Method and system for manufacturing railcar coupler locks

A rail car and coupler technology, applied in the direction of manufacturing tools, molding machines, casting and molding equipment, etc., can solve problems such as shortcomings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

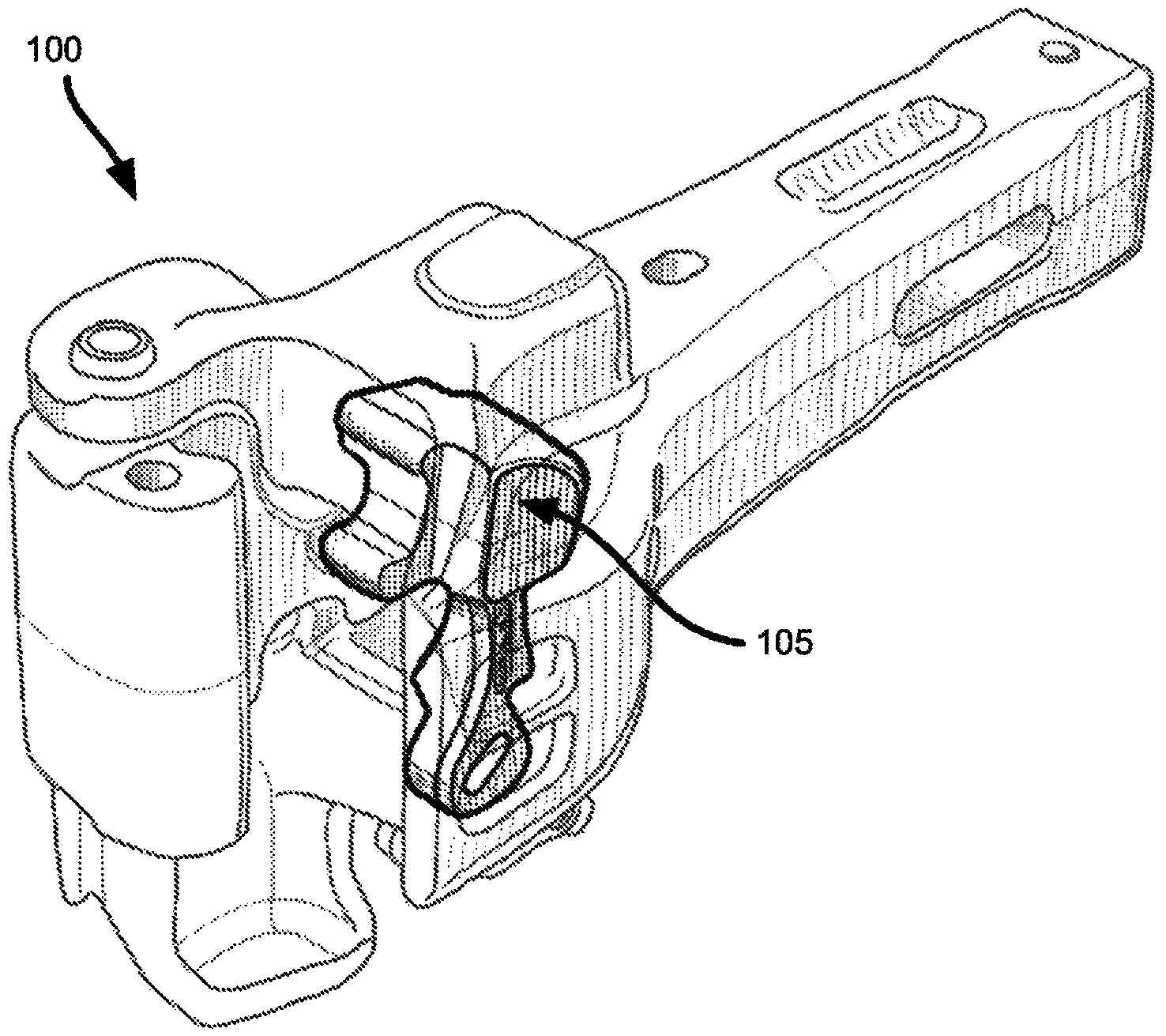

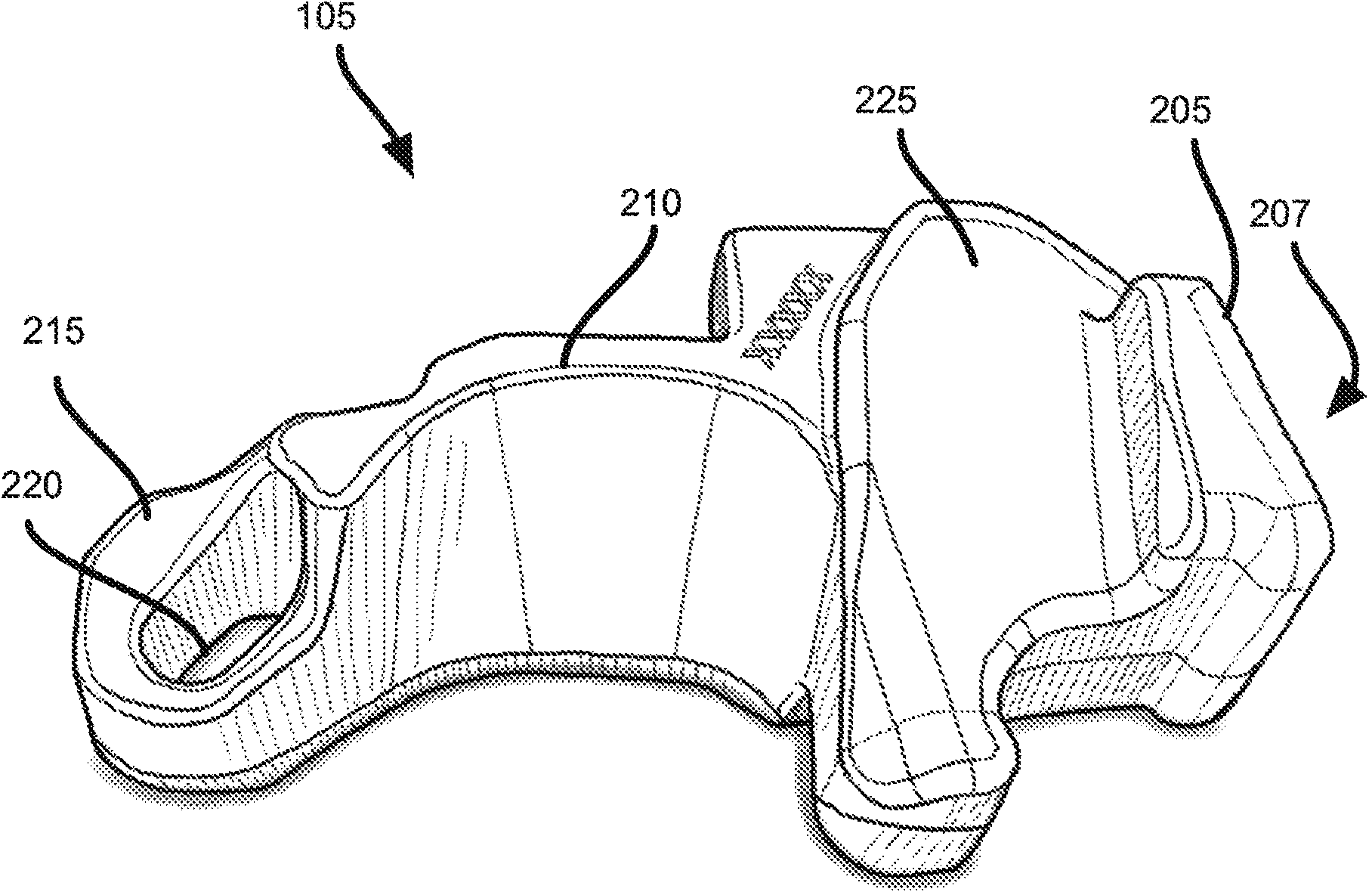

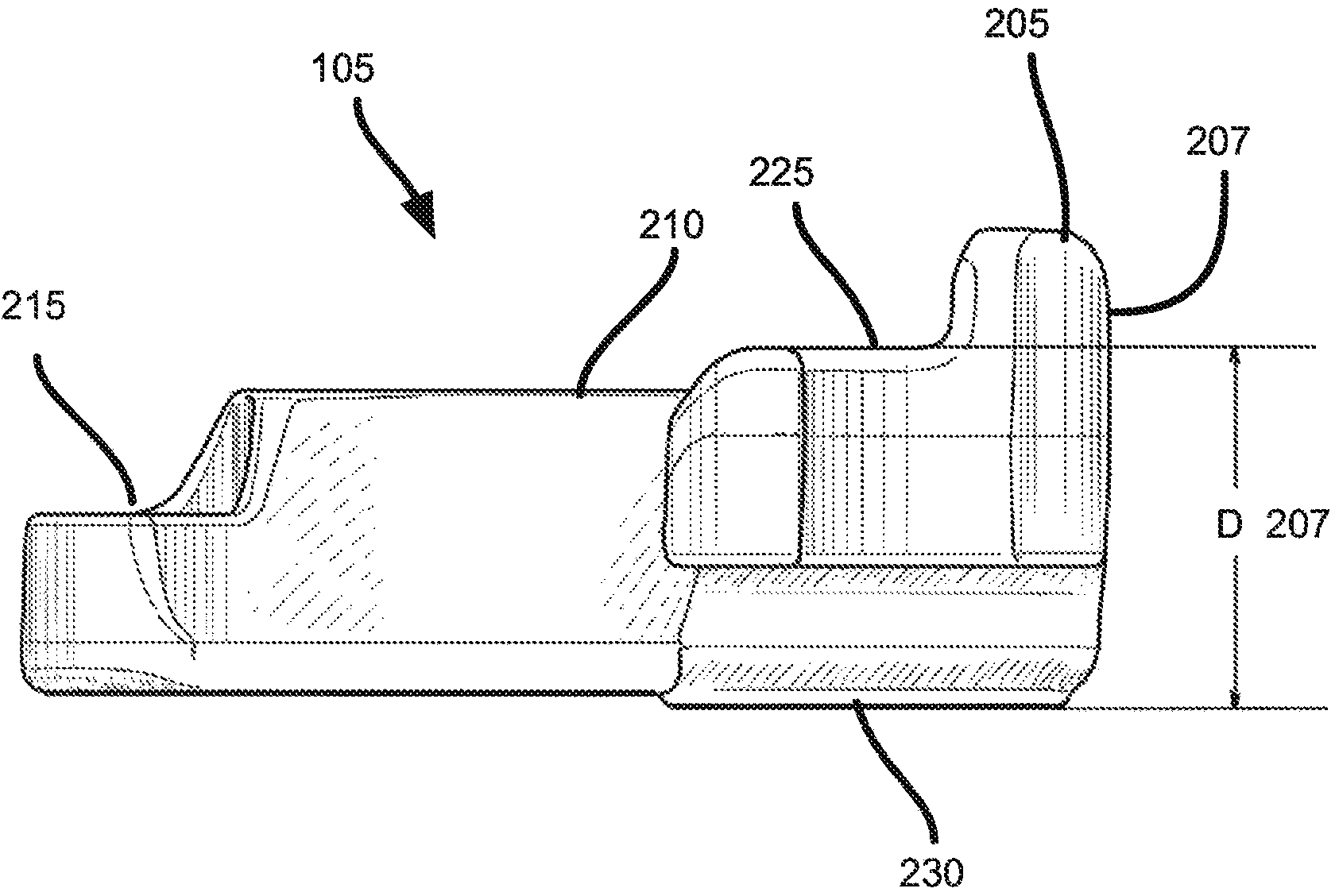

[0024] The following examples describe methods for making multiple locks in a single casting operation. Usually made into a set of shell shapes that define the shape of the lock. The shell type is a casting mold made of relatively expensive refined silica sand mixed with thermosetting phenolic resin. Refined silica sand allows the lock to have a smooth surface finish and relatively high dimensional accuracy compared to locks manufactured by other casting processes.

[0025] However, current shell production technology optimizes existing size shell machines and results in relatively small shells. Whereas the larger shell machines that exist tend to be very expensive. When technically feasible, it would be very expensive to increase the size of the shell to withstand the large discharge pressures required. Thus, the shell mold is put into the outer mold. The outer mold is made of less costly natural hardening or no-bake sand molding material and is configured to receive the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com