Patents

Literature

124results about How to "Increase surface lubricity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

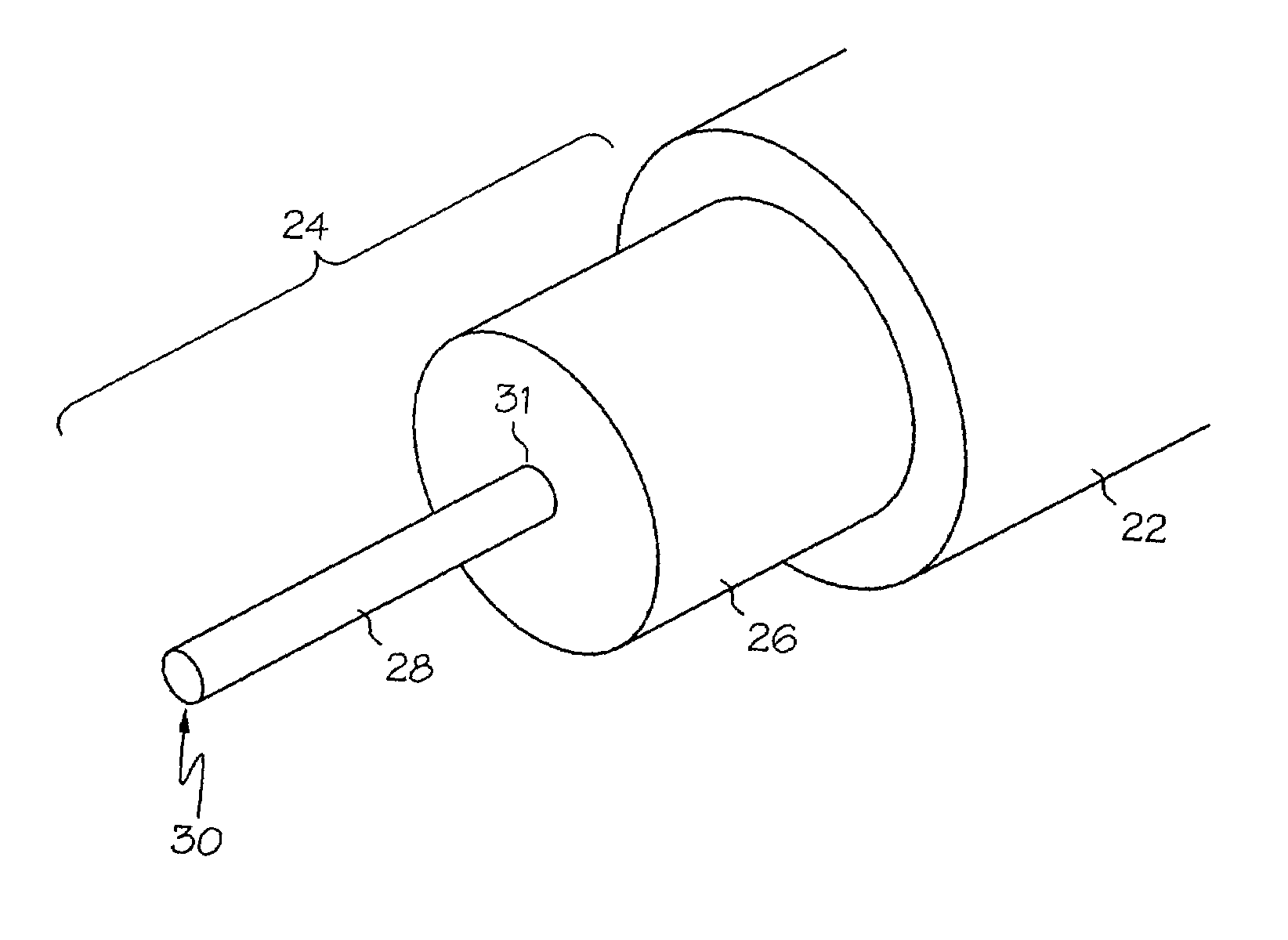

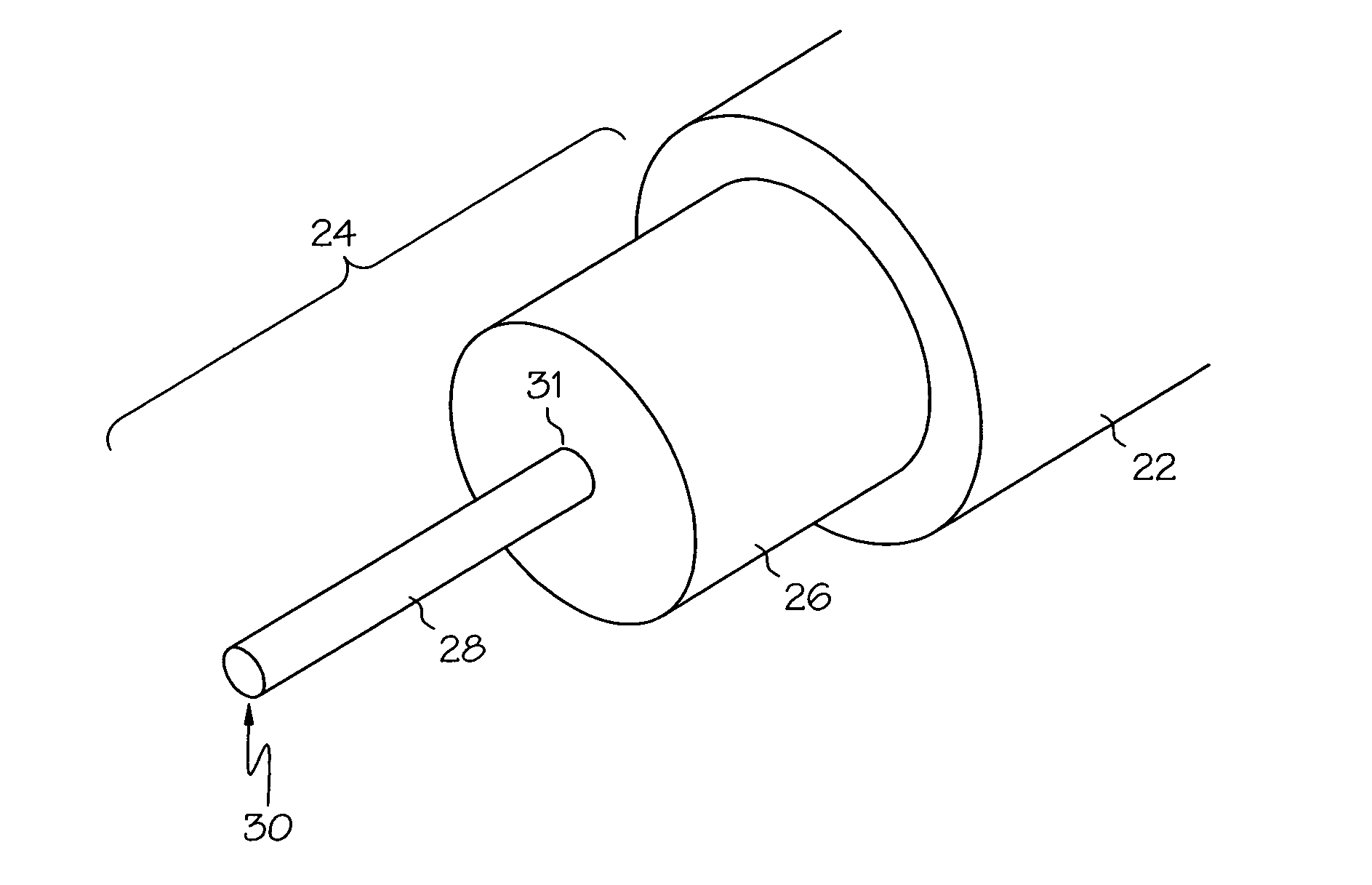

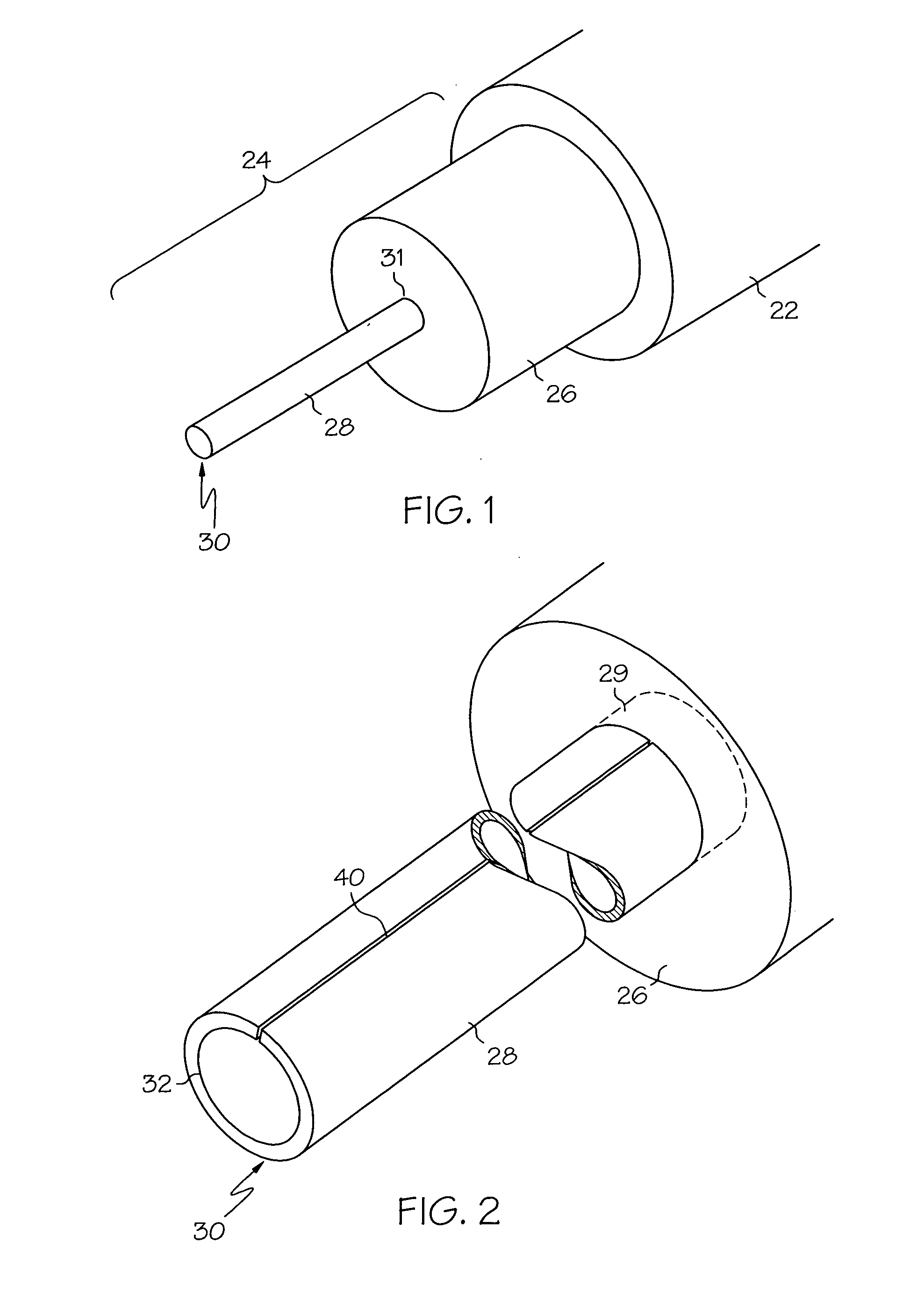

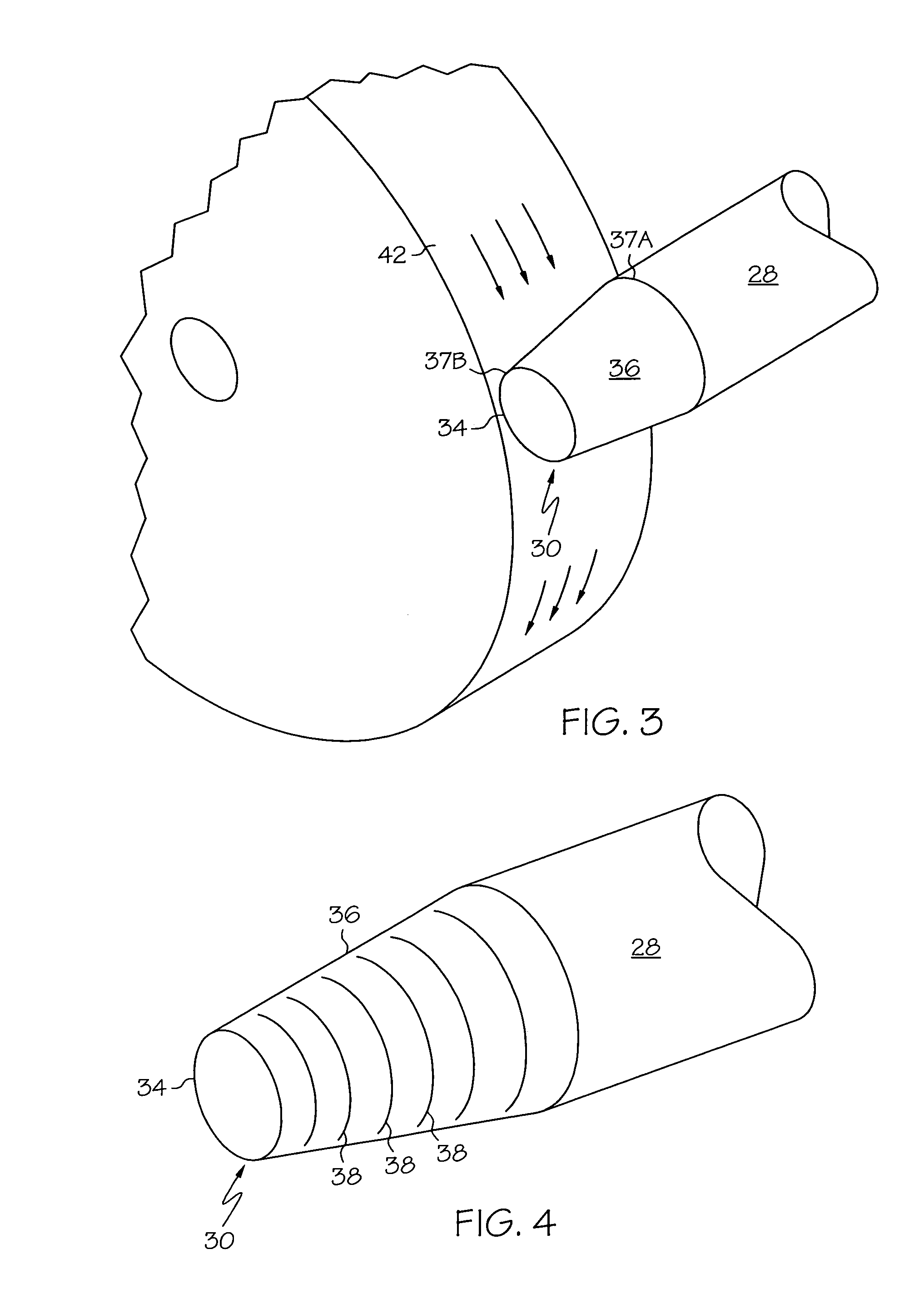

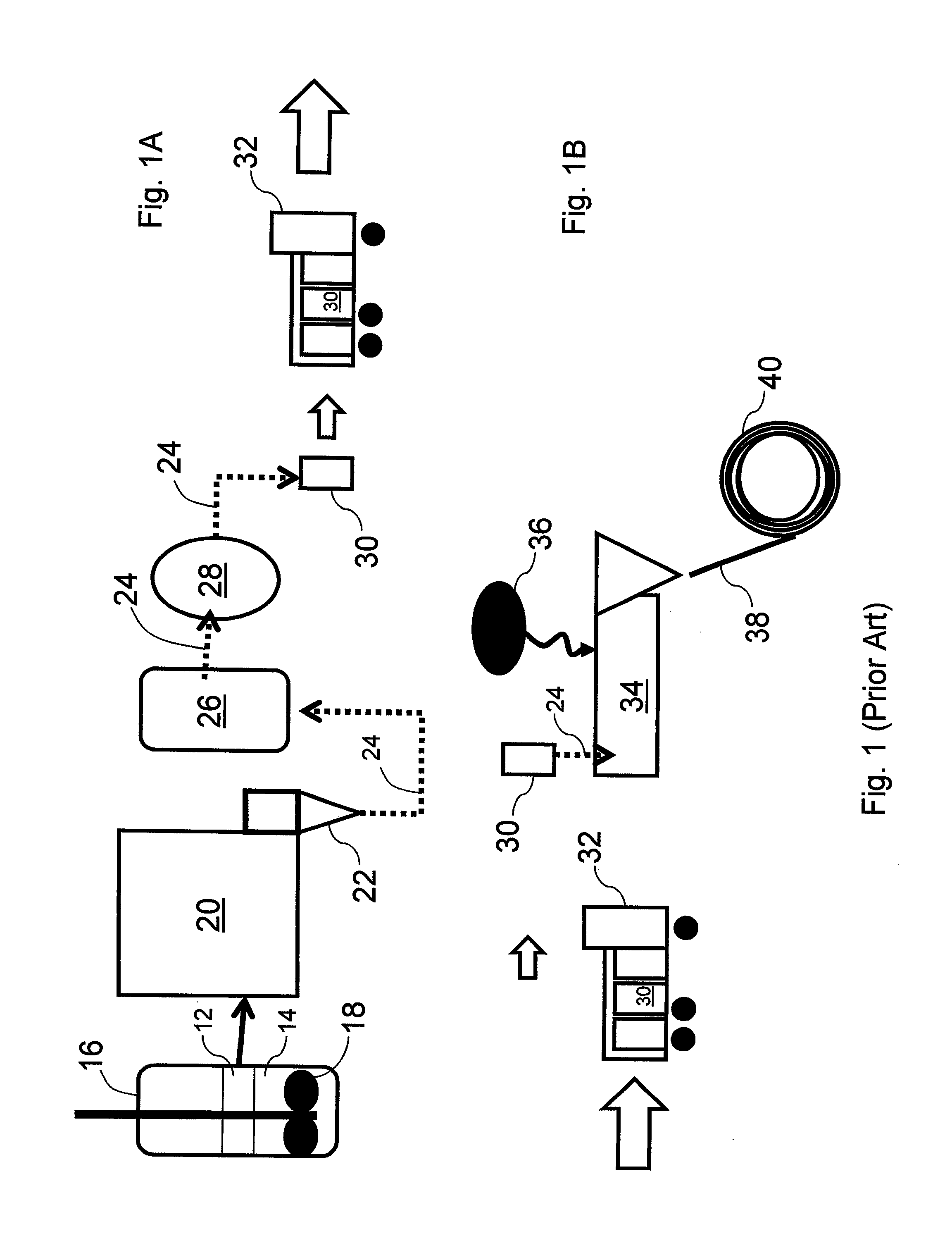

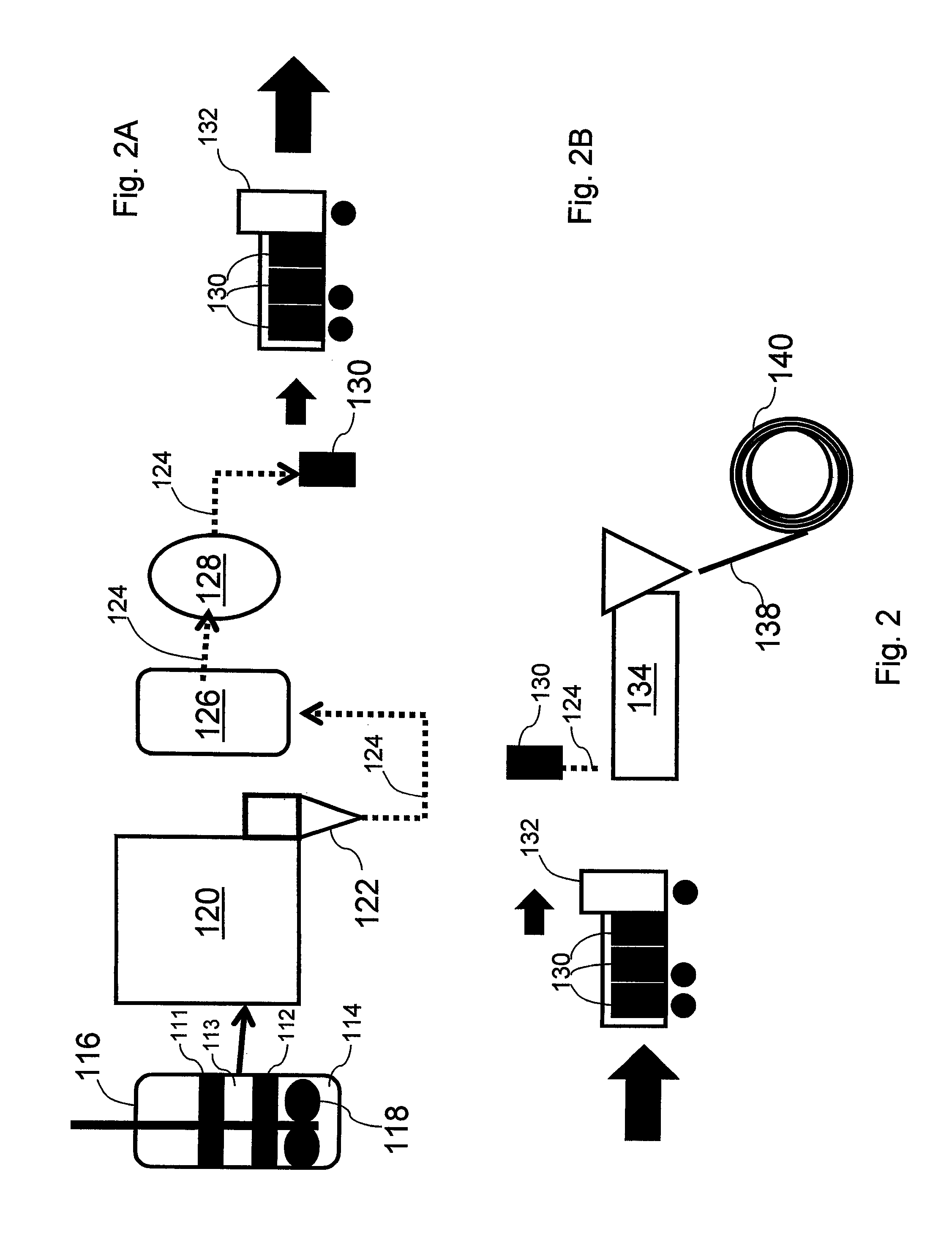

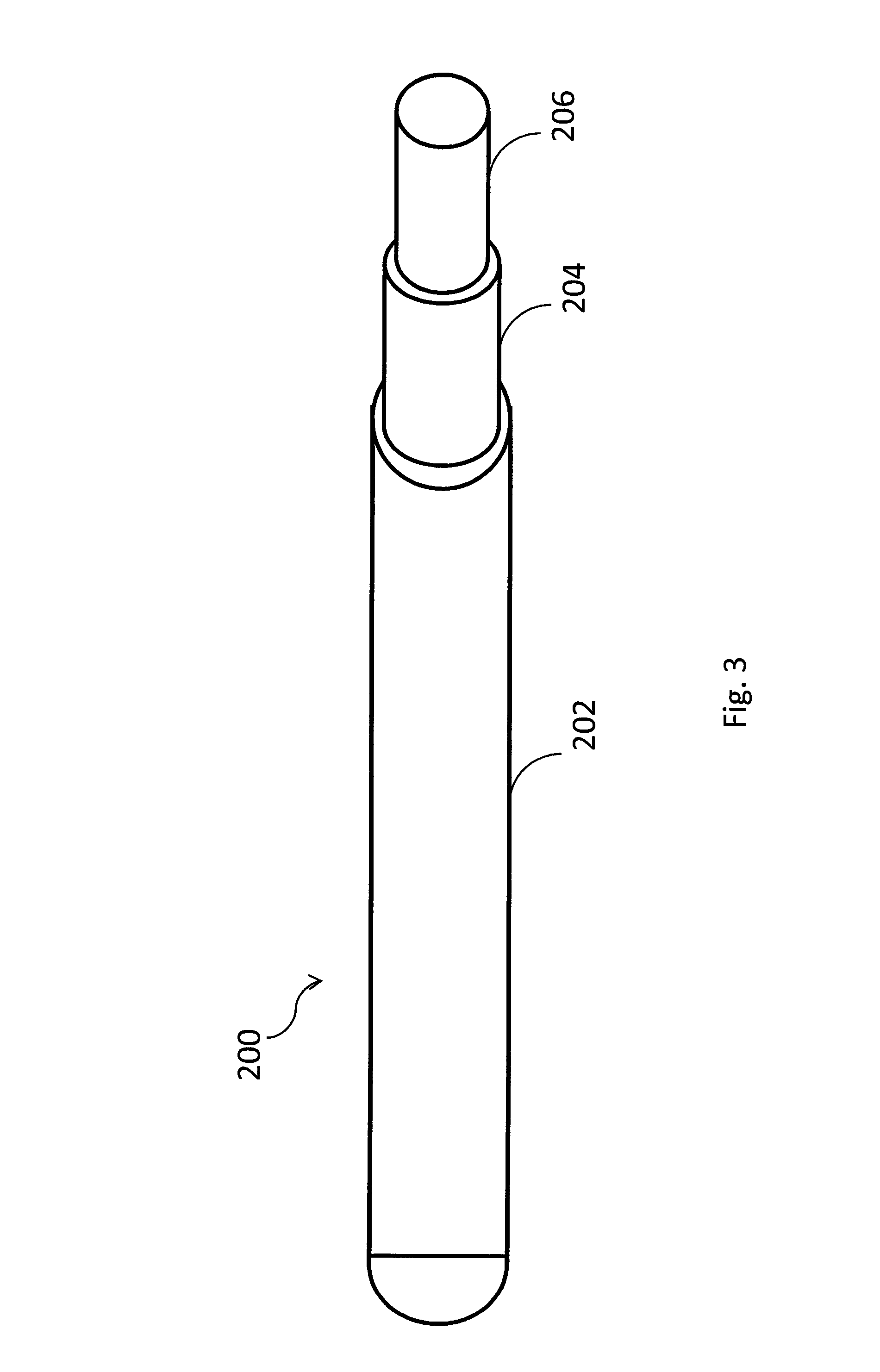

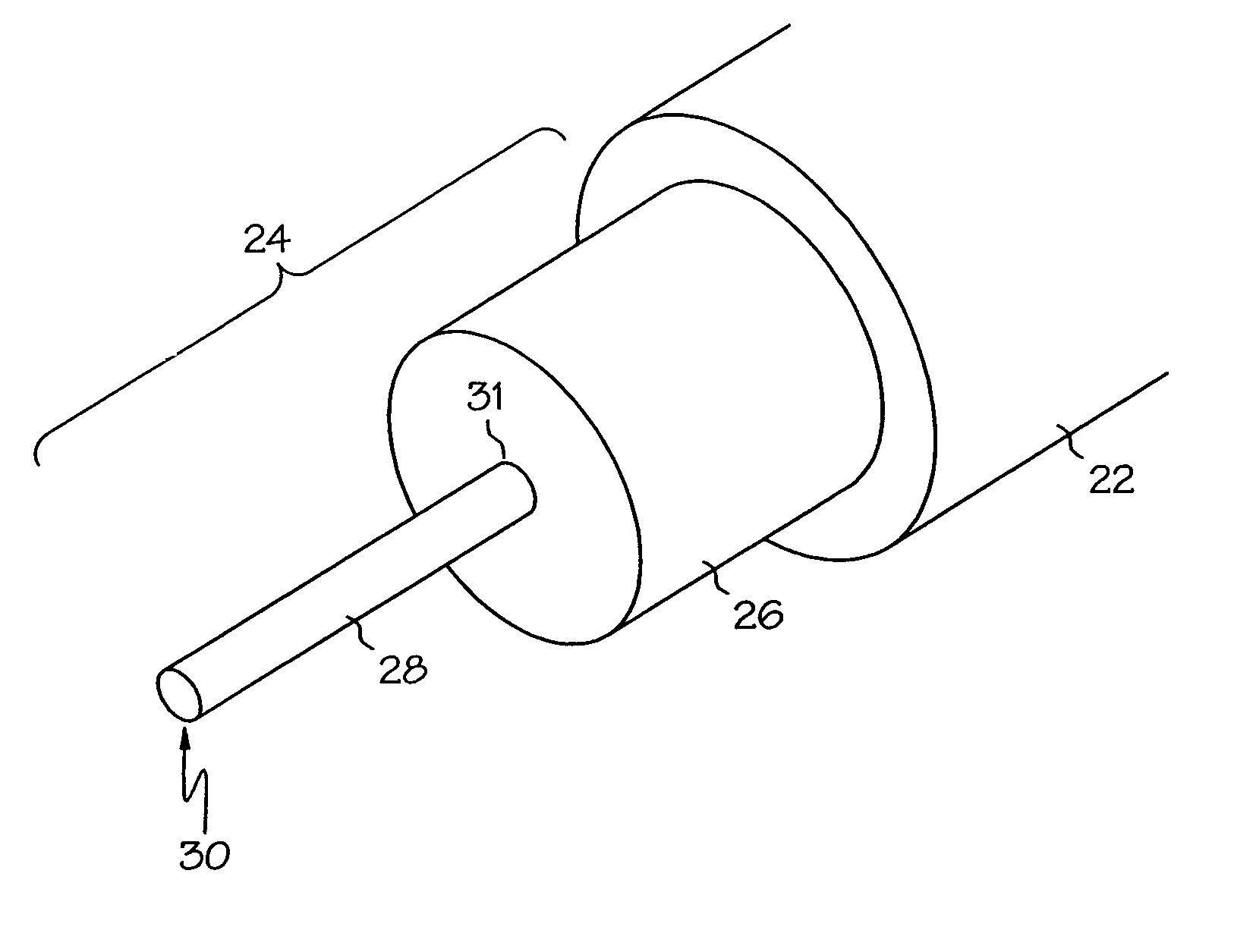

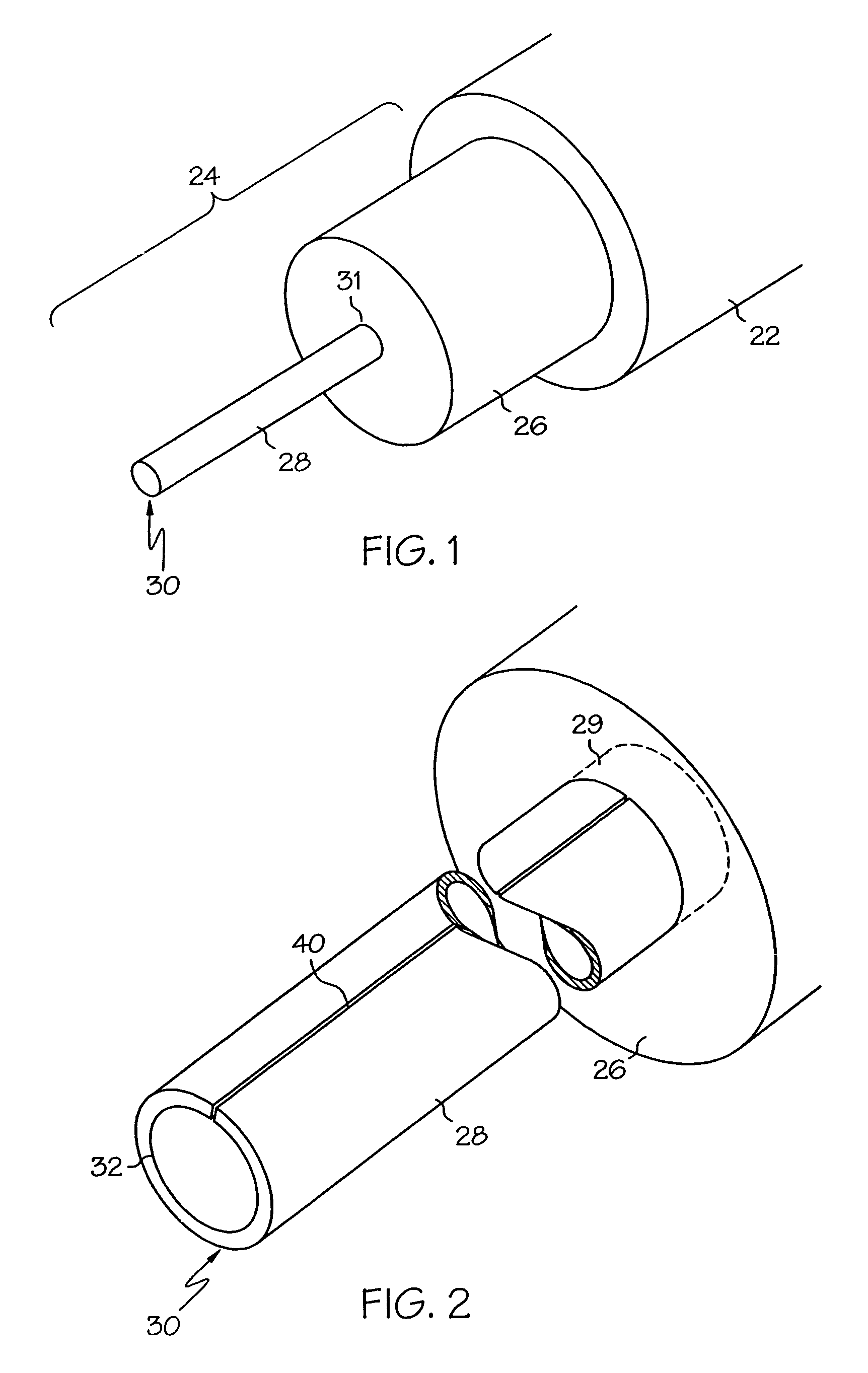

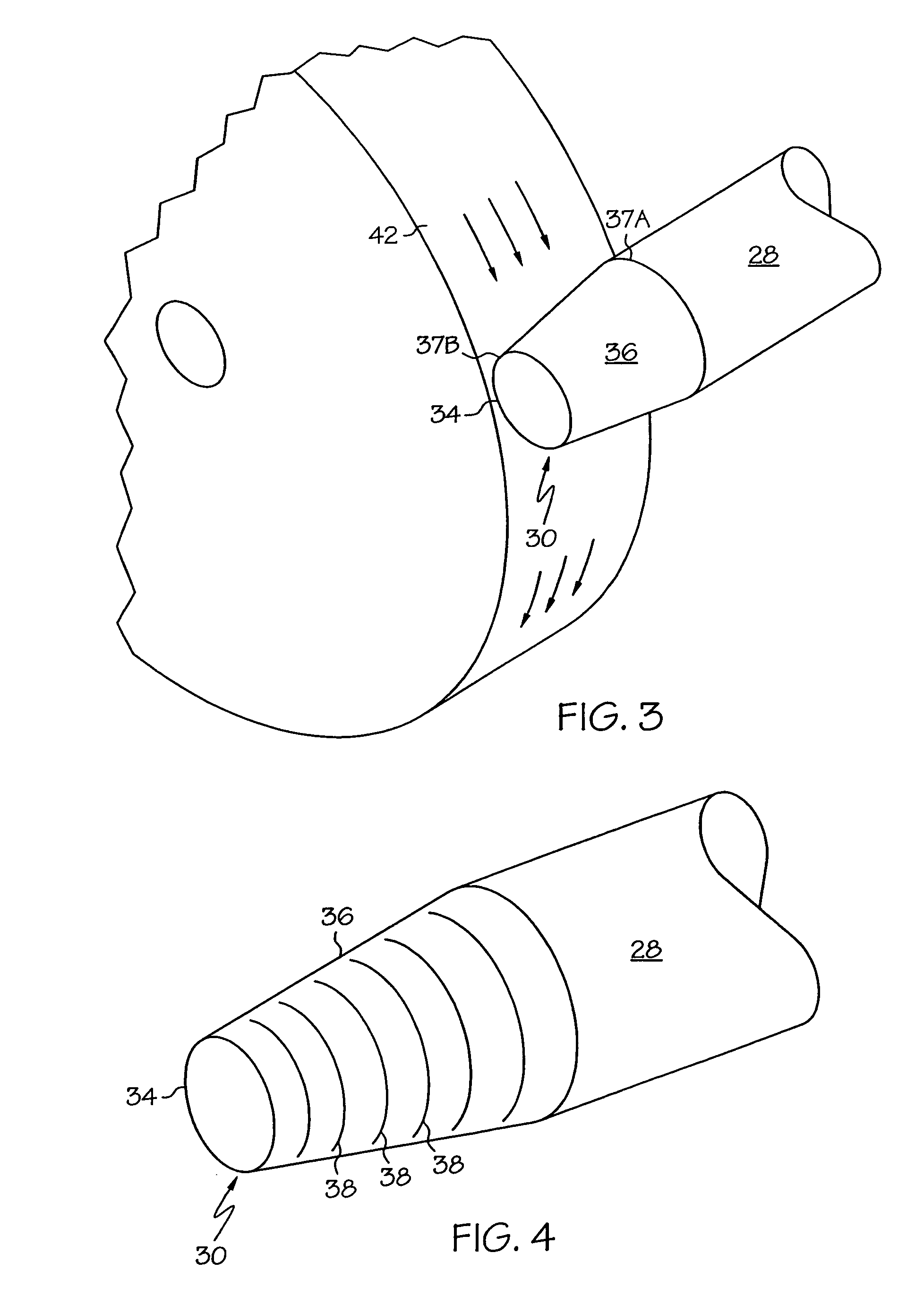

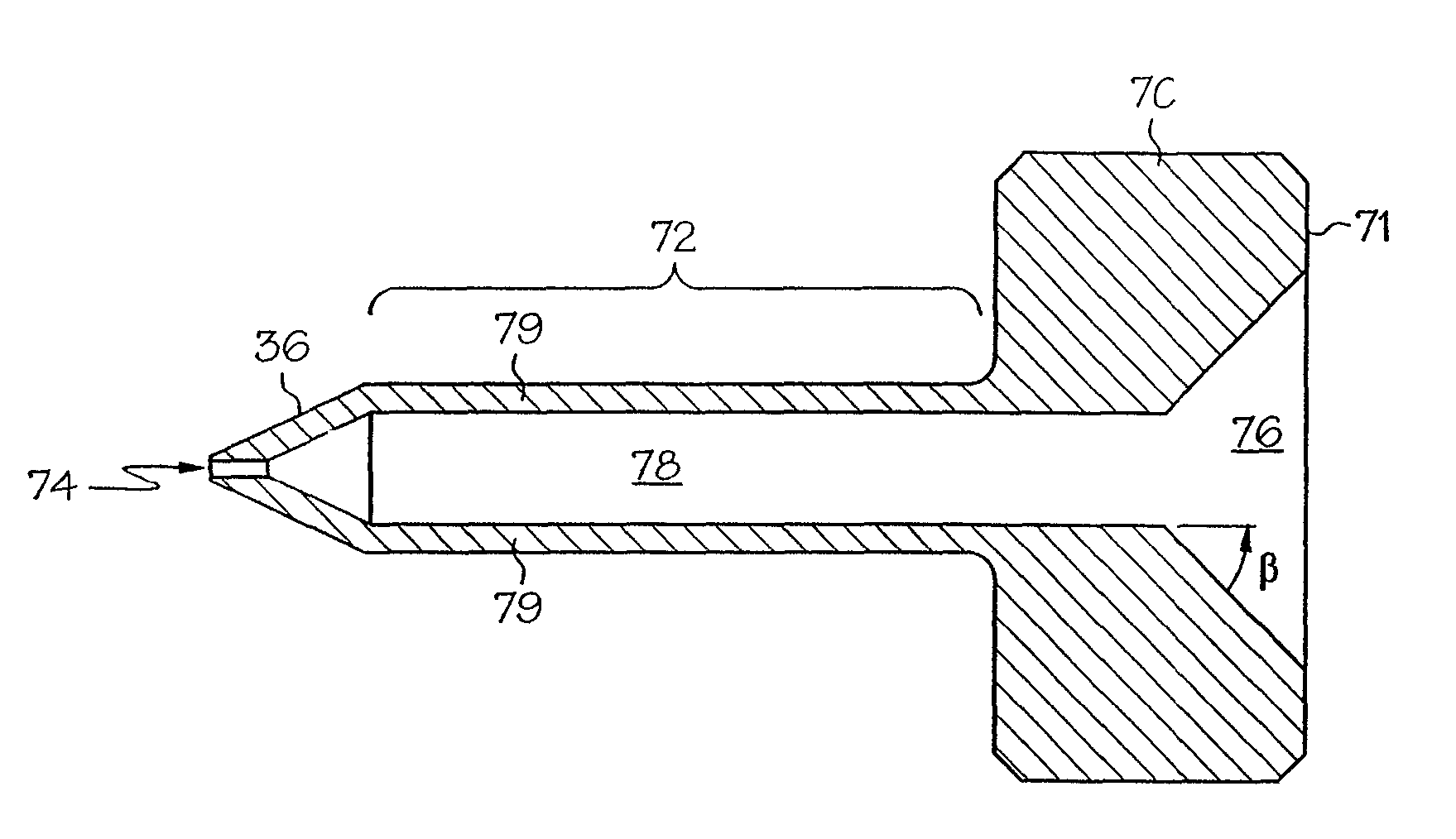

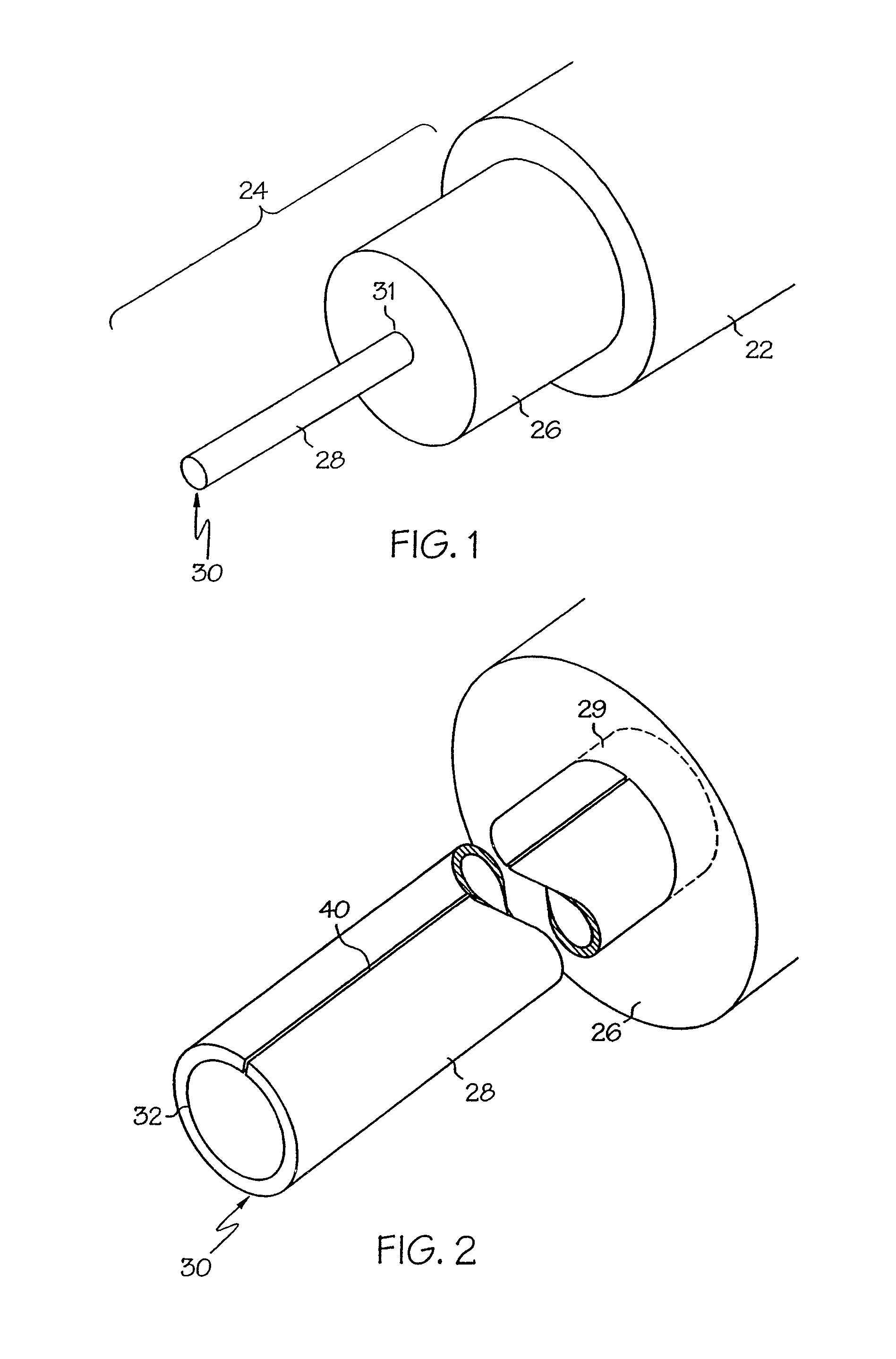

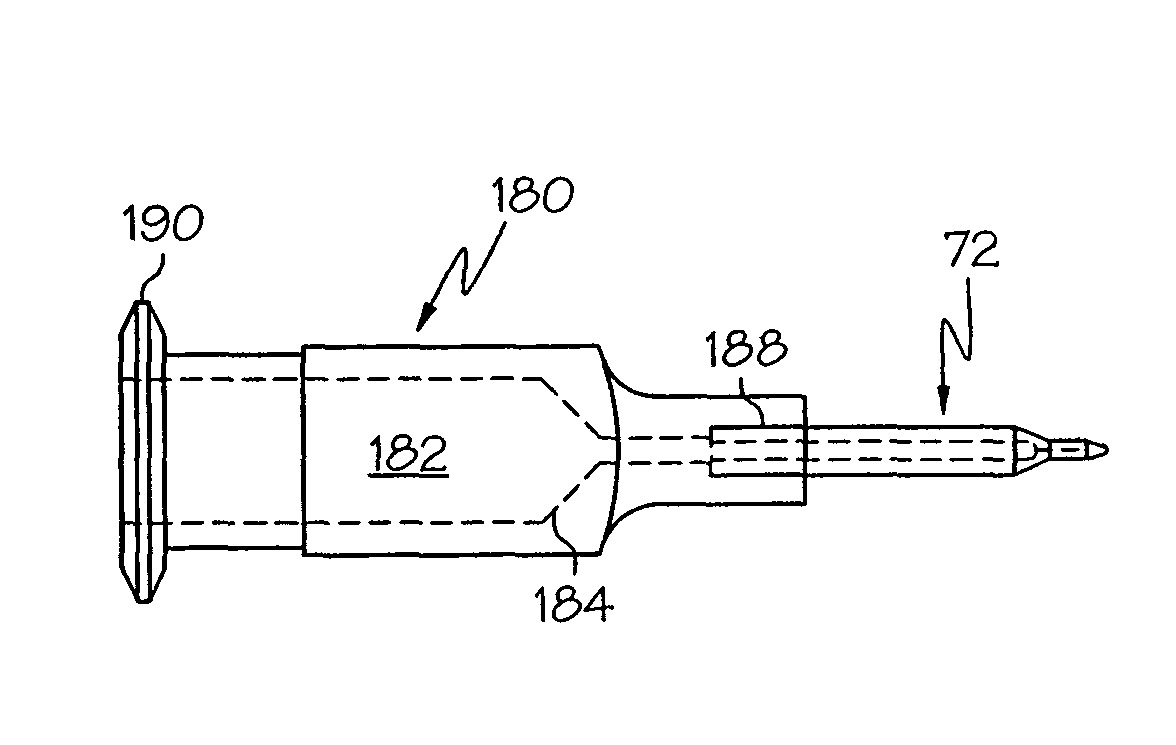

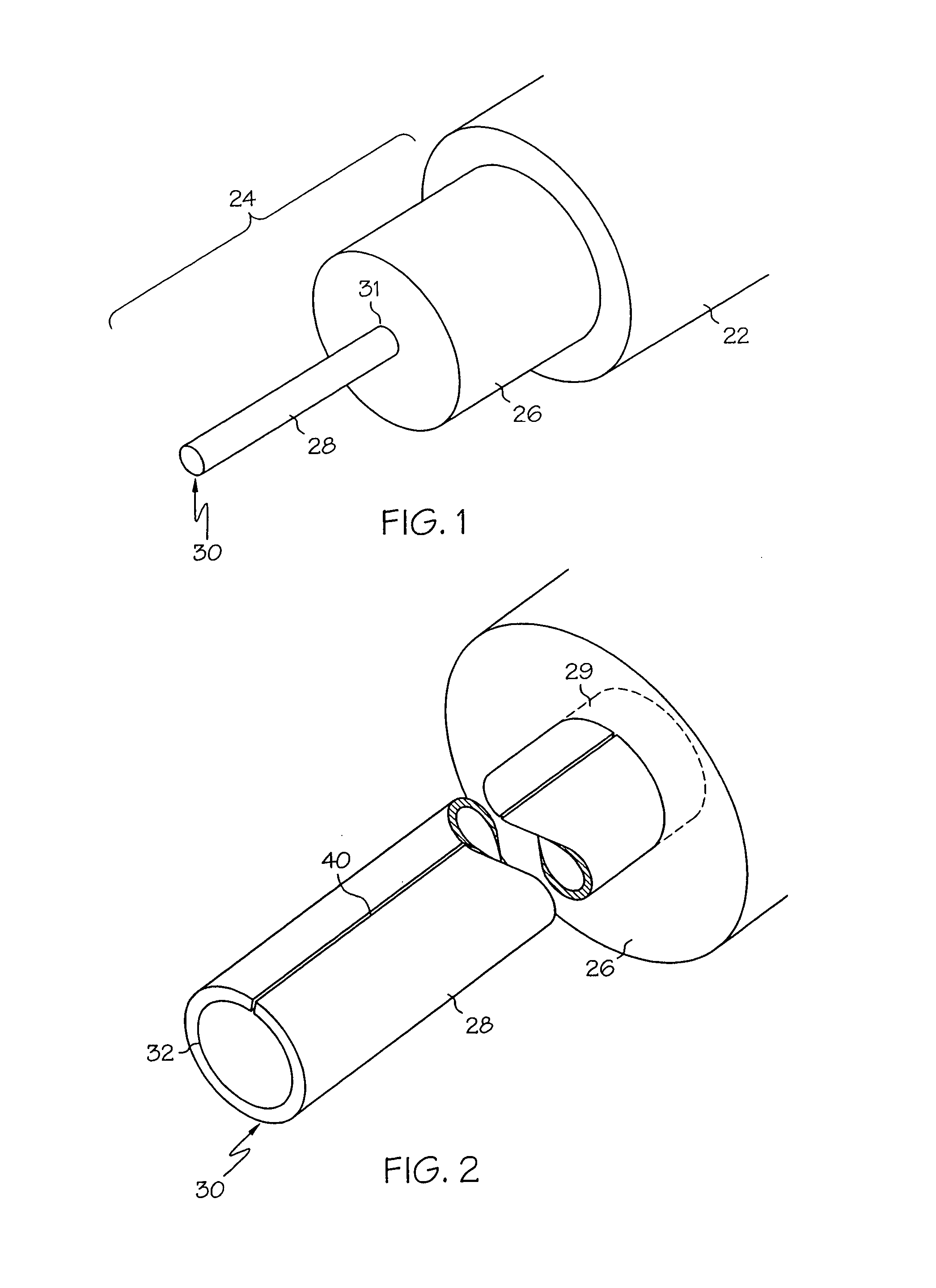

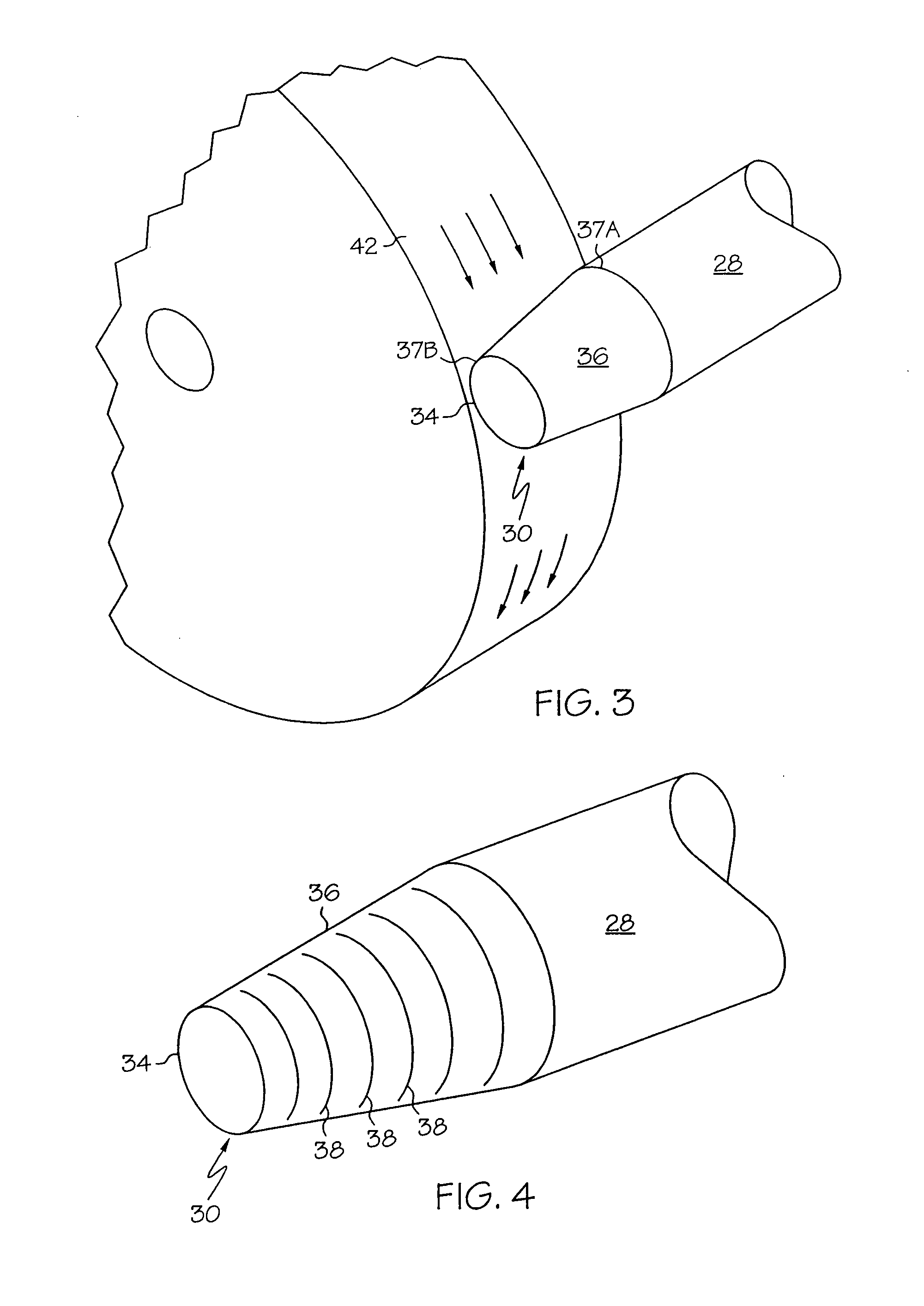

Fluid dispense tips

InactiveUS6981664B1Further-reduced surface tensionIncreased dispensing precision capabilityLiquid surface applicatorsClosuresDecreased pressureBiomedical engineering

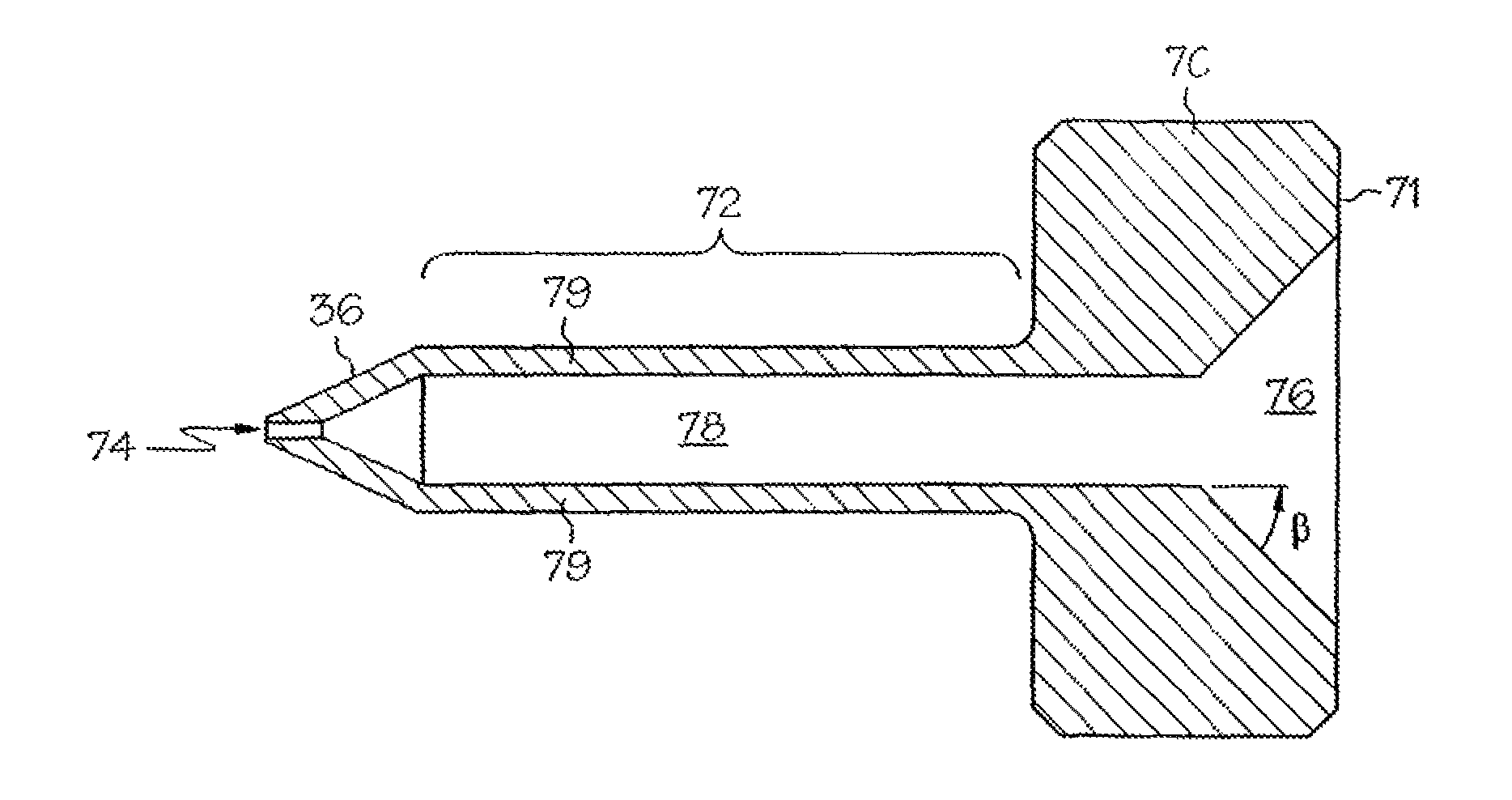

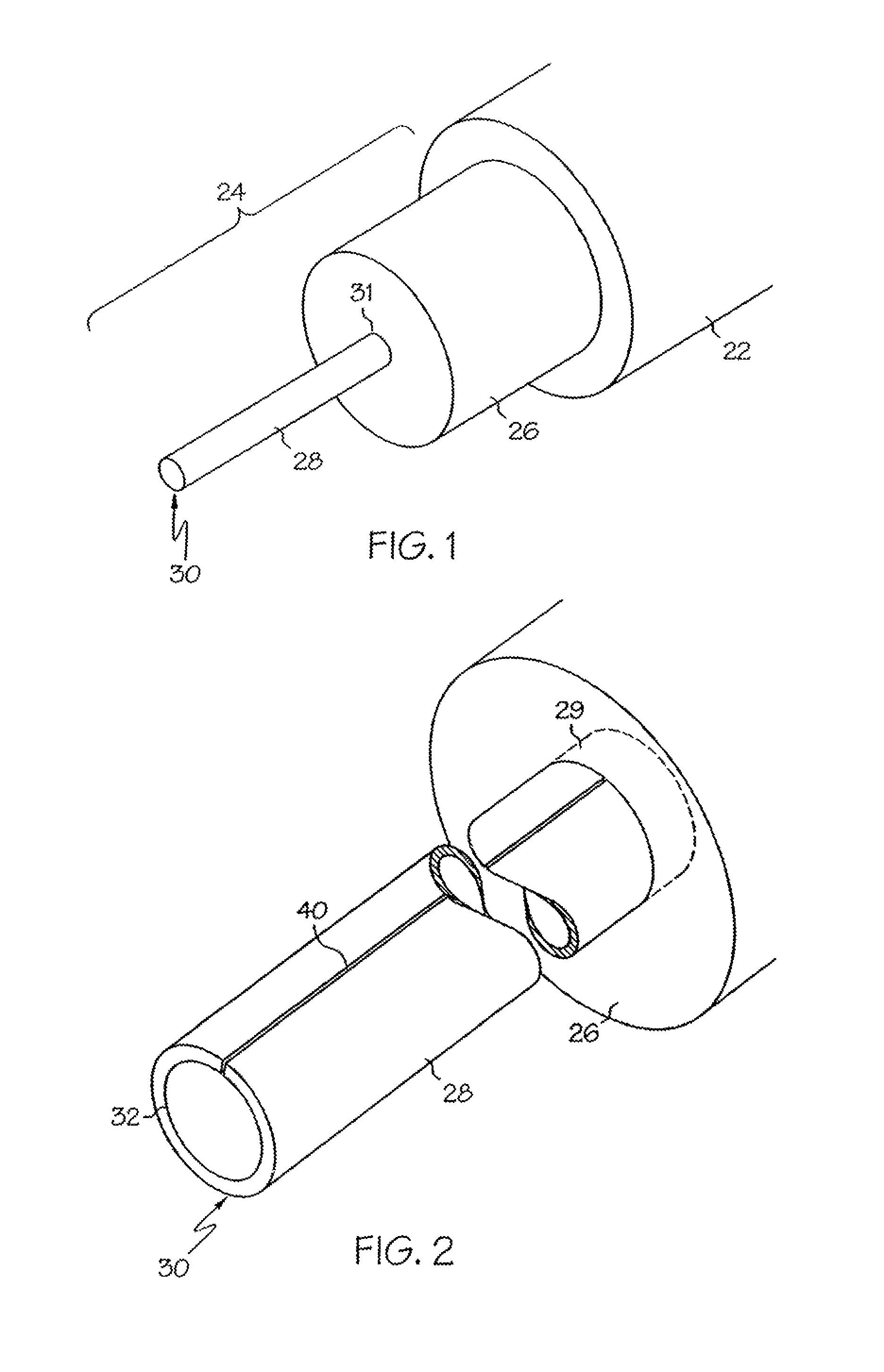

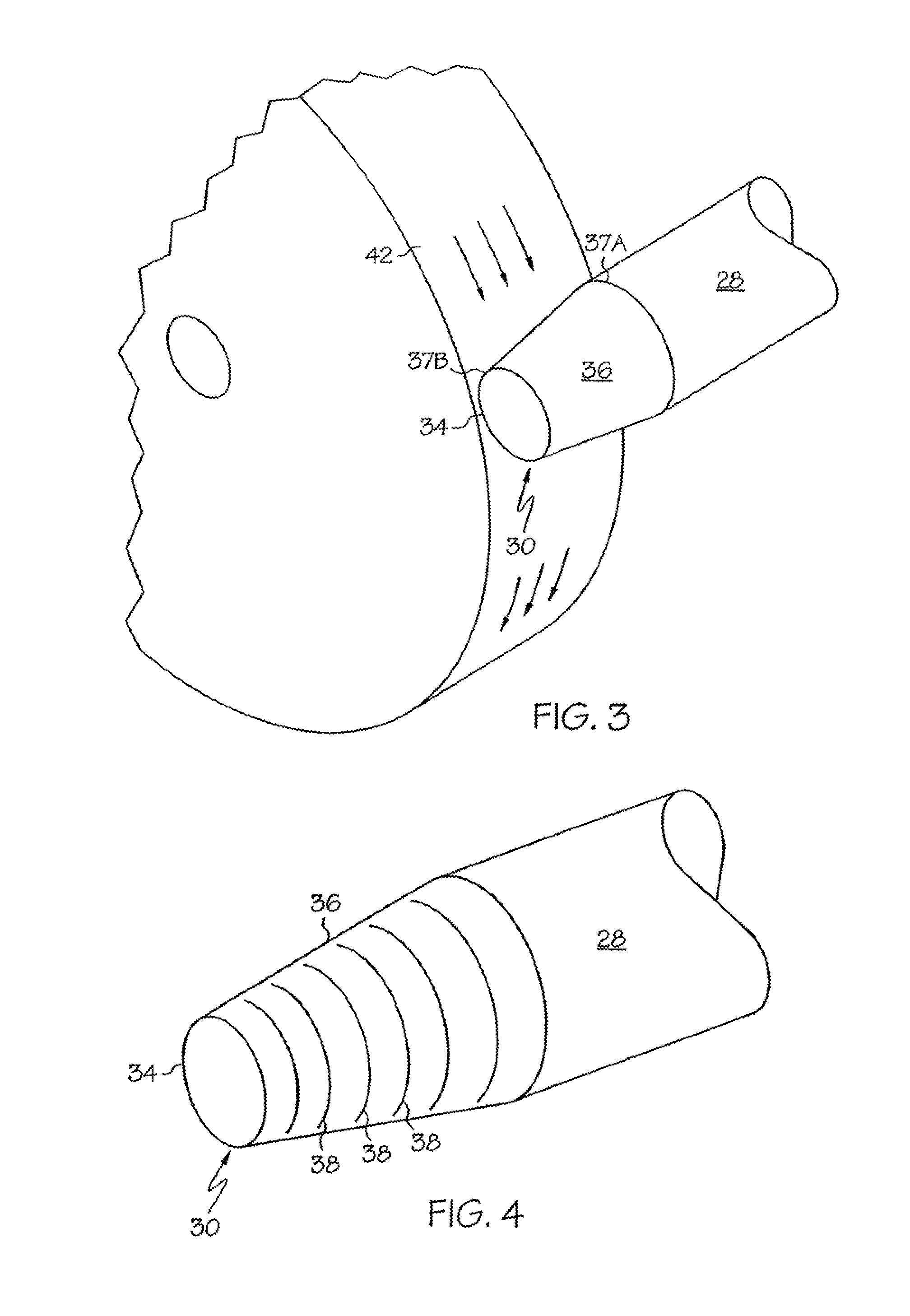

A fluid dispense tip includes a bevel at an opening to reduce the amount of surface tension, or “land”, at the opening. The bevel is formed by grinding in a longitudinal direction such that any tooling scars resulting from the grinding operation are likewise longitudinally oriented, further reducing the amount of surface tension in the tip, thereby leading to heightened dispensing accuracy. The tip may be machined from stock as a unitary piece, to increase its lifetime, and may be formed with a bore of a relatively large diameter that is tapered down to a smaller diameter near the tip opening, to allow for delivery of fluid through the tip body at a decreased pressure. The tip may optionally be formed with a Luer™-style fitting on the body, such that the tip is compatible with pumps that utilize such a fitting.

Owner:DL TECH

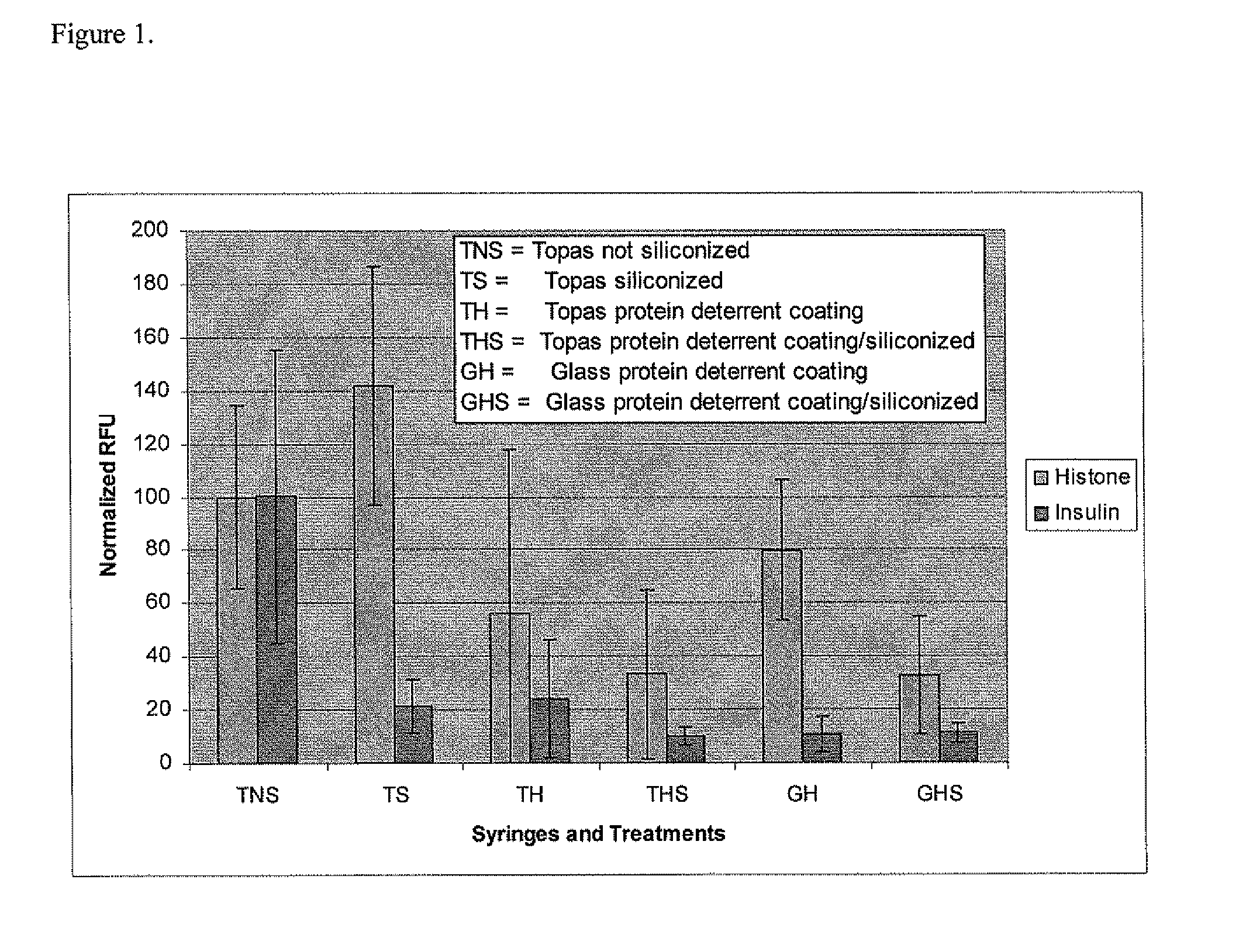

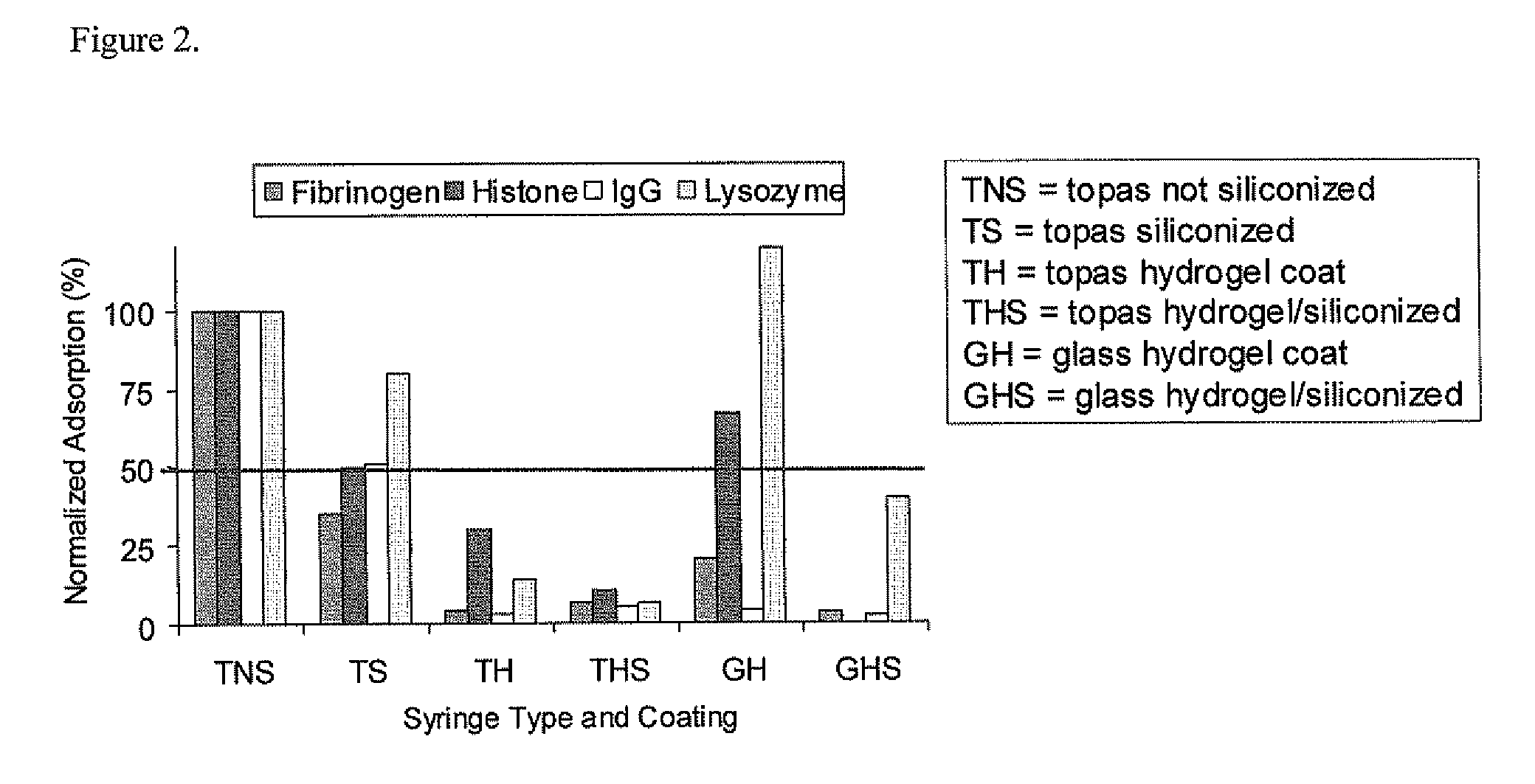

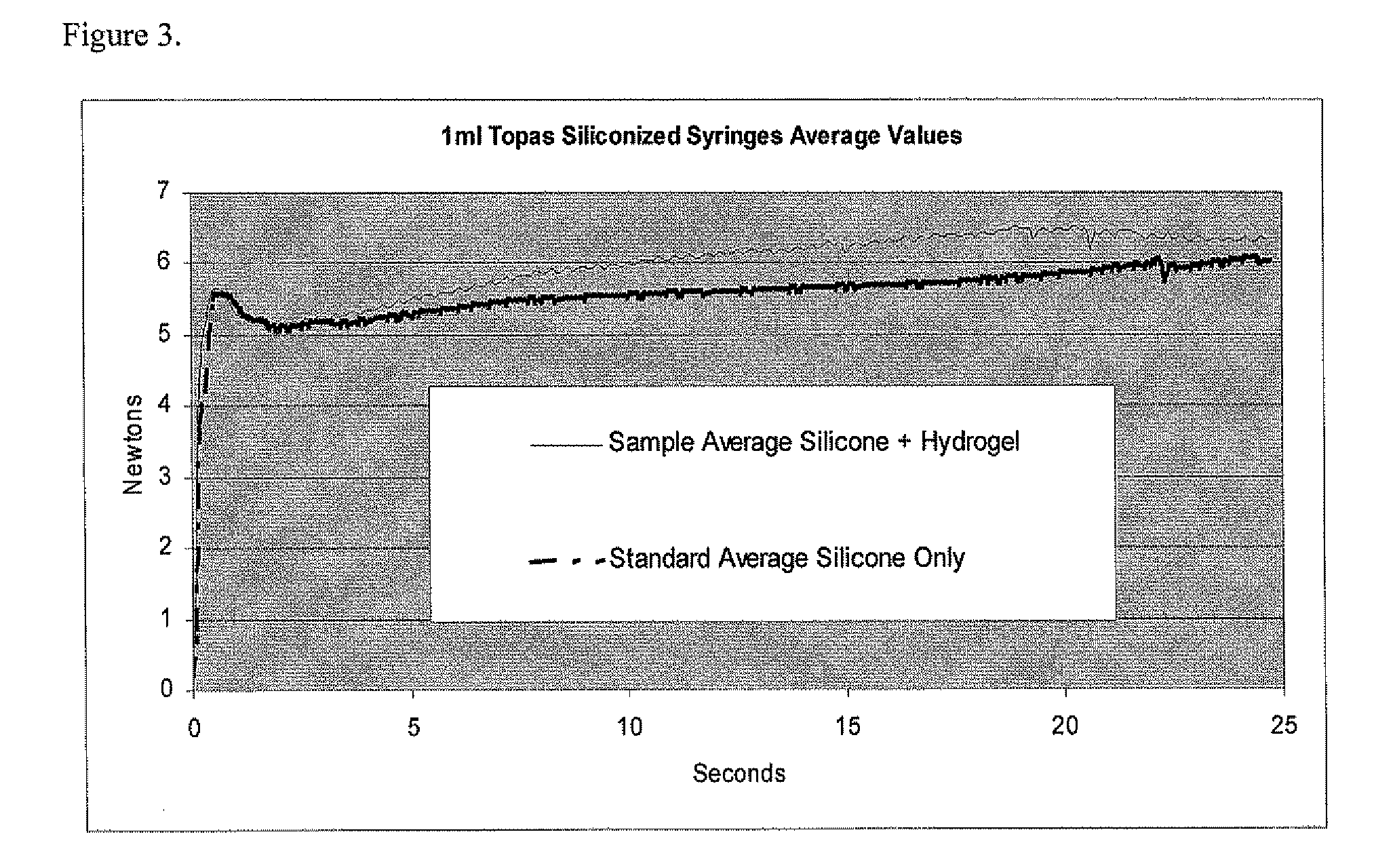

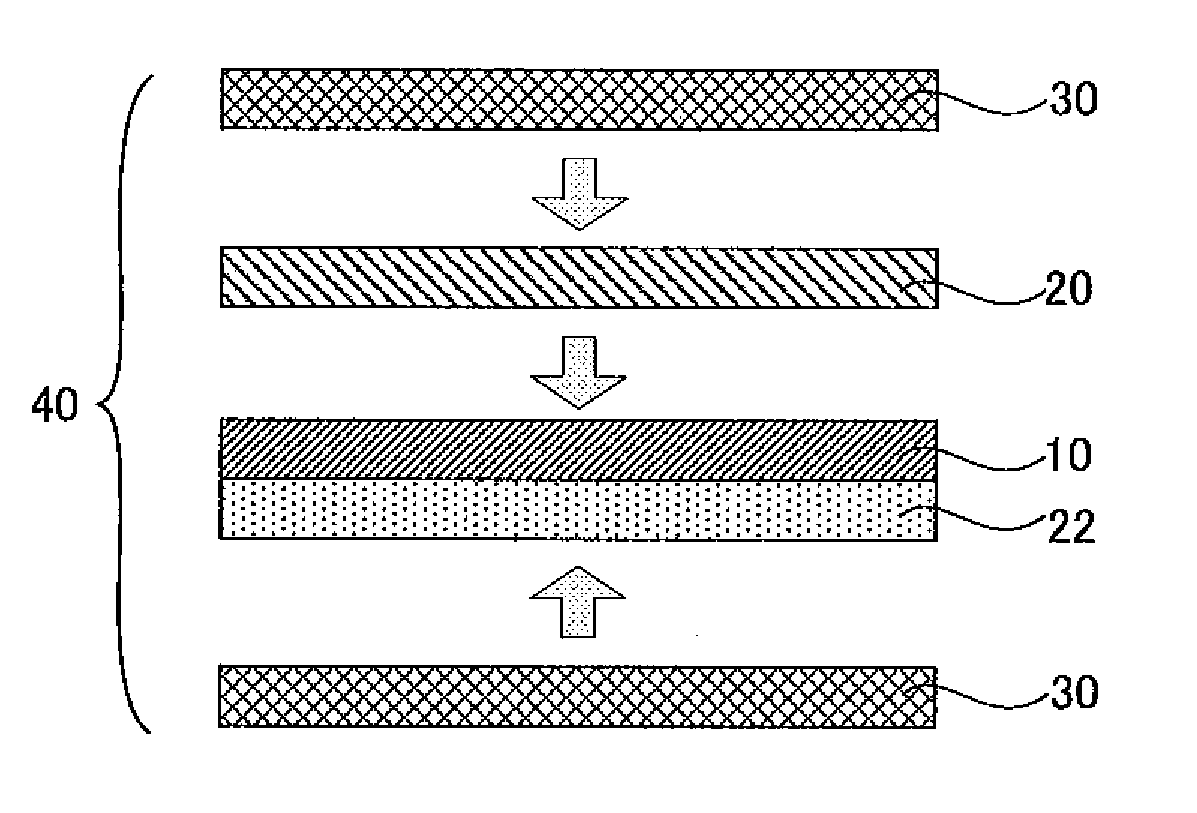

Pharmaceutical package having a multi-functional surface and a method of preparing a multi-functional surface on a pharmaceutical package

ActiveUS20100044268A1Reduce protein adsorptionReduce adsorptionSmall article dispensingLiquid surface applicatorsProtein solutionPharmaceutical packaging

The present invention relates to a multi-functional pharmaceutical package surface and a method of preparing a multi-functional pharmaceutical package surface. In particular, the present invention relates to a pharmaceutical package having a protein deterrent and lubricious surface and methods of preparing said surface by applying coatings directly to the pharmaceutical package that (a) reduce the adsorption of proteins onto pharmaceutical packaging while not affecting the activity of the protein solution and (b) provide a lubricious surface. The pharmaceutical package surface may also contain a barrier coating. Coatings can be deposited on a variety of pharmaceutical packaging materials and configurations by various methods.

Owner:SCHOTT AG

Polyphenyl ether resin material used for processing charger case

The invention discloses a polyphenyl ether resin material used for processing a charger case, which consists of polyphenyl ether resin, polystyrene resin, an elastic body, fire retardants, polyolefin, silicone masterbatch, main antioxidants and auxiliary antioxidants. Through adding proper auxiliary agents into a polyphenyl ether resin composition, the invention improves the surface lubricating effect of manufactured elements, reduces the pressure required during welding, and solves the problems of impression, scratches and the like occurring during the ultrasonic welding of products. The products are mainly applied to the fields requiring the ultrasonic welding, such as charger cases, wiring cases and the like.

Owner:NANTONG XINGCHEN SYNTHETIC MATERIAL +1

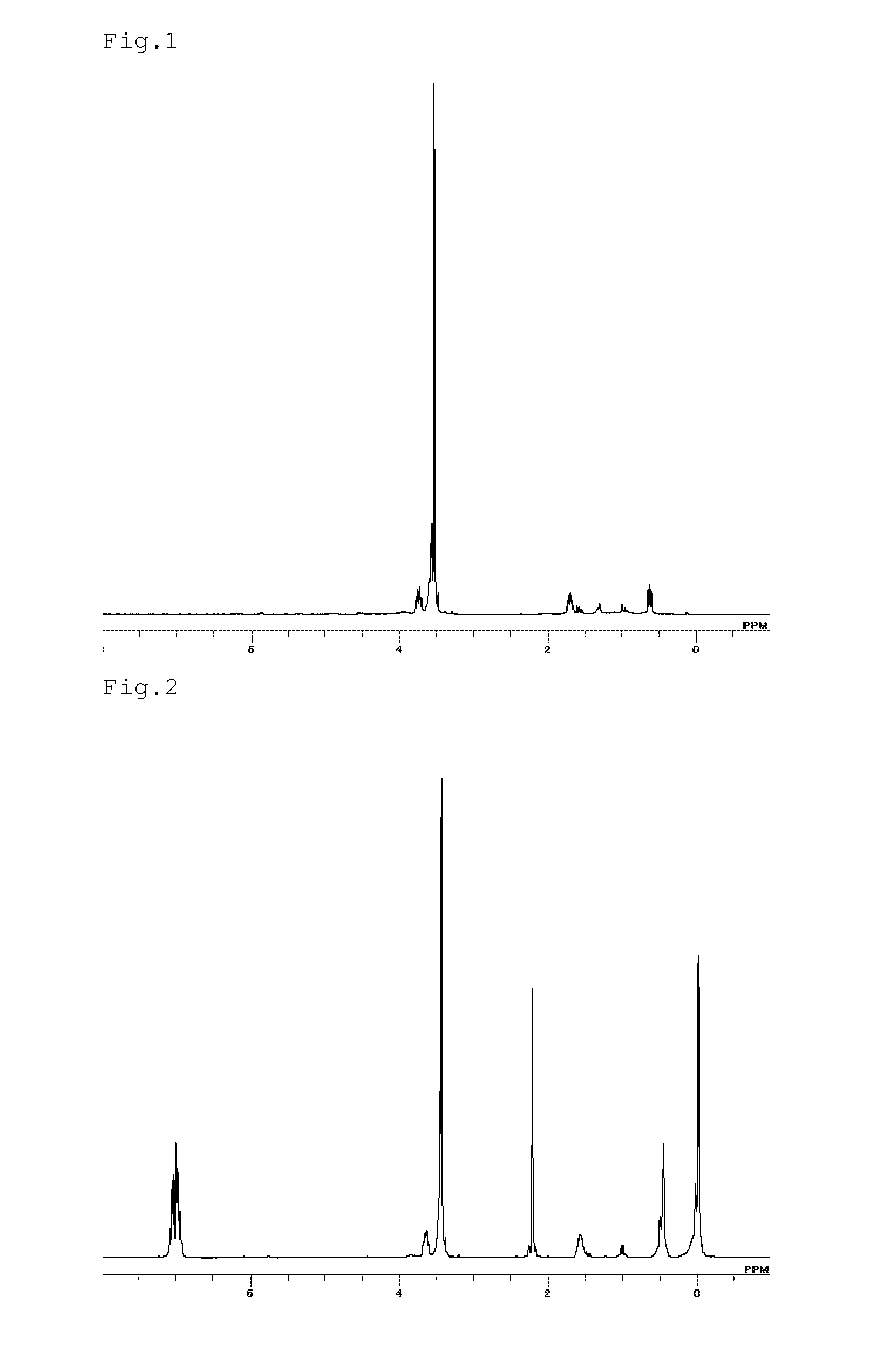

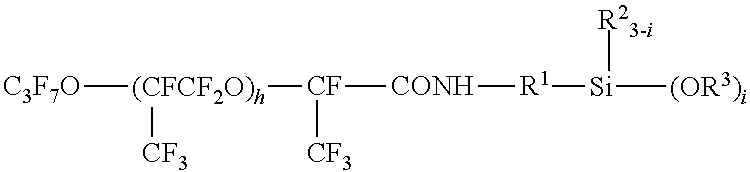

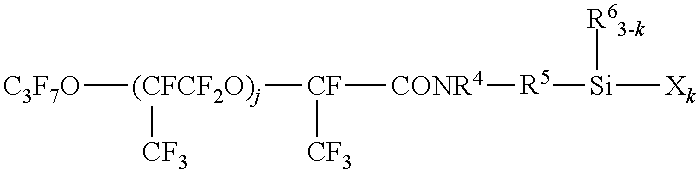

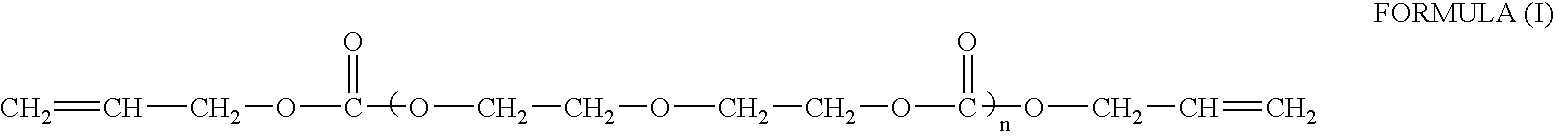

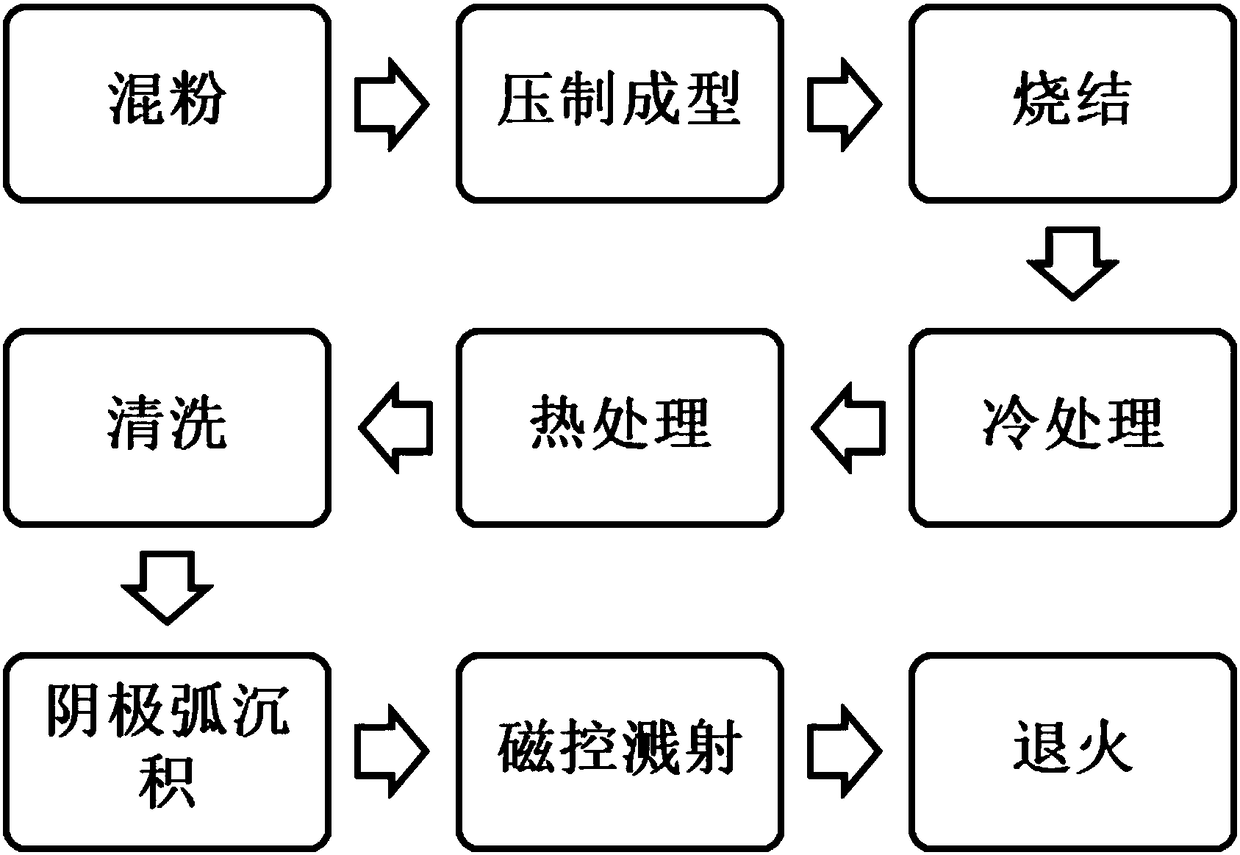

Fluorooxyalkylene group-containing polymer composition, a surface treatment agent comprising the same and an article treated with the agent

ActiveUS20110098402A1Increase surface lubricityImprove adhesionPolyether coatingsEmulsion paintsWear resistanceStain

An object of the present invention is to provide a fluorooxyalkylene group-containing polymer composition, which yields a coating having excellent adhesior to a substrate, good water- and oil-repellency, a low dynamic friction coefficient, good releasing property, good abrasion resistance and good stain resistance, and to provide a surface treatment agent comprising the same. The present inventors have found that a composition comprising a fluorooxyalkylene group-containing polymer having a fluorinated group and a hydrolyzable group at each terminal and a fluorooxyalkylene group-containing polymer having hydrolyzable groups at both terminals can form a coating which has excellent water- and oil-repellency, a low dynamic friction coefficient, good releasing property, good abrasion resistance, and good stain resistance.

Owner:SHIN ETSU CHEM IND CO LTD

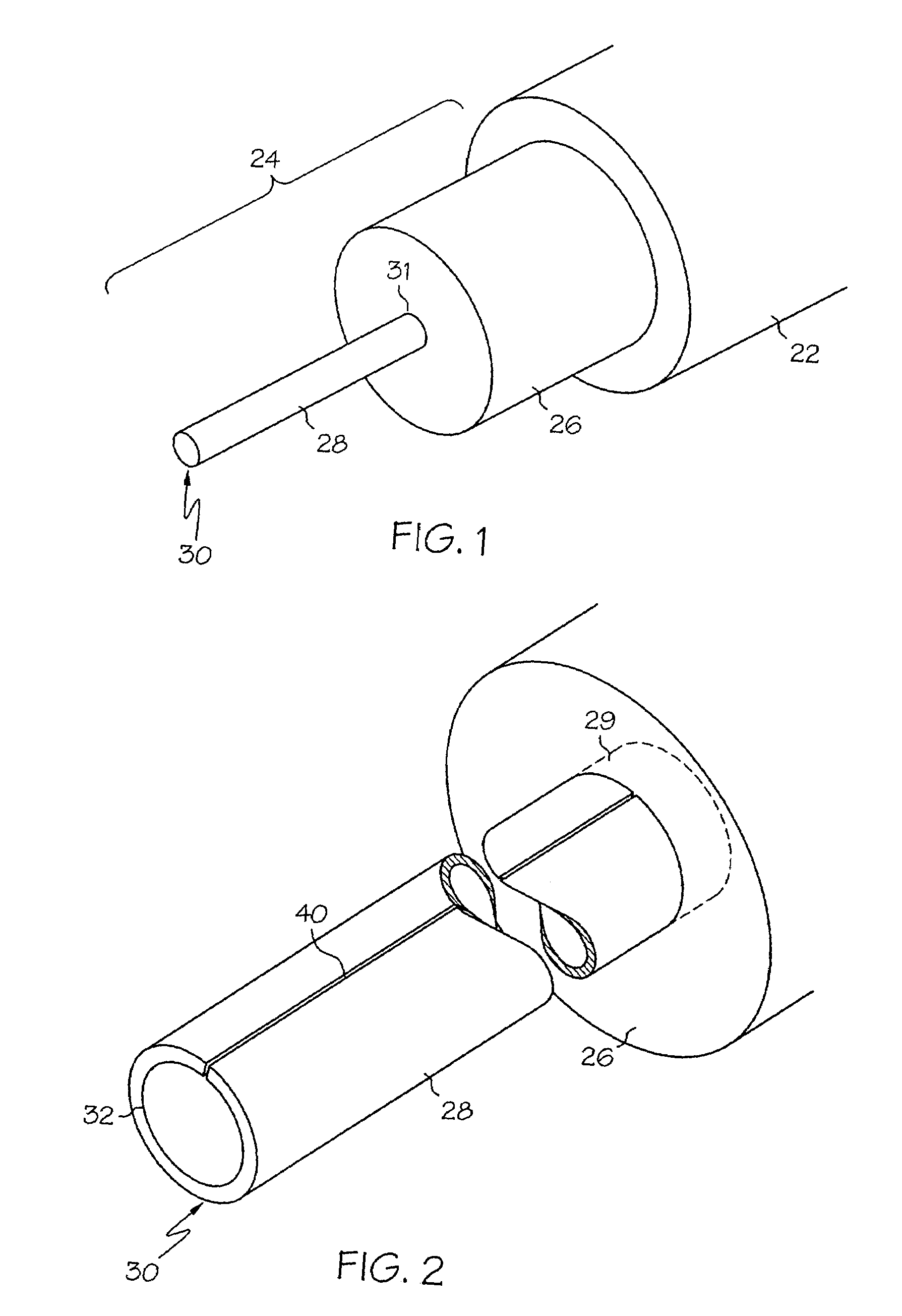

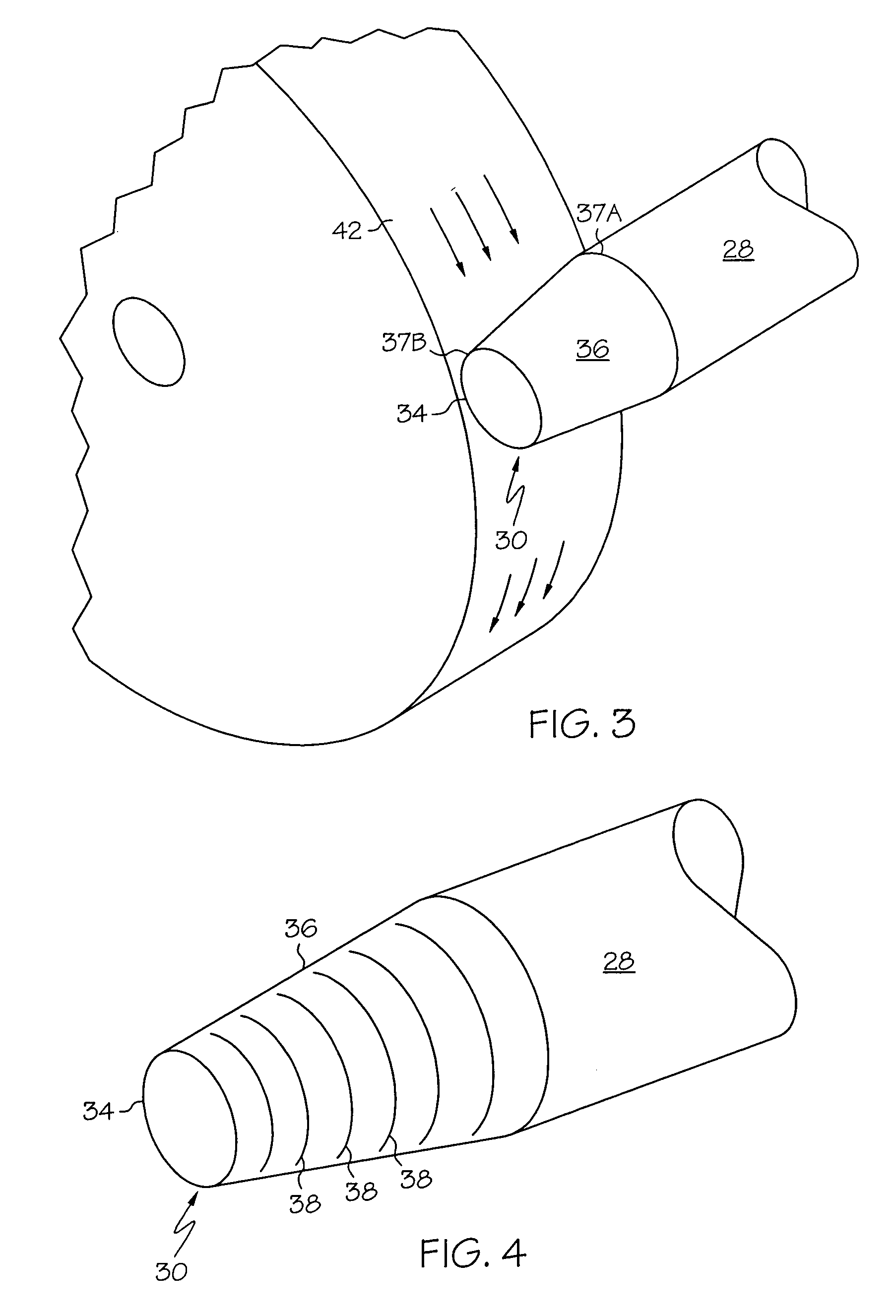

Fluid dispense tips

InactiveUS6896202B1Prevent buildupExtended service lifeLiquid surface applicatorsSpray nozzlesDecreased pressureEngineering

A fluid dispense tip includes a bevel at an opening to reduce the amount of surface tension, or “land”, at the opening. The bevel is formed by grinding in a longitudinal direction such that any tooling scars resulting from the grinding operation are likewise longitudinally oriented, further reducing the amount of surface tension in the tip, thereby leading to heightened dispensing accuracy. The tip may be machined from stock as a unitary piece, to increase its lifetime, and may be formed with a bore of a relatively large diameter that is tapered down to a smaller diameter near the tip opening, to allow for delivery of fluid through the tip body at a decreased pressure. A cleaning tool may be provided for removing residual material from the inner surfaces of the tip. A removable liner sleeve may be provided within the bore to reduce the effective inner diameter of the dispense tip.

Owner:DL TECH

Nylon polymers having a low coefficient of friction and method for the manufacture thereof

A method for the preparation of a polyamide-based composition provides for the substantially uniform dispersion of particulate silica and, optionally, mineral oil and any other lubricant additive, within a polyamide matrix. The method includes mixing particulate silica, and optionally, mineral oil and other lubricant additives, to one or more polyamide-producing monomers, and water, to form an emulsion or suspension wherein the particulate silica (and mineral oil and other lubricant additives, when added) are substantially uniformly dispersed therein, and then in situ polymerizing the monomer(s) to provide a polyamide matrix wherein the particulate silica, and optional mineral oil and other optional lubricant additives, remain substantially uniformly dispersed in the resulting polyamide matrix to form the polyamide-based composition. A polyamide-based composition comprising a polyamide matrix having silica and optionally, mineral oil and other lubricant additives, substantially uniformly dispersed within the polyamide matrix is also provided.

Owner:NYLON CORP OF AMERICA

Fluid dispense tips

InactiveUS7207498B1Surface tensionCorrection capabilityLiquid surface applicatorsWatering devicesDecreased pressureBiomedical engineering

A fluid dispense tip includes a bevel at an opening to reduce the amount of surface tension, or “land”, at the opening. The bevel is formed by grinding in a longitudinal direction such that any tooling scars resulting from the grinding operation are likewise longitudinally oriented, further reducing the amount of surface tension in the tip, thereby leading to heightened dispensing accuracy. The tip may be machined from stock as a unitary piece, to increase its lifetime, and may be formed with a bore of a relatively large diameter that is tapered down to a smaller diameter near the tip opening, to allow for delivery of fluid through the tip body at a decreased pressure. A cleaning tool may be provided for removing residual material from the inner surfaces of the tip. A removable liner sleeve may be provided within the bore to reduce the effective inner diameter of the dispense tip.

Owner:DL TECH

Biodegradable Polyester Resin Composition

InactiveUS20080090480A1Improve antistatic performanceIncrease surface lubricityWoven fabricsNon-woven fabricsPolyolPolyester resin

[Object] To provide a biodegradable polyester resin composition that can achieve excellent antistatic properties and surface lubricity while maintaining the molecular weight without deteriorating the appearance of the resin, even if a kneading method is employed. [Solving Means] A biodegradable polyester resin composition containing 0.05 to 10.0% by weight of a borate ester surfactant (a reactant of boric acid and a compound given by esterifying a polyol with a higher fatty acid, a salt of the reactant, a reactant obtained by reacting a higher fatty acid to a compound given by esterifying a polyol with boric acid, or the like) having one or more hydrophobic groups having 8 to 24 carbon atoms.

Owner:TOHO CHEM IND

Fluid dispense tips

InactiveUS7744022B1Surface tensionCorrection capabilityLiquid surface applicatorsSpray nozzlesDecreased pressureBiomedical engineering

Owner:DL TECH

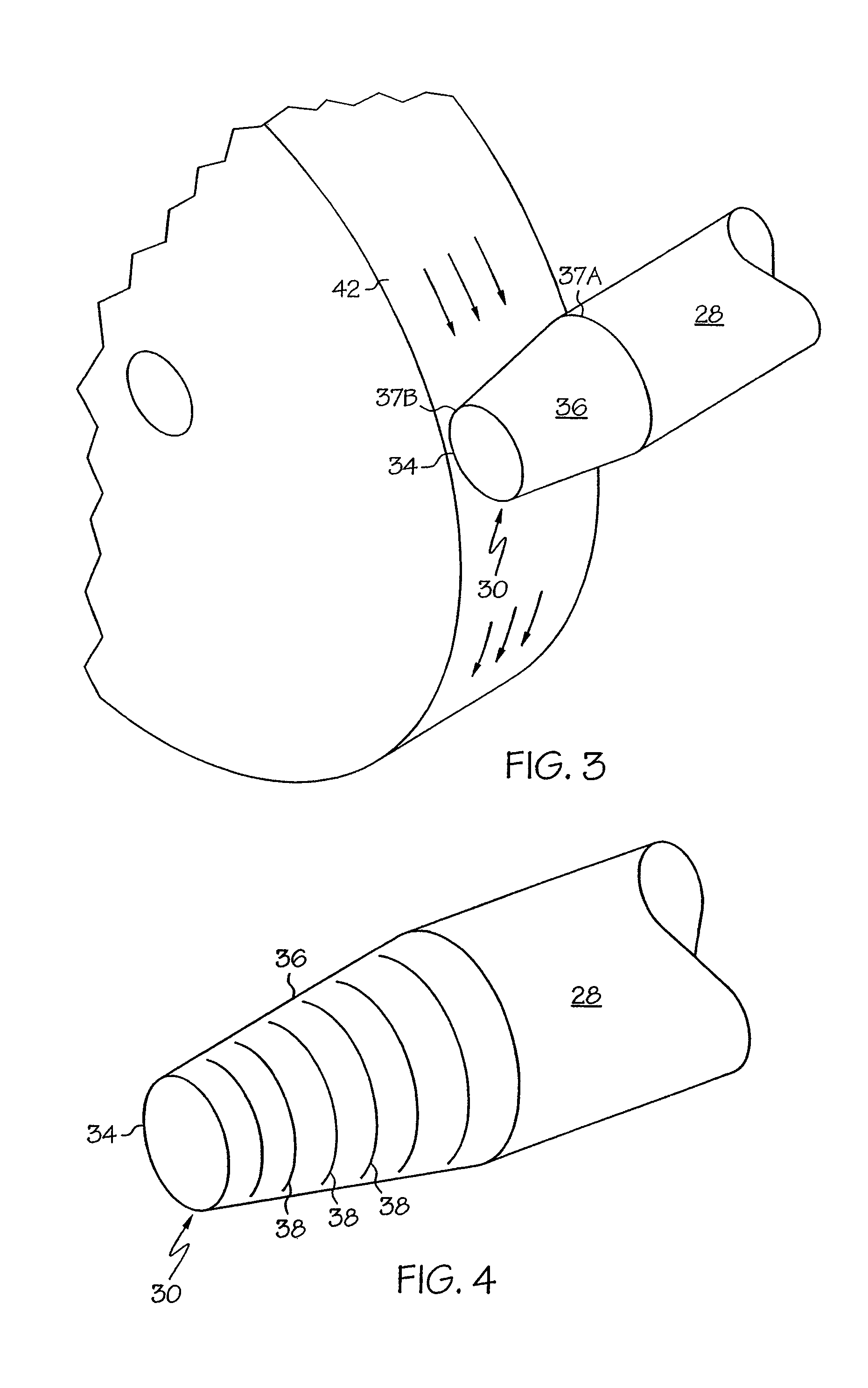

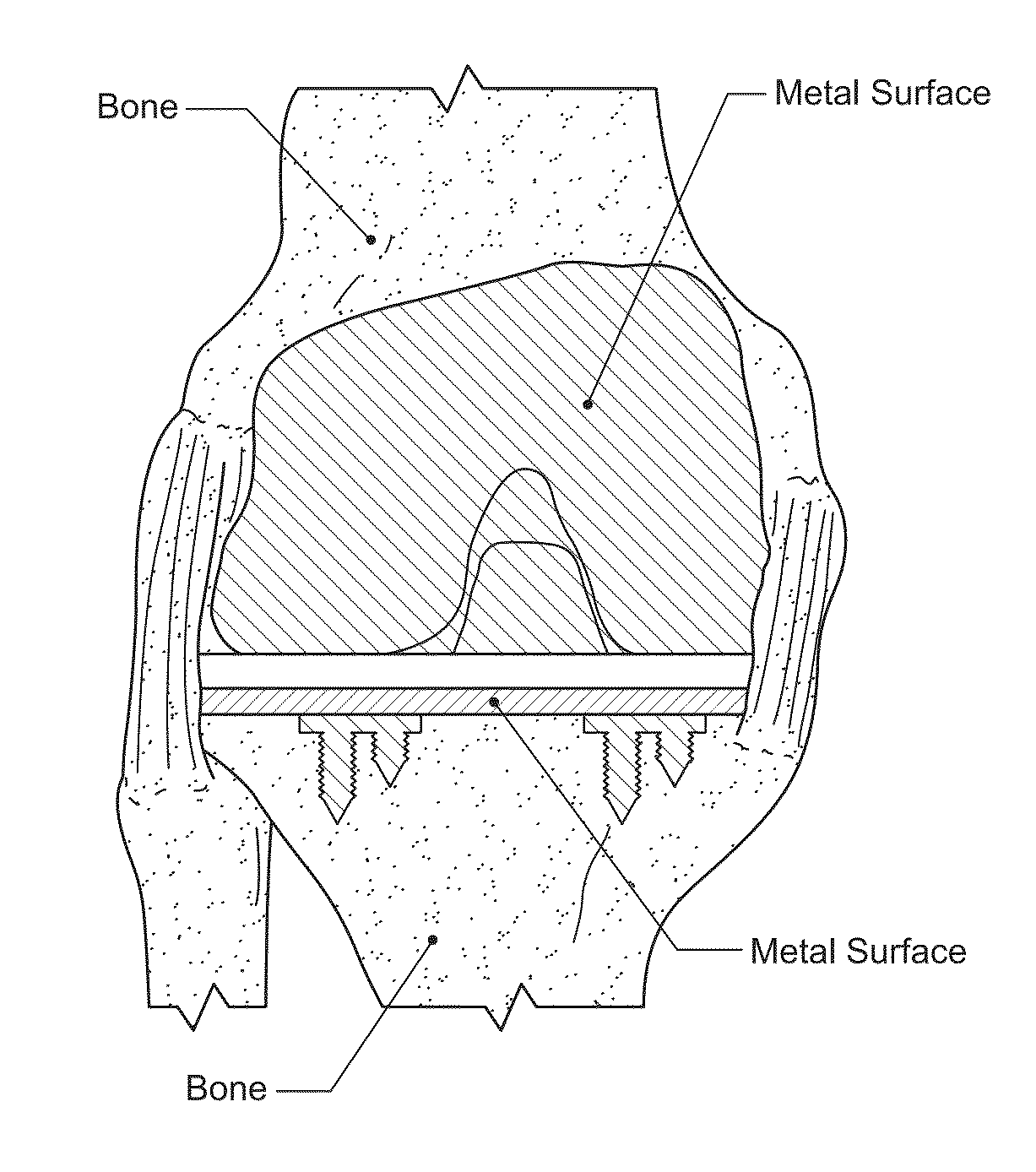

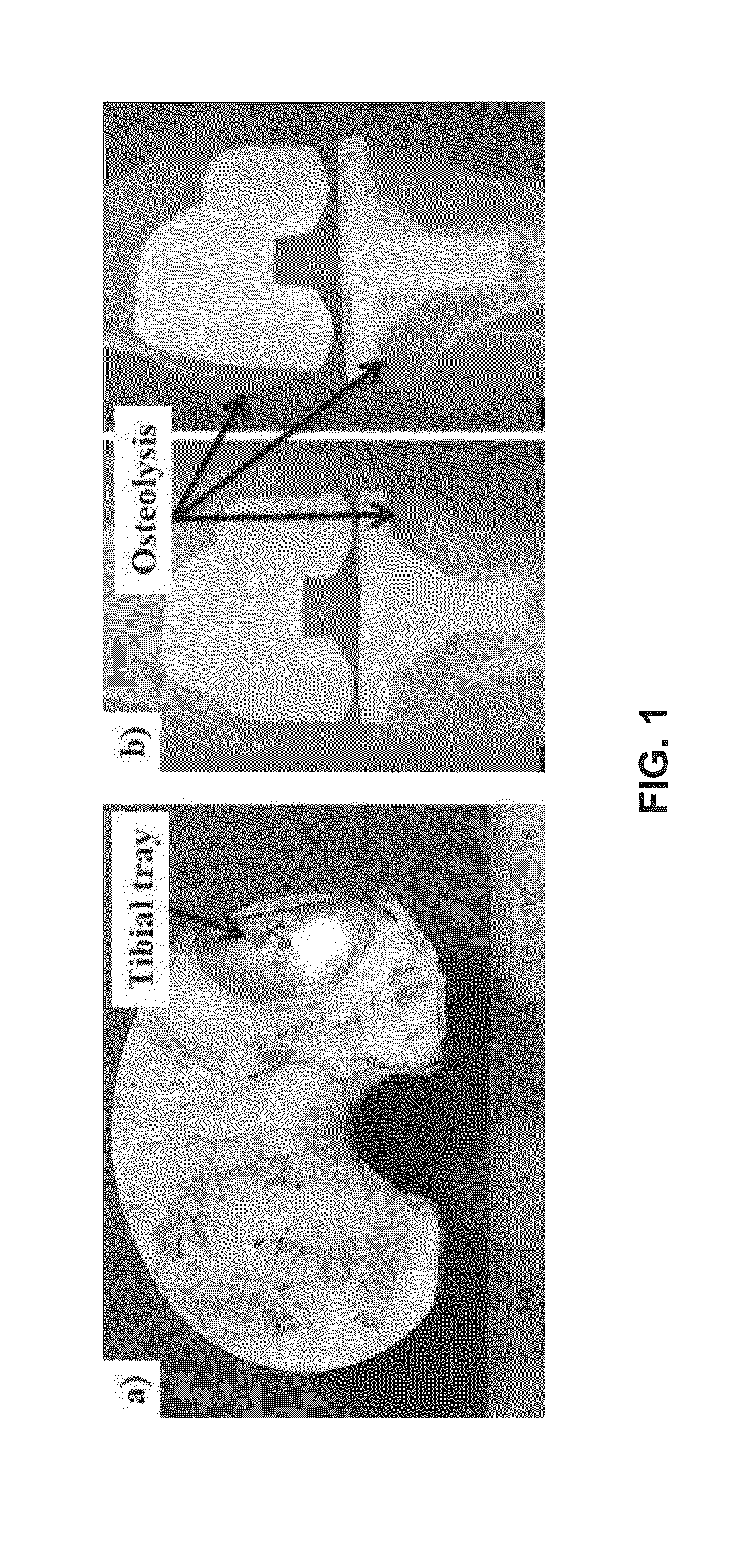

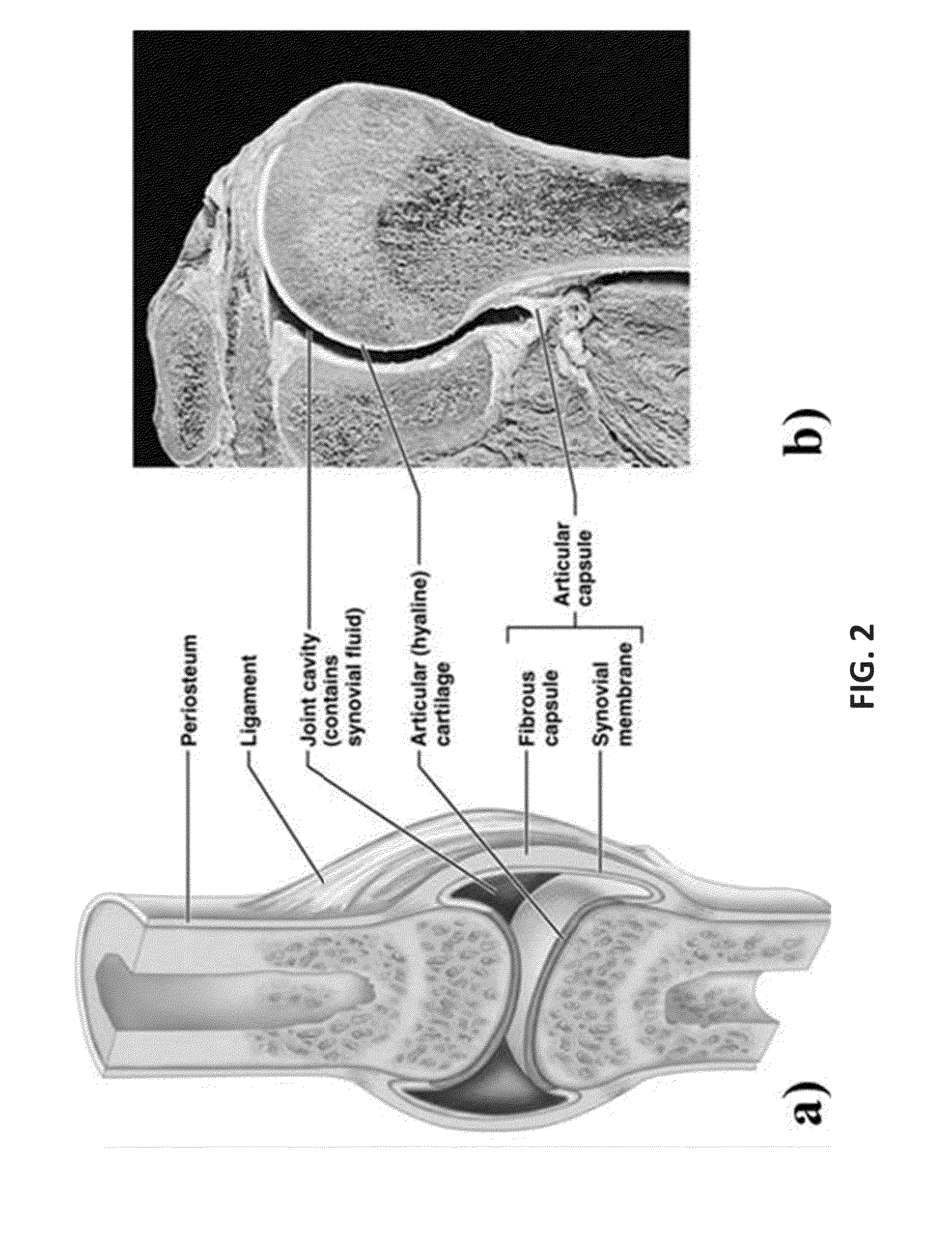

Orthopaedic Joints Providing Enhanced Lubricity

ActiveUS20150066152A1Increase surface lubricityWear minimizationJoint implantsProsthesisProsthetic joint component

The present disclosure provides, among other things, prosthetic joint components having textured surface(s) for improving lubrication and increasing the useful life of the prosthetic joint components. The textured surface includes solid features configured to stably contain a biological fluid or a synthetic biological fluid therebetween or therewithin for a non-zero residence time.

Owner:MASSACHUSETTS INST OF TECH

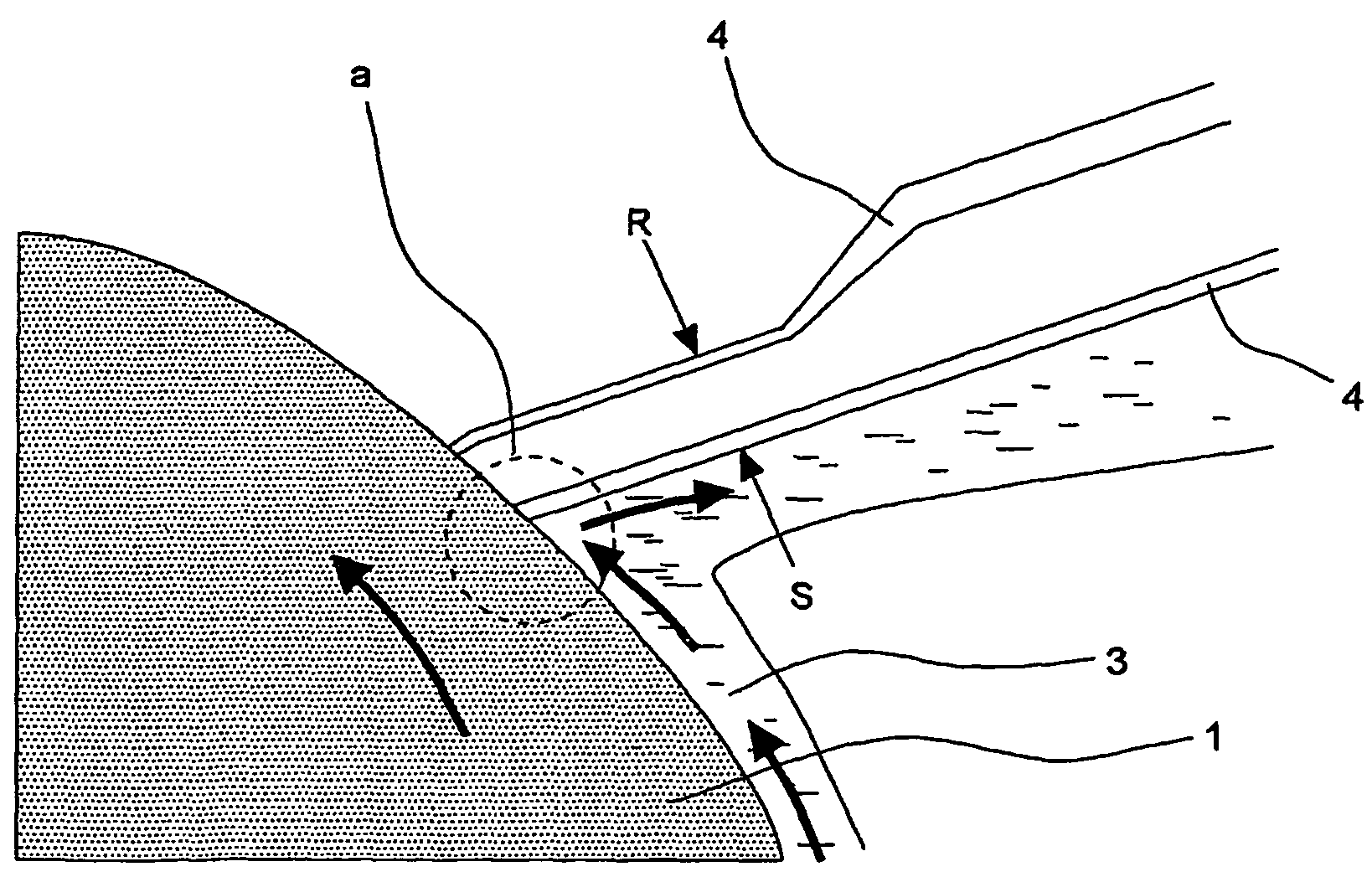

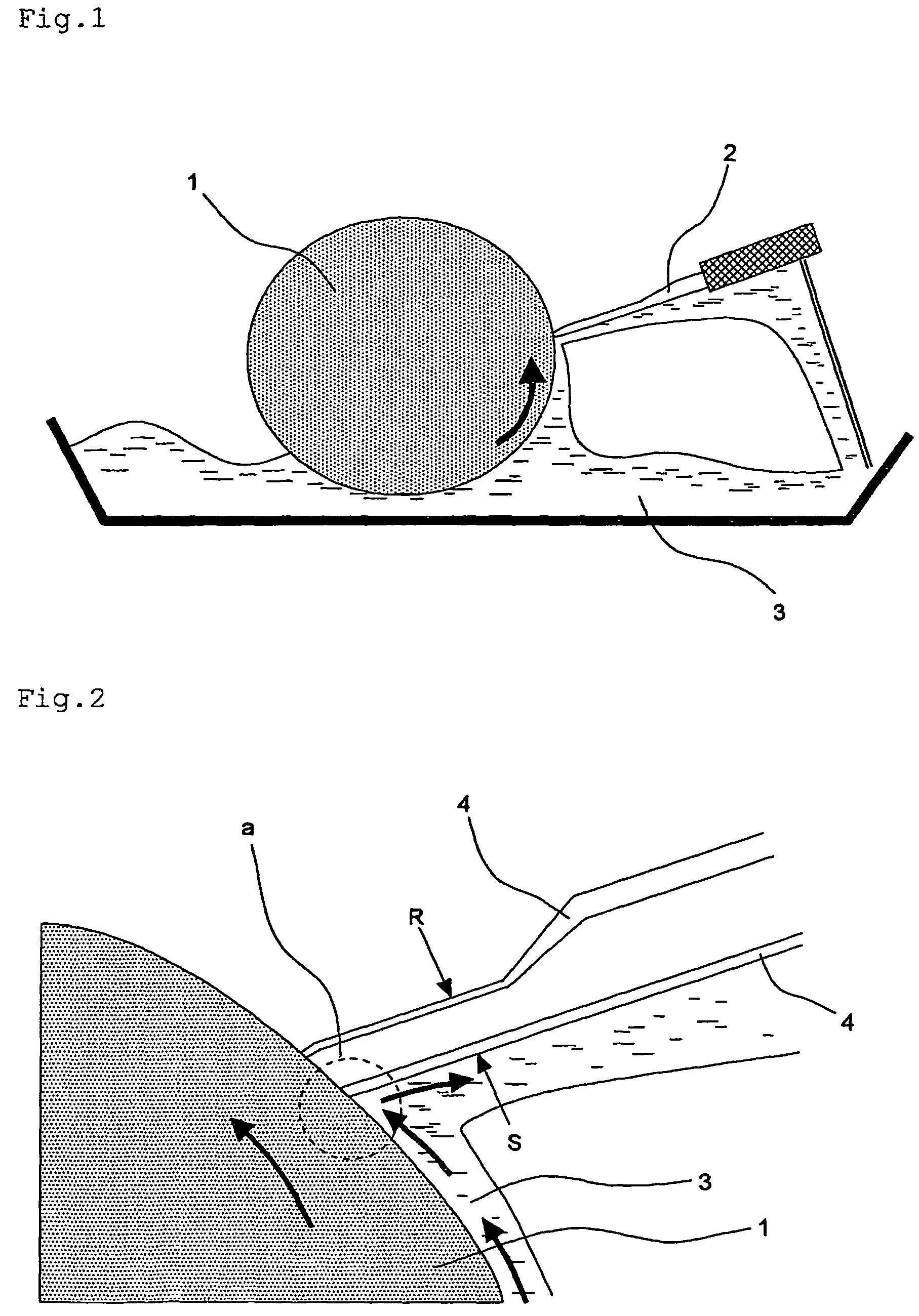

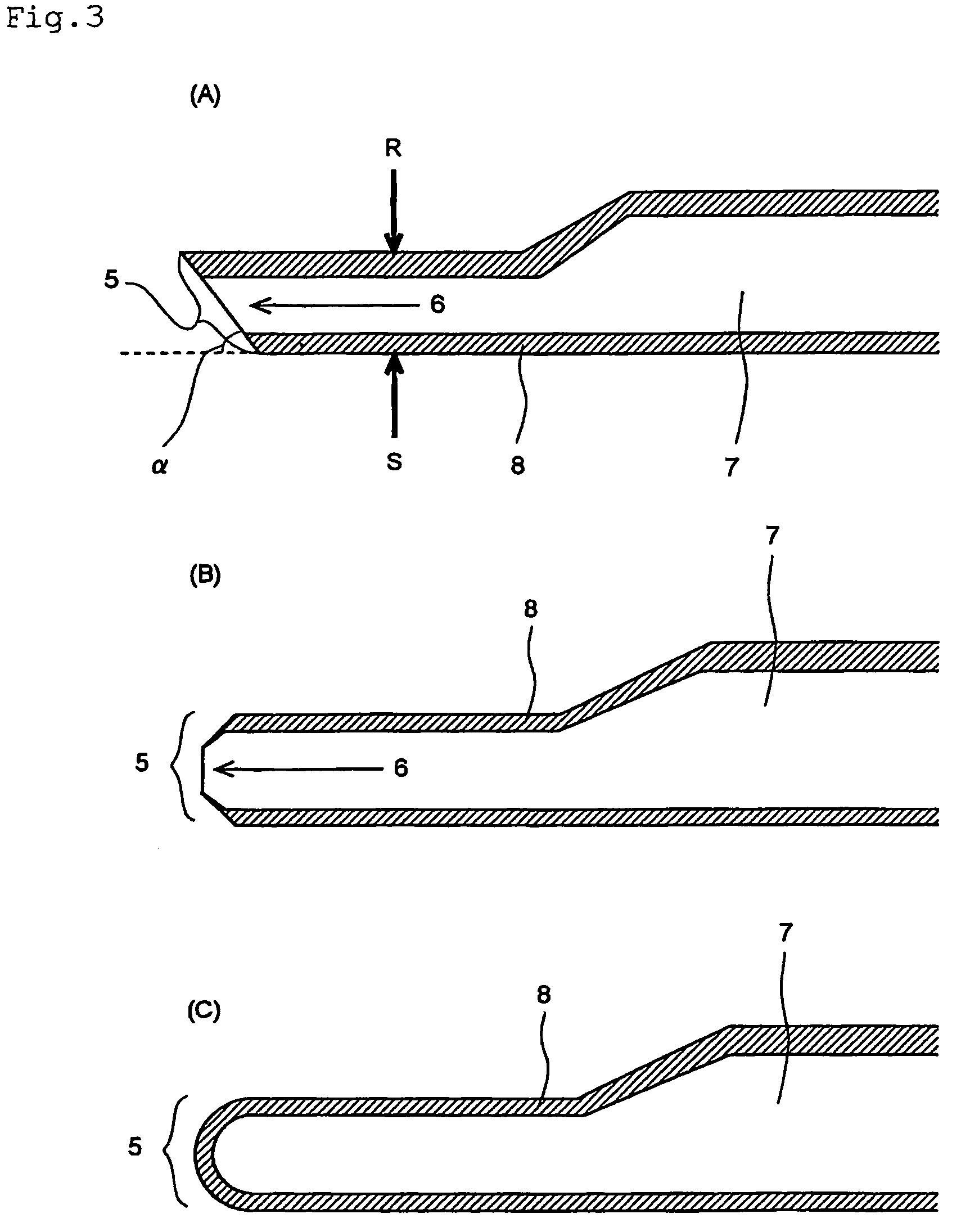

Surface treated doctor blade

InactiveUS7152526B2Lower surface energyAvoid failureRotary intaglio printing pressBrushesEngineeringKnife blades

Disclosed is a surface treated doctor blade in which the surface of at least the blade edge portion thereof consists of a surface treatment coating film composed of a first layer consisting of a specific nickel-based plating and a second layer provided thereon which has low surface energy, and in which preferably at least a part of the blade edge end portion of the blade base material is exposed. In the surface treated doctor blade of the present invention, it is possible to improve wear resistance of the blade edge end and to suppress generation of printing failures during continuous printing. Further, in the mode in which at least a part of the blade base material is exposed, it is possible to reduce running-in time for adjustment of contact of the blade edge with the cylinder after replacement of the doctor blade.

Owner:NIHON NEW CHROME

Method for preparing lubricating coating with strong stability on surface of medical polyurethane material

InactiveCN101612421AImprove the lubrication effectImprove stabilitySurgeryCatheterGas phaseGraft reaction

The invention discloses a method for preparing a lubricating coating with strong stability on the surface of a medical polyurethane material, comprising the following steps of: step 1, pretreating the medical polyurethane material so as to obtain positions with proper surface roughness and reaction activity; step 2, putting the polyurethane polymer material pretreated in the step 1 into a gas phase system of reaction solution or solute for grafting reaction; and step 3, cleaning and drying the reaction products from the step 2. The method can be widely used for preparing medical polymer materials and high-lubricity coating materials on the surface of medical instruments.

Owner:SOUTHEAST UNIV

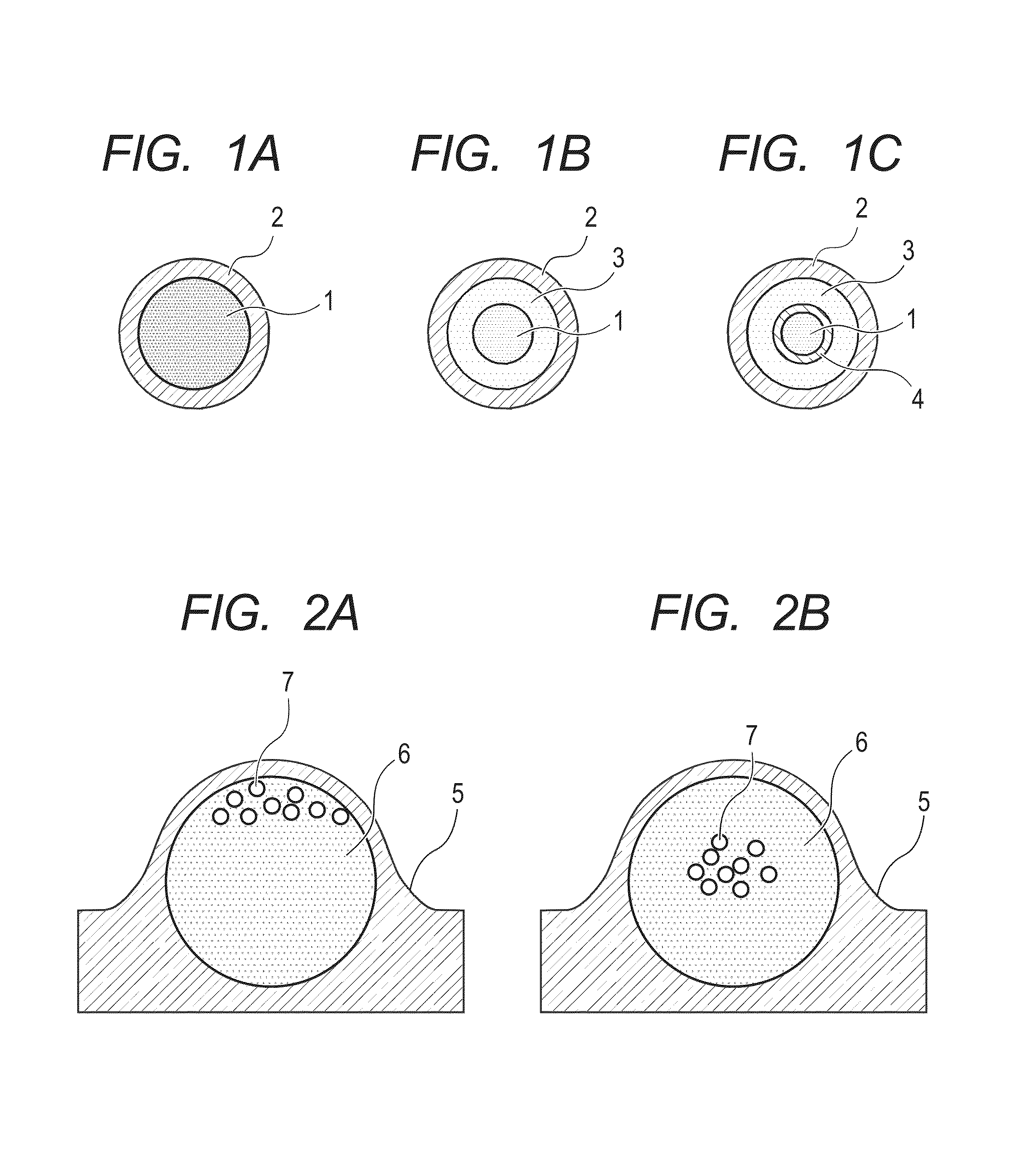

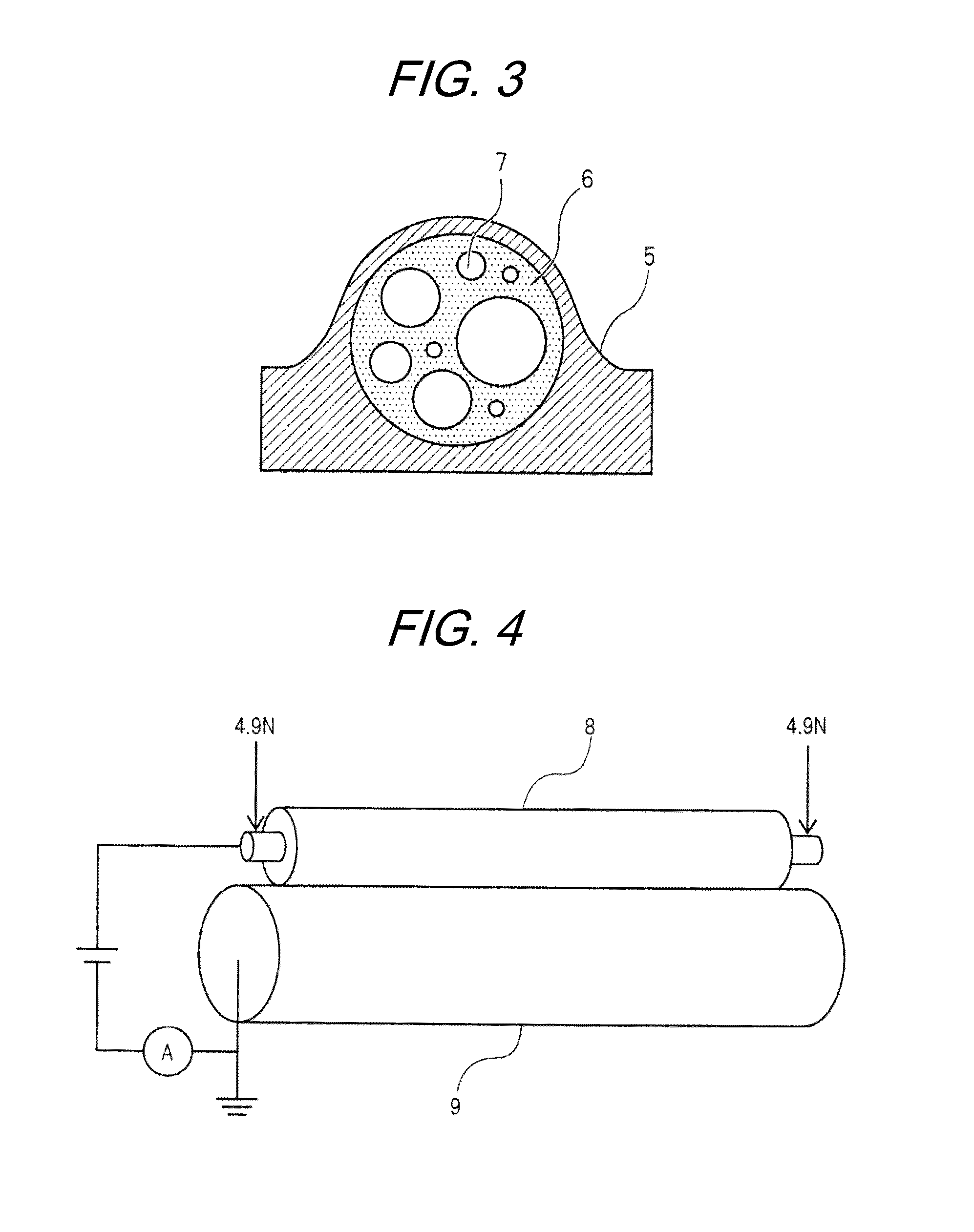

Electrophotographic process cartridge and electrophotographic apparatus

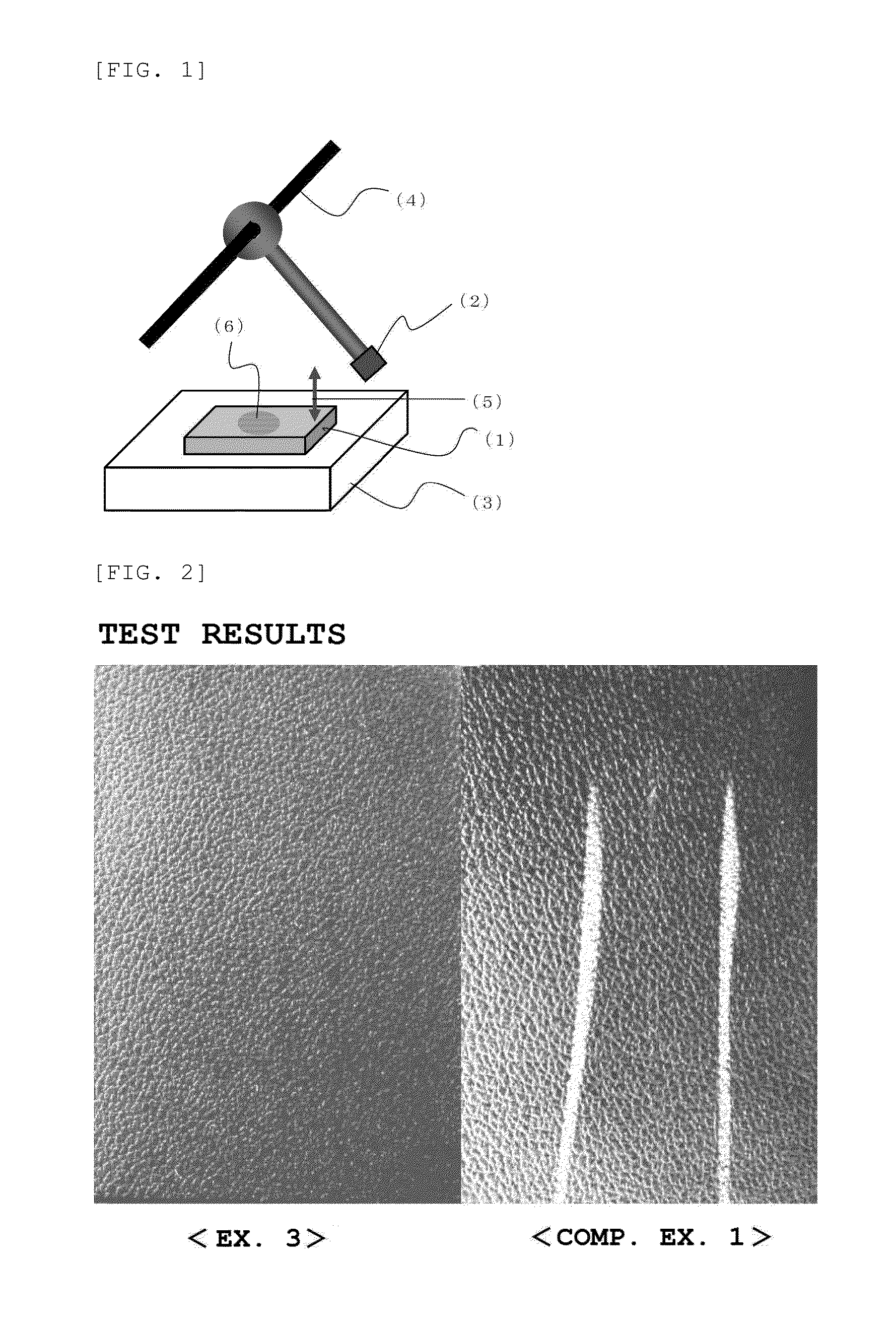

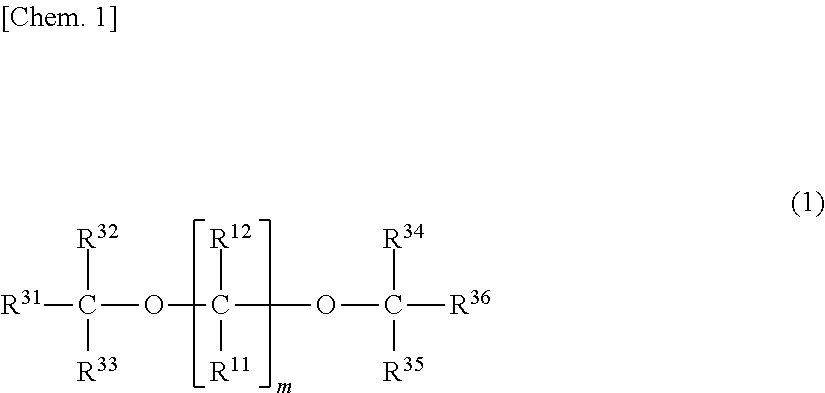

ActiveUS20140295336A1Charging unevennessHigh quality imagingLiquid surface applicatorsElectrographic process apparatusPolymer sciencePolymer chemistry

Uneven charging is improved, and production of a banding image attributed to a slip between the charging member and the electrophotographic photosensitive member is suppressed. An electrophotographic process cartridge including a charging member and an electrophotographic photosensitive member which is electrically charged upon being brought into contact with the charging member, wherein the charging member includes a electro-conductive substrate and a surface layer formed on the electro-conductive substrate; the surface layer contains at least a binder resin, an electron conductive agent, and a resin particle having a plurality of pores inside thereof; the surface of the surface layer has a protrusion derived from the resin particle; the electrophotographic photosensitive member includes a support and a photosensitive layer formed on the support; and the surface layer of the electrophotographic photosensitive member contains a specific component.

Owner:CANON KK

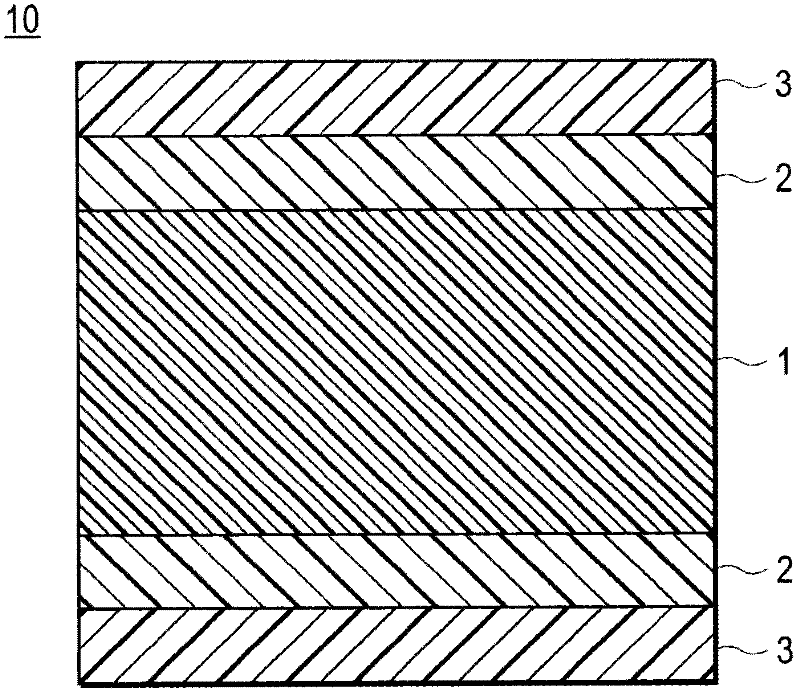

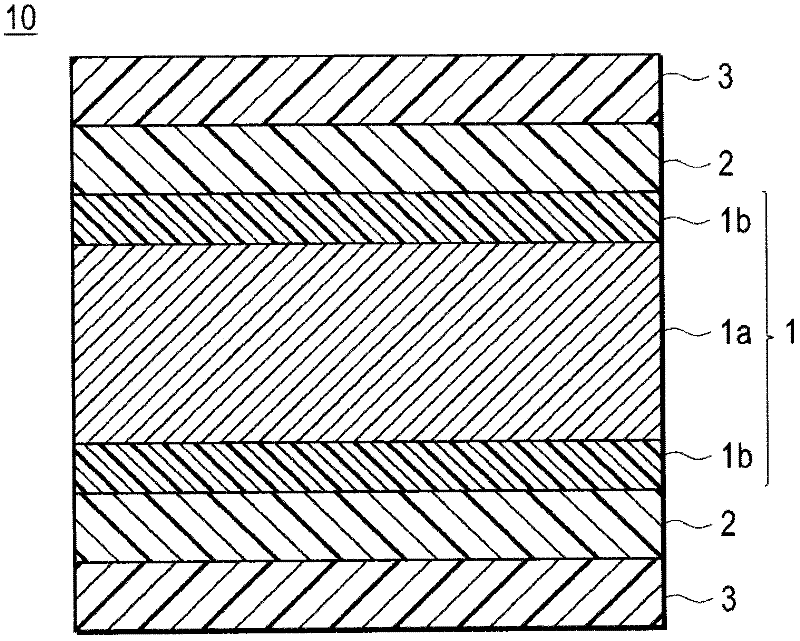

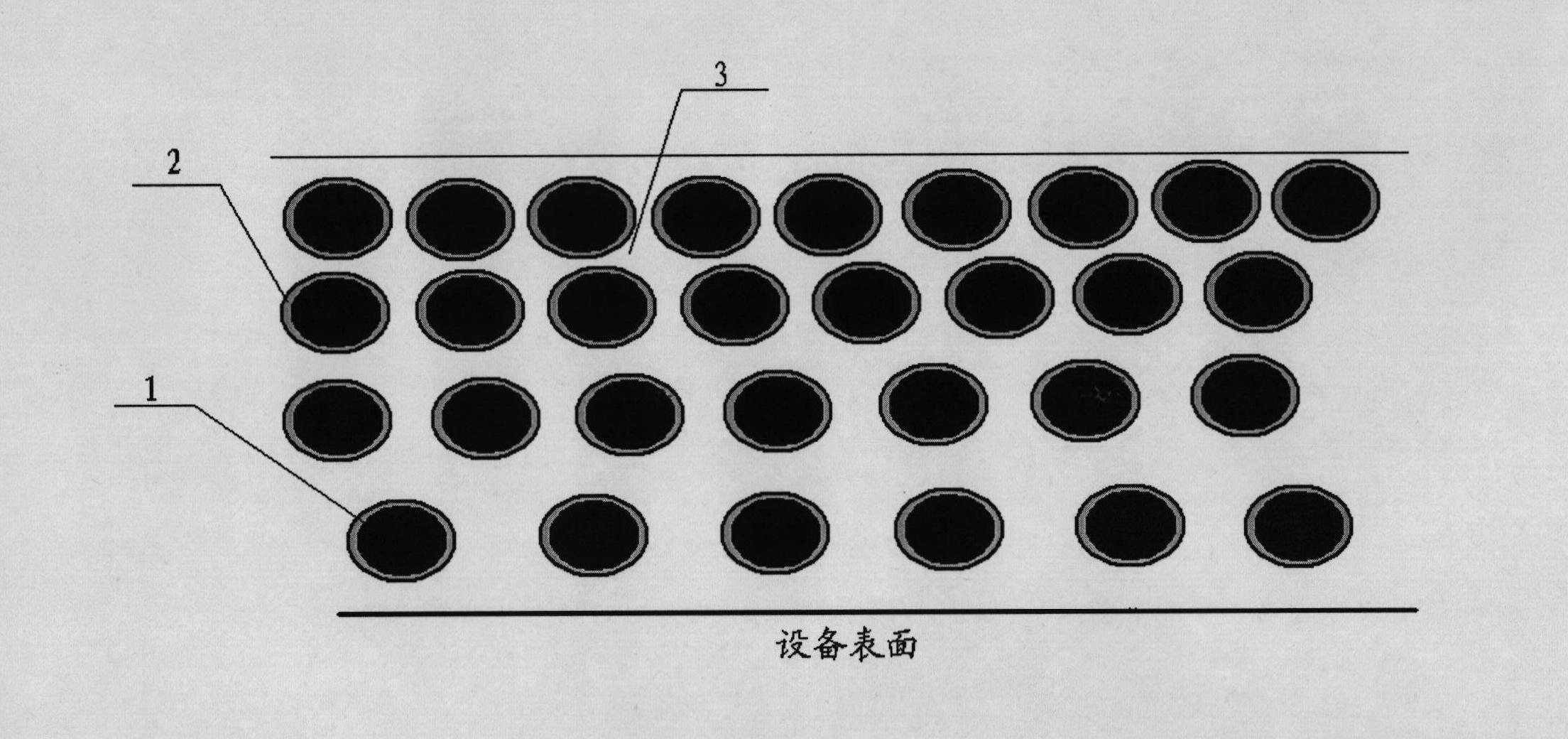

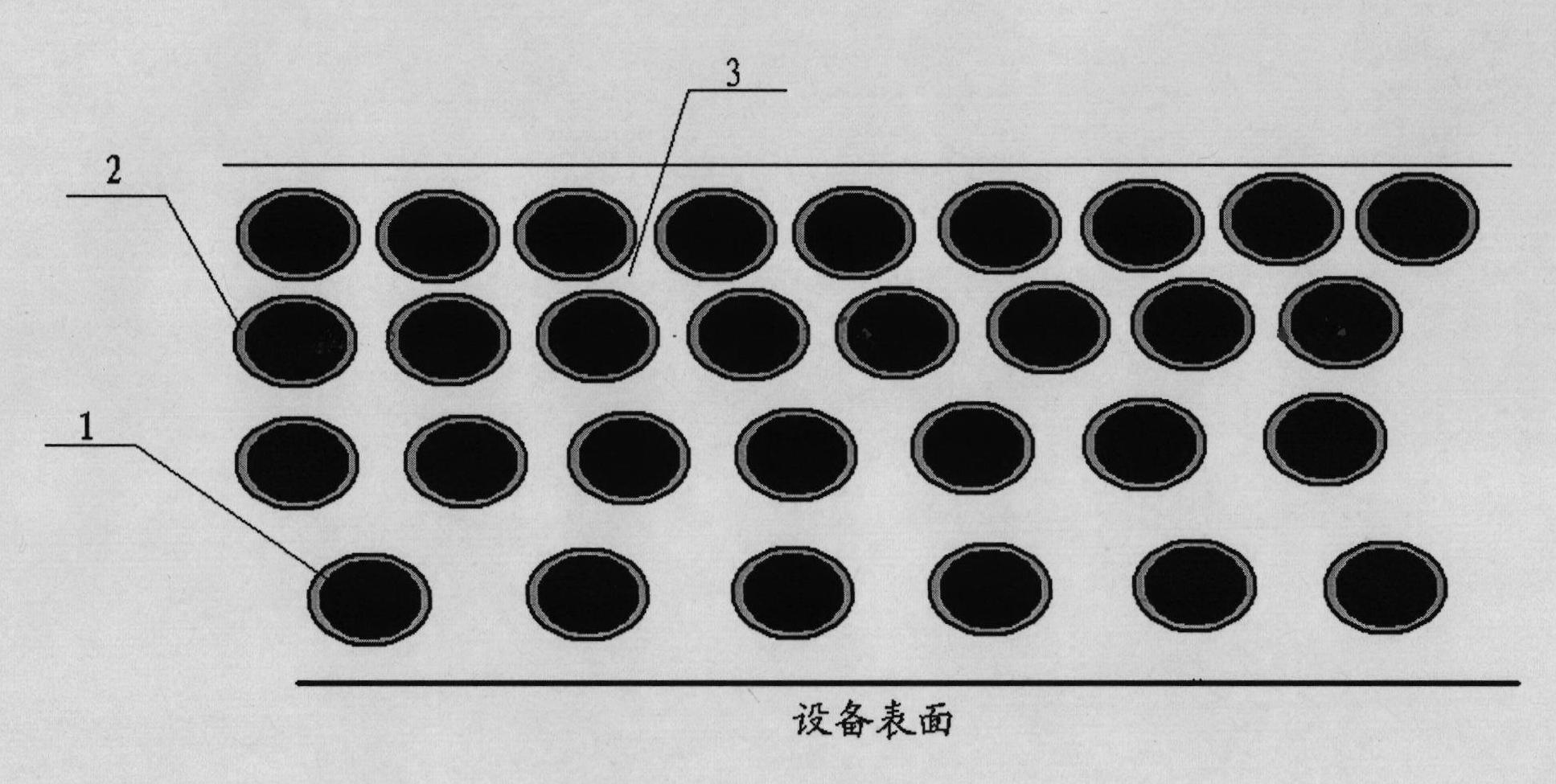

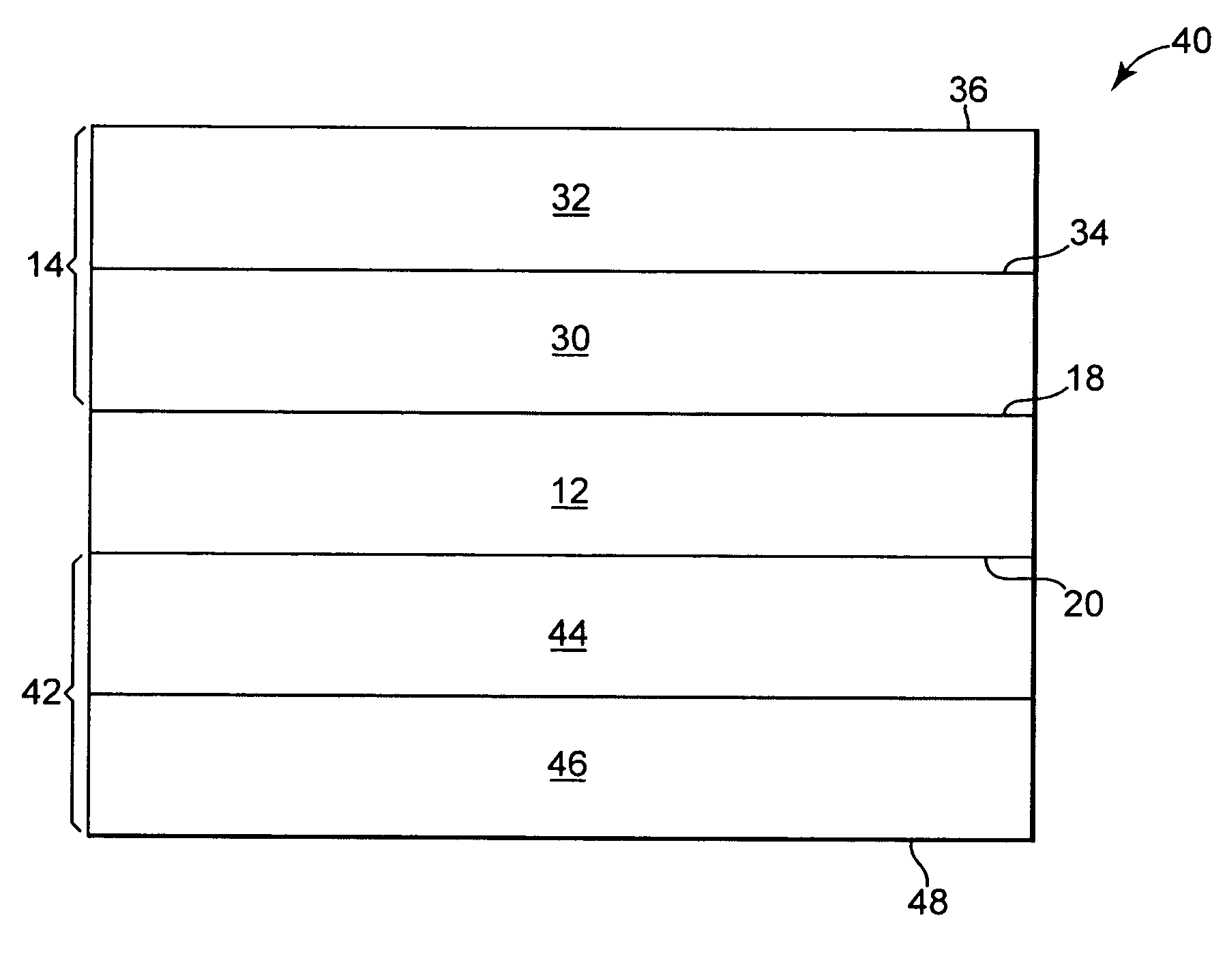

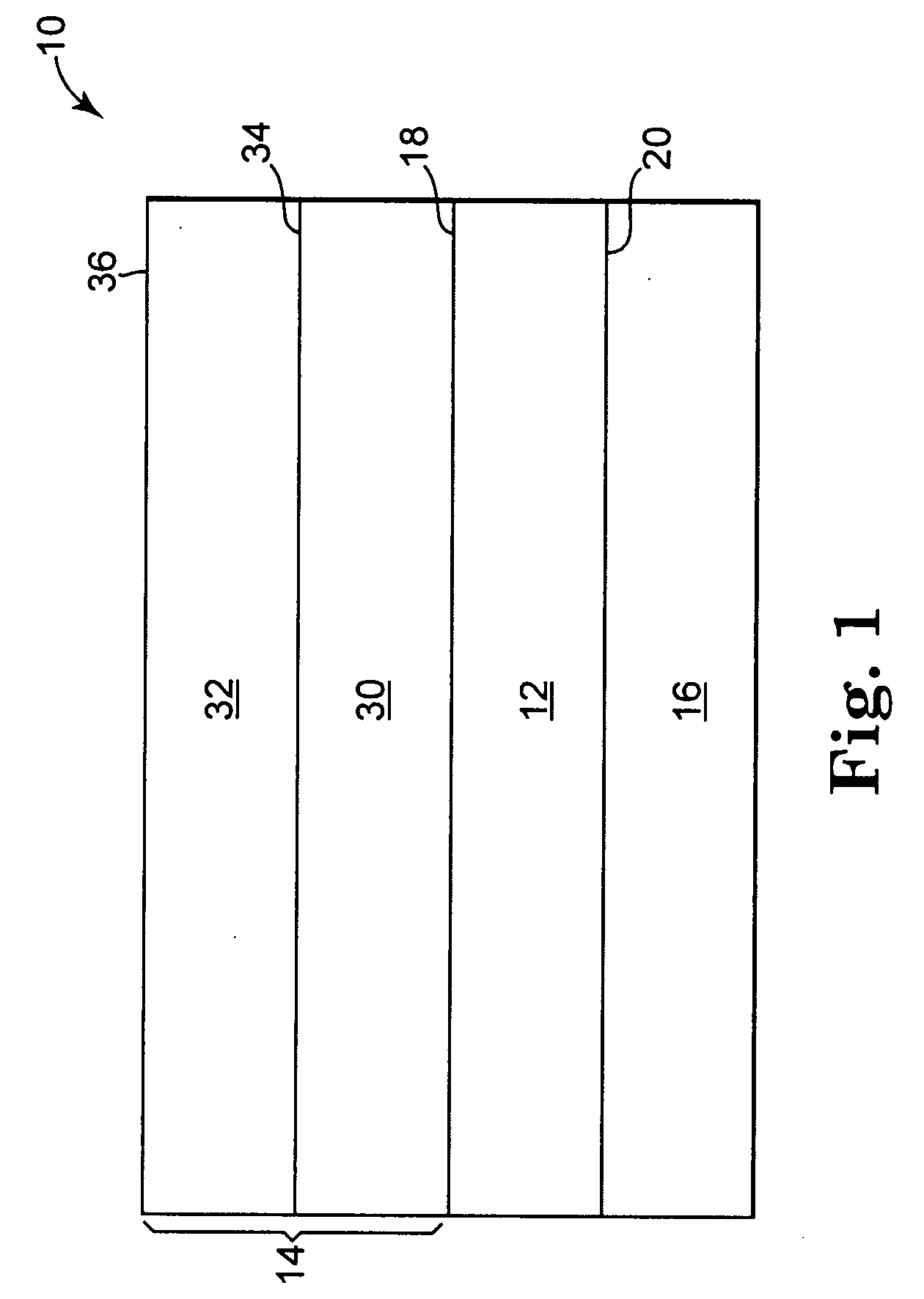

Medical devices with lubricious surfaces when wet

ActiveCN102264403AIncrease surface lubricitySurgeryPharmaceutical delivery mechanismChemistryChemical compound

Provided is a medical device wherein a surface lubricating layer and one of various polymer bases are fixed with each other firmly by a simpler technique. The medical device permanently exhibits excellent surface lubricity when in use. Specifically disclosed is a medical device (10) which has a lubricating surface when wet. The medical device (10) is characterized by comprising a base layer (1) at least the surface of which is composed of a polymer material, a compound (thiol compound) (2) which is supported by at least a part of the base layer (1) and has a plurality of thiol groups in each molecule, and a surface lubricating layer (3) which covers the thiol compound (2) and is composed of a hydrophilic polymer that has a reactive functional group. The medical device (10) is also characterized in that the thiol compound (2) is supported by (fixed to) the base layer (1) by irradiation of ionized gas plasma, and that the surface lubricating layer (3) is bonded to the base layer (1) by reacting the thiol compound (2) with the hydrophilic polymer that has a reactive functional group.

Owner:TERUMO KK

Fluid dispense tips

InactiveUS8690084B1Surface tensionCorrection capabilityLiquid surface applicatorsClosuresDecreased pressureBiomedical engineering

A fluid dispense tip includes a bevel at an opening to reduce the amount of surface tension, or “land”, at the opening. The bevel is formed by grinding in a longitudinal direction such that any tooling scars resulting from the grinding operation are likewise longitudinally oriented, further reducing the amount of surface tension in the tip, thereby leading to heightened dispensing accuracy. The tip may be machined from stock as a unitary piece, to increase its lifetime, and may be formed with a bore of a relatively large diameter that is tapered down to a smaller diameter near the tip opening, to allow for delivery of fluid through the tip body at a decreased pressure. The tip may optionally be formed with a Luer™-style fitting on the body, such that the tip is compatible with pumps that utilize such a fitting.

Owner:DL TECH

High-temperature anti-sticking material coating and manufacturing and application methods thereof

The invention discloses a high-temperature anti-sticking material coating and manufacturing and application methods thereof. The high-temperature anti-sticking material coating comprises self-lubricating material particles, a cladding material and a high-temperature-resistant adhesive, wherein the particle size of the self-lubricating material particles is micron-sized; the self-lubricating material particles are coated by the cladding materials; the melting point of the high-temperature-resistant adhesive is higher than that of the cladding material; the coated self-lubricating material particles are adhered together to form the high-temperature anti-sticking material coating; and the coated self-lubricating material particles are adhered together by aluminum dihydrogen phosphate serving as the adhesive to form the high-temperature anti-sticking material coating. The high-temperature anti-sticking material coating is simple in manufacturing process and flexible in application method, adapts to the high temperature of 1,600 DEG C, effectively prevents liquid metal in the metallurgy environment from being adhered to equipment because the liquid metal is changed into solid when encountering cold, and is widely applied, safe and reliable.

Owner:席君杰 +2

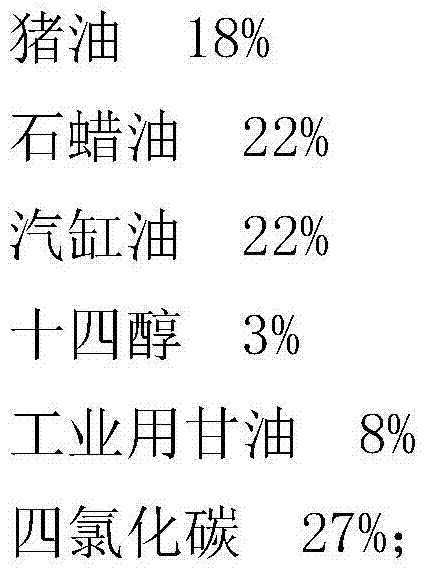

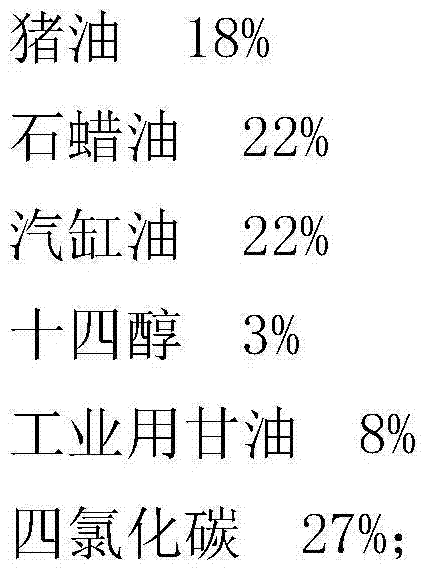

Lubricating liquid for lubricating surface of aluminum alloy material and preparation method thereof

InactiveCN104119995AEliminate surface defectsEliminates oil and scaleBase-materialsParaffin oilsOxide

The invention discloses a lubricating liquid for lubricating the surface of an aluminum alloy material and a preparation method thereof, and relates to the technical field of lubricating liquids. The lubricating liquid is composed of the following components: lard, paraffin oil, steam cylinder oil, tetradecyl alcohol, industrial glycerin, and carbon tetrachloride. The lubricating liquid can eliminate the surface defects of an aluminum alloy material, oil stains and oxide scales, so the lubricating effect is better, the fluidity and lubricity of aluminum alloy products are better during the extrusion process, and the part quality is improved.

Owner:ANHUI CHENGYOU AUTO PARTS MFG

Fluid dispense tips

InactiveUS8480015B1Surface tensionCorrection capabilityLiquid surface applicatorsSpray nozzlesDecreased pressureScars

A fluid dispense tip includes a bevel at an opening to reduce the amount of surface tension, or “land”, at the opening. The bevel is formed by grinding in a longitudinal direction such that any tooling scars resulting from the grinding operation are likewise longitudinally oriented, further reducing the amount of surface tension in the tip, thereby leading to heightened dispensing accuracy. The tip may be machined from stock as a unitary piece, to increase its lifetime, and may be formed with a bore of a relatively large diameter that is tapered down to a smaller diameter near the tip opening, to allow for delivery of fluid through the tip body at a decreased pressure. A cleaning tool may be provided for removing residual material from the inner surfaces of the tip. A removable liner sleeve may be provided within the bore to reduce the effective inner diameter of the dispense tip.

Owner:DL TECH

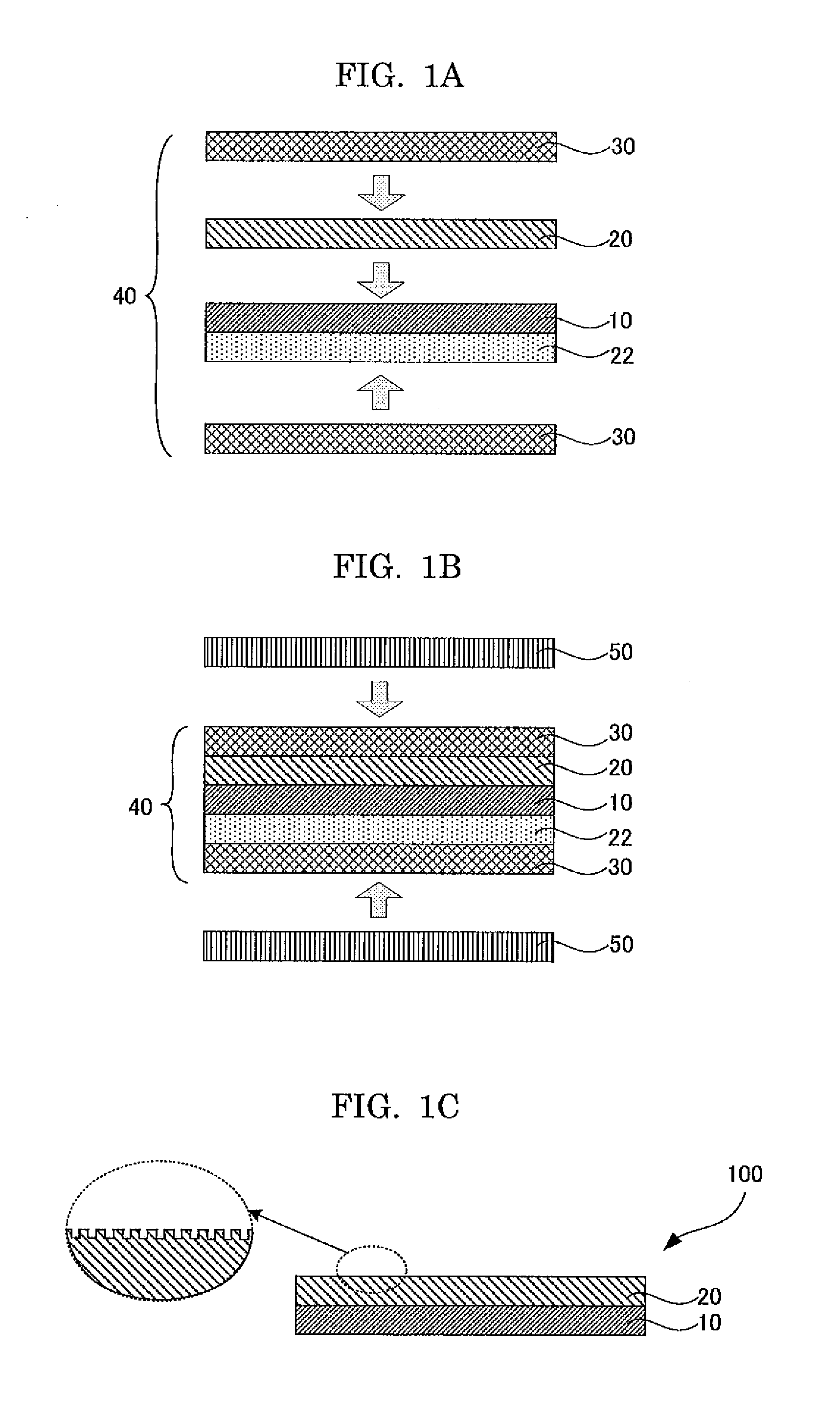

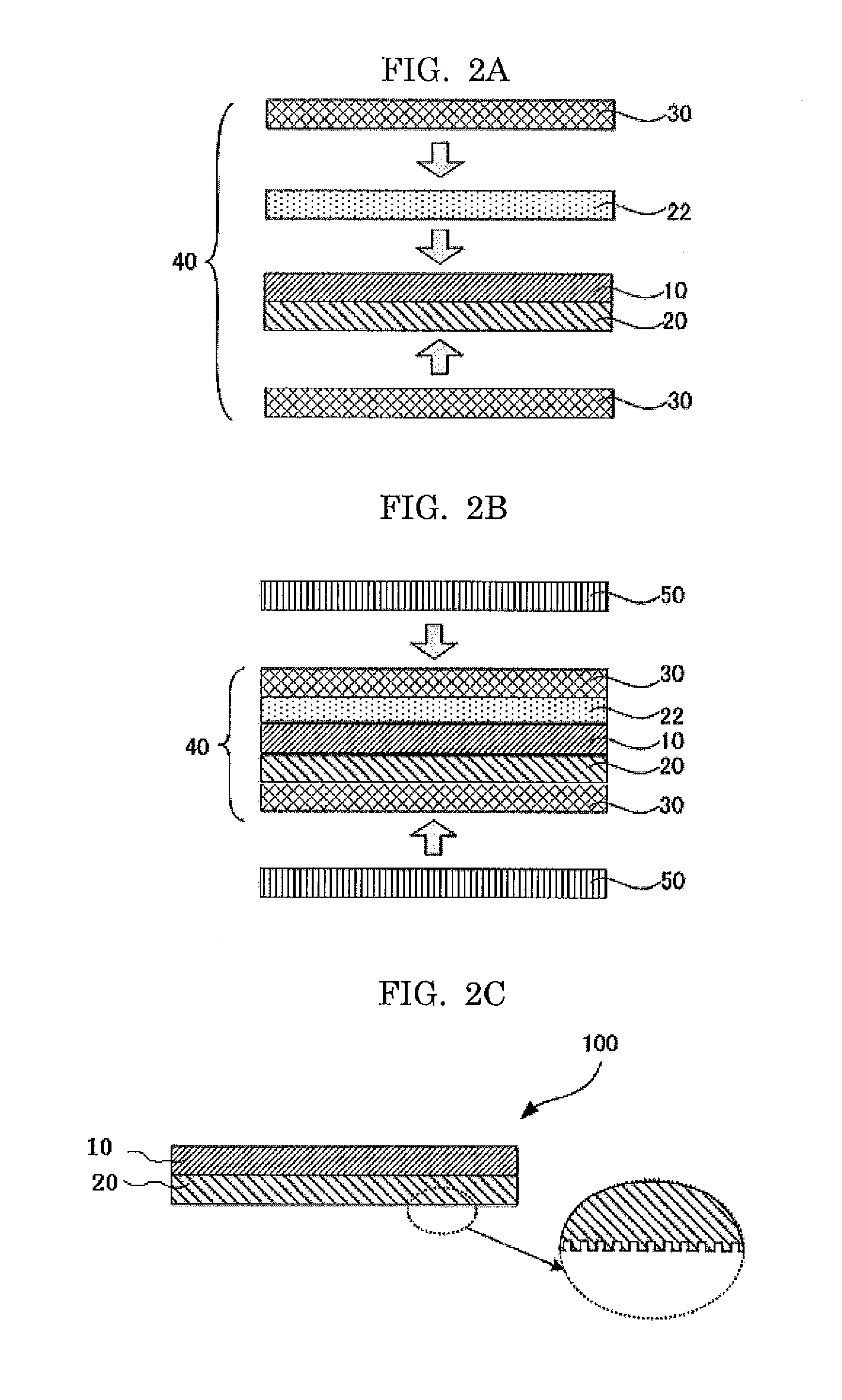

Magnetic sheet and production method thereof

ActiveUS20090324982A1Preventing electromagnetic disorderIncrease surface lubricityMagnetic/electric field screeningParticle applicationPolyresinMaterials science

A magnetic sheet, which contains: a magnetic layer including a magnetic powder and a resin composition containing the magnetic powder therein; and a convex-concave forming layer, in which the convex-concave forming layer has Bekk smoothness of 70 sec / mL or less. A method for producing a magnetic sheet, which contains: adding a magnetic powder to a resin composition to prepare a magnetic composition, and giving the magnetic composition a shape to form a magnetic layer; and placing and stacking a convex-concave forming layer and a pattern transferring material on a surface of the magnetic layer in this order, and hot pressing the stacked layers so as to bond the convex-concave forming layer with the magnetic layer to form a laminate, as well as to transfer a surface configuration of the pattern transferring material to a surface of the laminate of the convex-concave forming layer and the magnetic layer.

Owner:DEXERIALS CORP

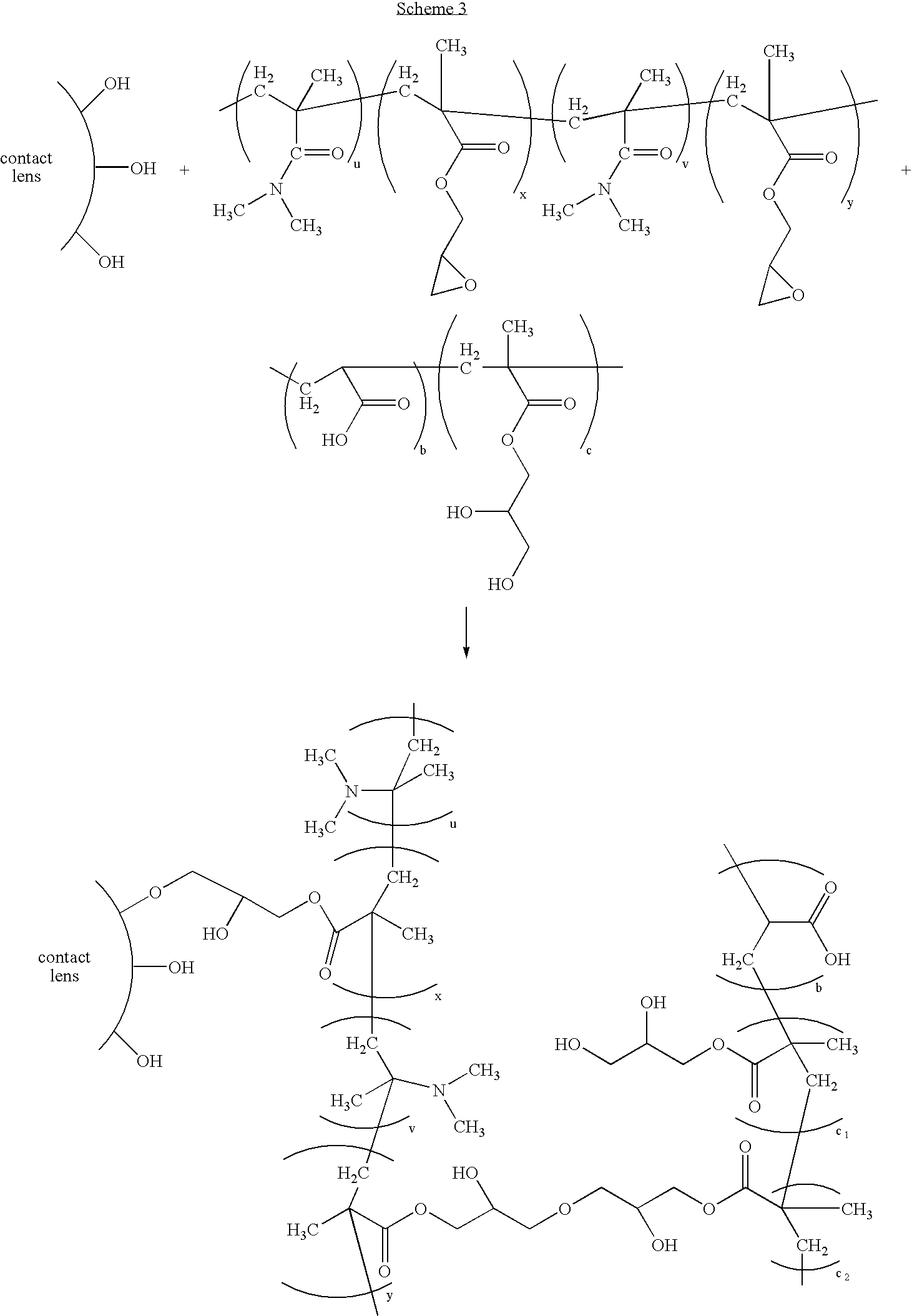

Polymers comprising polyhydric alcohols, medical devices modified with same, and method of making

InactiveUS20070264503A1High levelReduce rateSynthetic resin layered productsThin material handlingHydrophilizationPolyol

A medical device having an increased surface hydrophilicity comprises a coating polymer comprising units of a polymerizable hydrophilic compound, such as a polymerizable polyhydric alcohol. The coating polymer can be applied to a medical device comprising a hydrogel material. The medical device can have a reduced dehydration rate compared to a device that is devoid of such a coating polymer and / or provide increased comfort to a user.

Owner:BAUSCH & LOMB INC

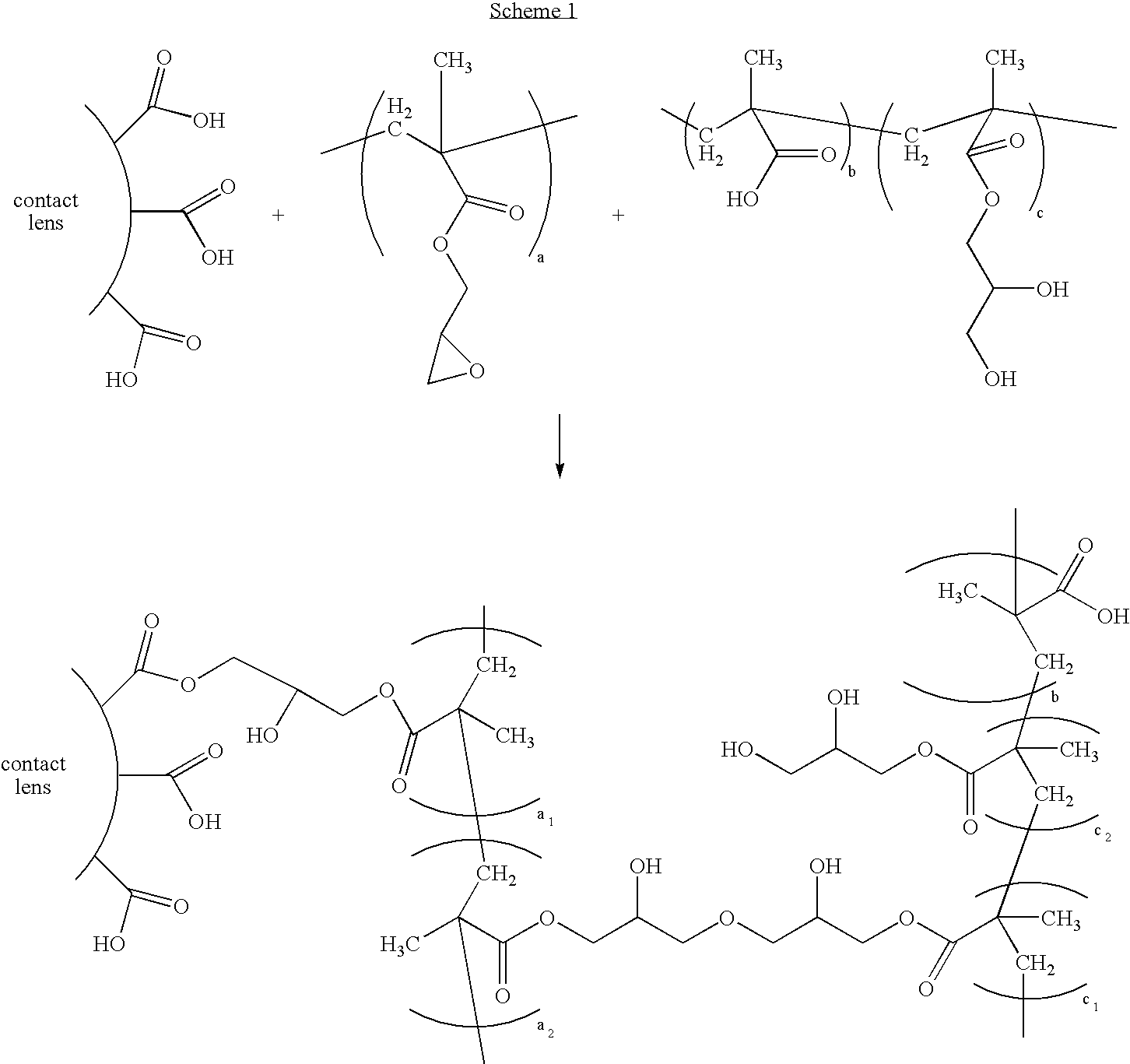

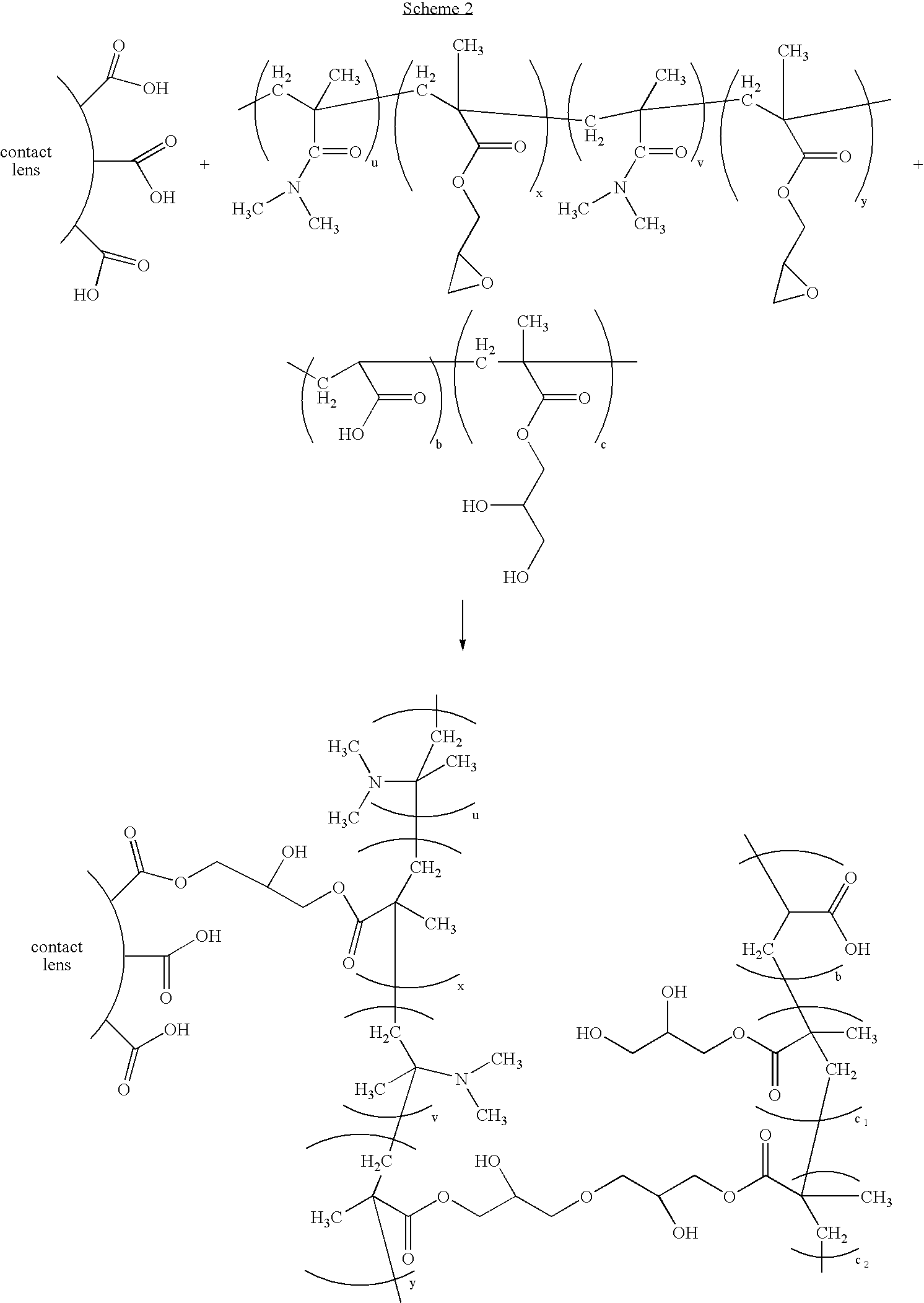

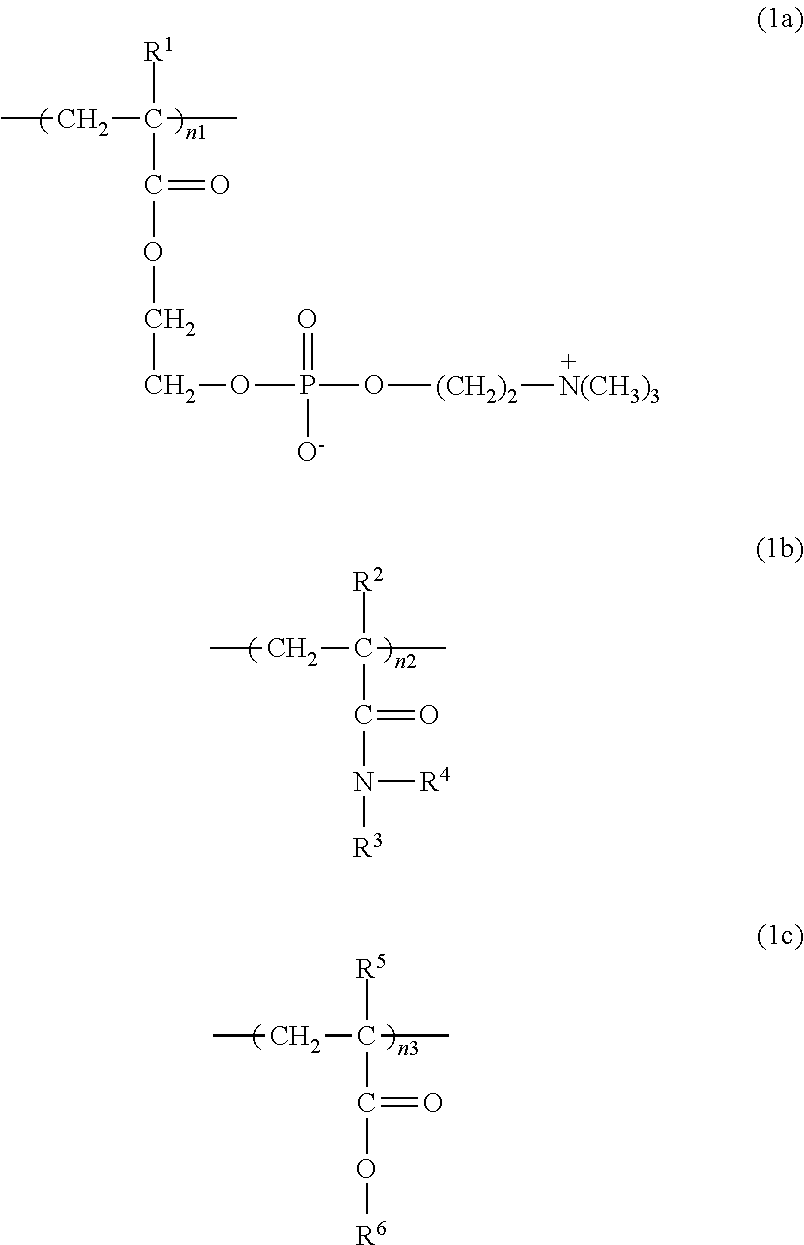

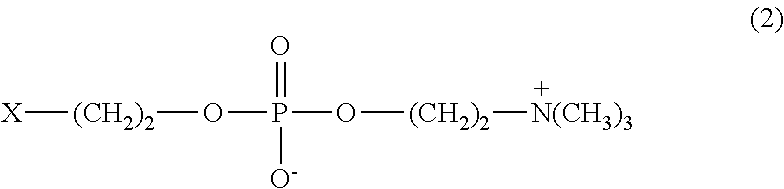

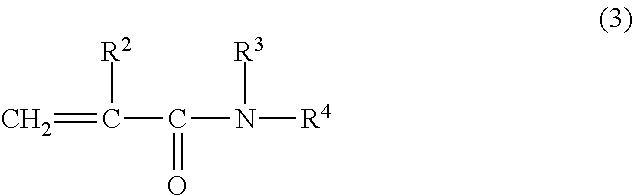

Contact lens care preparation and packaging solution

ActiveUS20150024987A1Simple treatmentIncrease surface lubricityLens cleaning compositionsChemicalsMeth-Ophthalmology

Provided are a contact lens care preparation capable of imparting durable surface lubricity and amebic adhesion inhibitory effect to a contact lens surface through a simple treatment, and a contact lens packaging solution utilizing the same. The contact lens care preparation is composed of a solution containing 0.01 to 2 weight / volume % of a polymer having particular monomer units with a phosphorylcholine-like group, particular (meth)acrylamide derivative units, and particular monomer units with a hydrophobic group at a particular ratio, and a weight average molecular weight of 5,000 to 2,000,000, and is useful as a contact lens packaging solution.

Owner:NOF CORP

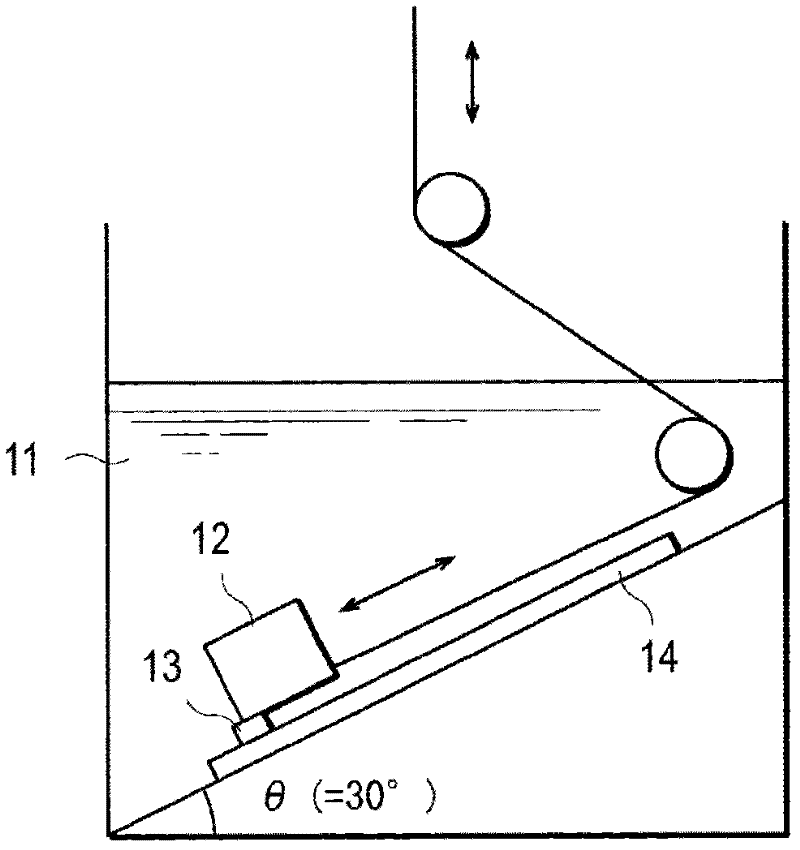

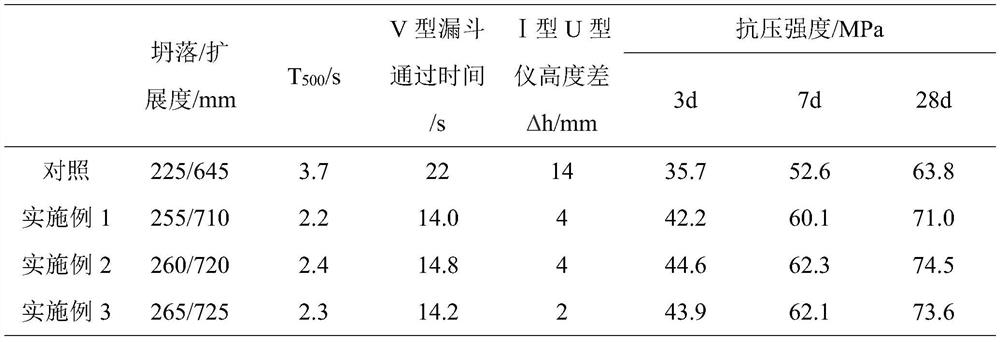

Slope self-compacting concrete and pouring construction method thereof

InactiveCN111777385AIncreased pozzolanic activityImprove early strengthRoof covering using sealantsCoastlines protectionSlagSilicon dioxide

The invention provides a slope self-compacting concrete. The slope self-compacting concrete is prepared from the following components in parts by weight: 60 to 70 parts of Portland cement, 60 to 100 parts of coarse aggregate, 48 to 78 parts of fine aggregate, 15 to 30 parts of mineral admixture and 0.6 to 2.1 parts of an additive, wherein the water-binder ratio is 0.26 to 0.35; the coarse aggregate is granite stone; the fine aggregate is river sand; the mineral admixture is a mixture of steel slag, fly ash and silicon powder according to a mass ratio of 1: 1: 0.5; the additive is a water reducing agent; and the steel slag is steel slag micro-powder subjected to surface modification by nano silicon dioxide. The steel slag micro-powder is subjected to surface silicon dioxide modification, the volcanic ash activity of the steel slag micro-powder is improved, the steel slag micro-powder can replace a part of a conventional admixture, meanwhile, the early strength of the doped concrete is improved, the application range of the steel slag concrete is expanded, and the production cost is also reduced.

Owner:SHANDONG WATER CONSERVANCY CONSTR ENG CO LTD

Imaging member

InactiveUS20070054208A1Extended functional lifeIncreased wear and ozone attack resistanceRadiation applicationsPhotoprinting processesOligomerOzonolysis

An imaging member having an enhanced anti-curl back coating is disclosed. The anti-curl back coating comprises a liquid oligomer. Additionally, a slip agent can also be included. The resulting anti-curl back coating contains little to no residual solvent, shows improved resistance to wear and ozonolysis, and increased lubricity to prevent static charge built-up.

Owner:XEROX CORP

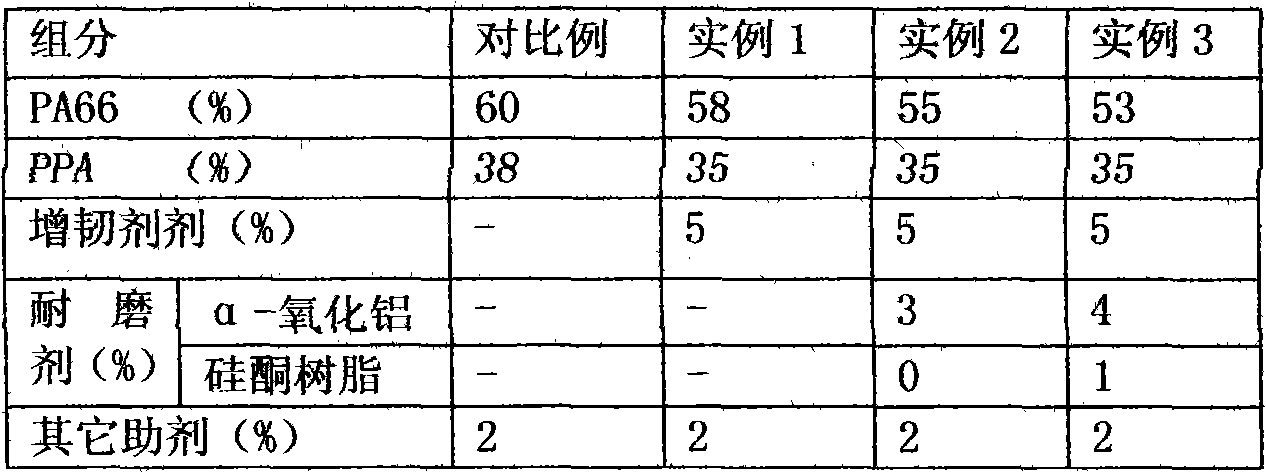

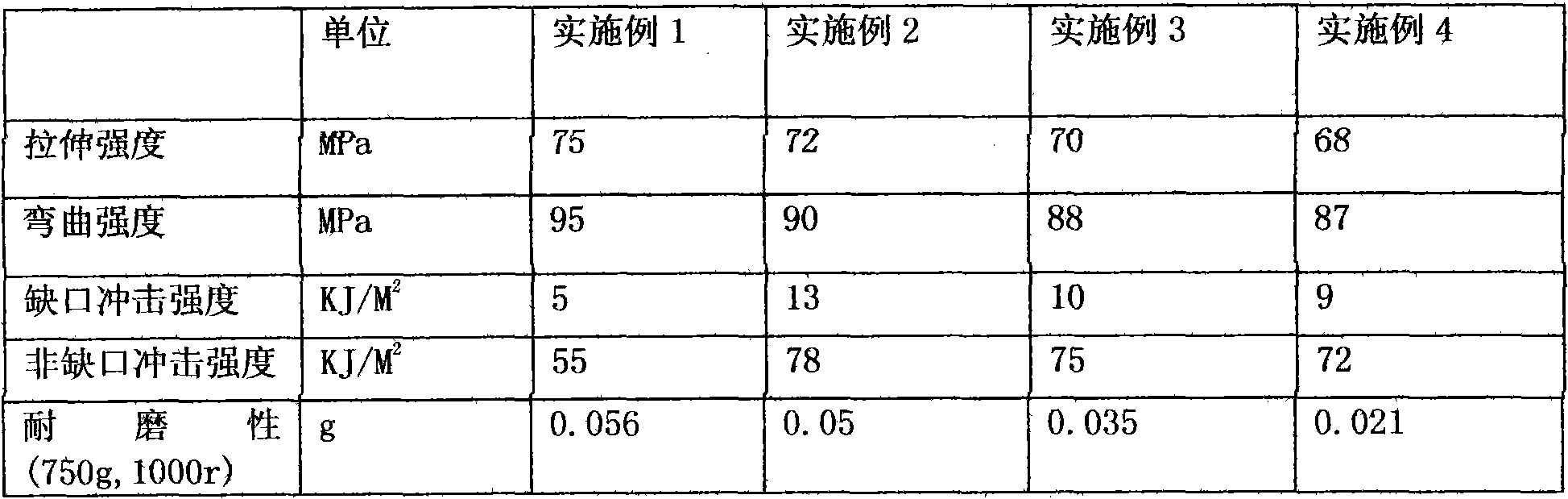

Preparation and application of high-wear-resistance modified nylon composition

The invention discloses preparation and application of a high-wear-resistance modified nylon composition. The high-wear-resistance modified nylon composition comprises the following components in percentage by weight: 30-70 parts of PA66 (Polyamide) resin, 20-50 parts of PPA (Polyphthalamide) resin, 4-8 parts of toughening agent, 4-7 parts of wear-resisting agent and 2-5 parts of other auxiliary agents. The material has wide application in the fields of automobiles, machinery and the like and has an obvious advantage of substituting metal in the aspects of a wear-resistant shaft bushing, a slip sheet and the like. A preparation method for the high-wear-resistance modified nylon composition comprises the following process steps of: uniformly mixing the raw materials according to a proportion; adding into a double-screw extruder; and controlling the temperature at 250-330 DEG C for granulation to obtain the high-wear-resistance modified nylon composition. The high-wear-resistance modified nylon composition with superior comprehensive performance is prepared.

Owner:BEIJING SHOUSU NEW MATERIAL TECH

Weather-proof anti-flaming high-performance glass surface protection film and preparation method thereof

The invention discloses a weather-proof anti-flaming high-performance glass surface protection film which comprises the following raw materials in parts by weight: 26-32 parts of polytetrafluoroethylene, 10-14 parts of polyvinyl alcohol, 2-6 parts of lubricating auxiliaries, 18-24 parts of polyurethane resin, 8-10 parts of a processing agent, 9-13 parts of silicone resin, 10-12 parts of an anti-flaming additive, 6-8 parts of vinyl silicone oil, 1-2 parts of a catalyst, 4-8 parts of a metallic oxide additive, 3-7 parts of a coupling agent and 16-22 parts of water. The protection film disclosed by the invention is higher in adhesive force and has excellent light transmittance performance and impact strength, better anti-scraping property, better fireproof anti-flaming property and excellent weather-proof property; meanwhile, the raw material components are safe and reliable, are harmless to environment and are easily acquired according to the preparation method disclosed by the invention; the cost is lower, the technology is simple, the operation is easy, and the industrial production is easily realized; and the protection film has higher practical values and good application prospects.

Owner:HEFEI FANTENG ENVIRONMENTAL PROTECTION TECH CO LTD

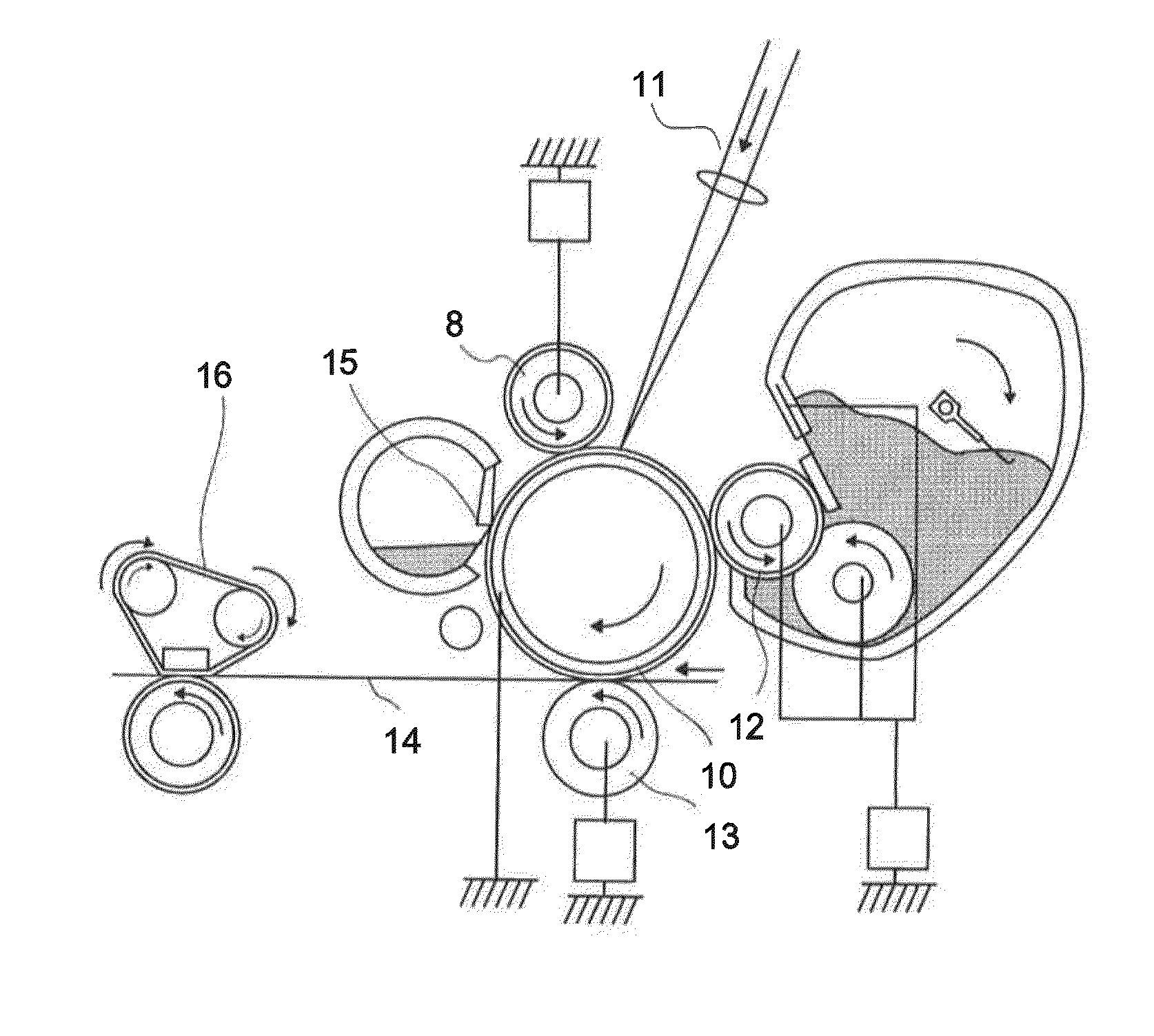

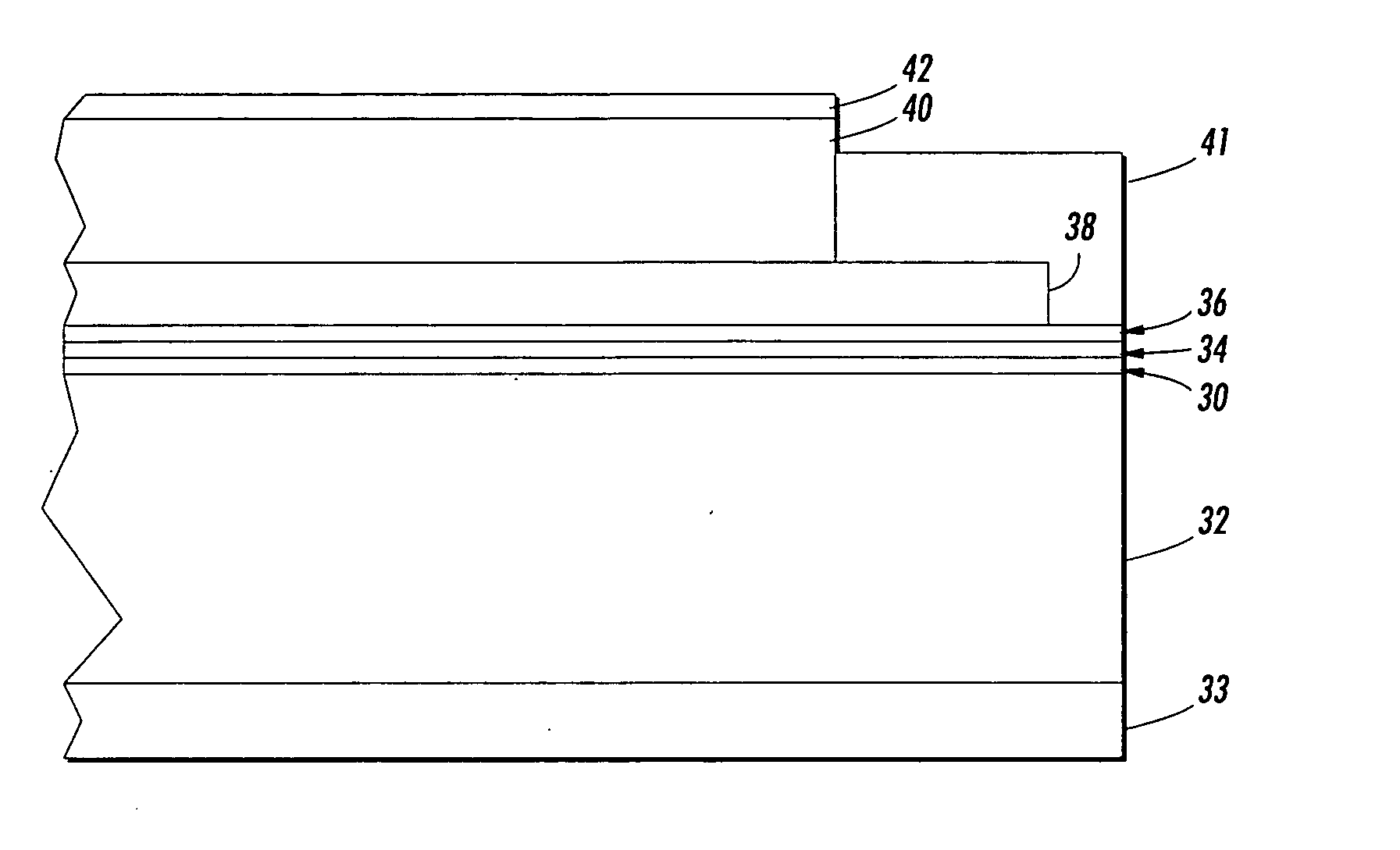

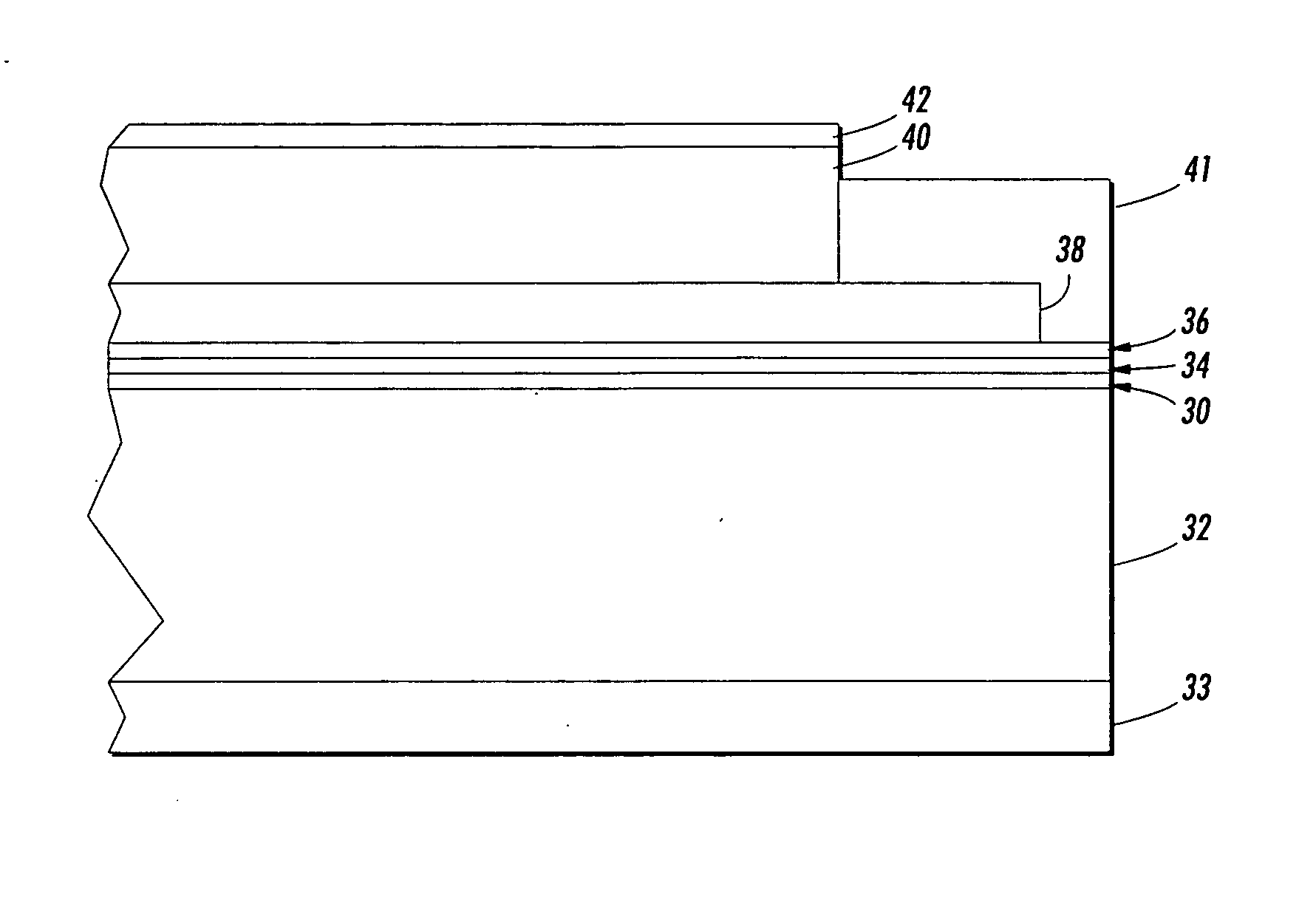

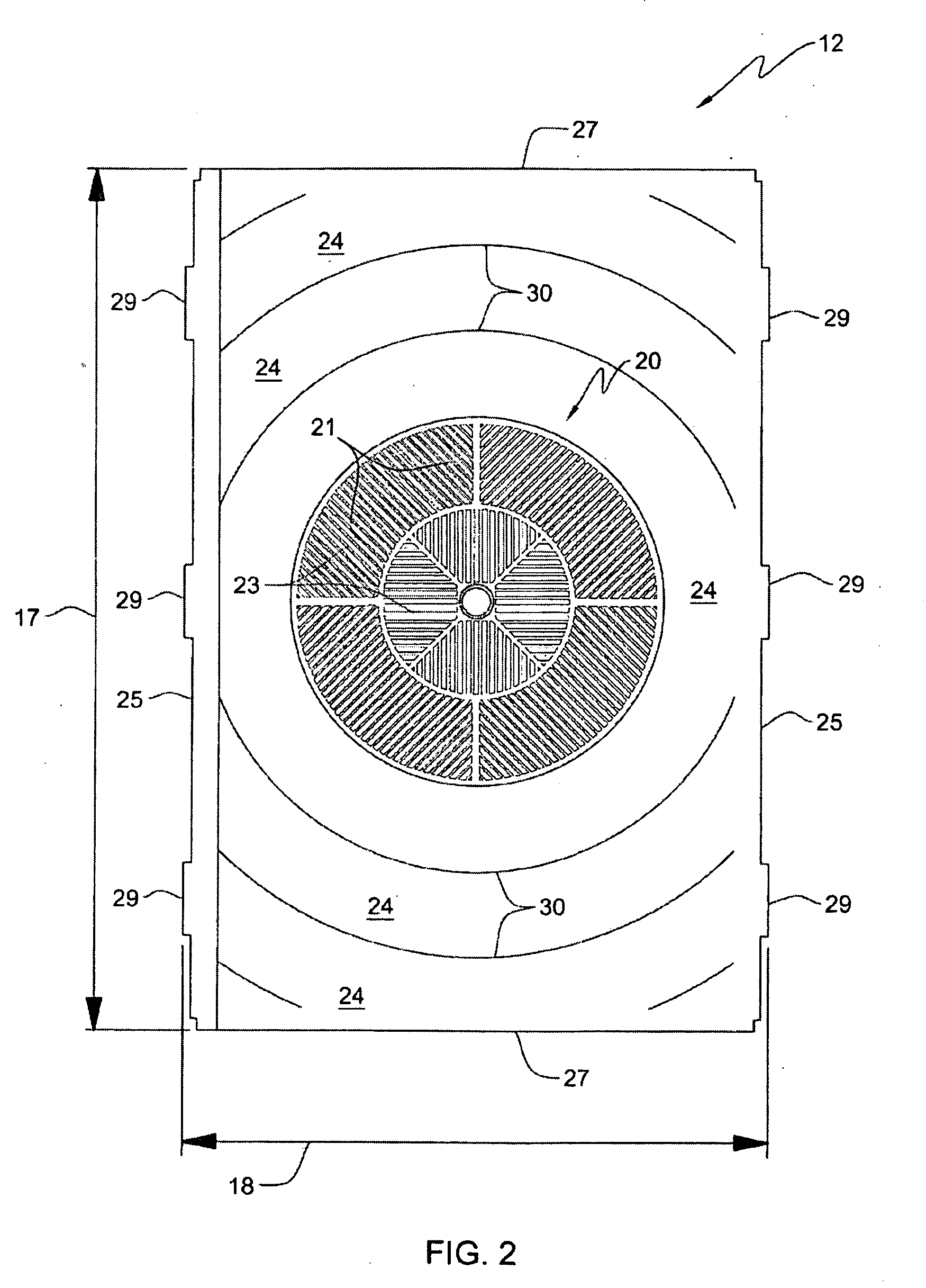

Magnetic recording tape configured for improved surface lubricity

InactiveUS20080305366A1Increase surface lubricityRecord information storageMagnetic recordingLubricationNanometre

A magnetic recording tape configured for increased surface lubricity includes an elongated substrate and a magnetic side disposed on the substrate. The magnetic side includes a magnetic recording layer defining an exposed magnetic recording surface opposite the substrate, and a support layer deposited on the substrate between the substrate and the magnetic recording layer. The support layer includes nano-particles configured to release lubrication to the exposed magnetic recording surface. In this regard, the support layer configures the exposed magnetic recording surface to have a surface lubrication to total lubrication ratio (SL ratio) of greater than about 5%.

Owner:IMATION

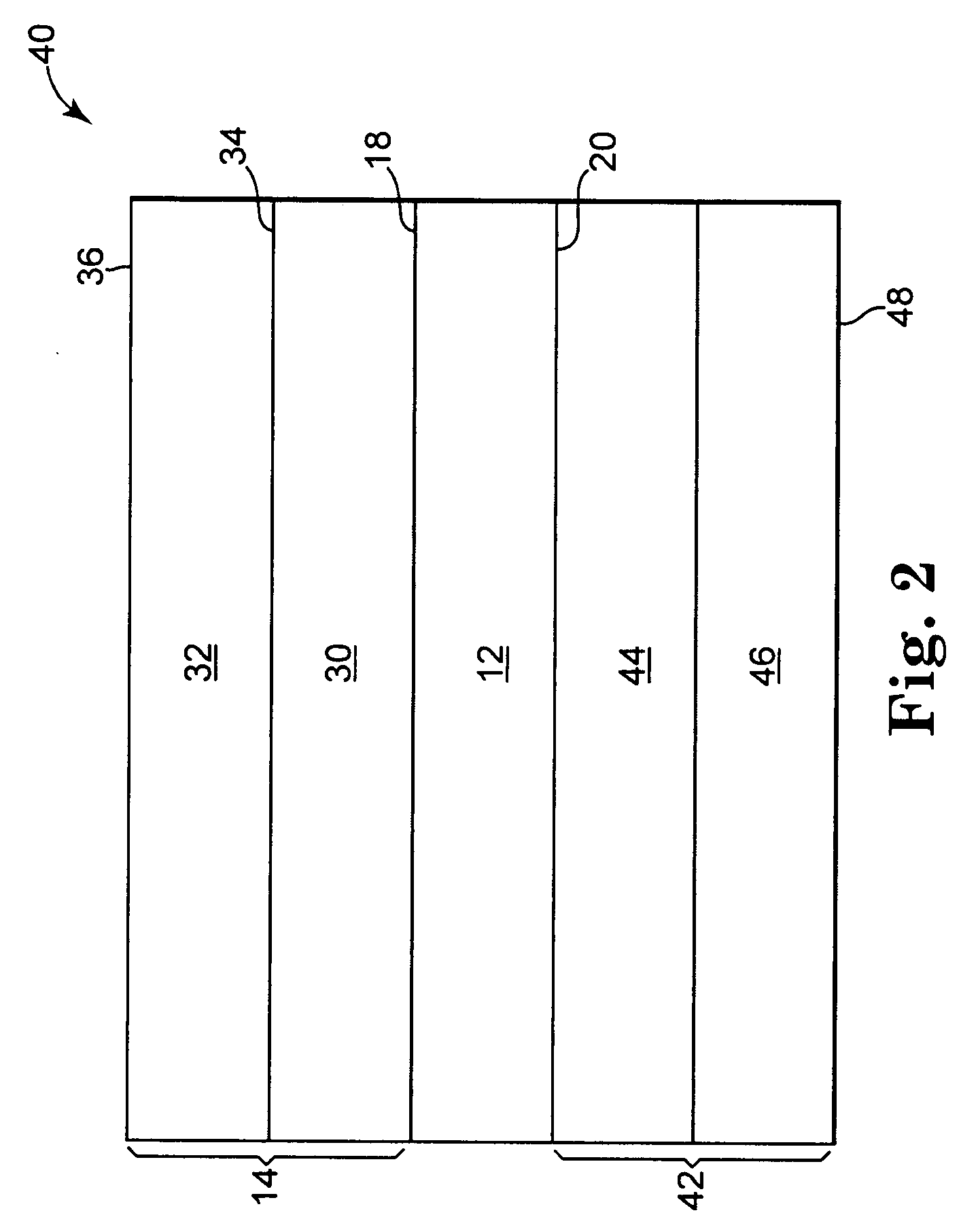

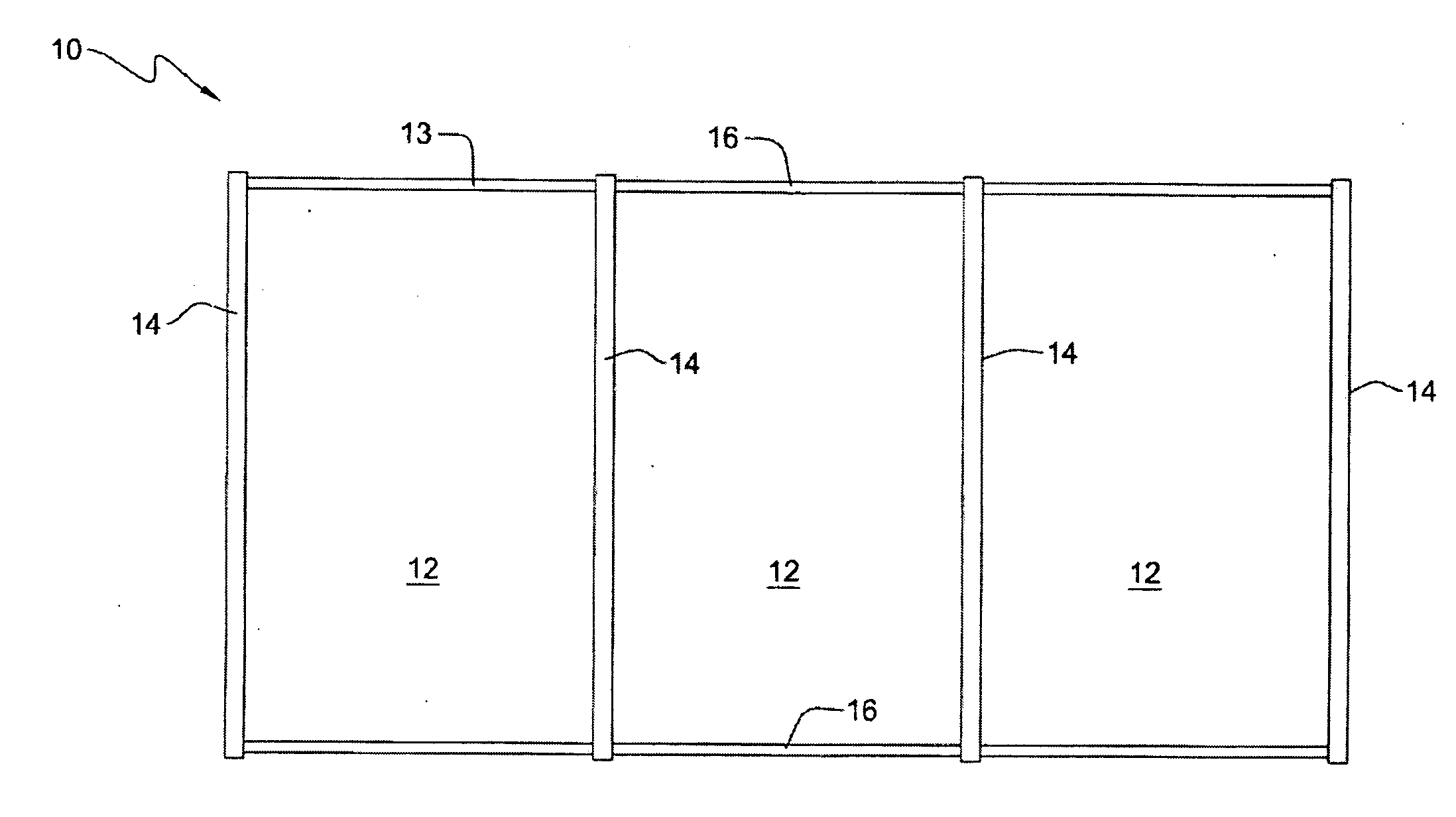

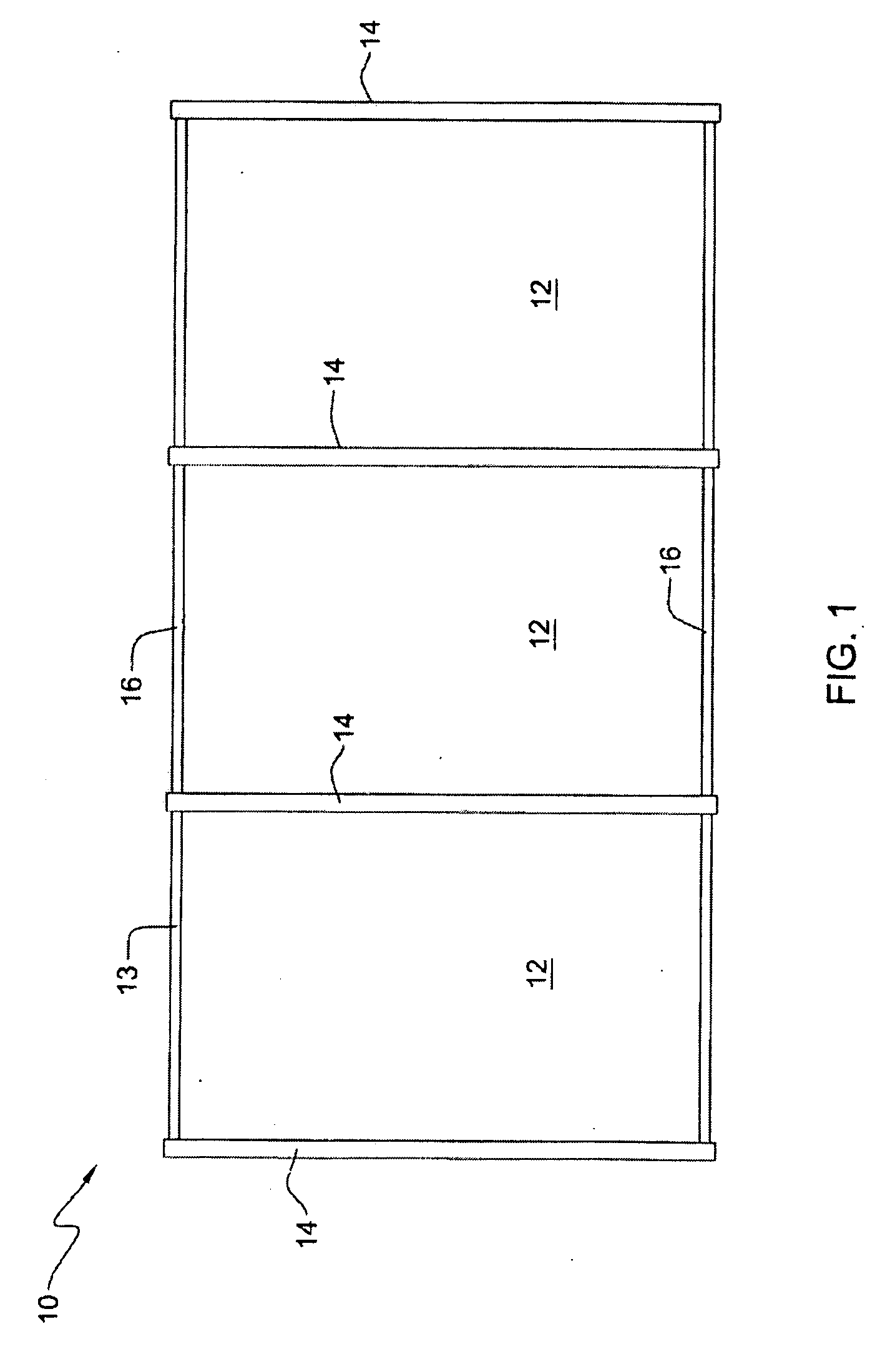

Drying tray and method of use

InactiveUS20090126221A1Easily absorb or transfer flavors and odorsImprove pollutionDrying solid materials with heatDrying chambers/containersEngineeringMechanical engineering

A tray, for example, a drying tray, a method for drying, and a structural member engagement system are provided. The drying tray includes at least one perforated panel; and a frame adapted to support the perforated panel. The frame may include a plurality of interconnecting plastic support members adapted to receive the perforated panel. The tray may be used to dry fruits, vegetables, fish, and meat. A method of using the tray and a structural member engagement system are also disclosed The member engagement system includes a first elongated member, a second elongated member, and a plug and pin adapted to engage the first member with the second member.

Owner:HARTWELL WARREN R +1

Medical device and production thereof

InactiveUS6066118AIncrease surface lubricityHigh friction durabilitySynthetic resin layered productsSurgeryPolymer chemistryMedical treatment

A medical device having good surface lubricity in the wet condition, high frictional durability and surface lubricity stability includes a body and a smoothing or lublicating coating on a surface of the body. The coating is produced by applying a solution of a mixture of maleic anhydride high polymer and polyurethane having allophanate bond on a surface of the body, insolubilizing the resultant coating by heating, and then hydrophilizing the coating with a hydrophilizing agent such as ammonia, amine or alcohol.

Owner:NISSHO CORP

Polypropylene resin composition and use thereof

ActiveUS20150274948A1Good shaping effectAvoid serious impactVehicle seatsOther chemical processesPolymer scienceAlpha-olefin

[Solution]A polypropylene resin composition includes 100 parts by weight of basic components including a polypropylene resin (A) including a propylene polymer, the propylene polymer having a MFR of 10 to 300 g / 10 min and containing 98 mol % or more of structural units derived from propylene, an ethylene.α-olefin copolymer (B) having an ethylene content of 65 to 90 mol %, and optionally an inorganic filler (E); 0.2 to 1 part by weight of a fatty acid amide (C); and 0.2 to 1 part by weight of a surfactant (D).[Effect]The polypropylene resin compositions of the invention have excellent shaping properties such as injection molding properties and can give shaped articles which exhibit excellent properties such as rigidity and impact resistance and which are effectively prevented from deteriorations in surface properties due to friction with soft substances such as rubbers (namely, have excellent kicking scuff resistance), thus finding suitable applications in automobile interior and exterior parts.

Owner:PRIME POLYMER CO LTD +1

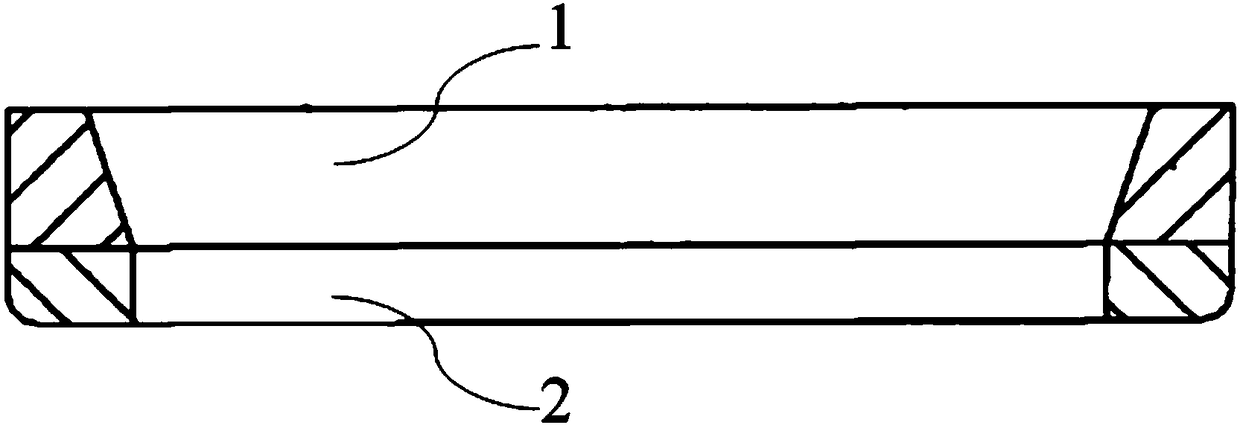

Valve retainer and preparation process thereof

ActiveCN108588577AHigh hardnessImprove thermal stabilityVacuum evaporation coatingSealing arrangements for enginesDlc coatingCorrosion

The invention provides a valve retainer and a preparation process thereof. The preparation process comprises the following steps of: preparing powder, wherein the powder comprises high alloy layer powder and low alloy layer powder; carrying out compression moulding and sintering on the powder to prepare a valve retainer; carrying out cold treatment, heat treatment, cleaning and drying on the prepared valve retainer; carrying out deposition on a base surface of the valve retainer by adoption of a cathode arc deposition technology and magnetron sputtering technology combined manner so as to forma transition layer and a DLC coating; and finally annealing the valve retainer. By adoption of the preparation process, the valve retainer has relatively high heat stability, relatively high corrosion resistance and relatively low friction coefficient, so that the wear resistance, service life and system reliability of the valve retainer are effectively improved.

Owner:WEICHAI POWER CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com