Engine test propellant supply low frequency ripple suppression method and system

A pulsation suppression and propellant technology, applied in jet engine testing, gas turbine engine testing, etc., can solve problems such as reducing engine stability, resonance, and heavy equipment weight, and achieve improved stability, reduced pulsation, and uniform injection devices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

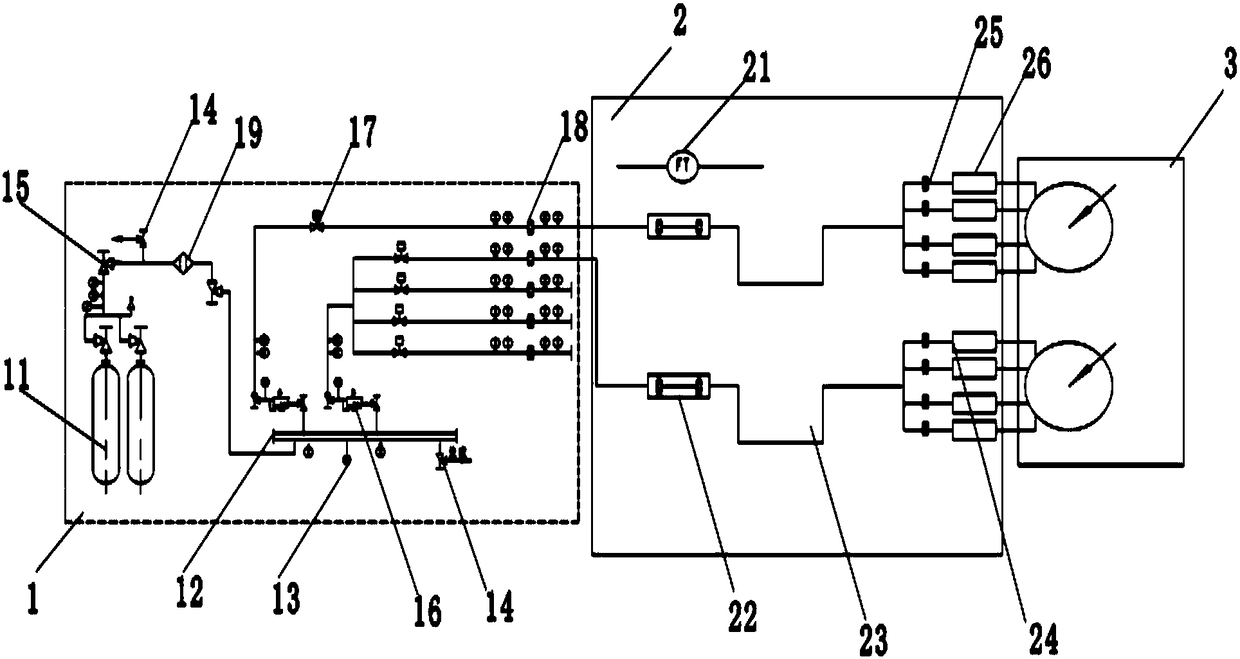

[0063] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

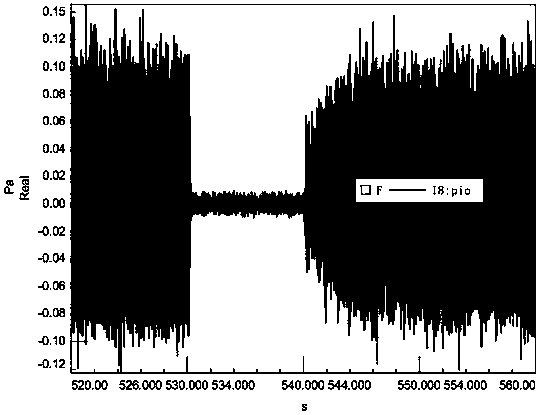

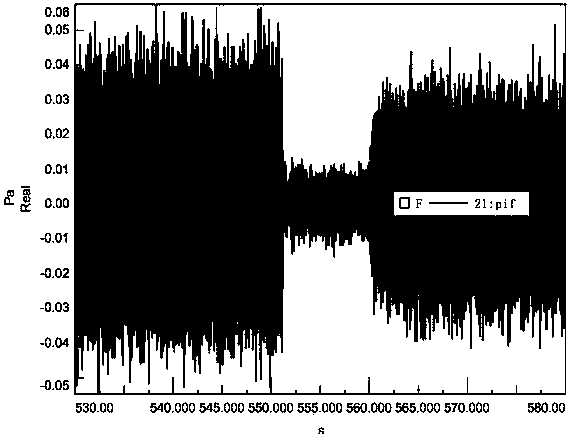

[0064] The method of the present invention calculates parameters such as helium injection gas volume, gas distribution, and injected gas form of the propellant supply pipeline through simulation simulation, and the mixing of the simulated gas changes the natural frequency of the propellant supply system to adjust the self-pulsation of the propellant. Reduced coupling of the propellant supply system to the engine. Due to the cavitation margin of the engine turbo pump, it will not affect the work of the engine under the condition that the form gas volume is controllable. Through the application of this method, the pulsation of propellant supply is reduced, the stability of propellant supply is improved, and the stability of the entire engine pump system is further improved. This method was applied in engine tests.

[0065] Combining simulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com