High-ultraviolet-transmittance fluorphosphate glass and preparation method thereof

A fluorophosphate glass, transmittance technology, applied in the field of high ultraviolet transmittance glass, can solve the problems of complex preparation process, high melting temperature, narrow transmittance range, etc., achieve high ultraviolet transmittance, crystallization The effect of small tendency and large transmission range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Composition by molar percentage, P 2 o 5 : 17 mol%, AlF 3 : 30 mol%, CaF 2 : 30 mol%, NaF: 12 mol%, BaF 2 : 10 mol%, La 2 o 3 : 1 mol%, the sum of the above components is 100 mol% for batching.

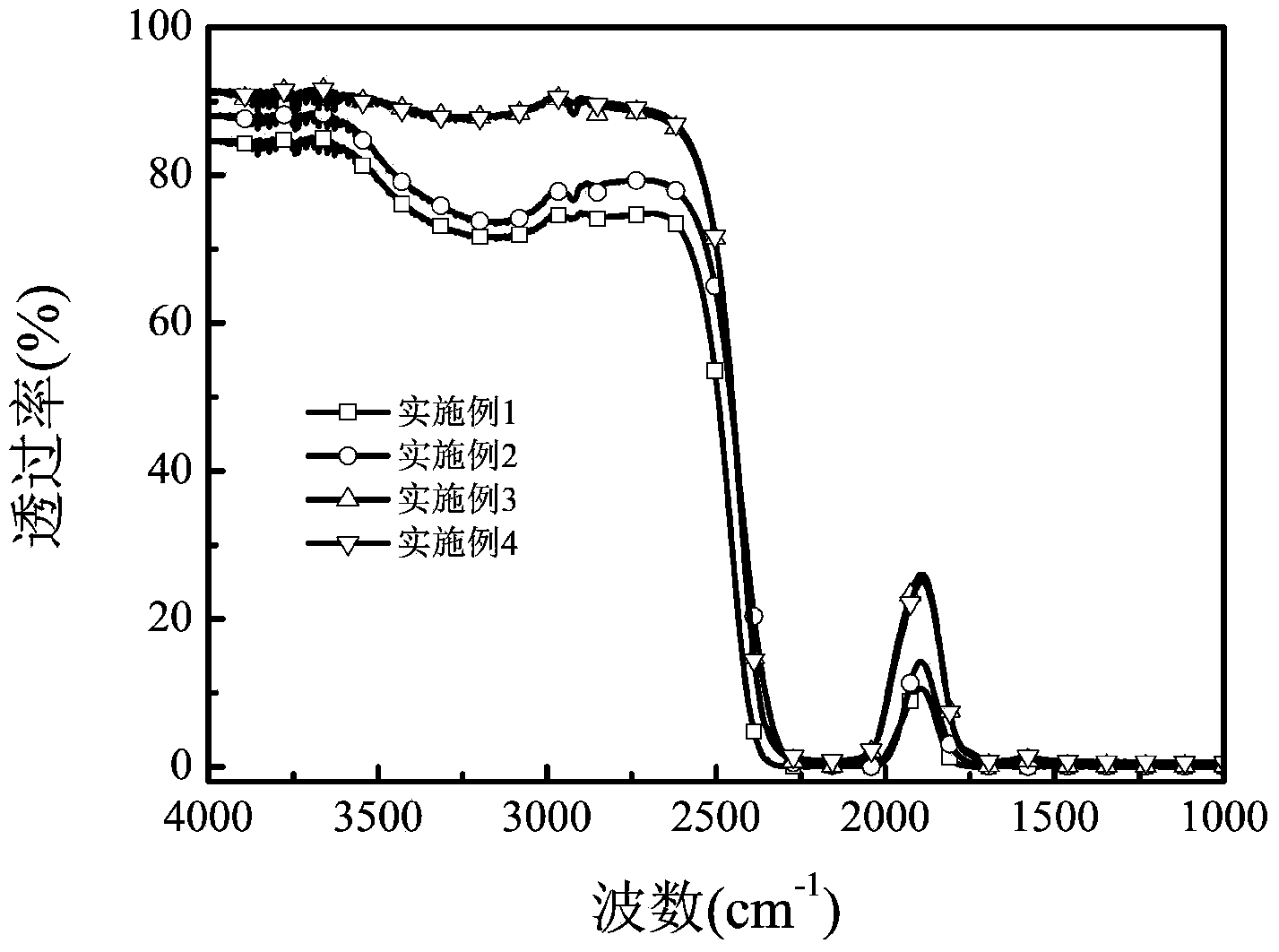

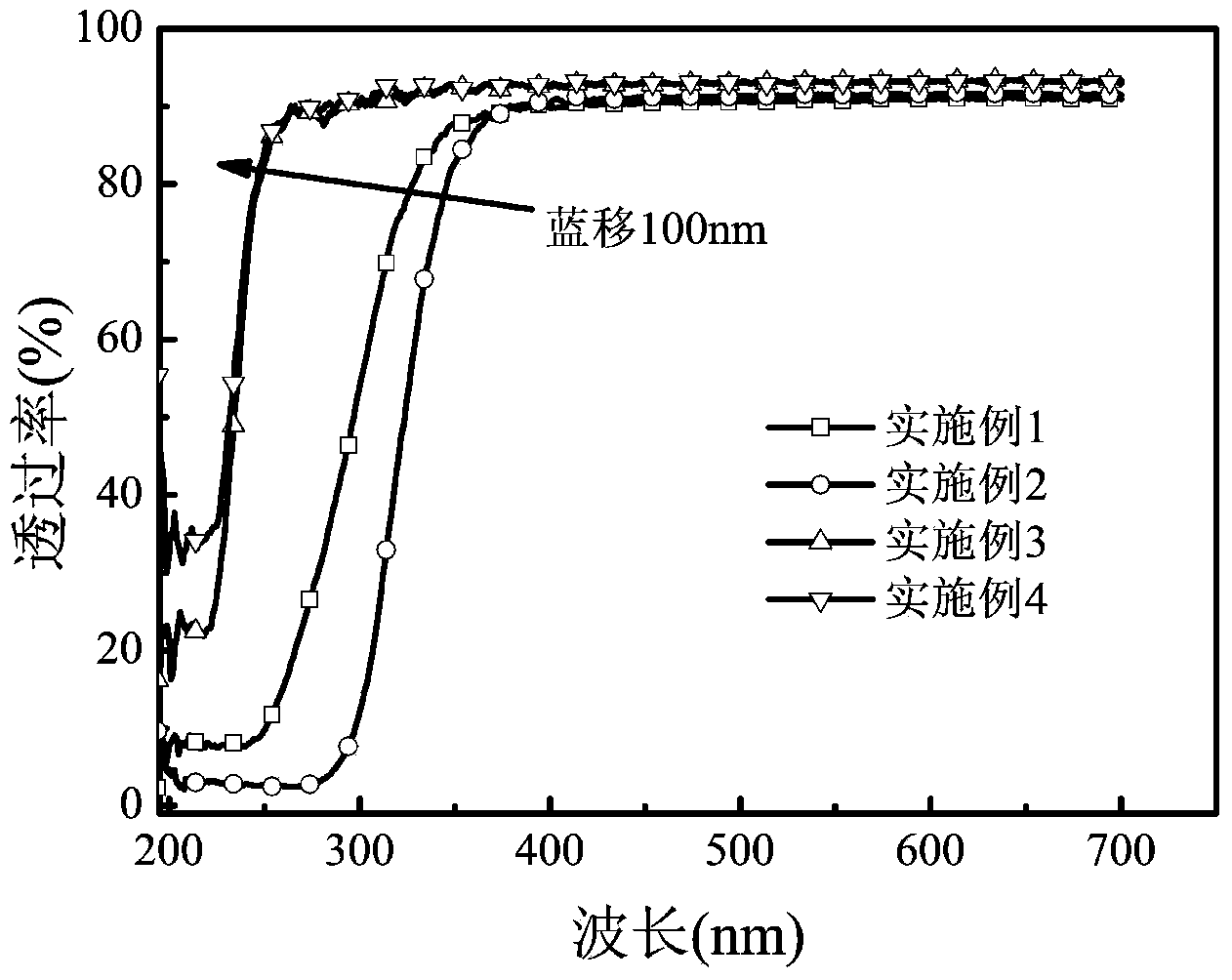

[0025] The preparation method is as follows: Weigh the raw material according to the formula, mix it well and add it into the corundum crucible; heat it up to 1000-1100 degrees in the silicon carbide rod furnace and keep it for 30-40 minutes; temperature in a muffle furnace for 3 hours, and then annealed to room temperature at a cooling rate of 10°C per hour. After the annealed sample is ground and processed, the performance analysis is carried out, and the test results are shown in figure 1 , figure 2 .

Embodiment 2

[0027] Composition by molar percentage, P 2 o 5 : 20 mol%, AlF 3 : 28 mol%, CaF 2 : 30 mol%, NaF: 13 mol%, BaF 2 : 8 mol%, La 2 o 3 : 1 mol%, the sum of the above components is 100 mol% for batching.

[0028] The preparation method is as follows: Weigh the raw material according to the formula, mix it well and add it into the corundum crucible; raise the temperature to 1000-1100 degrees in the silicon carbide rod furnace and keep it for 30-40 minutes, and use argon gas plus carbon tetrachloride to heat the glass liquid. Soak for water removal treatment; cool down, take out the glass and place it in a muffle furnace heated to its glass transition temperature for 3 hours, and then anneal to room temperature at a cooling rate of 10°C per hour. After the annealed sample is ground and processed, the performance analysis is carried out, and the test results are shown in figure 1 , figure 2 .

Embodiment 3

[0030] Composition by molar percentage, P 2 o 5 : 17 mol%, AlF 3 : 30 mol%, CaF 2 : 28 mol%, NaF: 14 mol%, BaF 2 : 10 mol%, La 2 o 3 : 1 mol%, the sum of the above components is 100 mol% for batching.

[0031] The preparation method is as follows: Weigh the raw material according to the formula, mix well and add it into a glassy carbon crucible, place the crucible in a quartz cover and pass it on for protection with argon; heat it up to 1000-1100 degrees in a high-frequency furnace and keep it warm for 30-40 minutes; cool down , take out the glass and place it in a muffle furnace heated to its glass transition temperature for 3 hours, and then anneal it to room temperature at a cooling rate of 10°C per hour. After the annealed sample is ground and processed, the performance analysis is carried out, and the test results are shown in figure 1 , figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com