Lubricating liquid for lubricating surface of aluminum alloy material and preparation method thereof

A technology of aluminum alloy materials and lubricating fluids, applied in the field of lubricating fluids, can solve the problems of improving the deformation resistance of deformed metals, and achieve the effects of improving quality, eliminating surface defects, and eliminating oil stains and oxide scales

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific examples.

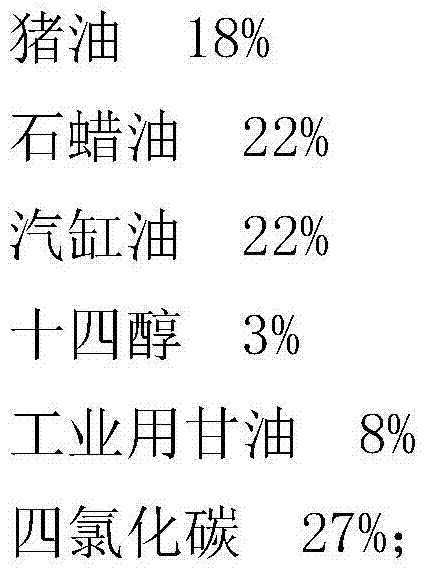

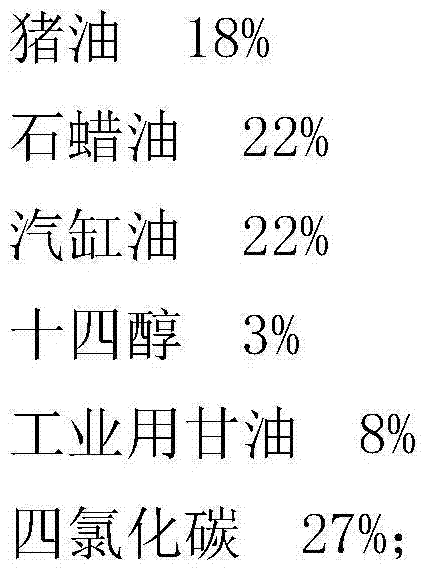

[0016] A lubricating fluid suitable for surface lubrication of aluminum alloy materials, composed of the following components in parts by mass:

[0017]

[0018] A method for preparing a lubricating liquid suitable for surface lubrication of aluminum alloy materials, comprising the following preparation steps:

[0019] (1) Heat the lard to 200 degrees Celsius with heating equipment, and cool it after the heating is completed. The cooling time is 30-60 minutes, and it is advisable to wait for the temperature to drop to about 120-150 degrees Celsius;

[0020] (2) After the cooling of the lard is completed, add 1 / 3 of the original amount of carbon tetrachloride for stirring, and use a constant speed mixer to continue stirring for 20-30 minutes;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com