Scratch-resistant and external-impact-resistant ion exchange glass and preparation method thereof

A technology of ion exchange and impact force, which is applied in the field of ion exchange glass and its preparation, can solve the problems of affecting the display effect of display products, the damaged surface of the screen, and endangering the service life, so as to prevent impact and scratch damage, good protection ability, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] SnO 2 In the process of glass preparation, it mainly plays a clarifying role, SnO 2 The content is 0.3% to 1%.

[0039] CeO 2 : 0.2% to 1.5%.

[0040] CeO 2 It also acts as a clarifier during the glass preparation process. Its content is 0.2% to 1.5%, which can eliminate bubbles in the molten glass, preferably 0.4% to 1.2%. It can also achieve the effect of completely removing bubbles while saving raw materials.

[0041] ZrO 2 , SnO 2 and CeO 2 Simultaneous use can improve the chemical resistance stability of the glass, and the sum of their mass percentages is preferably 2% to 7%. In addition, SnO 2 and CeO 2 At the same time, it can improve the appearance color of the glass, because CeO 2 The content is higher, the ultraviolet absorption is enhanced, and the absorption cut-off end is shifted to visible light, resulting in obvious yellow in the glass, so the use of SnO 2 Replace part of CeO 2 Can improve the transmittance of glass.

[0042] The production p...

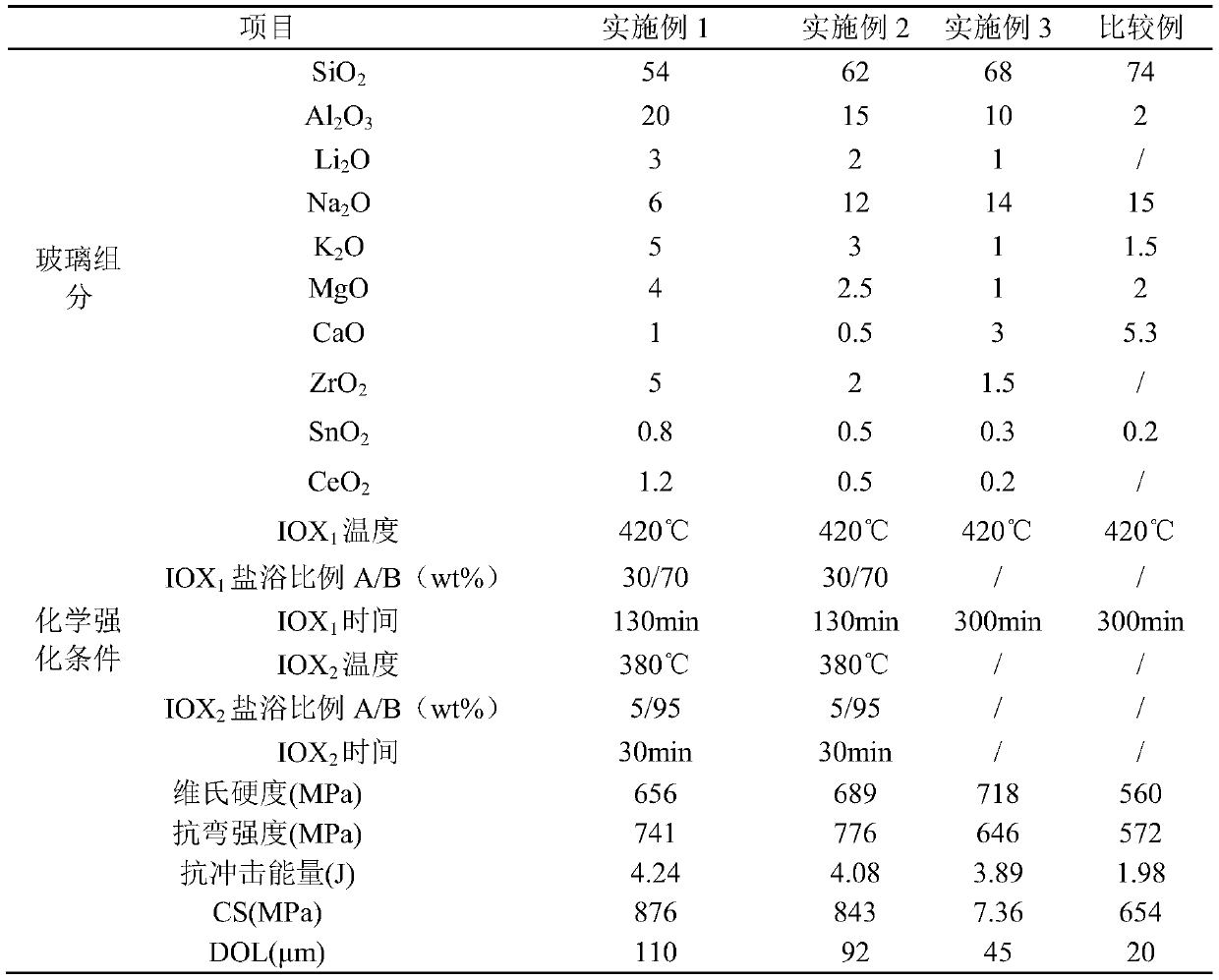

Embodiment 1

[0051] First, select raw materials according to the glass composition listed in Table 1, so that the ingredients meet the glass composition of Example 1, wherein the purity of the quartz sand is 99.8%, the Fe content is below 100ppm, the particle size is below 100 mesh, and other glass raw materials are chemically pure; Put the above-mentioned batch materials into a platinum crucible, melt and clarify in a high-temperature furnace at 1680 °C for 6 hours, and then cast a glass plate of a specified shape in a stainless steel template, then anneal, grind and polish, and make a glass plate with a thickness of Five pieces of glass with different formulations of 1mm each, and these glass samples were respectively immersed in the high-temperature molten liquid of potassium nitrate and sodium nitrate to carry out chemical strengthening treatment according to the temperature and time of Example 1. Table 1 shows the basic properties of the sample. The Vickers hardness is 656MPa, the bend...

Embodiment 2

[0053] Select raw materials by the glass composition listed in table 1, make its batching meet the glass composition of embodiment 2, wherein the purity of quartz sand is 99.8%, Fe content below 100ppm, particle size below 100 orders, other glass raw materials are all chemically pure; The batch material is put into a platinum crucible, melted and clarified in a high-temperature furnace at 1680 ° C for 6 hours, and then cast into a glass plate of a specified shape in a stainless steel template, and then annealed, ground and polished to make a glass plate with a thickness of 1 mm. Five pieces of glass with different formulations were used, and these glass samples were respectively immersed in the high-temperature molten liquid of potassium nitrate and sodium nitrate to carry out chemical strengthening treatment according to the temperature and time in Example 2. Table 1 shows the basic properties of the sample. The Vickers hardness is 689MPa, the bending strength is 776MPa, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com