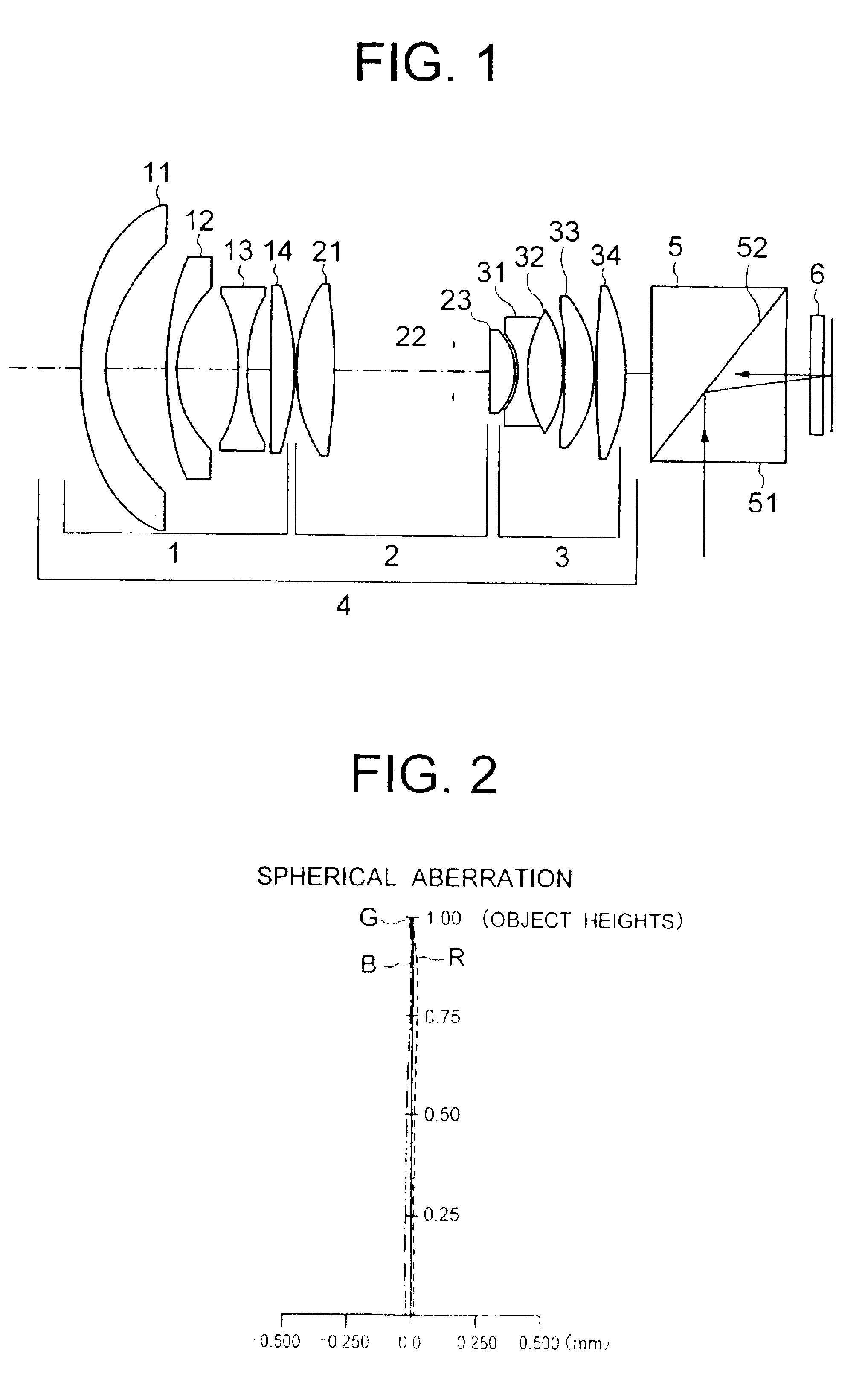

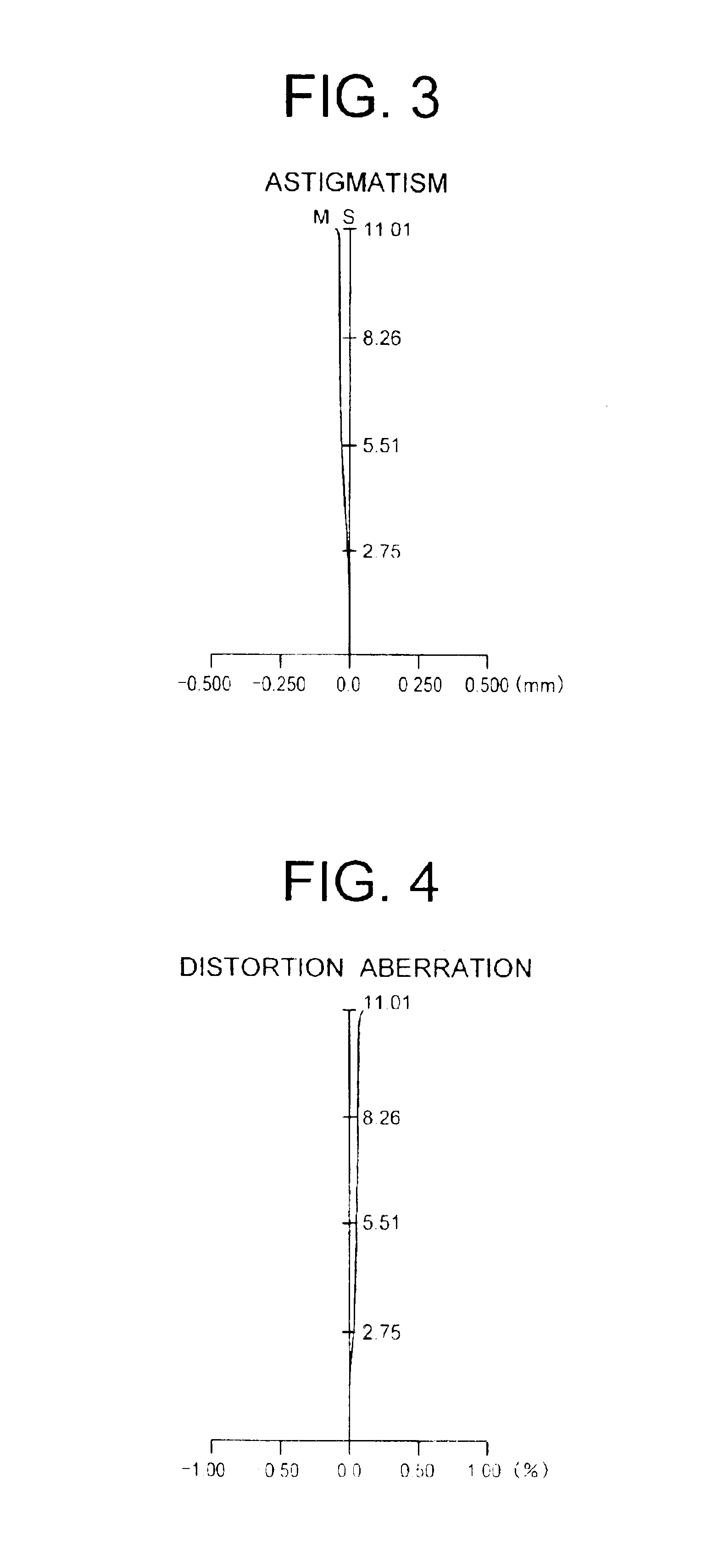

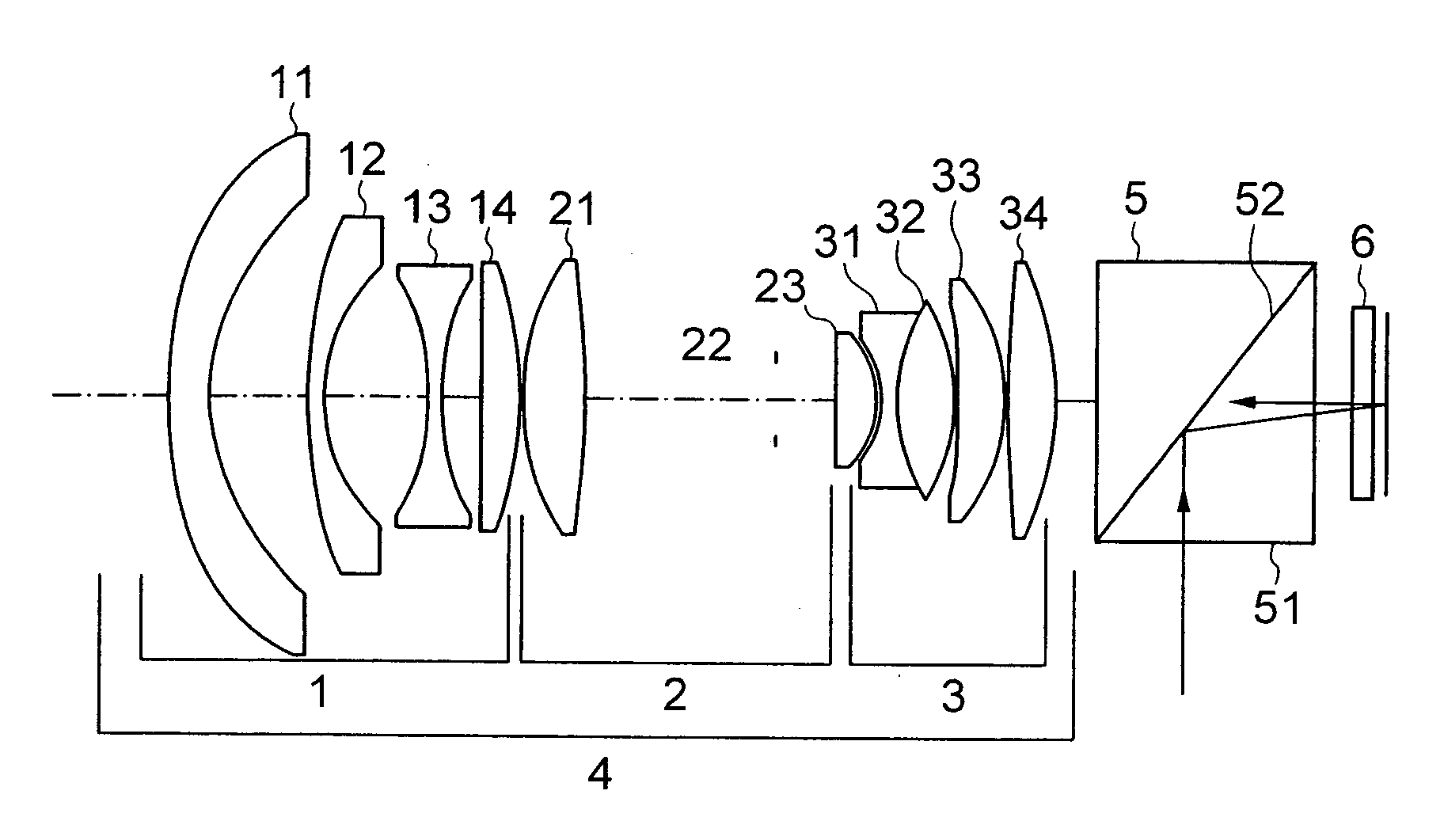

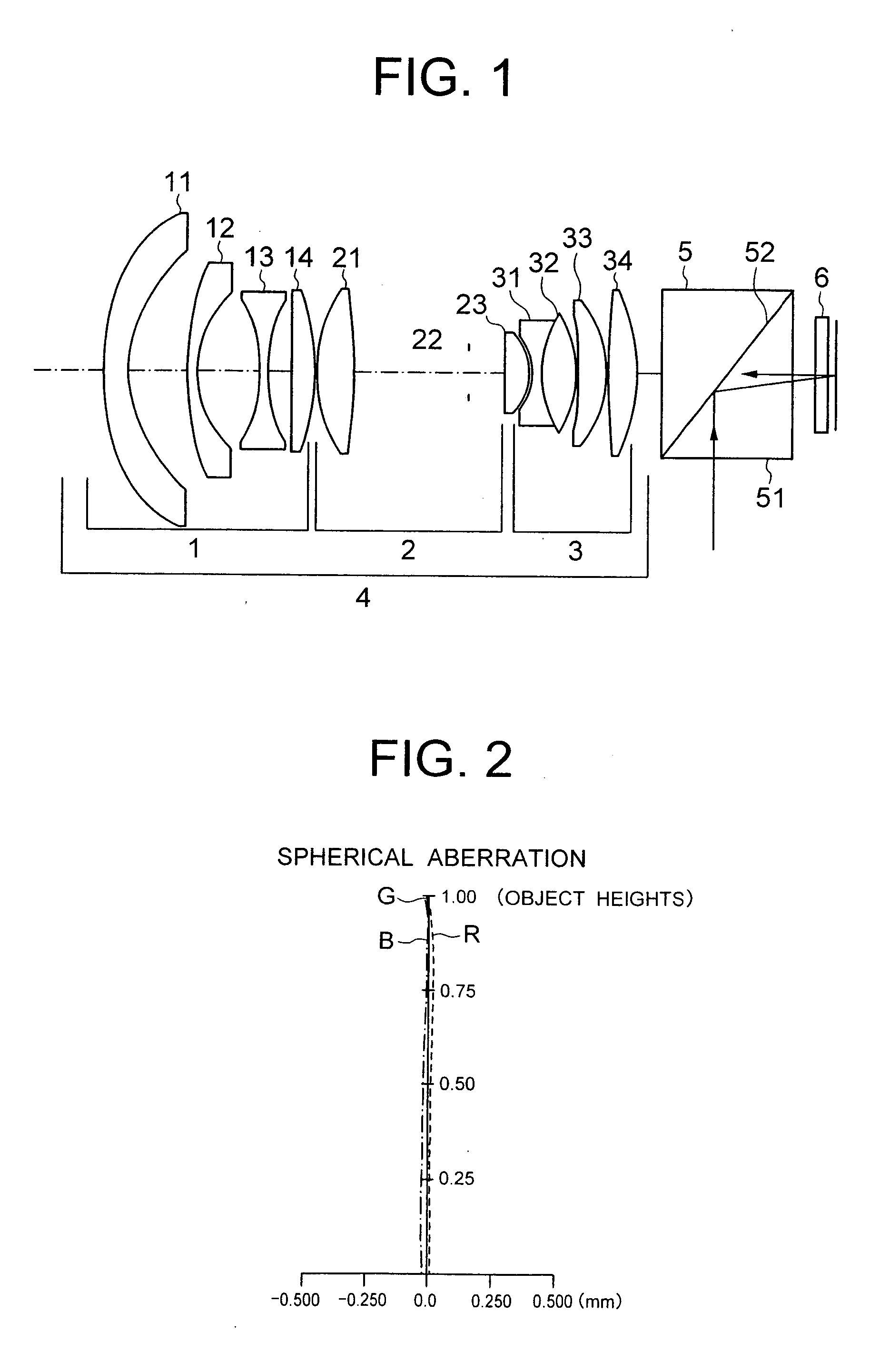

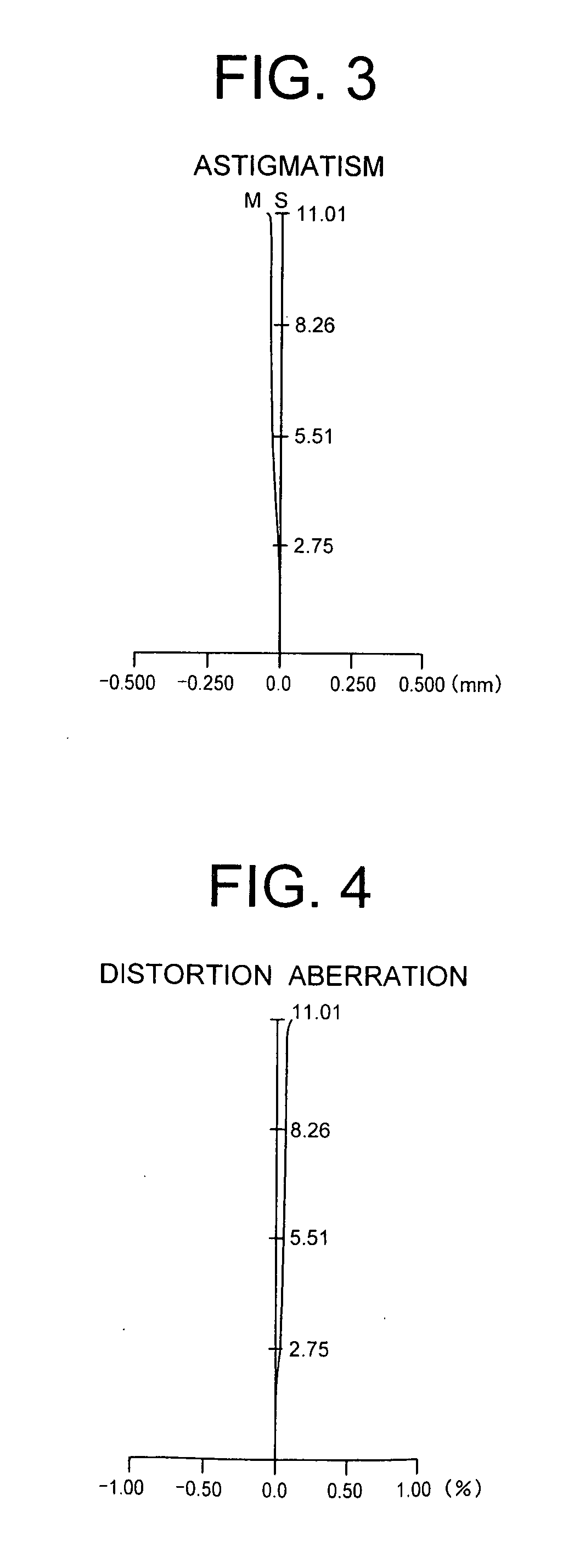

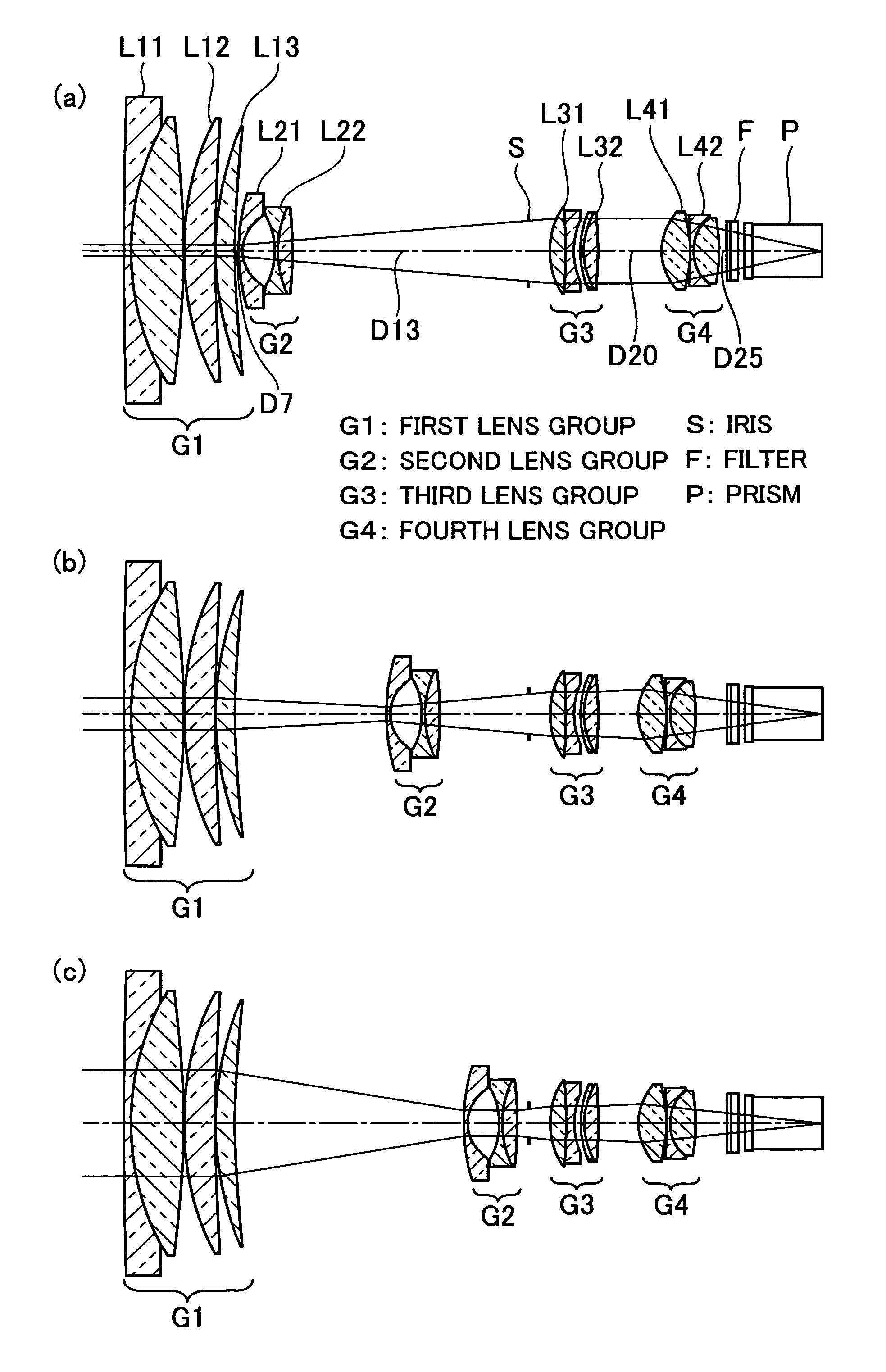

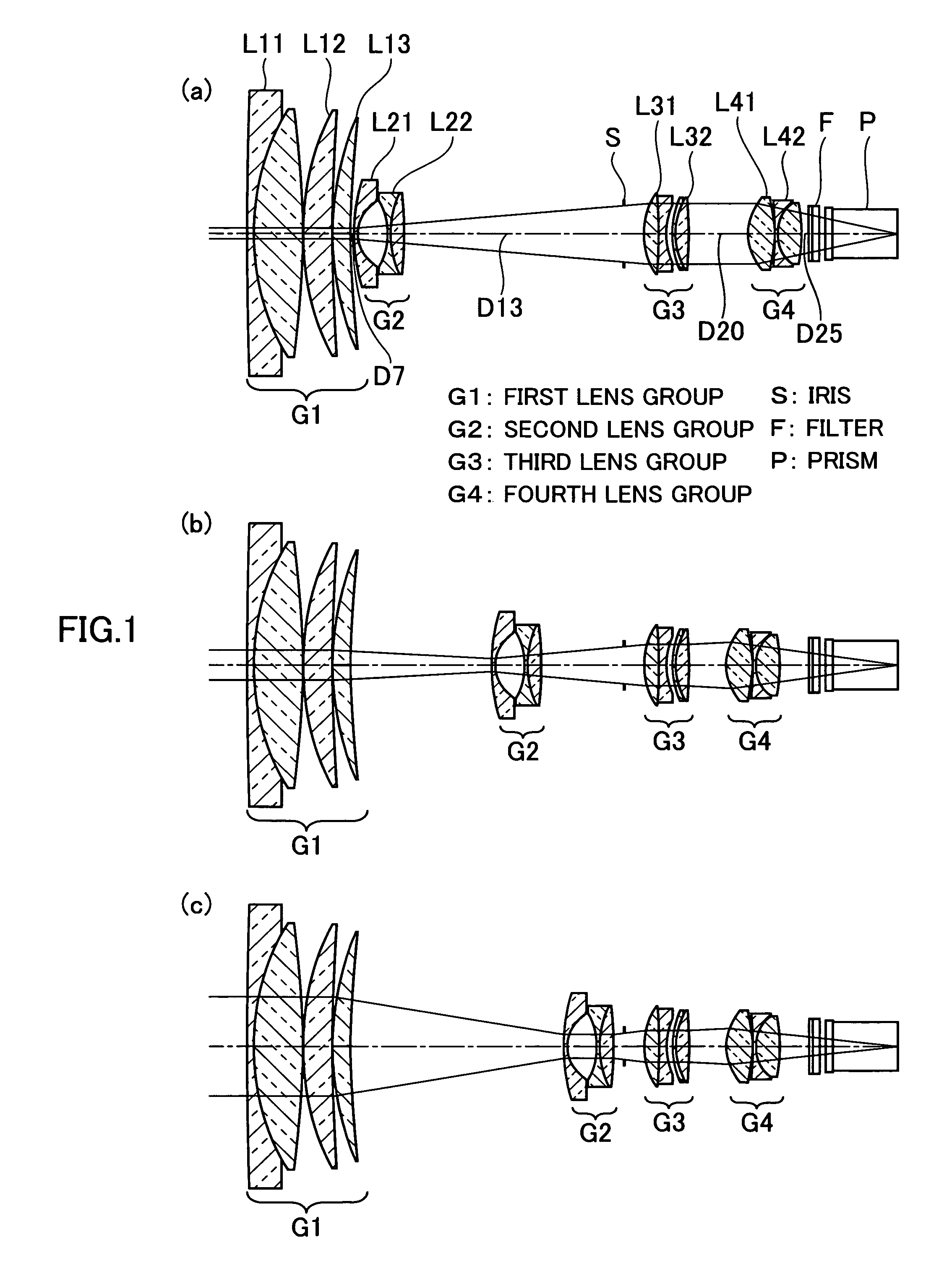

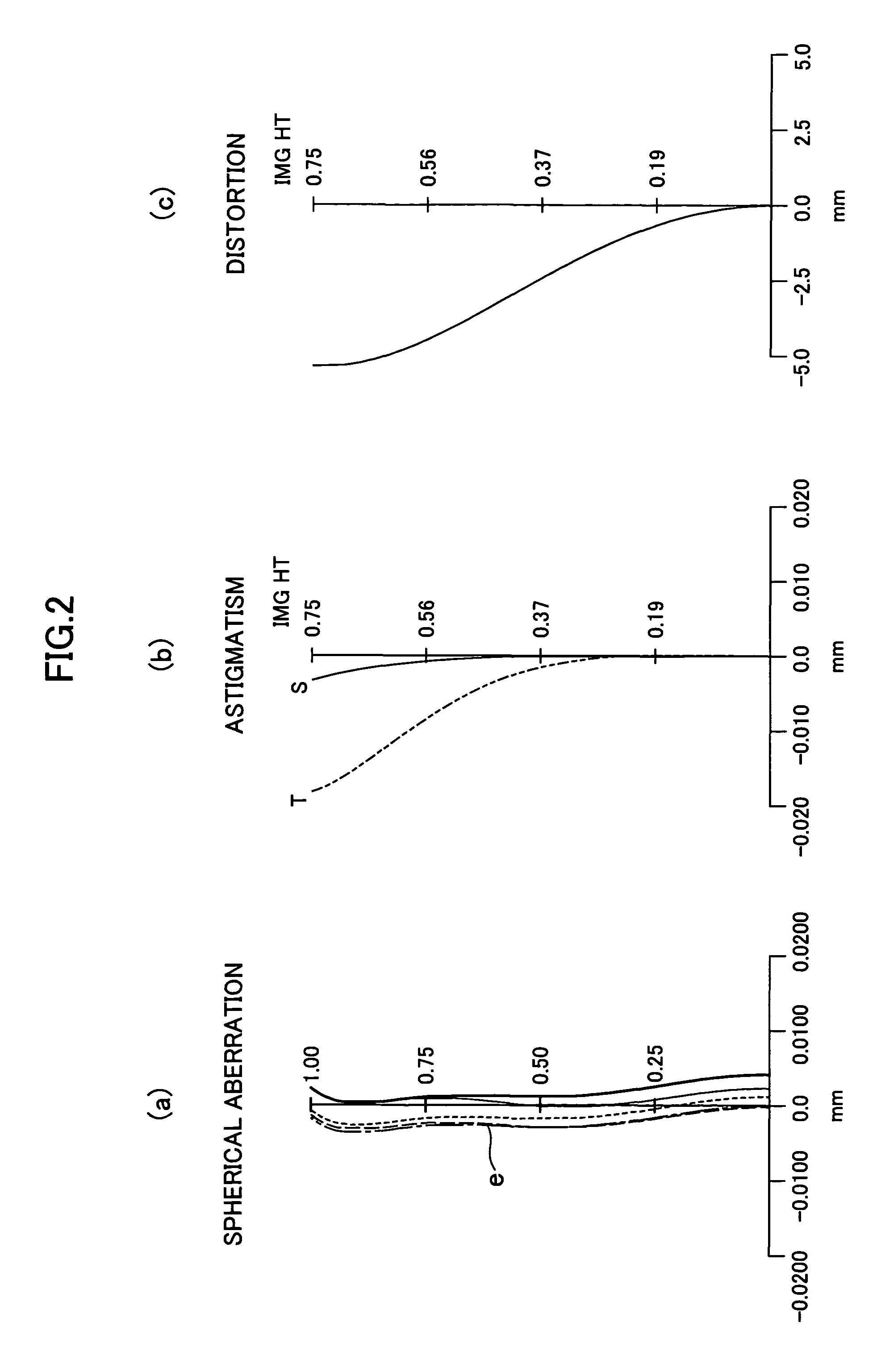

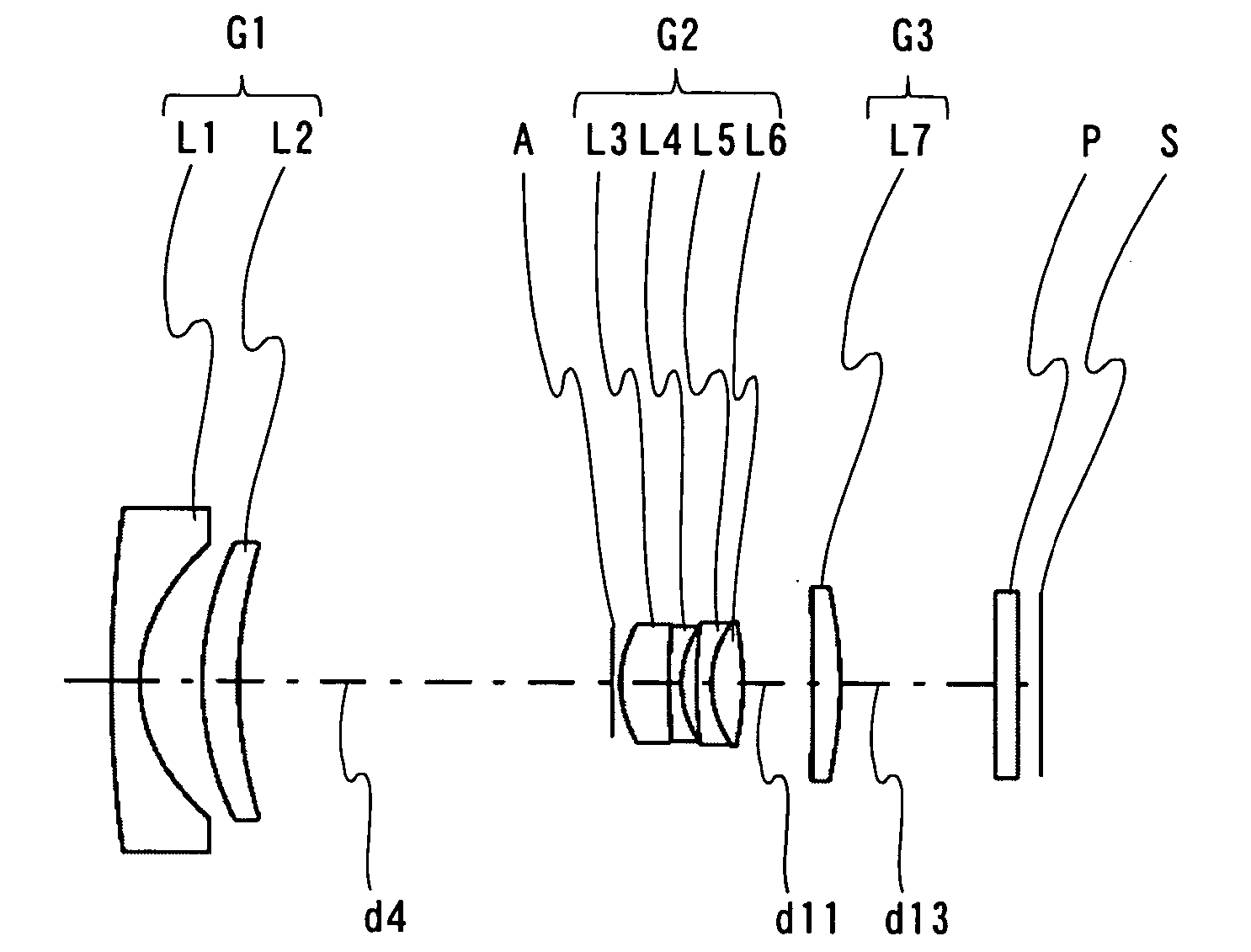

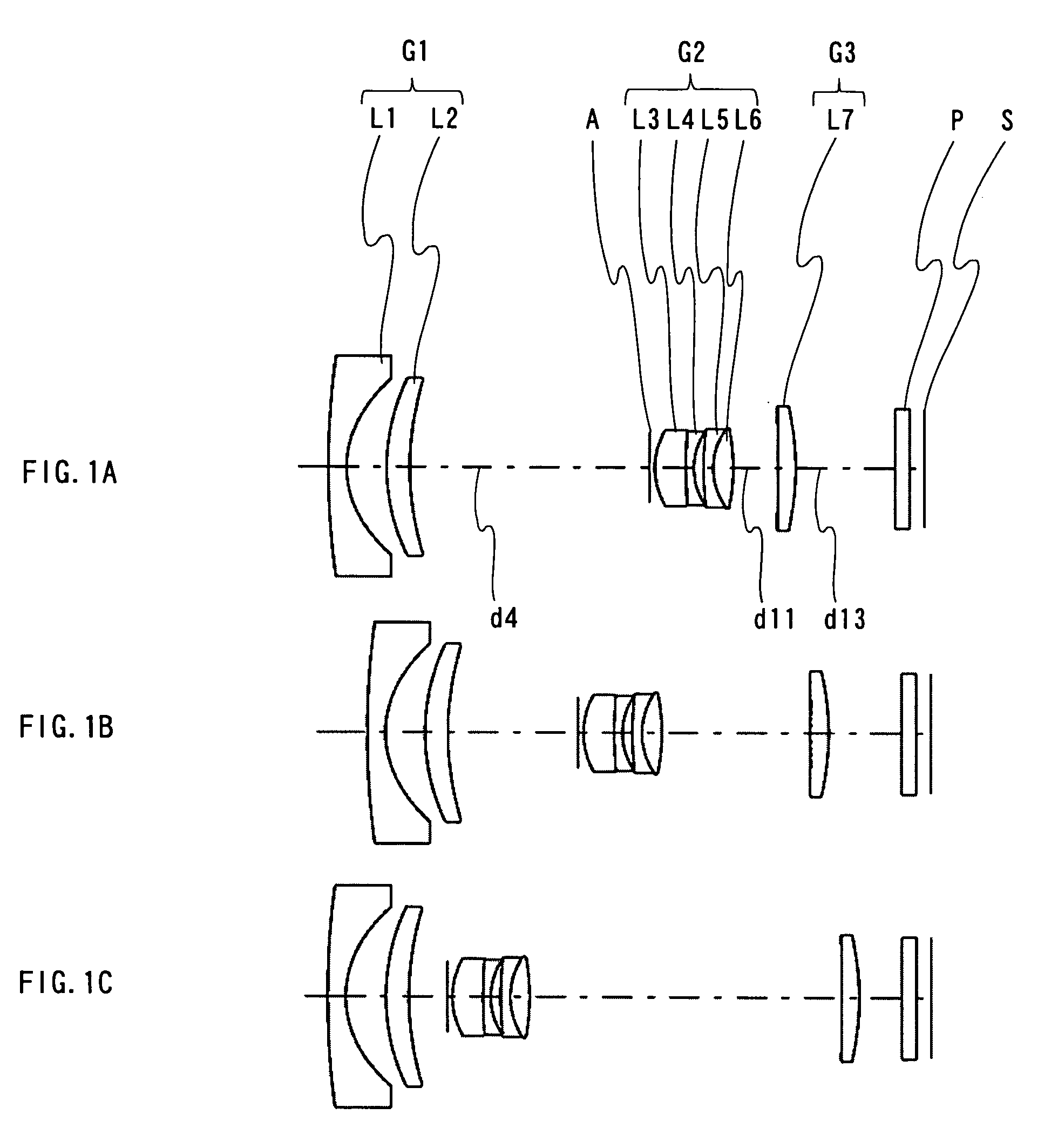

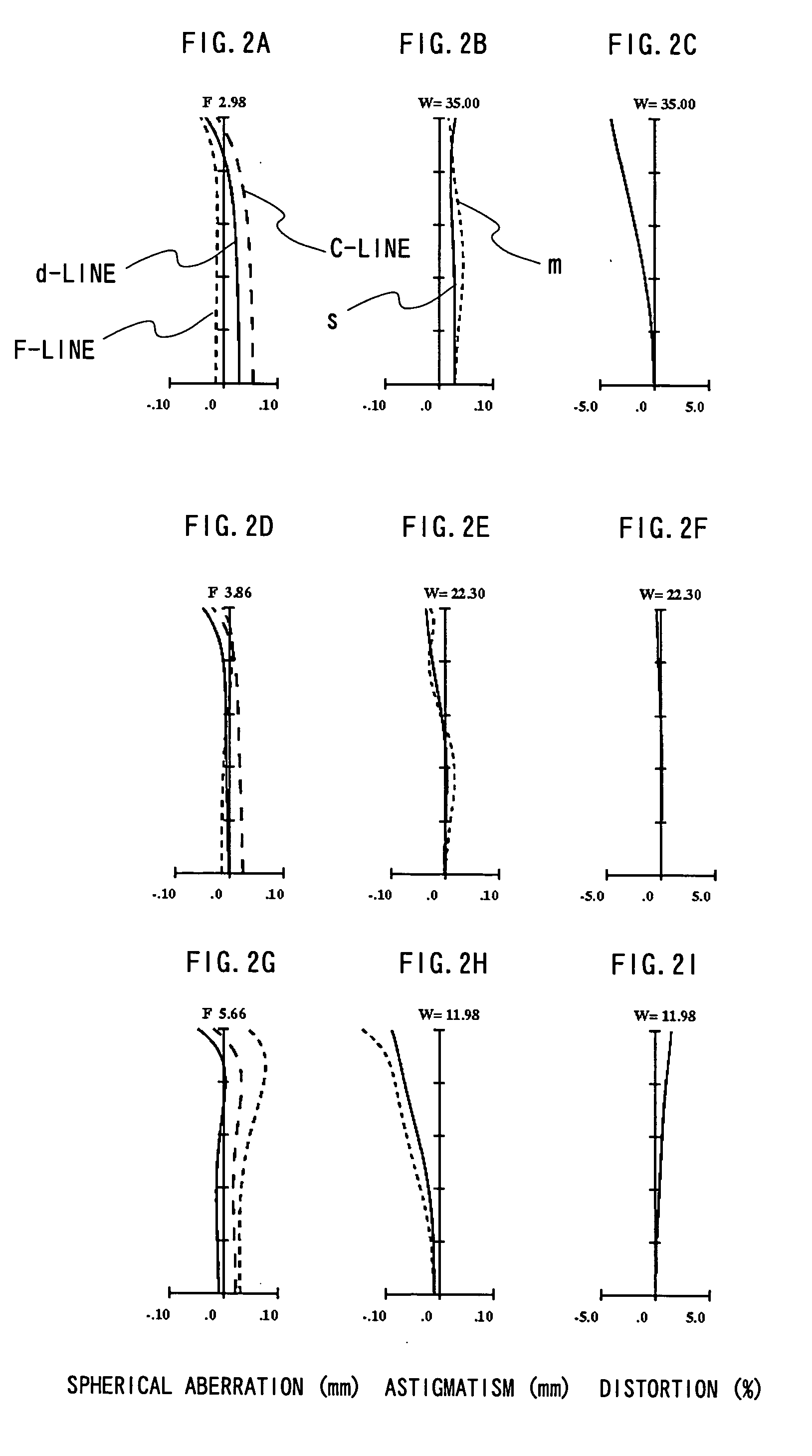

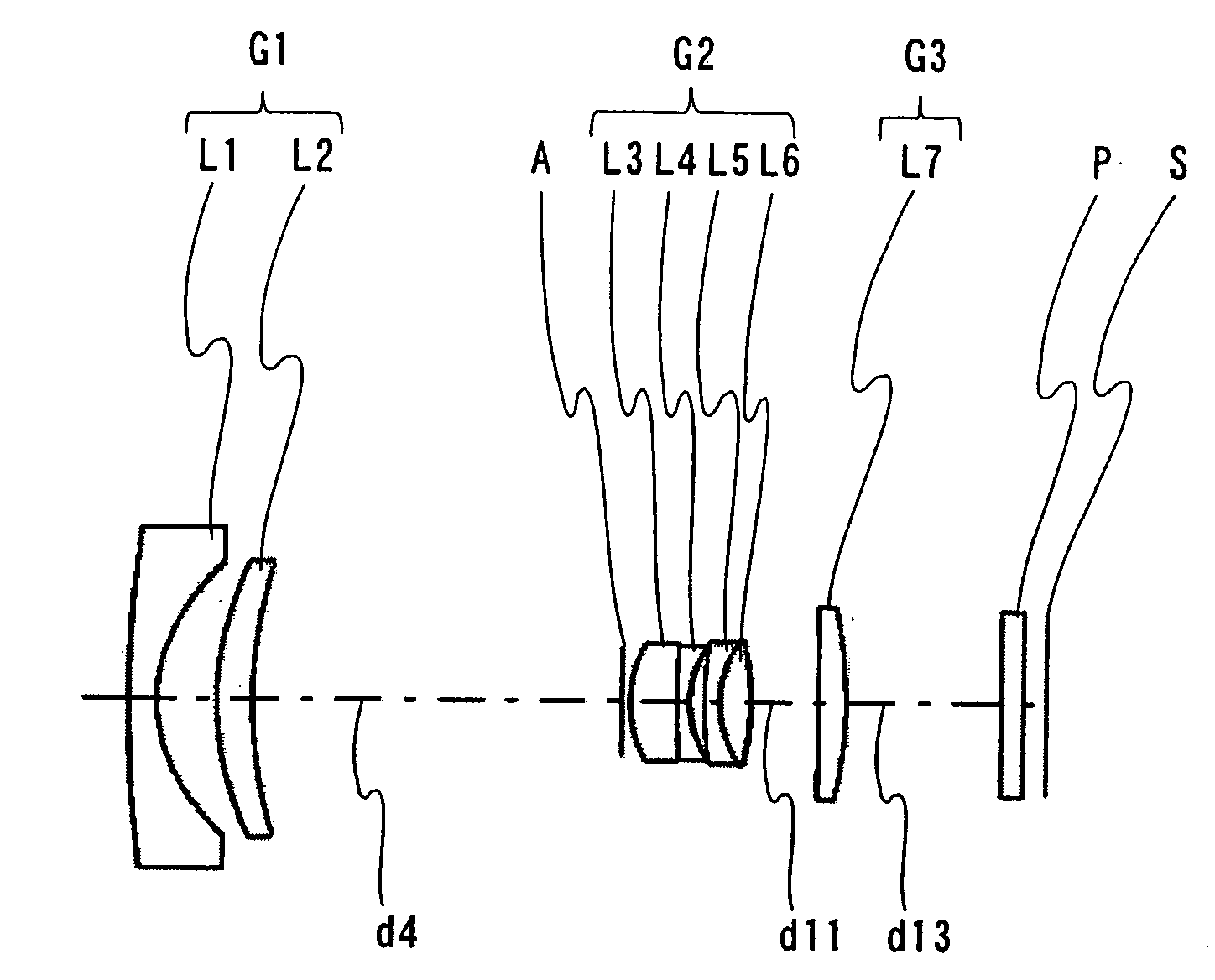

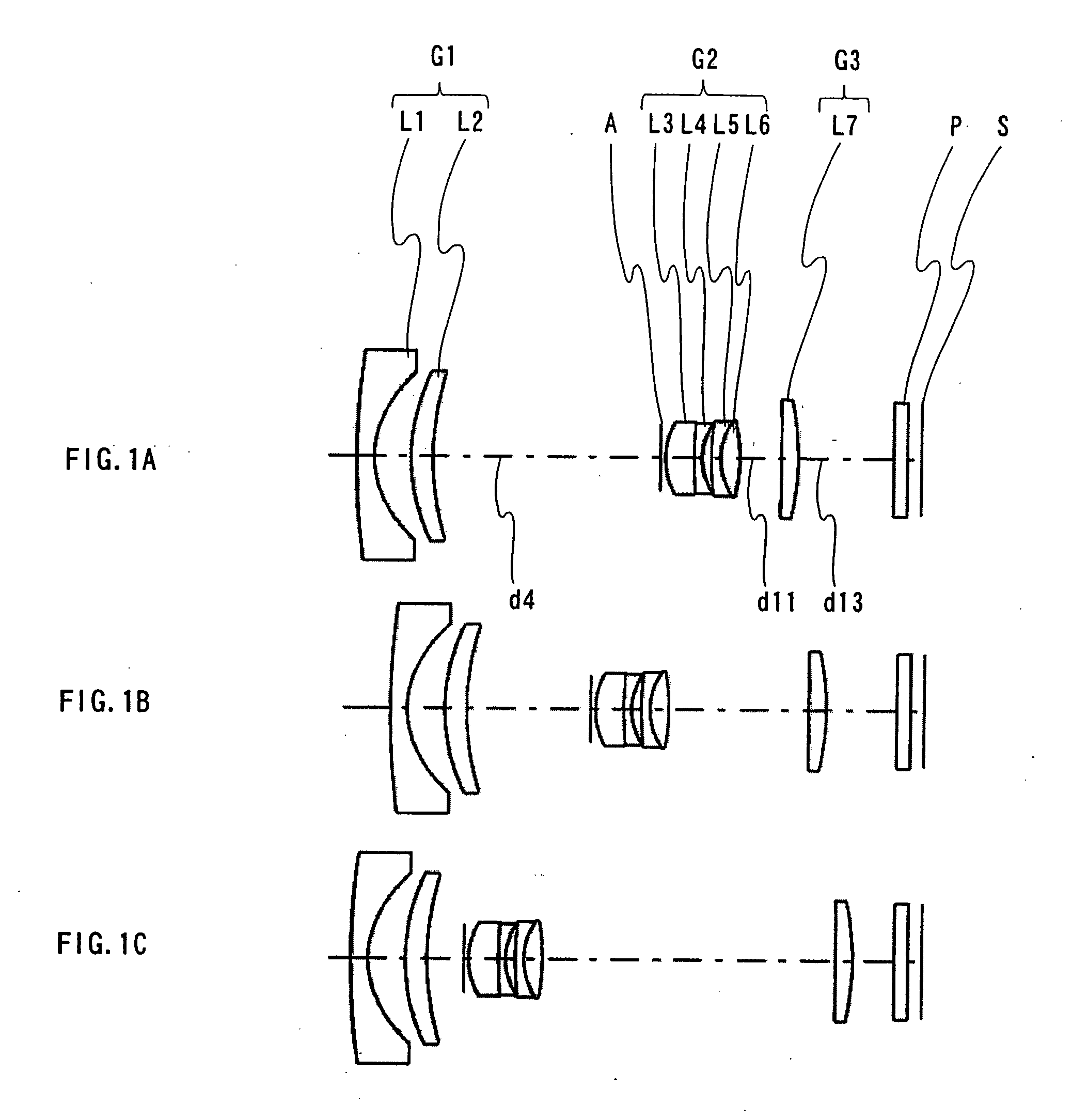

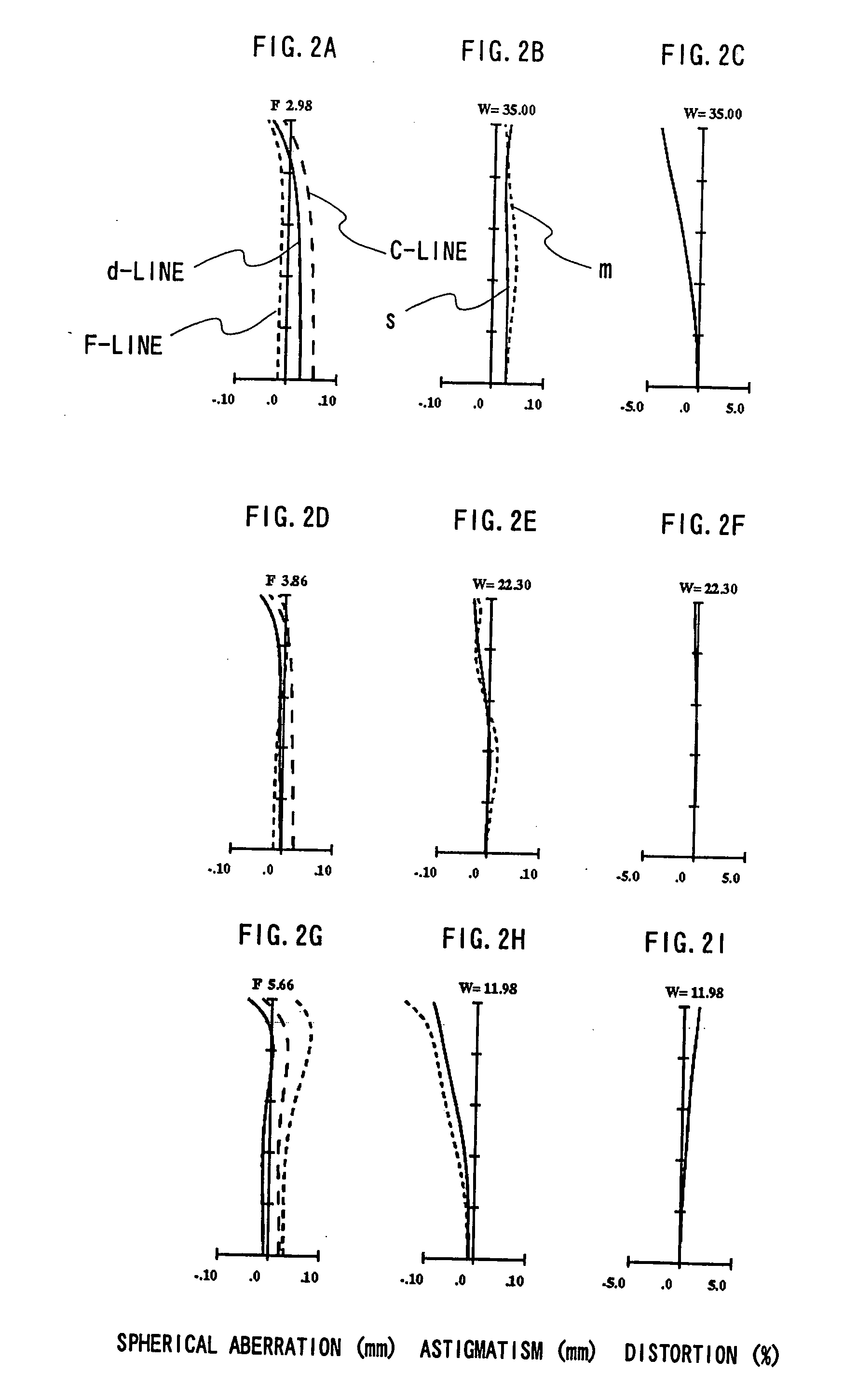

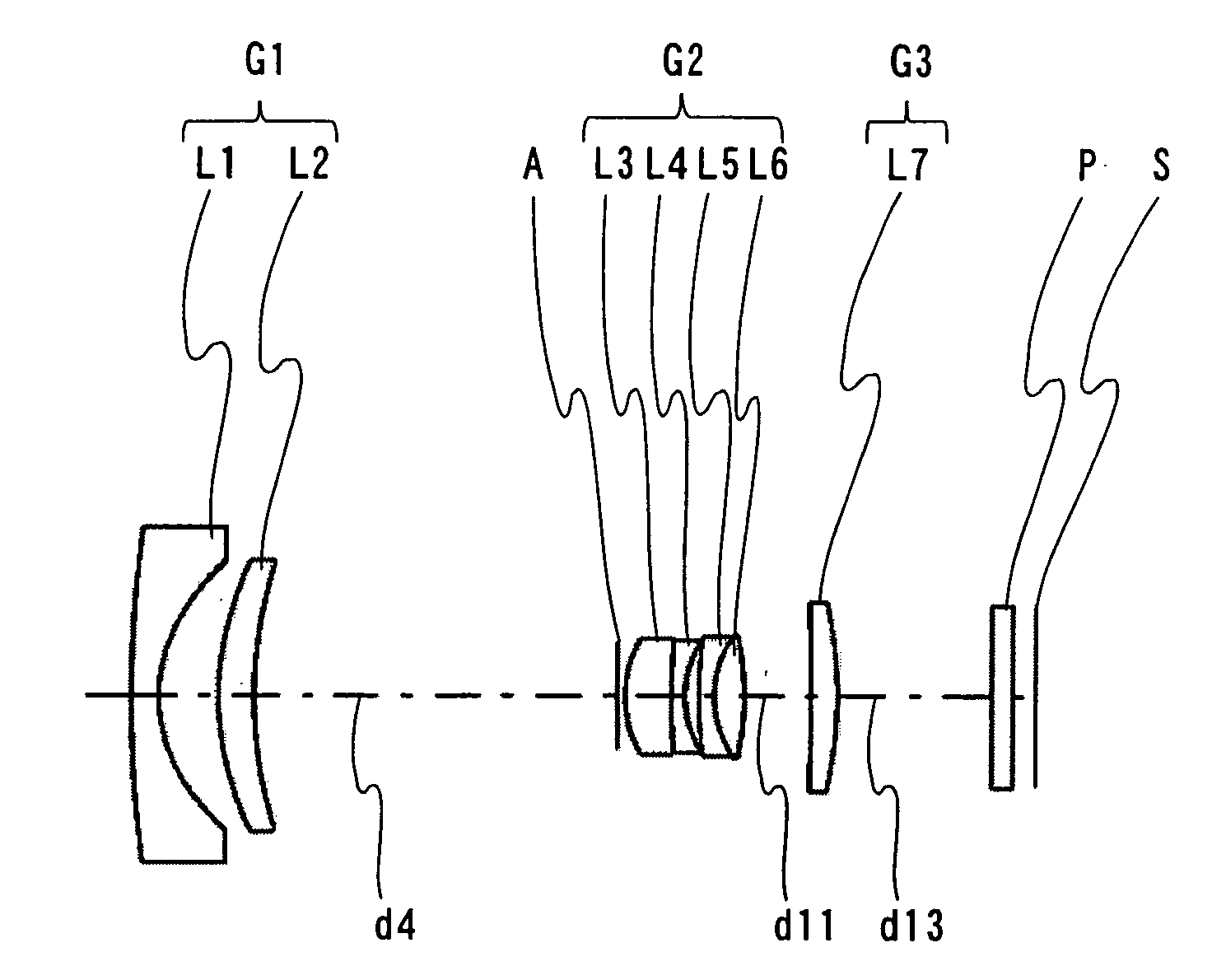

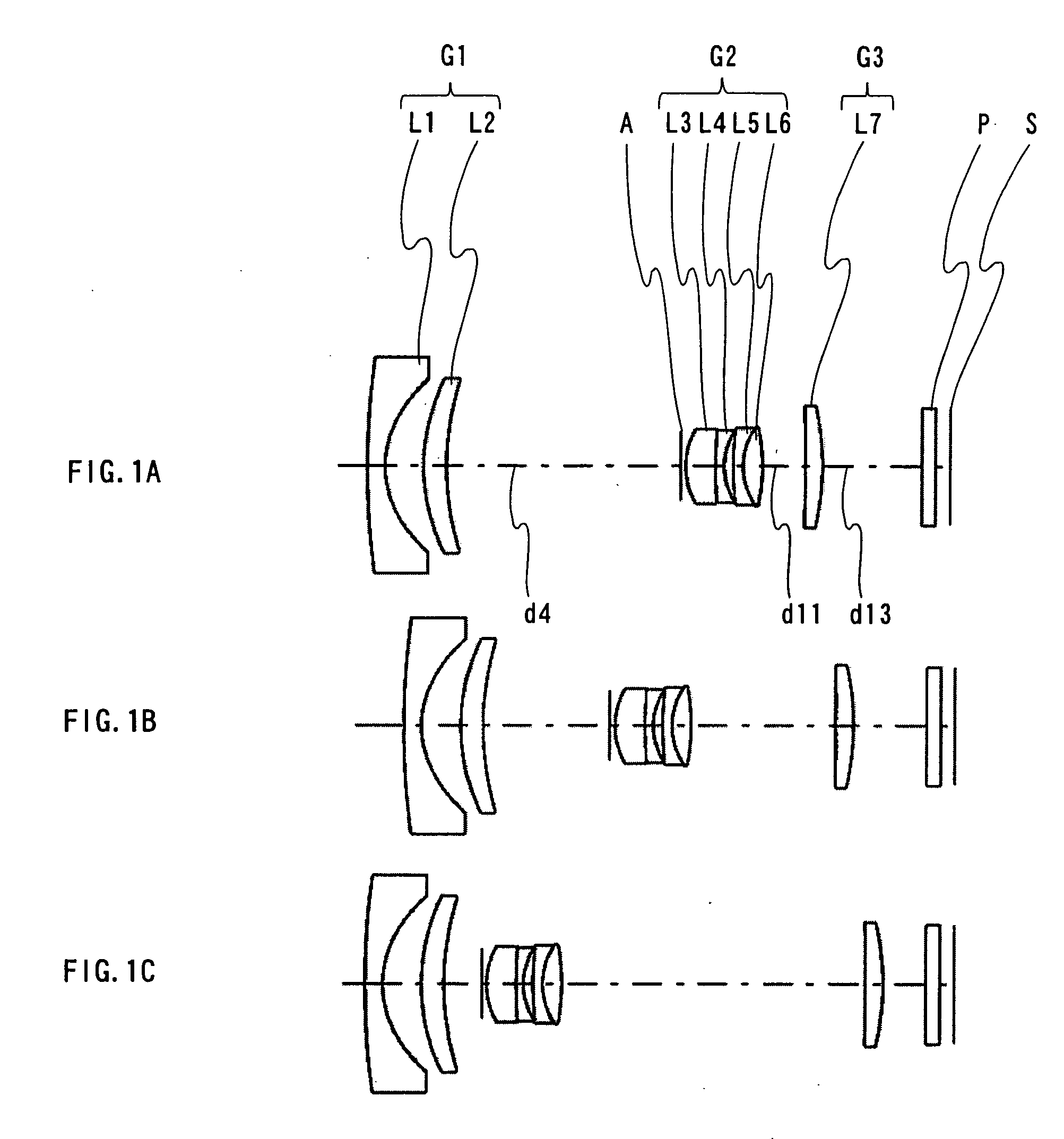

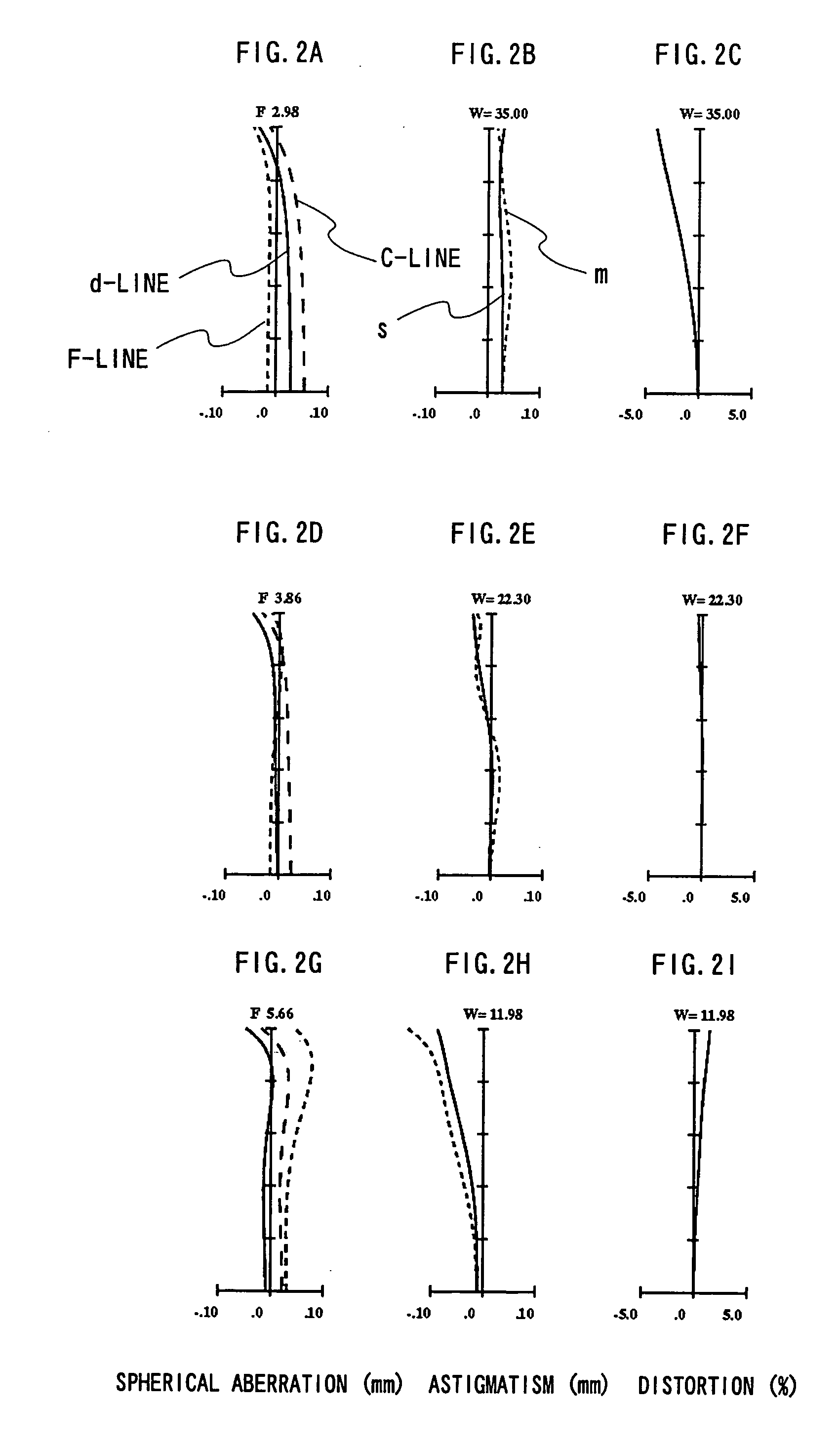

Zoom lens system, imaging device and camera

InactiveUS7310191B2High resolutionSufficient periphery illuminanceOptical elementsOptical axisNegative power

A zoom lens system comprising a first lens unit of negative power, a second lens unit of positive power and a third lens unit of positive power, wherein in zooming, the lens units move respectively along an optical axis so that an interval of first lens unit and second lens unit decreases while an interval of second lens unit and third lens unit changes with variable magnification, the first lens unit comprises one object side negative lens element and one image side positive lens element, which have an aspheric surface, and the conditions: n12>1.88, nu12<26 AND 3.0<F3 / fW<5.5 (omegaW>30, n12 and nu12 are refractive index and Abbe number, respectively, of the image side positive lens element of the first lens unit, f3 is a composite focal length of the third lens unit, fW is a focal length of the entire zoom lens system at a wide-angle limit) are satisfied.

Owner:PANASONIC CORP

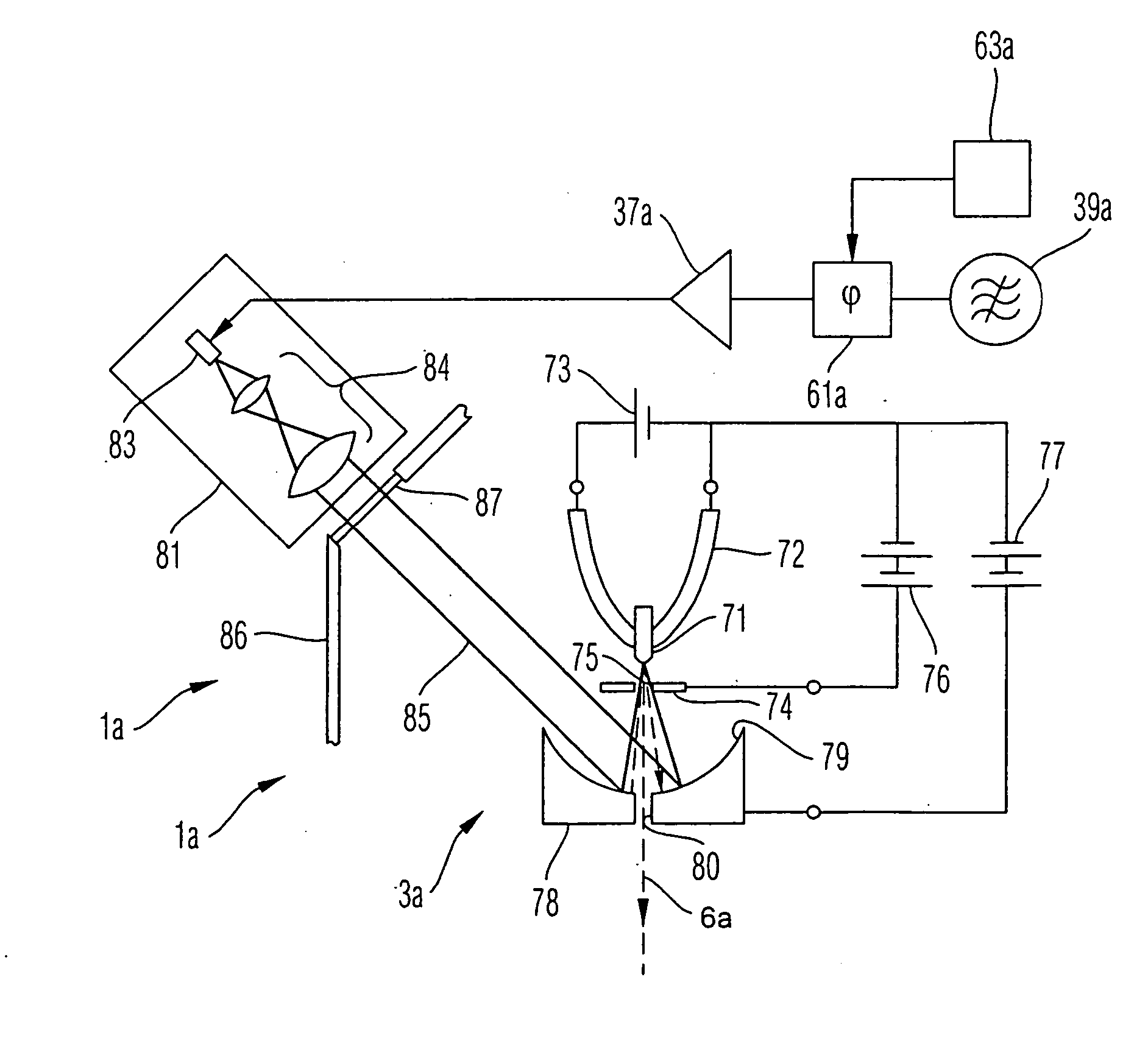

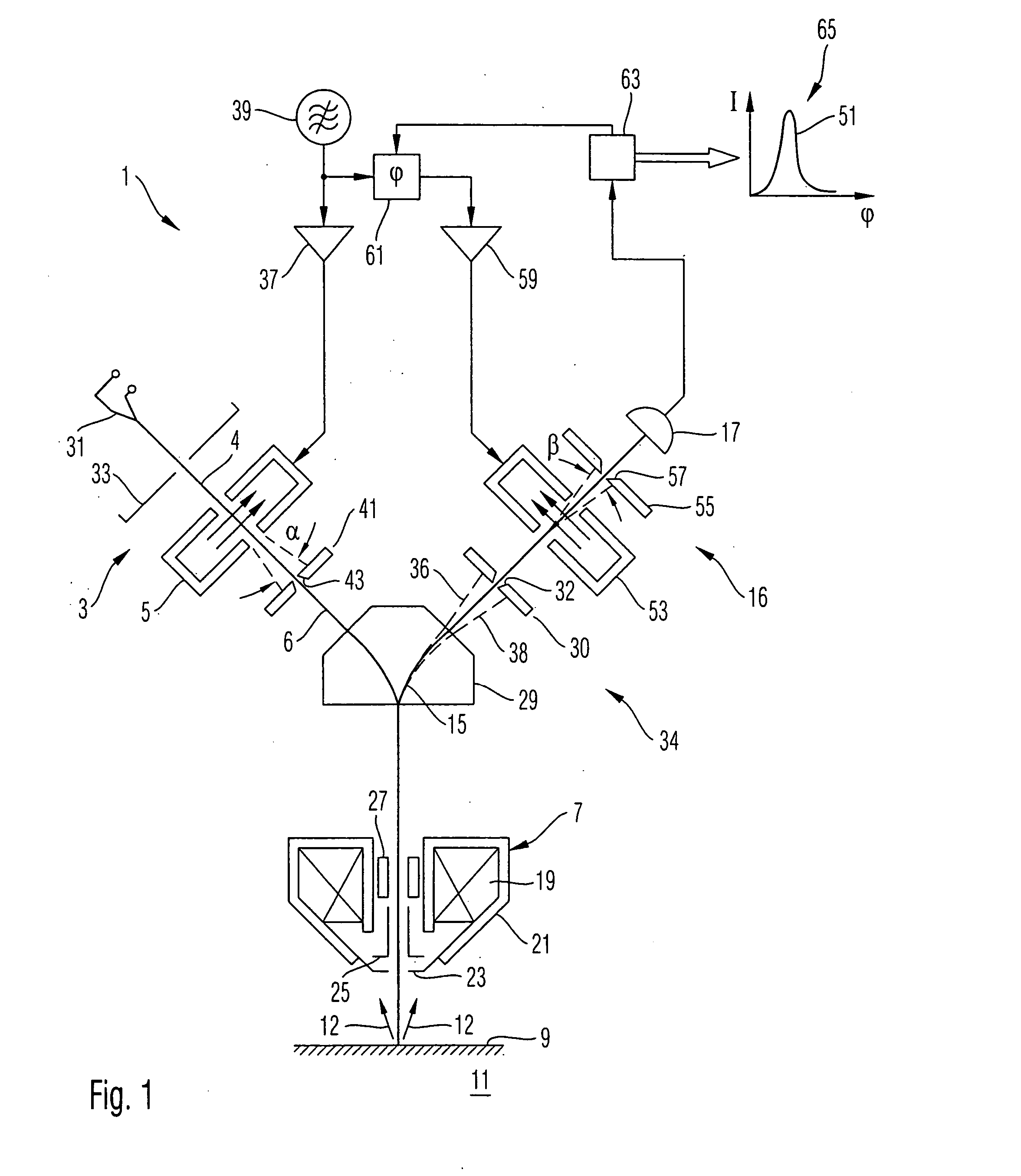

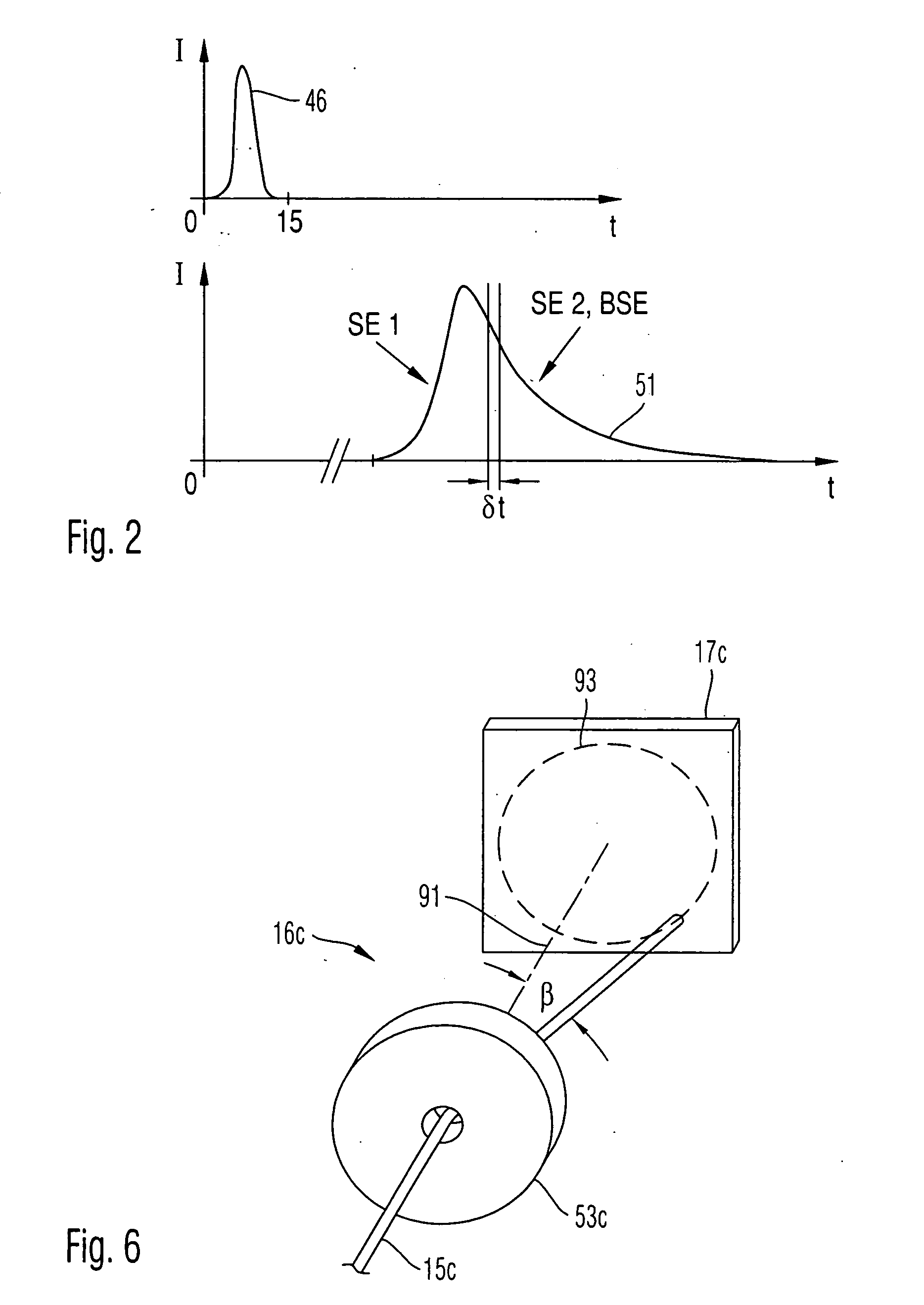

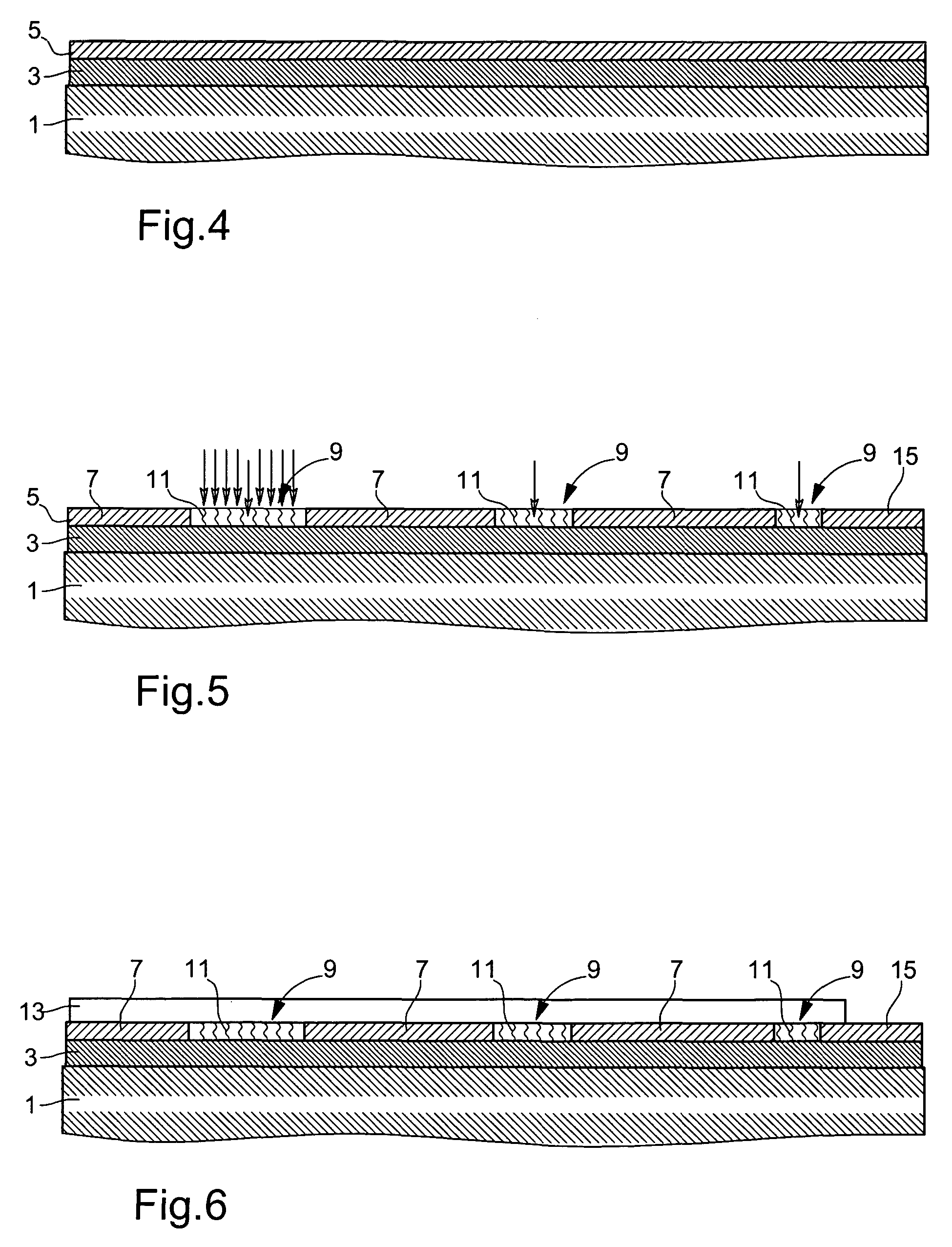

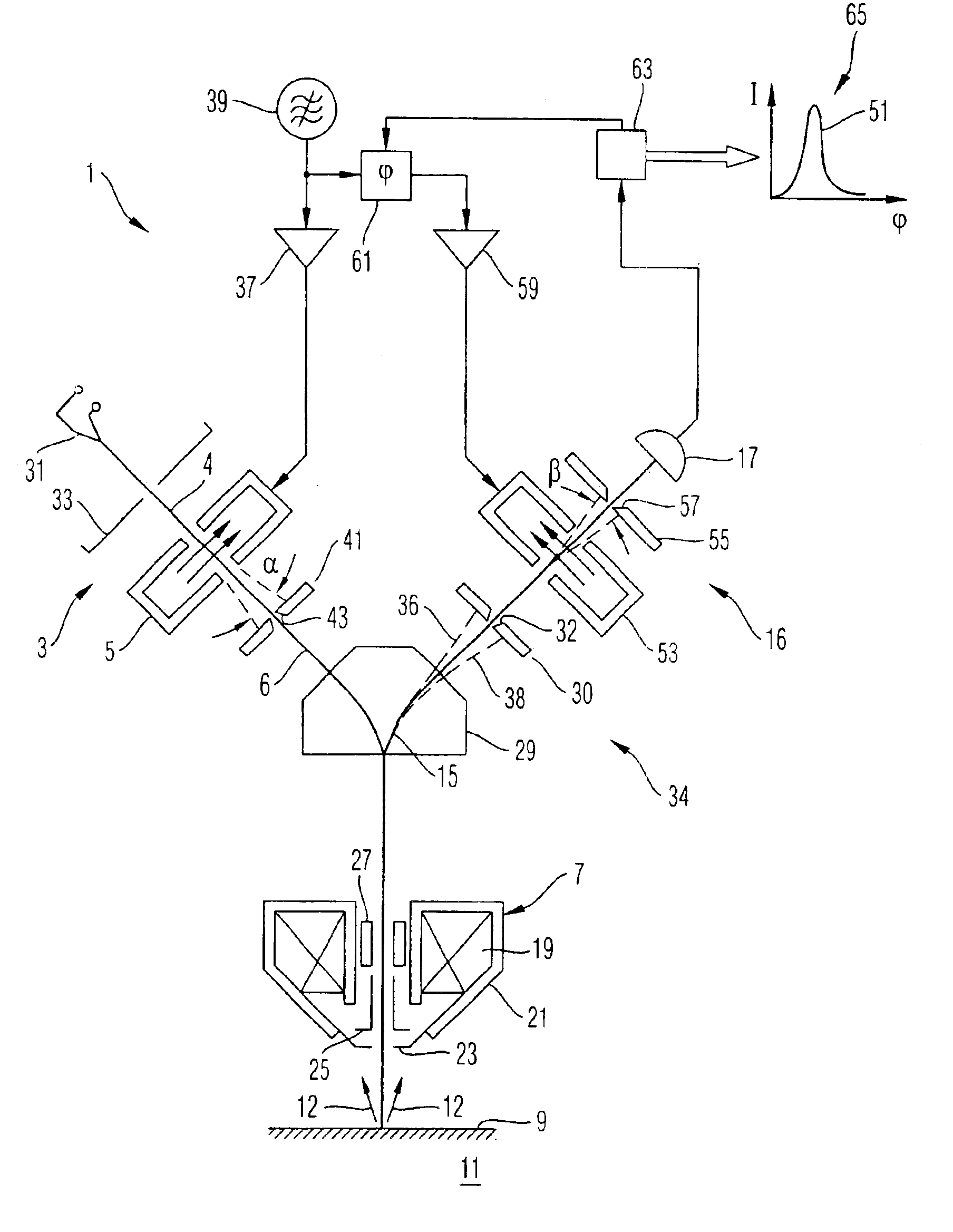

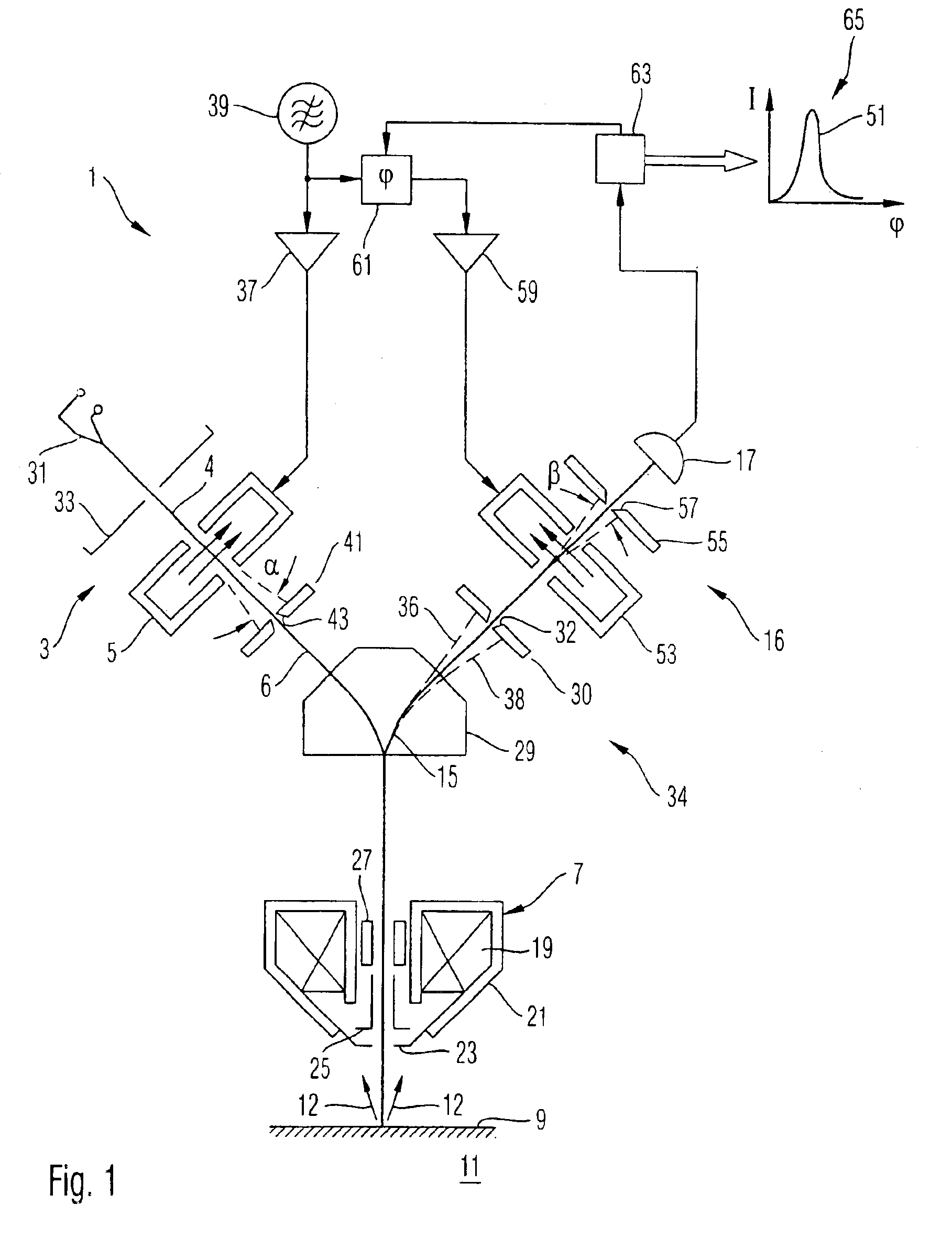

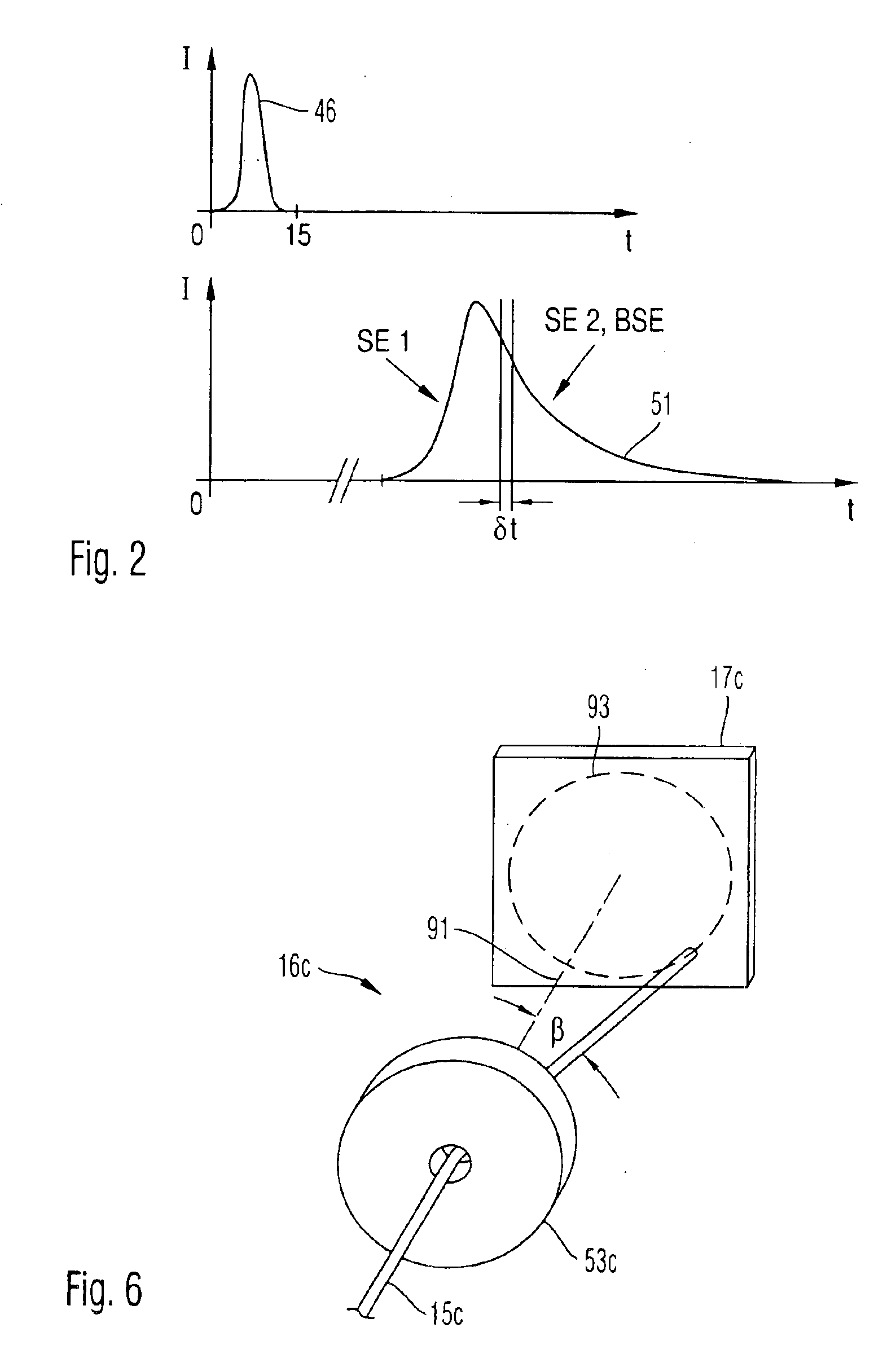

Electron microscopy system, electron microscopy method and focusing system for charged particles

ActiveUS20050006582A1Fast influenceImprove time resolutionThermometer detailsMaterial analysis using wave/particle radiationSecondary electronsElectron microscope

An electron microscopy system and an electron microscopy method for detection of time dependencies of secondary electrons generated by primary electrons is provided, in which the primary electron pulses are directed onto a sample surface and electrons emanating from the sample surface are detected, time resolved. To this end the system comprises in particular a cavity resonator. A cavity resonator can also be used to reduce aberrations of focusing lenses.

Owner:CARL ZEISS SMT GMBH

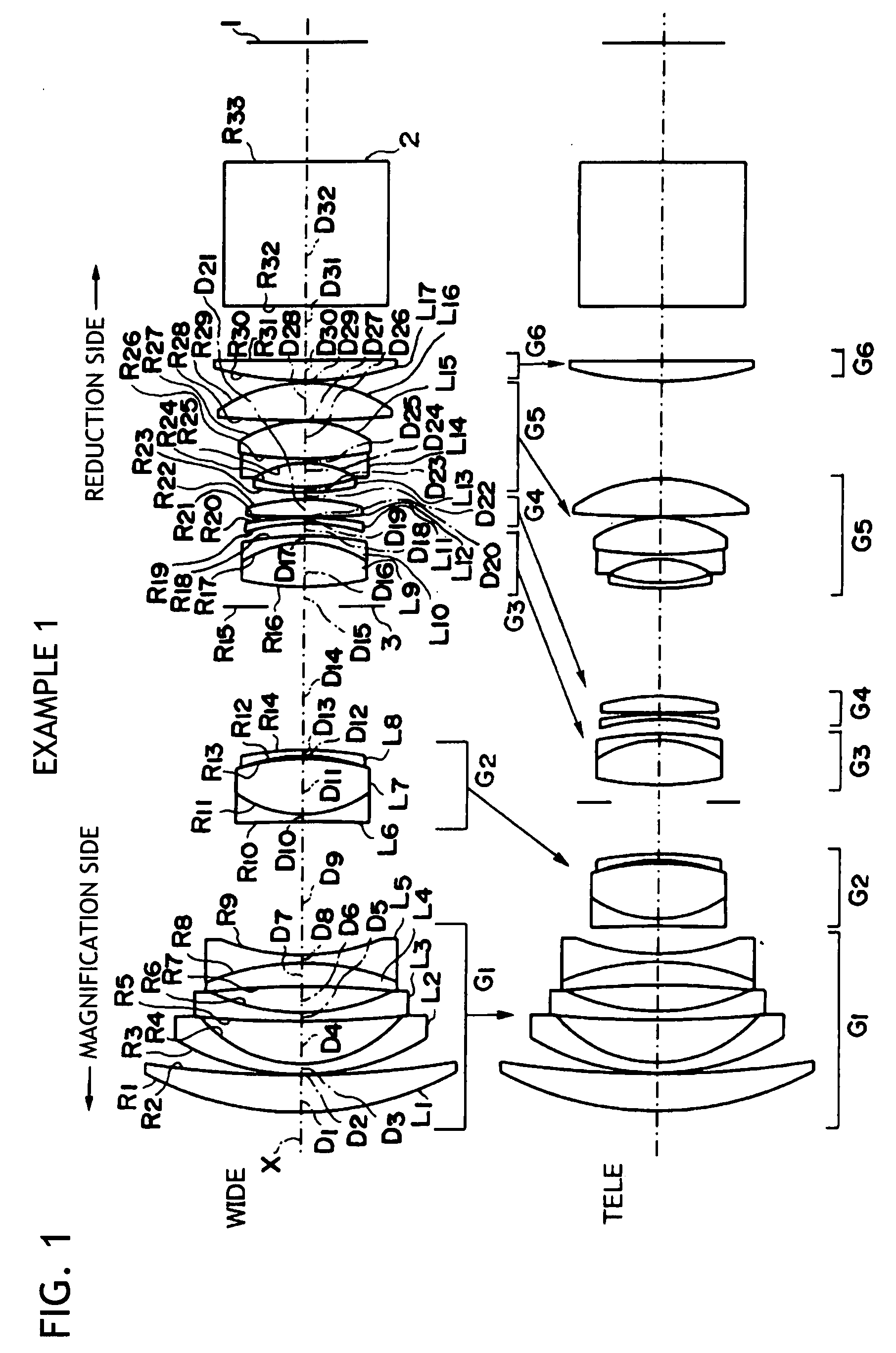

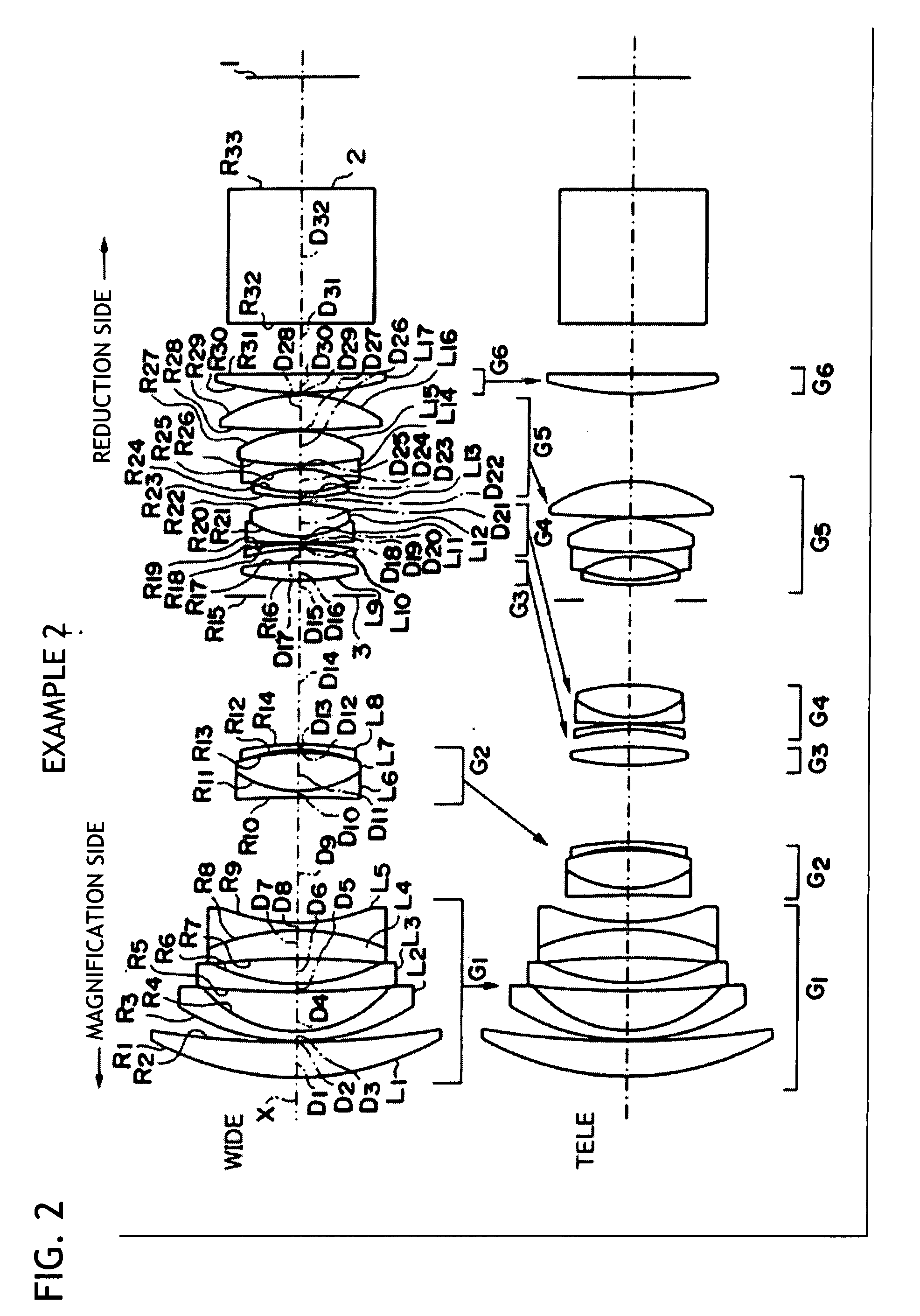

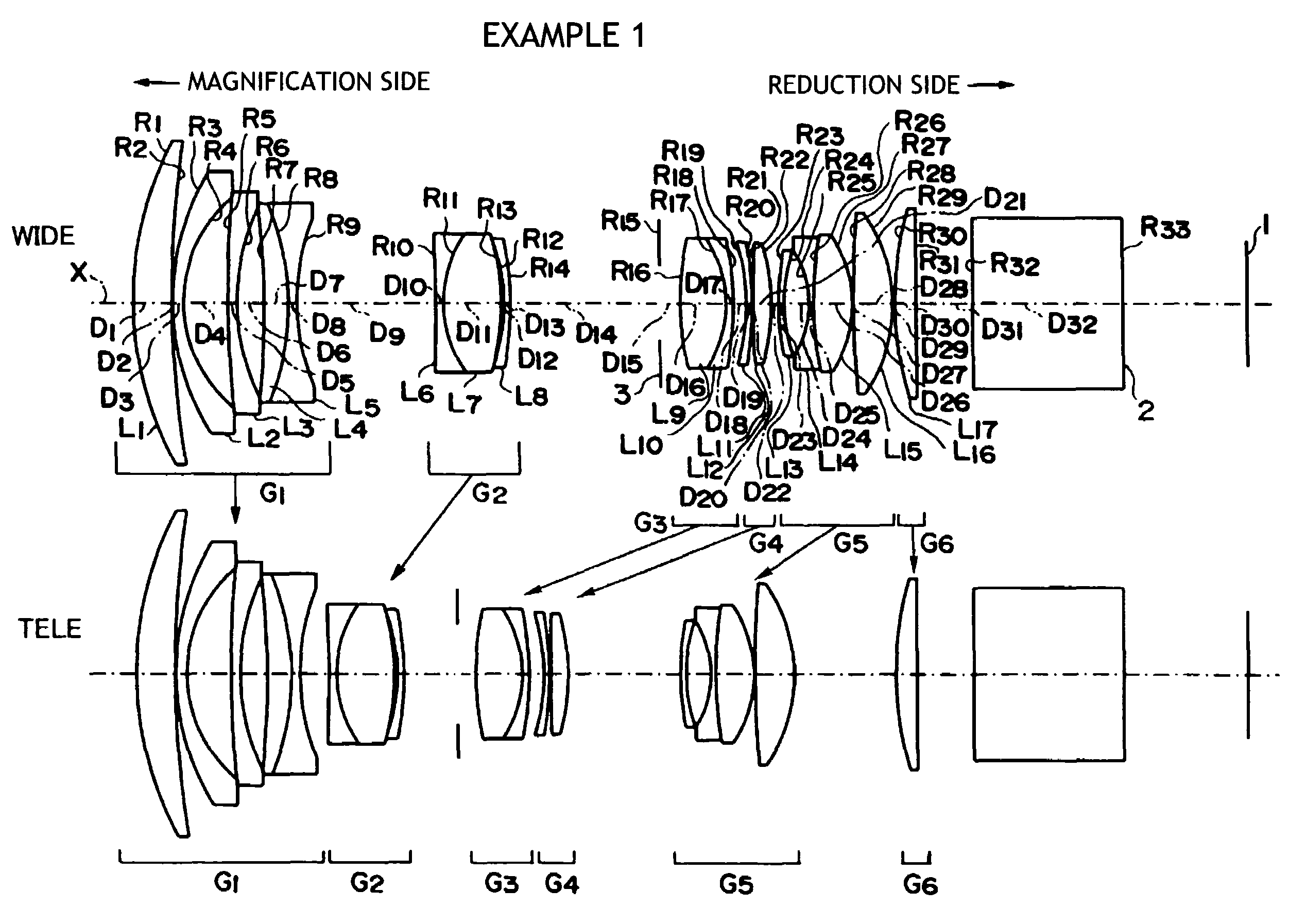

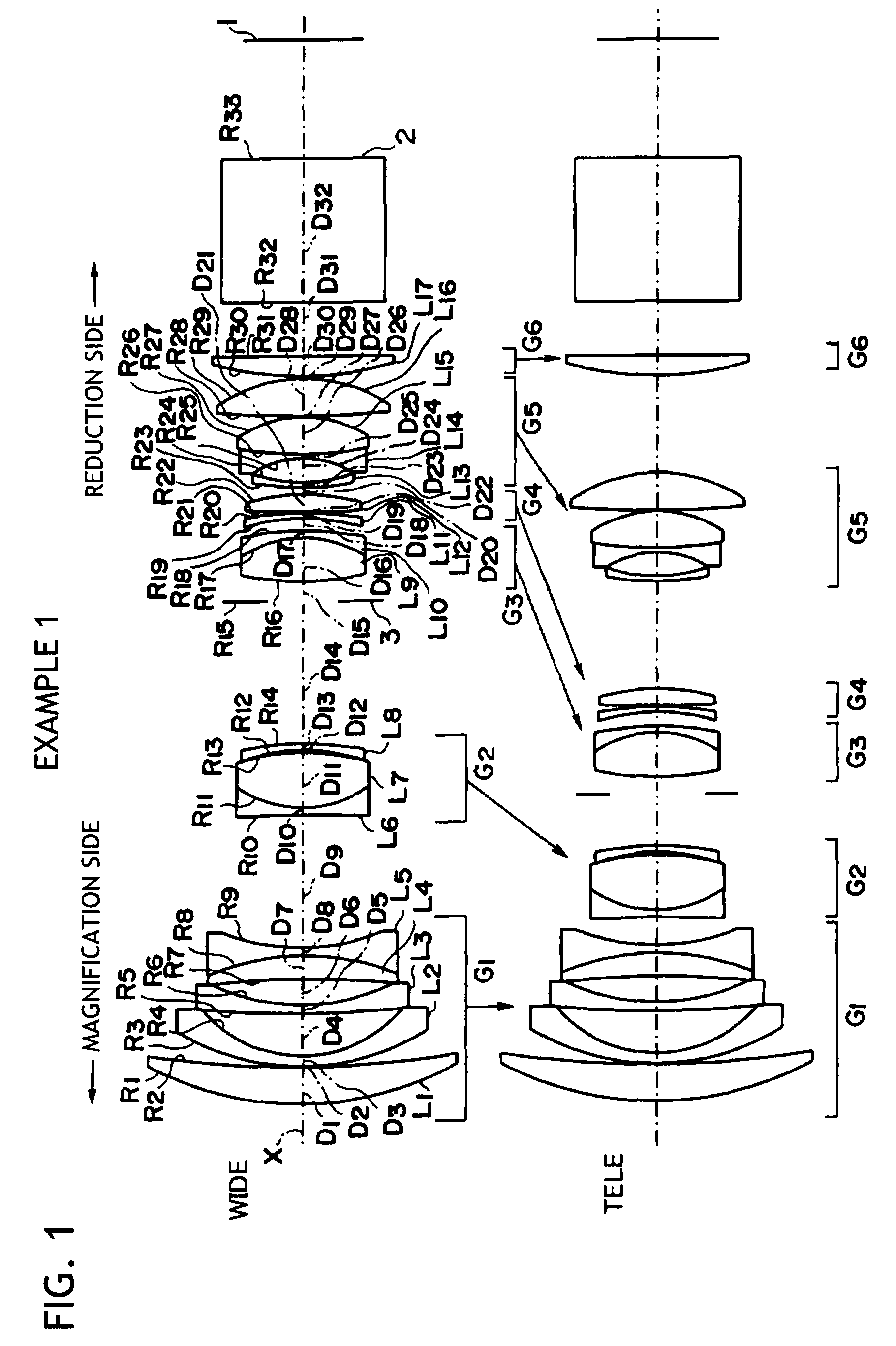

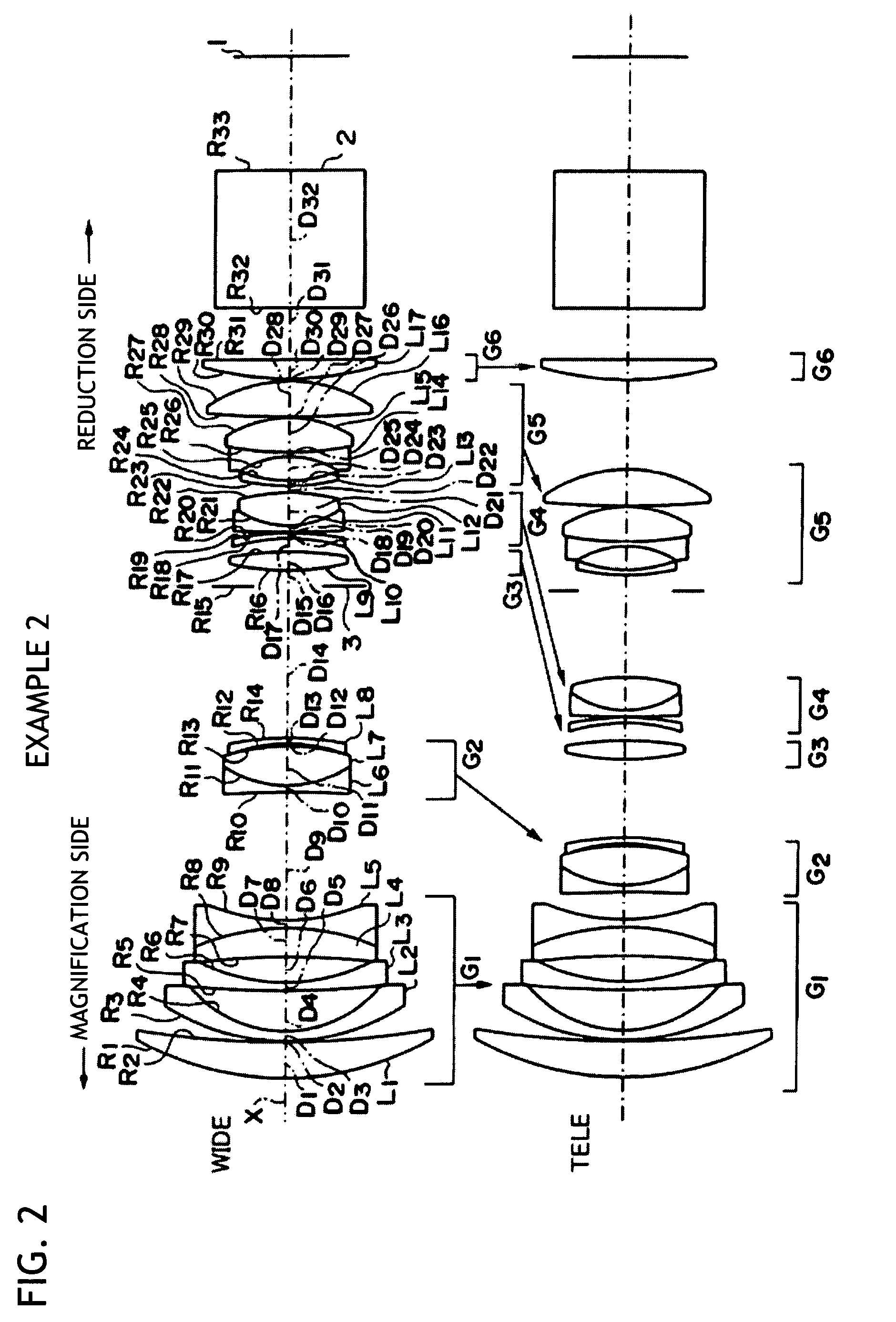

Projection type zoom lens and projection type display apparatus

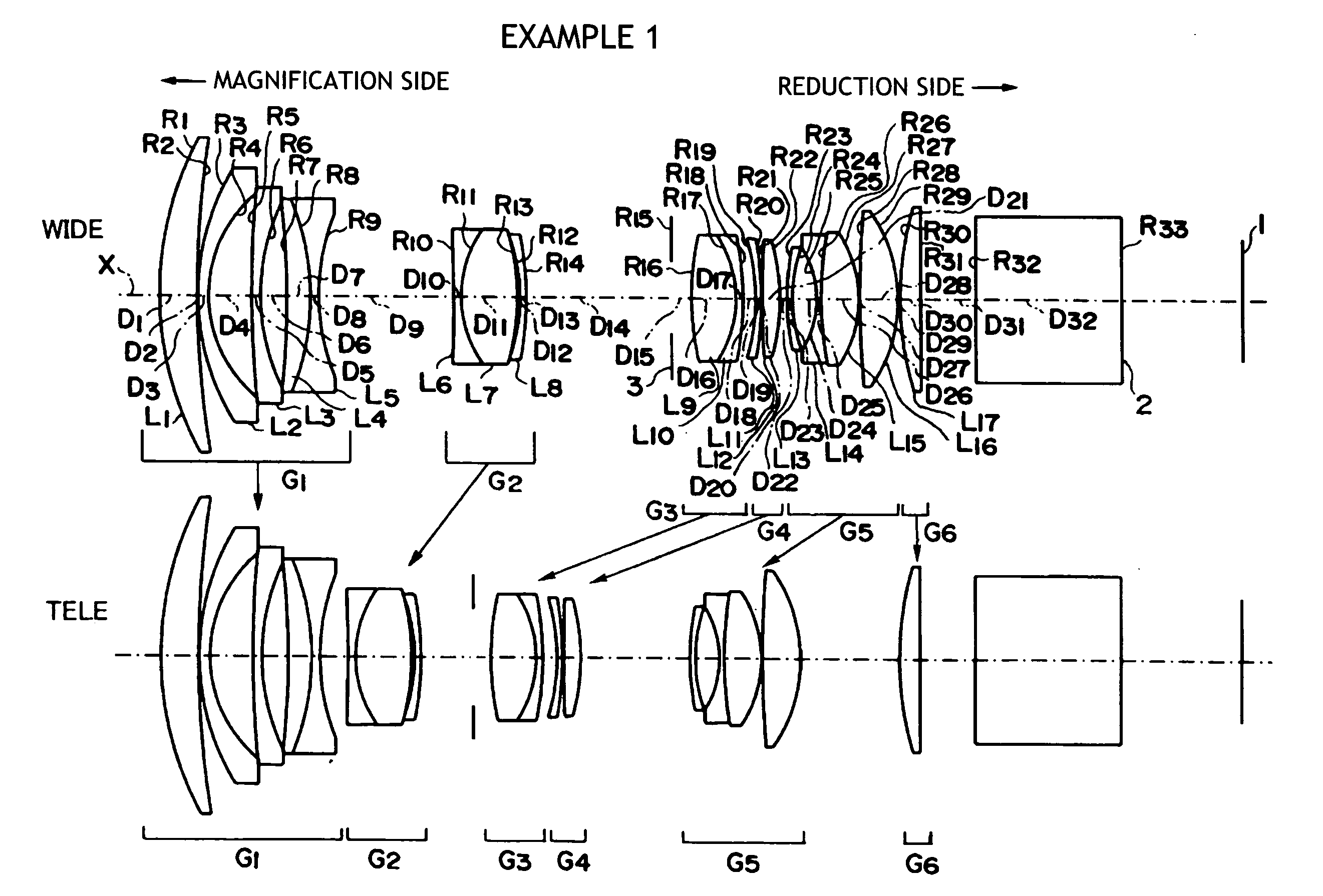

Disposed in order from a magnification side are a negative first group which is fixed during zooming to effect focusing, second to fifth groups of positive refractive power which move with mutual relationship during magnification variation, and a fixed sixth group. A negative lens made of a glass material which has an anomalous dispersion property and which has 70 or more in Abbe number is disposed in the first lens group. A positive lens made of a glass material which has an anomalous dispersion property and which has 70 or more in Abbe number is disposed in the third group located closer to a reduction side than a diaphragm. The negative lens and the positive lens are cemented to their adjacent lenses, respectively. Also, bf / fw≧2.7 is satisfied where bf denotes a back focus, and fw denotes a focal length of the entire system at a wide-angle end.

Owner:FUJI PHOTO OPTICAL CO LTD

Projection type zoom lens and projection type display apparatus

Disposed in order from a magnification side are a negative first group which is fixed during zooming to effect focusing, second to fifth groups of positive refractive power which move with mutual relationship during magnification variation, and a fixed sixth group. A negative lens made of a glass material which has an anomalous dispersion property and which has 70 or more in Abbe number is disposed in the first lens group. A positive lens made of a glass material which has an anomalous dispersion property and which has 70 or more in Abbe number is disposed in the third group located closer to a reduction side than a diaphragm. The negative lens and the positive lens are cemented to their adjacent lenses, respectively. Also, bf / fw ≧2.7 is satisfied where bf denotes a back focus, and fw denotes a focal length of the entire system at a wide-angle end.

Owner:FUJI PHOTO OPTICAL CO LTD

Zoom lens system, imaging device and camera

InactiveUS20070211350A1High resolutionSufficient periphery illuminanceOptical elementsAngle of incidenceOphthalmology

A zoom lens system comprising a first lens unit of negative power, a second lens unit of positive power and a third lens unit of positive power, wherein in zooming, the lens units move respectively along an optical axis so that an interval of first lens unit and second lens unit decreases while an interval of second lens unit and third lens unit changes with variable magnification, the first lens unit comprises one object side negative lens element and one image side positive lens element, which have an aspheric surface, and the conditions: n 12>1. 88, ν12<26 and 5.0<αiW<20.0 (ωW>30, n12 and ν12 are refractive index and Abbe number, respectively, of the image side positive lens element of the first lens unit, αi W is an incident angle of the principal ray onto the image sensor at the maximum image height at a wide-angle limit) are satisfied.

Owner:PANASONIC CORP

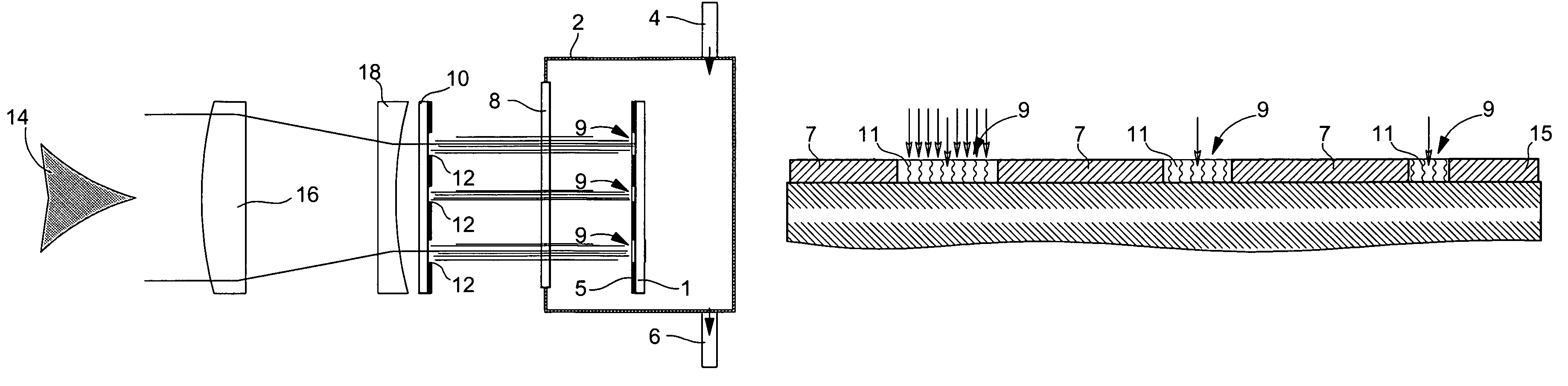

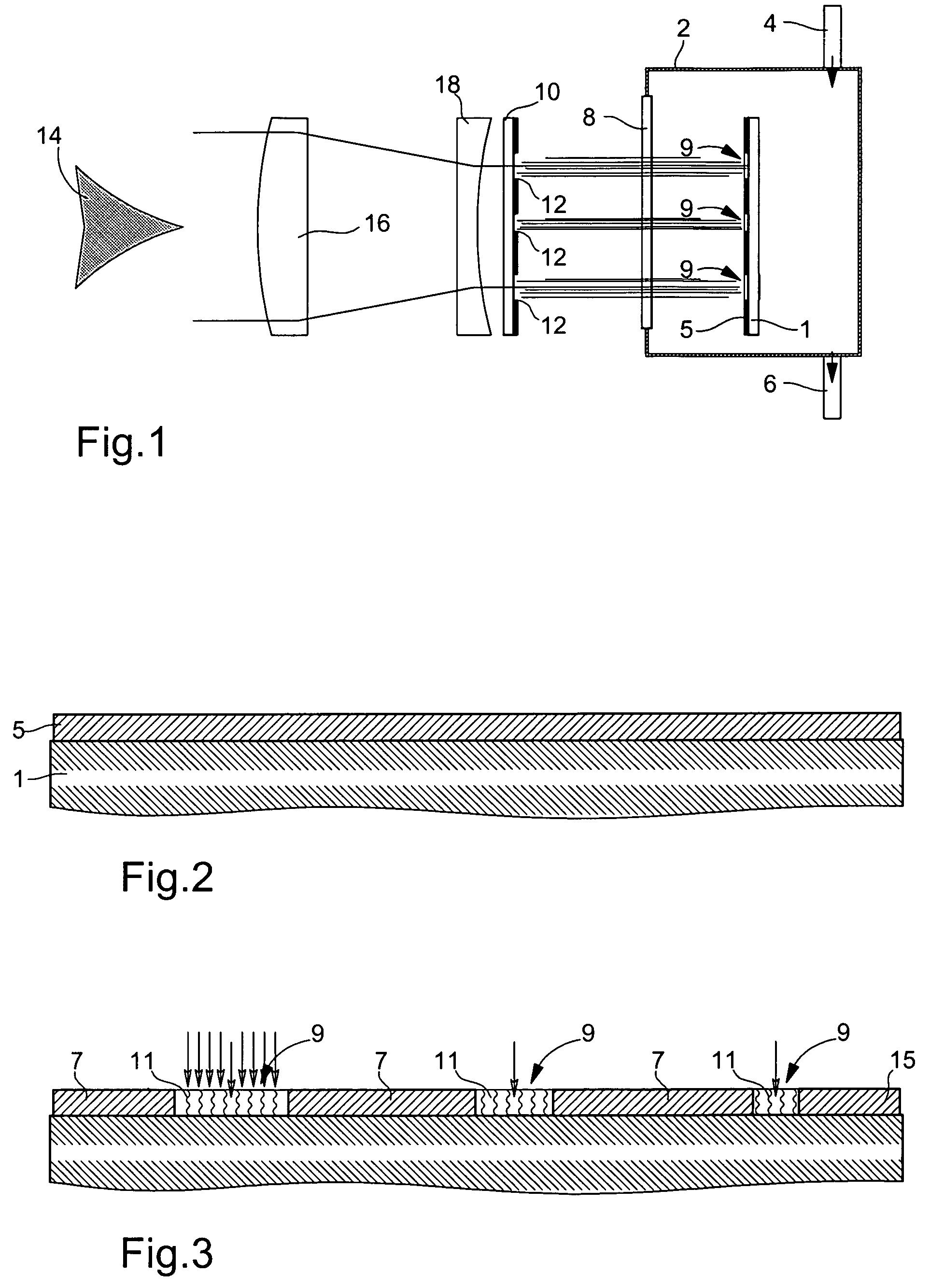

Transparent substrate with invisible electrodes and device incorporating the same

ActiveUS7843061B2Electrical conductivitySatisfy Compensation RequirementsNanotechConductive layers on insulating-supportsDielectricNanometre

The electrodes (7) and the contact zones (15) are structured in a film of a transparent conductive oxide (TCO), deposited on a transparent support (1) possibly coated with an intermediate film (3), while being separated by dielectric spaces (9) formed by nano fissures (11) obtained by UV radiation and passing through the TCO film. A protective film (13) can coat the electrodes (7) and the dielectric spaces (9).

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

Zoom lens system, imaging device and camera

InactiveUS20070217025A1High resolutionSufficient periphery illuminanceOptical elementsCamera lensOptical axis

A zoom lens system comprising a first lens unit of negative power, a second lens unit of positive power and a third lens unit of positive power, wherein in zooming, the lens units move respectively along an optical axis so that an interval of first lens unit and second lens unit decreases while an interval of second lens unit and third lens unit changes with variable magnification, the first lens unit comprises one object side negative lens element and one image side positive lens element, which have an aspheric surface, and the conditions: n12>1.88, ν12<26 and 3.0<f3 / fW<5.5 (ωW>30, n12 and ν12 are refractive index and Abbe number, respectively, of the image side positive lens element of the first lens unit, f3 is a composite focal length of the third lens unit, fW is a focal length of the entire zoom lens system at a wide-angle limit) are satisfied.

Owner:PANASONIC CORP

Zoom lens system, imaging device and camera

InactiveUS7599126B2High resolutionSufficient periphery illuminanceOptical elementsOptical axisNegative power

A zoom lens system comprising a first lens unit of negative power, a second lens unit of positive power and a third lens unit of positive power, wherein in zooming, the lens units move respectively along an optical axis so that an interval of first lens unit and second lens unit decreases while an interval of second lens unit and third lens unit changes with variable magnification, the first lens unit comprises one object side negative lens element and one image side positive lens element, which have an aspheric surface, and the conditions: n12>1. 88, v12<26 and 5.0<alphaiW<20.0 (omegaW>30, n12 and v12 are refractive index and Abbe number, respectively, of the image side positive lens element of the first lens unit, alphai W is an incident angle of the principal ray onto the image sensor at the maximum image height at a wide-angle limit) are satisfied.

Owner:PANASONIC CORP

Projection lens apparatus and projection type image display apparatus

InactiveUS6975460B2Satisfy Compensation RequirementsMore versatilityBuilt-on/built-in screen projectorsNon-linear opticsComputer graphics (images)Optical axis

A projection type image display apparatus having an image display element outputting an image ray, a projection lens apparatus for performing overhead projection of the image ray from the image display element, the projection lens apparatus having a plurality of lens elements, a reflection mirror reflecting the image ray from the projection lens apparatus, and a screen on which the image ray reflected by the reflection mirror is projected. An optical axis of the projection lens apparatus is decentered from a center of the screen.

Owner:HITACHI LTD

Projection lens apparatus and projection type image display apparatus

InactiveUS20060012755A1Satisfy Compensation RequirementsMore versatilityBuilt-on/built-in screen projectorsNon-linear opticsComputer graphics (images)Projection lens

Owner:MAXELL HLDG LTD

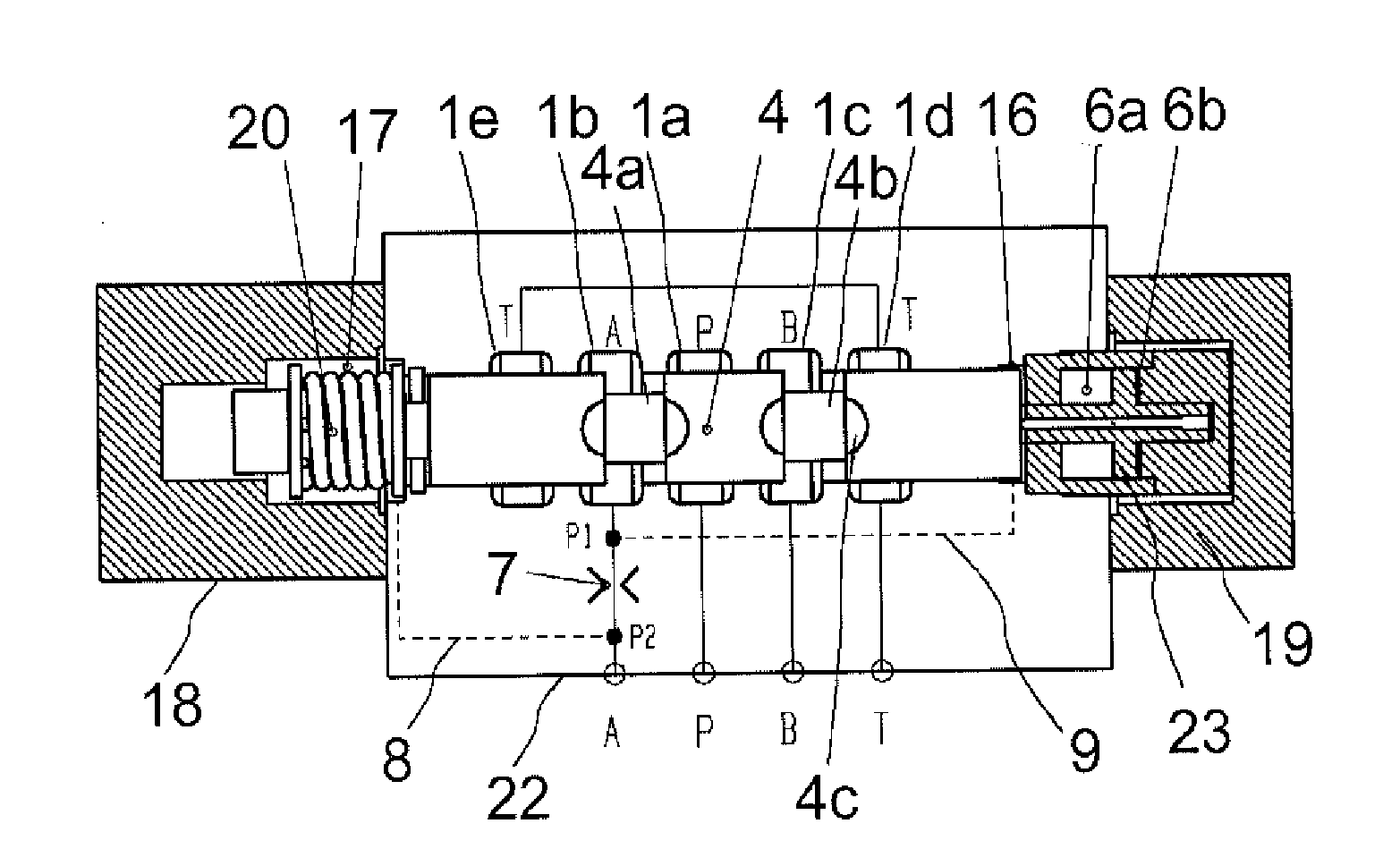

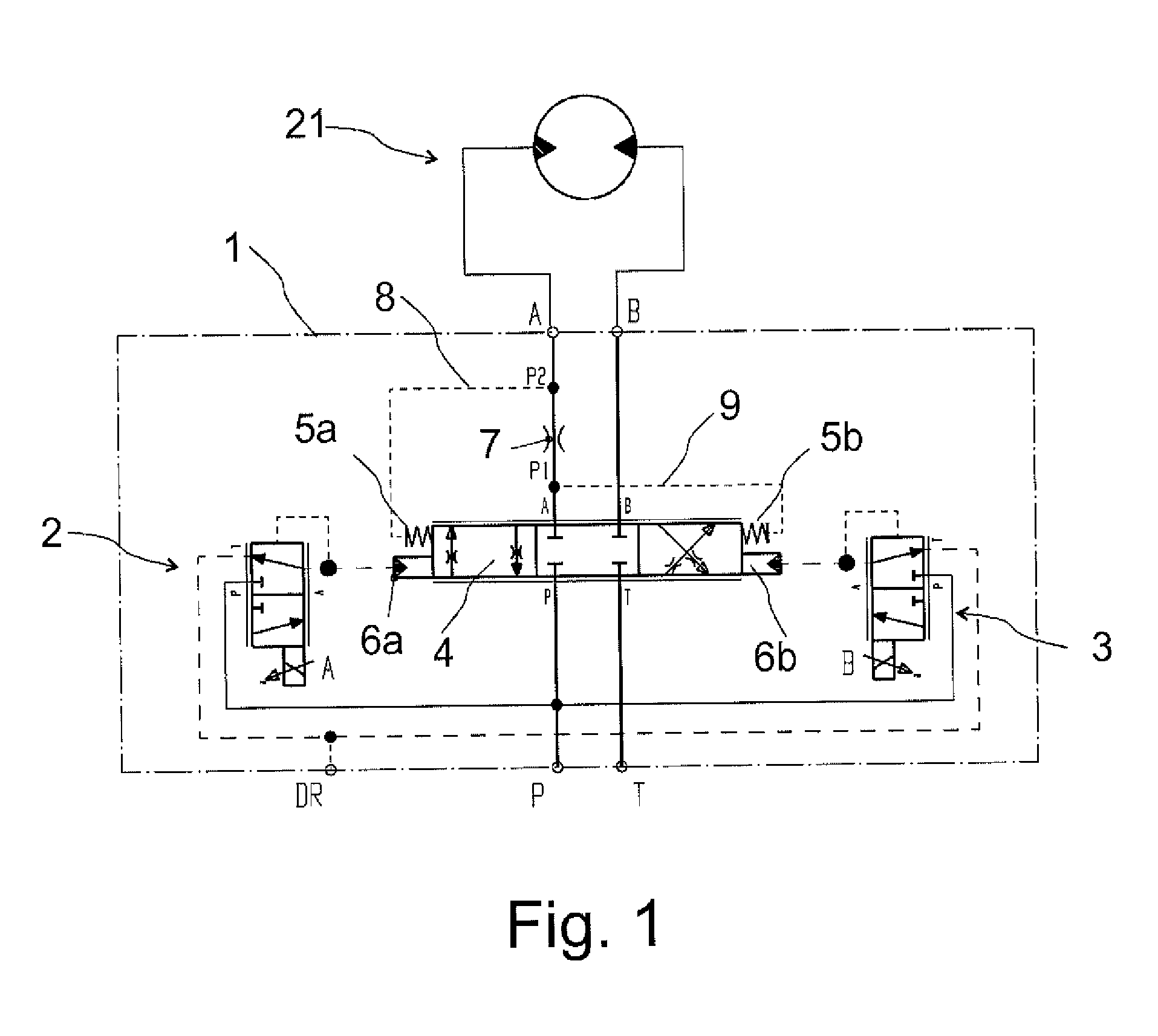

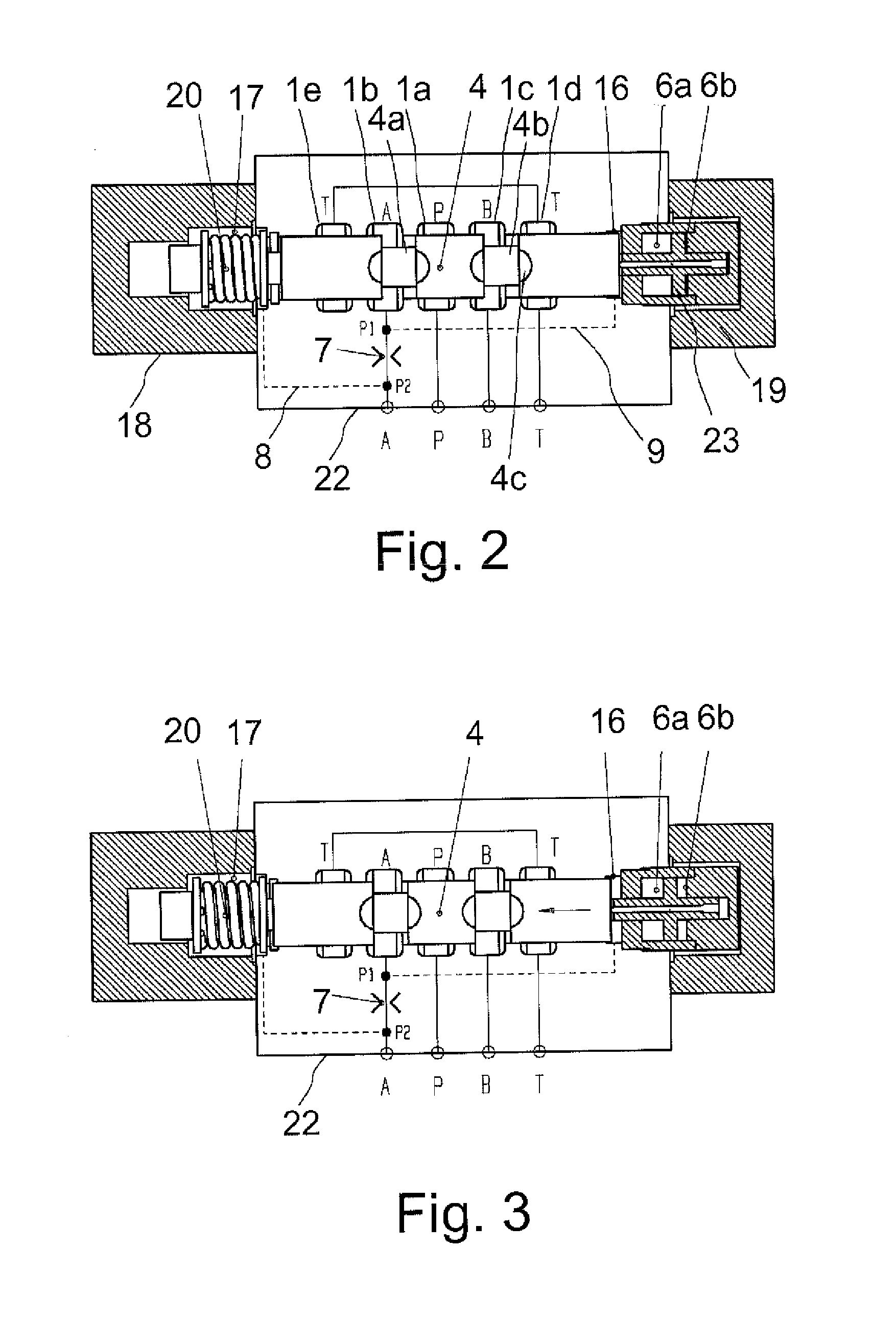

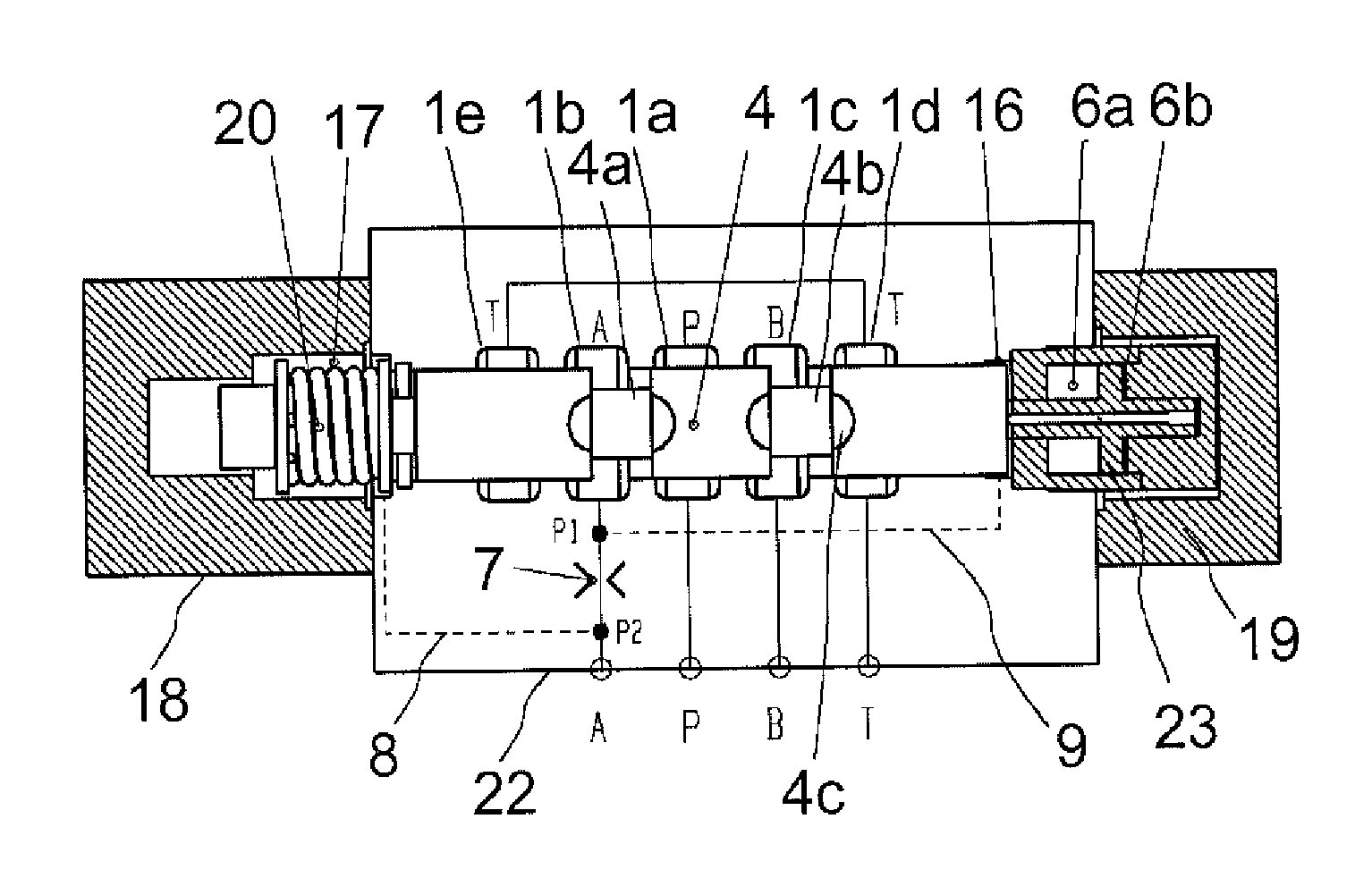

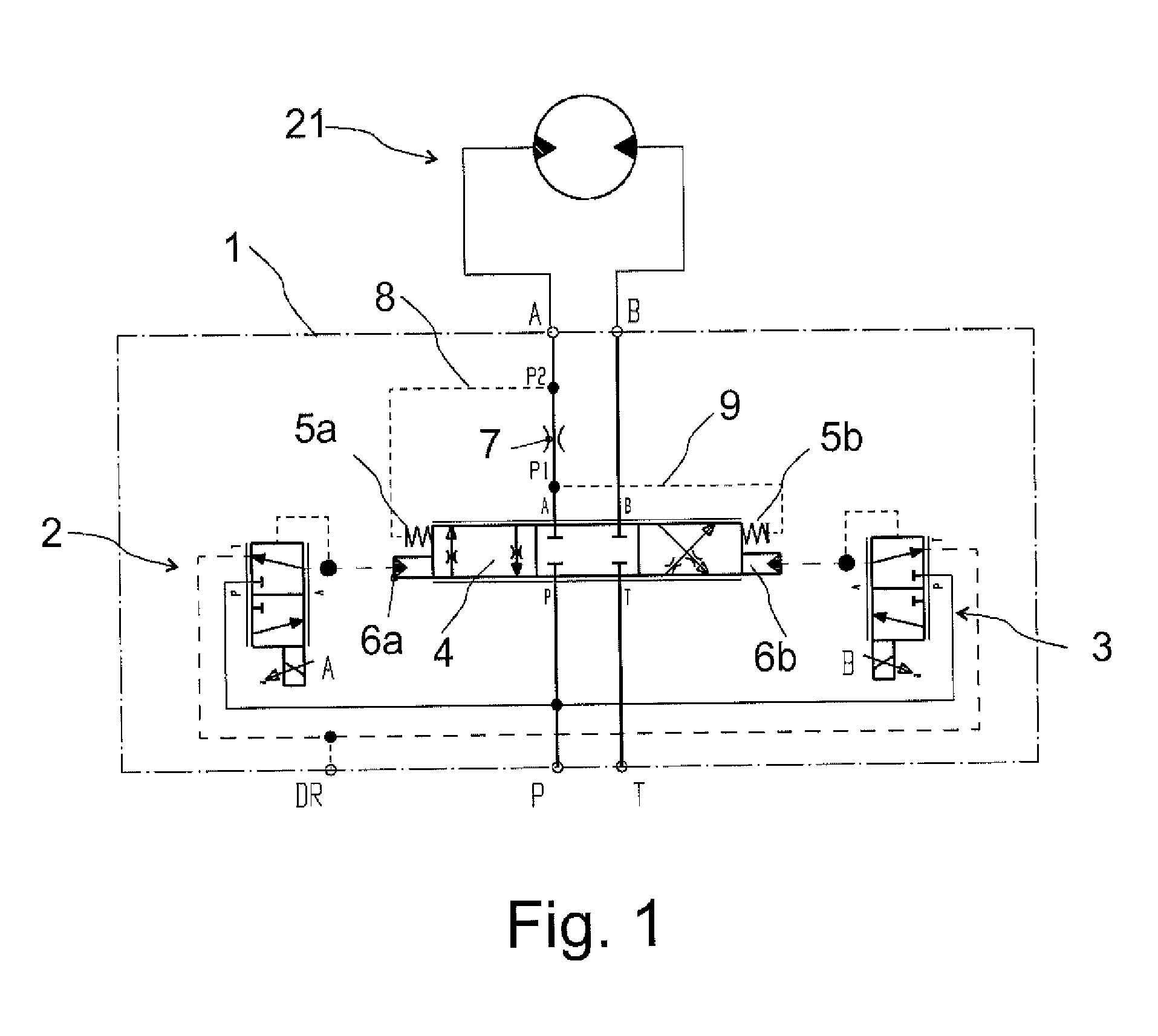

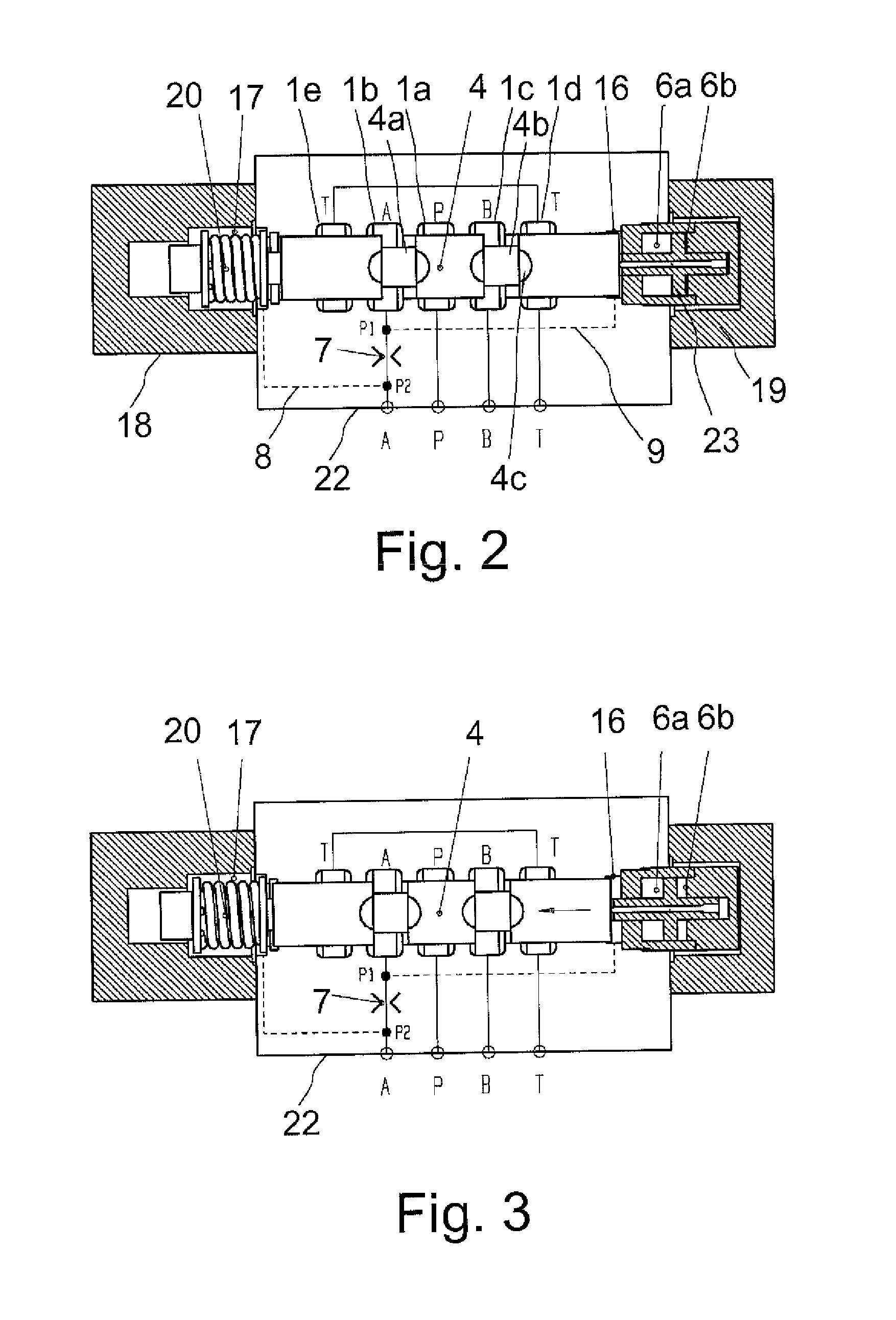

Directional valve equipped with pressure compensation

ActiveUS20130269808A1Reduce total pressure lossSave volumeServomotor componentsServomotorsEngineeringPressure difference

A directional valve for controlling an actuator by means of pressurized medium, including: a spool fitted to move axially inside the directional valve; a first position of the spool, in which the spool tends to be set; and a second position of the spool, to which the spool can be moved by a pilot control force. Additionally, the directional valve includes a metering orifice placed in the pressure port or in the first work port or in the second work port or in the tank port, and across which a pressure difference is effective. The spool further includes a second position, to which the spool can be moved by a pilot control force. When the spool is in at least the second position, the directional valve is fitted to generate a compensating force proportional to said pressure difference, to move the spool to compensate for the flow.

Owner:PARKER HANNIFIN MFG FINLAND

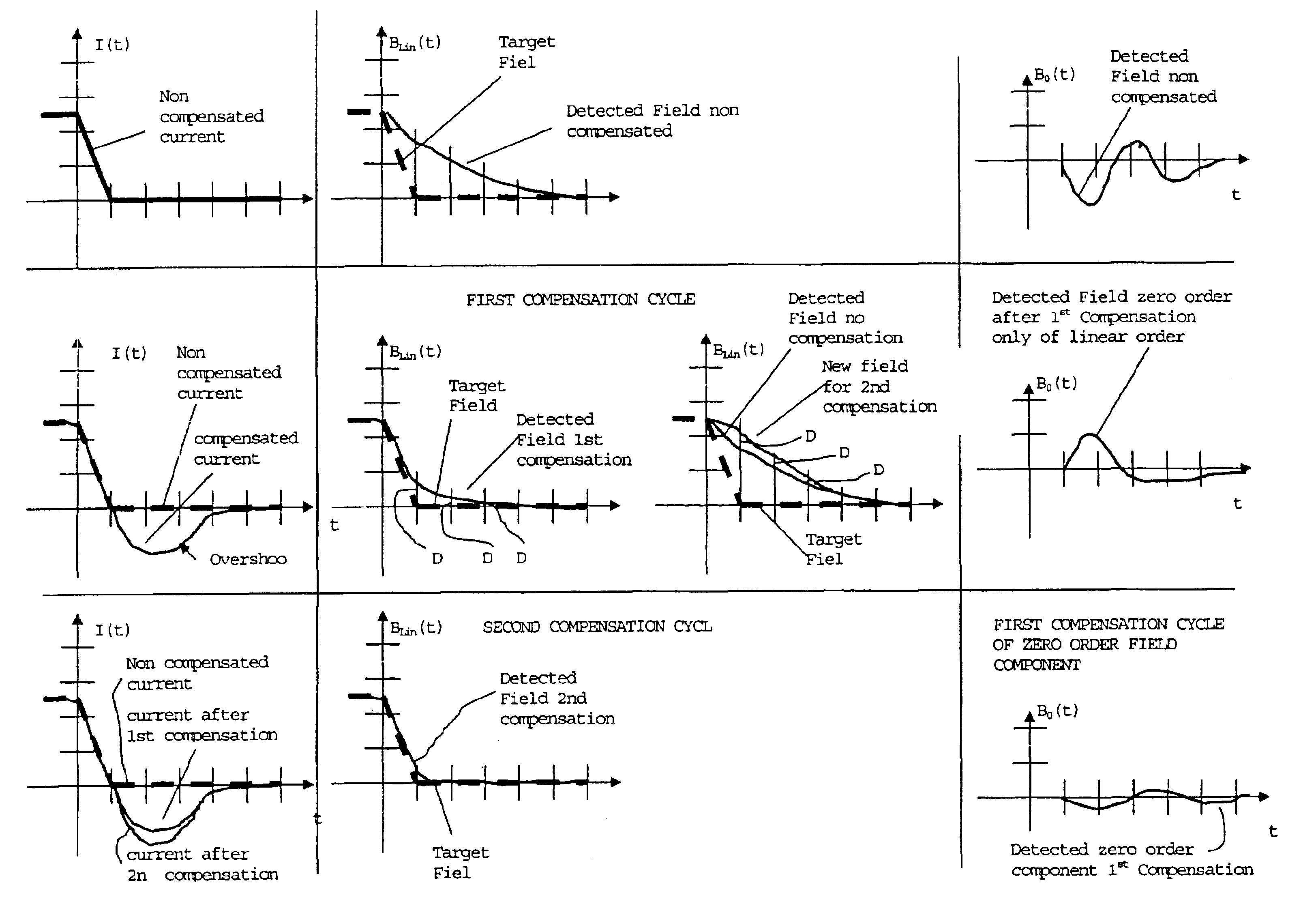

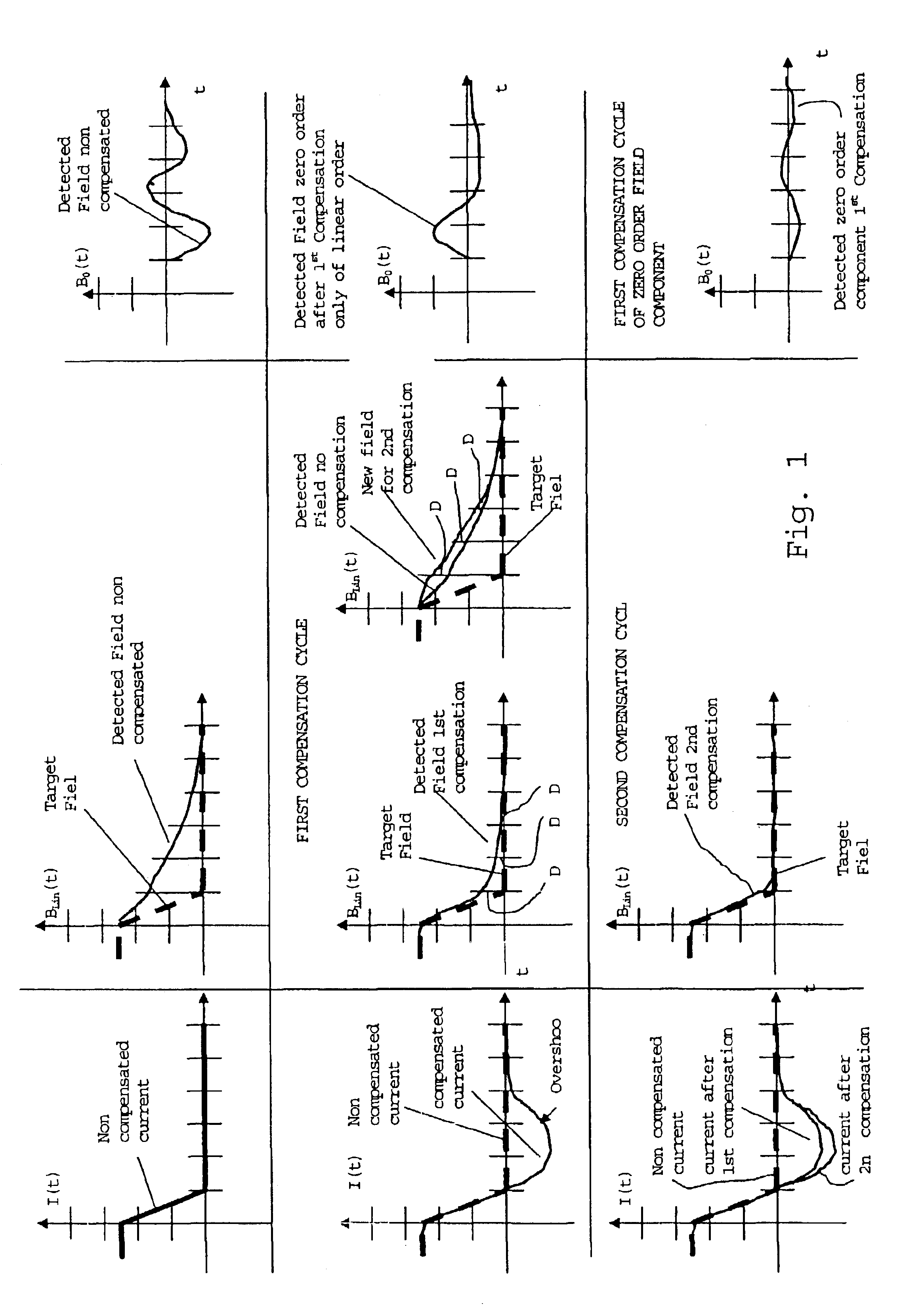

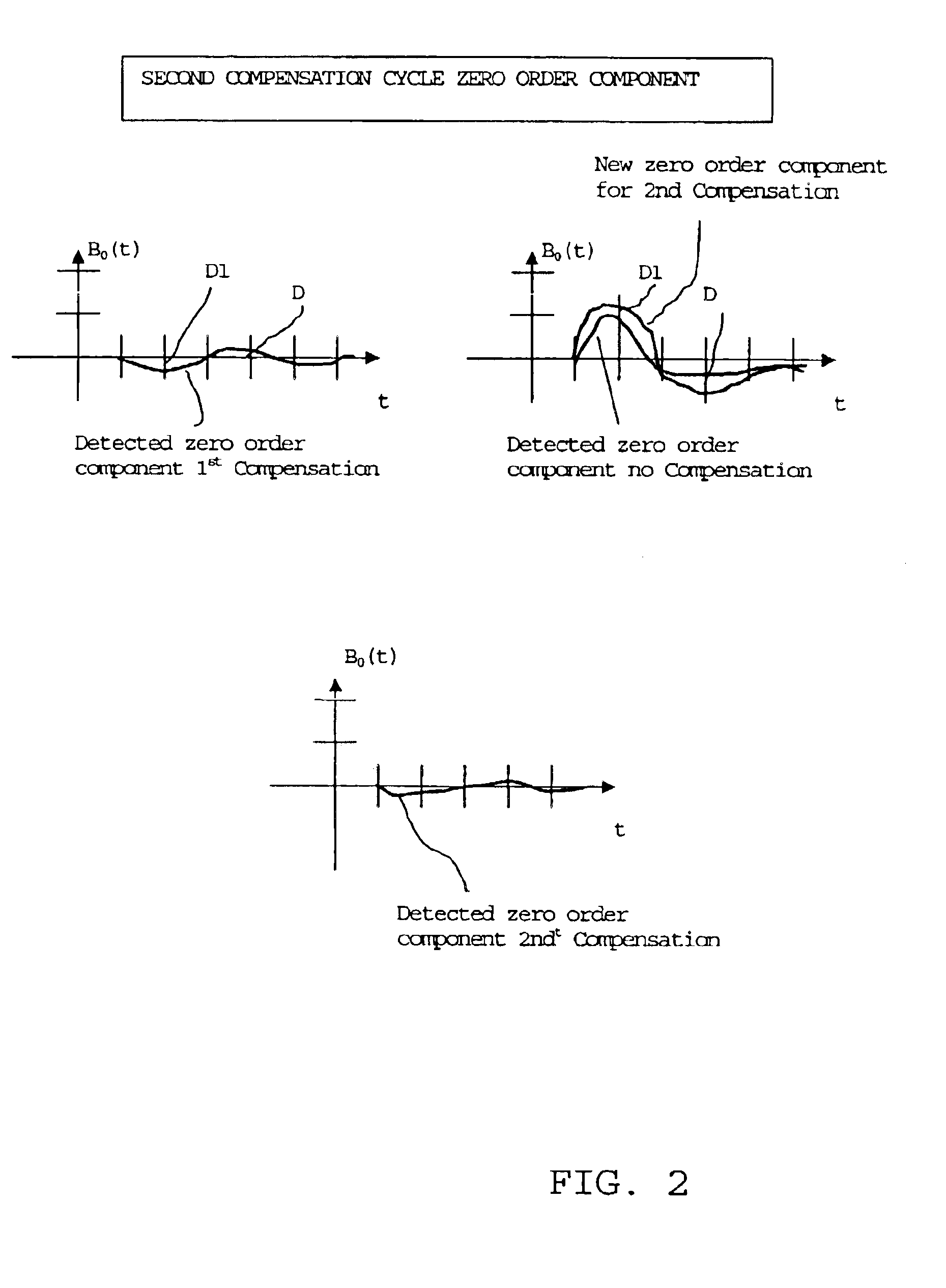

Method of compensating for gradient induced eddy currents in NMR imaging apparatuses

InactiveUS6867590B2Shorten the timeKnown methodMeasurements using NMR imaging systemsElectric/magnetic detectionExcitation currentEddy current effect

A method of compensating for eddy currents induced by the switching on and off magnetic fields in gradient coils in NMR imaging apparatuses, which method includes at least one compensation cycle including the steps of performing at least one detection of the magnetic field generated by the current flowing in a gradient coil, i.e., a gradient field; extrapolating the course of the effectively generated gradient field from the data of said at least one detection; generating a gradient fields excitation current compensating the eddy current effects on the gradient fields on the basis of the comparison of the effectively generated gradient fields and of the target gradient field.

Owner:ESAOTE

High magnification compact zoom lens

The present invention is directed to high magnification compact zoom lenses that are reduced in diameter of groups of lens pieces closer to the imaging plane to provide downsized lightweight zoom lenses of magnification as high as 20 diameters, with an image stabilizer or vibration compensating mechanism being also reduced in dimensions. An exemplary improved high magnification zoom lens has four groups of lens pieces, namely, the first or leading lens group G1 of positive refractivity in the foremost position closer to the subject, the second lens group G2 of negative refractivity, the third lens group G3 of positive refractivity, and the fourth lens group G4 of positive refractivity in the rearmost position closer to the imaging plane, all arranged in this order. In displacing the entire lens optics of the zoom lens from the wide-angle end to the telephoto end, the second lens group G2 are moved toward the imaging plane and the fourth lens group G4 are moved to compensate for a varied position of the resultant image while the first and third lens groups, G1 and G3, have their respective positions fixed along the optical axis. The zoom lens satisfies the requirements as defined in the following formulae: f3 / f4>2.0 and v4>65 where f3 is a focal length of the third lens group G3, f4 is the focal length of the fourth lens group, v4 is an average of Abbe contrasts of all the convex lens pieces in the fourth lens group G4.

Owner:TAMRON

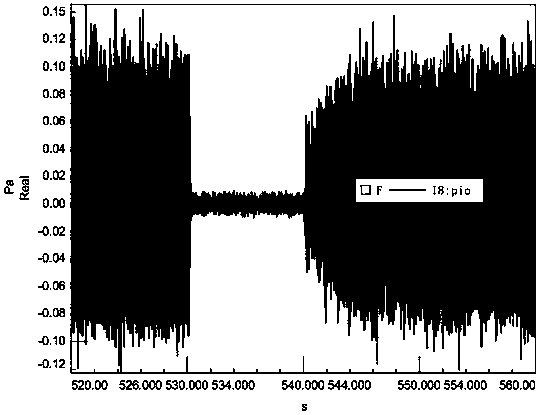

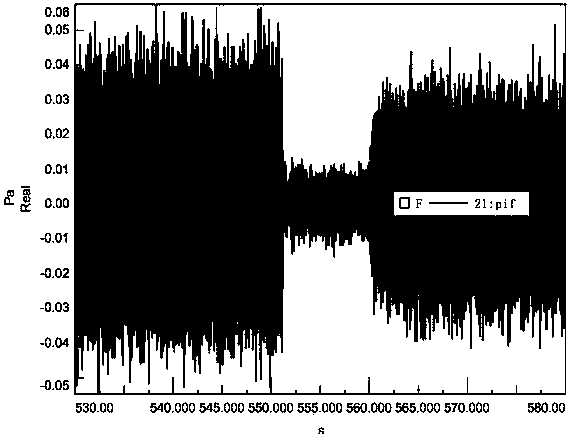

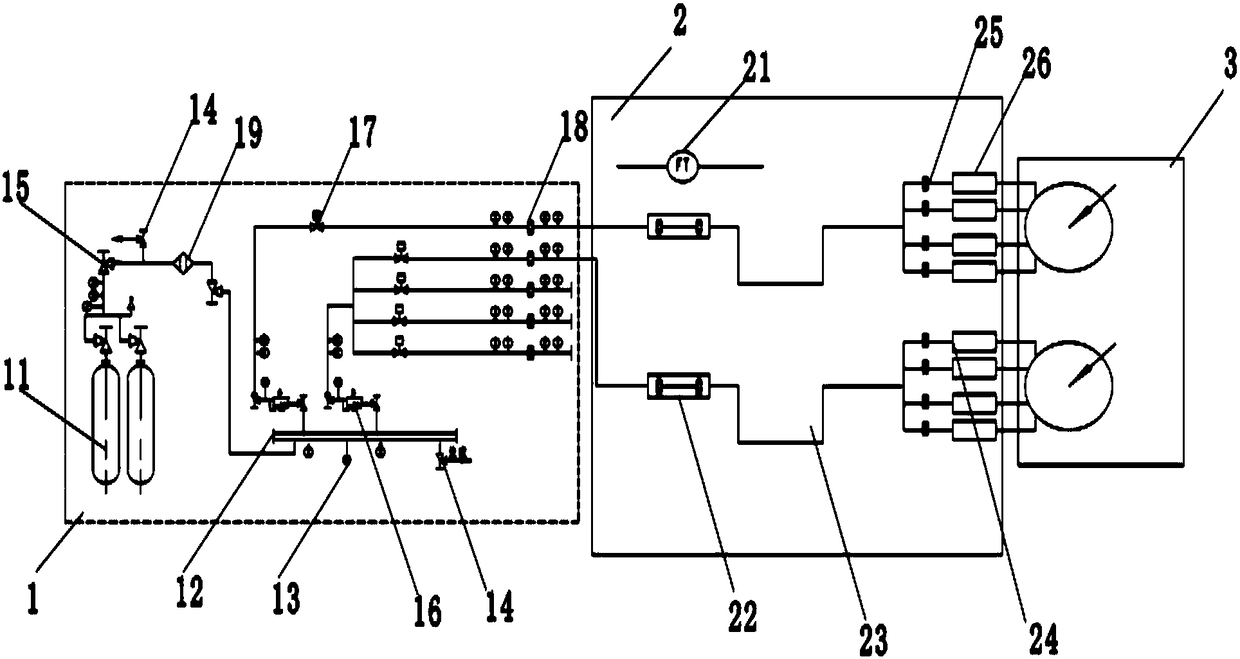

Engine test propellant supply low frequency ripple suppression method and system

ActiveCN108387378AEvenly distributedSelf-pulsation regulationGas-turbine engine testingJet-propulsion engine testingHeliumGas mixing

The invention relates to an engine test propellant supply low frequency ripple suppression method and system. Accurate helium injection is performed on the propellant supply pipeline, the inherent frequency of the propellant supply system is changed through gas mixing, and the ripple of the propellant can be adjusted through accurate control of the injection gas volume, the gas distribution and the injection gas form and the coupling situation of the propellant supply system and the engine can be reduced. With application of the method, the propellant supply ripple can be reduced, the propellant supply stability can be enhanced and thus the stability of the whole engine pump system can be enhanced. The method and the system are applied to the engine test.

Owner:XIAN AEROSPACE PROPULSION TESTING TECHN INST

Directional valve equipped with pressure compensation

ActiveUS9140274B2Good compensation and restrictionSatisfy Compensation RequirementsServomotor componentsServomotorsEngineeringActuator

A directional valve for controlling an actuator by means of pressurized medium, including: a spool fitted to move axially inside the directional valve; a first position of the spool, in which the spool tends to be set; and a second position of the spool, to which the spool can be moved by a pilot control force. Additionally, the directional valve includes a metering orifice placed in the pressure port or in the first work port or in the second work port or in the tank port, and across which a pressure difference is effective. The spool further includes a second position, to which the spool can be moved by a pilot control force. When the spool is in at least the second position, the directional valve is fitted to generate a compensating force proportional to said pressure difference, to move the spool to compensate for the flow.

Owner:PARKER HANNIFIN MFG FINLAND

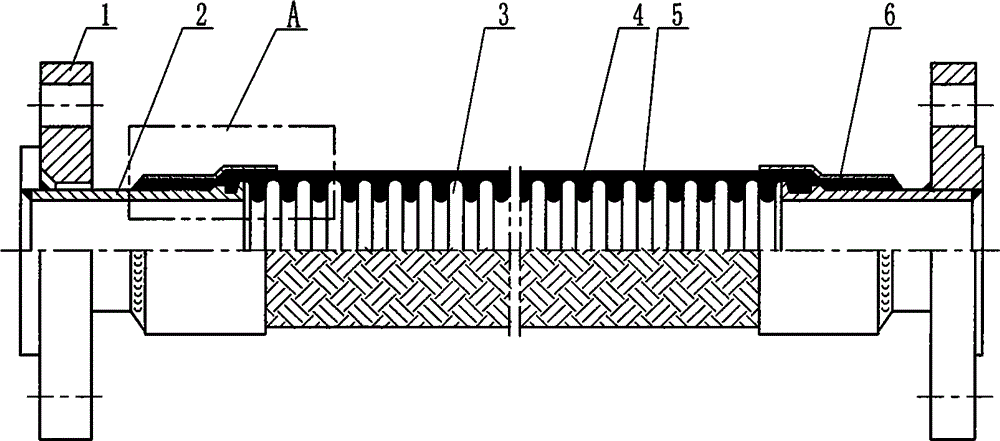

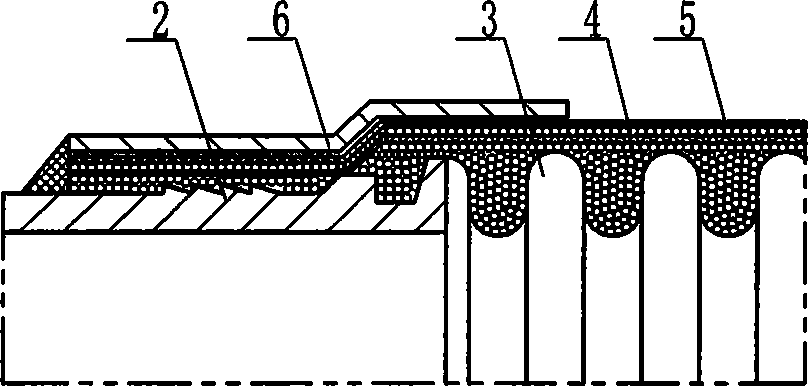

Ultrahigh pressure metal hose with external strengthened layer

InactiveCN105987240ASimple structureEasy to industrializeFlexible pipesUltra high pressureEngineering

The invention discloses an ultrahigh pressure metal hose with an external strengthened layer. The ultrahigh pressure metal hose comprises a flange, a connecting pipe, a corrugated pipe, steel wires, metal mesh sleeves and a hose. The corrugated pipe is sequentially in sealed connection with the connecting pipe and the flange. The steel wire is wound into the trough of the corrugated pipe until leveling with the crest, the metal mesh sleeves are axially sleeved along all crests of the corrugated pipe, at least one layer of steel wire and at least one layer of metal mesh sleeve are alternatively arranged on the layer of metal mesh sleeve, the steel wire is wound to form the circumferential strengthened layer of the corrugated pipe, and the metal mesh sleeve forms the axial strengthened layer of the corrugated pipe. In order to realize integrated connection, the end parts of the metal mesh sleeve and the steel wire uniformly extend to the outer wall of the middle section of the connecting pipe, are gathered and bound up with a jacket and then are fixedly connected uniformly. According to the invention, the strengthened layer is additionally arranged on a conventional corrugated pipe, the structure is simple, multiplication of bearing capability and temperature resistance can be realized, and the requirements of working conditions of ultrahigh pressure and extreme temperature resistance can be met. In addition, the strengthened layers are all of a flexible structure, thus having little influence on the flexible compensation capability of the corrugated pipe.

Owner:蒋新锋

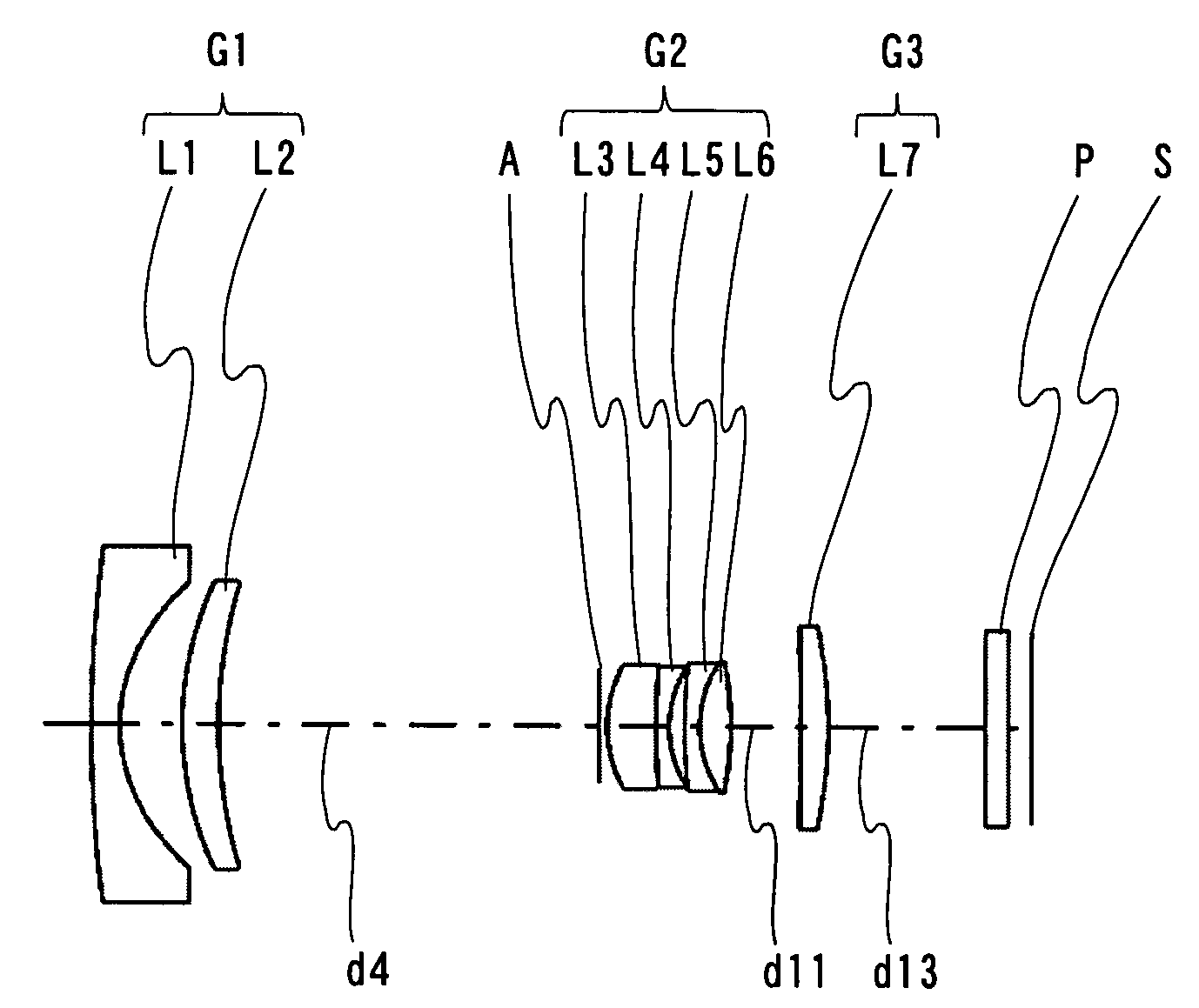

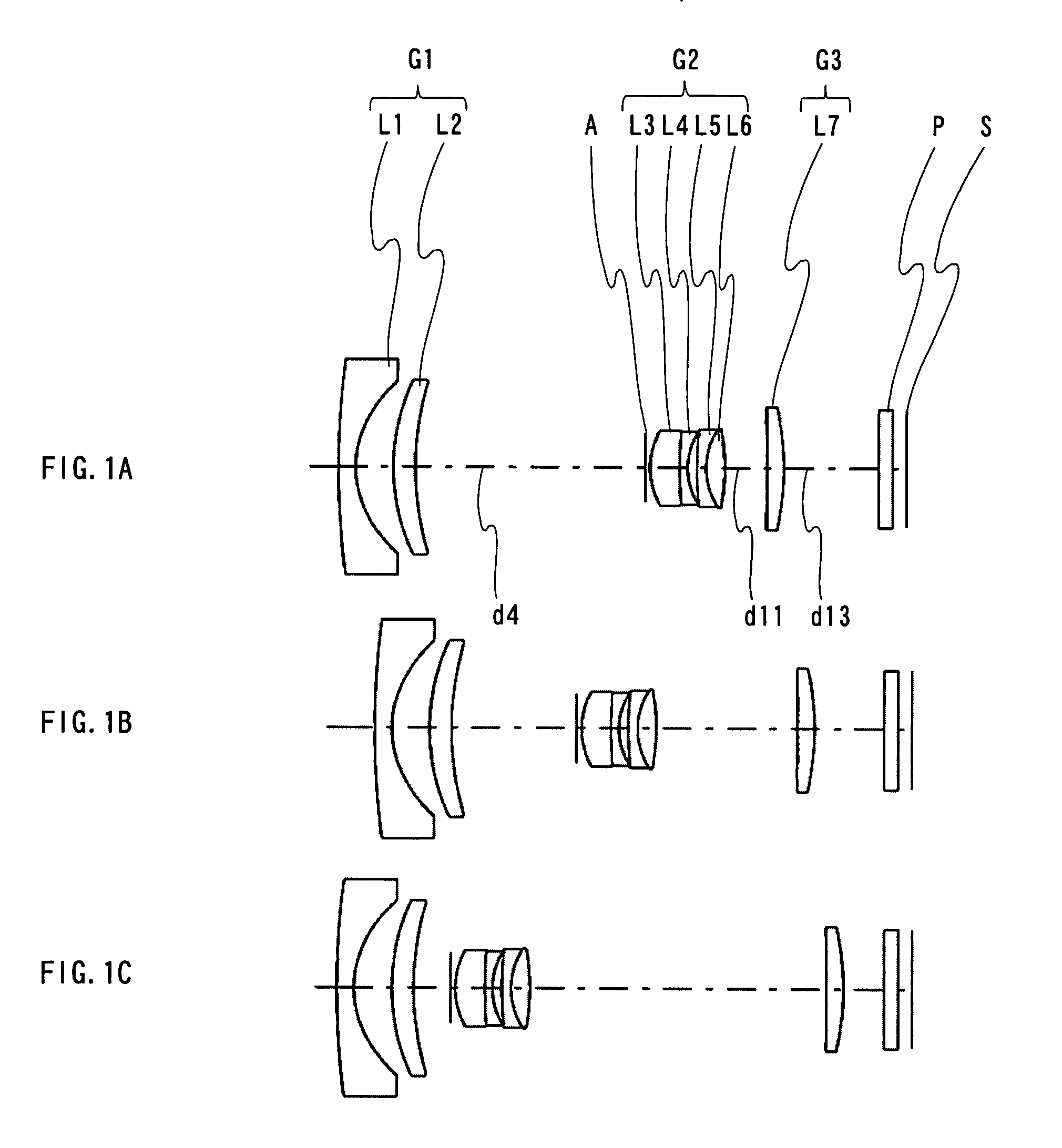

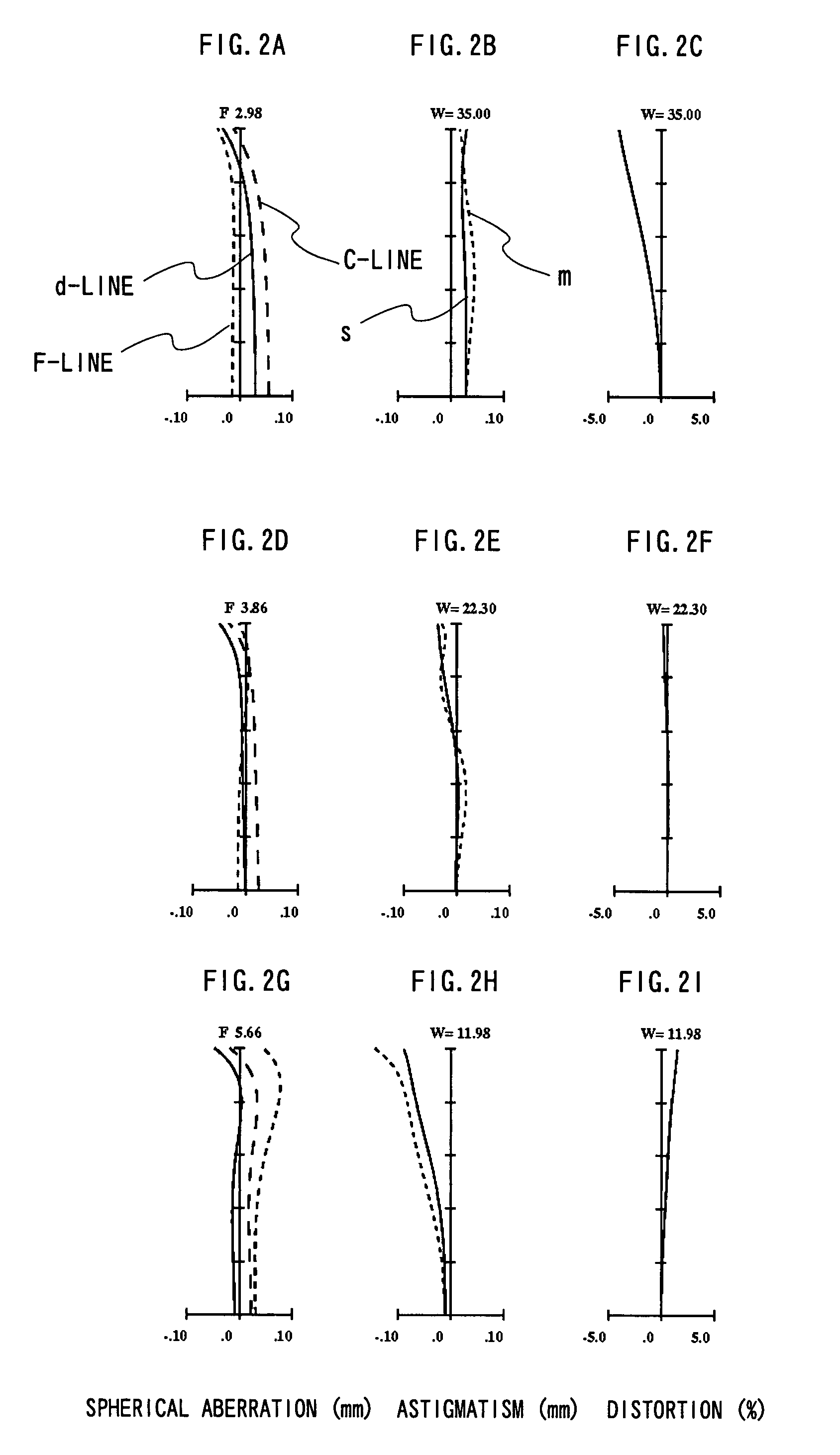

Zoom lens system, imaging device and camera

A zoom lens system comprising a first lens unit having negative power, a second lens unit having positive power and a third lens unit having positive power, wherein in zooming from a wide-angle limit to a telephoto limit, the lens units move respectively along an optical axis in such a manner that an interval between the first lens unit and the second lens unit decreases while an interval between the second lens unit and the third lens unit changes so that variable magnification is achieved, the first lens unit comprises one object side negative lens element and one image side positive lens element with a convex surface facing the object side, which have an aspheric surface, and the conditions: n12>1.88 and ν12<26 (n12 and ν12 are refractive index and Abbe number, respectively, of the image side positive lens element of the first lens unit) are satisfied.

Owner:PANASONIC CORP

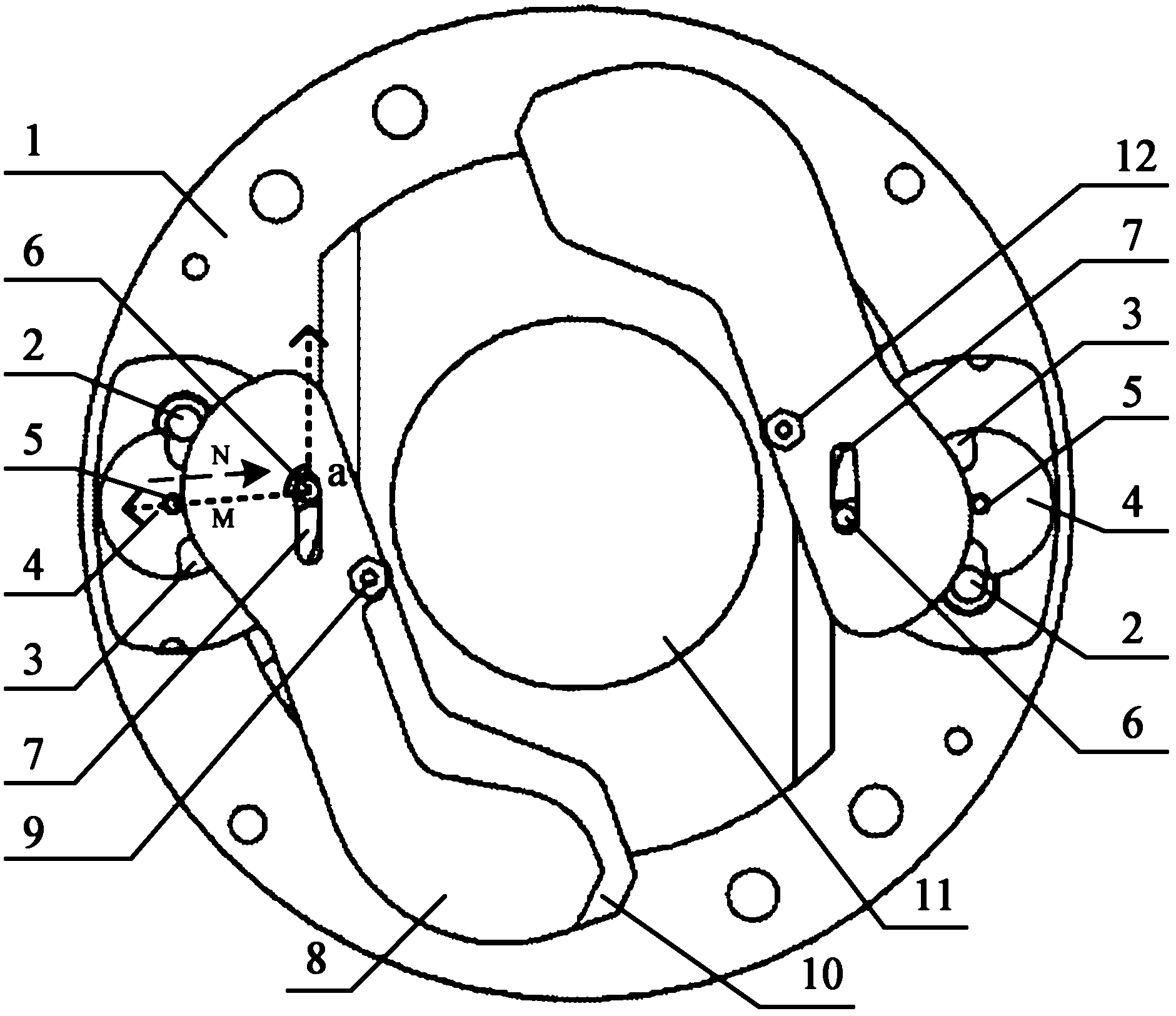

Self-locking type shutter device with high impact resistance

The invention relates to a self-locking type shutter device with high impact resistance, which includes an image sensor support, separation blades, acting arms and driving motors, wherein a photosensitive window is arranged at the middle part of the image sensor support; the separation blades are provided with sliding grooves, and can be rotationally mounted on the image sensor support through separation blade shafts, and the separation blades can completely shield the photosensitive window when closed, and are within the range of the image sensor support when opened normally on two sides of the photosensitive window; the acting arms are rotationally mounted on the image sensor support through rotating shafts, and are provided with convex columns which are arranged at one end of each acting arm respectively, pass through the sliding grooves of the separation blades, and can slide along the sliding grooves; the connection lines between the centers of the rotating shafts of the acting arms and the axes of the convex columns are orthogonally intersected with the groove lines of the sliding grooves of the separation blades, or form included angles slight larger than 90 degrees; and the driving motors are mounted on the image sensor support, and are connected with the acting arms for driving the acting arms. The self-locking type shutter device with high impact resistance has the characteristics of self-locking, high impact resistance, high overload resistance and the like in the normally-open state, and capability of realizing non-uniformity correction or exposure control of an image sensor focal plane in the closed state, so that the opening and closing time can be regulated and controlled conveniently according to requirements, the volume is small and the structure is compact.

Owner:中国兵器工业导航与控制技术研究所

Electron microscopy system, electron microscopy method and focusing system for charged particles

ActiveUS6949744B2Satisfy Compensation RequirementsAberration compensationThermometer detailsStability-of-path spectrometersElectron microscopeSecondary electrons

An electron microscopy system and an electron microscopy method for detection of time dependencies of secondary electrons generated by primary electrons is provided, in which the primary electron pulses are directed onto a sample surface and electrons emanating from the sample surface are detected, time resolved. To this end the system comprises in particular a cavity resonator. A cavity resonator can also be used to reduce aberrations of focusing lenses.

Owner:CARL ZEISS AG

Internal combustion engine control device

InactiveUS7043352B2Satisfy Compensation RequirementsGuaranteed uptimeElectrical controlInternal combustion piston enginesControl modeAir–fuel ratio

An internal combustion engine control device is configured to take a fuel property into account when compensating for torque decline that occurs when a prescribed combustion control mode is executed. The internal combustion engine control device is configured to calculate a first modification coefficient designed to modify a first torque correction coefficient corresponding to a air-fuel ratio based on the specific gravity of the fuel, a second modification coefficient designed to modify a second torque correction coefficient corresponding to a working gas quantity based on the specific gravity of the fuel, and a third modification coefficient designed to modify a third torque correction coefficient corresponding to a fuel injection timing based on an aromatic component content ratio of the fuel. The internal combustion engine control device is then configured to multiply the first, second and third modification coefficients together to calculate a modification coefficient for modifying a torque correction value.

Owner:NISSAN MOTOR CO LTD

Zoom lens system, imaging device and camera

InactiveUS20080247057A1High resolutionShorter overall optical lengthOptical elementsCamera lensOptical axis

A zoom lens system comprising a first lens unit having negative power, a second lens unit having positive power and a third lens unit having positive power, wherein in zooming from a wide-angle limit to a telephoto limit, the lens units move respectively along an optical axis in such a manner that an interval between the first lens unit and the second lens unit decreases while an interval between the second lens unit and the third lens unit changes so that variable magnification is achieved, the first lens unit comprises one object side negative lens element and one image side positive lens element with a convex surface facing the object side, which have an aspheric surface, and the conditions: n12>1.88 and ν12<26 (n12 and ν12 are refractive index and Abbe number, respectively, of the image side positive lens element of the first lens unit) are satisfied.

Owner:PANASONIC CORP

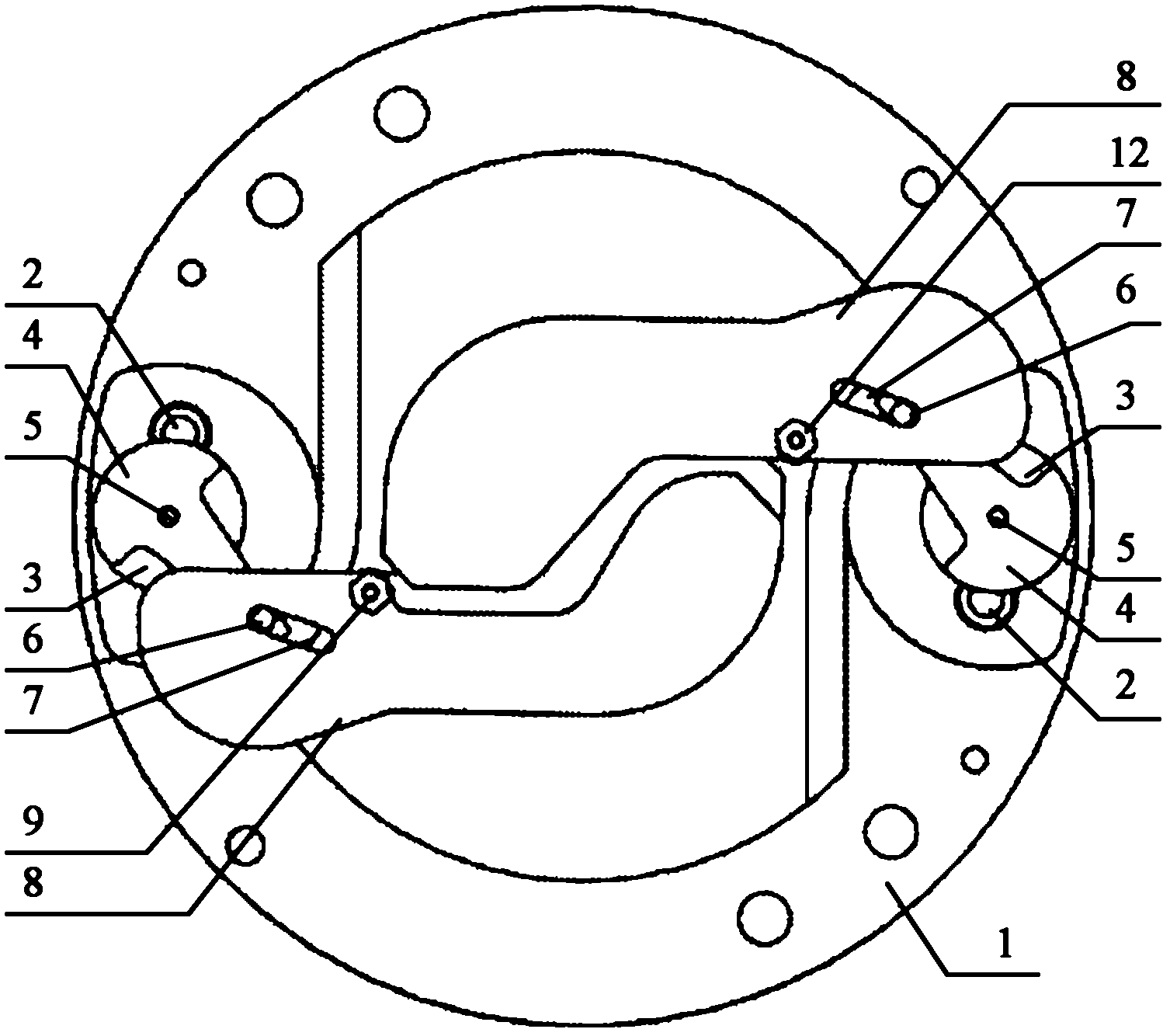

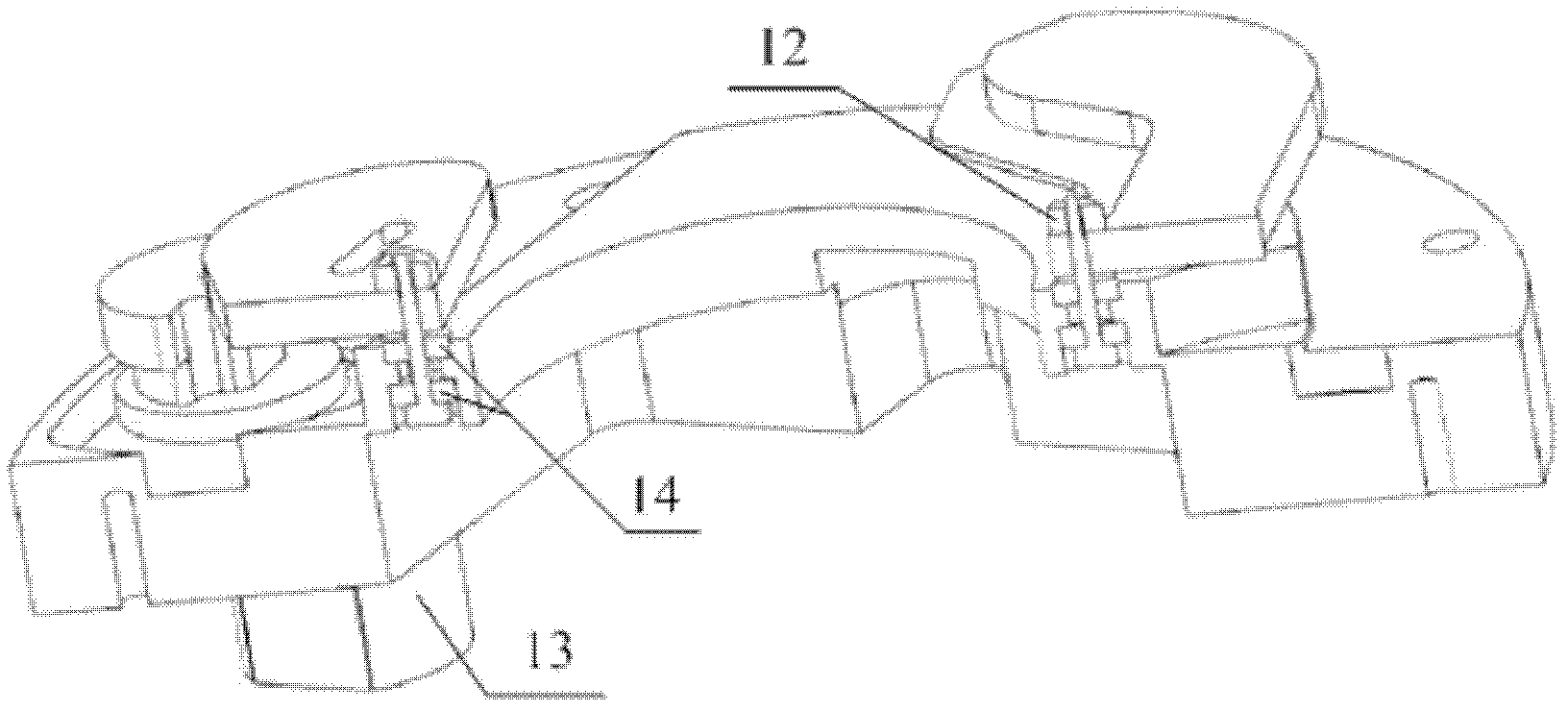

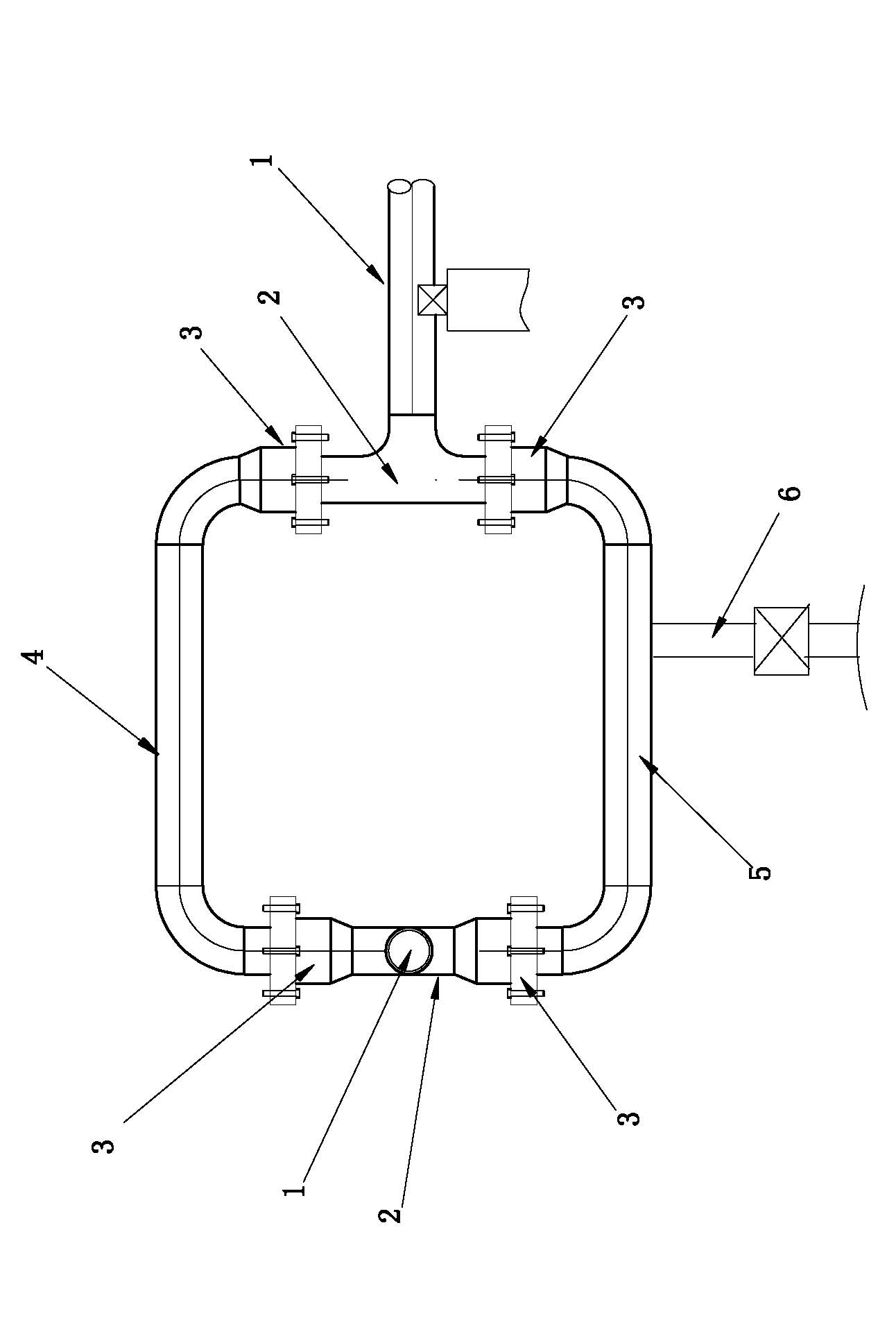

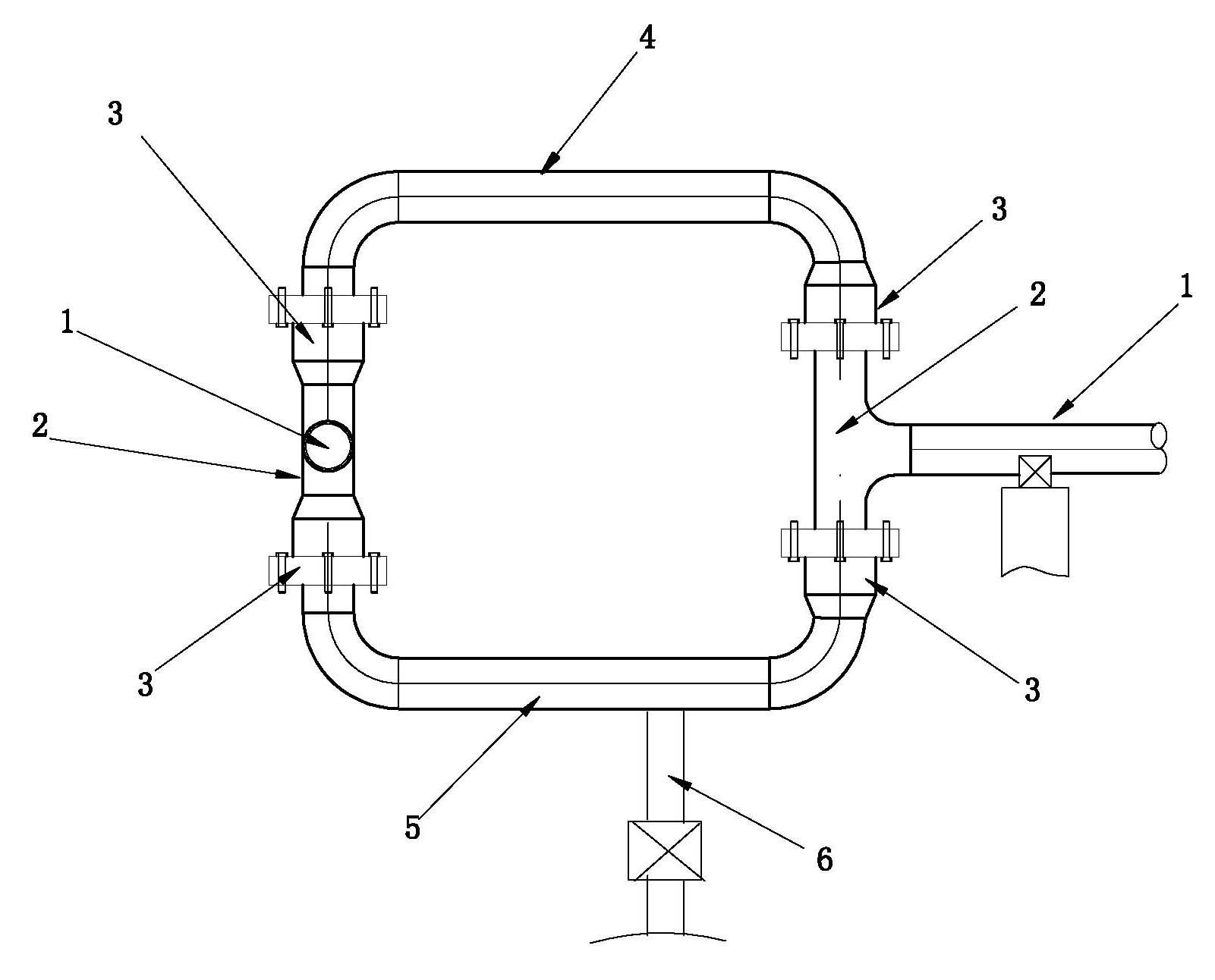

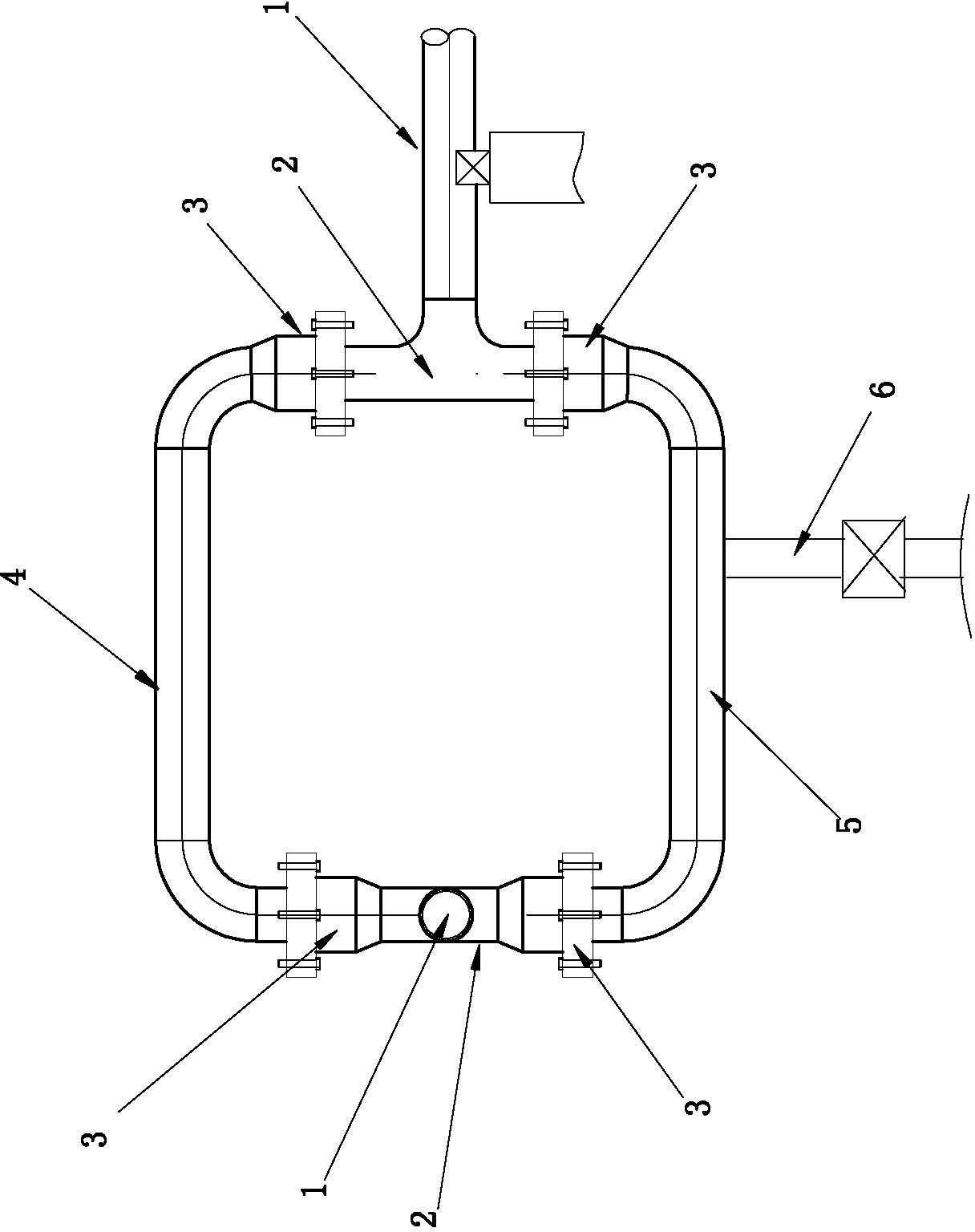

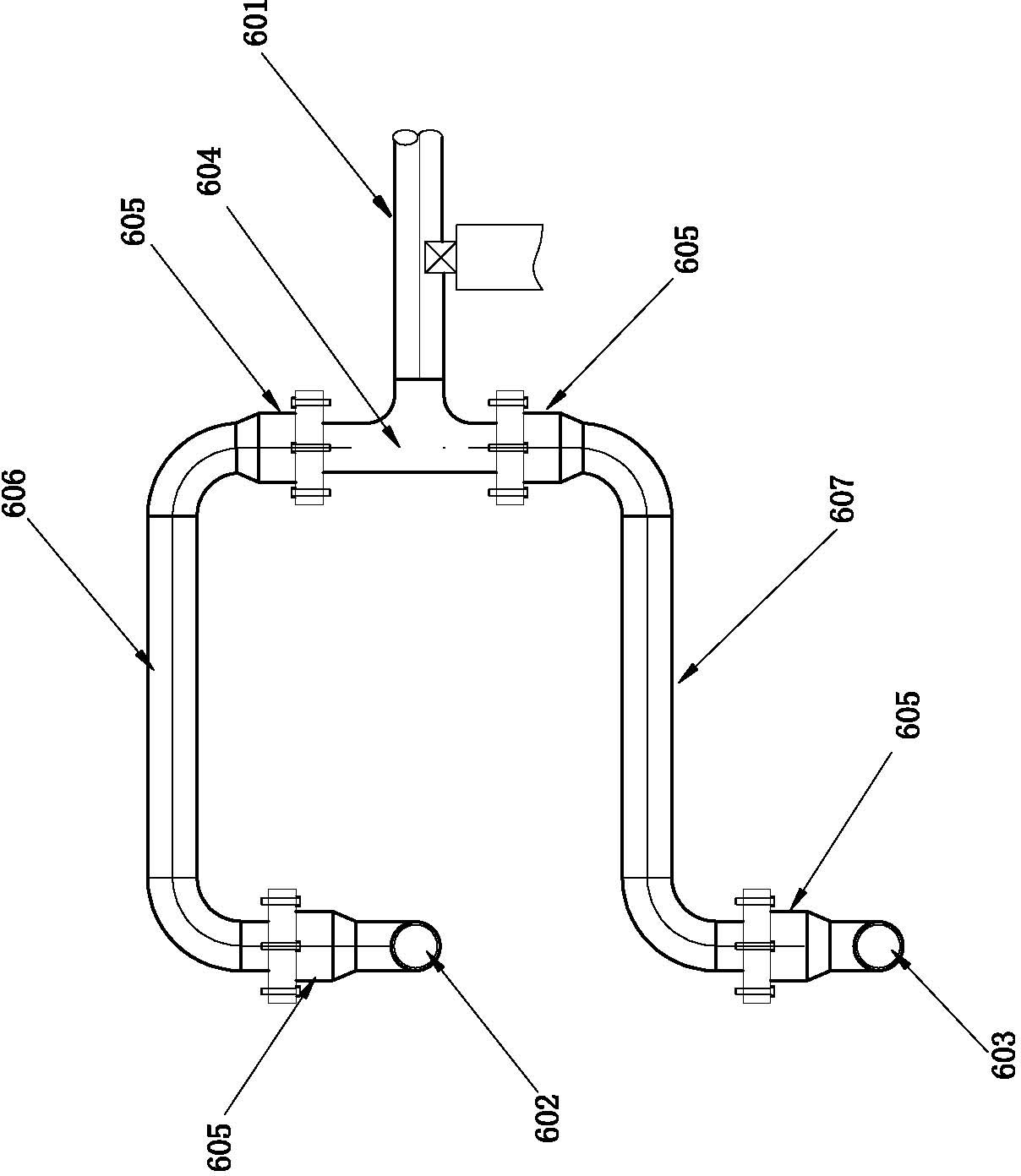

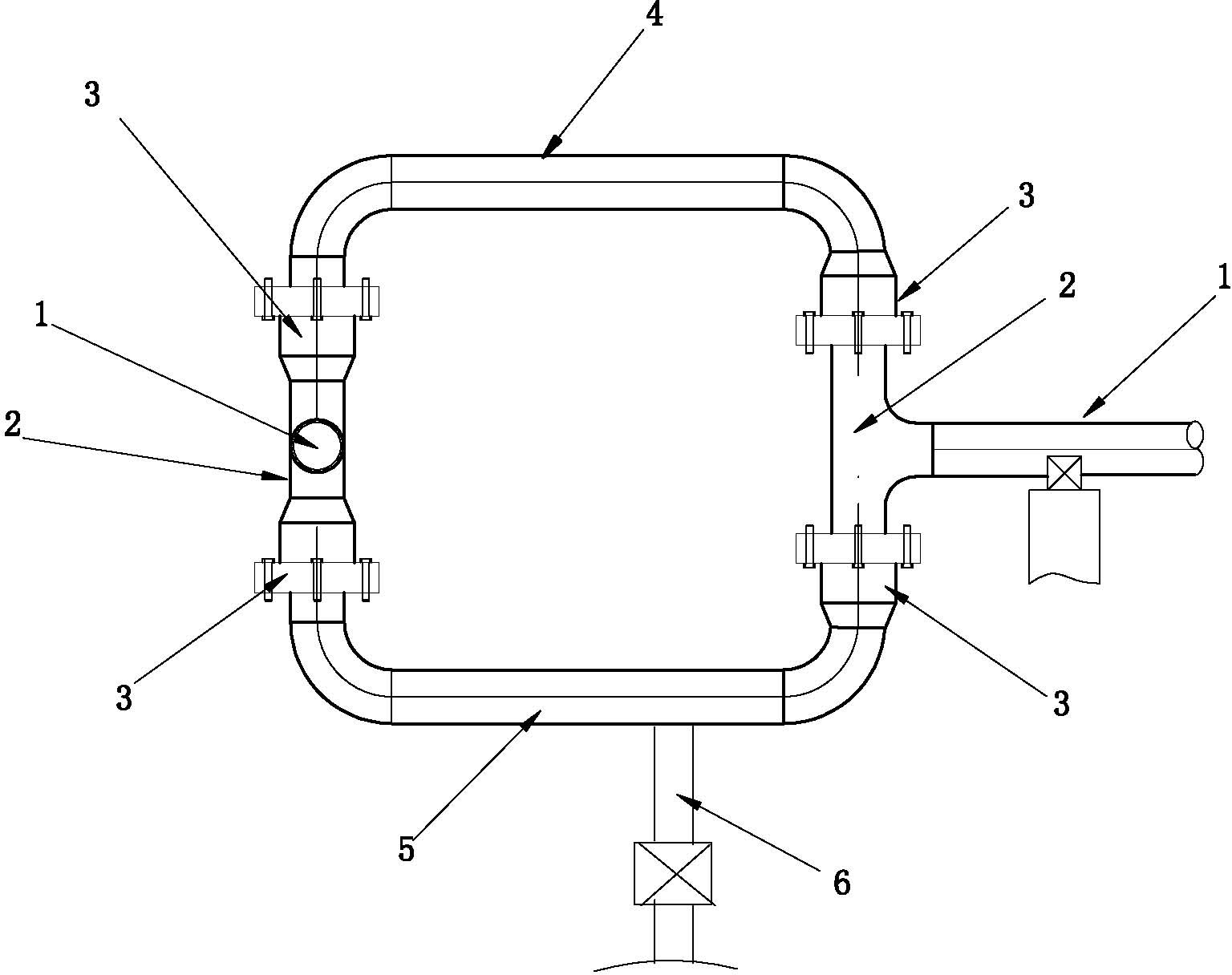

Deformation Compensation System for Closed Petroleum and Petrochemical Flare Horizontal Pipeline Based on Rotary Compensator

InactiveCN102278560AExtended service lifeSave investmentPipeline expansion-compensationLiquid mediumTorch

A closed-type petroleum and petrochemical flare horizontal pipeline deformation compensation system based on a rotary compensator is characterized in that it includes at least one closed rotary compensator installed on the flare horizontal pipeline, and the closed rotary compensator consists of four rotary compensators The compensator (3) is composed of two vertically installed tee pipes (2), the upper connecting pipe (4) and the lower connecting pipe (5). The corresponding ports of the horizontal torch pipe (1) of the same straight line are connected, and the two vertical nozzles of each three-way pipe (2) are respectively connected with a rotary compensator (3), and the upper ends of the two three-way pipes (2) The rotary compensator (3) is connected through the upper connecting pipe (4) to form a pipeline for the circulation of the gaseous medium, and the rotary compensator (3) located at the lower end of the two tee pipes (2) is connected through the lower connecting pipe (5) to form a pipeline for the circulation of the gaseous medium. Pipelines for the flow of liquid media. The invention has the advantages of long compensation distance, small investment, safety and reliability.

Owner:JIANGSU HONGXIN REVOLVING COMPENSATOR TECH

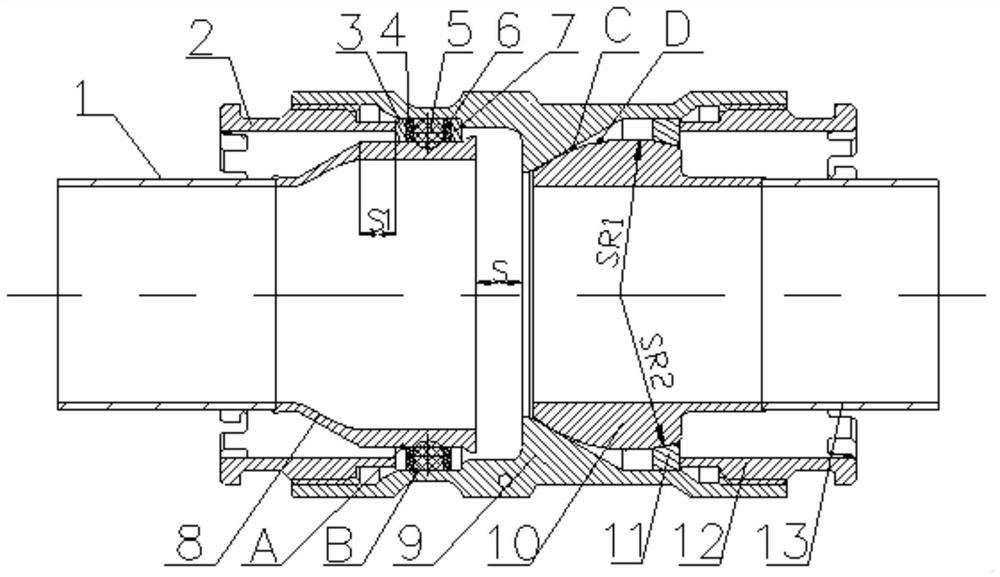

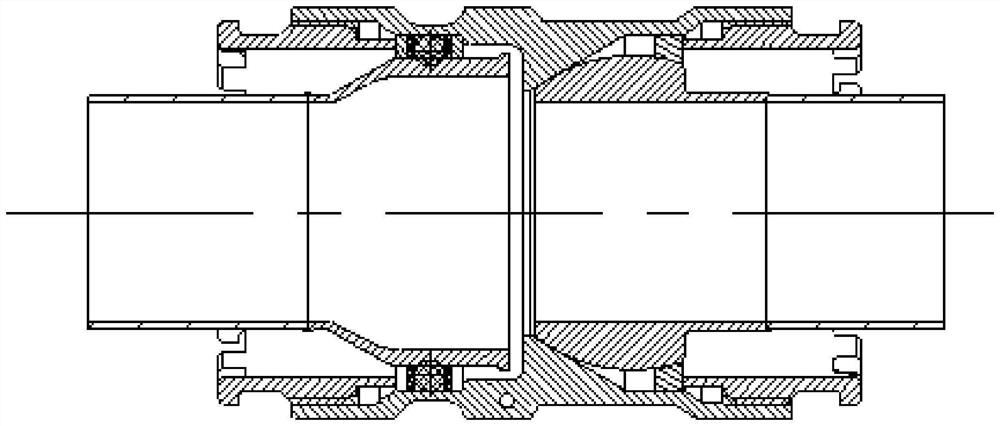

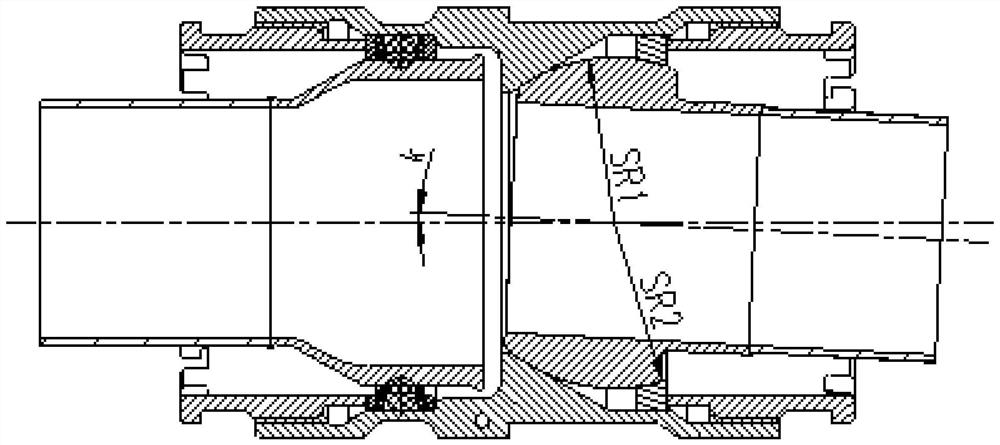

Pipeline connecting device with multidirectional displacement compensation capability

PendingCN113932078ASimplify design difficultyImprove maintainabilityAdjustable jointsStructural engineeringMechanical engineering

The invention belongs to the field of aero-engine external pipeline design, and particularly relates to a pipeline connecting device with multidirectional displacement compensation capability. The pipeline connecting device comprises a first pipeline, wherein one end of the first pipeline is a columnar port, the outer wall is an outer cylindrical surface, and the tail end protrudes to form a flange; a second pipeline, wherein one end of the second pipeline is a spherical port; and a connecting pipe which comprises a first sleeve opening and a second sleeve opening, wherein the first sleeve opening sleeves the first pipeline, an elastic O-shaped ring is arranged between the first sleeve opening and the outer cylindrical surface, the second sleeve opening sleeves the second pipeline, the position, corresponding to the spherical port of the second pipeline, of the second sleeve opening is in a horn shape, and a first connecting piece and the connecting pipe are matched in shape to clamp the elastic O- shaped ring. Through the integrated design of axial compensation and angular compensation, the compensation requirements of the pipeline in all directions can be met while the sealing performance is guaranteed; and the pipeline connecting device has the advantages of a simple structure, small occupied space and strong compensation capability.

Owner:AECC SHENYANG ENGINE RES INST

Petroleum and petrochemical torch horizontal pipeline deformation compensation method and system based on rotary compensator

ActiveCN102230559AExtended service lifeNo fatigue damagePipeline expansion-compensationLiquid mediumPetrochemical

The invention discloses a petroleum and petrochemical torch horizontal pipeline deformation compensation method and a petroleum and petrochemical torch horizontal pipeline deformation compensation device based on a rotary compensator. The method is characterized by comprising the following steps of: firstly, connecting two pipe ends at a corner of a torch horizontal pipeline or pipe ends of two parallel pipelines with a three-way pipe respectively; secondly, connecting two vertical straight ends of each three-way pipe with rotary compensators; and finally, communicating the rotary compensators at upper ends of two three-way pipes through an upper communicating pipe so as to circulate a gaseous medium, and communicating the rotary compensators at lower ends of the two three-way pipes through a lower communicating pipe so as to circulate a liquid medium; therefore, the whole petroleum and petrochemical torch horizontal pipeline is subjected to deformation compensation in a length direction, and the circulation of gaseous and liquid phase media is not influenced. The compensation system consists of an enclosed compensation system and a branch compensation system, which consist of three-way pipes and rotary compensators. The system has the advantages of long compensation distance, low investment, safety and reliability.

Owner:JIANGSU HONGXIN REVOLVING COMPENSATOR TECH

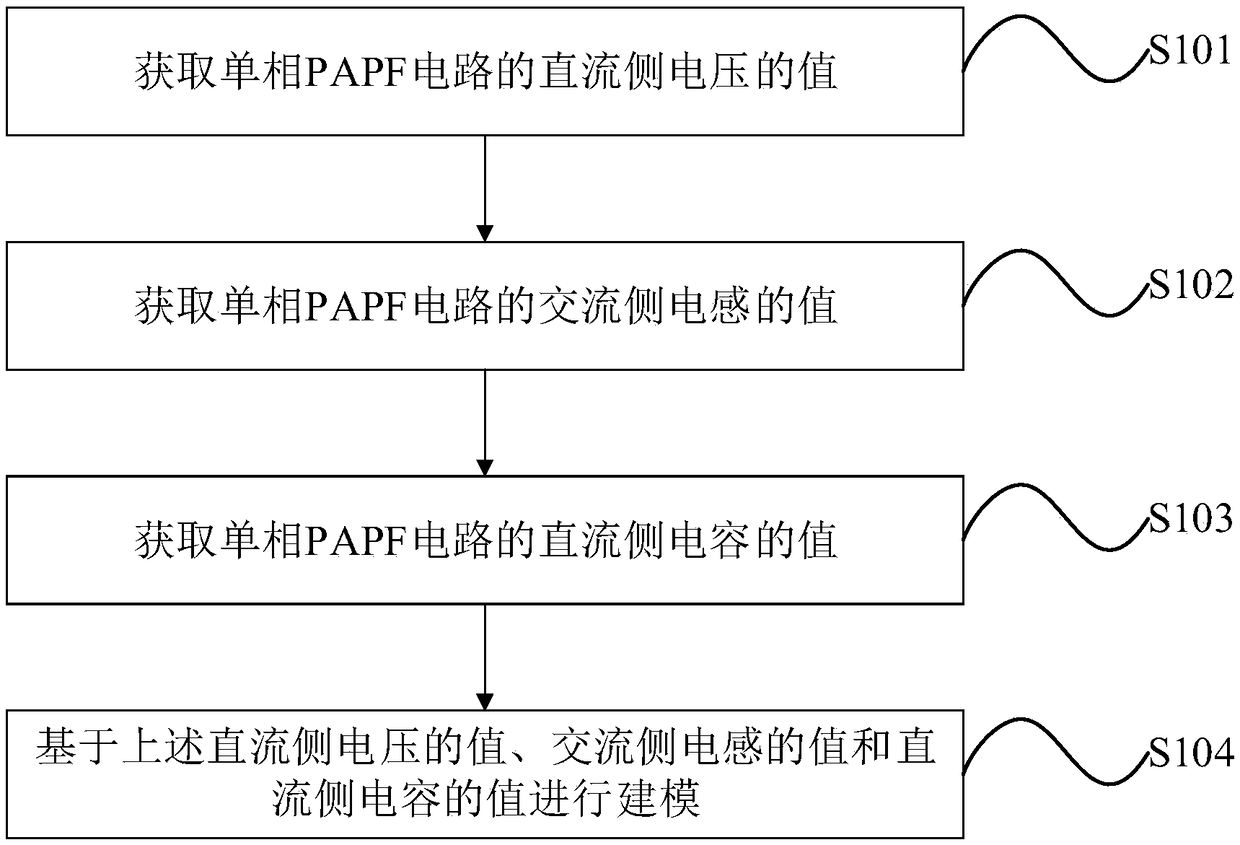

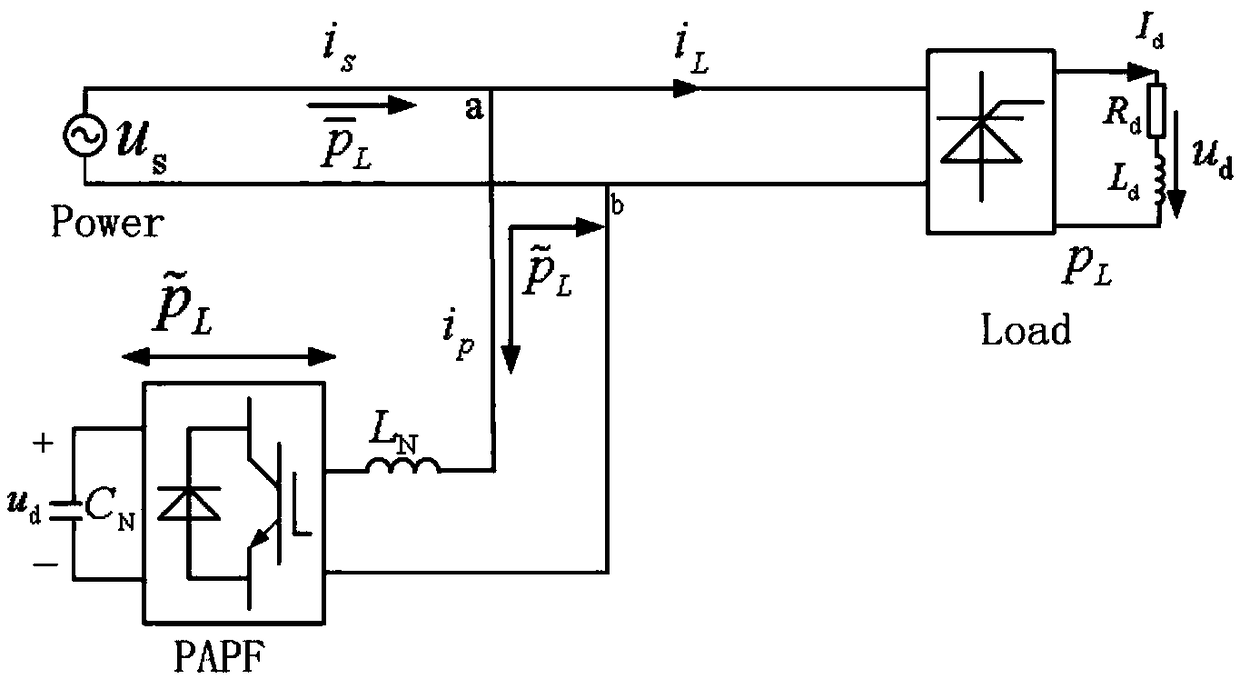

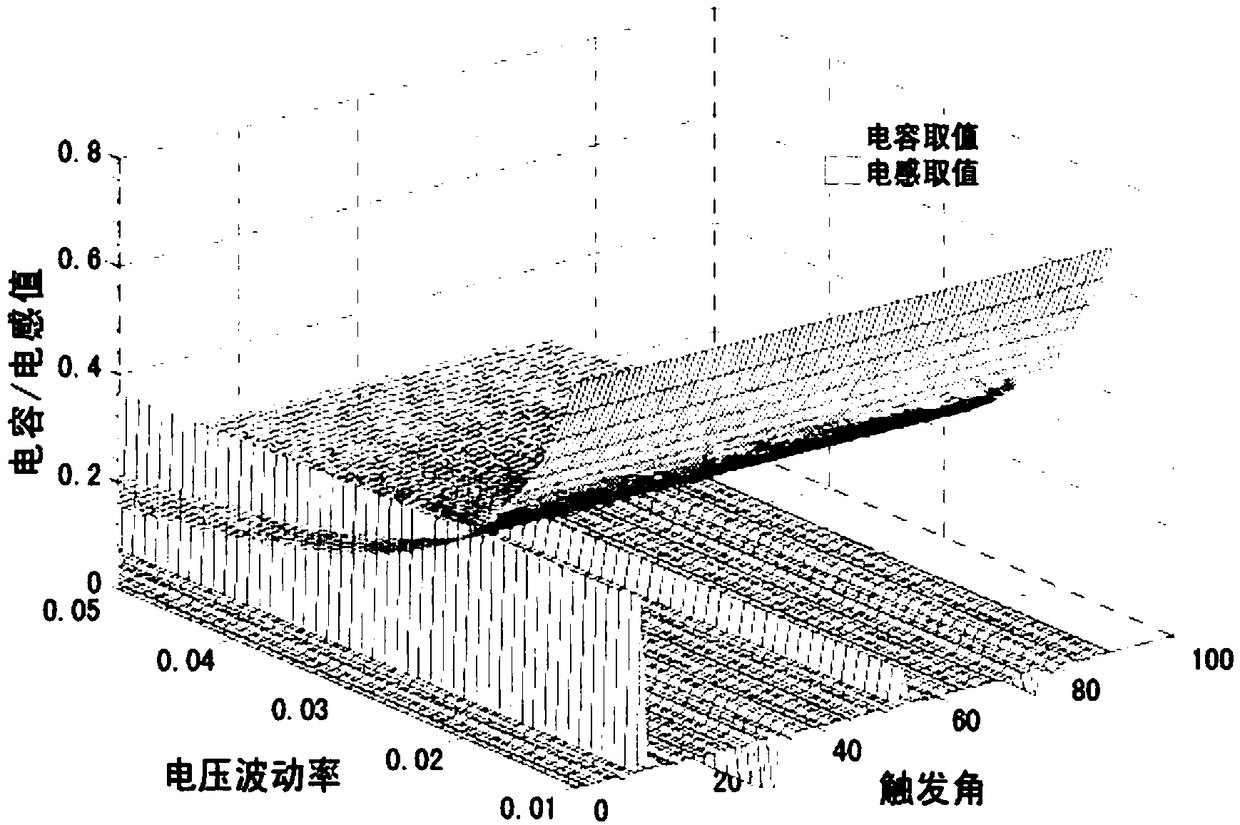

A single-phase PAPF circuit modeling method considering coupling relation

ActiveCN109241652ASatisfy Compensation RequirementsWell formedActive power filteringSpecial data processing applicationsSingle phaseCapacitance

The invention discloses a single-phase PAPF circuit modeling method considering coupling relation, which comprises the following steps: obtaining the value of DC side voltage of the single-phase PAPFcircuit; Acquiring a value of the AC side inductance of the single-phase PAPF circuit; Obtaining a value of the DC side capacitance of the single-phase PAPF circuit; Based on the value of the DC-sidevoltage, modeling the value of the AC-side inductance and the value of the DC-side capacitance. By reasonably choosing the parameters of single-phase PAPF circuit, the compensation requirements underall conditions of a particular load can be met, and the form is simple, the calculation is convenient, the versatility is strong, the equipment cost can be reduced, the compensation effect can be improved and the stability of the whole system can be improved. At the same time, aiming at the coupling relationship between the parameters of the main circuit, starting from the actual operating conditions, through the MATLAB three-dimensional modeling and data optimization, a clear parameter selection method is obtained. The simulation and experimental results verify the correctness and feasibilityof the method.

Owner:LANZHOU JIAOTONG UNIV

Zoom lens system, imaging device and camera

InactiveUS20080247056A1High resolutionShorter overall optical lengthOptical elementsCamera lensOptical axis

A zoom lens system comprising a first lens unit having negative power, a second lens unit having positive power and a third lens unit having positive power, wherein in zooming from a wide-angle limit to a telephoto limit, the lens units move respectively along an optical axis in such a manner that an interval between the first lens unit and the second lens unit decreases while an interval between the second lens unit and the third lens unit changes so that variable magnification is achieved, the first lens unit comprises one object side negative lens element and one image side positive lens element with a convex surface facing the object side, which have an aspheric surface, and the conditions: n12>1.88 and ν12<26 (n12 and ν12 are refractive index and Abbe number, respectively, of the image side positive lens element of the first lens unit) are satisfied.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com