Hydrofinishing method for glycol

A technology of hydrorefining and ethylene glycol, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of unstable product quality and low light transmittance of ethylene glycol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0074] Preparation of Raney nickel catalyst supported by polymer material:

[0075] (1) Extrude polypropylene powder (Maoming Petrochemical, F280M) with a twin-screw extruder and cut it into Φ3mm×3~5mm particles;

[0076] (2) Weigh 100g of polypropylene particles and place them in the nickel-aluminum alloy particles. The Ni content in the nickel-aluminum alloy is 48wt%, the Fe metal content is 1.5wt%, the Cr metal content is 1.5wt%, and the La metal content is 1.0wt% %, the Al metal content is 48wt%, molded with a flat vulcanizer for 10min under the conditions of a temperature of 220°C and a pressure of 7MPa, took out and cooled, sieved, and sieved out spherical particles, and the surface of the particles was completely covered by Raney alloy particles, that is, the catalyst was obtained. Weighing 420g;

[0077] (3) configure 20% NaOH aqueous solution 400g with deionized water, add step (2) gained catalyst 40g, keep temperature 85 ℃, filter out solution after 8 hours, promptl...

preparation example 2

[0079] Preparation of composite hydrogenation catalyst CAT-1:

[0080] (1) 100 mass parts of liquid epoxy resin (Baling Petrochemical, CYD-128), 85 mass parts of curing agent methyltetrahydrophthalic anhydride (MeTHPA) (Guangdong Shengshida Technology and Trade Co., Ltd.), curing accelerator triethanolamine (TEA) (Tianjin Chemical Reagent No. 1 Factory) 1.5 parts by mass were stirred evenly;

[0081] (2) Take by weighing 50g of the epoxy curing system prepared in step (1) and 150g of nickel-aluminum alloy particles and fully stir and mix. In the nickel-aluminum alloy, the Ni content is 48wt%, and the aluminum content is 52wt%. Take an appropriate amount of mixture and add it to the cylinder In the mold, use a flat vulcanizer to press for 30 minutes at a temperature of 120 ° C and a pressure of 7 MPa, and use a flat vulcanizer to press for 90 min at a temperature of 150 ° C and a pressure of 7 MPa, and take it out after cooling to obtain a granular catalyst precursor;

[0082]...

preparation example 3

[0085] Preparation of composite hydrogenation catalyst CAT-2:

[0086] (1) 100 mass parts of liquid epoxy resin (Baling Petrochemical, CYD-128), 85 mass parts of curing agent methyltetrahydrophthalic anhydride (MeTHPA) (Guangdong Shengshida Technology and Trade Co., Ltd.), curing accelerator triethanolamine (TEA) (Tianjin Chemical Reagent No. 1 Factory) 1.5 parts by mass were stirred evenly;

[0087] (2) Take by weighing 40g of the epoxy curing system prepared in step (1) and 180g of nickel-aluminum alloy particles and fully stir and mix, the Ni content in the nickel-aluminum alloy is 48wt%, the aluminum content is 52wt%, and an appropriate amount of mixture is added to the cylinder In the shaped mold, press with a flat vulcanizer at a temperature of 120° C. and a pressure of 7 MPa for 30 minutes, and with a flat vulcanizer at a temperature of 150° C. and a pressure of 7 MPa for 90 minutes, and take it out after cooling to obtain a granular catalyst precursor;

[0088] (3) Me...

PUM

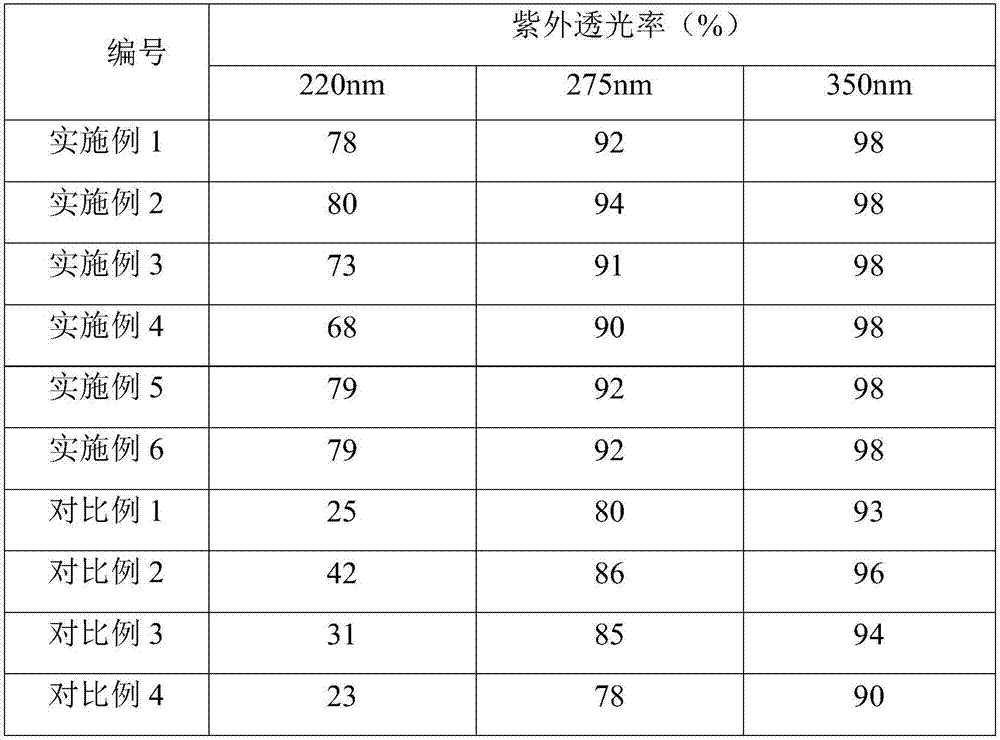

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com