Patents

Literature

90results about How to "Reduce the tendency of devitrification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Optical glass with high refractive index

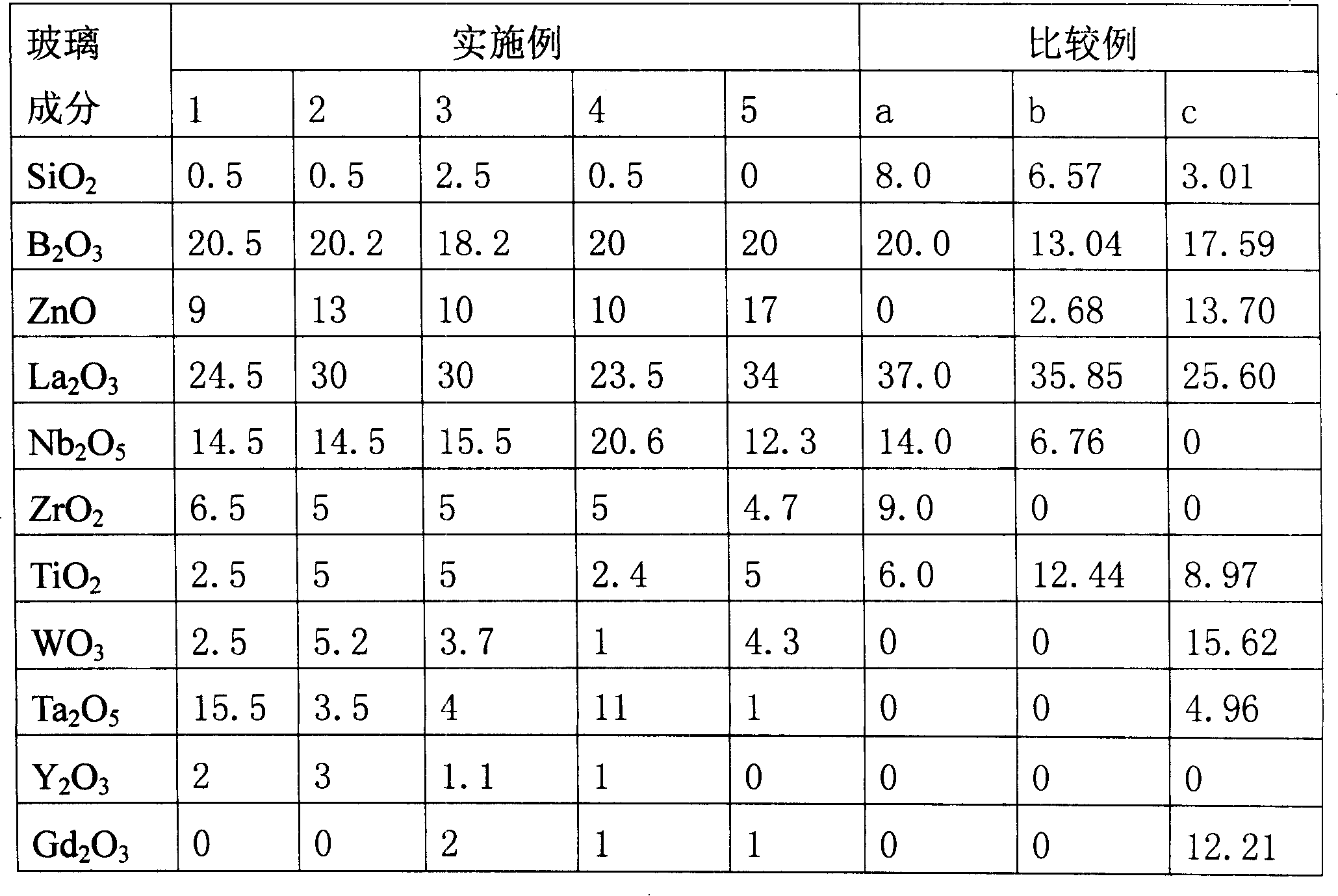

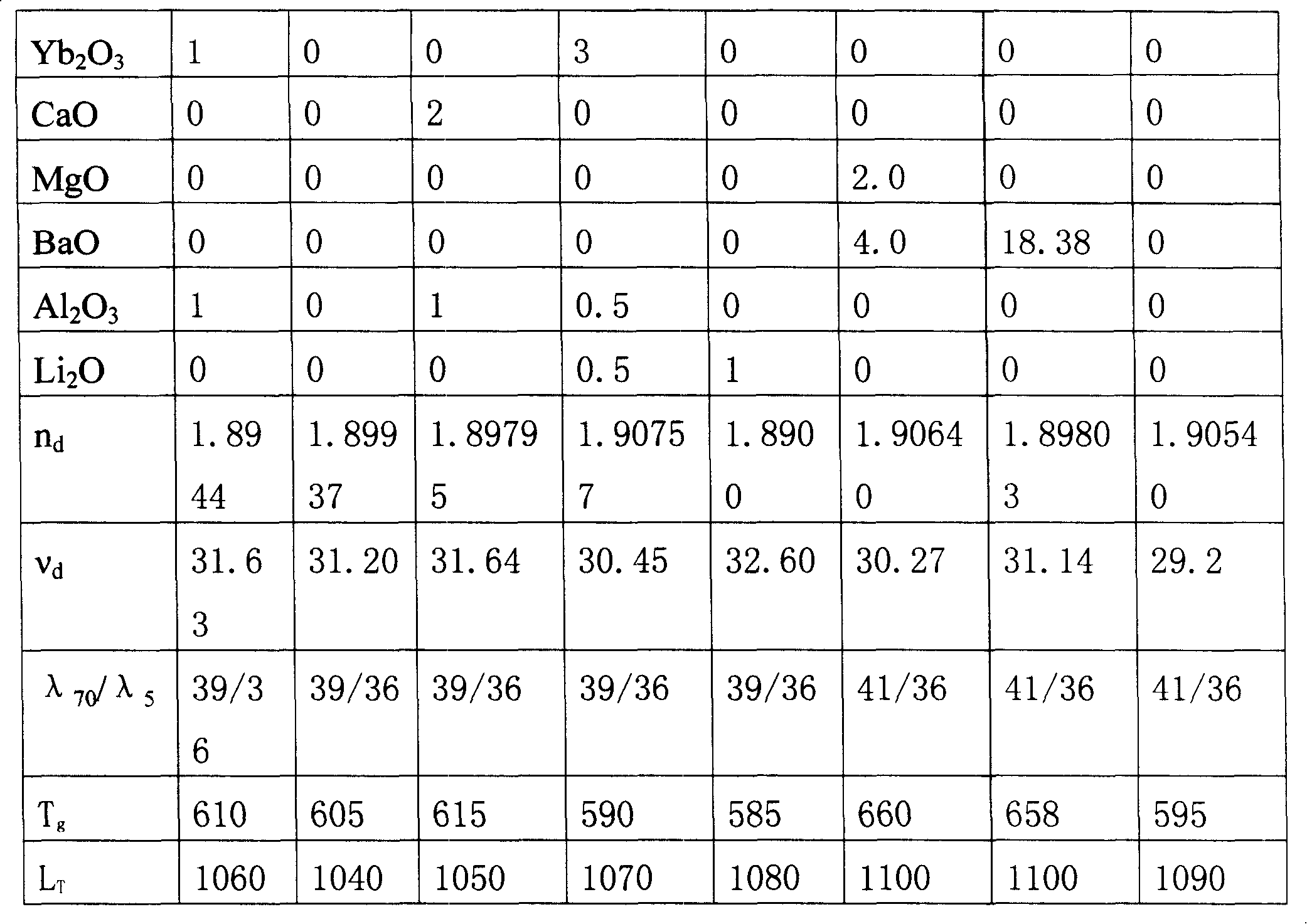

The invention is an optical glass with high refractive index, which belongs to the technical field of optical glass. The invention mainly resolves the problems that the refractive index of the exsisting optical glass is not high enough or the transforming temperature is not low enough though the refractive index is high enough. The common glass of the invention is characterized in that the invention has the following weight percentage of oxide, 0-5% SiO2, 15-30% B2O3, 0-3% Al2O3, 20-40% La2O3, 0-6% Y2O3, 0-10% Gd2O3, 0-6% Yb2O3, 1-10% TiO2, 3-10% ZrO2, 10-30% Nb2O5, 0-20% Ta2O3, 1-10% WO3, 1-25% ZnO, 0-6% CaO, 0-3% Li2O, 0-0.5% Sb2O3, the glass with low transforming temperature is characterized in that apart from the components of 1-5% WO3 and 8-25% ZnO, the rest components are the same as the above scheme. The refractive index (nd) of the invention is between 1.89-1.91, and the abbe coefficient (vd) is with the range of 30-32. The invention is further equipped with a lower transforming temperature (Tg), and is mainly applied for small size lens glass which needs high refractive index.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

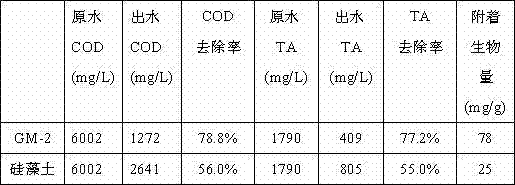

Multi-hole foam glass carrier for fast mass transfer biological fluidized bed and preparation method and application thereof

InactiveCN102515551AEvenly distributedImprove chances of interphase contactTreatment with anaerobic digestion processesBiocompatibilityFoam glass

The invention relates to a multi-hole foam glass carrier for a fast mass transfer biological fluidized bed and a preparation method and application thereof, which belong to sewage disposal technology. The multi-hole foam glass carrier is prepared by using waste glass as a raw material to be composited with volcanic rocks, coal ash, coal gangue, furnace clinker, iron powder, aluminum powder, binding agents, foaming agents, foam stabilizer and fluxing agents by weight, and multi-hole foam glass is obtained by stages of preheating, fast sintering, foaming, fast cooling and annealing. The preparation process of the multi-hole foam glass carrier is simple in route, easy to control and low in cost, and the prepared carrier is stable in performance, high in porosity, large in specific surface area, resisting in impact, good in mechanical performance, high in biocompatibility, favorable to efficient fixing of the microorganism, and suitable to the fast mass transfer biological fluidized bed. The multi-hole foam glass carrier solves the problem that biological immobilization carriers in the prior art are easy to abrade, small in bio-film formation amount, low in mass transfer effects and the like in the fast mass transfer biological fluidized bed. The preparation method opens up new approaches for preparing the biological carriers, and fills blank spaces in using of foam glass materials in sewage disposal.

Owner:NANJING UNIV OF TECH

Ultralow-expansion coefficient high transparent glass-ceramics and method for producing its product

The present invention relates to a Li2O-Al2O3-SiO2 system ultra-low expansion coefficient high-transparency glass-ceramic and production method of the products. Calculated by weight percentage, the ultra-low expansion coefficient high-transparency glass-ceramic is composed of 3.2 to 4.6 percent of Li2O, 18.0 to 23.6 percent of Al2O3, 64.1 to 69.4 percent of SiO2, 0.3 to 0.8 percent of MgO, 0.8 to 2.5 percent of BaO, 0.3 to 0.8 percent of R2O, 0.01 to 0.4 percent of Y2O3, 1.8 to 2.5 percent of TiO2, 1.6 to 2.4 percent of ZrO2, 1.1 to 1.8 percent of P2O5, 0.6 to 1.5 percent of Sb2O3, 0.3 to 1.0 percent of NaCl and 1.0 to 2.0 percent of NH4NO3. The heat-resistant glass plates and heat-resistant glass products can be manufactured by using the formula and the corresponding forming die. The present invention has the advantages that the production technique is simple, the produced products have low expansion coefficient, good transparency, high thermal impact temperature, high strength, have constant transparency when being used under the temperature of 700 Celsius system for a long time, the products have long service life, etc.

Owner:广东科迪微晶玻璃实业有限公司 +1

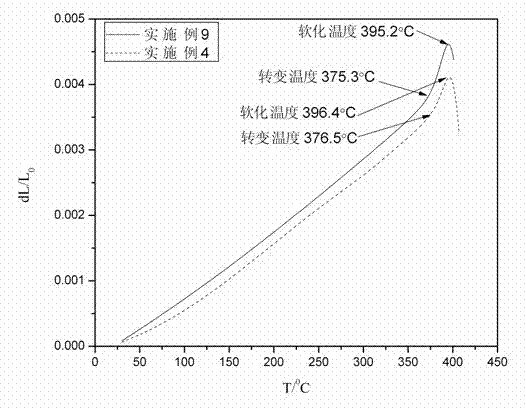

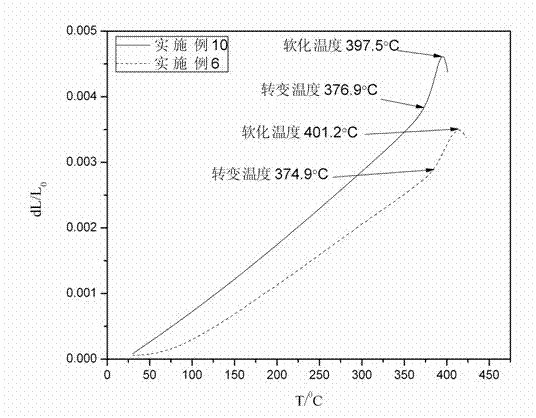

Bismuthate low-melting point and lead-free sealing grass and preparation method thereof

The present invention discloses a bismuthate low-melting point and lead-free sealing grass and a preparation method thereof. The bismuthate low-melting point and lead-free sealing grass powder comprises, by mass, 75-90% of base glass and 10-25% of a filler, wherein the filler is a zirconium phosphate salt with an expansion coefficient of -5*10<-6>k<-1>-5*10<-6>k<-1>. The bismuthate low-melting point and lead-free sealing grass of the present invention has characteristics of lead-free property and green environmental protection, can replace the lead-containing glass so as to eliminate the pollution due to the lead, and has excellent chemical stability. The production process is simple and the cost is low. Compared to other filler-doped sealing glass powders, the sealing temperature of the present invention is low, the glass transition temperature of the present invention is 330-370 DEG C, the softening temperature of the present invention is 370-410 DEG C, the sealing temperature of the present invention is less than 450 DEG C. With adjusting the proportion of the filler, the adjustable expansion coefficient can be realized at the low sealing temperature, wherein the adjustment range is (70-90)*10<-7> / DEG C, such that different requirements of the sealing device to the expansion coefficient of the sealing material can be met, and the sealing for VFD, PDP, CRT and other glass products can be directly performed.

Owner:CHINA JILIANG UNIV

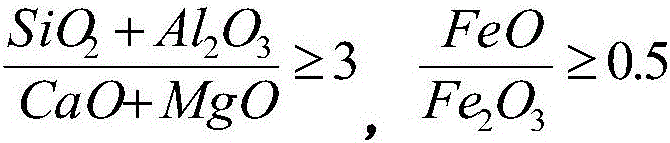

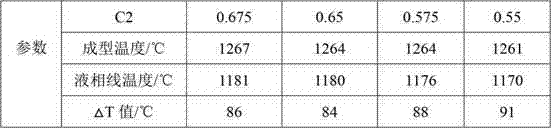

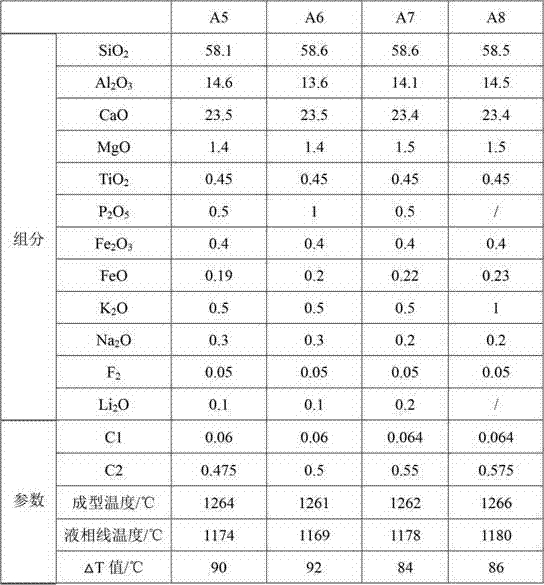

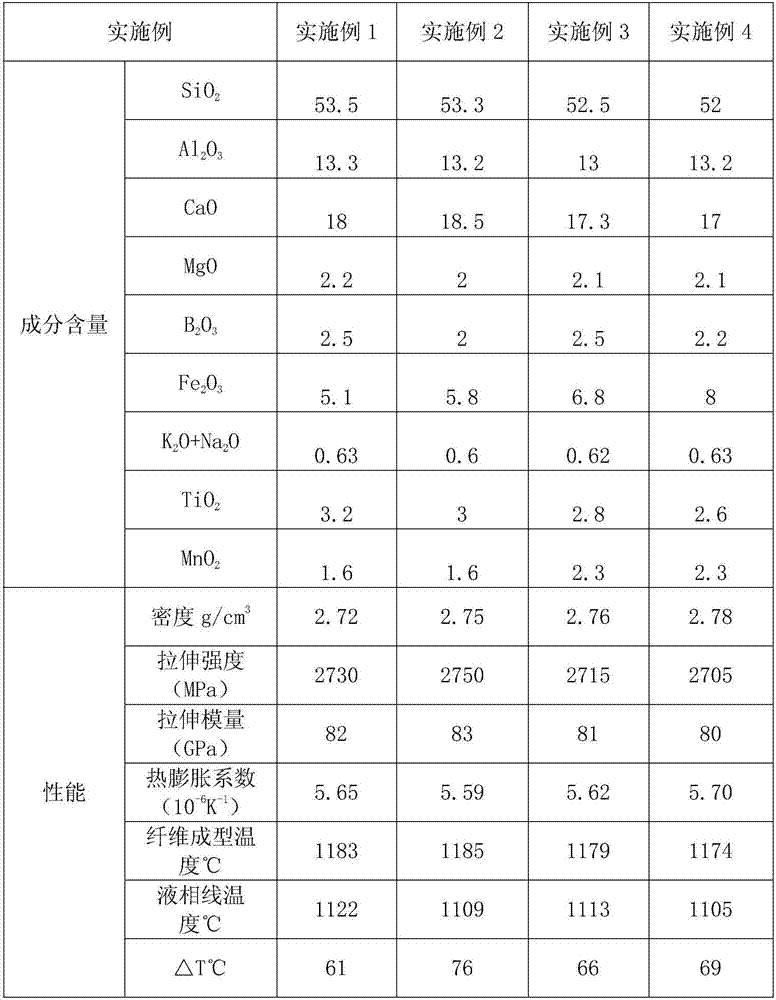

Floride-free low-boron and alkaline-free glass fiber prescription and preparation method

The invention relates to a glass fiber production prescription, in particular to an environment-friendly alkaline-free glass fiber prescription emitting less toxic gas. The prescription is characterized in that the components include SiO2, Al2O3, B2O3, CaO, MgO, K2O and Na2O2. Compared with the E glass fiber widely applied presently, the glass fiber prepared with the prescription of the invention is improved as follows: the raw material containing floride which is most harmful is completely abandoned and the raw material containing volatile boron is largely reduced, but the glass fiber of the invention still remains similar electric performance and mechanical performance. The invention is characterized in that an alkaline-free glass fiber using blast furnace slag as one of the main raw materials, realizing reduction of operation difficulty and great reduction of exhaust emission is preferential and can be produced directly in large scale in a tank furnace including an electric boosting structure. The use of an industrial raw material easy for melting and clearing, namely, the blast furnace slag, ensures the glass fiber to have similar operating performance as the E glass fiber and to adapt to large-scale production under the existing E glass fiber tank furnace production technology.

Owner:TAISHAN FIBERGLASS INC

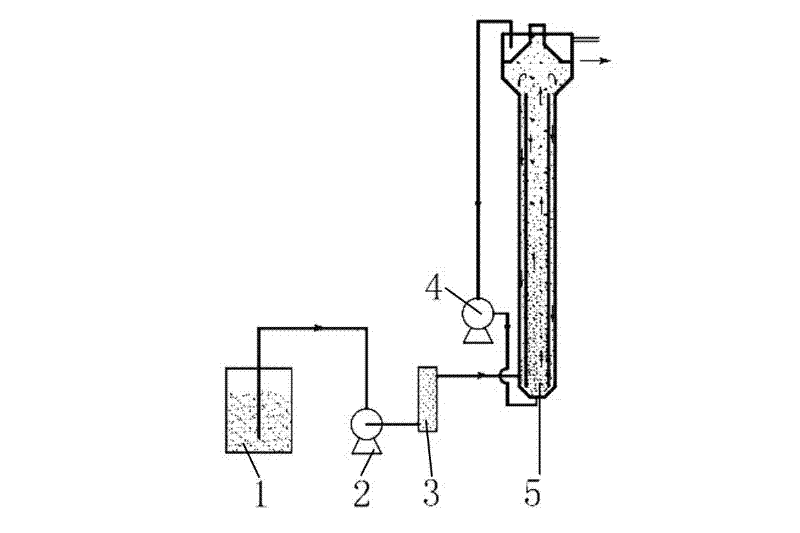

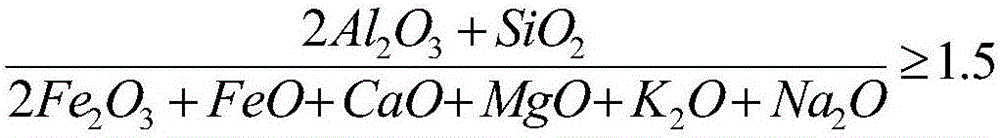

Production method for continuous basalt fiber

ActiveCN106396421AImprove accuracyImprove rapid effectivenessGlass furnace apparatusTO-18Chemical composition

The invention discloses a production method for continuous basalt fiber. The production method is characterized by comprising the following steps: 1) material selection, i.e., comprehensive determination of raw basalt materials for production of the continuous basalt fiber based on the chemical components and mineral components of basalt: analyzing the content of SiO2 in the chemical components of basalt, selecting basalt with SiO2 content of 48 to 63% and with saturated or oversaturated SiO2, analyzing the mineral component of basalt, removing basalt containing olivine and selecting basalt with mineral components consisting of, by weight, 15 to 27% of quartz, 10 to 18% of orthoclase, 30 to 50% of plagioclase or 45 to 60% of plagioclase, and 15 to 30% of pyroxene; and 2) fusing and fiber molding of the selected raw basalt materials so as to obtain the continuous basalt fiber. The production method provided by the invention can substantially improve accuracy in basalt selection and optimize the fusing process and fiber molding process of a basalt melt, enables the basalt melt to be easy to homogenize and provides effective bases and criteria for production of the continuous basalt fiber.

Owner:SOUTHEAST UNIV

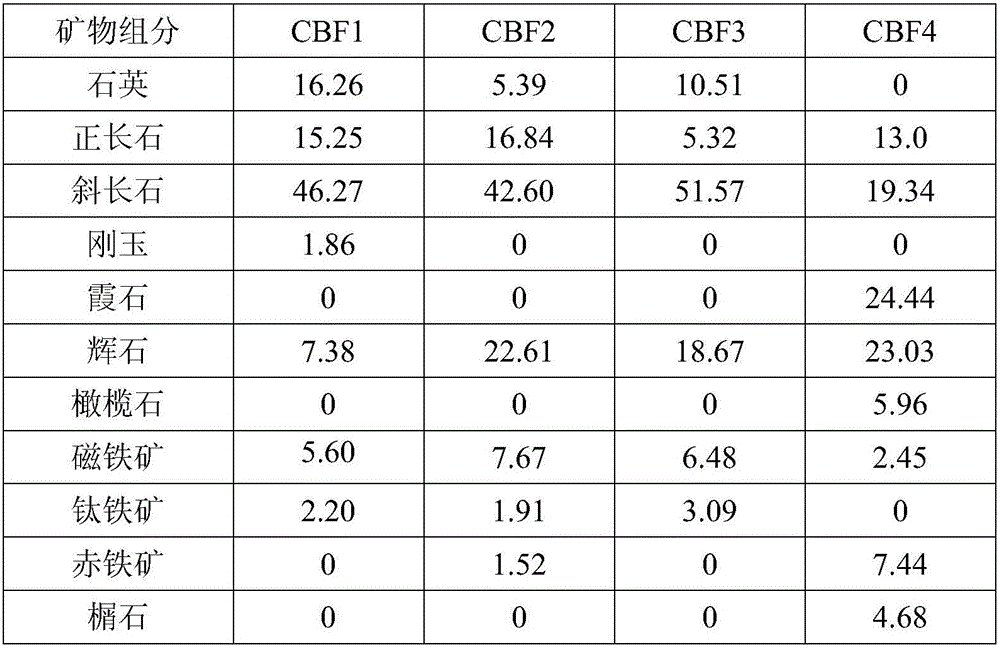

Boron-free glass fiber composition

ActiveCN102849956AReduce the tendency of devitrificationImprove molding performanceMolten glassFiber

The invention discloses a boron-free glass fiber composition, comprising the following components, based on SiO2, Al2O3, CaO, MgO, Fe2O3, Li2O, Na2O and K2O, by weight: 57.5%<= SiO2<59%, 13-16% of Al2O3, 23-25% of CaO, 1-1.5% of MgO, 0.1-1% of Fe2O3, R2O=Li2O+Na2O+K2O<1.5%, and K2O>0.2%, wherein Li2O is no less than 0, and when Li2O is no less than 0.1%, a ratio of K2O to Na2O is higher than 1. The glass fiber composition provided by the invention not only can obviously decrease the crystallization tendency of boron-free glass and improve the forming performance of the boron-free glass fiber, but also can obviously reduce surface tension of high temperature molten glass, and improve the melting properties of the boron-free glass.

Owner:JUSHI GRP CO

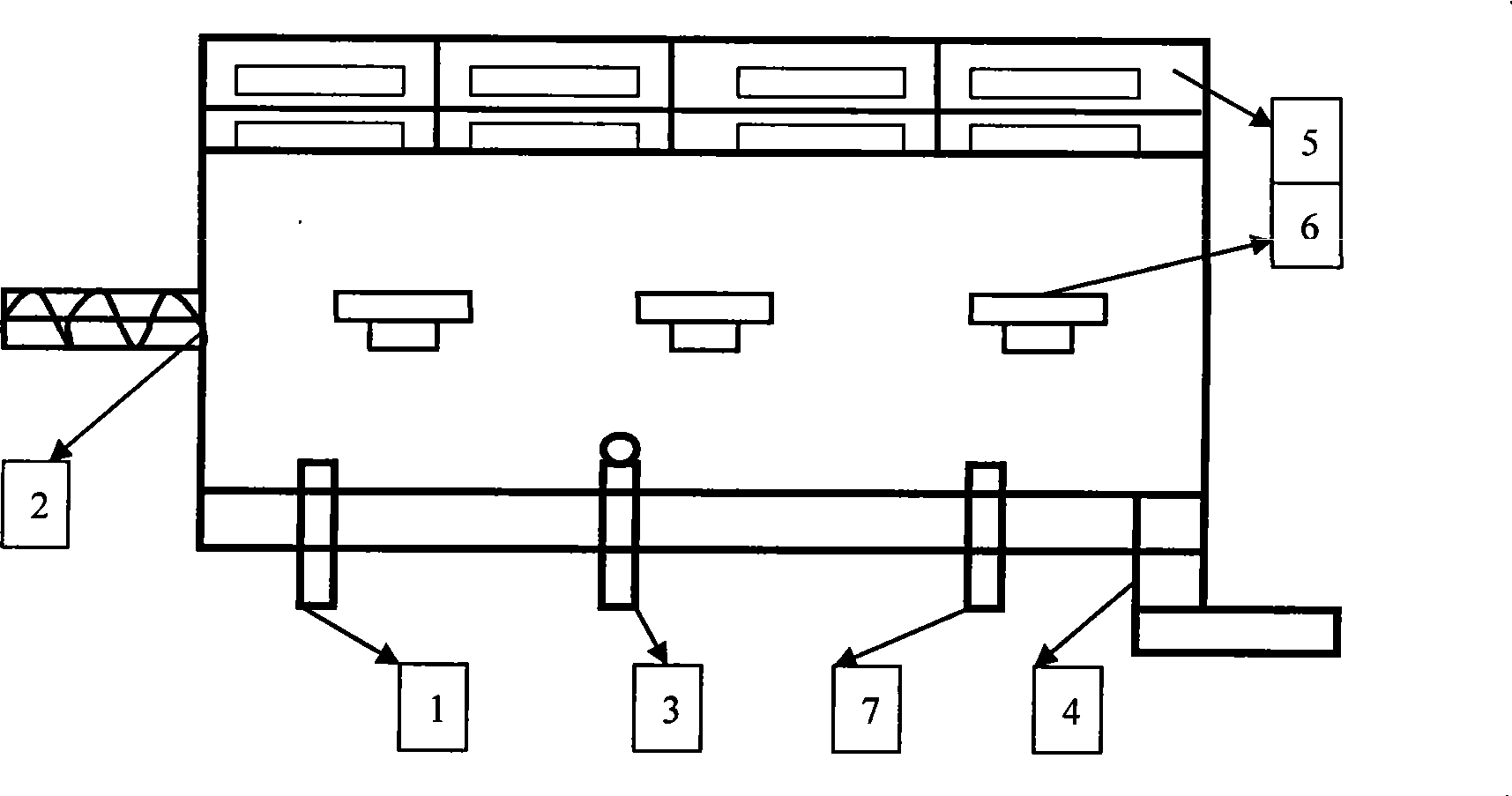

Fluxing apparatus of LCD glass melting furnace

InactiveCN101381197AHigh clarification temperatureClarification temperature is goodGlass furnace apparatusGlass productionViscosityGlass production

The invention relates to a liquid-crystal glass tank furnace fluxing device and a method for solving the difficult problems that liquid-crystal glass is high in melting temperature, high in high temperature viscosity, low in melting rate and high in volatility when melting. A tank bottom between a charging opening and a bubble of a tank furnace is provided with a row of electrodes; the tank bottom in a clarification area close to a liquid flow hole is provided with a row of electrodes as well; and a pure oxygen burner jetting flame into the furnace is arranged on the tank furnace. The device aids in melting through a plurality of fluxing modes, homogenizes the temperature of molten glass, raises the internal temperature of the molten glass, speeds up convection, accelerates glass clarification process, reduces crystallization tendency, and can obtain the glass with higher quality. Therefore, the device is especially applicable to the liquid-crystal glass production harsh in requirement on glass quality.

Owner:HENAN ANFEI ELECTRONICS GLASS

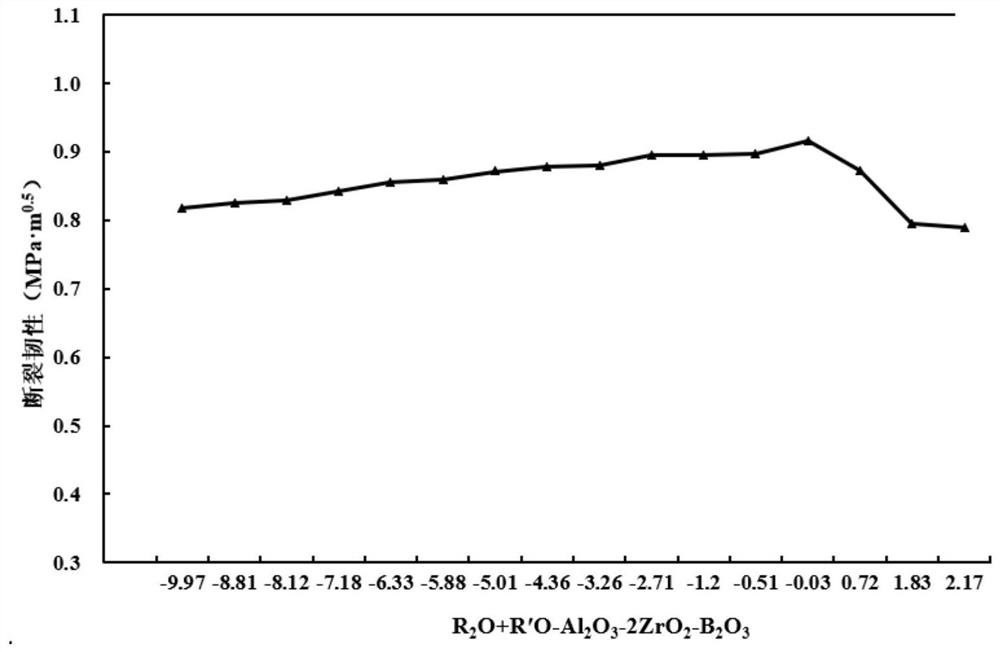

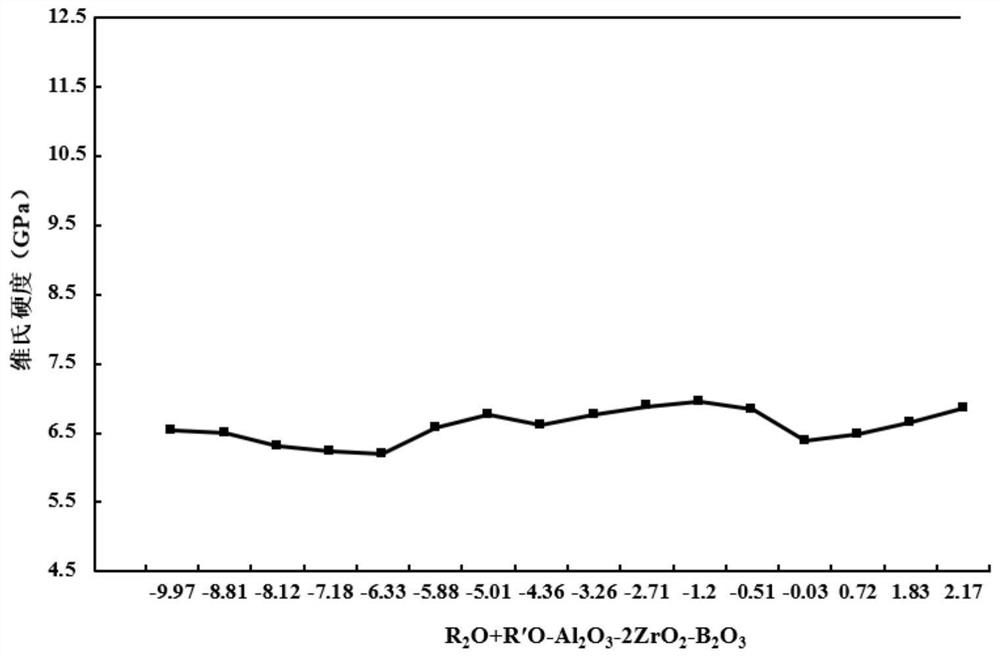

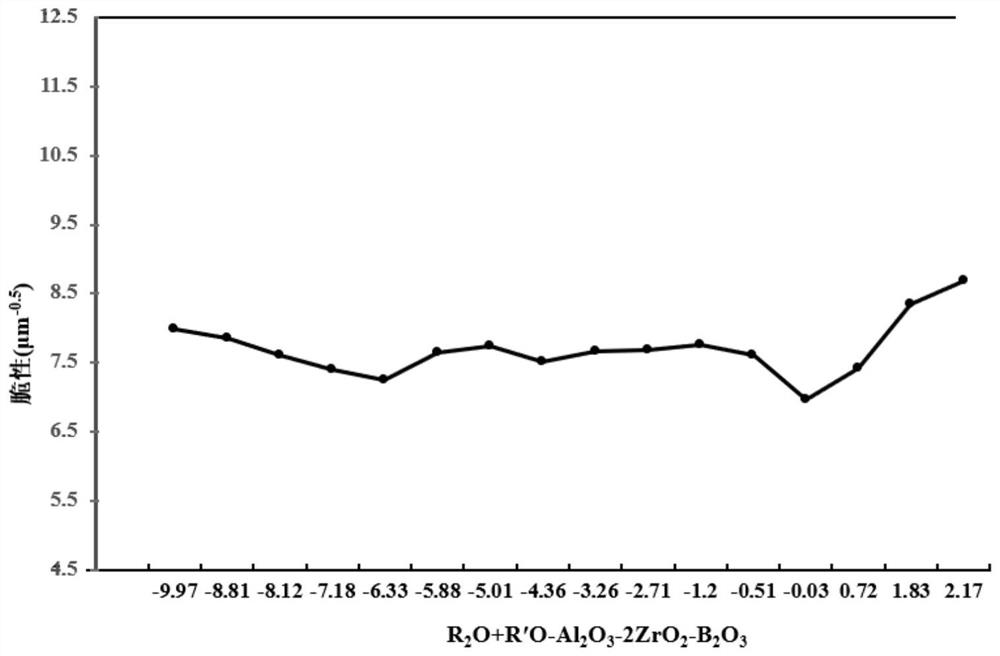

High-strength and low-brittleness aluminosilicate glass as well as strengthening method and application thereof

The invention provides high-strength and low-brittleness aluminosilicate glass as well as a strengthening method and an application thereof. The glass is prepared from the following components in percentage by mole; 56%-70% of SiO2, 8%-25% of Al2O3, 1%-10% of B2O3, 0-15% of Li2O, 6%-20% of Na2O, 0-10% of K2O, 0-5% of MgO, 1%-5% of ZrO2 and 0.1%-1% of SnO2. The strengthening method comprises the following steps: preparing raw materials according to the components of the glass, melting and clarifying the raw materials, and forming the glass; and carrying out ion exchange on the glass in a salt bath of potassium nitrate and sodium nitrate at 360-450 DEG C to obtain the chemically strengthened aluminosilicate glass which can be applied to mobile device protection and fixed device protection.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

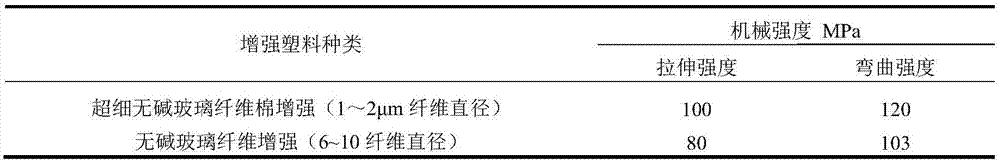

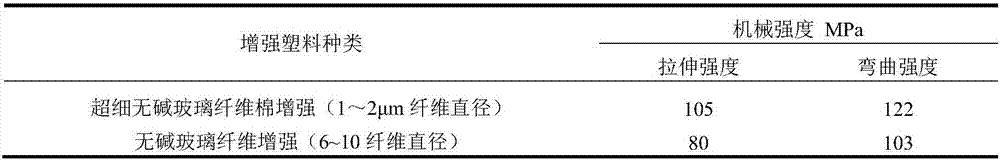

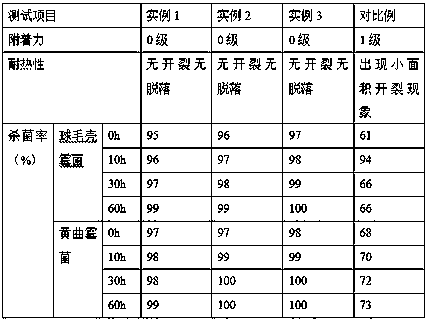

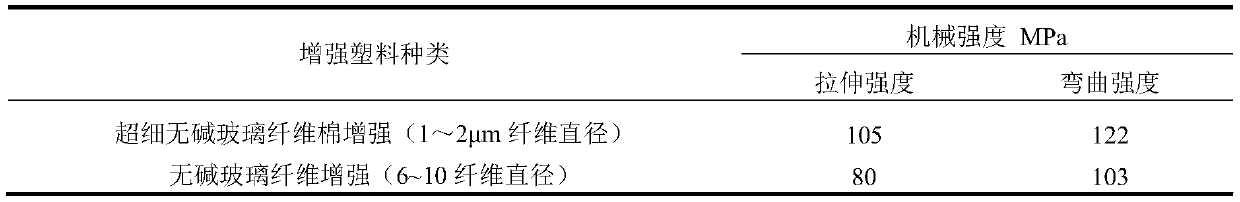

Superfine alkali-free glass fiber cotton and preparation method thereof

ActiveCN107012585AHigh mechanical strengthReduce the tendency of devitrificationGlass making apparatusNon-woven fabricsGlass fiberFiber

The invention relates to superfine alkali-free glass fiber cotton. The superfine alkali-free glass fiber cotton is prepared from, by weight, 80-90% of superfine alkali-free glass fiber and 10-20% of adhesive assistant; the superfine alkali-free glass fiber is prepared from, by weight, 55-59% of SiO2, 13-18% of Al2O3, 2.5-4.5% of MgO, 15-24% of CaO, 0-0.5% of Na2O, 0-0.3% of K2O, 0.15-0.4% of Fe2O3, 6-8.5% of B2O3 and 0.5-1.5% of TiO; the total content of alkaline metal oxide Na2O and k2O is smaller than 0. 6%, and the sum of the contents of SiO2, Al2O3, MgO and CaO is greater than 92.5%. The invention further relates to a preparation method of the superfine alkali-free glass fiber cotton, the superfine alkali-free glass fiber is light in weight and supper thin and uniform in diameter, and has excellent mechanical performance.

Owner:宣汉正原微玻纤有限公司

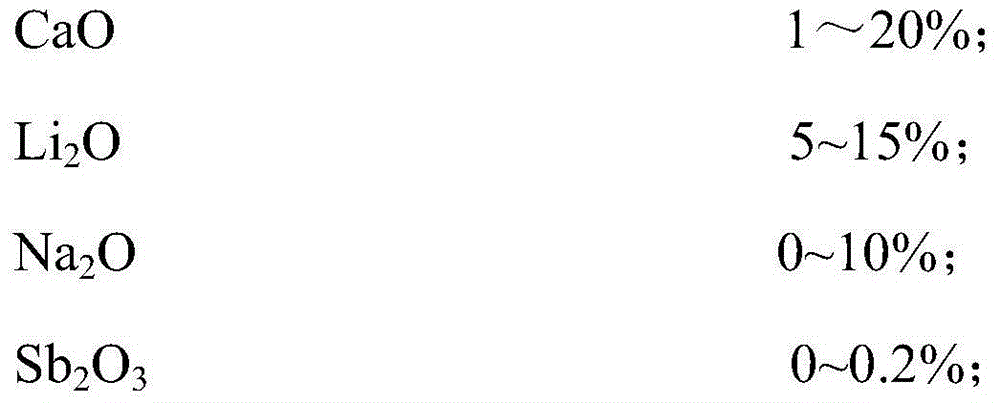

Optical glass

The invention provides optical glass. The optical glass comprises the following components (measured by oxide) in percentage by weight: 30-40% of SiO2, 1-10% of B2O3, 33-45% of SiO2+B2O3, 0-10% of La2O3, 25-40% of Nb2O5, 60-75% of Nb2O5+SiO2, 3-10% of ZrO2, 1-20% of CaO, 5-15% of Li2O, 0-10% of Na2O and 0-0.2% of Sb2O3, wherein 3<= SiO2 / B2O3<=14 and 0.65<=Nb2O5 / SiO2<=1.3; the optical glass does not contain TiO2, ZnO, BaO, Th, Pb, As, Cd, Hg, GeO2, TeO2, Ta2O5 and Yb2O3; and the refractive index nd of the optical glass is within the range of 1.70-1.75, and the Abbe number upsilon d is within the range of 32-38. The optical glass is low in devitrification tendency, high in transmittance, low in maximum crystallization temperature and suitable for mass production, and is mainly used for digital products, cameras, liquid crystal projectors and the like.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

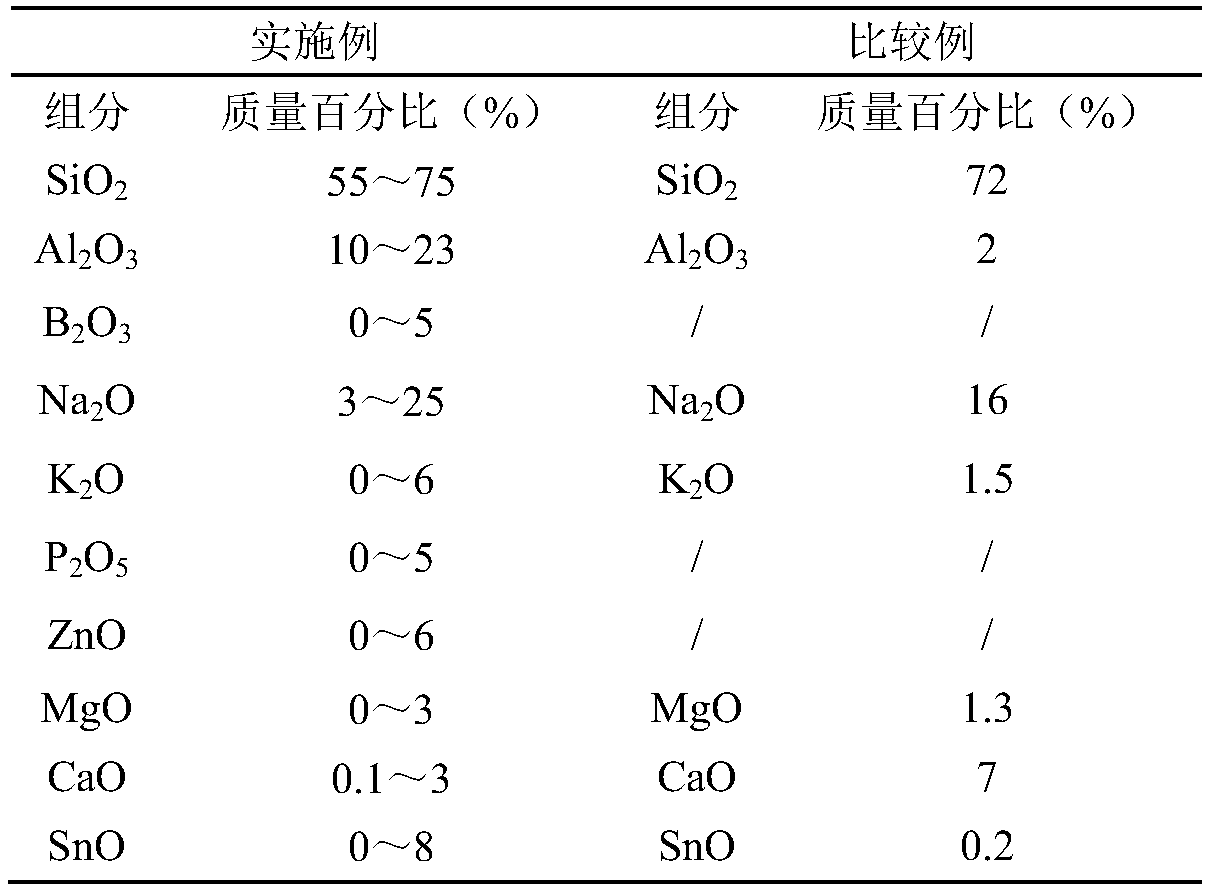

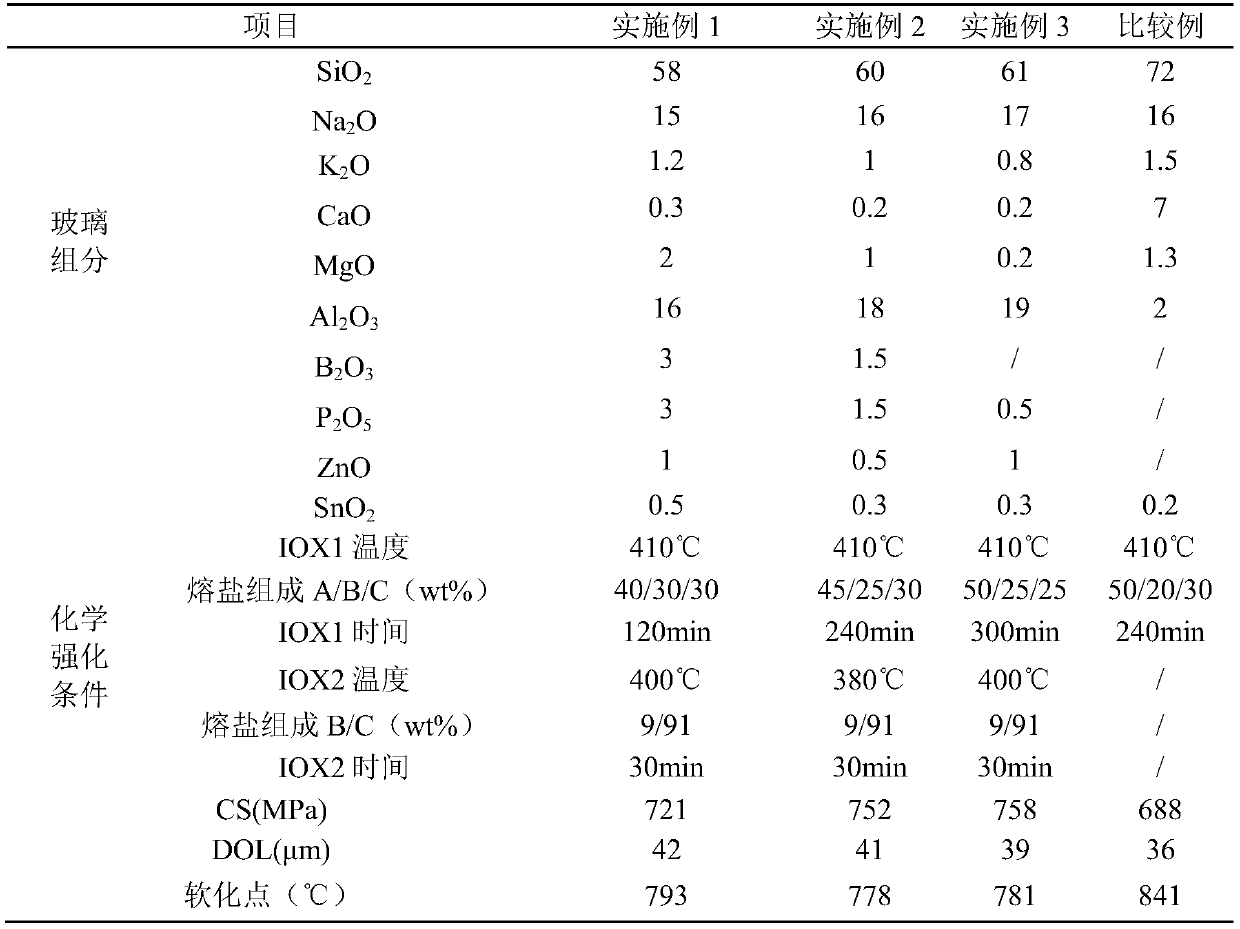

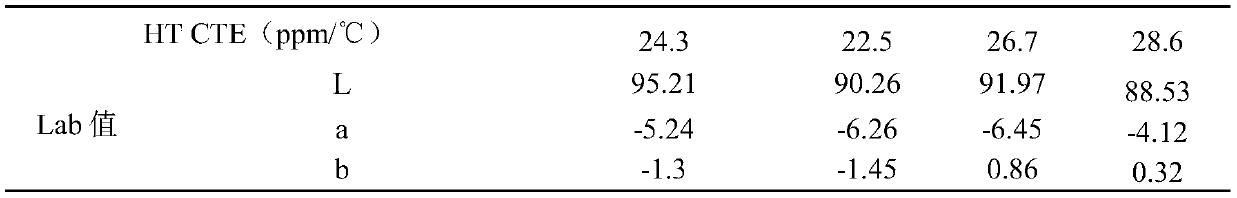

3D-shaped colorable ion exchange glass and preparation method thereof

The invention discloses 3D-shaped colorable ion exchange glass and a preparation method thereof. The glass comprises 55-75% of SiO2, 7-23% of Al2O3, 0-5% of B2O3, 3-25% of Na2O, 0-6% of K2O, 0-5% of P2O5, 0-6% of ZnO, 0-3% of MgO, 0.1-3% of CaO and 0-4% of SnO2. The preparation method comprises the following steps: step 1, subjecting the above raw materials to melting and molding to form flat glass; step 2, performing high-temperature annealing treatment; step 3, carrying out ion exchange in the molten salt of a coloring agent at 380-450 DEG C for 1-6 h, wherein the molten salt of the coloring agent molten salt is composed of 30%-50% of copper nitrate, 20%-35% of potassium nitrate and 20%-35% of sodium nitrate; and step 4, carrying out cooling to 80 DEG C from 400 DEG C within 1 h to obtain the glass. The glass has a low softening point and can meet the artistic demand on product shapes through reprocessing.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

High modulus glass fiber

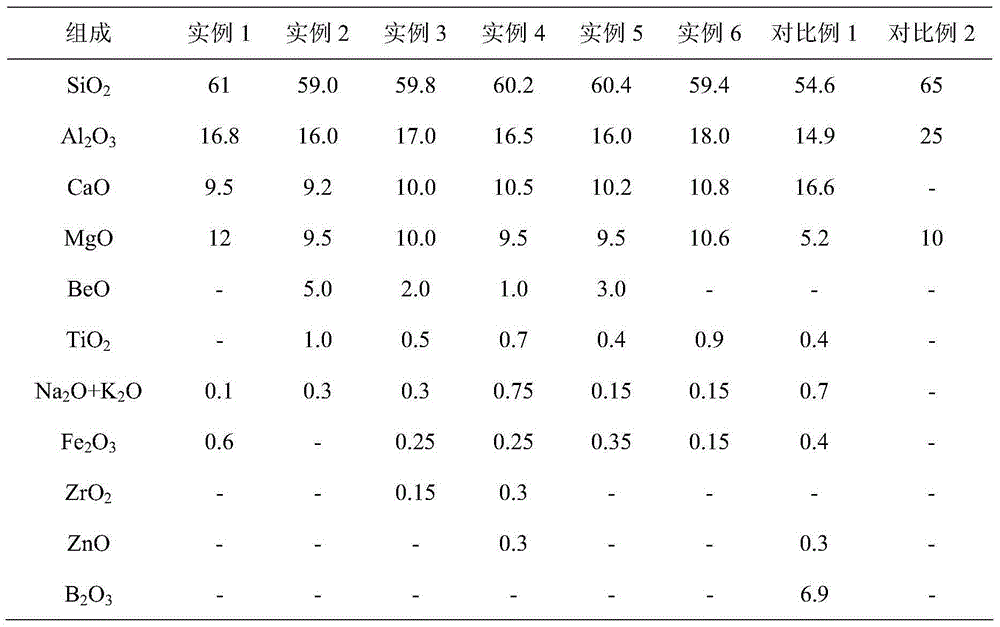

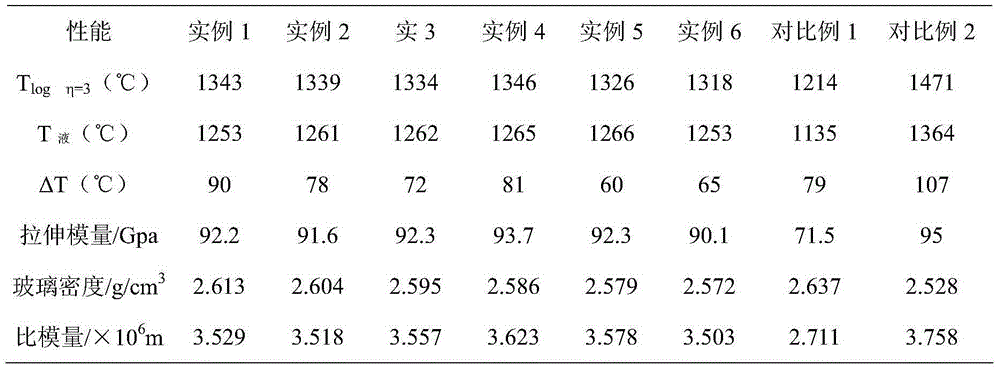

The invention provides a high modulus glass fiber, which belongs to the technical field of an inorganic nonmetal material. The high modulus glass fiber comprises the following components by weight percent: 59 to 61 percent of SiO2, 16 to 18 percent of Al2O3, 9.5 to 10.9 percent of CaO, 9.5 to 12 percent of MgO, 0 to 5 percent of BeO, 0 to 1.2 percent of TiO2, 0 to 0.6 percent of Fe2O3, 0.1 to 0.8 percent of Na2O+K2O, and also comprises less than or equal to 2 percent of one or two of ZrO2 and ZnO, so that the stretching modulus of the glass fiber is further improved. By adopting the high modulus glass fiber, an optimum proportioning ratio of the high modulus glass fiber is found, so that the mechanical performance of the glass fiber is greatly improved, under the condition of not increasing the fusion difficulty, the production cost is reduced, the product performance is improved, and the market prospect is promising.

Owner:CHONGQING POLYCOMP INT

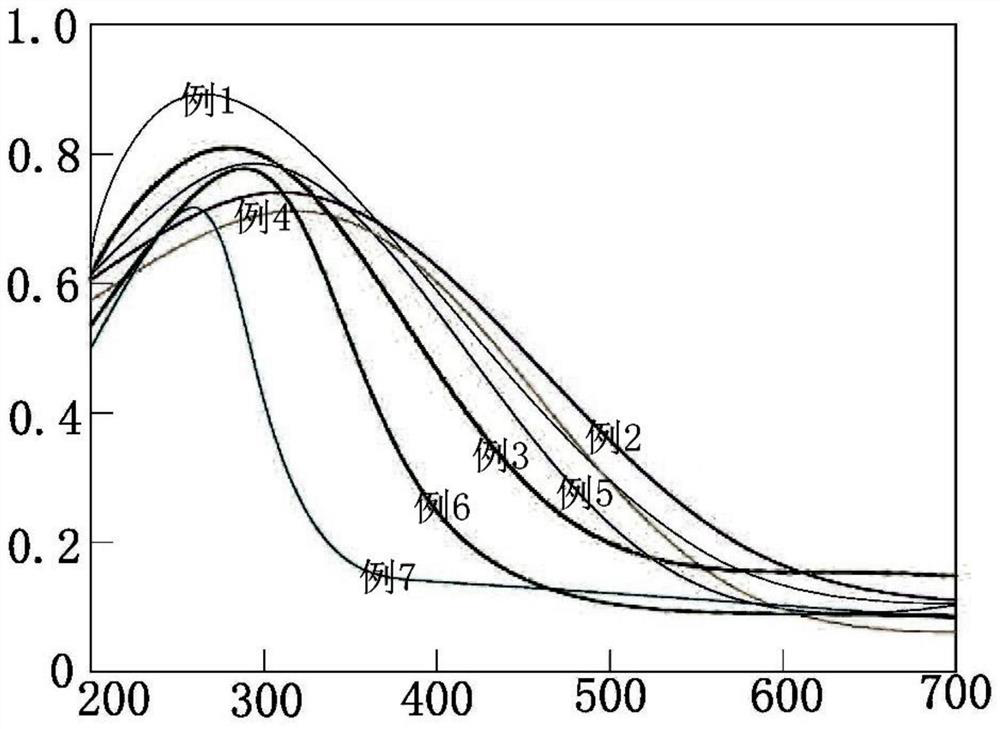

Titanium-containing high-niobium and low-lanthanum optical glass preparation method

The invention discloses a titanium-containing high-niobium and low-lanthanum optical glass preparation method comprising the following steps: (1) uniformly mixing the following raw materials: quartz sand, anhydrous boric anhydride, barium carbonate, barium nitrate, titanium dioxide, lanthanum trioxide, calcium carbonate, zirconium dioxide, anhydrous sodium carbonate, niobium pentoxide, aluminum hydroxide and antimonous oxide to prepare a mixture material; (2) high-temperature melting the mixture material in an air atmosphere to obtain glass liquid; (3) cast-moulding the glass liquid and rapidly cooling the glass to room temperature; (4) crushing the glass, adding less amount of raw materials and re-melting the glass in a multi-grade melting furnace; (5) stirring, clarifying and homogenizing the glass liquid and moulding glass; and (6) performing inspection and secondary annealing to prepare the titanium-containing, high-lanthanum and low-niobium optical glass. The optical glass is high in refractive index, is low in chromatic dispersion and is high in light transmittance, is low in crystallization tendency, is excellent in chemical stability, is free of heavy metal oxides, such as Gd2O3, Ta2O5, PbO, WO3 and the like, can achieve large size, zero defect and continuous production, is simple in preparation process, is low in cost and is suitable for industrial production.

Owner:湖北戈碧迦光电科技股份有限公司

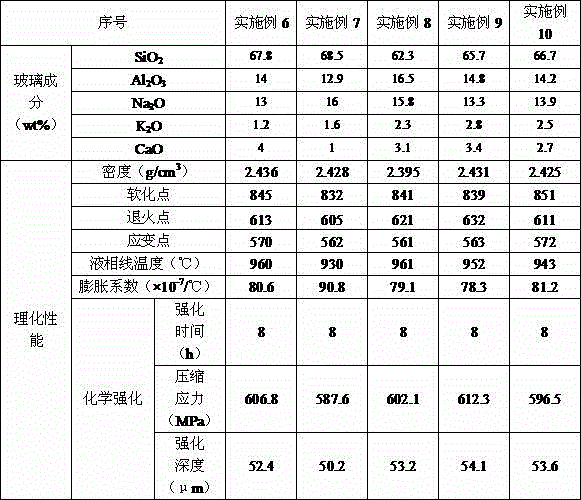

Chemical reinforced glass for electronic device and preparation method thereof

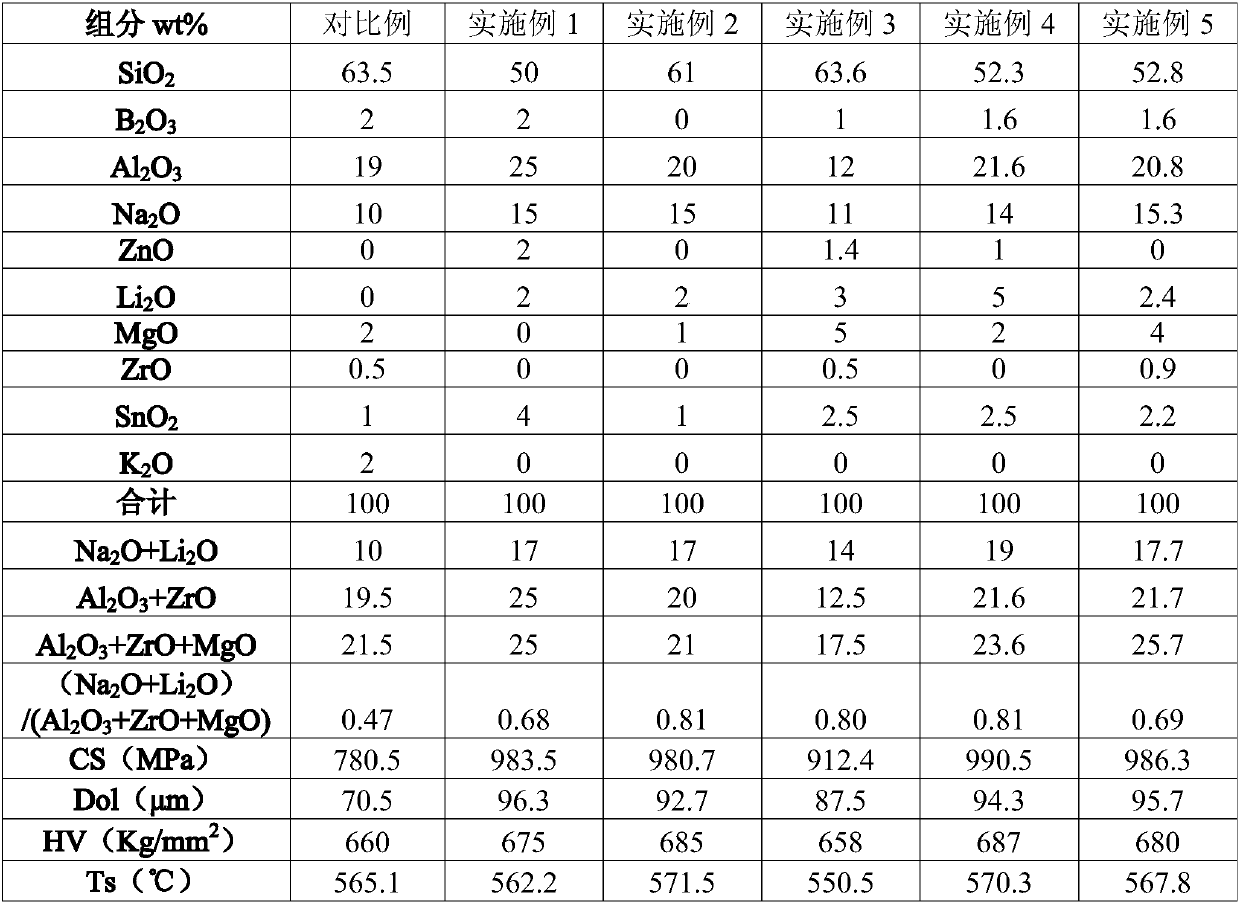

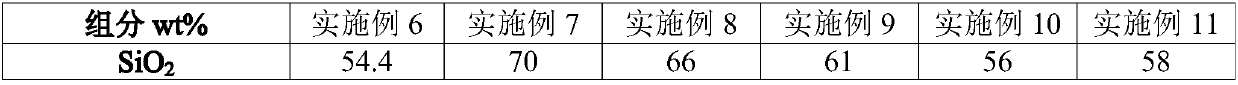

The invention provides chemical reinforced glass for an electronic device and a preparation method thereof. An ideal compression stress layer depth is obtained at relatively low reinforcing temperature and relatively short reinforcing time. The method comprises the following steps: 1) taking raw materials: greater than or equal to 50 percent and less than or equal to 70 percent of SiO2, greater than or equal to 0 percent and less than or equal to 2 percent of B2O3, greater than or equal to 12 percent and less than or equal to 25 percent of Al2O3, greater than or equal to 11 percent and less than or equal to 15 percent of Na2O, greater than or equal to 0 percent and less than or equal to 5 percent of ZnO, greater than or equal to 2 percent and less than or equal to 5 percent of Li2O, greater than or equal to 0 percent and less than or equal to 5 percent of MgO, greater than or equal to 0 percent and less than or equal to 1 percent of ZrO2, greater than or equal to 1 percent and less than or equal to 4 percent of SnO2 and greater than or equal to 0.67 and less than or equal to 0.97 of (Na2O+Li2O) / (Al2O3+ZrO2+MgO); 2) melting and clarifying and carrying out ion change. The surface compressive stress of the reinforced glass is 882.4MPa to 990.5MPa, the surface stress layer depth is 80.5mu m to 96.3mu m, the Vickers hardness is 658kg / mm<2> to 690kg / mm<2> and the strain point temperature is 550.5 DEG C to 572.2 DEG C.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

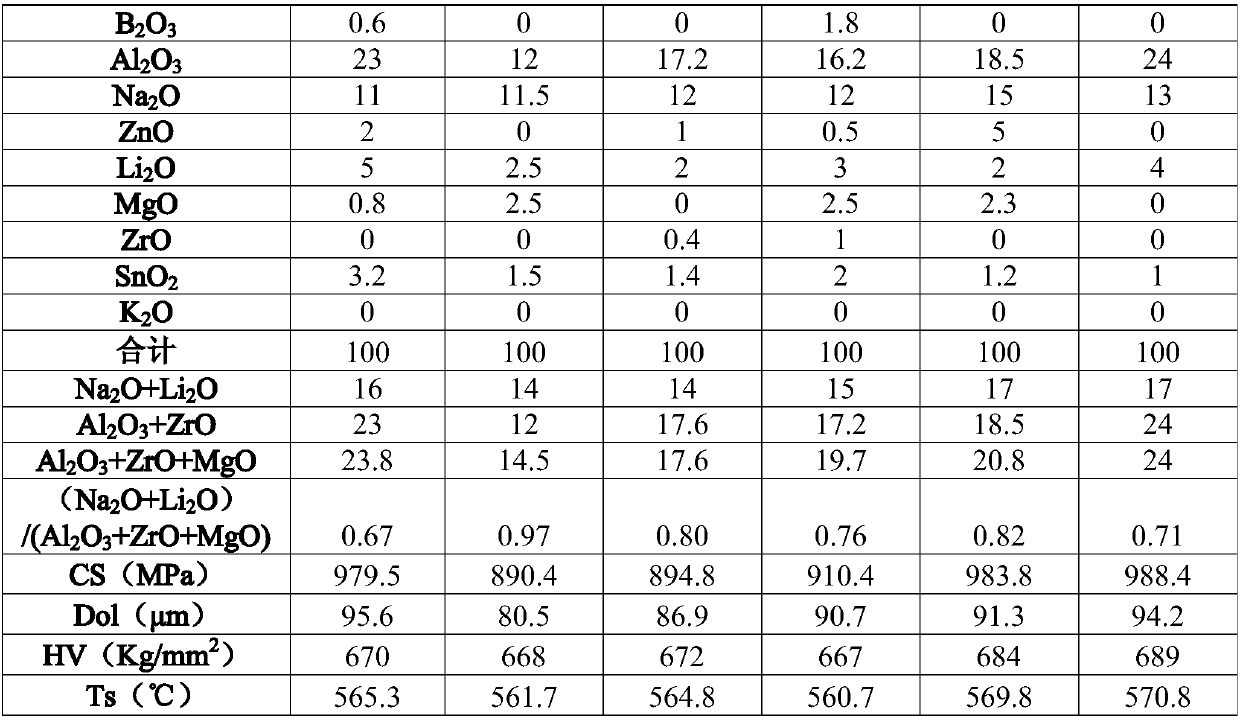

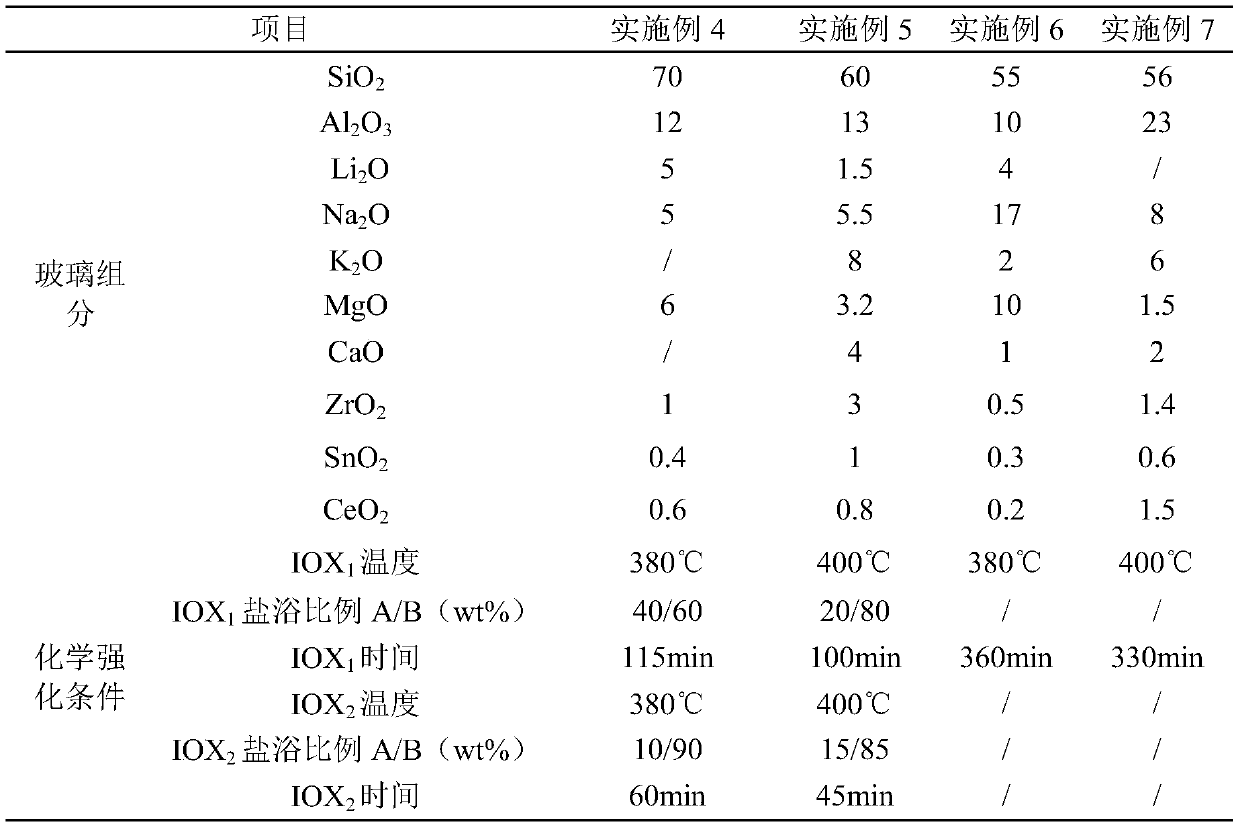

Scratch-resistant and external-impact-resistant ion exchange glass and preparation method thereof

The invention relates to a scratch-resistant and external-impact-resistant ion exchange glass and a preparation method thereof. The glass comprises the following components in percentages by mass: 54%-70% of SiO2, 10%-23% of Al2O3, 0-5% of Li2O, 5%-17% of Na2O, 0-8% of K2O, 1%-10% of MgO, 0-4% of CaO, 1%-5% of ZrO2, 0.3%-1% of SnO2 and 0.2%-1.5% of CeO2. The preparation method comprises the following steps of step 1, preparing raw materials according to the components of the glass in percentages by mass, melting and clarifying the raw materials, and then molding the raw materials into the glass; and step 2, chemically strengthening the glass to obtain the scratch-resistant and external-impact-resistant ion exchange glass. Compared with soda-lime glass, the glass has stronger impact strength and surface scratch resistance, and has better protection capability on electronic products.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

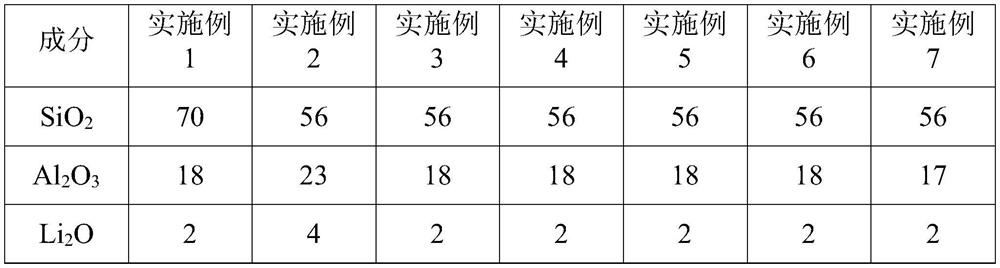

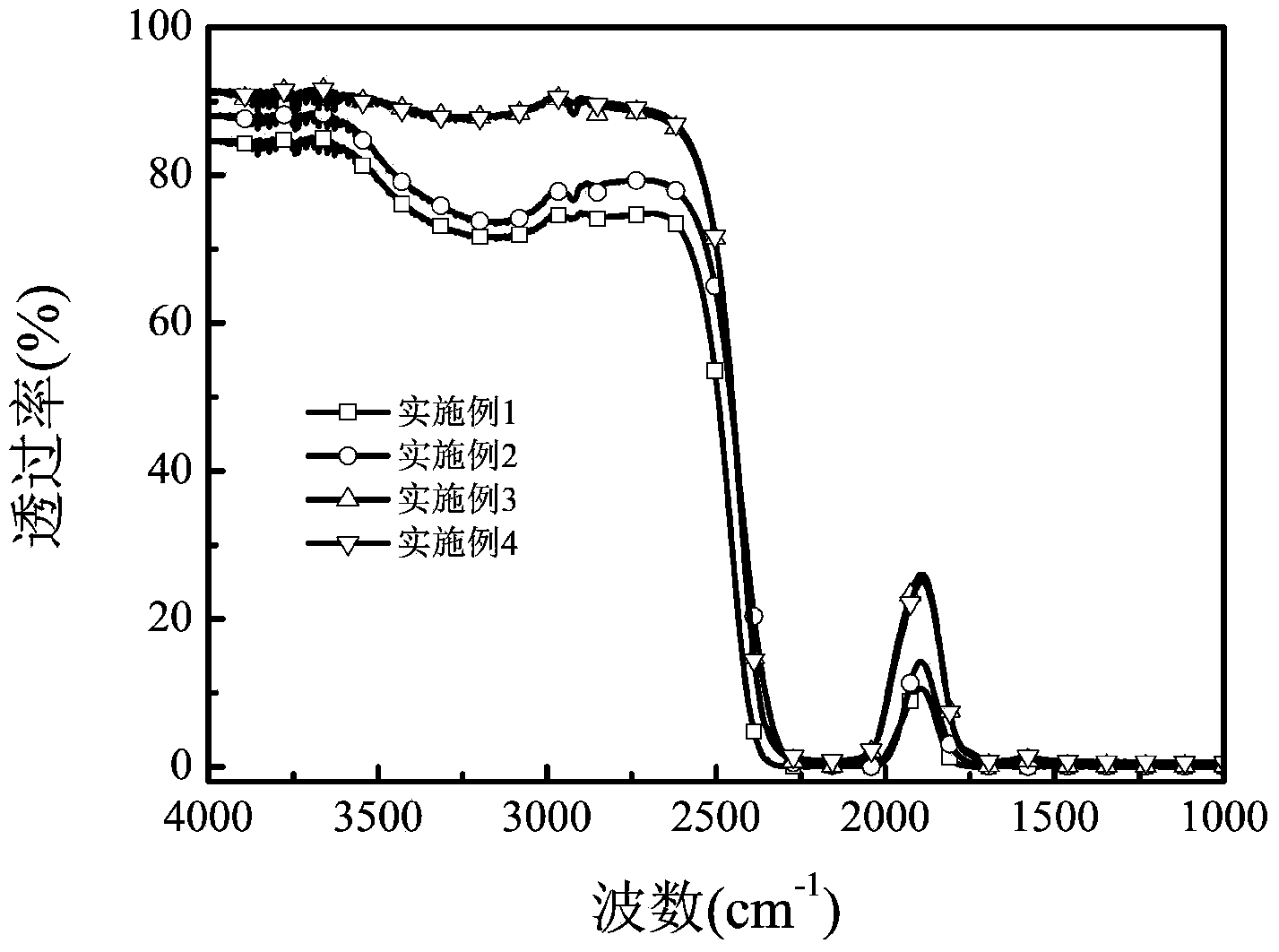

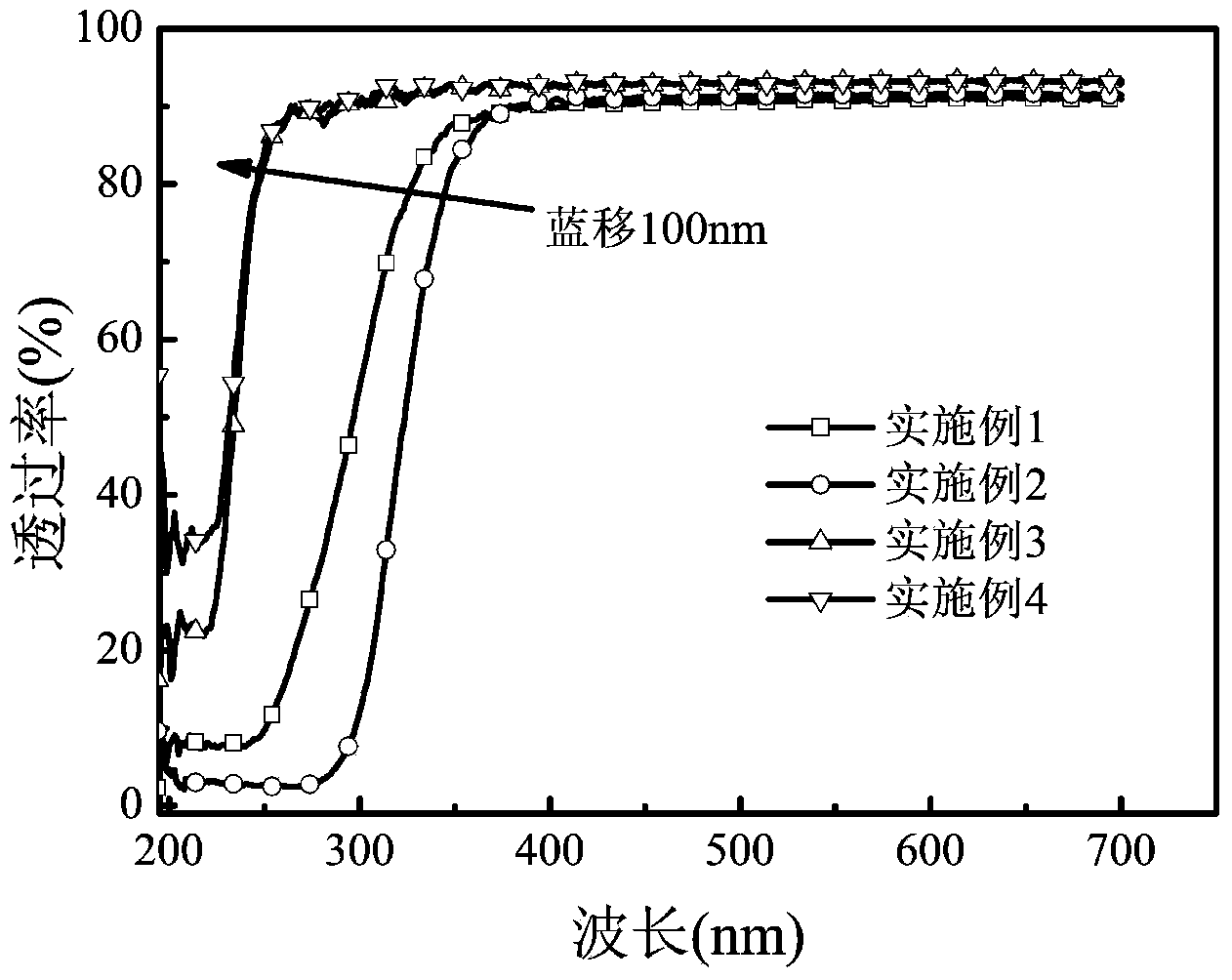

Anti-blue-light high-strength lithium-aluminum-silicon cover plate glass and preparation method and application thereof

PendingCN113121109AIncrease intrinsic strengthFacilitate ion exchangeGlass shaping apparatusGlass tempering apparatusPhysical chemistrySilicon

The invention relates to the technical field of cover plate glass, in particular to anti-blue-light high-strength lithium-aluminum-silicon cover plate glass which is prepared from the following raw materials in percentage by mass: 56%-70% of SiO2, 18%-23% of Al2O3, 2%-4% of Li2O, 6%-15% of Na2O, 1%-10% of MgO, 0.5%-6% of ZnO, 1%-5% of ZrO2, 0.05%-3% of CdS, 0.05%-2% of CdSe, 0.6%-1.5% of SnO2, 0-8% of K2O, 0-5% of B2O3 and 0.01%-1% of a reducing agent. The invention further discloses a preparation method of the anti-blue-light high-strength lithium-aluminum-silicon glass, the anti-blue-light high-strength lithium-aluminum-silicon glass is prepared through mixing, founding, annealing, secondary developing treatment and then composite chemical strengthening, and the anti-blue-light high-strength lithium-aluminum-silicon glass has an anti-blue-light effect, is suitable for being used as a screen protection material of electronic equipment such as a mobile phone and can effectively prevent the surface of a panel display product from being impacted or scratched and damaged.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

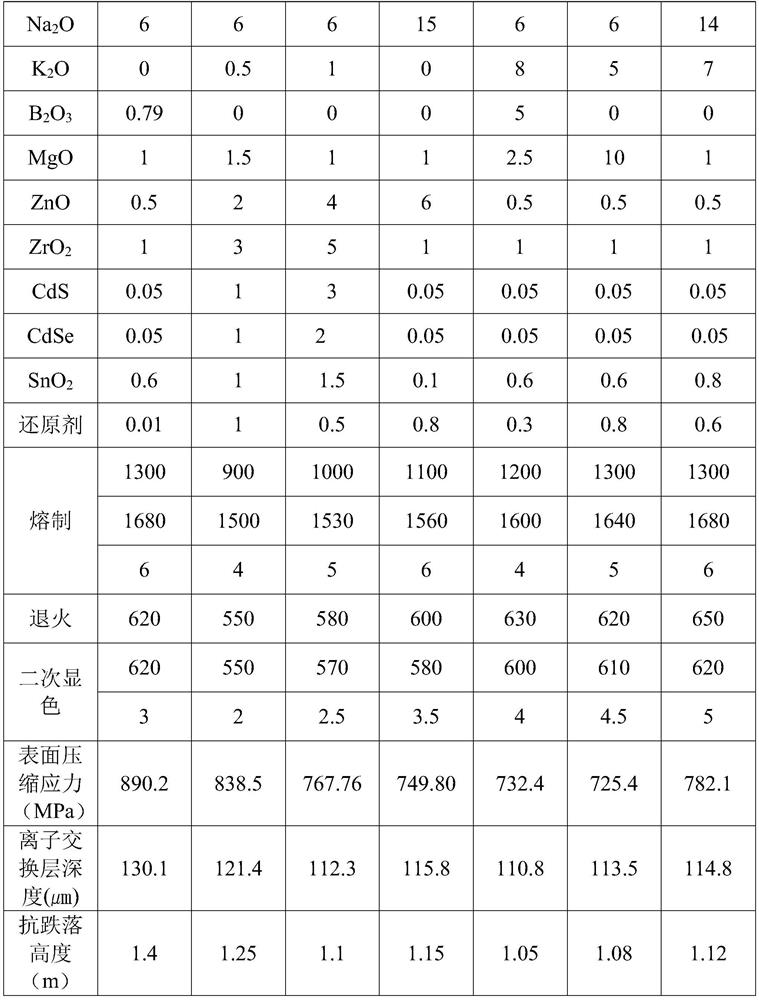

Black glass fiber and preparation method thereof

InactiveCN106927672AImprove coloring abilityGood crystallization performanceGlass making apparatusFiberGlass fiber

The invention provides black glass fiber and a preparation method thereof. The black glass fiber prepared by virtue of the preparation method contains SiO2, Al2O3, CaO, MgO, B2O3, Fe2O3, TiO2, MnO2 and K2O+Na2O. The black glass fiber is prepared through direct wiredrawing in a preparation process, and secondary dip dyeing is omitted, so that the problems in the prior art that the dyeing is not uniform, the dyeing adhesive force is poor and the fiber is easy to fall in a secondary dip dyeing process are solved. The preparation method provided by the invention has the beneficial effects that the prepared black glass fiber is low in melting temperature and high in acid-base resistance, and the main raw material is basalt which is widely distributed, high in reserve and low in cost, so that the production cost is greatly lowered.

Owner:TAISHAN FIBERGLASS INC

Glass fiber

The invention discloses a glass fiber and relates to the technical field of inorganic non-metallic materials. The glass fiber comprises, by weight, 60.0-64.0 parts of SiO2, 14.3-22.0 parts of Al2O3, 5.0-8.0 parts of CaO, 9.0-12.0 parts of MgO, 0.1-2.0 parts of ZnO, 0.5-1.6 parts of TiO, 0.3-0.9 parts of Fe2O3, 0.2-1.1 parts of Li2O and 0.6-4.3 parts of B2O3. Through optimization of a ratio of the above components, the prepared glass fiber has large curing mechanical strength, good chemical stability and good heat stability.

Owner:TONGCHENG GLASS FIBER OF ANHUI DANFENG GROUP

Titanium-containing high-lanthanum and low-niobium optical glass preparation method

The invention discloses a titanium-containing high-lanthanum and low-niobium optical glass preparation method comprising the following steps: (1) uniformly mixing the following raw materials: quartz sand, germanium oxide, niobium pentoxide, titanium dioxide, calcium carbonate, lanthanum trioxide, anhydrous boric anhydride, barium nitrate, barium carbonate, anhydrous sodium nitrate, zirconium dioxide, gallium oxide and antimonous oxide to prepare a mixture material; (2) high-temperature melting the mixture material in an air atmosphere to obtain glass liquid; (3) cast-moulding the glass liquid and rapidly cooling the glass to room temperature; (4) crushing the glass, adding less amount of raw materials and re-melting the glass in a four-grade melting furnace; (5) stirring, clarifying and homogenizing the glass liquid and moulding glass; and (6) performing inspection and secondary annealing to prepare the titanium-containing high-lanthanum and low-niobium optical glass. The optical glass is high in refractive index, is low in chromatic dispersion and is high in light transmittance, is low in crystallization tendency, is excellent in chemical stability, is free of heavy metal oxides, such as Gd2O3, Ta2O5, Y2O3, PbO, WO3 and the like, can achieve large size, zero defect and continuous production, is simple in preparation process, is low in cost and is suitable for industrial production.

Owner:湖北戈碧迦光电科技股份有限公司

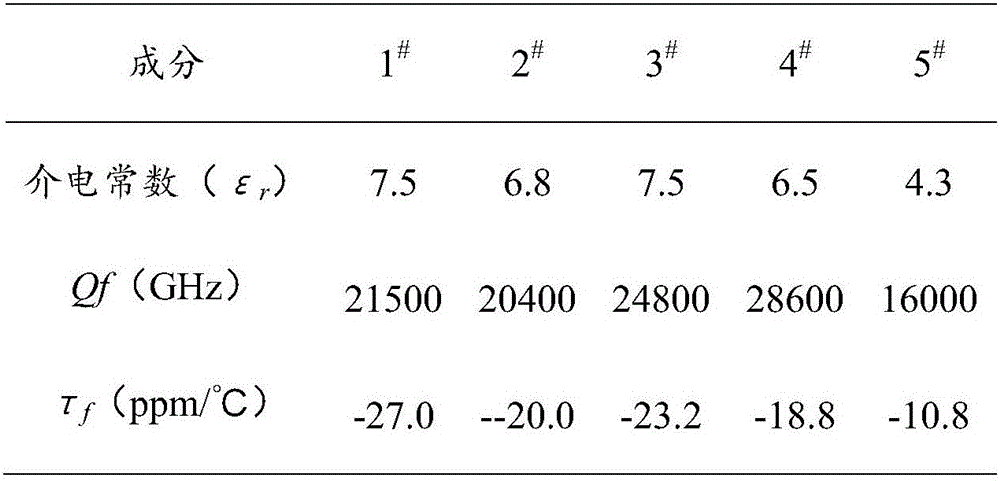

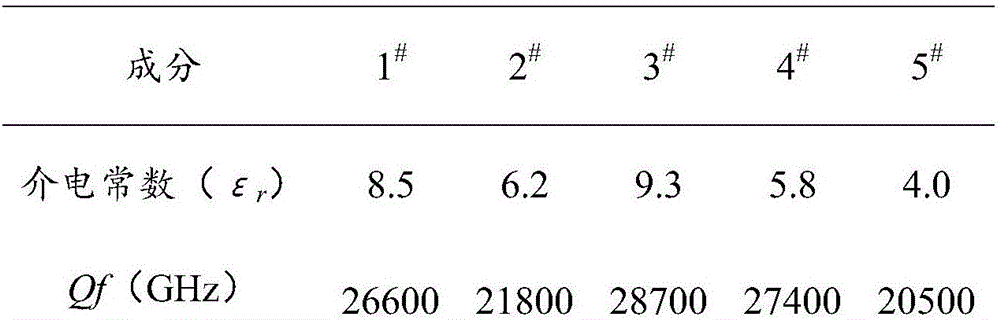

Low-dielectric-constant high-frequency glass ceramic LTCC material and preparation method thereof

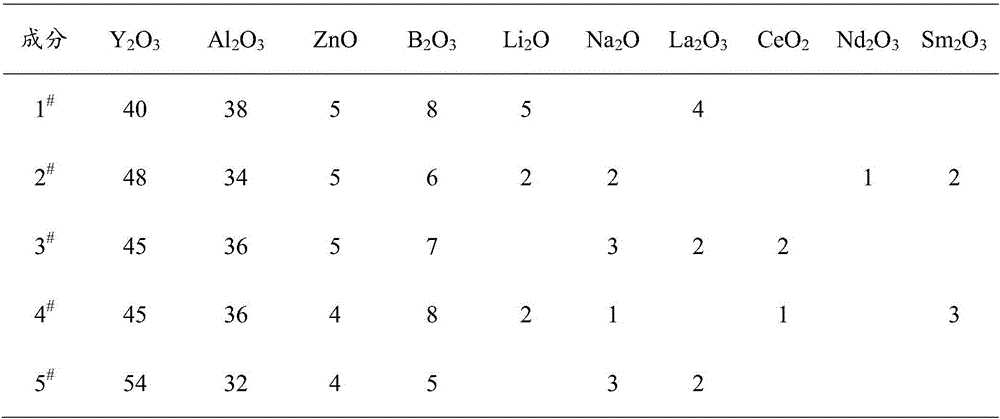

ActiveCN106673446ASintered denseHigh mechanical strengthGlass shaping apparatusAlkali metal oxideRare earth

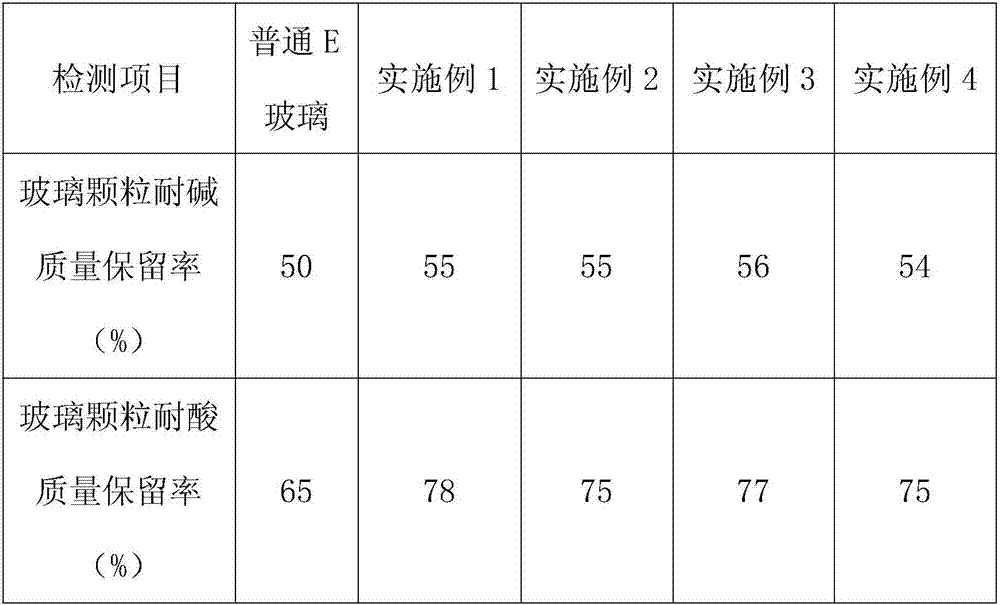

The invention discloses a low-dielectric-constant high-frequency glass ceramic LTCC material and a preparation method thereof. The material comprises the following components: 40-54wt% of Y2O3, 32-38wt% of Al2O3, 4-5wt% of ZnO, 5-8wt% of B2O3, 3-5wt% of alkali metal oxide, and 2-4wt% of rare earth oxide. The low-dielectric high-frequency glass ceramic LTCC material and the preparation method thereof provided by the invention solve the technical problem of over-large loss of an existing glass ceramic material system under a high frequency, the preparation process is simple and stable in quality, a YAG phase can be effectively controlled to be precipitated, and a series of glass ceramics having dielectric constants ranging from 5 to 9 is obtained.

Owner:NANJING INST OF TECH

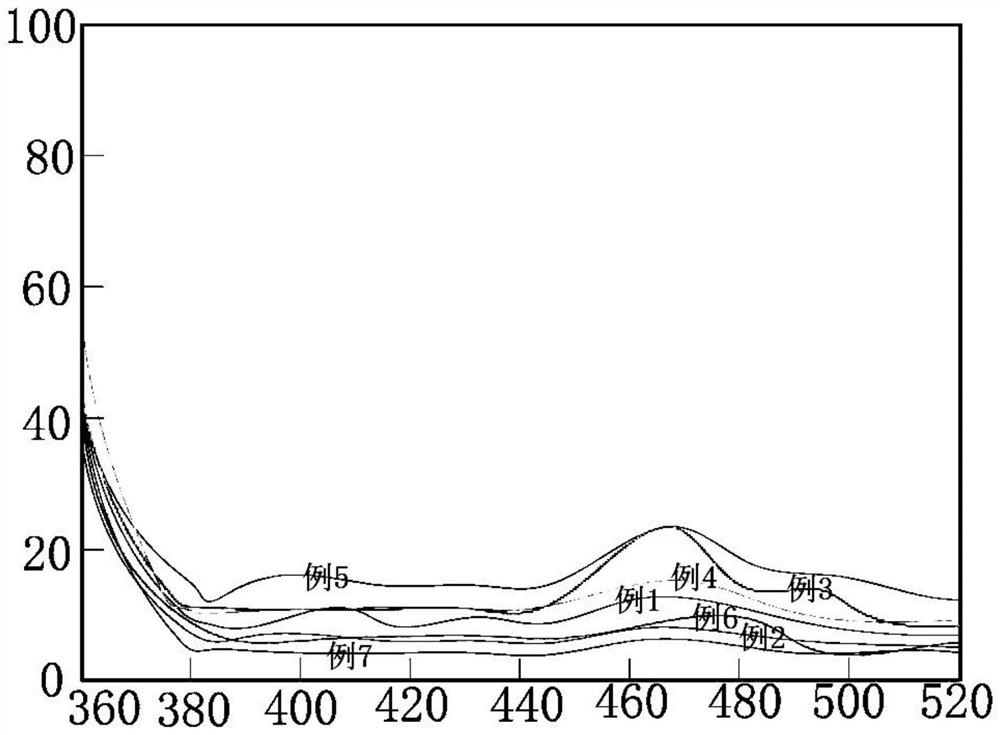

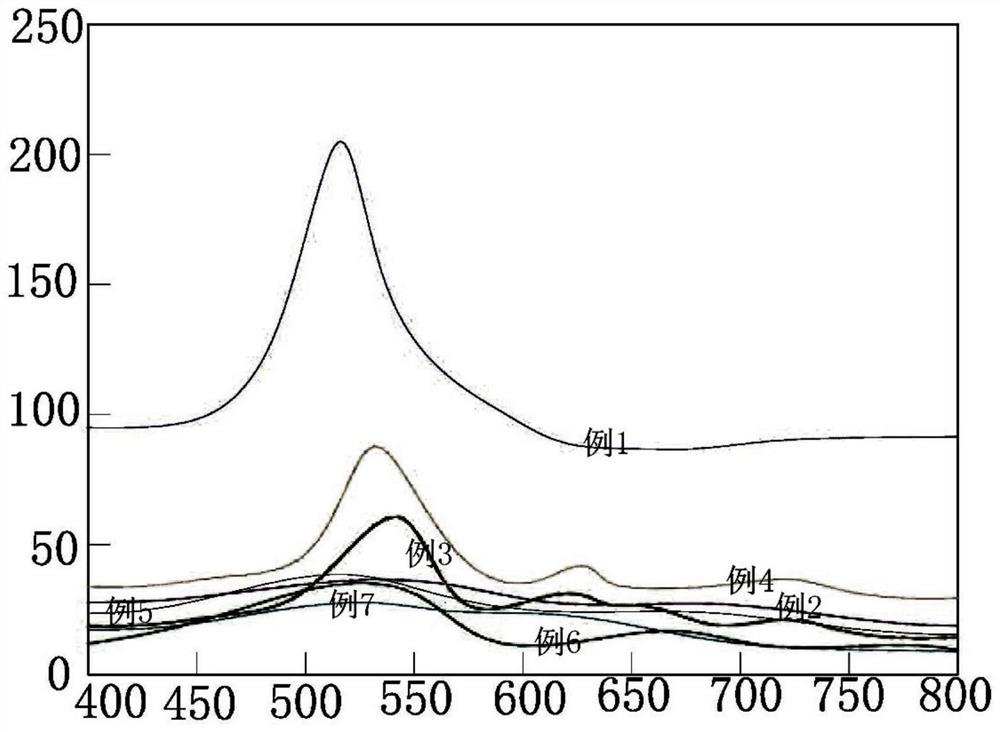

Quantum dot luminescent glass, and preparation method and application thereof

The invention relates to a quantum dot luminescent glass, and a preparation method and application thereof. Glass comprises 60-65% of SiO2, 15-25% of Al2O3, 0.1-5% of B2O3, 10-20% of Na2O, 0.1-5% of P2O5, 0.1-5% of MgO and 0.1-5% of SnO. A quantum dot comprises 5-15% of ZnO, 1-5% of CdS and 1-5% of Se. The preparation method comprises the following steps: preparing CdSxSe1x / ZnS powder from the quantum dot component; and uniformly mixing CdSxSe1x / ZnS powder with glass powder to obtain quantum dot luminescent glass powder, dissolving the quantum dot luminescent glass powder, casting to obtain aglass block, annealing, and cooling to room temperature to obtain the quantum dot luminescent glass.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

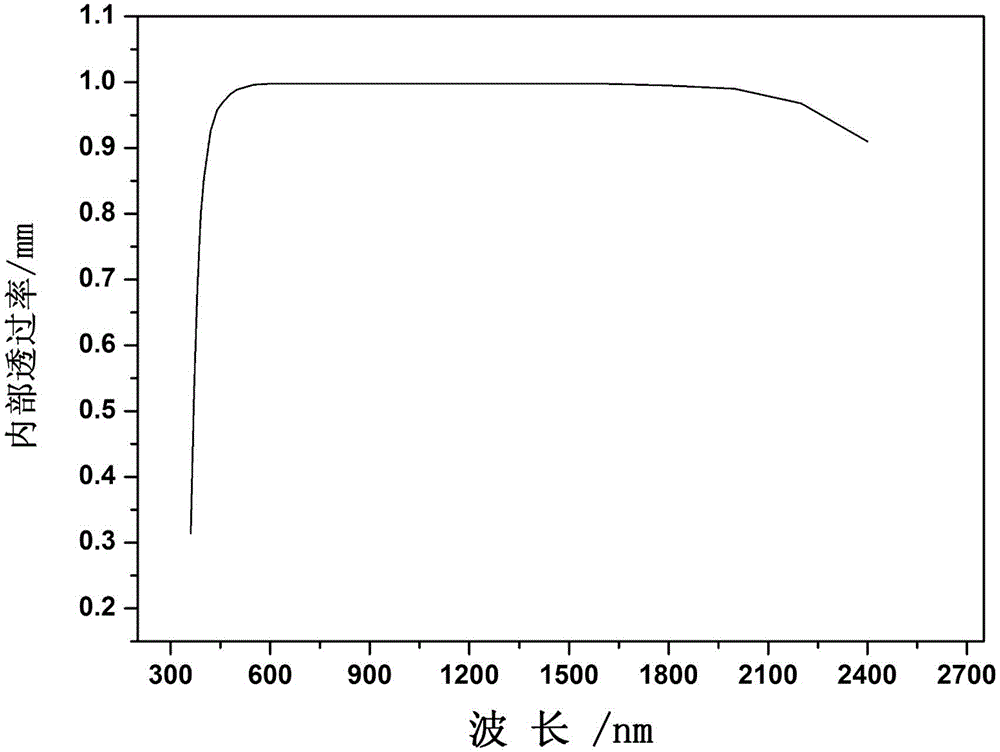

High-ultraviolet-transmittance fluorphosphate glass and preparation method thereof

The invention discloses high-ultraviolet-transmittance fluorphosphate glass and a preparation method thereof. The high-ultraviolet-transmittance fluorphosphate glass comprises components in percentage by mole as follows: 15 mol%-20 mol% of P2O5, 25 mol%-30 mol% of AlF, 25 mol%-35 mol% of CaF, 10 mol%-20 mol% of NaF, 8 mol%-15 mol% of BaF2 and 0.5 mol%-1.5 mol% of La2O3, and the sum of the percentages of the components is 100 mol%. The preparation method comprises steps as follows: raw materials are weighed according to a formula and placed into a crucible after uniformly mixed; the materials are placed in a high frequency furnace or a silicon carbide rod furnace and heated to 1,000 DEG C-1,100 DEG C for heat preservation for 30-40 minutes, and dehydration treatment is performed on a glass liquid simultaneously; and the cooling is performed, glass is taken out and placed in a muffle furnace heated to the glass transition temperature for heat preservation for 3 hours, and the glass is tempered to the room temperature at the cooling speed of 10 DEG C per hour. The glass has good ultraviolet transmittance performance, and the ultraviolet cutoff wavelength is 245 nm (T=80%).

Owner:NANJING UNIV OF POSTS & TELECOMM

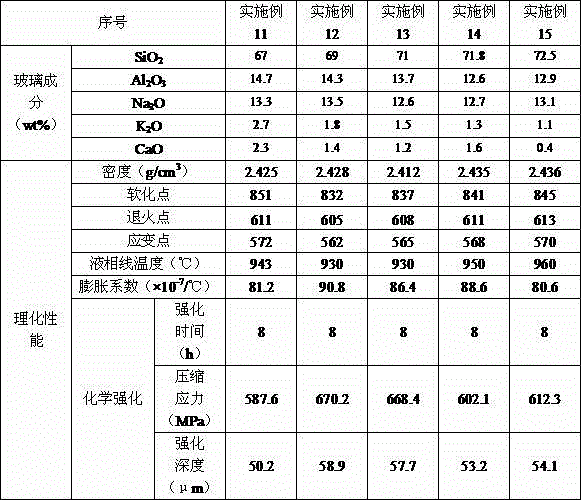

Prescription of cover plate glass for light touch screen

The invention discloses a prescription of a cover plate glass for a light touch screen. Experiments show that the major ingredients of the cover plate glass contain SiO2, Al2O3, Na2O, K2O and CaO, for the glass prepared according to the prescription provided by the invention, the aim of improving the coefficient of thermal expansion is realized by regulating the contents of the ingredients in the prescription, and simultaneously, improving the coefficient of thermal expansion of the glass by using the large proportion of metals containing Ba and Sr is avoided; in the prescription provided by the invention, CaO is selected instead of MgO, the MgO is not added, devitrification tendency of the glass can be lowered, the high-temperature viscosity can be lowered, melting is facilitated, and after being enhanced chemically, the glass can effectively prevent the impact and the scratch damage to the protective screen surface of the touch products, and prolong the service life of the products with touch screens.

Owner:TUNGHSU GRP

Preparation method of high-storing-capacity high-thermal-stability oxygen storage material

InactiveCN107694556AImprove adhesionLarge specific surface areaMetal/metal-oxides/metal-hydroxide catalystsOxygen preparationCerium nitrateAluminium hydroxide

The invention relates to the technical field of preparation of oxygen storage materials, in particular to a preparation method of a high-storing-capacity high-thermal-stability oxygen storage material; a solution of hydrogen peroxide, white sugar and polyethylene glycol is used to modify cerium nitrate, zirconium nitrate, aluminum nitrate and yttrium nitrate, high-temperature calcining is performed then; the white sugar may bind with other ingredients in the oxygen storage material; by adding polyethylene glycol solution, ions can be dispersed evenly, the specific surface area is increased, and oxygen-storing capacity of the oxygen storage material is improved. The surfactant, the polyethylene glycol solution, added herein may be effectively protected during calcining. Precipitate convertsslowly into oxide during calcining, and thermal stability and oxygen-storing capacity of the oxygen storage material are improved. Boric sludge and aluminum hydroxide are added, the modified aluminumhydroxide is decomposed into alumina at high temperature during reaction, and accordingly the thermal stability of the oxygen storage material is further improved; the preparation method has a promising application prospect.

Owner:高俊

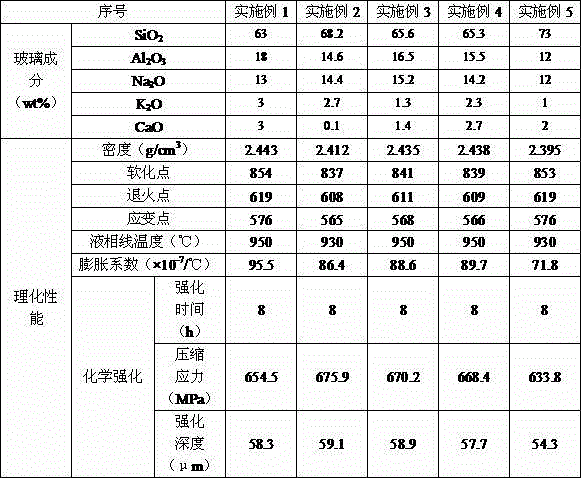

Preparation method of silver-loaded palygorskite heat-resistant liquid wallpaper

The invention relates to the technical field of building material preparation, in particular to a preparation method of silver-loaded palygorskite heat-resistant liquid wallpaper. According to the preparation method of the silver-loaded palygorskite heat-resistant liquid wallpaper, the silver-loaded palygorskite heat-resistant liquid wallpaper is prepared by taking modified epoxy resin as a matrix, taking a modified self-made nano-silicon dioxide powder, self-made silver-loaded palygorskite and modified aluminium hydroxide as fillers, and taking simethicone, gelatin and the like as auxiliary materials; firstly, the epoxy resin is modified by utilizing a silane coupling agent and diphenyl silanediol; the nano-silicon dioxide powder is subjected to surface modification through a dispersant,a coupling agent and an acidic solution, so that the antibacterial property of the wallpaper is improved; under a high-temperature condition, aluminium hydroxide is modified through a titanate coupling agent, so that the compatibility of the aluminium hydroxide and other filler is improved, the modified aluminium hydroxide is decomposed into aluminium oxide at a high temperature, and the aluminiumoxide can improve the chemical stability and the mechanical strength of glass, reduce a thermal expansion coefficient of the glass and remarkably improve the heat resistance of the liquid wallpaper,and has a wide application prospect.

Owner:义乌市君胜科技有限公司

Superfine non-alkali glass fiber cotton and preparation method thereof

ActiveCN107012585BHigh mechanical strengthReduce the tendency of devitrificationGlass making apparatusNon-woven fabricsGlass fiberFiber

The invention relates to superfine alkali-free glass fiber cotton. The superfine alkali-free glass fiber cotton is prepared from, by weight, 80-90% of superfine alkali-free glass fiber and 10-20% of adhesive assistant; the superfine alkali-free glass fiber is prepared from, by weight, 55-59% of SiO2, 13-18% of Al2O3, 2.5-4.5% of MgO, 15-24% of CaO, 0-0.5% of Na2O, 0-0.3% of K2O, 0.15-0.4% of Fe2O3, 6-8.5% of B2O3 and 0.5-1.5% of TiO; the total content of alkaline metal oxide Na2O and k2O is smaller than 0. 6%, and the sum of the contents of SiO2, Al2O3, MgO and CaO is greater than 92.5%. The invention further relates to a preparation method of the superfine alkali-free glass fiber cotton, the superfine alkali-free glass fiber is light in weight and supper thin and uniform in diameter, and has excellent mechanical performance.

Owner:宣汉正原微玻纤有限公司

Production technology of high-toughness and break-resistant glass bowl

InactiveCN107117815AImprove toughnessExcellent hardness performanceGlass pressing apparatusPlatesHuman healthHardness

The invention relates to the field of glass bowl manufacturing, in particular to a production process for a high-toughness and shatter-resistant glass bowl. The raw materials required for this solution include: 120-150 parts of silicon dioxide powder, 40-50 parts of bisphenol siloxane type benzo Oxyzine, 14-19 parts of diatomaceous earth, 8-14 parts of aluminate coupling agent, 15-20 parts of polyvinyl chloride, 1-3 parts of zinc stearate, 2-4 parts of dioctyl phthalate, 4-10 parts of mica powder, 4-7 parts of CaCO3, 5-9 parts of Na2O, and an appropriate amount of water are heated and melted, extruded, annealed, and tempered to obtain a high-toughness and drop-resistant glass bowl; the technology provided by the present invention The scheme can effectively overcome the defects that the glass bowl made in the prior art has low hardness, low notched impact strength, easy brittle fracture and damage to human health.

Owner:安徽晶晶玻璃制品有限公司

Tellurium oxide and antimonic fluoride system matrix glass and preparation method thereof

InactiveCN106430951AHigh glass forming abilityThe proportion of ingredients is easy to obtainGlass shaping apparatusAbsorption capacitySystem matrix

The invention relates to fluorotellurite glass and a preparation method thereof. The fluorotellurite glass is simple in proportion of components, easy in obtaining of the components and good in stability; furthermore, in introduced antimony fluoride, as heavy metal, antimony ions can significantly improve the glass formation ability of a tellurate system, and improves the system optical absorption capacity, thus enabling the infrared cut off of a glass system to offset towards a long wavelength band, and further realizing excellent optical performance; therefore, excellent oxyfluoride tellurate matrix glass is obtained. The fluorotellurite glass is smaller in glass formation range; the ratio of TeO2 to SbF3 is moderate, so that the glass is small in crystallization tendency, has good physical and chemical stability, can be used as rare earth ion-doped matrix glass, and also can form a new glass system by adding other fluorides or oxides; therefore, the fluorotellurite glass has good development and technology application prospects.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

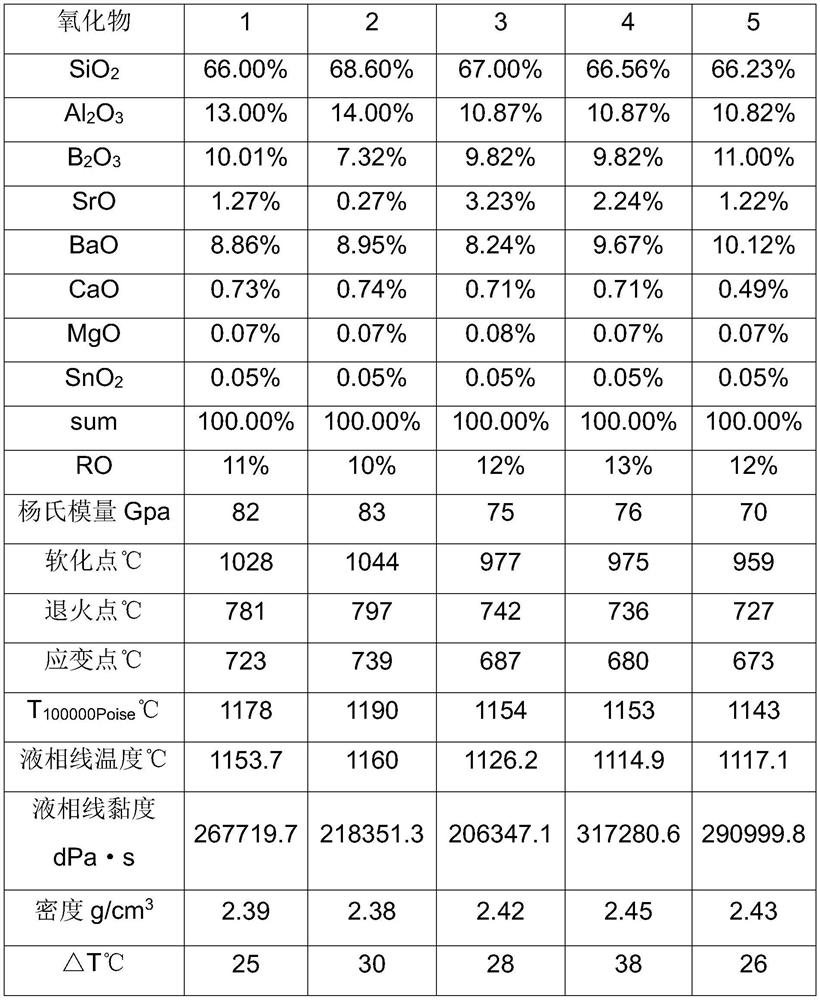

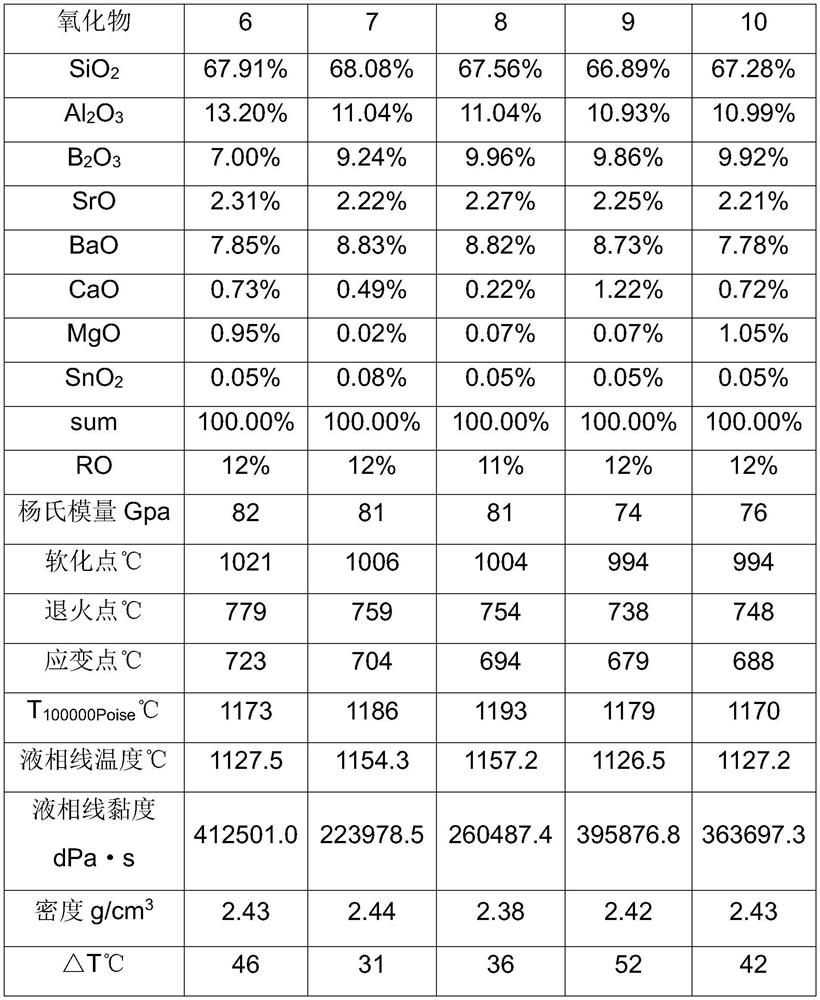

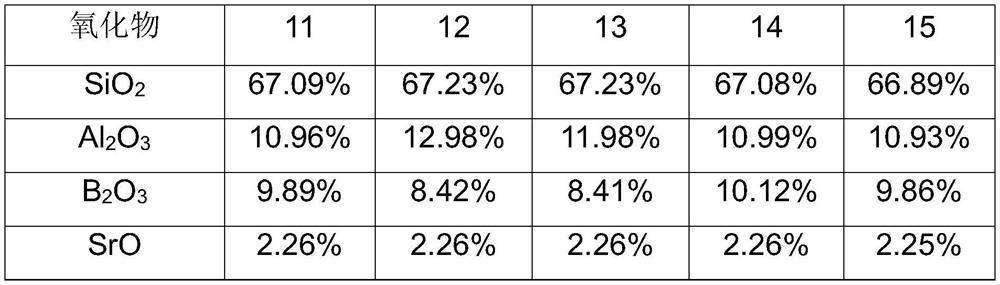

Electronic glass with high liquidus viscosity and preparation method

PendingCN114685043AHigh viscosityAffect lifeGlass forming apparatusPhysical chemistryYoung's modulus

The invention discloses electronic glass with high liquidus viscosity and a preparation method of the electronic glass. The electronic glass comprises the following raw materials in percentage by weight: 65.56-68.6% of SiO2; the content of Al2O3 is 10.58 to 14 percent; 7 to 11 percent of B2O3; 0.27% to 3.26% of SrO; 7.20% to 10.12% of BaO (BaO); 0.22%-1.22% of CaO (calcium oxide); 0 to 1.05 percent of MgO; less than 13% of MgO + CaO + SrO + BaO; the liquidus viscosity of the electronic glass is greater than 200,000 poise. The minimum value obtained by subtracting the temperature corresponding to 100,000 poise from the liquidus temperature of the electronic glass is 22 DEG C. The strain point temperature of the electronic glass is 670-739 DEG C, the Young modulus of the electronic glass is 70-83 MPa, the density of the electronic glass is 2.38-2.45 g / cm < 3 >, the liquidus viscosity of the electronic glass is ensured to be higher than 200,000 poise, overflow pull-down forming is facilitated, and a small density value can be obtained.

Owner:IRICO DISPLAY DEVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com