Deformation Compensation System for Closed Petroleum and Petrochemical Flare Horizontal Pipeline Based on Rotary Compensator

A rotary compensator and rotary compensation technology, applied in the direction of expansion compensation devices, pipe components, pipes/pipe joints/pipe fittings for pipelines, etc., can solve the problems of large investment in deformation compensation, short life, blockage, etc., to reduce work Load, low cost, and the effect of broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

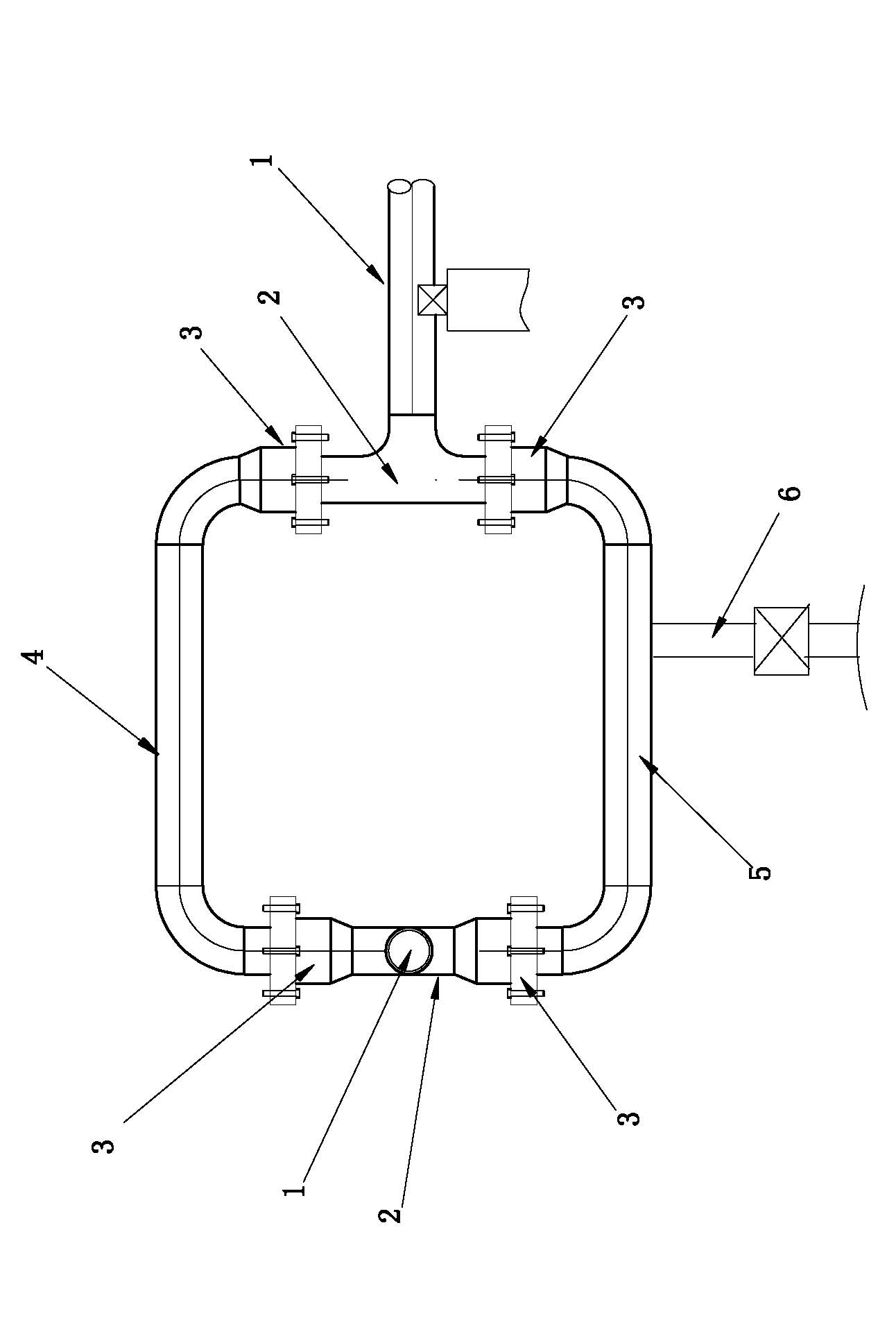

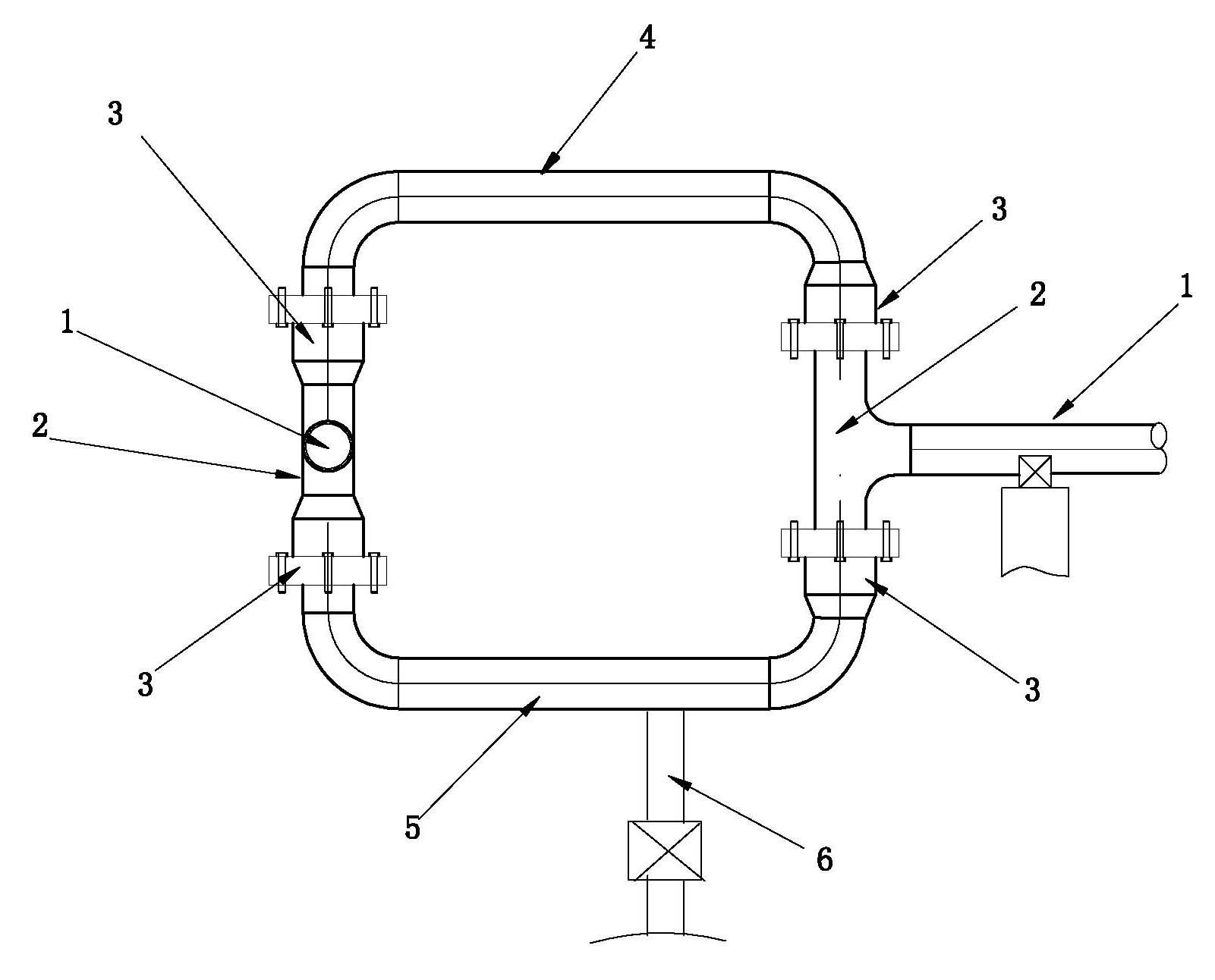

[0016] Such as figure 1 shown.

[0017] A closed-type petroleum and petrochemical flare horizontal pipeline deformation compensation system based on a rotary compensator, which includes at least one closed rotary compensation device (gate type) installed on the flare horizontal pipeline, and the closed rotary compensation device consists of four The rotary compensator 3 is composed of two vertically installed tee pipes 2, the upper connecting pipe 4 and the lower connecting pipe 5, and the two horizontal nozzles with the vertically installed tee pipe 2 are respectively corresponding to the horizontal pipes 1 of the torch that are not in the same straight line. The two vertical nozzles of each three-way pipe 2 are connected with a rotary compensator 3, and the rotary compensators 3 at the upper ends of the two three-way pipes 2 are connected through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com