High magnification compact zoom lens

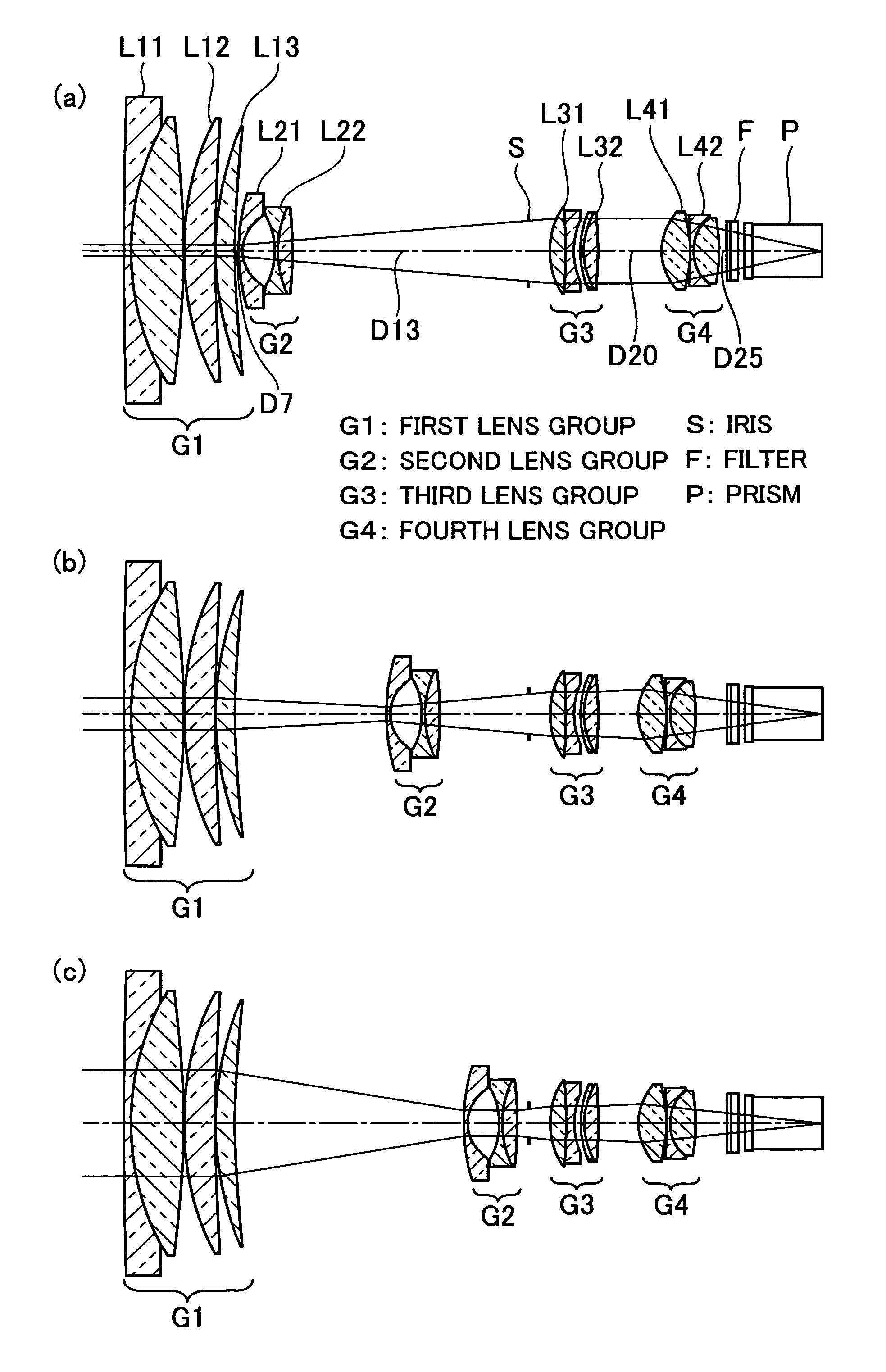

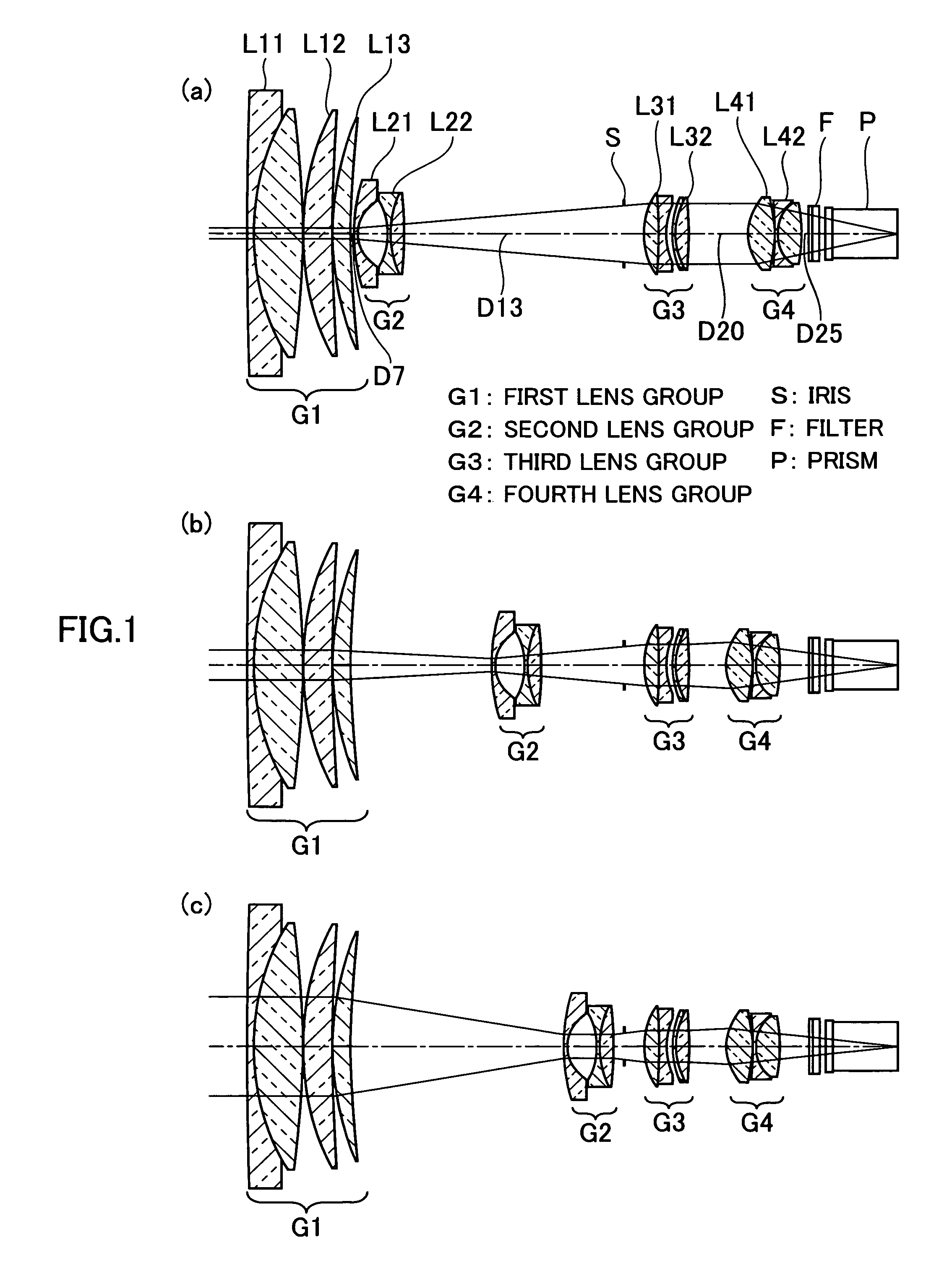

a compact, zoom lens technology, applied in the field of compact zoom lenses, can solve the problems of image blur increased power consumption required to move the fourth lens group for focusing, etc., to achieve the effect of reducing the weight, reducing the magnification ratio, and reducing the weight of the integrated image stabilizer or the vibration compensating mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

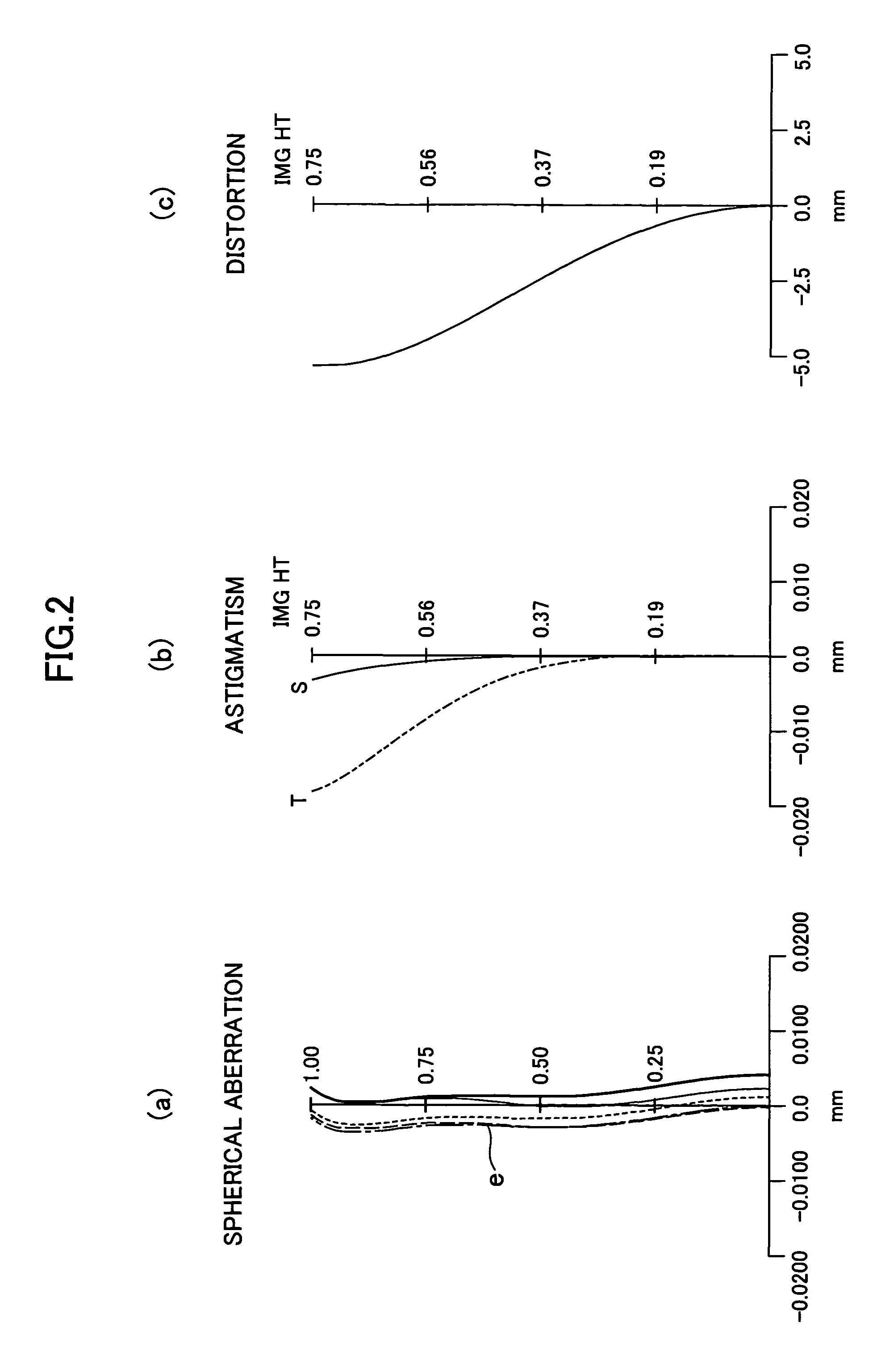

embodiment 1

[0066]Table 1 below shows various numerical data on a first preferred embodiment of a wide-view anti-vibration zoom lens according to the present invention where all the values are scaled to a normalized minimum focal length of 1 millimeter (mm). In Table 1, S is a number of surfaces, ASPH designates an aspherical surface, R is a radius of curvature in millimeters (mm), D is a thickness or a distance in millimeters (mm), Nd is a refractive index of the d-line (λ=587.6 nm), and ABv is an Abbe constant in relation with the d-line.

[0067]Aspherical surfaces can be expressed as in the following formula (20):

[0068]z=y2R(1+1-(1+K)y / R2)2+Ay4+By6+Cy8+Dy10(20)

where z is a depth of the aspherical surfaces, y is a height, R is a paraxial radius of curvature, K, A, B, C, and D denote a degree of asphericity, and the aspherical surfaces have their respective degrees of asphericity as listed in Table 1 below.

[0069]

TABLE 1SRDNdABv 1185.65560.40281.9036631.31 213.47782.83101.4970081.61 3−45.08820.0...

embodiment 2

[0077]Various numerical data on a second preferred embodiment of the wide-view anti-vibration zoom lens according to the present invention are listed in Table 2 similar to Table 1 where all the values are scaled to a normalized minimum focal length of 1 millimeter (mm).

[0078]

TABLE 2SRDNdABv 1187.95720.39101.9036631.31 214.50512.59791.4970081.61 3−43.71270.0355 414.68791.50341.7291654.67 584.13690.0355 616.23510.85691.8348142.72 732.0543(D7) 8 ASPH13.99320.04741.5361041.20 910.11020.18961.8830040.80102.15641.565811−3.29170.14221.8830040.8012−14.21800.03551325.70720.14221.9036631.31149.71560.66721.9459517.9815−9.7156(D15)Aperture0.00001.1848173.96270.70541.6668033.051872.37950.21331.8147437.0319 ASPH4.37890.4823208.97020.14221.8061033.27215.39910.70171.4874970.4422−14.5476(D22)23 ASPH3.42741.54031.6935053.3424 ASPH−8.88830.035525−19.96510.14221.8340037.34262.41711.12561.4970081.6127−7.6964(D27)280.00000.10191.5168064.20290.00000.46451.6180063.39300.00000.2915310.00000.40281.5168064.20...

embodiment 3

[0086]Various numerical data on a third preferred embodiment of the wide-view anti-vibration zoom lens according to the present invention are listed in Table 3 similar to Table 1 where all the values are scaled to a normalized minimum focal length of 1 millimeter (mm).

[0087]

TABLE 3SRDNdABV 1187.20380.40281.9036631.31 214.57352.59601.4970081.61 3−44.78670.0355 414.79861.54041.7291654.67 595.97160.0355 616.32700.85591.8348142.72 731.2796(D7) 8 ASPH17.67480.04741.5361041.20 911.75230.18961.8830040.80102.19341.531311−3.37430.14221.8830040.8012−14.21800.03551326.51080.14221.9036631.31149.66410.67031.9459517.9815−9.6641(D15)Aperture0.00001.184817 ASPH3.46090.78331.6889331.161844.08760.14221.8061033.27193.61800.5368208.03600.14221.8061033.27214.93640.71311.4874970.4422−15.98853.640223 ASPH3.38501.50061.6935053.3424 ASPH−8.87830.035525−20.02600.14221.8340037.34262.41711.16531.4970081.6127−7.7420(D27)280.00000.10191.5168064.20290.00000.46451.6180063.39300.00000.2915310.00000.40281.5168064.20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com