Ultrahigh pressure metal hose with external strengthened layer

A metal hose and reinforcement layer technology, applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of insufficient flexibility, insufficient functions, poor radial displacement flexibility, etc., and achieve high structural strength and high performance. Stable, good flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

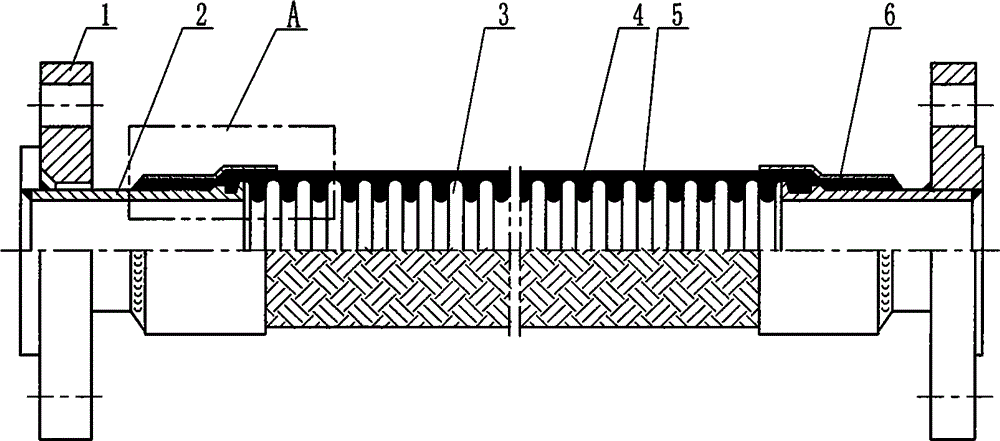

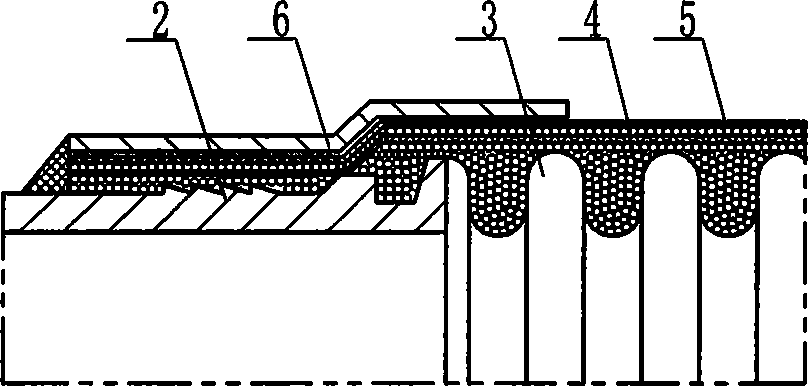

[0019] figure 1 The shown embodiment of the ultra-high pressure metal hose with an external reinforcement layer is matched in the liquid ammonia transmission pipeline, with a diameter of 150mm, a bearing pressure of 25MPa, and a transmission medium temperature of -196°C. The ultra-high pressure metal hose with an external reinforcement layer includes a flange 1 , a connecting pipe 2 , a corrugated pipe 3 , a steel wire 4 , a metal mesh sleeve 5 and a sheath 6 . Both ends of the corrugated pipe 3 are sealed and connected to a connecting pipe 2 respectively, and the free ends of the connecting pipe 2 are sealed and connected to the flange 1 to form a conventional metal hose. The connecting pipe 2 is a round straight pipe, and the middle section of the connecting pipe 2 is provided with an annular groove. The purpose of opening the annular groove is to strengthen the fitting of the steel wire 4 and the metal mesh sleeve 5, so as to improve the interconnection strength to meet the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com