Preparation method of recycled concrete based on house construction

A technology for recycling concrete and concrete blocks, applied in the field of concrete, can solve the problems of increasing the amount of cement, easy solidification of concrete, and rough surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

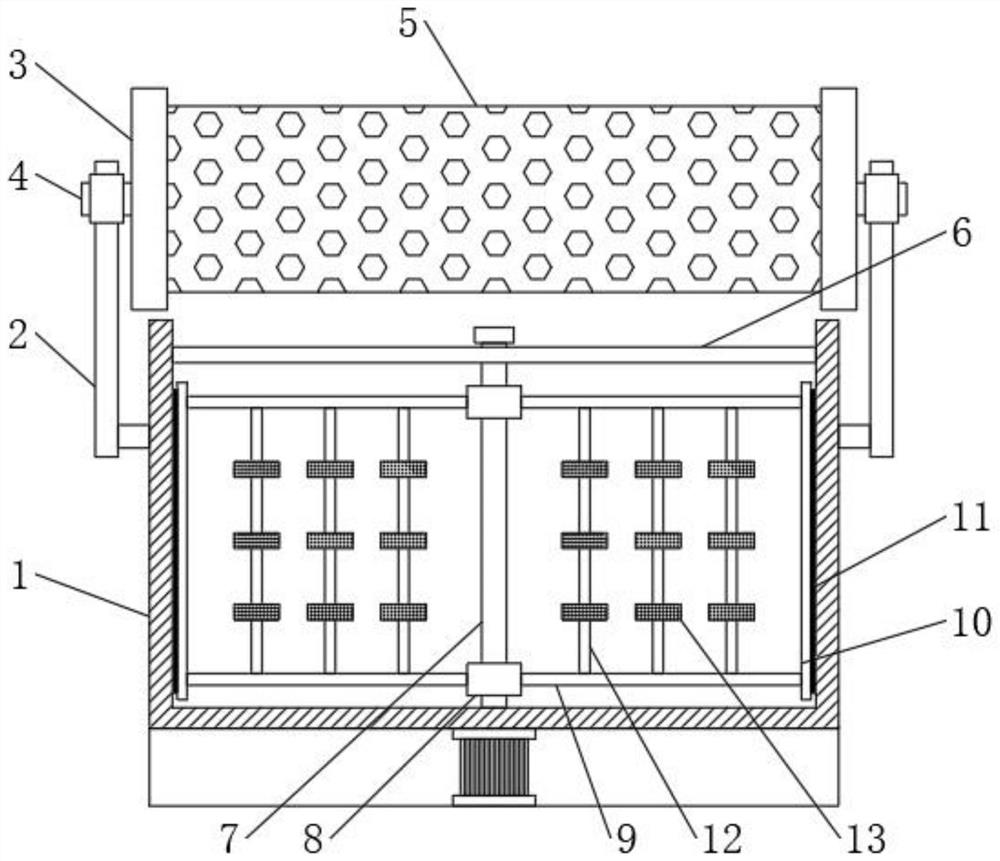

[0043] see Figure 1-7 , a method for preparing recycled concrete based on building construction, comprising a mixing tank 1, the preparation method comprising the following steps:

[0044] S1. Prepare waste gas concrete blocks, crush the discarded concrete blocks into stone blocks, and clean the impurities and metal substances in the waste gas concrete blocks;

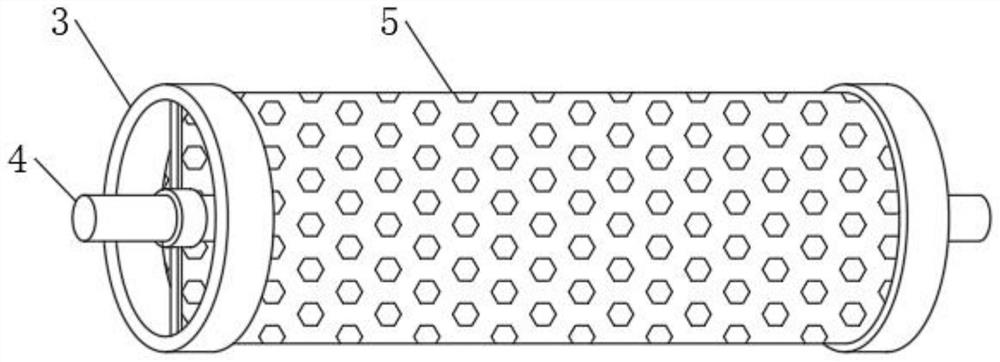

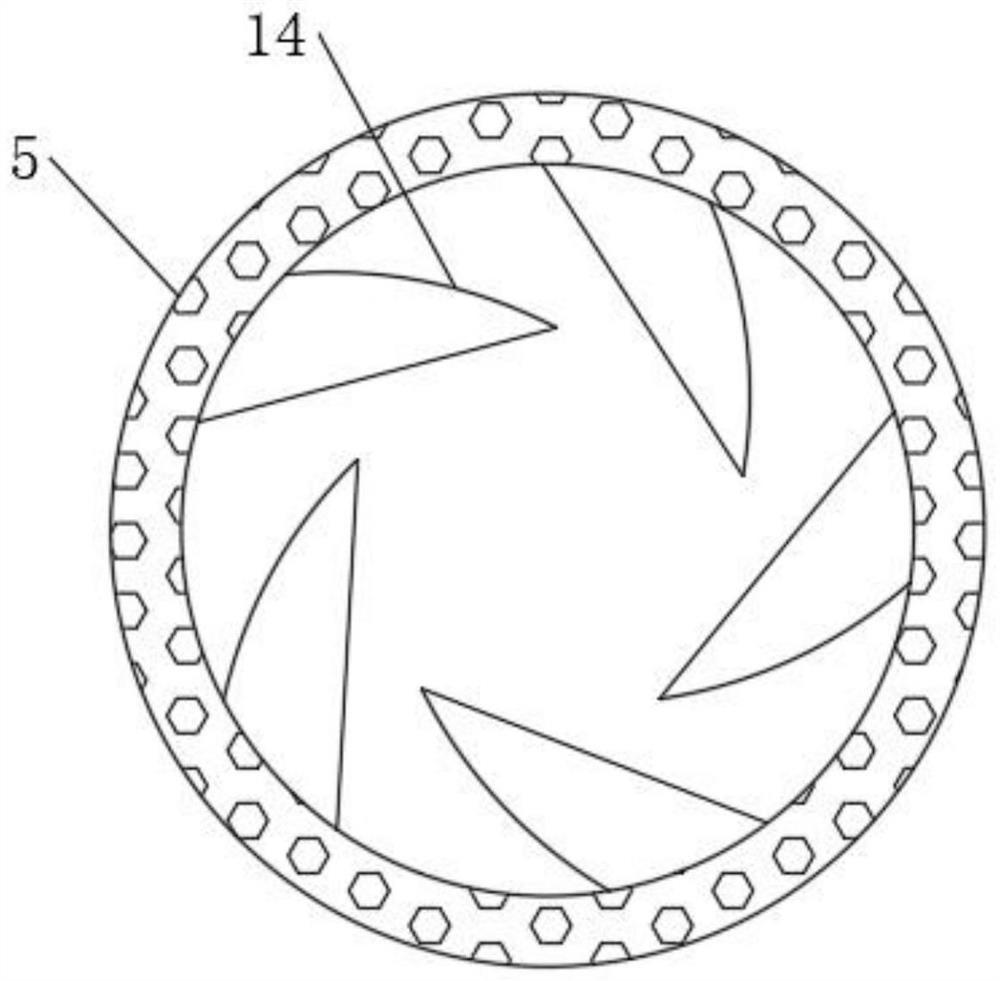

[0045] S2. Screening the crushed and cleaned concrete blocks through the screening cylinder 5 to remove larger concrete blocks;

[0046] S3. The sieved concrete blocks are dropped into the anti-condensation mixing device, and the inside of the anti-condensation mixing device is filled with cement and water to form new concrete.

[0047] see Figure 1-4 A pair of support rods 2 are fixedly connected to the outer end of the mixing bucket 1, a rotating shaft 4 is fixedly connected between the pair of supporting rods 2, a pair of fixed rings 3 are connected to the outer side of the rotating shaft 4, and a pair of fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com