High-temperature anti-sticking material coating and manufacturing and application methods thereof

A technology of anti-adhesive materials and application methods, applied in the direction of coating, etc., can solve the problems of low temperature resistance, limited high temperature resistance, affecting the frequency of use and the use environment, etc., achieve good thermal shock resistance, avoid cleaning time, and solve the problem of workers' work Effect of harsh conditions and job safety concerns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

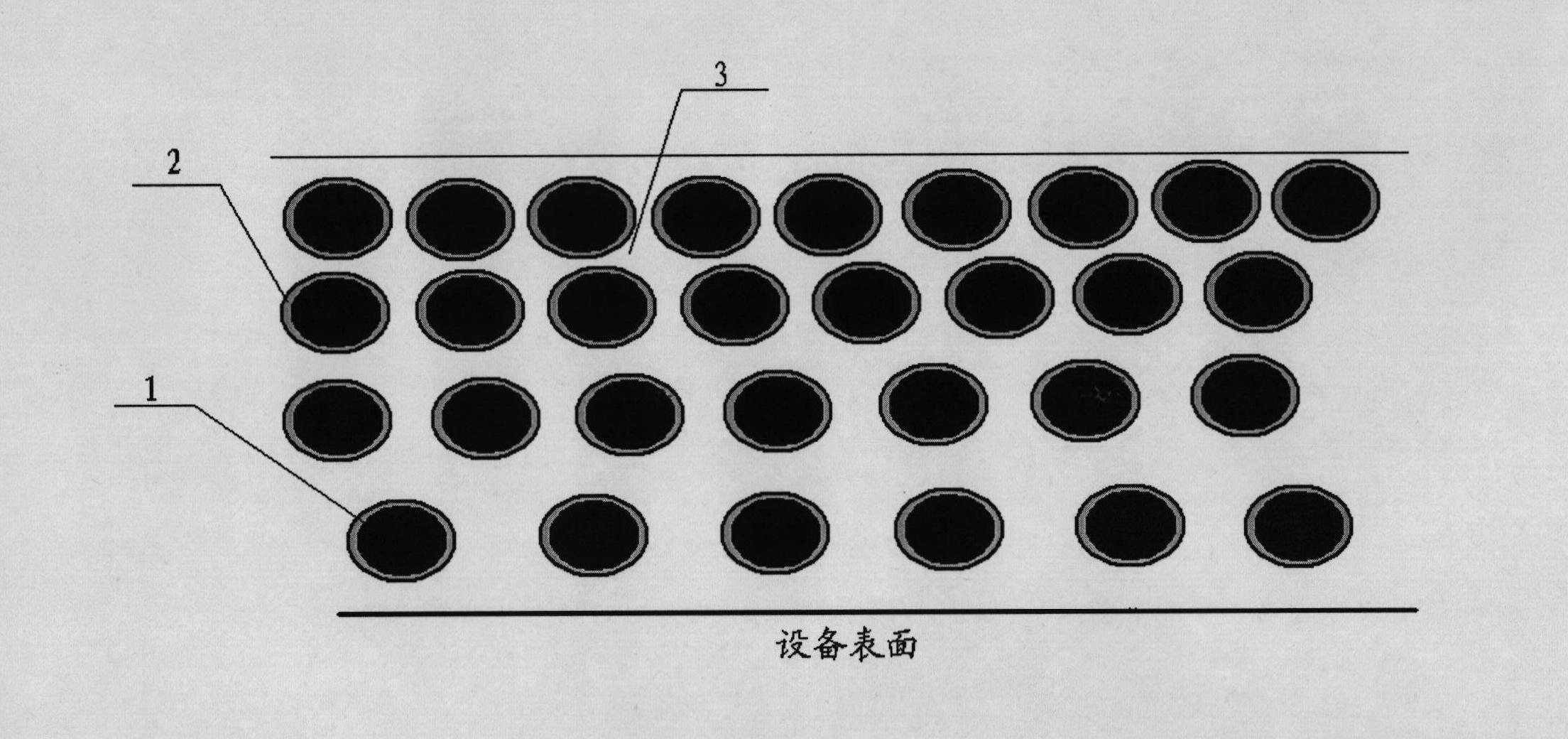

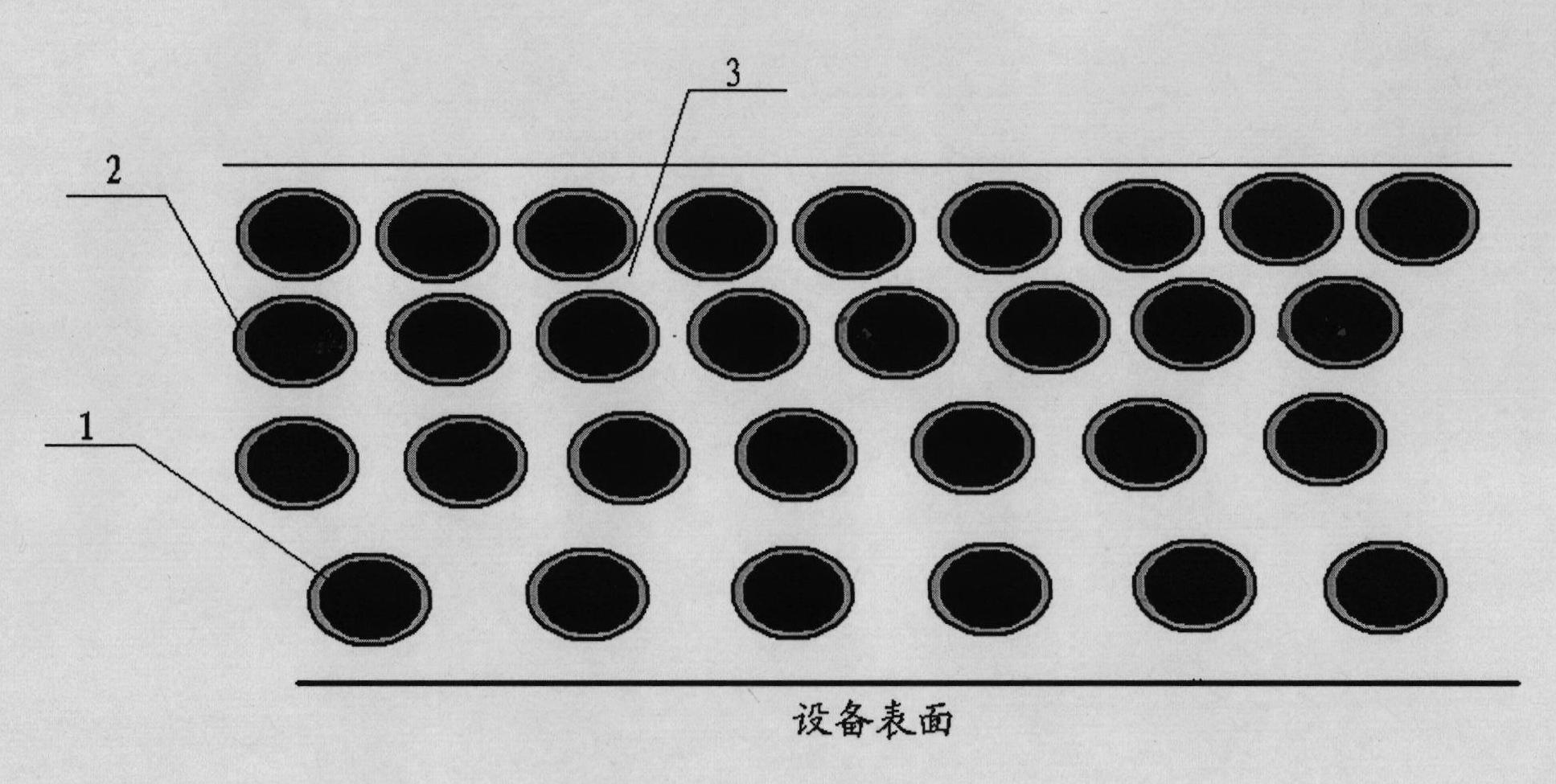

[0029] Example 1: Such as figure 1 Shown (in fact, the particles are different in size and arranged irregularly. For clarity, there is a regular arrangement here):

[0030] A high-temperature anti-sticking material coating, with self-lubricating material particles 1, coating material 2 and high-temperature adhesive 3; the particle size of the self-lubricating material particles is micron, 100 microns; the coating material 2 is nickel (nickel , Copper, aluminum and other metals, alumina and other ceramics, phosphates, or rare earth materials) coating the self-lubricating material particles 1; the high temperature resistant adhesive 3 has a higher melting point than the coating material 2 Melting point, bonding the coated self-lubricating material particles 1 together to form a high-temperature anti-sticking material coating;

[0031] Self-lubricating materials are one or more of boron nitride, graphite, calcium fluoride, barium fluoride, chromium oxide, silver, nickel, copper, alum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com