Prescription of cover plate glass for light touch screen

A cover glass and touch screen technology, which is applied in the field of touch screen cover glass and the formulation of cover glass for lightweight touch screen, can solve the problems that cannot meet the requirements of light weight of cover glass, lower production efficiency and glass quality, and hinder chemical strengthening speed and other issues, to achieve the effect of short chemical strengthening time, which is beneficial to melting and reducing glass density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

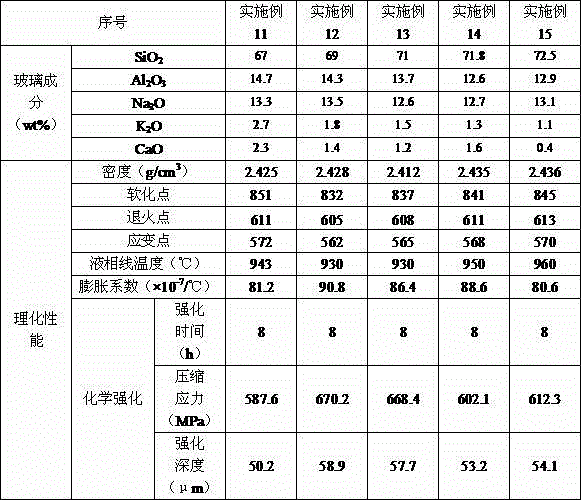

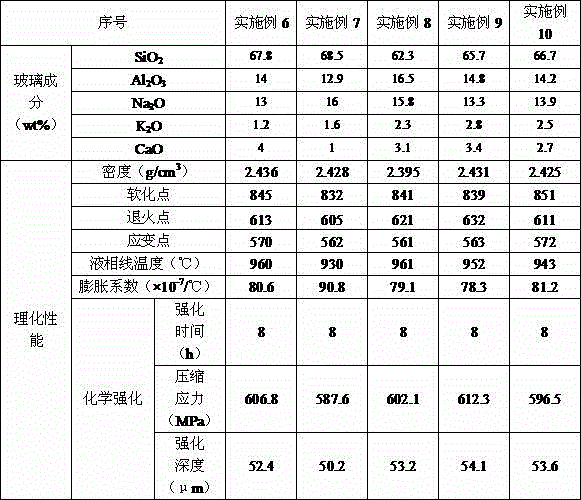

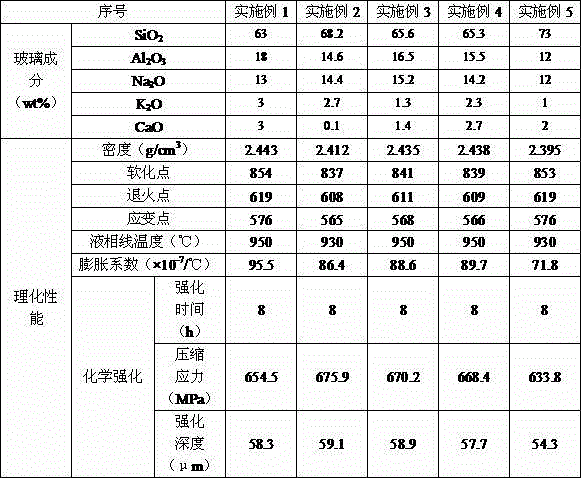

[0008] A recipe for a cover glass for a lightweight touch screen, the components of the above-mentioned glass include: 63-73% SiO 2 , 12-18% Al 2 o 3 , 0.1-4% CaO, 12-16% Na 2 O, 1-3% K 2 O.

[0009] Among the above components, Na 2 O and K 2 The total mass percentage of O is not less than 13%.

[0010] SiO above 2 The content is preferably: 65-70%.

[0011] Al above 2 o 3 The content is preferably: 14-16%.

[0012] The above CaO content is preferably: 0.1-3%.

[0013] above Na 2 The O content is preferably 13-15%.

[0014] K above 2 O content is preferably: 1.2-2.4%.

[0015] The most introduced ingredient in the glass composition of the present invention is SiO 2 , SiO 2 It is an essential component of the glass skeleton. The higher the content, the more the chemical resistance and mechanical strength of the glass can be improved, and the density of the glass can be reduced. On the other hand, because it has a tendency to increase the viscosity, SiO 2 If th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com