Patents

Literature

294results about How to "Avoid scratch damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

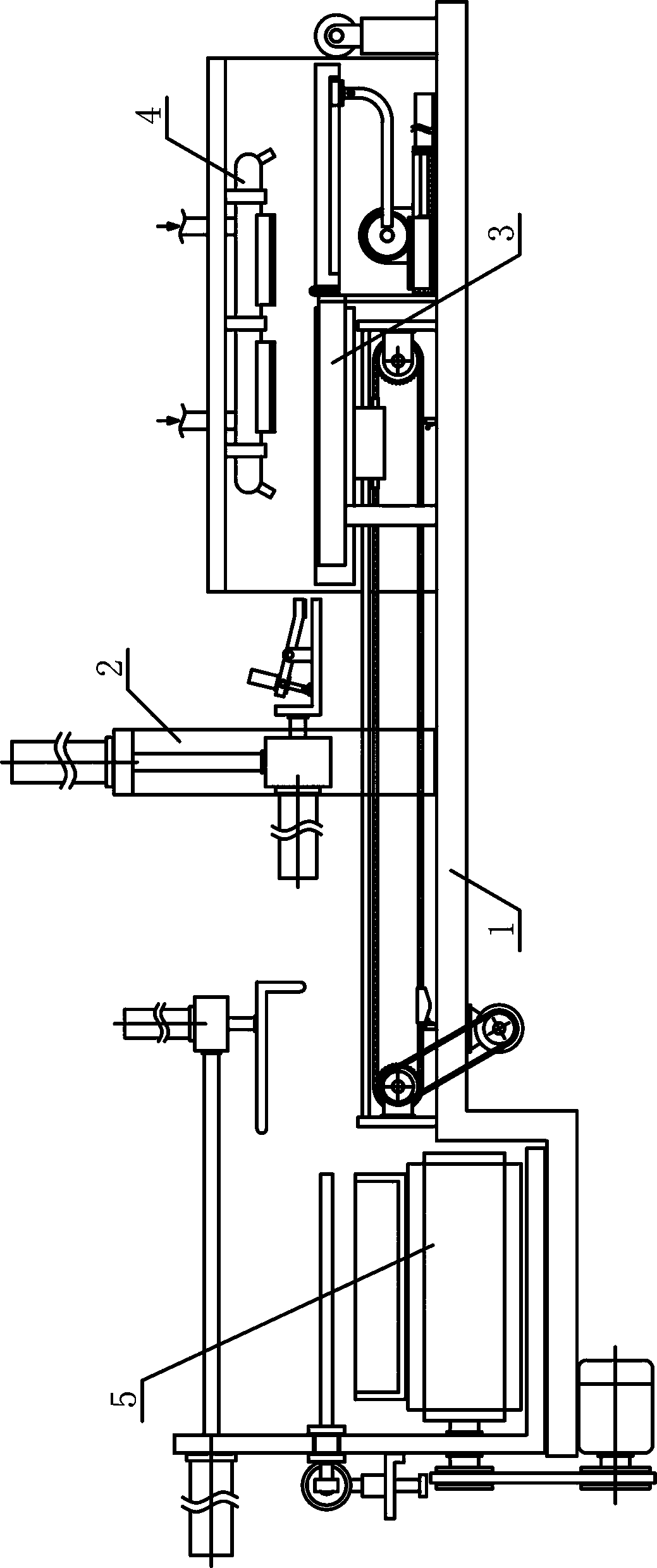

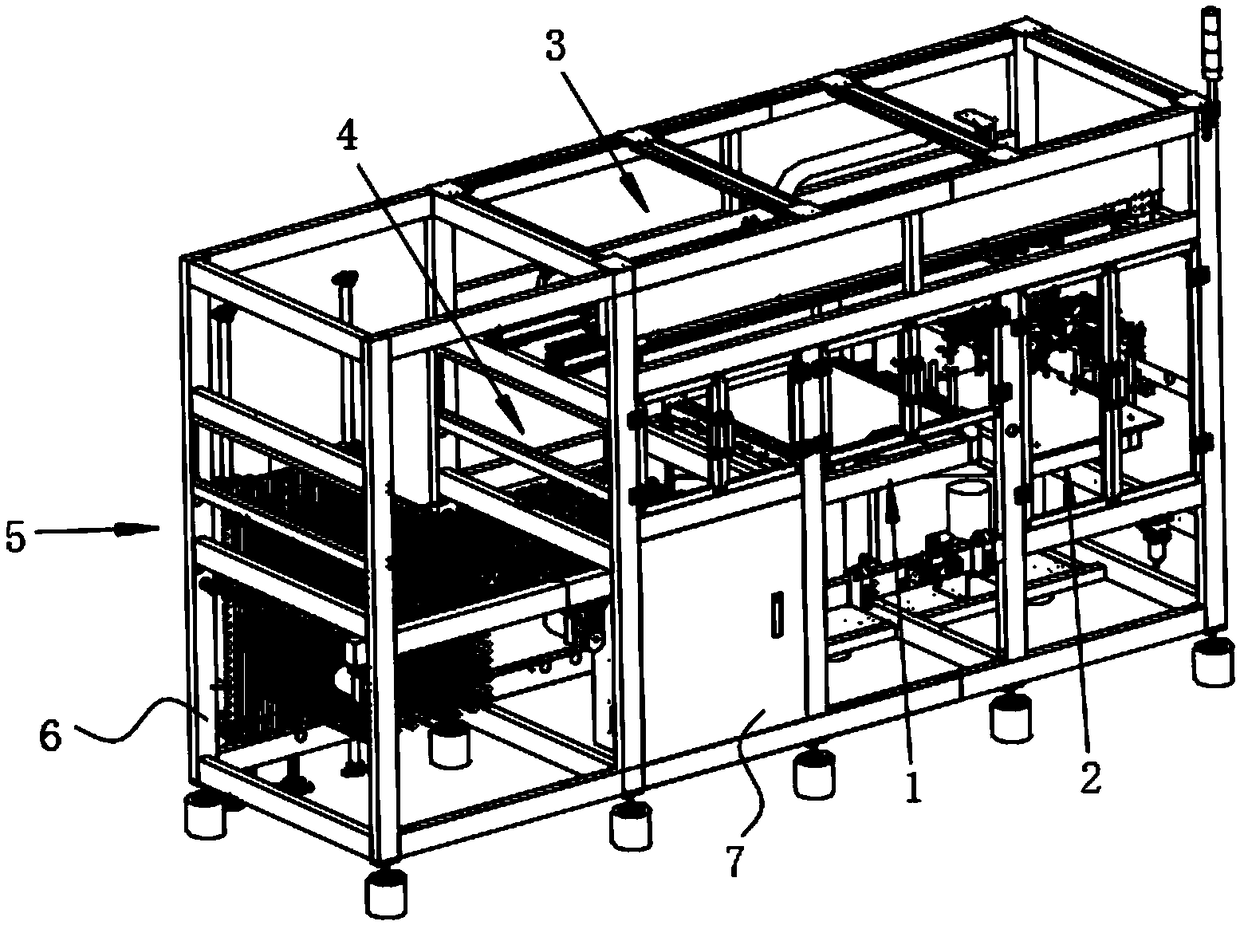

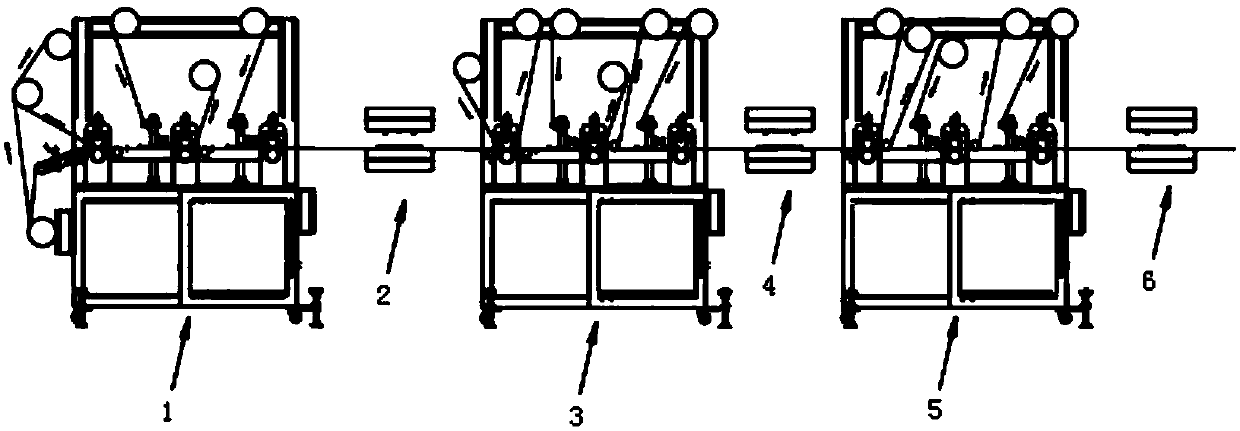

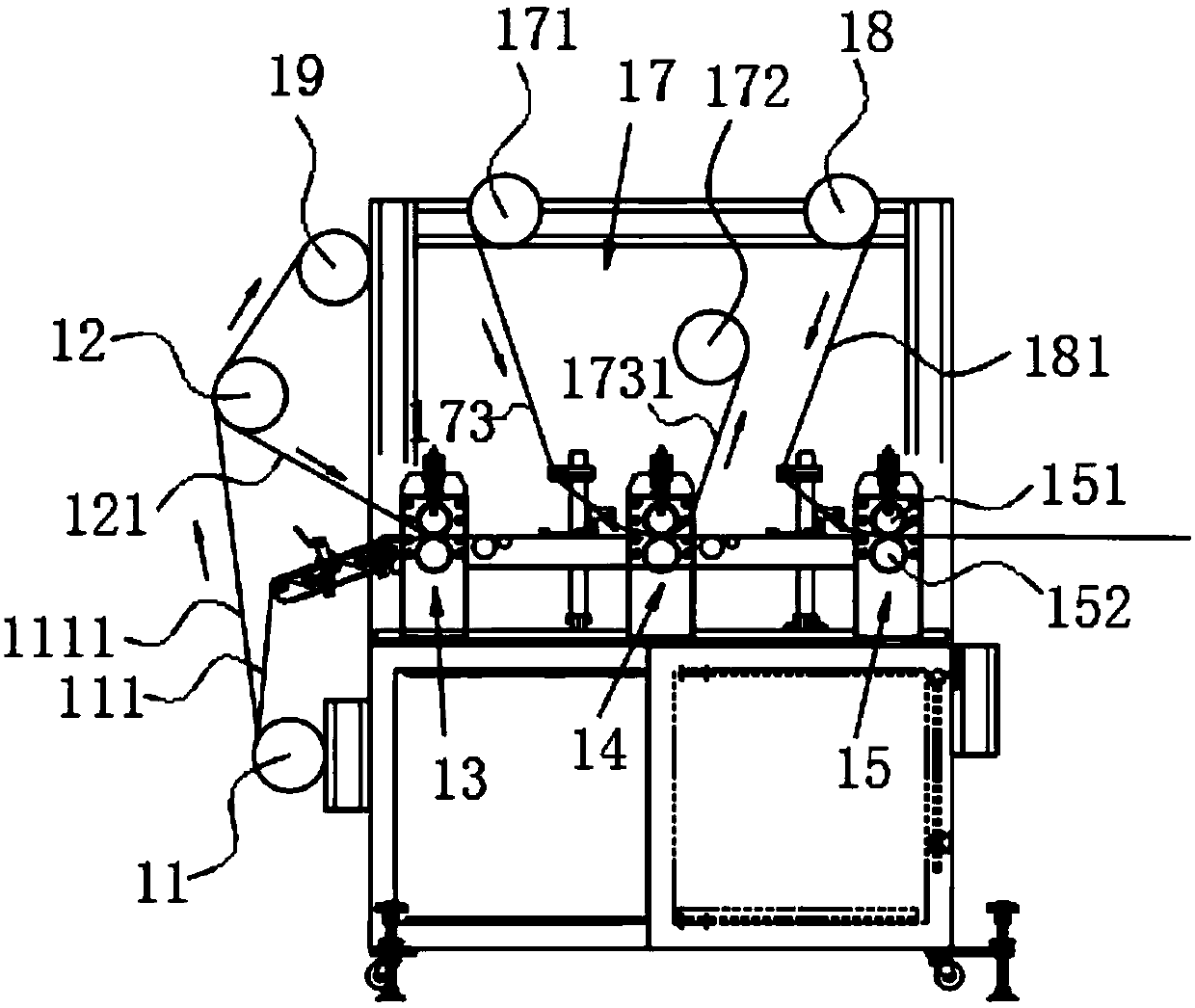

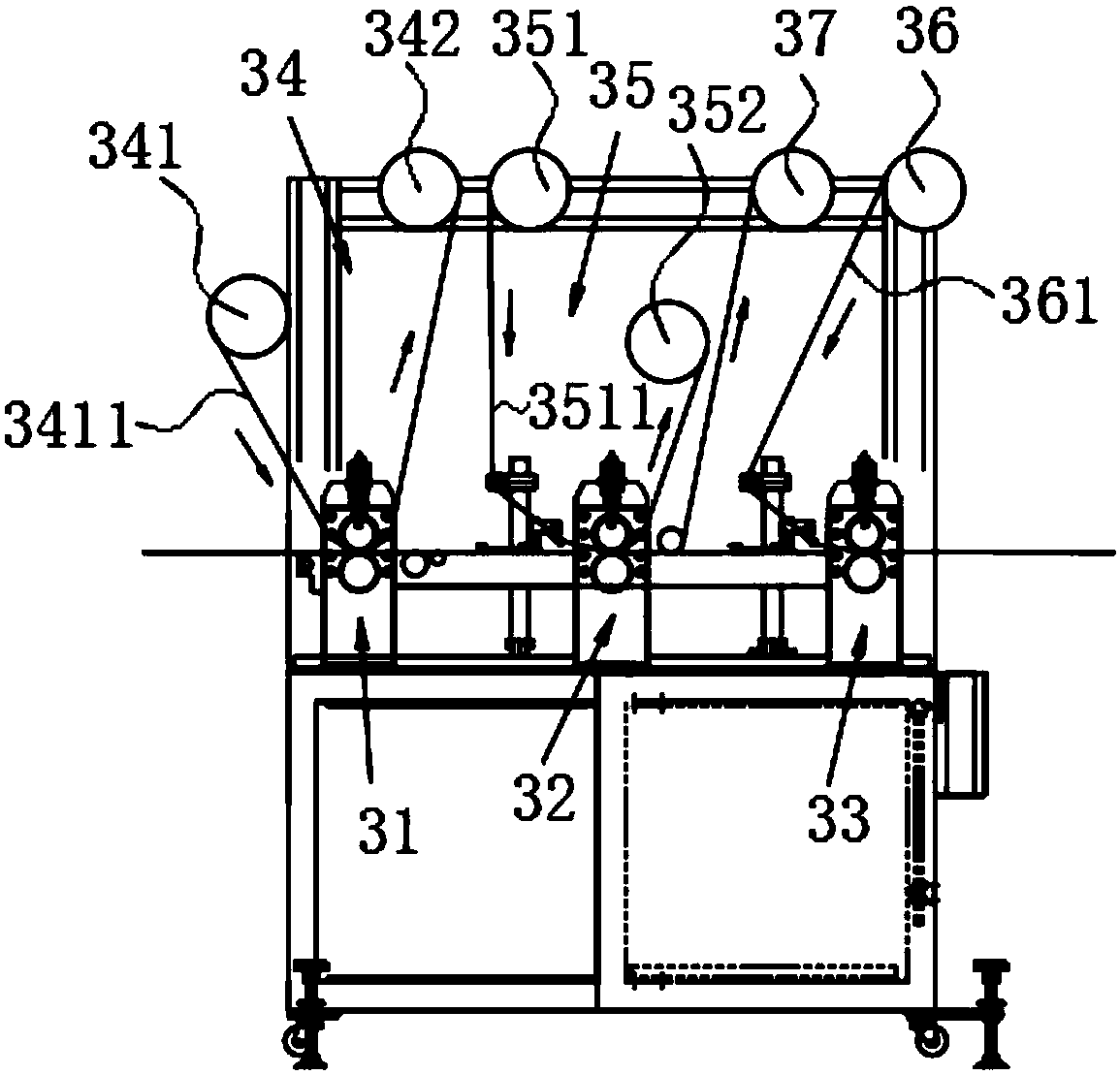

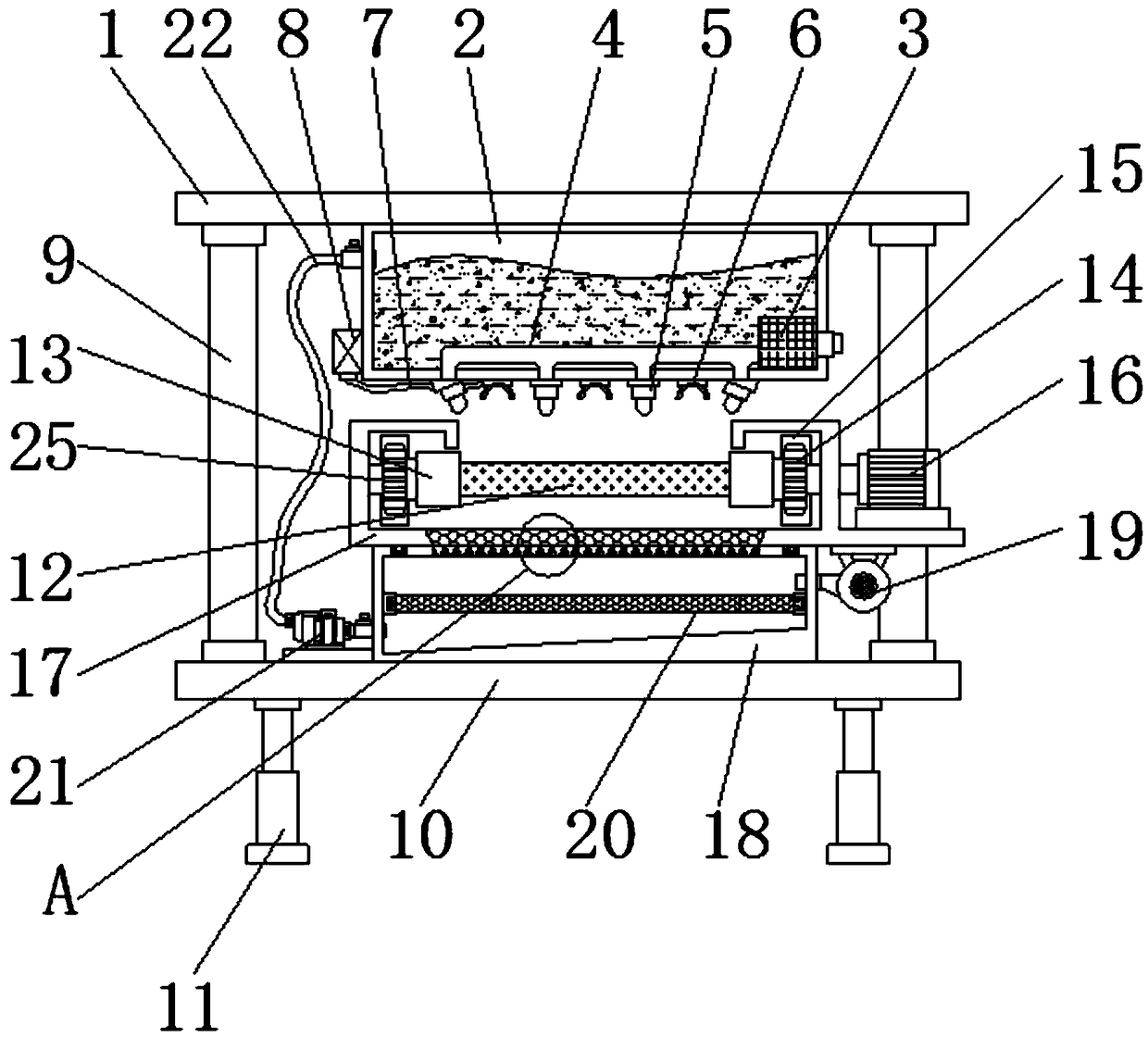

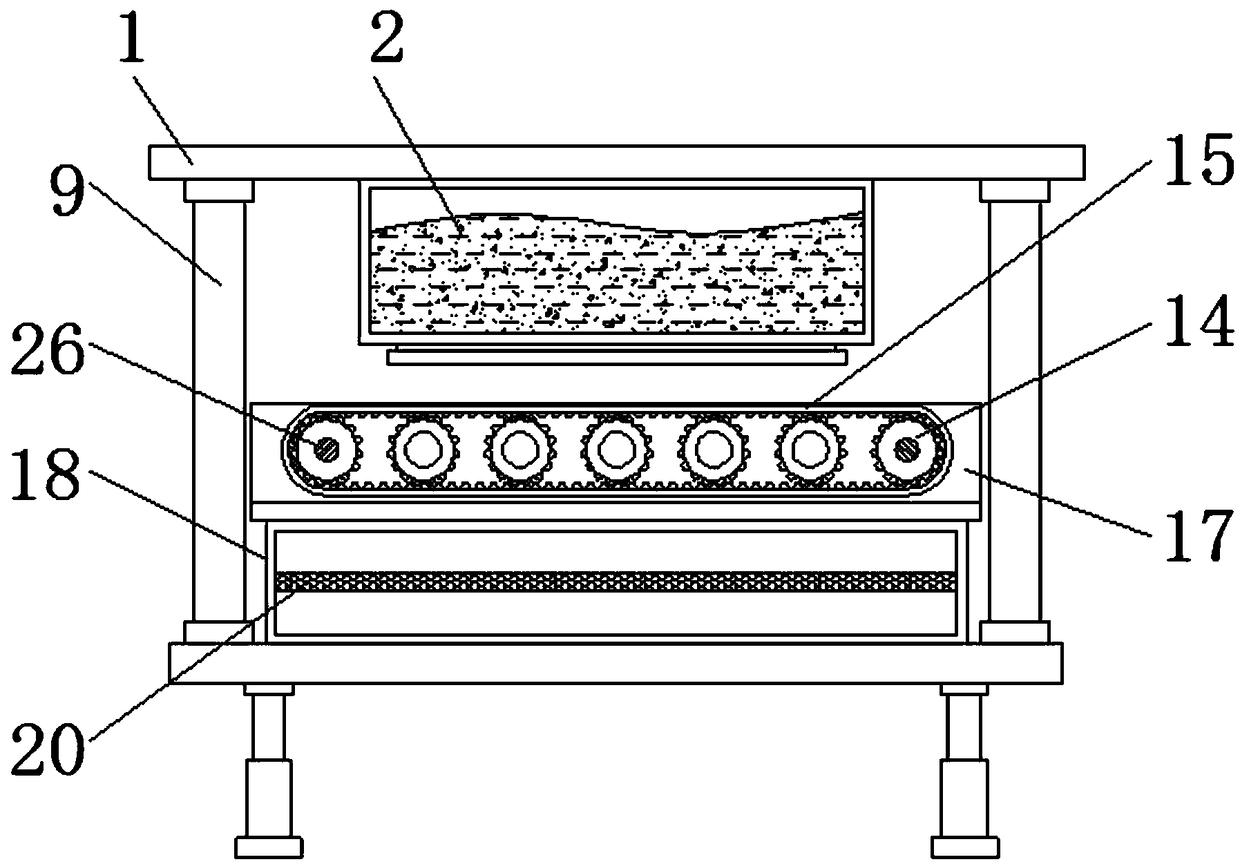

Automatic spool replacing device for woolen sweater fabric weaving

PendingCN110077906AHigh degree of automationImprove replacement efficiencyConveyorsFilament handlingYarnEngineering

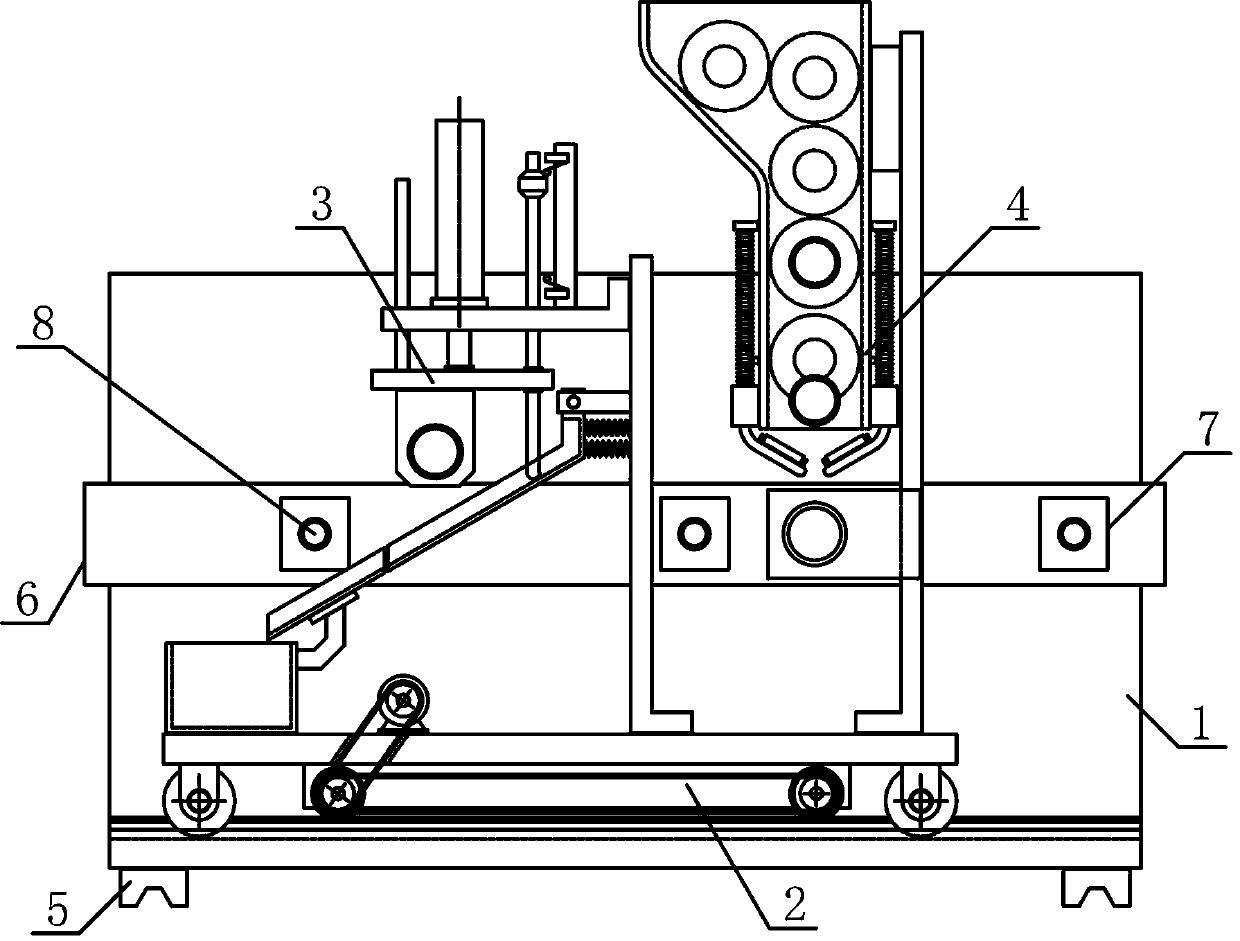

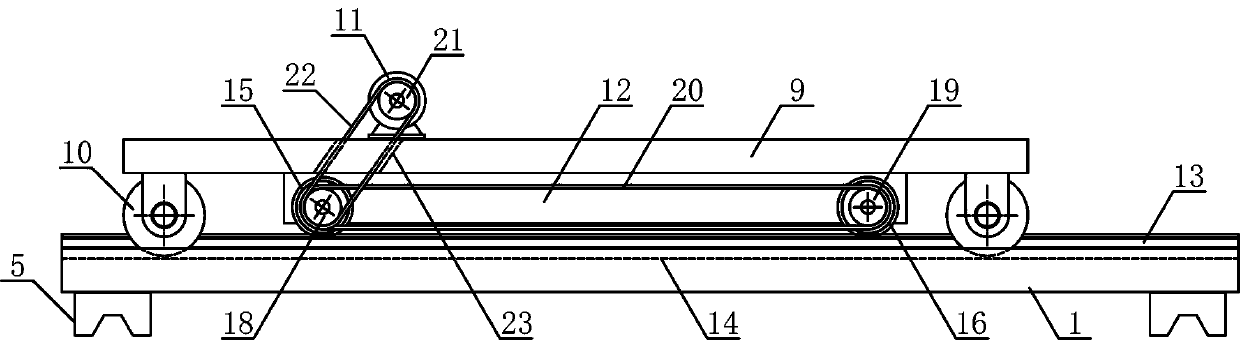

The invention discloses an automatic spool replacing device for woolen sweater fabric weaving and belongs to the field of textile and garment machining mechanical devices. An empty spool discharging mechanism and a full spool feeding mechanism are sequentially and vertically arranged on the two sides of the upper side of a reciprocating horizontal movement mechanism in the horizontal direction. Air expansion rotating shafts are horizontally and rotationally connected to yarn conveying bases. The two sides of the lower side of a reciprocating support are symmetrically and rotationally connectedwith two horizontal movement guide wheels correspondingly. The output end of a lifting air cylinder is horizontally and fixedly provided with a spool fetching connection plate. The end of the upper side of a rotational sliding groove is hinged to a rotating support seat. A fixed sliding groove is fixedly arranged on the upper side of a spool holding material frame in the inclined direction. The upper side of a full-spool holding pipe is provided with a full-spool storage hopper in a communicating manner. The lower end of a full-spool falling guide rod is fixedly provided with a full-spool bearing inclined rod. A full-spool pushing connection plate is fixedly arranged at the output end of the full-spool pushing air cylinder. The automatic spool replacing device for woolen sweater fabric weaving is reasonable in structural design and can achieve one-by-one continuous feeding and replacing of the spool after yarn taking-off is completed, the automation degree of spool replacement is improved, and production and use demands are met.

Owner:浙江富士佳实业有限公司

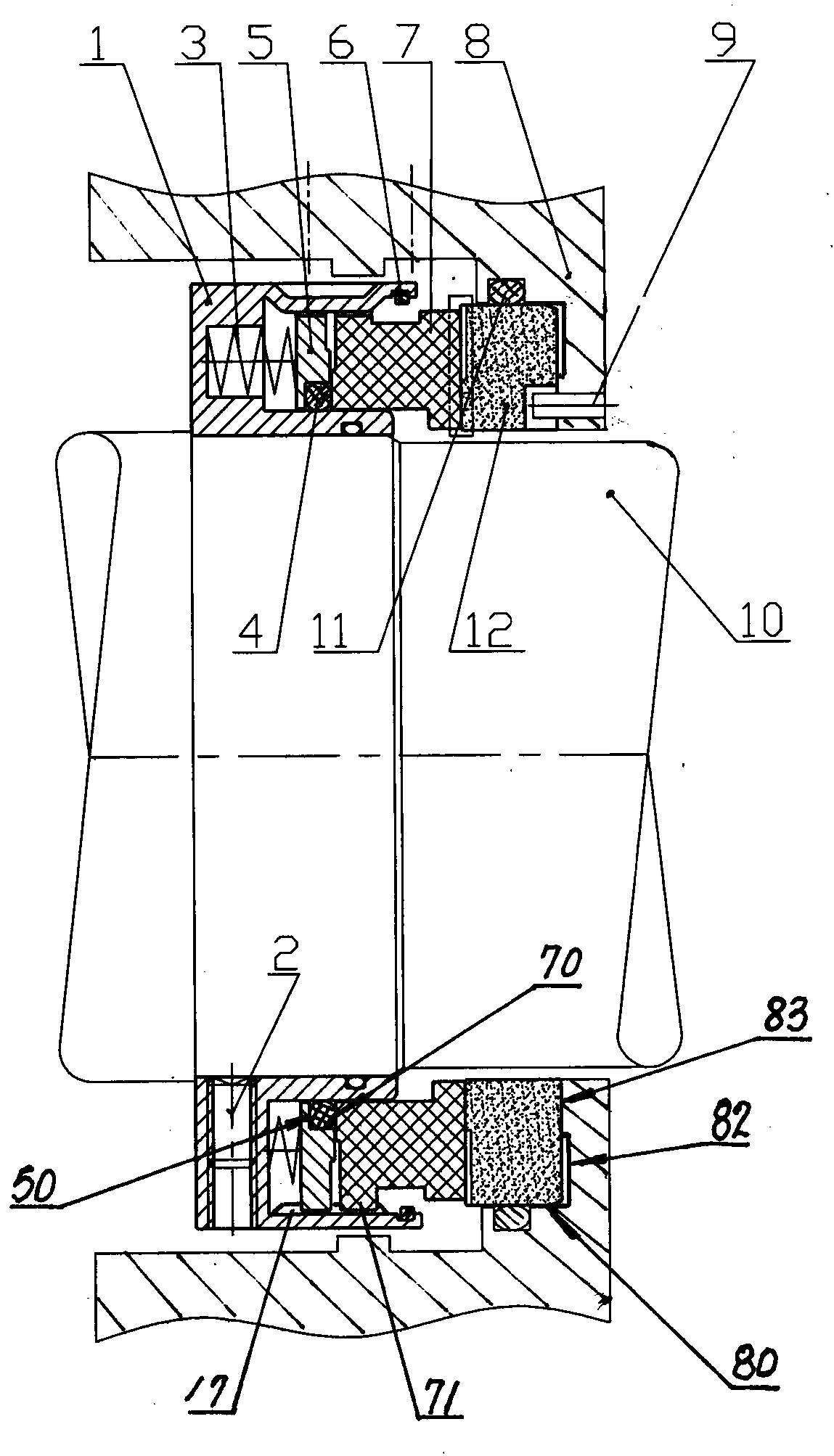

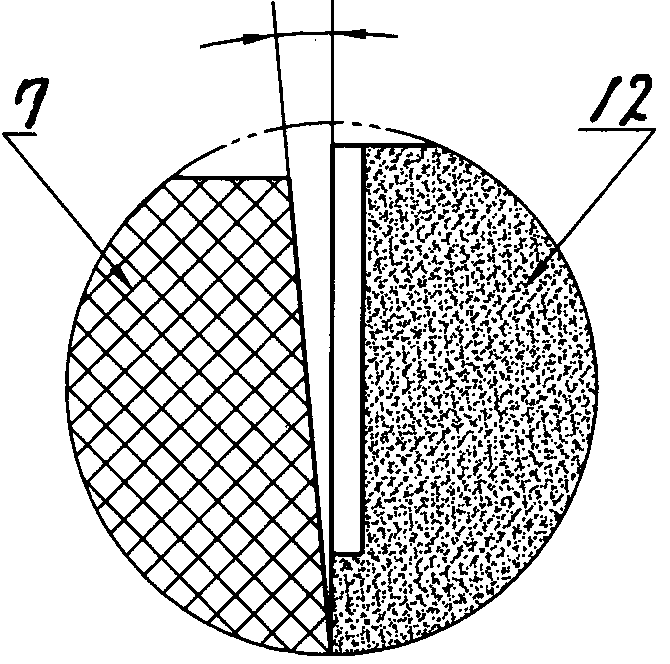

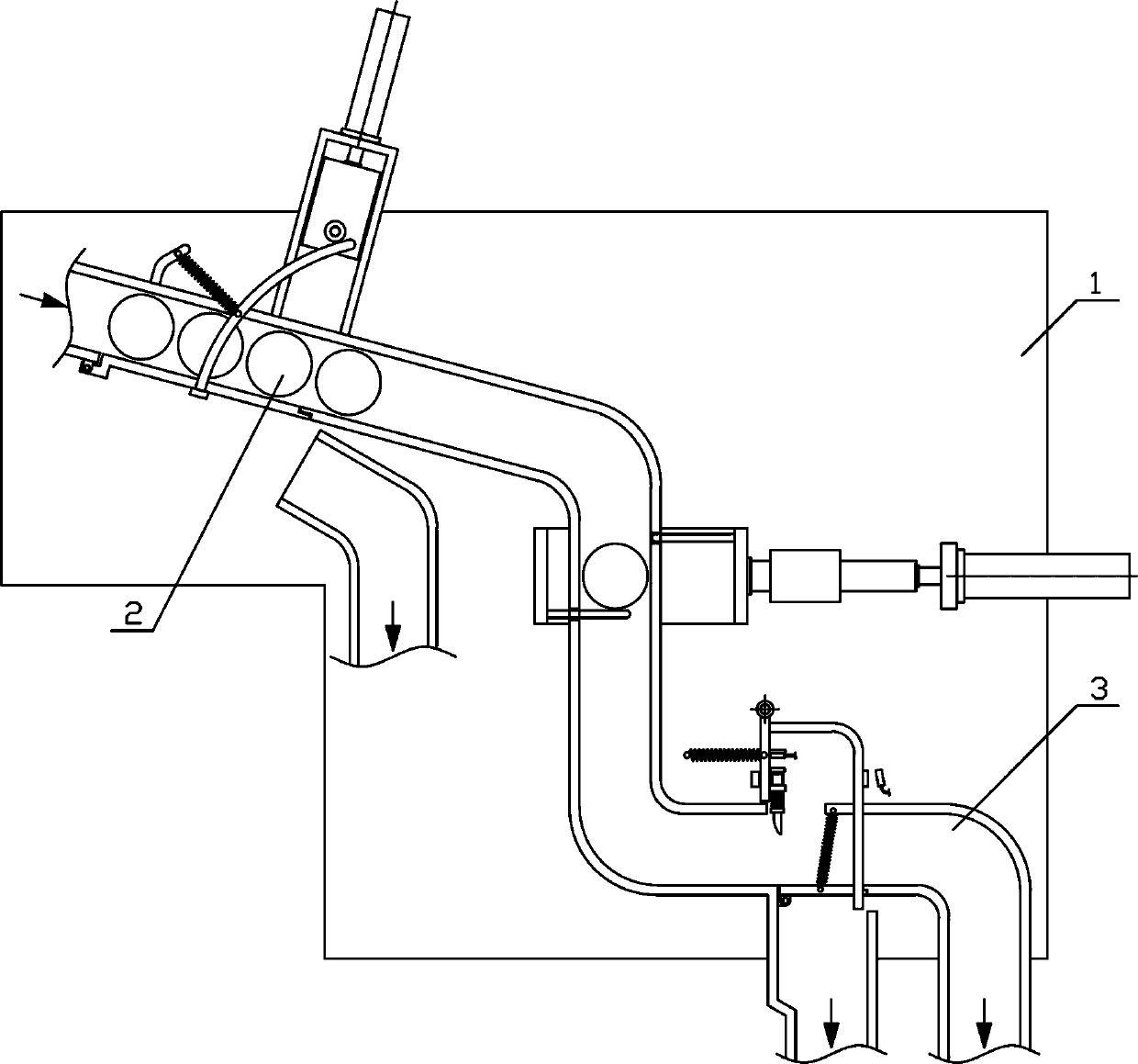

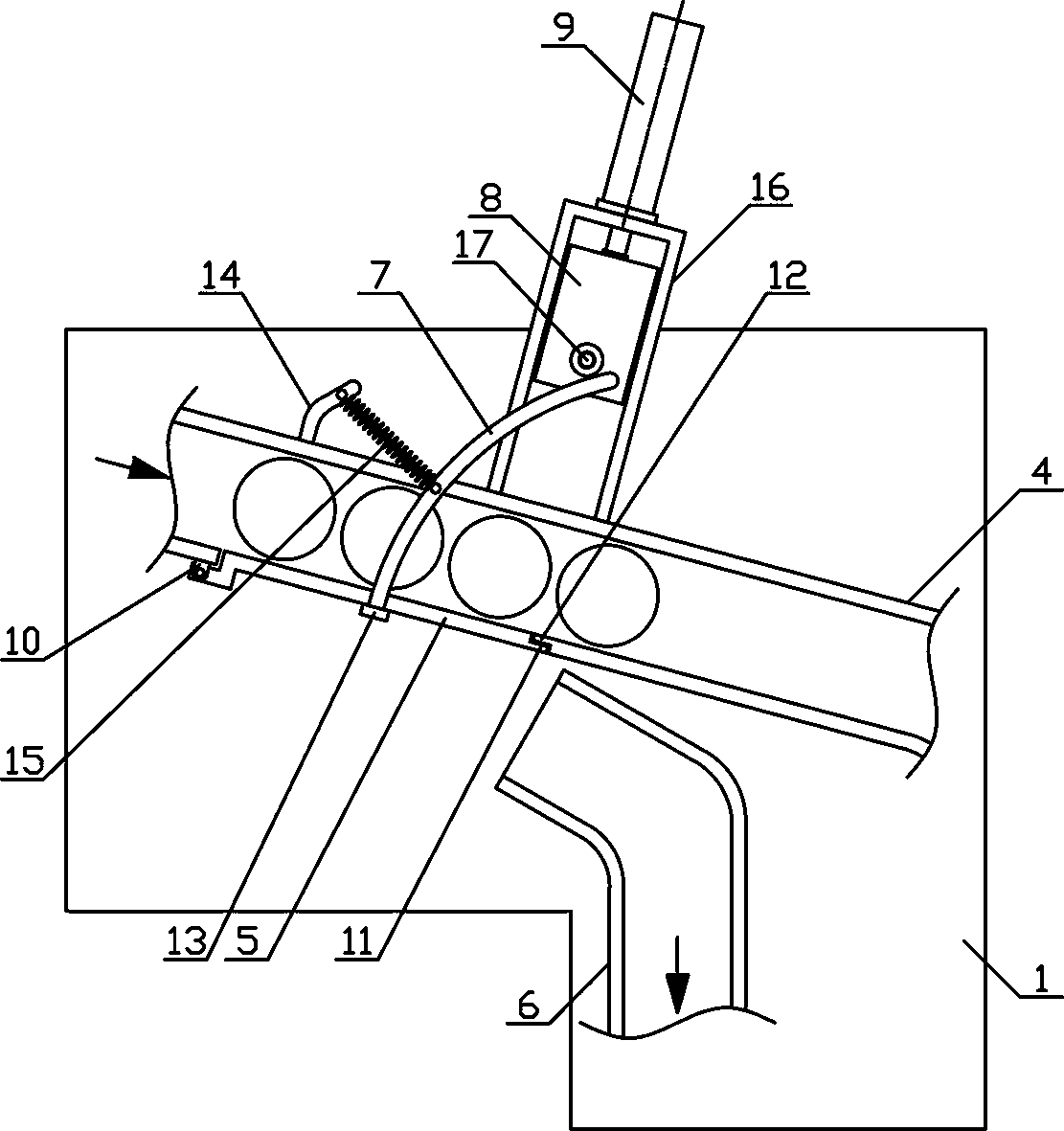

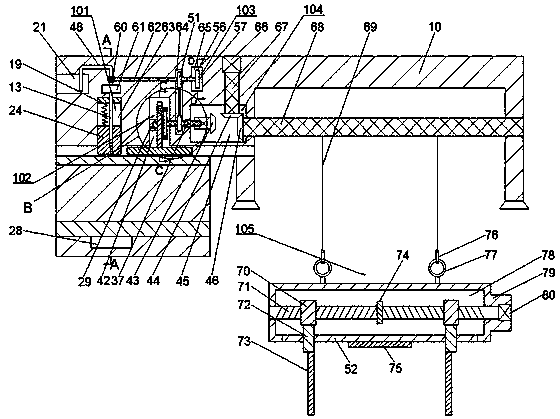

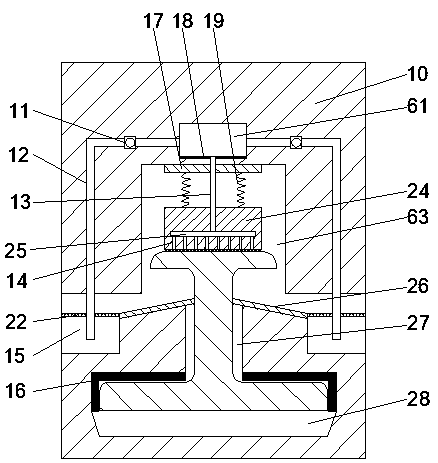

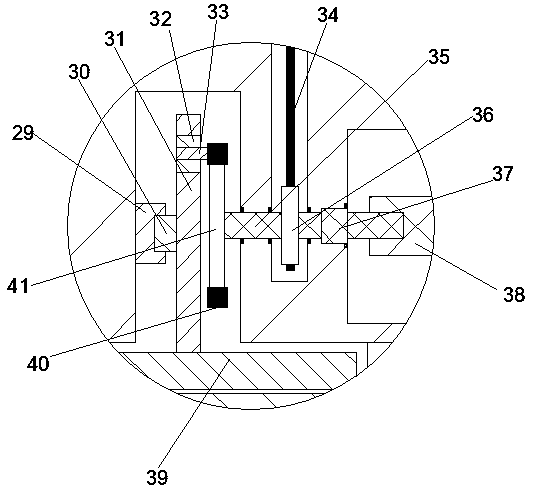

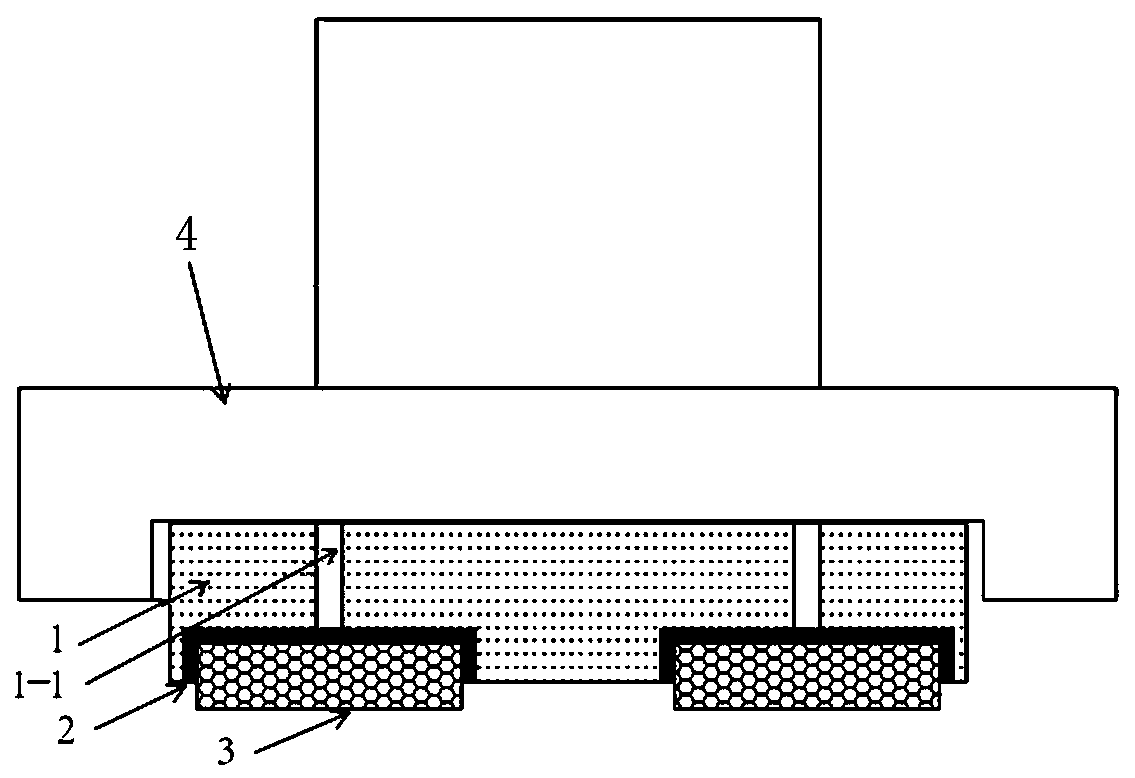

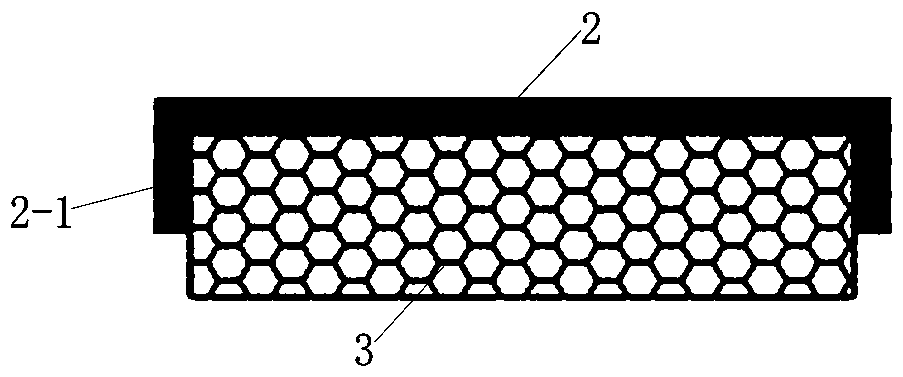

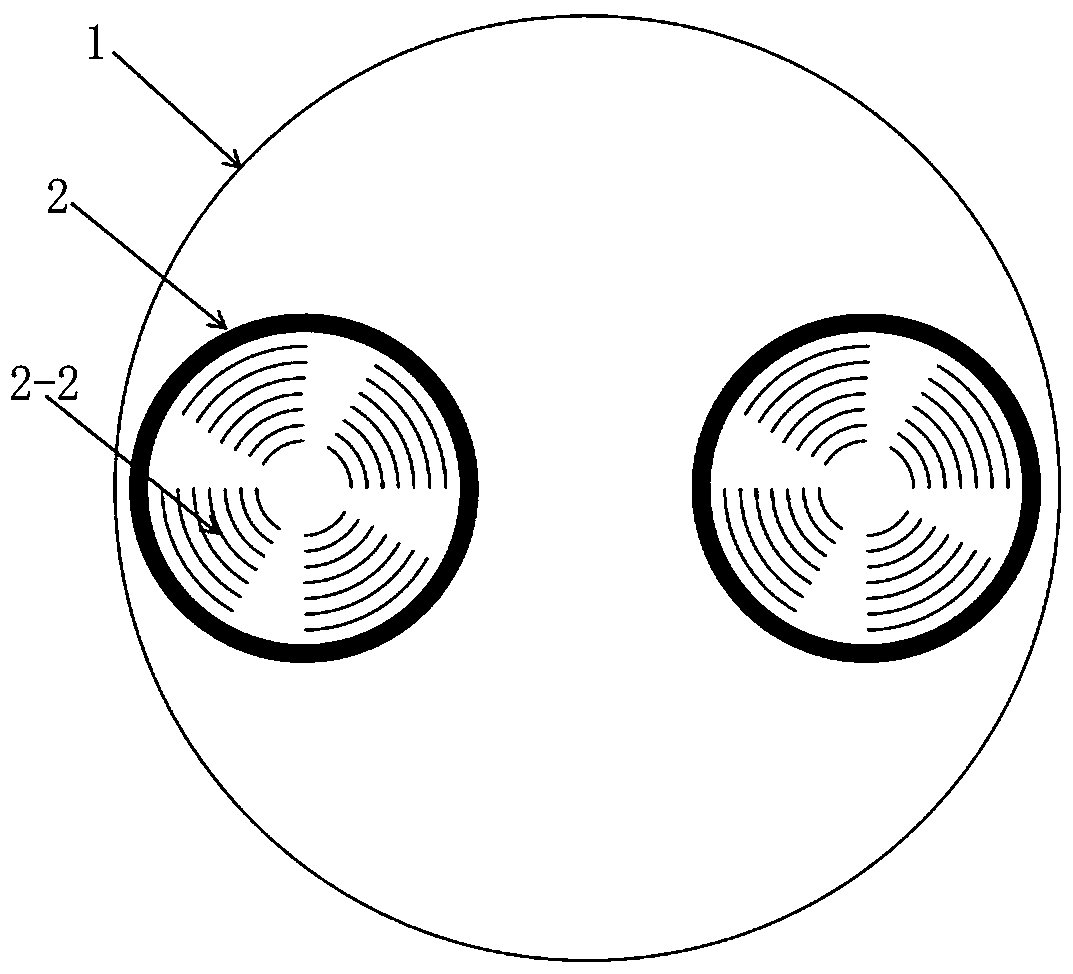

Mechanical dry gas sealing device for pumps

ActiveCN103486268AReduce frictional resistanceGood followabilityEngine sealsInterference resistanceEngineering

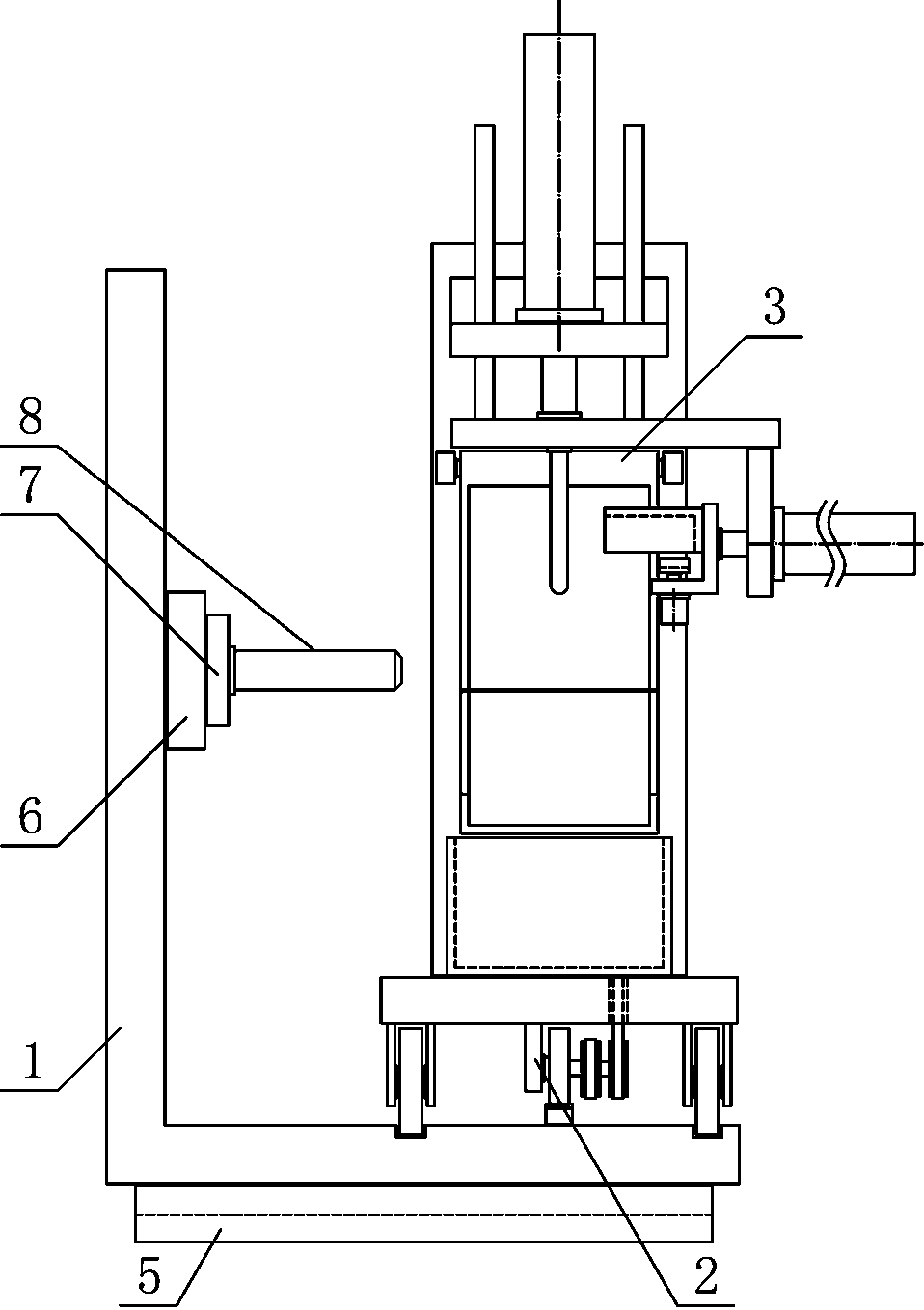

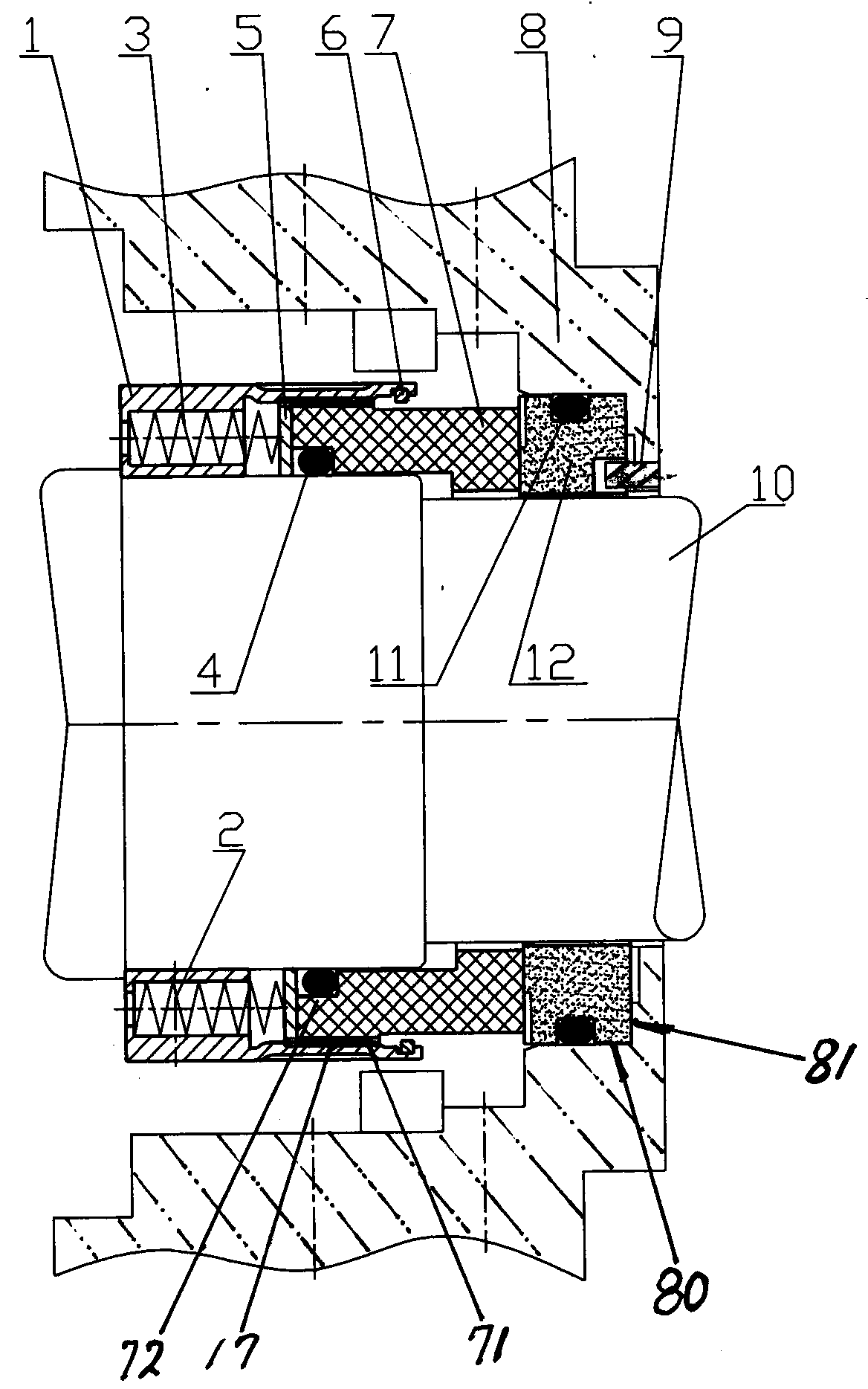

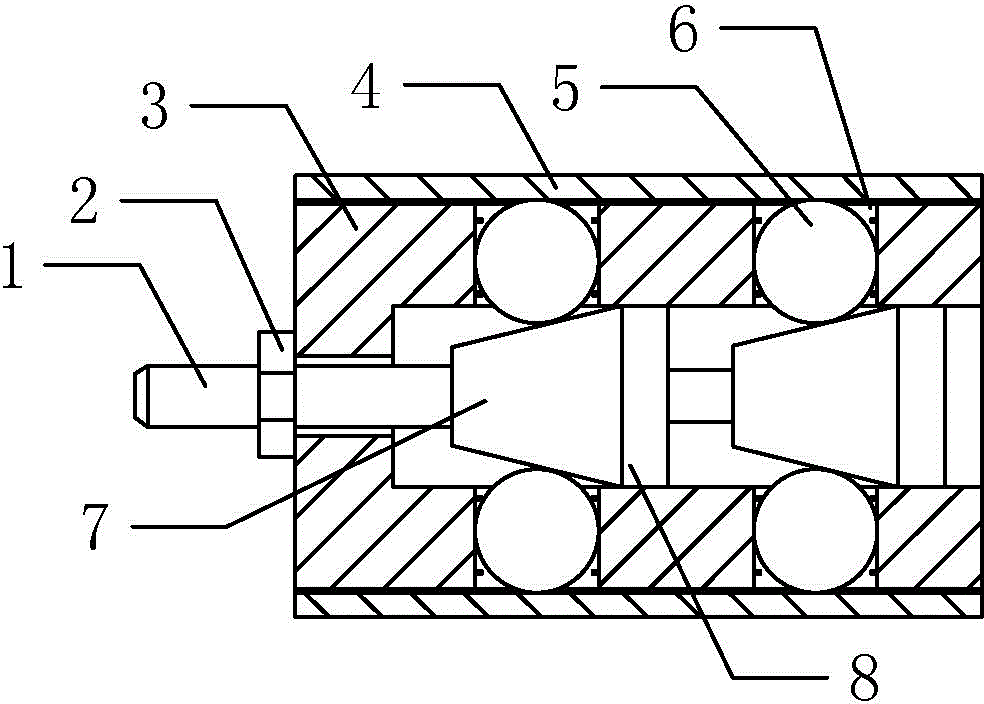

The invention discloses a mechanical dry gas sealing device for pumps. The mechanical dry gas sealing device comprises a movable ring component and a fixed ring component, wherein the movable ring component comprises a spring box (1), a stopper screw (2), a spring (3), a sealing ring (4), a pushing ring (5), a snap spring (6) and a movable ring (7), and the fixed ring component comprises a fixed ring (12), an anti-rotating pin (9), a sealing ring (11) and a gland (8). The mechanical dry gas sealing device is characterized in that the sliding sealing ring (4) is mounted in a seam allowance groove (50) on the inner diameter of the front end of the pushing ring (5), the pushing ring (5) is in close fit with the rear end face (70) of the movable ring (7), and compression rate of the O-shaped sliding sealing ring (4) ranges from 2% to 5%. A sealing end face of the movable ring (7) of a compensation ring is a conical surface. A boss (83) is arranged on the inner diameter of a vertical end face (82) mounting a seam allowance groove (80) of the fixed ring (12) and is matched with the inner diameter of the inner end face of the fixed ring (12) in a support manner. An end face of the compensation ring of the mechanical dry gas sealing device is good in adherence. Besides, the mechanical dry gas sealing device is stable to run, high in interference resistance, good in sealing performance and suitable for diversified working conditions.

Owner:DANDONG COLOSSUS GROUP

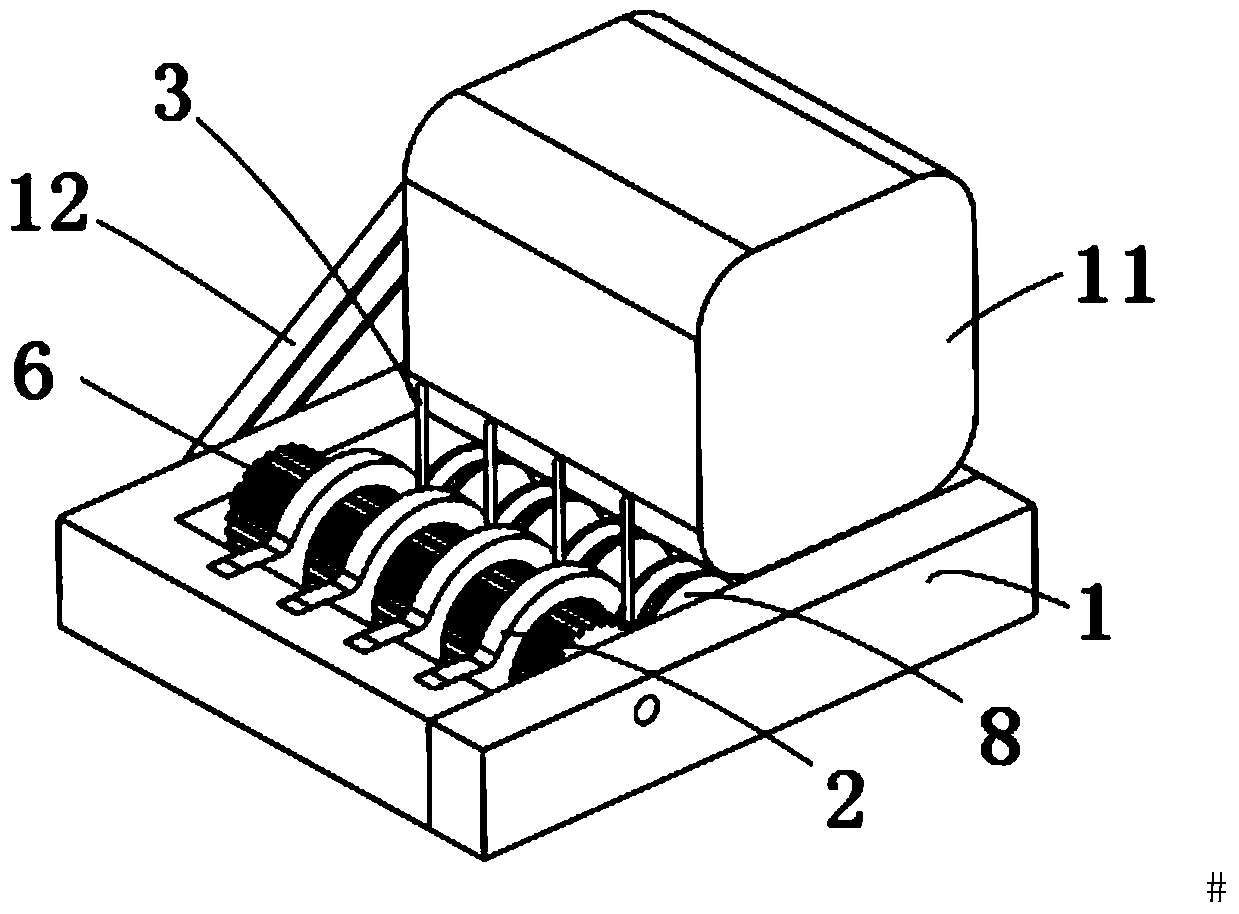

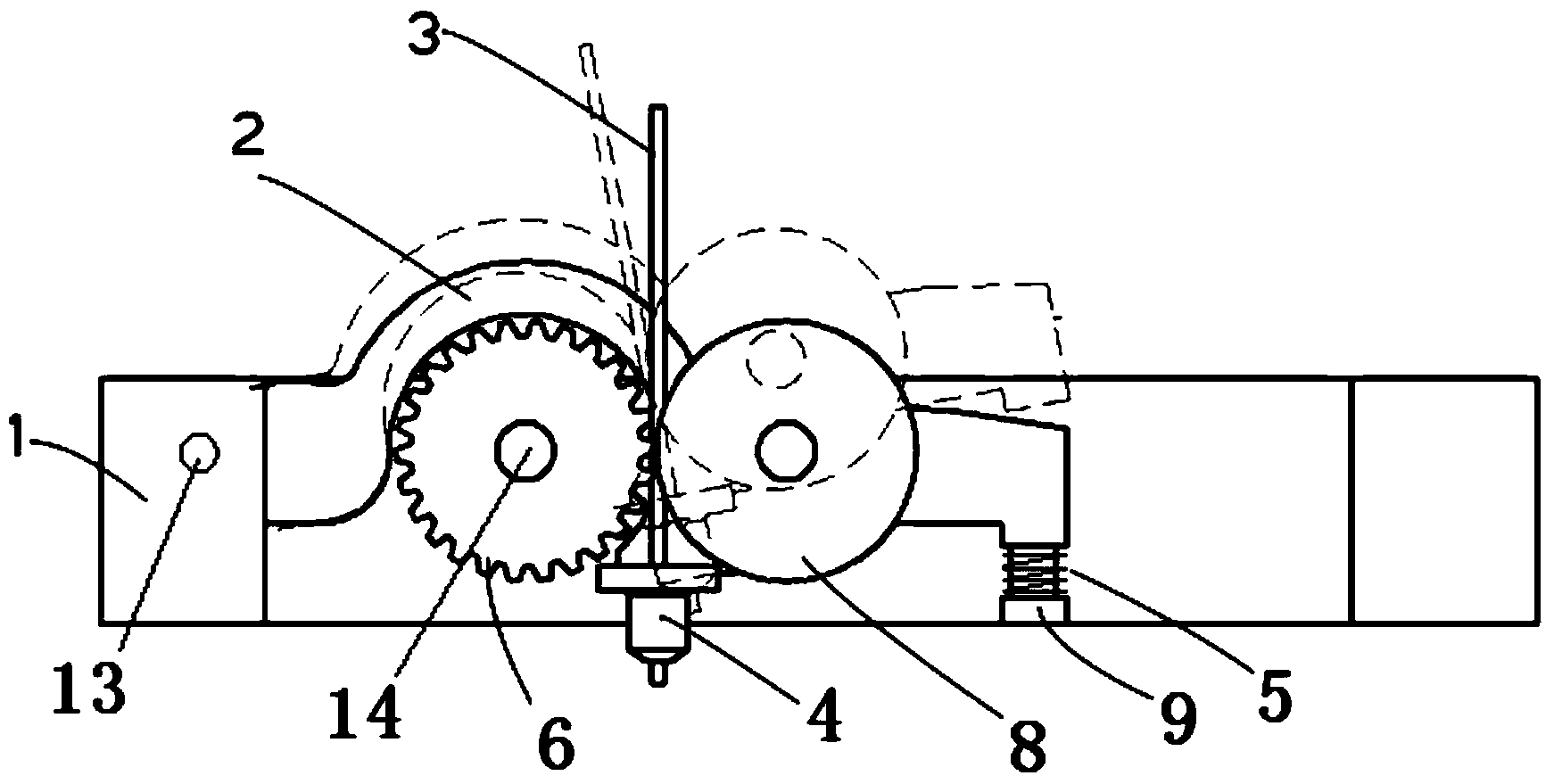

Expandable multi-material sprayer system for 3D (Three-Dimensional) printing

The invention discloses an expandable multi-material sprayer system for 3D (Three-Dimensional) printing. The system comprises a base, a plurality of wire feed units and a driving unit, wherein each wire feed unit comprises a connecting rod, a nozzle, a first wire feed wheel, a second wire feed wheel and an electromagnet; one end of each connecting rod is hinged on one side of the base through an installation base; the second wire feed wheels of the wire feed units are installed on the base through one rotary shaft; the first wire feed wheels and the nozzles are installed on the connecting rods; a plurality of electromagnets corresponding to the other ends of the connecting rods are fixedly arranged on the base; the driving unit for driving the rotary shaft to rotate is installed on the base. According to the system disclosed by the invention, on the premise of not adding the quantity of motors, the wire feed units can be expanded according to demand; whether each wire feed unit works or not is randomly controlled; the nozzles on the wire feed units in work are lower than other nozzles in a non-working state in position when the connecting rods swing downward, so that the surface of a part in the process of 3D printing by the nozzles in the non-working state is prevented from being scratched and damaged.

Owner:XI AN JIAOTONG UNIV +1

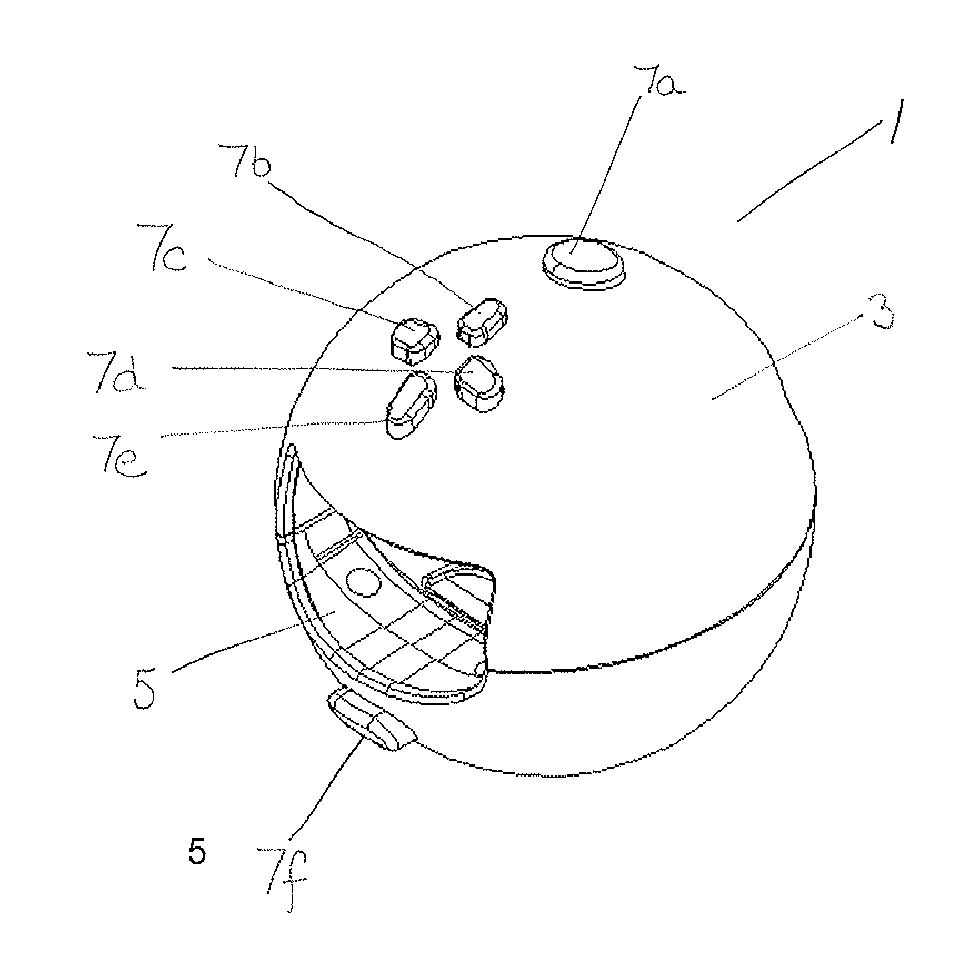

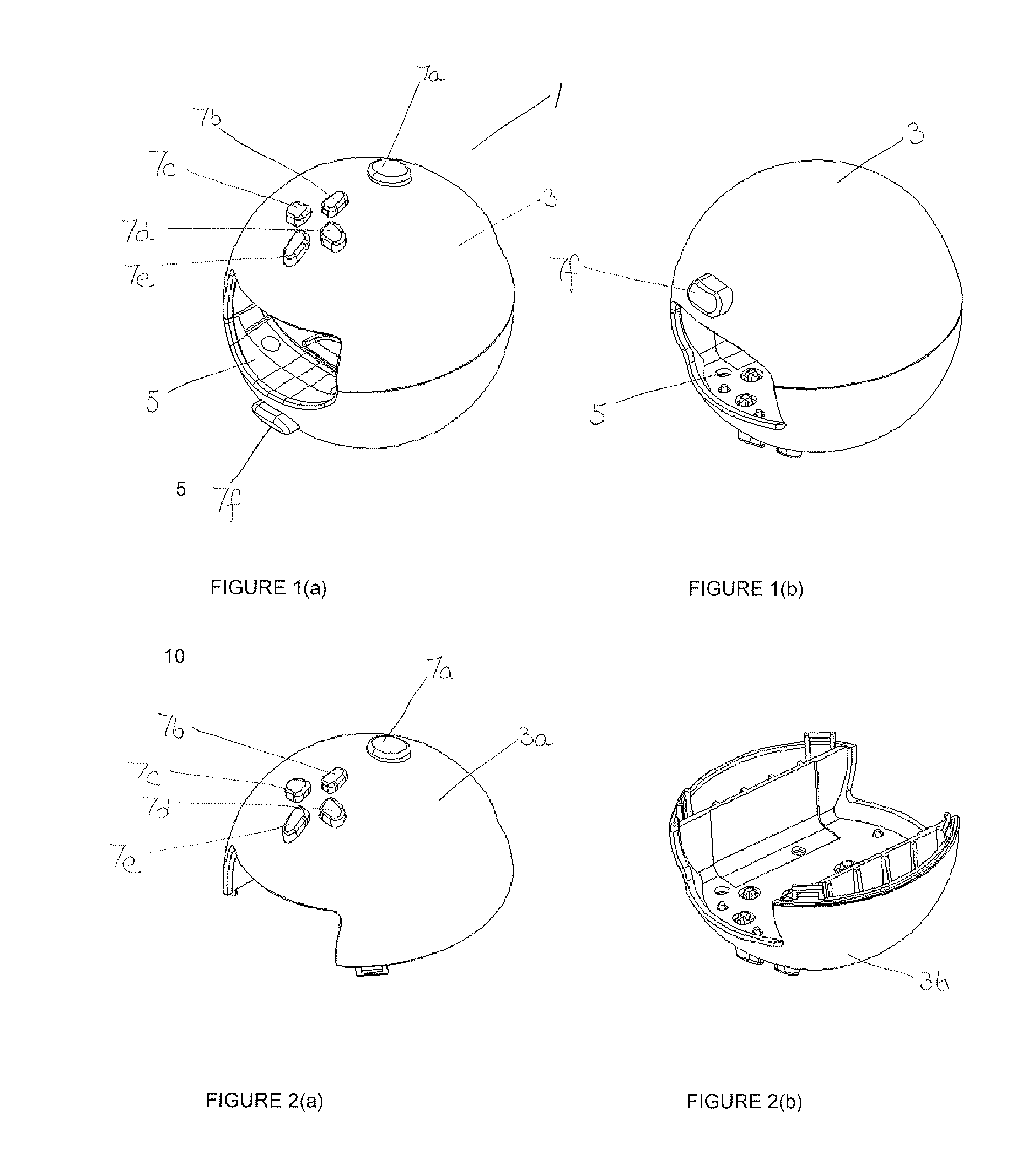

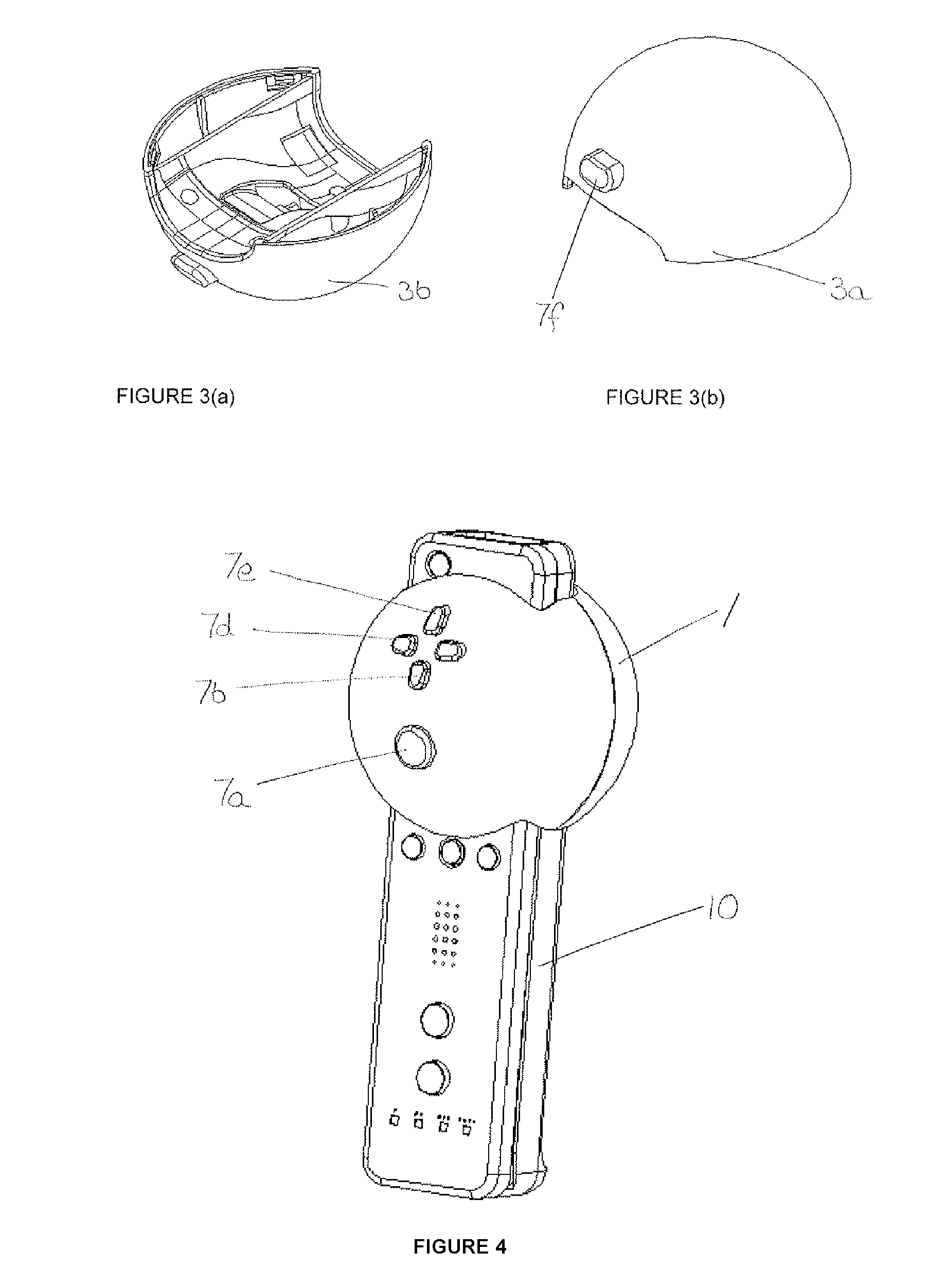

Accessory for a game console controller

InactiveUS20120252584A1Improve gaming experienceAvoid scratch damageVideo gamesSpecial data processing applicationsEngineeringActuator

An accessory for electronic gaming that can receive part of a game console controller. The accessory has one or more actuators for operating one or more press buttons of the controller.

Owner:FUTURETRONICS COM AU

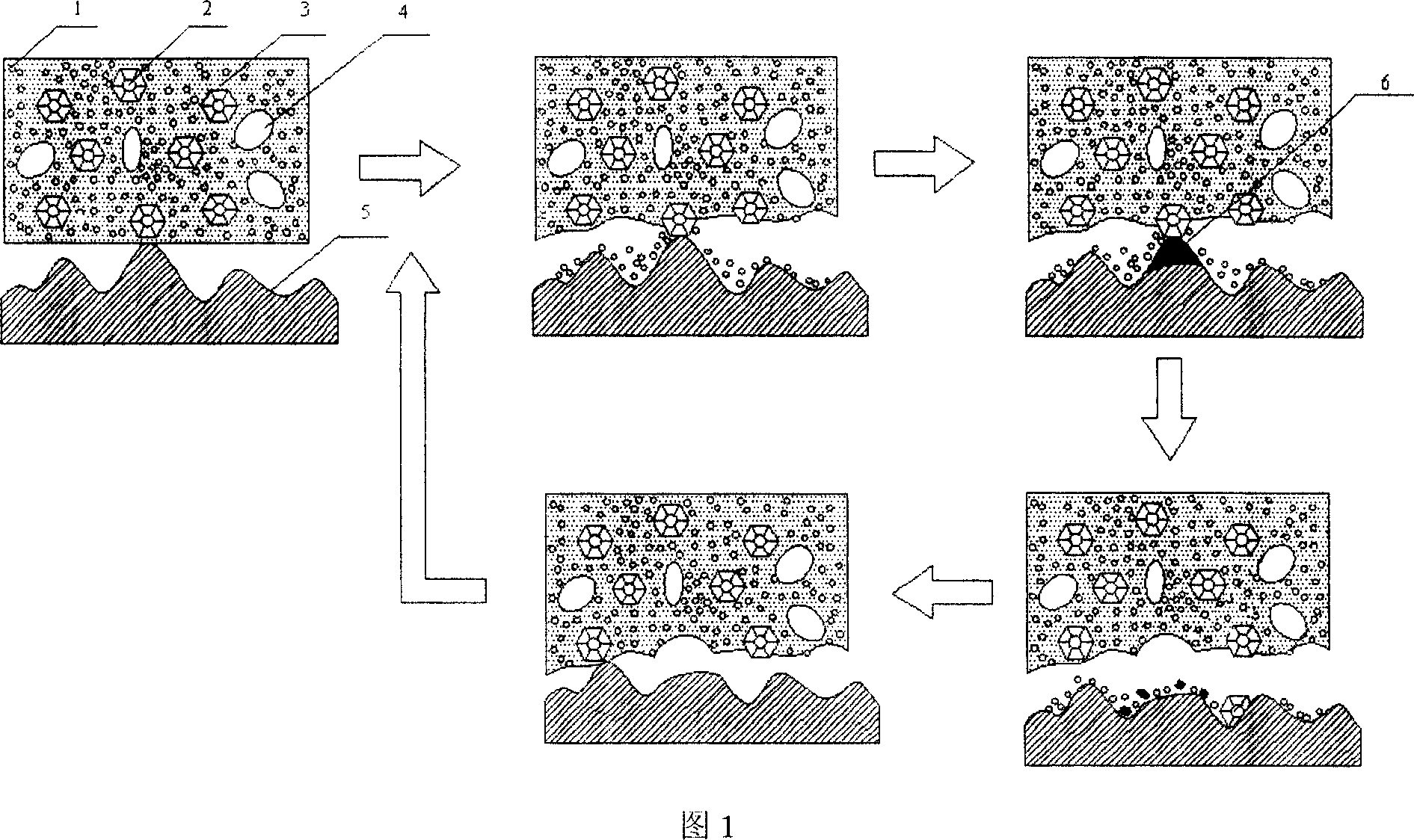

Scatheless grinding method for rigid, fragile crystal wafer

ActiveCN1958233AImprove grinding accuracyReduce processing costsAbrasion apparatusSemiconductor/solid-state device manufacturingIonCooling fluid

A nondestructive grinding method for the hard and crisp crystal substrate of semiconductor or photoelectric crystal features used of a special abrasive disc prepared from the grinding material chosen from CeO2, SiO2 and barium carbonate and the filler containing activator, oxidant and pH regulator, a finishing disc composed of metallic substrate and electroplated diamond particles, and a deionized water as cooling liquid. Its grinding parameters are also disclosed.

Owner:DALIAN UNIV OF TECH

Automatic pipe fitting path distribution conveying mechanism

InactiveCN108674955AAvoid stackingTo achieve the effect of diversionConveyorsConveyor partsPipe fittingMechanical equipment

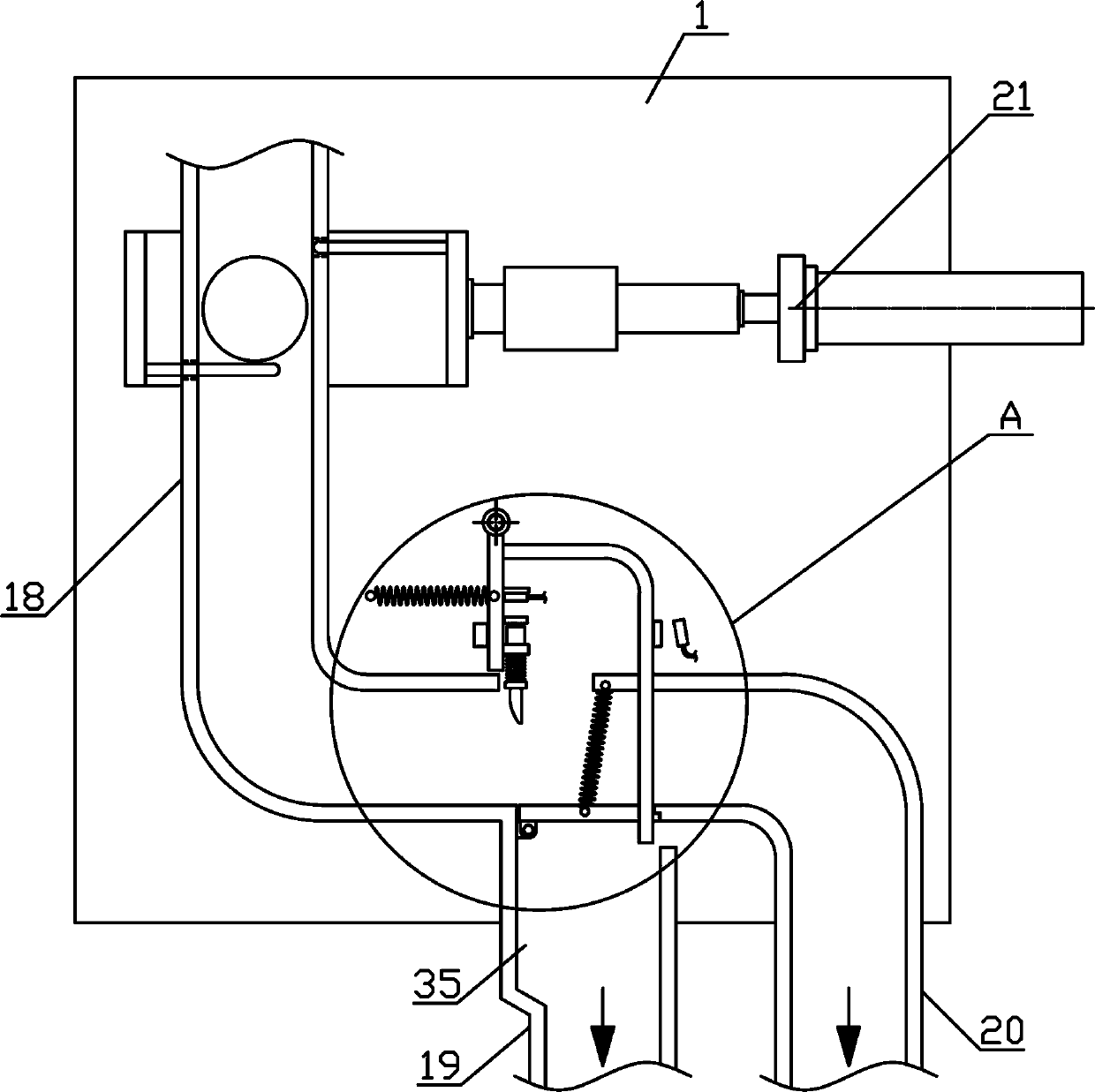

The invention discloses an automatic pipe fitting path distribution conveying mechanism, and belongs to the field of workpiece machining conveying mechanical equipment. A guide pipe mechanism and a path distribution mechanism of the automatic pipe fitting path distribution conveying mechanism are sequentially arranged on one side of a fixed bracket from top to bottom; a distribution pipe materialpipe is obliquely arranged in the position, on the lower side of a guide pipe material pipe, of the fixed bracket; the lower side of the guide pipe material pipe is provided with a bearing pipe baffle; the upper end of a material supplying pipe communicates with the lower end of the guide pipe material pipe; a front path distribution material pipe is vertically arranged in the middle of the lowerside of the material supplying pipe, and a rear path distribution material pipe is vertically arranged at the tail end of the lower side of the material supplying pipe; a material separation mechanismis horizontally arranged on the upper side of the material supplying pipe; and the upper end of the front path distribution material pipe is provided with a rotary baffle, and one side of the lower end of a hook rotary plate located on one side of a reciprocating rotary plate is provided with a hook mechanism. The automatic pipe fitting path distribution conveying mechanism is reasonable in structural design, can stably and efficiently distribute pipe fittings into paths for conveying and can discharge the pipe fittings according to the rear path pipe fitting machining load requirement, the automation degree of pipe fitting path distribution conveying is increased, and the production using requirements are met.

Owner:海宁市波菲特进出口有限公司

Pipe fitting inside expansion clamping device

The invention discloses a pipe fitting inside expansion clamping device which comprises a positioning cylinder. The side wall of the positioning cylinder is provided with two sets of through holes, the centers of each set of the through holes are located on the same circumference, the circle center of the circumference is located on the axis line of the positioning cylinder, positioning balls are arranged in the through holes and in clearance fit with the through holes, and the diameter of the positioning balls is larger than the depth of the through holes; two conical tables are arranged in the positioning cylinder and face the same direction, both the big diameter ends of the two conical tables make contact with the inner wall of the positioning cylinder, the two conical tables abut against the positioning balls in the two sets of through holes respectively, a connection rod is arranged between the two conical tables, the small diameter ends, located on the outer sides of the conical tables, of the two conical tables are connected with a pull rod, and the pull rod stretches out of the positioning cylinder. The pipe fitting inside expansion clamping device overcomes the technical defects that a pipe fitting is easy to fracture when an existing pipe fitting clamp clamps the pipe fitting, and the existing pipe fitting clamp cannot finish pipe fitting outer wall machining at a time and achieves the purposes that the pipe fitting is not prone to fracture when the pipe fitting is clamped, and pipe fitting outer wall machining can be finished at a time.

Owner:CHONGQING YUANCHUANG AUTOMATION EQUIP

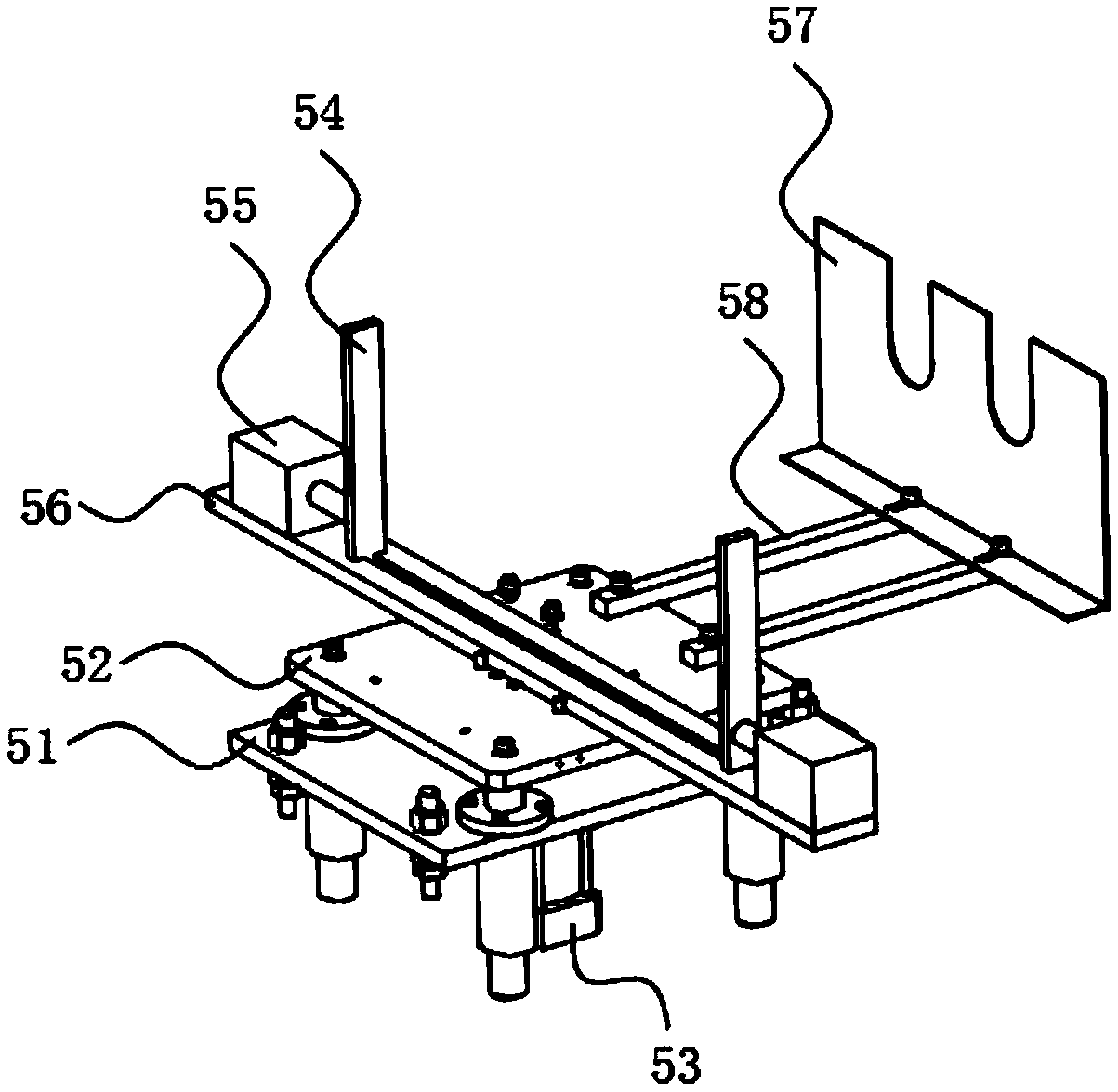

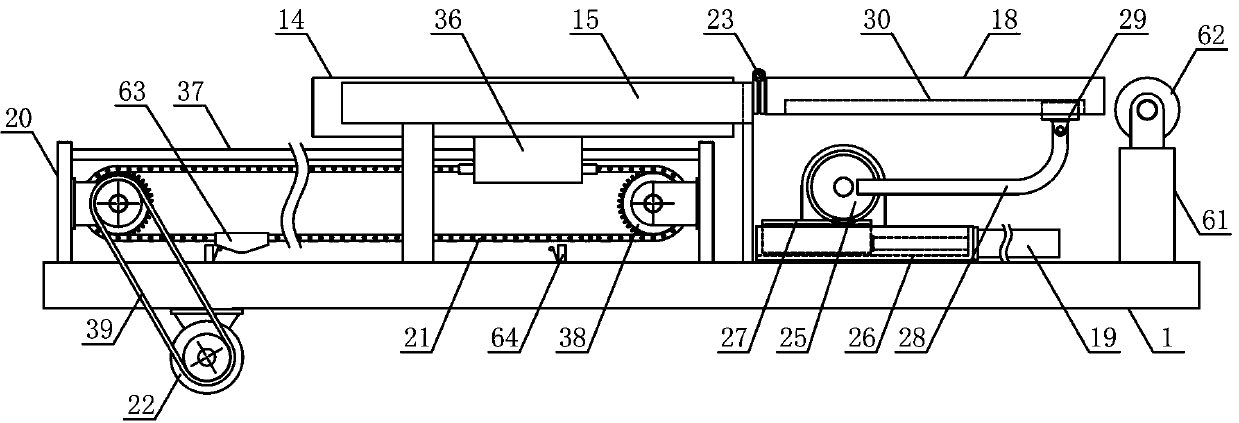

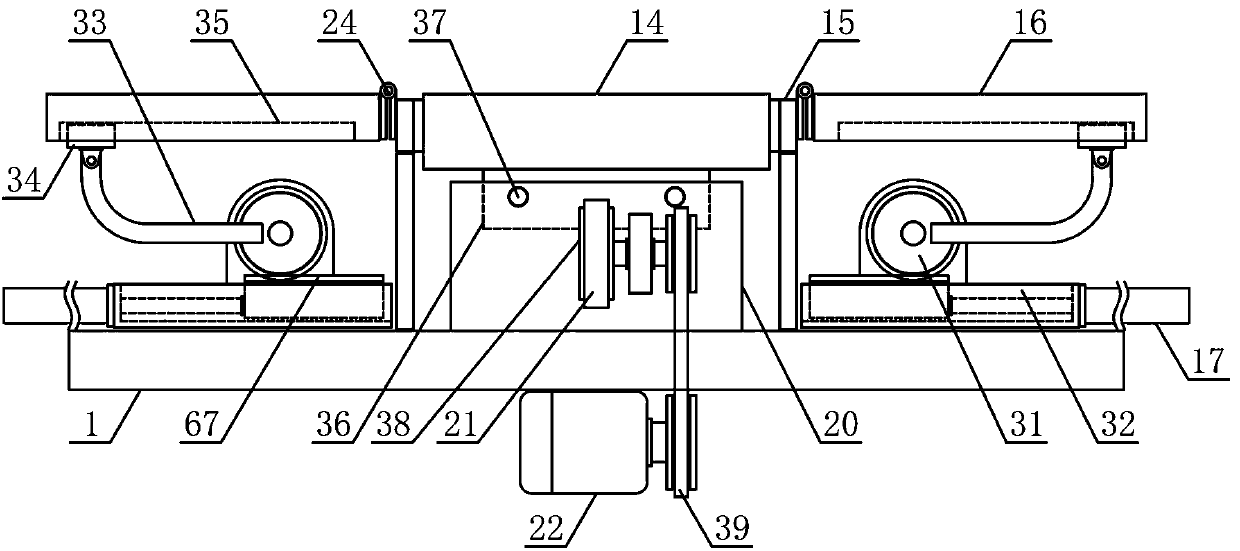

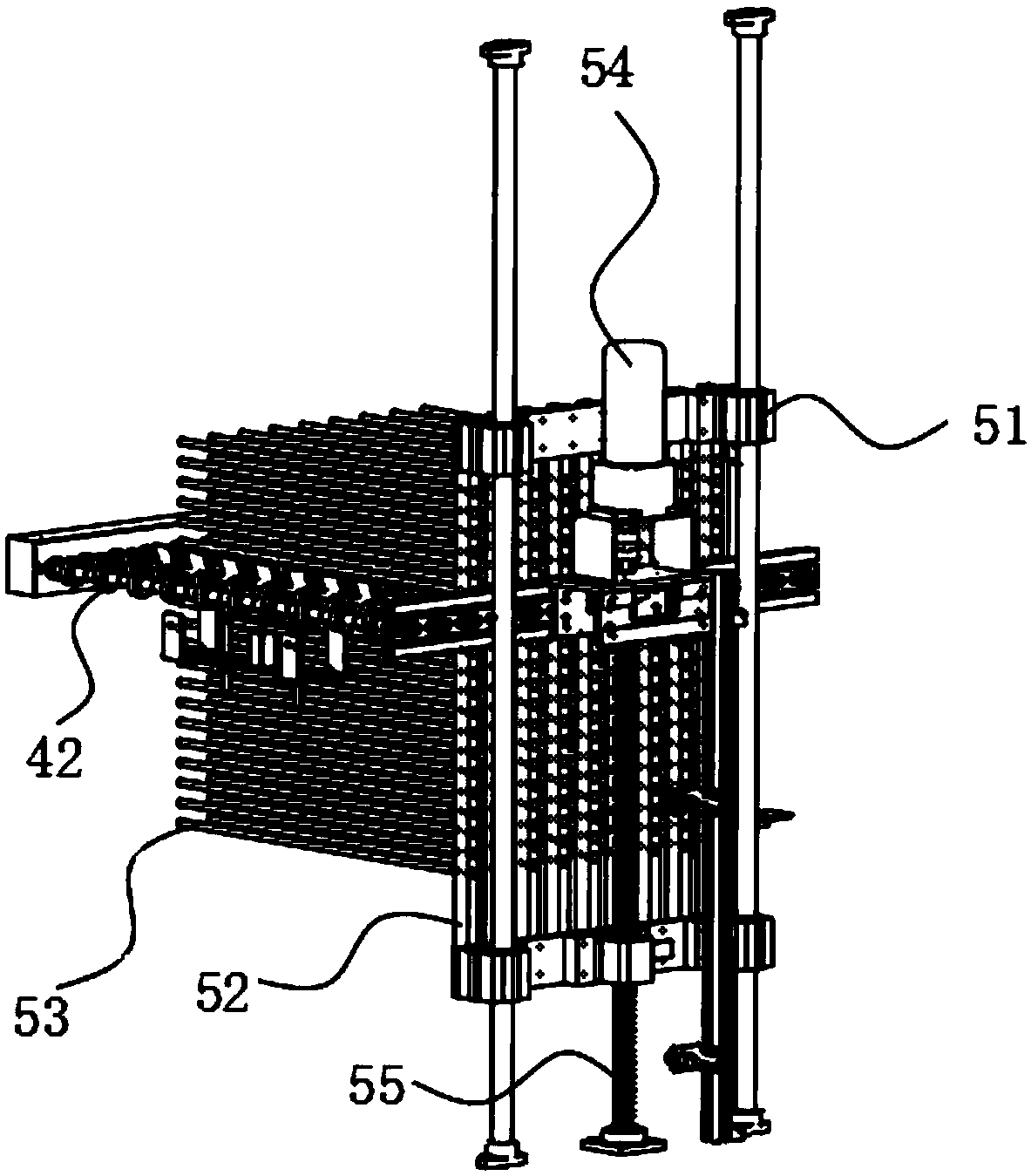

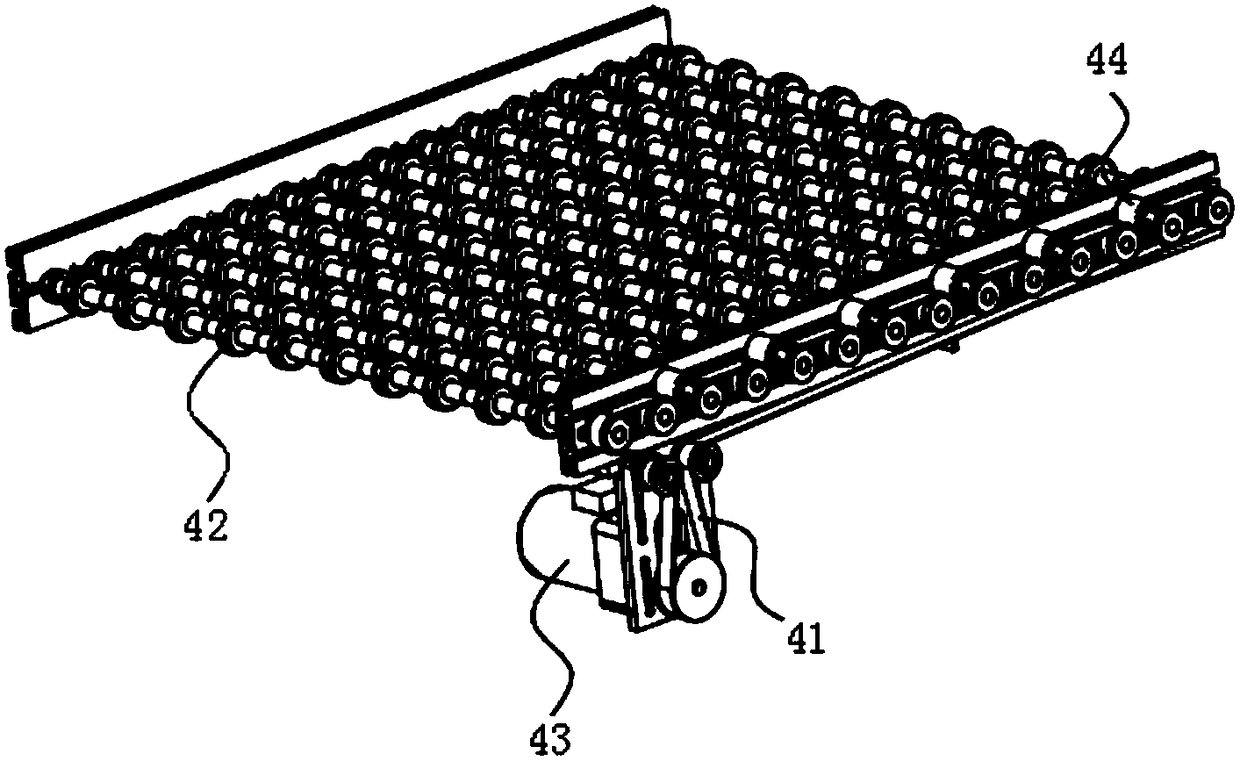

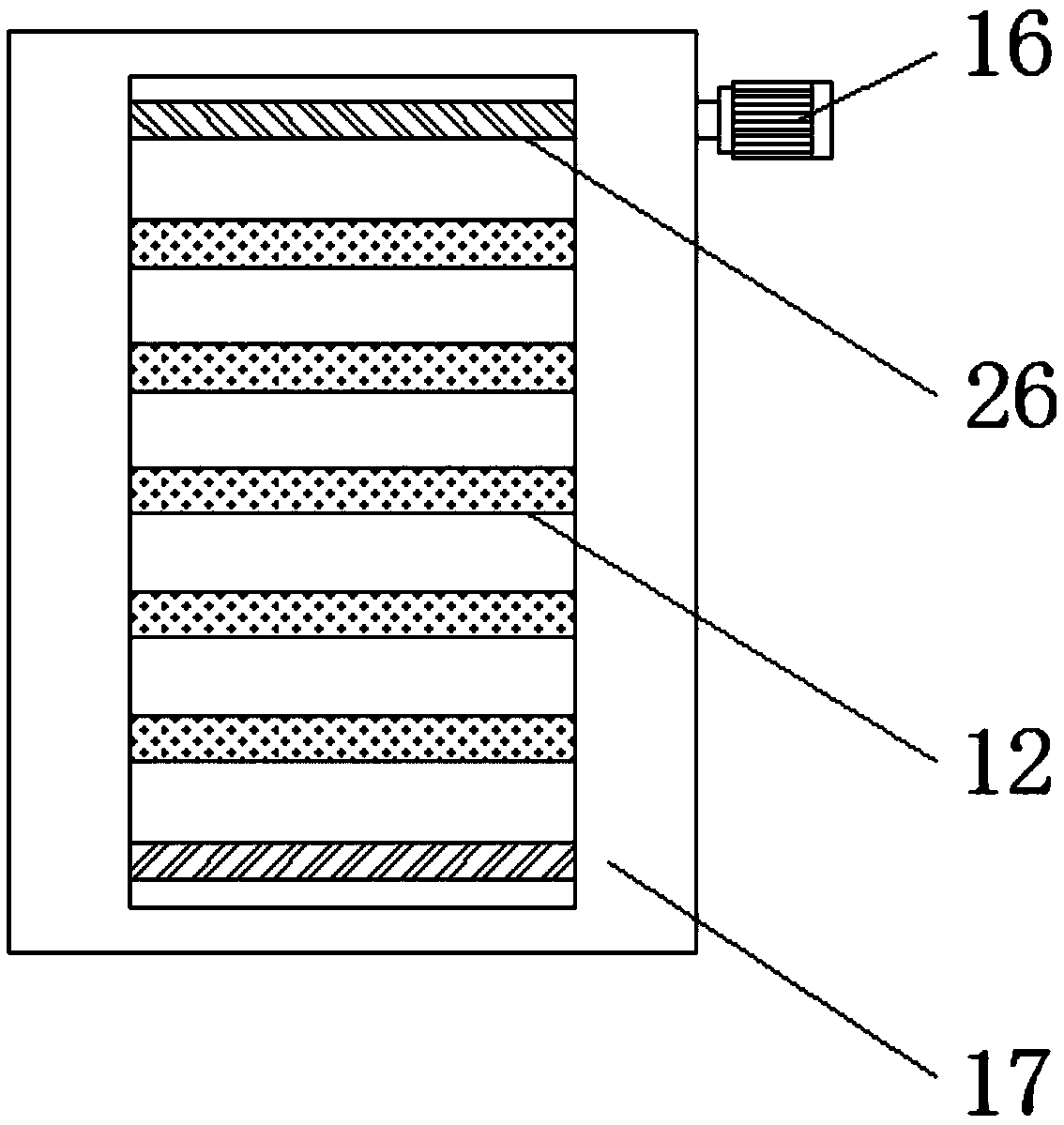

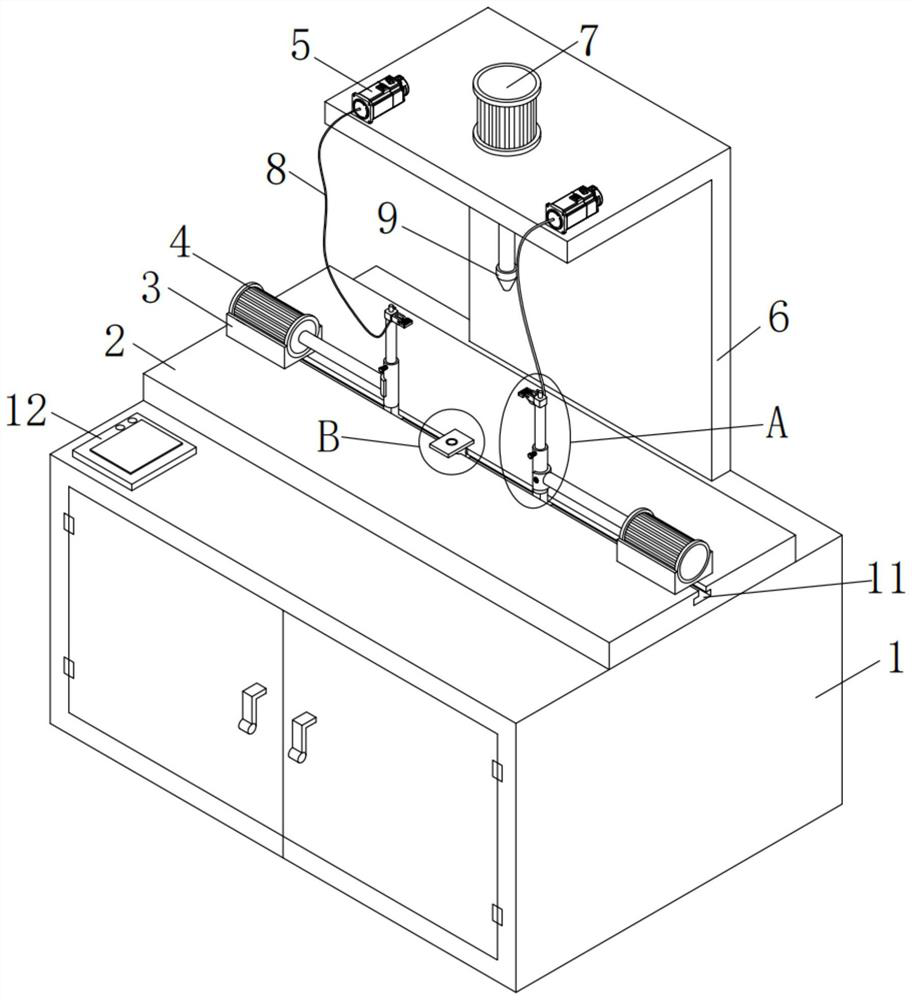

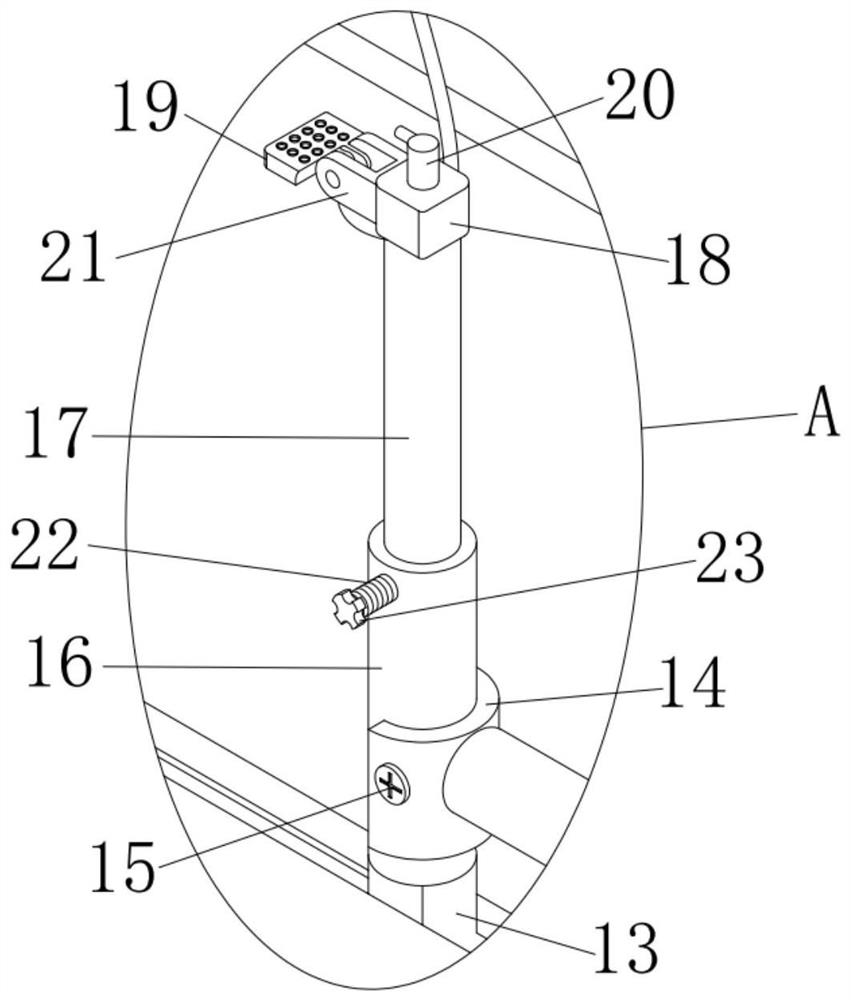

High-precision horizontal board placing machine

InactiveCN109279352AGuaranteed accuracyFlexibleConveyorsStacking articlesTransmission beltDrive motor

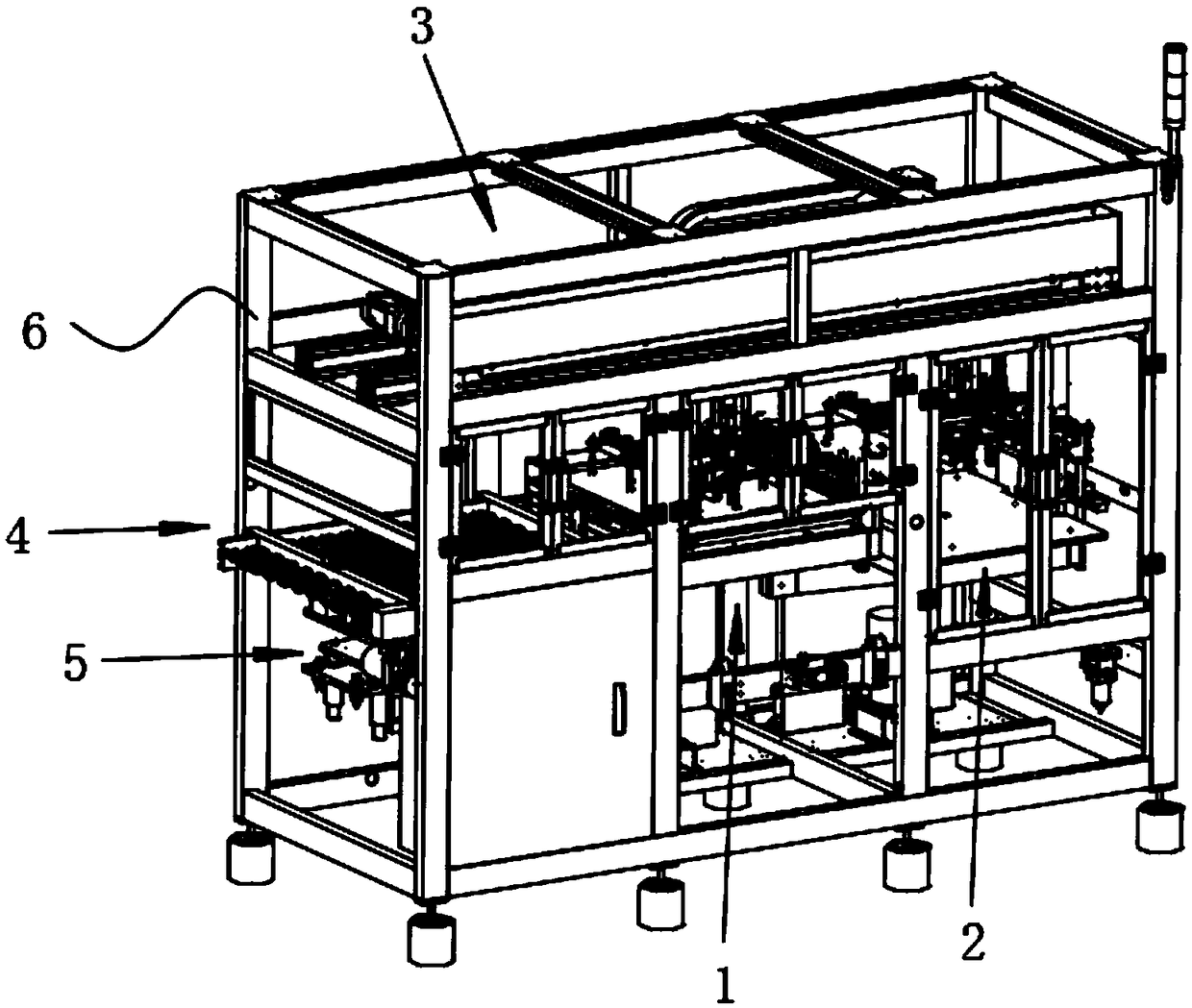

The invention discloses a high-precision horizontal board placing machine, which comprises a PCB feeding mechanism, a packing paper feeding mechanism, a taking mechanism, a conveying mechanism and a positioning mechanism. The PCB feeding mechanism and the packing paper feeding mechanism are both located at the upstream part of the taking mechanism, the taking mechanism is located at the upstream part of the conveying mechanism and the positioning mechanism, and the PCB feeding mechanism, the packing paper feeding mechanism, the taking mechanism, the conveying mechanism and the positioning mechanism are all fixed to a rack; the PCB feeding mechanism and the packing paper feeding mechanism each comprise a transmission belt, a lifting table and a lifting-up driving motor for driving the lifting table to ascend; and the lifting-up driving motor is fixed to the rack, an output shaft of the lifting-up driving motor and a synchronous wheel are sleeved with the transmission belt, and a lifting-up lead screw is fixed to the center of the synchronous wheel and is in threaded connection with the lifting table. According to the high-precision horizontal board placing machine, PCBs and packingpaper are positioned, subsequent board collecting precision is ensured, the automation degree is high, the PCBs are separated by the packing paper, thus the PCBs are prevented from being scraped and damaged, and the quality of the PCBs is ensured.

Owner:大江南电子科技(昆山)有限公司

Automatic clothing stacking equipment

ActiveCN110451039ARealize automatic finishing and processingAchieve compactionPackagingBiochemical engineering

The invention discloses automatic clothing stacking equipment, and belongs to the field of clothing production and finishing processing. A laminating translation mechanism, a clamping and clothes pulling mechanism and a clothes placing and conveying mechanism are sequentially and fixedly arranged on the upper side of a clothes stacking support in the horizontal direction, a clothes clamping pressing plate is arranged on the upper side of a clothes clamping bearing plate, a main folding plate is arranged on one side of the middle of the clothes stacking frame, side folding plates are symmetrically arranged on the two sides of the clothes stacking frame correspondingly, a clothes placing plate is horizontally arranged in the clothes stacking frame, the clothes placing plate is arranged on atranslation guide rod in a sliding mode, a flattening ring tube is arranged on an arrangement support on the upper side of the clothes stacking frame, and a material falling mechanism is horizontallyarranged on a clothes conveying support on the upper side of a clothes conveying belt. According to the automatic clothing stacking equipment, the structural design is reasonable, the clothes can be stably and efficiently folded and processed, the clothes which can be folded and processed can be conveniently and smoothly placed into a packaging box in a convenient and smooth manner, automatic finishing processing of the clothes is realized, and the requirements of production and use are met.

Owner:亘美集团有限公司

High-strength and low-brittleness aluminosilicate glass as well as strengthening method and application thereof

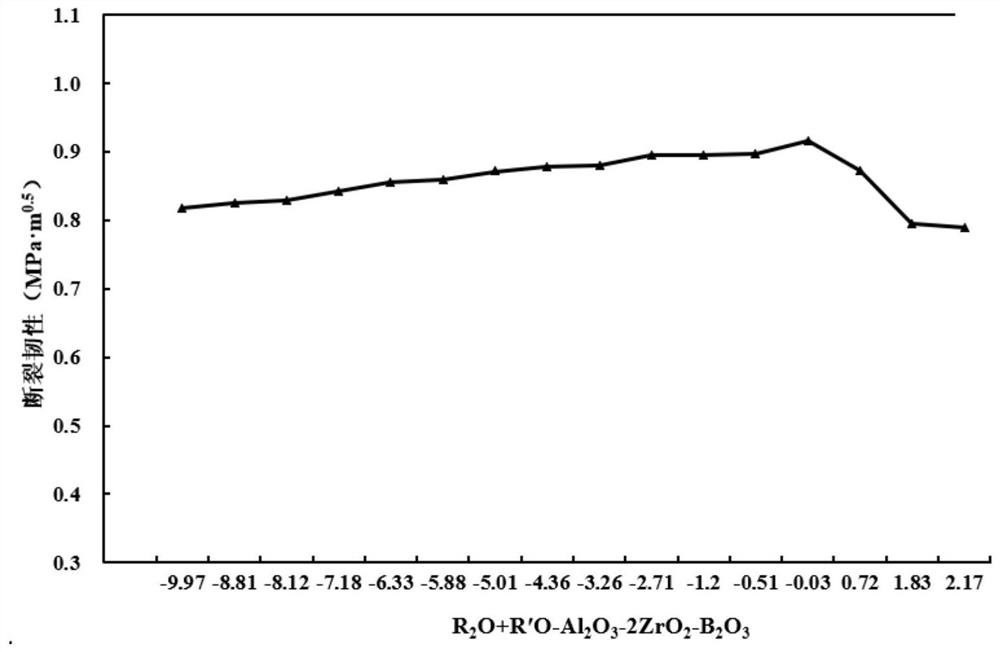

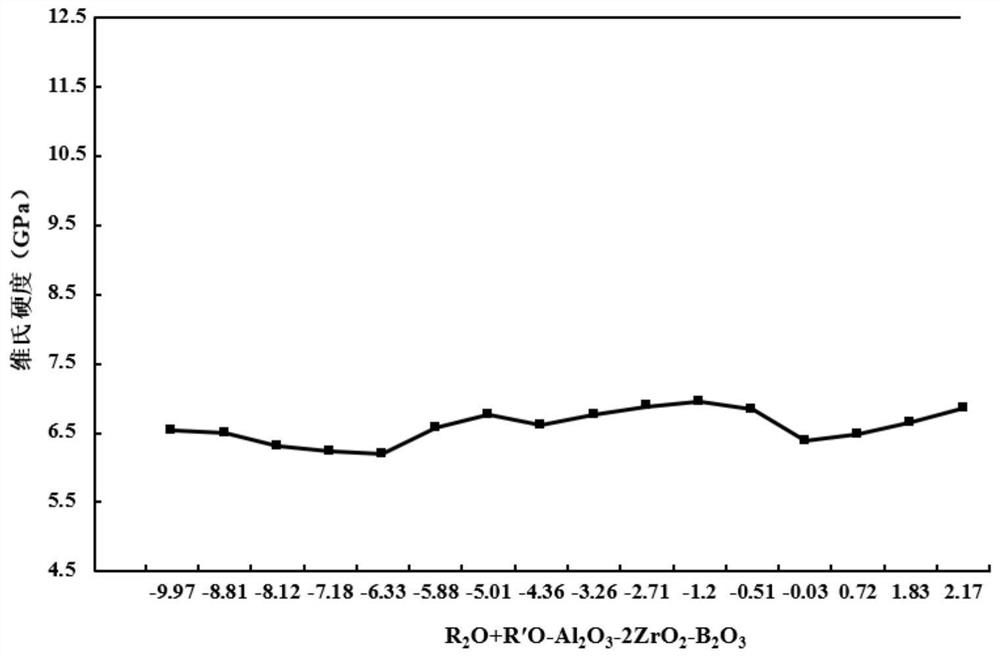

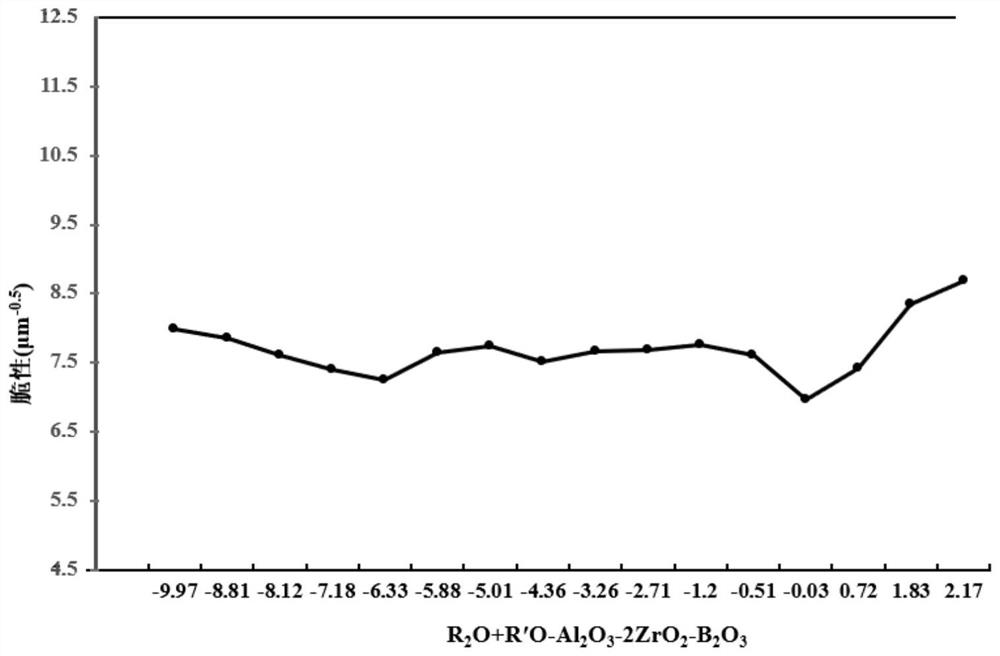

The invention provides high-strength and low-brittleness aluminosilicate glass as well as a strengthening method and an application thereof. The glass is prepared from the following components in percentage by mole; 56%-70% of SiO2, 8%-25% of Al2O3, 1%-10% of B2O3, 0-15% of Li2O, 6%-20% of Na2O, 0-10% of K2O, 0-5% of MgO, 1%-5% of ZrO2 and 0.1%-1% of SnO2. The strengthening method comprises the following steps: preparing raw materials according to the components of the glass, melting and clarifying the raw materials, and forming the glass; and carrying out ion exchange on the glass in a salt bath of potassium nitrate and sodium nitrate at 360-450 DEG C to obtain the chemically strengthened aluminosilicate glass which can be applied to mobile device protection and fixed device protection.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

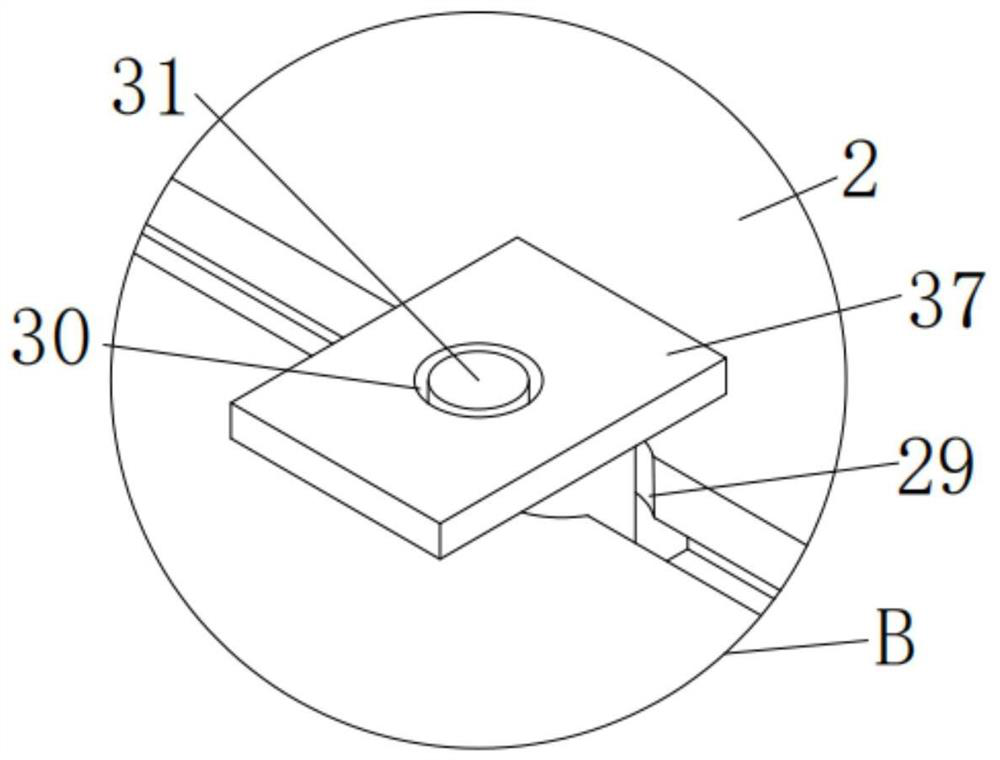

Plate placing machine with temporary storage function

The invention discloses a plate placing machine with a temporary storage function. The plate placing machine with the temporary storage function comprises a PCB feeding mechanism, a packing paper feeding mechanism, a taking mechanism, a conveying mechanism and a temporary storage mechanism. The PCB feeding mechanism and the packing paper feeding mechanism are both positioned at the upstream of thetaking mechanism, the taking mechanism is positioned at the upstream of the conveying mechanism and the temporary storage mechanism, and the PCB feeding mechanism, the packing paper feeding mechanism, the taking mechanism, the conveying mechanism and the temporary storage mechanism are all fixed to a machine frame. The taking mechanism comprises a transverse moving mechanism and a suction mechanism. The suction mechanism is fixed to the transverse moving mechanism, and the transverse moving mechanism comprises a transverse moving plate, a synchronous belt, a driven wheel, a driving wheel anda transverse moving driving motor for driving the driving wheel to rotate. According to the plate placing machine with the temporary storage function, a PCB is separated by packing paper, so that thePCB is prevented from being scratched and damaged, and the quality of the PCB is ensured; and when a circuit board is placed askew or damaged, the PCB can be temporarily stored on a supporting frame rod, and rapid, efficient and high-quality production is realized.

Owner:大江南电子科技(昆山)有限公司

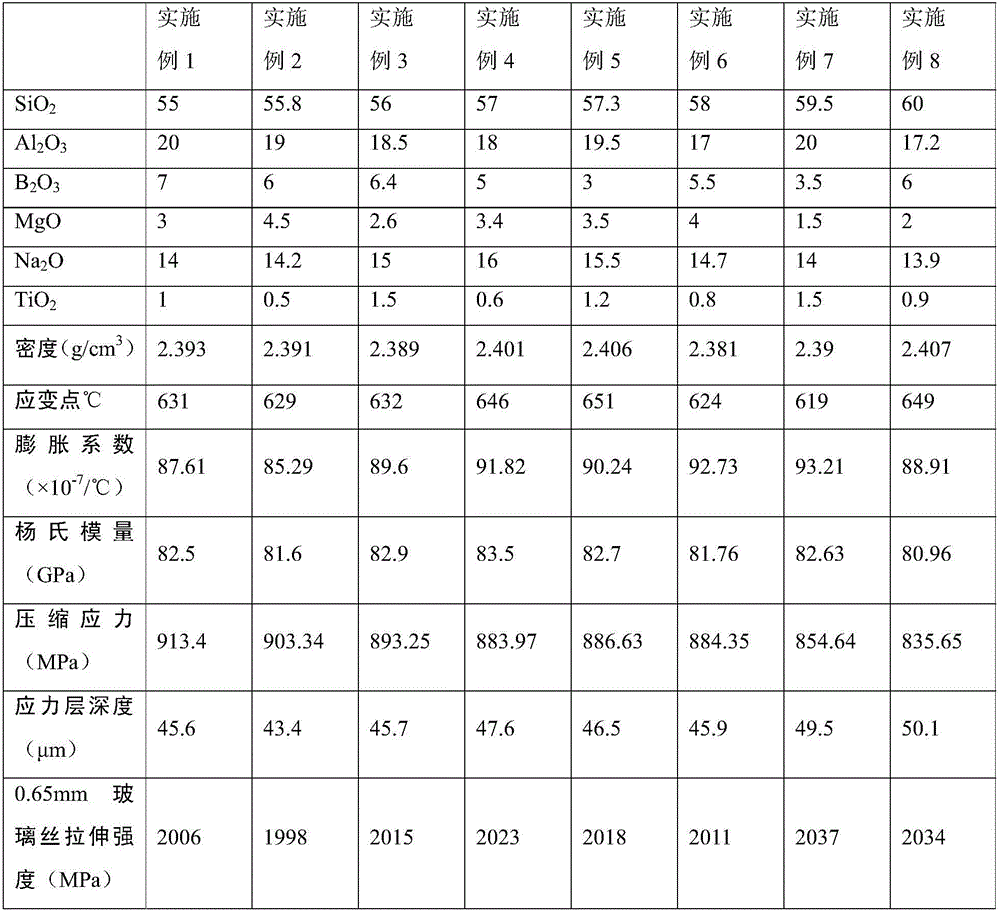

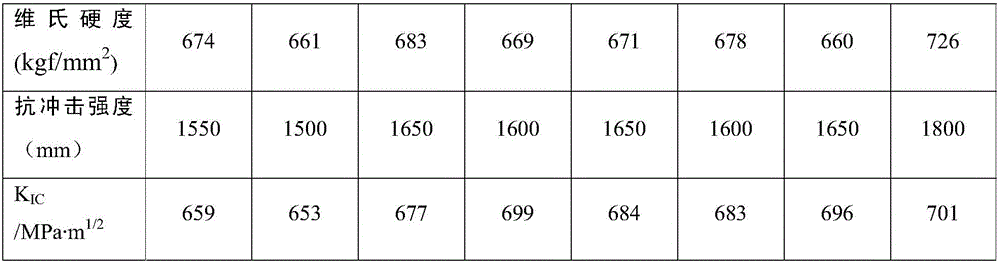

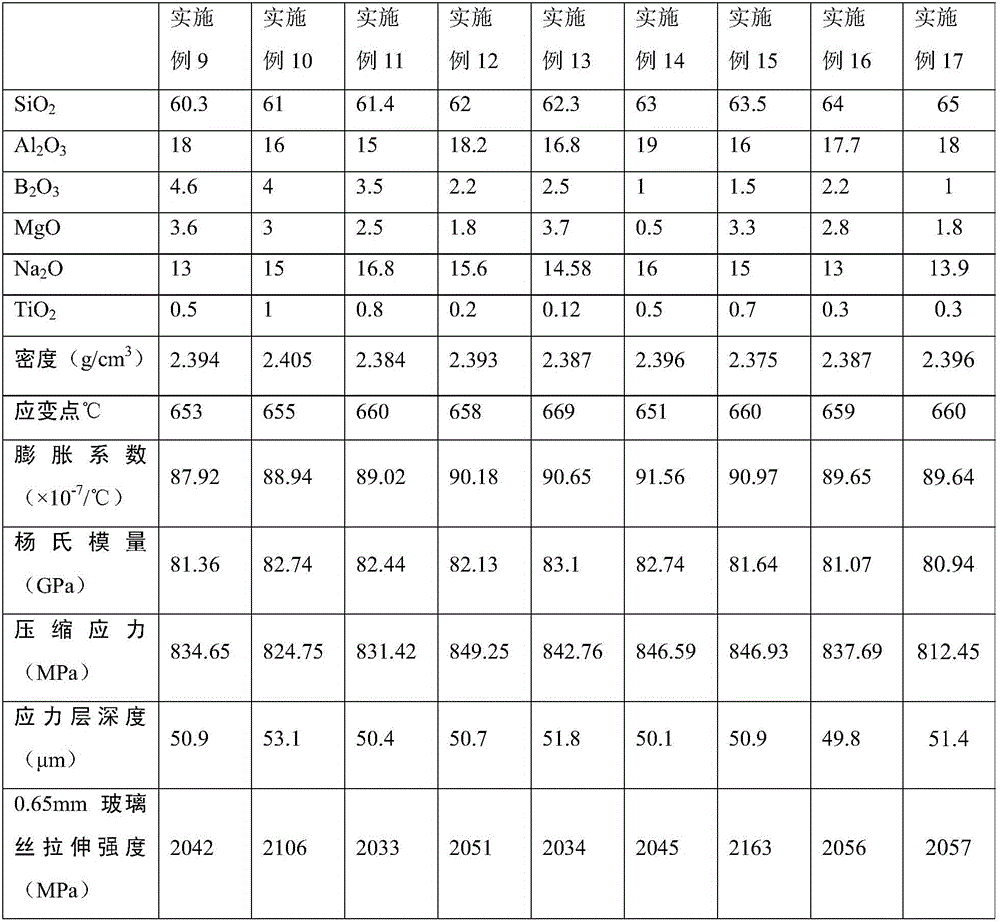

Composition for glass, aluminosilicate glass, preparation method and application thereof

The invention relates to the field of glass, and discloses a composition for glass, aluminosilicate glass, and a preparation method and application thereof. Based on the weight of the composition, measured by oxides, the composition contains 55-68wt% of SiO2, 10-25wt% of Al2O3, 1-8wt% of B2O3, 0.01-5wt% of MgO, 10-19wt% of Na2O and 0.12-2wt% of TiO2. The flexible aluminosilicate glass disclosed by the invention has low brittleness and high fracture toughness and strength.

Owner:TUNGHSU TECH GRP CO LTD +1

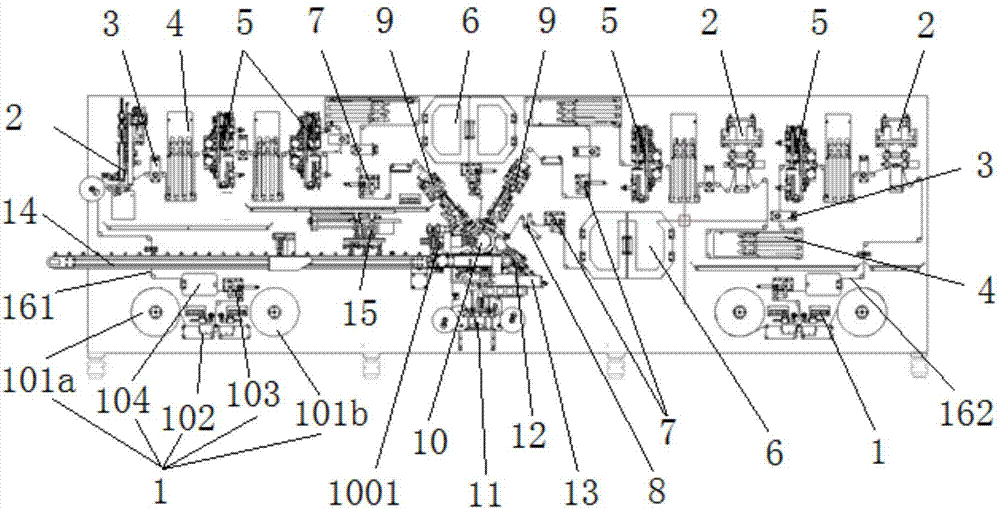

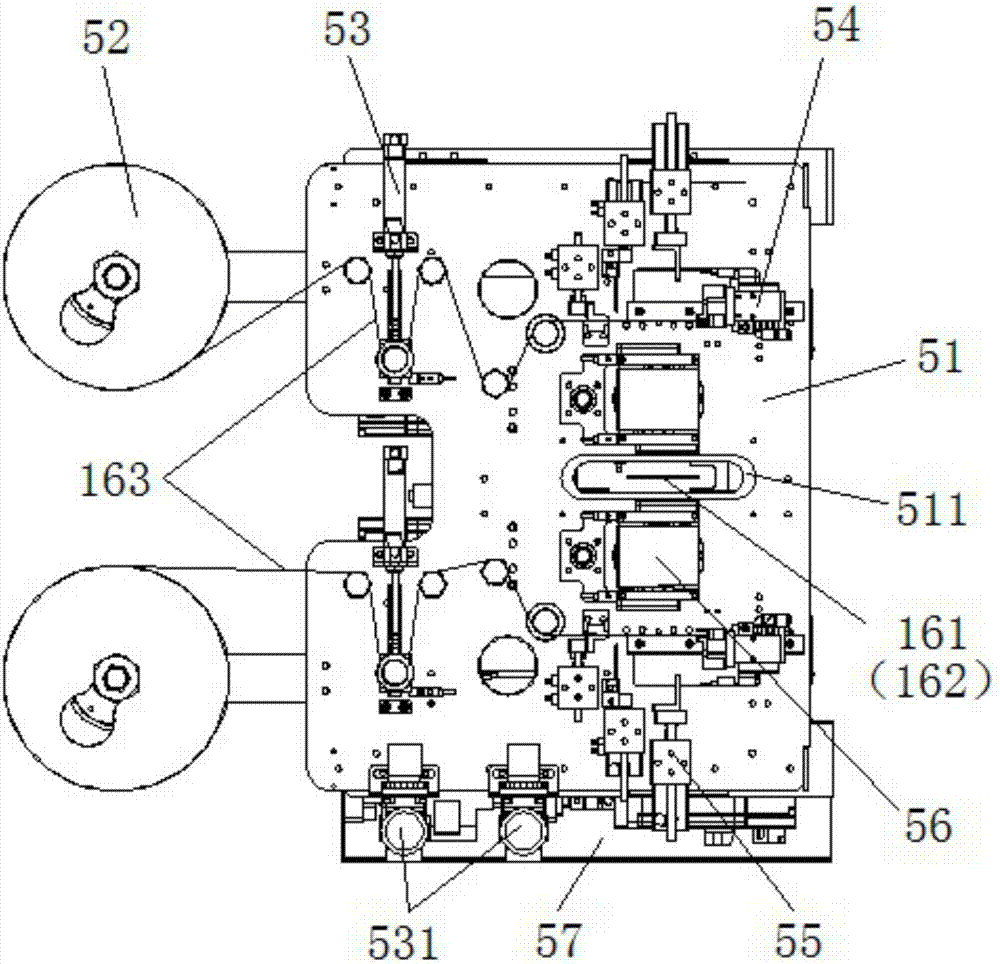

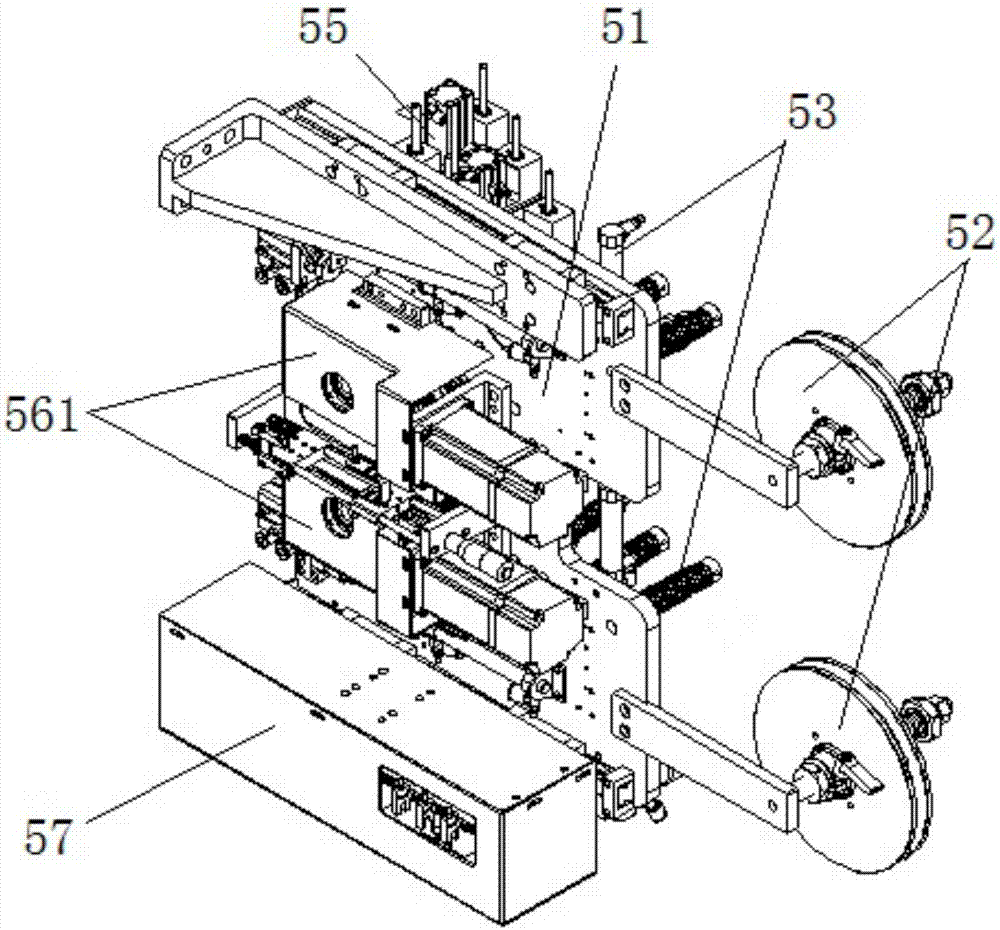

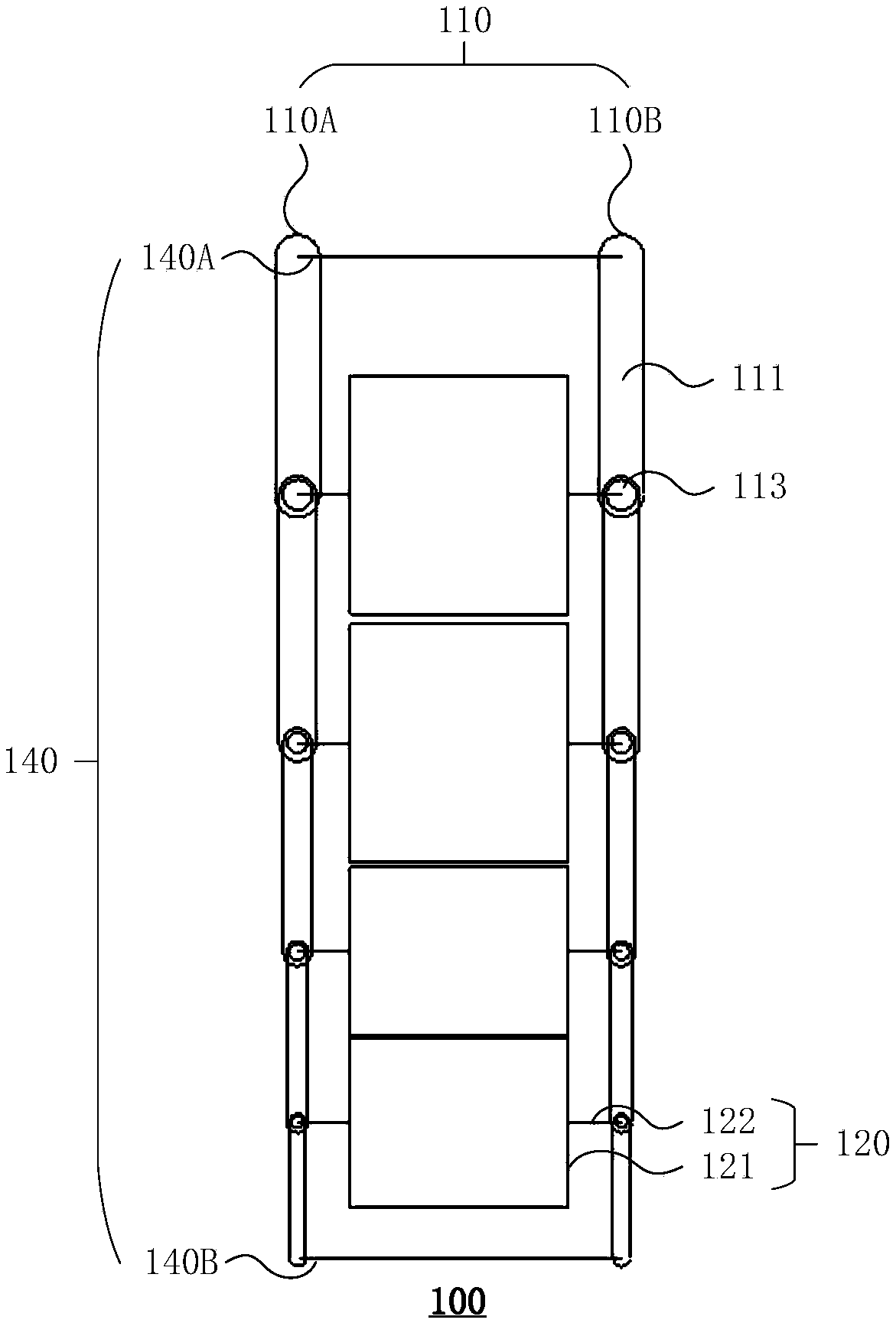

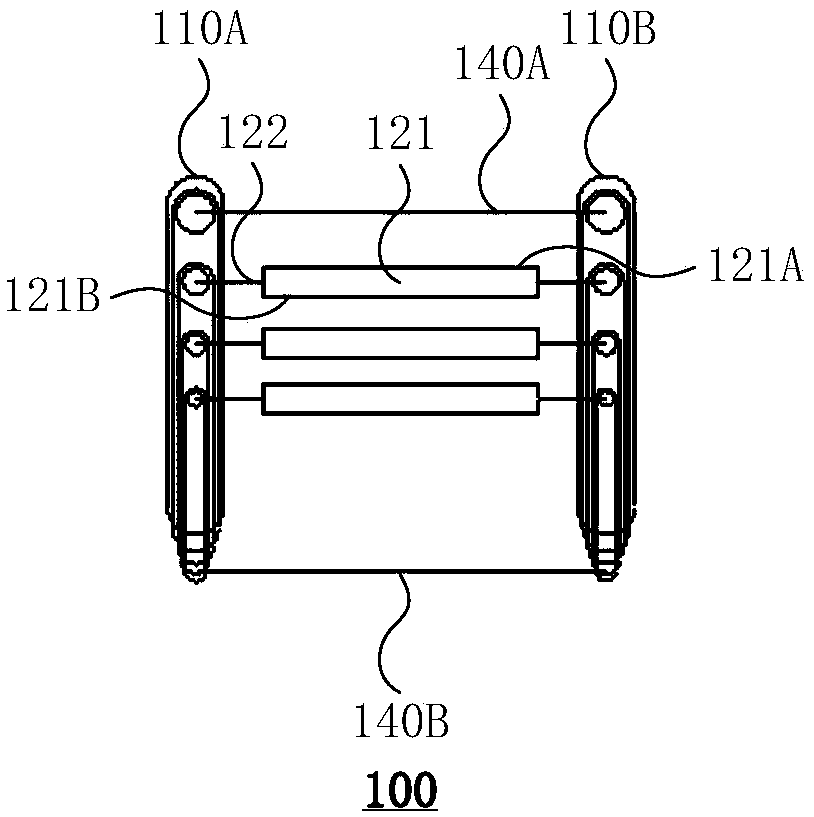

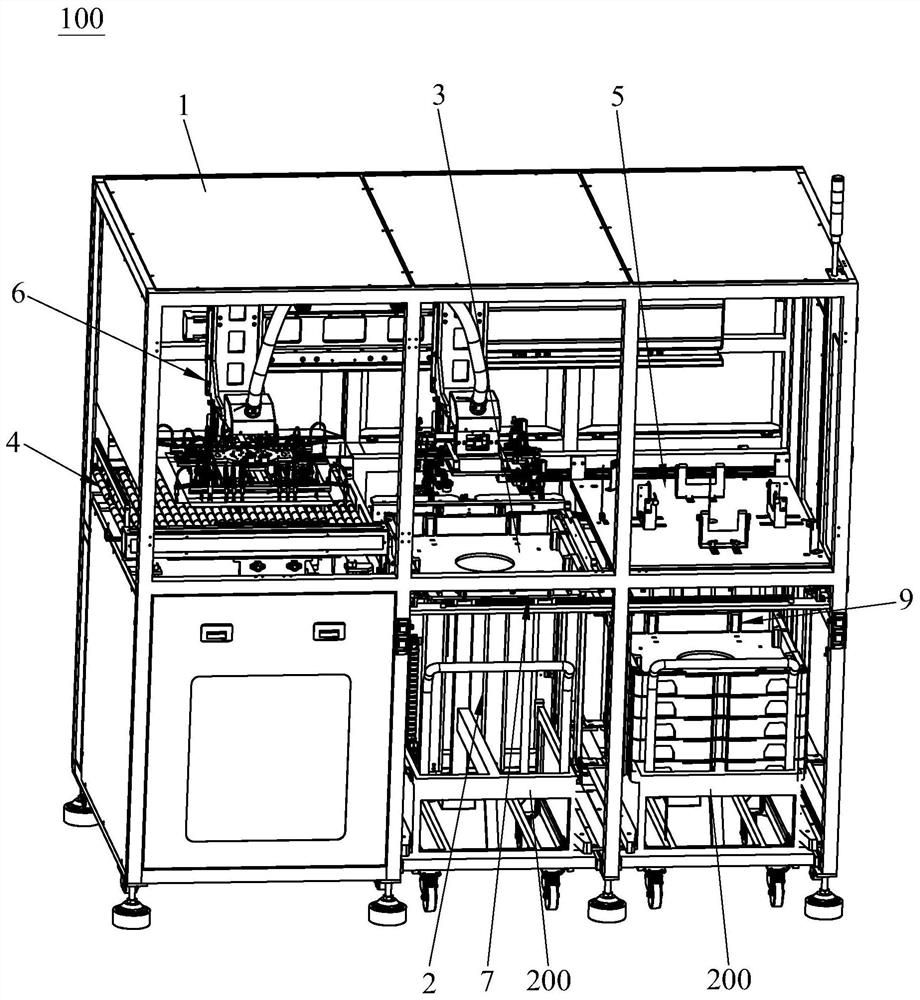

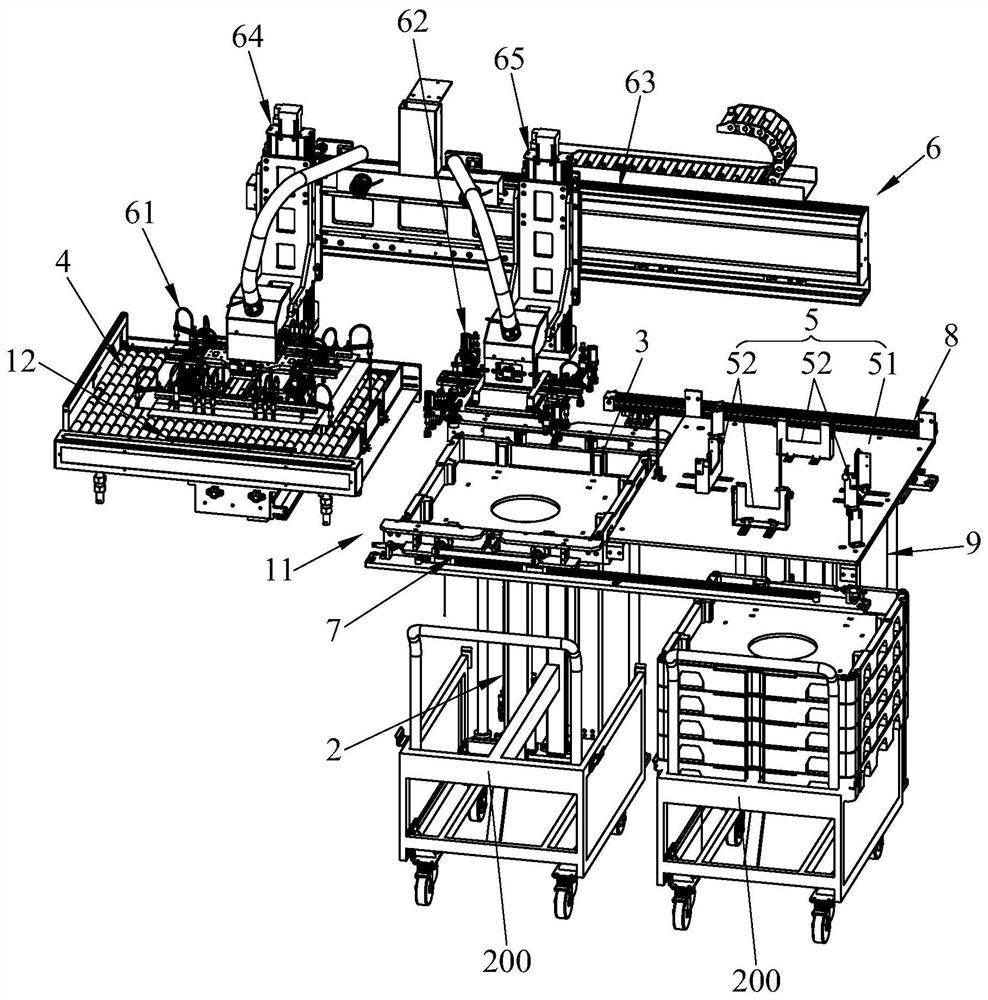

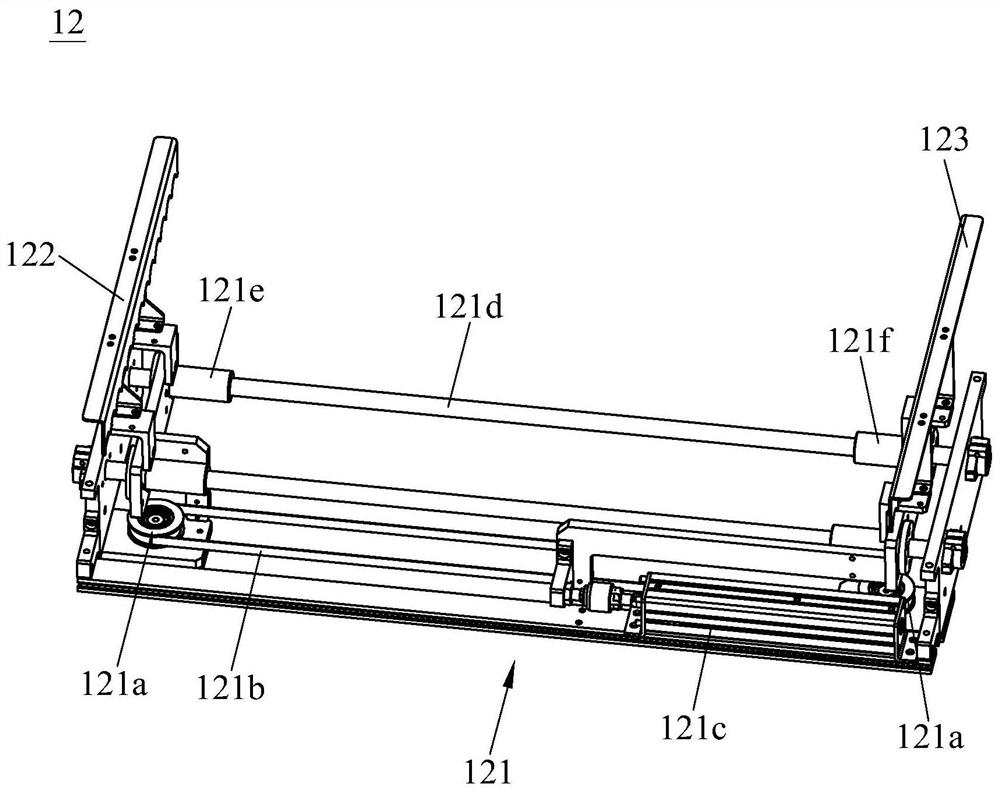

Battery cell polar piece making and winding all-in-one machine capable of cutting polar piece at high speed

ActiveCN107887653AQuick cutNeat sectionAssembling battery machinesFinal product manufactureEngineeringCam

The invention belongs to the technical field of battery manufacturing and relates to a battery cell polar piece making and winding all-in-one machine capable of cutting a polar piece at a high speed.The battery cell polar piece making and winding all-in-one machine comprises a polar piece conveying and cutting mechanism, wherein the polar piece conveying and cutting mechanism comprises a tractioncomponent and a cutting component arranged at the rear of the traction component. The polar piece conveying and cutting mechanism completes traction and cutting in a moving state respectively, and apolar piece cutter is utilized for driving a cam bit to drive a polar piece cutter follower, so as to realize rapid cutting of a polar piece cutter device, action is neatly, and section is tidy.

Owner:BOZHON PRECISION IND TECH CO LTD

Slow release fertilizer and preparation method thereof

ActiveCN106396886AImprove qualityNutrient balanceAnimal corpse fertilisersOrganic fertiliser preparationAqueous solutionKonjac glucomannan

The invention relates to the technical field of slow release fertilizers, and especially relates to a slow release fertilizer and preparation method thereof. An anti-sticking agent is added to an inner wrapped core, and is added after coating with a coating liquid in order to make the obtained slow release fertilizer effectively avoid clustering and agglomerating phenomena, and selection of the anti-sticking agent makes the anti-sticking agent avoid bonding of fertilizer components in the inner wrapped core, allows an inner wrapped core layer to be wrapped with an outer coating layer and avoids contact bonding between materials of the coating layer, so uniformity of nutrients in the slow release fertilizer is ensured; and an aqueous solution of konjac glucomannan and an aqueous solution of guanidine gum are adopted as the coating layer materials in the invention to make the slow release fertilizer have a good slow release cycle, and are combined to realize a better slow release cycle than individual adoption of the aqueous solution of konjac glucomannan and the aqueous solution of guanidine gum as a coating material film fertilizer, so nutrient demands of medium-and-short stage crops are well meet in the invention, thereby 90% of nutrients are released in the 30th to 80th days.

Owner:GUIYANG KAILIN FERTILIZER CO LTD

Environment-friendly clean water-based automobile cleaning agent and preparation method thereof

InactiveCN102533460ANot harmful to healthReduce pollutionNon-ionic surface-active compoundsOrganic detergent compounding agentsLimoneneCleansing Agents

The invention discloses an environment-friendly clean water-based automobile cleaning agent, which comprises the following components: disodium fatty acid amido sulphosuccinate, fatty alcohol-polyoxyethylene ether sodium sulfate, limonene and deionized water. The invention further discloses a preparation method of the cleaning agent. The environment-friendly clean water-based automotive cleaning agent disclosed by the invention has the advantages of simple preparation process, low production cost, good deterging effect, natural and non-toxic components and good biodegradability, and meets the requirements for high efficiency and environmental friendliness.

Owner:任航

Display device

The invention provides a display device, which comprises a telescopic mechanism, a supporting and rolling mechanism and a plurality of display modules; the telescopic mechanism comprises a first telescopic part and a second telescopic part which are oppositely arranged, wherein the first telescopic part and the second telescopic part respectively comprise a plurality of telescopic pipes which aremutually sleeved; the supporting and rolling mechanism is arranged between the first telescopic part and the second telescopic part and comprises a plurality of supporting frames and a plurality of matching shafts, the supporting frames are fixedly connected with the matching shafts, and the matching shafts are rotatably connected with the telescopic pipes; the display modules are arranged on thesupporting frames and are fixedly connected with the supporting frames. Therefore, the display device can be unfolded and folded, the display device can display on a large screen when unfolded and isconvenient to carry when folded, the display modules are prevented from being mutually rubbed and damaged, a non-bending display panel can be adopted or a bendable display panel can be adopted to achieve angle-adjustable displaying, the bending angle of the bendable display panel does not limit the unfolding and folding range of the display device.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

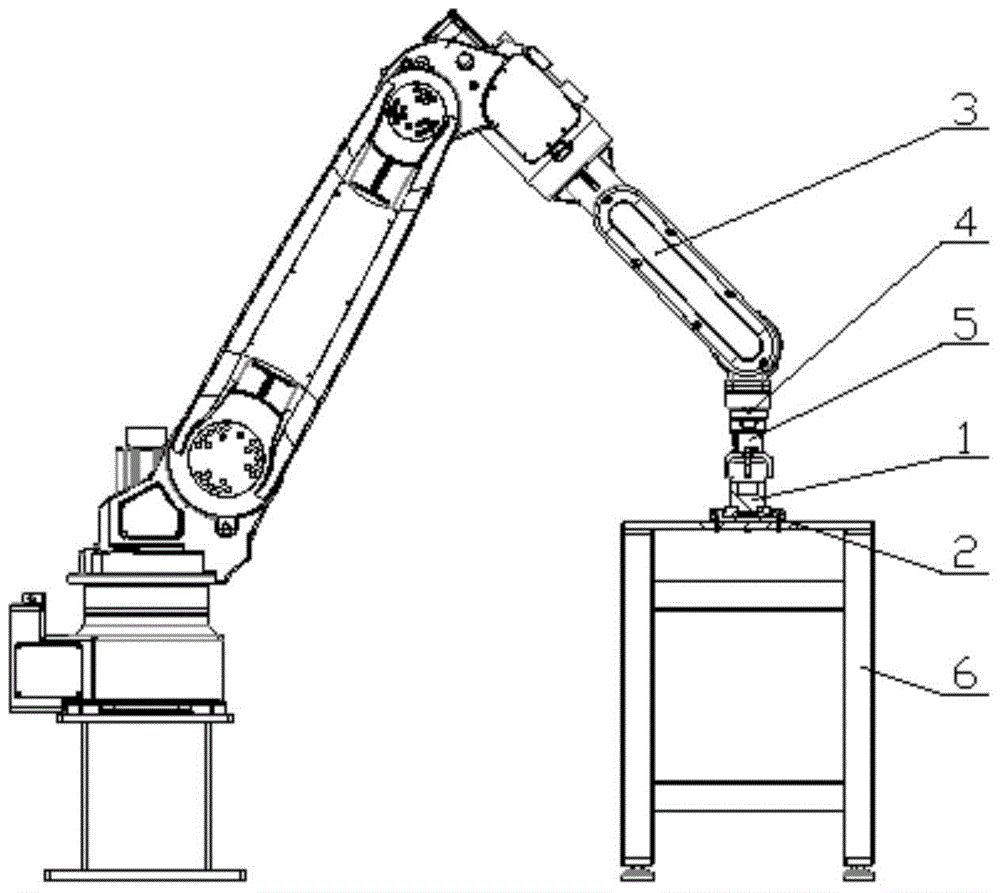

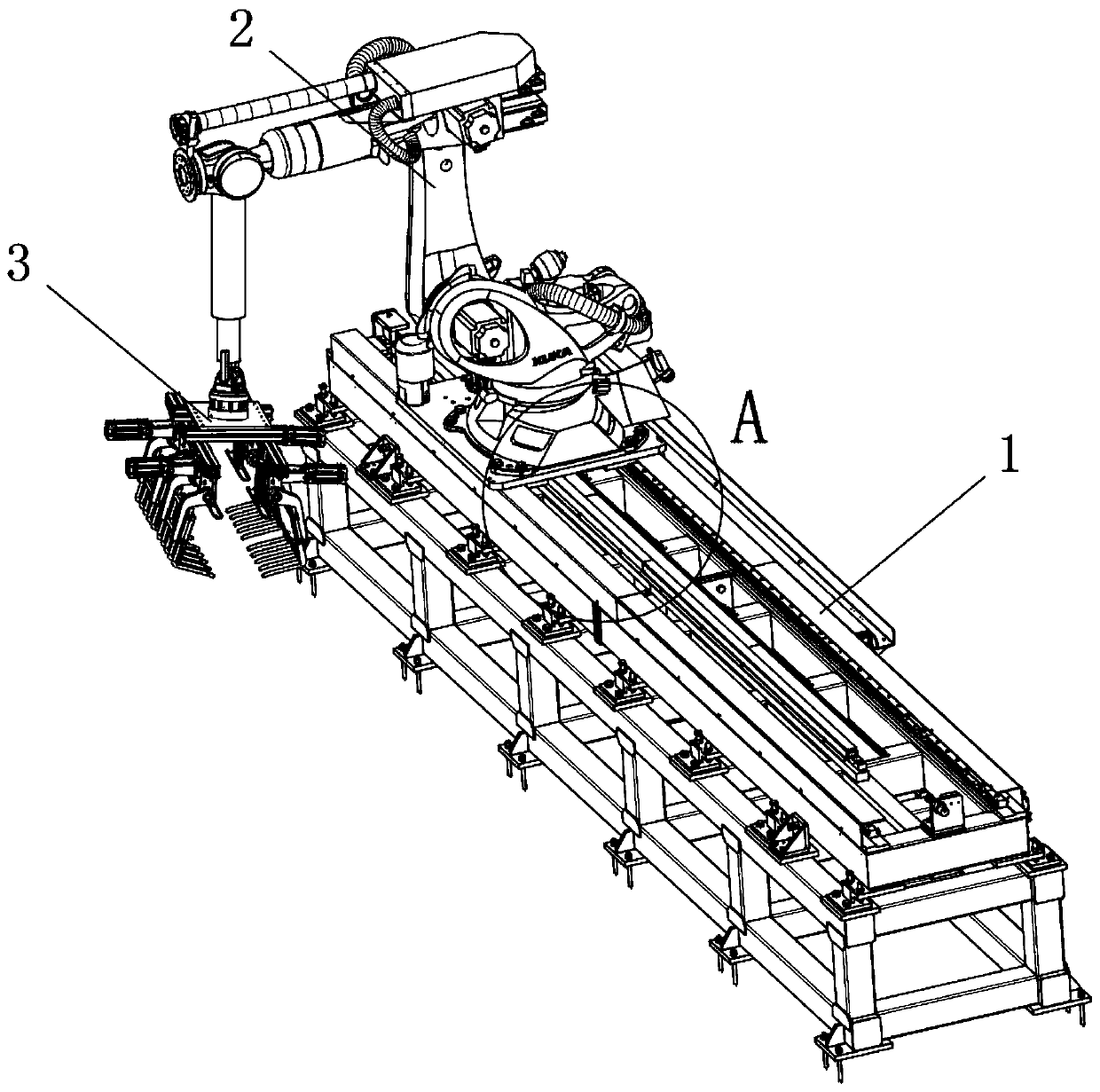

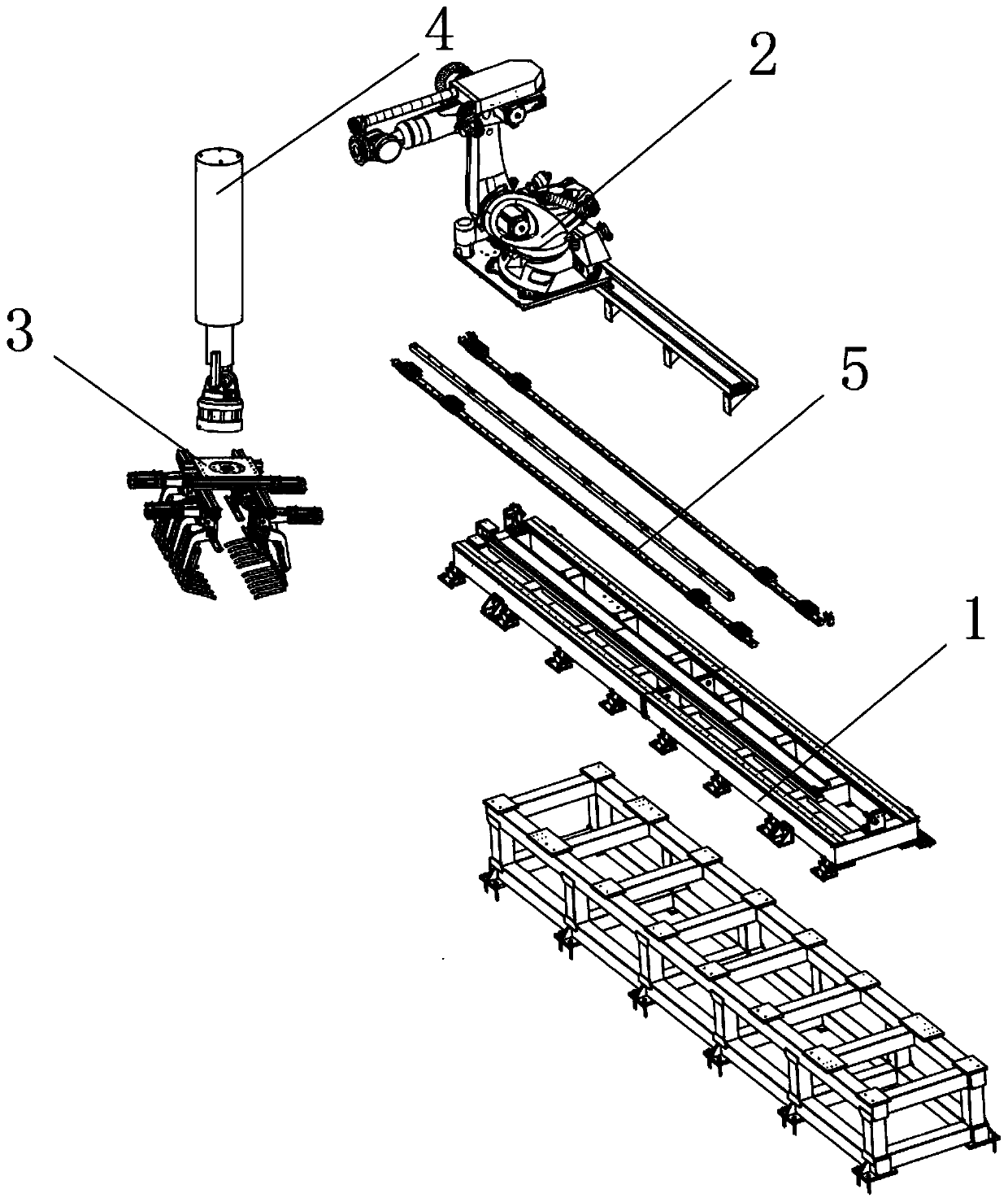

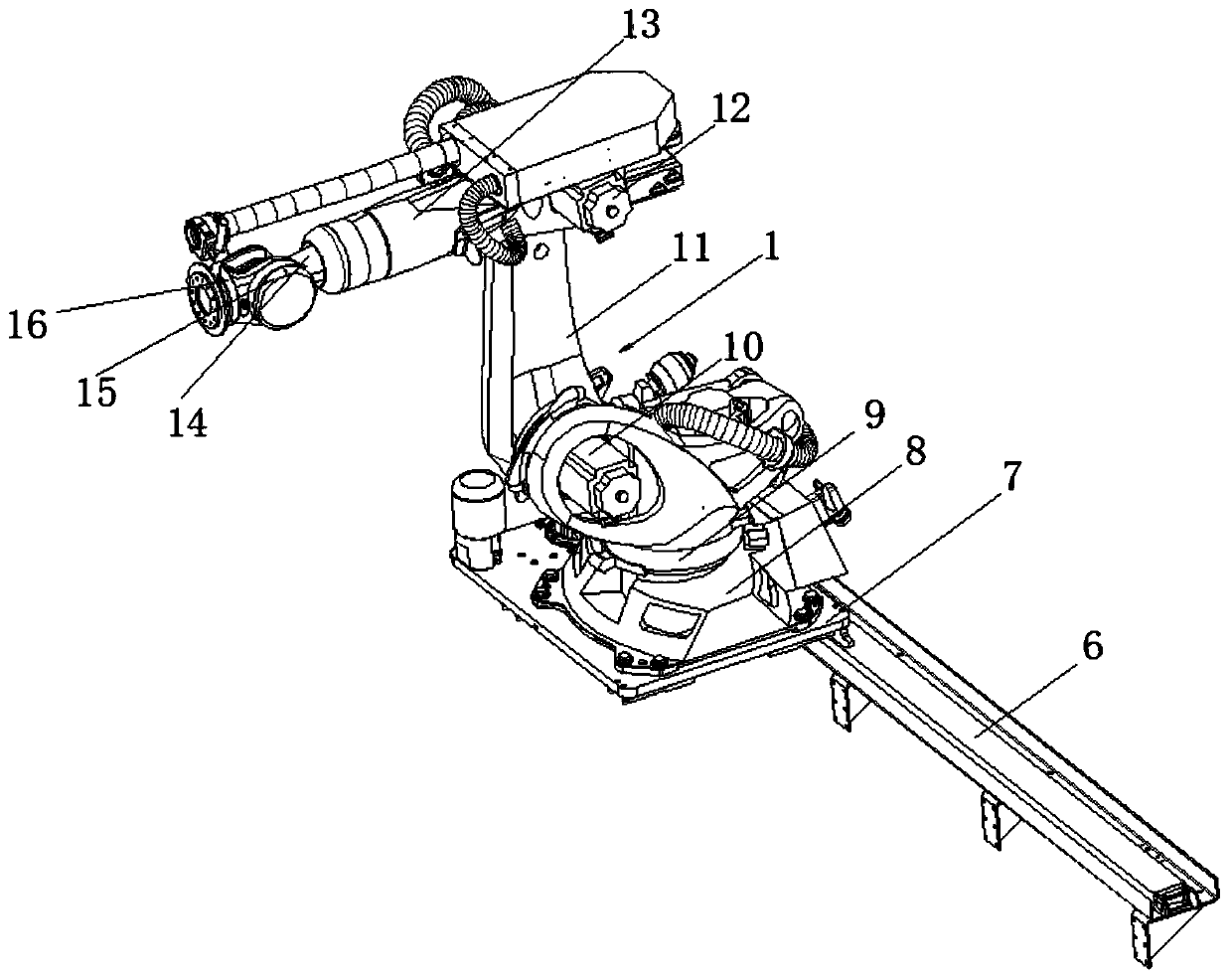

Mechanical arm force control assembling device and method

InactiveCN105643267AMeet high-precision assembly needsAvoid scratch damageProgramme-controlled manipulatorMetal working apparatusControl systemEngineering

The invention provides a mechanical arm force control assembling device and method. The mechanical arm force control assembling device comprises a mechanical arm body provided with a complete moving mechanism, a control system, a force sensor, a clamping hand and an assembling platform provided with a clamp. The control system is installed inside the mechanical arm body. The force sensor is installed at the end of the mechanical arm body and connected with the control system. The clamping hand is installed on the force sensor. The assembling platform is arranged on the lateral portion of the mechanical arm body and located under the clamping hand. According to the mechanical arm force control assembling device and method, high-precision assembly of a shaft and a hole is guaranteed through pressure recognition assembly.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

PCB partition paper collecting machine

PendingCN113264358AImplement automatic placementAvoid scratch damageStacking articlesDe-stacking articlesMechanical engineeringIndustrial engineering

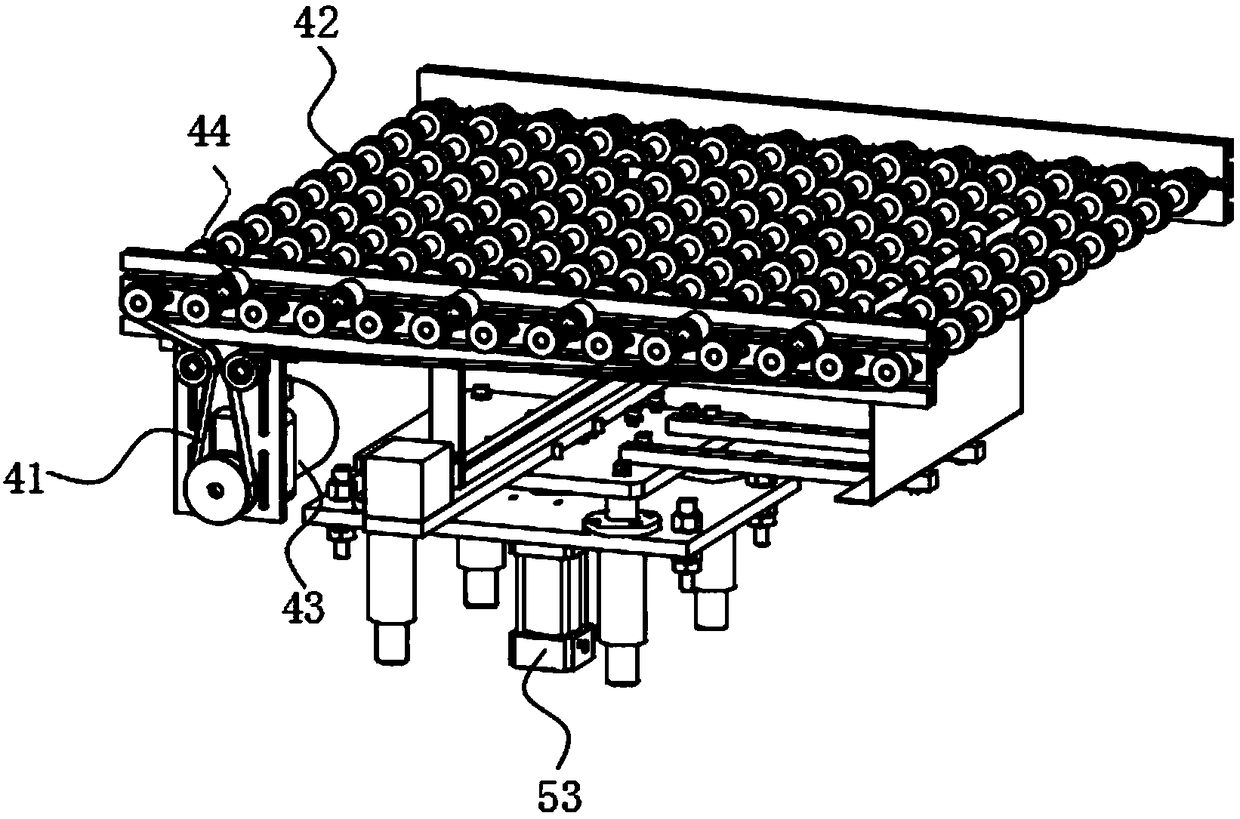

The invention provides a PCB partition paper collecting machine, which comprises a rack, a discharging driving mechanism, a material frame, a PCB conveying mechanism, a paper storage mechanism and a board collecting mechanical arm; a board collecting station is arranged on the rack; the material frame is arranged on the discharging driving mechanism and located on the board collecting station; the discharging driving mechanism can drive the material frame to move and leave the board collecting station; the PCB conveying mechanism is arranged on the rack and located on one side of the board collecting station; the paper storage mechanism is arranged on the rack and located on the other side of the board collecting station; and the board collecting mechanical arm is provided with a first material taking assembly and a second material taking assembly. The first material taking assembly and the second material taking assembly are driven by the board collecting mechanical arm to move together, so that the first material taking assembly sucks PCBs located on the PCB conveying mechanism, the second material taking assembly places sucked partition paper in the material frame, or the first material taking assembly places the sucked PCBs in the material frame, and the second material taking assembly sucks the partition paper located on the paper storage mechanism.

Owner:东莞思沃智能装备有限公司

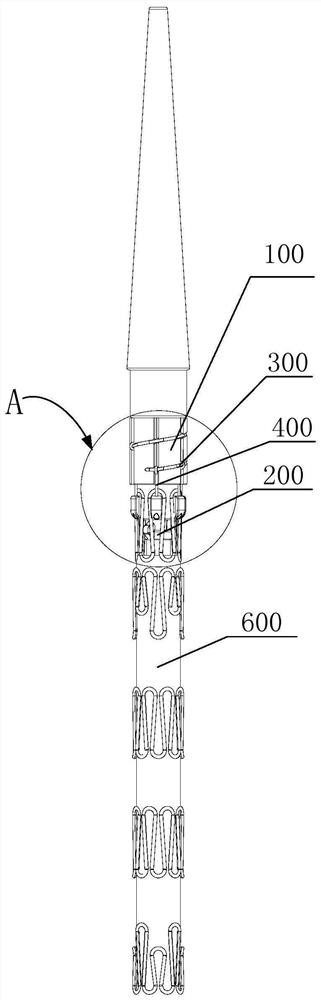

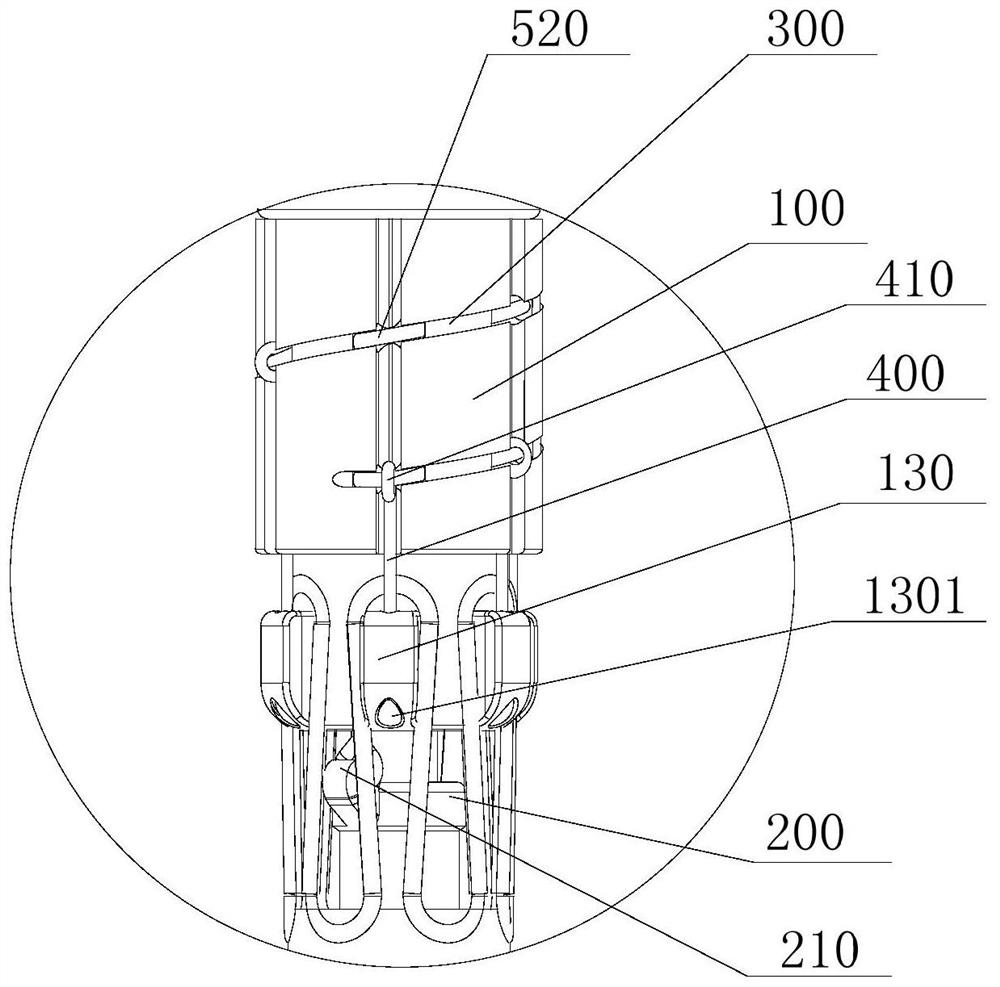

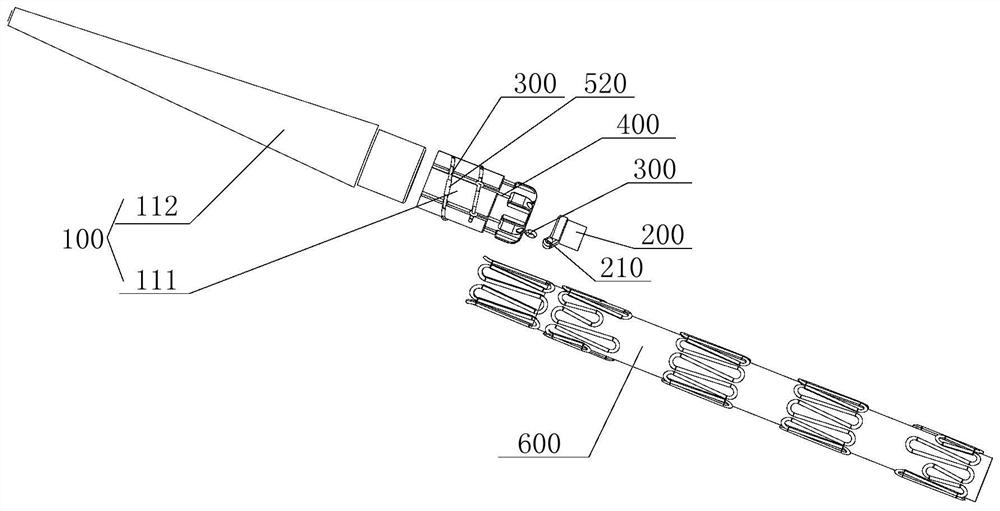

Covered stent post-release device and covered stent implantation system

PendingCN111743670AReduce scratch damageProtect blood vesselsStentsBiomedical engineeringBlood vessel injury

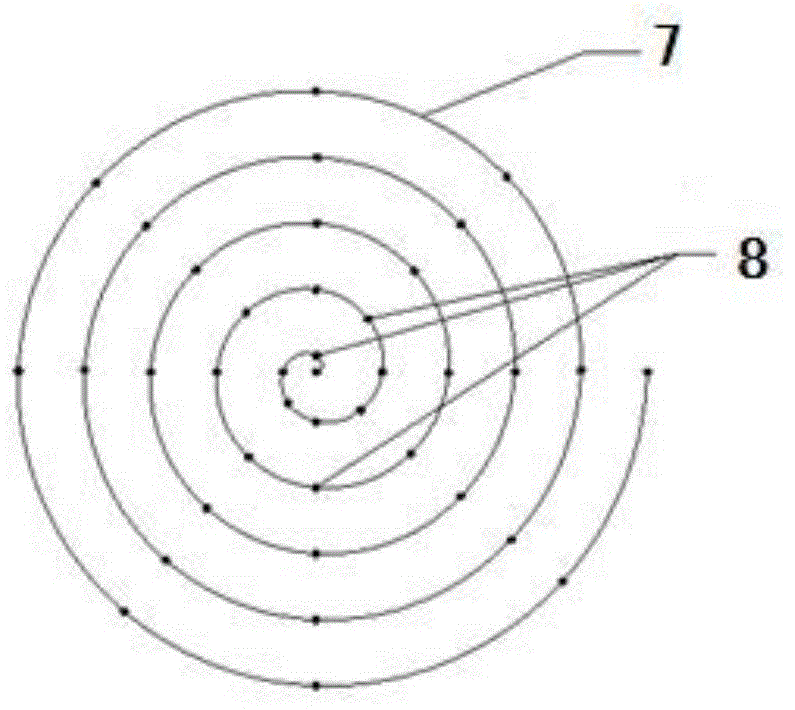

The invention provides a covered stent post-release device and a covered stent implantation system, and relates to the technical field of medical instruments, the covered stent post-release device comprises a guide seat, a pull wire seat, a locking structure, and a first pull wire and a plurality of second pull wires which are made of flexible materials; the first stay wire is wound on the outer or inner circumferential surface of the guide seat, one end of the first stay wire is fixedly connected to the pull wire seat, and the other end is fixed to the guide seat through the locking structure; one end of each second pull wire is fixedly connected to the guide seat, and the free end of each second pull wire is fixed between the first pull wire and the guide seat; and under the condition that the pull wire seat moves away from the guide seat, the first pull wire can be separated from the guide seat, so that the free ends of the plurality of second pull wires are released. According to the invention, the technical problems of high operation difficulty and low operation success rate caused by the fact that the blood vessel is easily scratched, the blood vessel is damaged and even broken by the existing post-covered stent release device and the blood vessel is greatly damaged because all parts of the near-end part of the covered stent are simultaneously released and bounced off outwards when the near end of the covered stent is released are solved.

Owner:BEIJING PERCUTEK THERAPEUTICS CO LTD

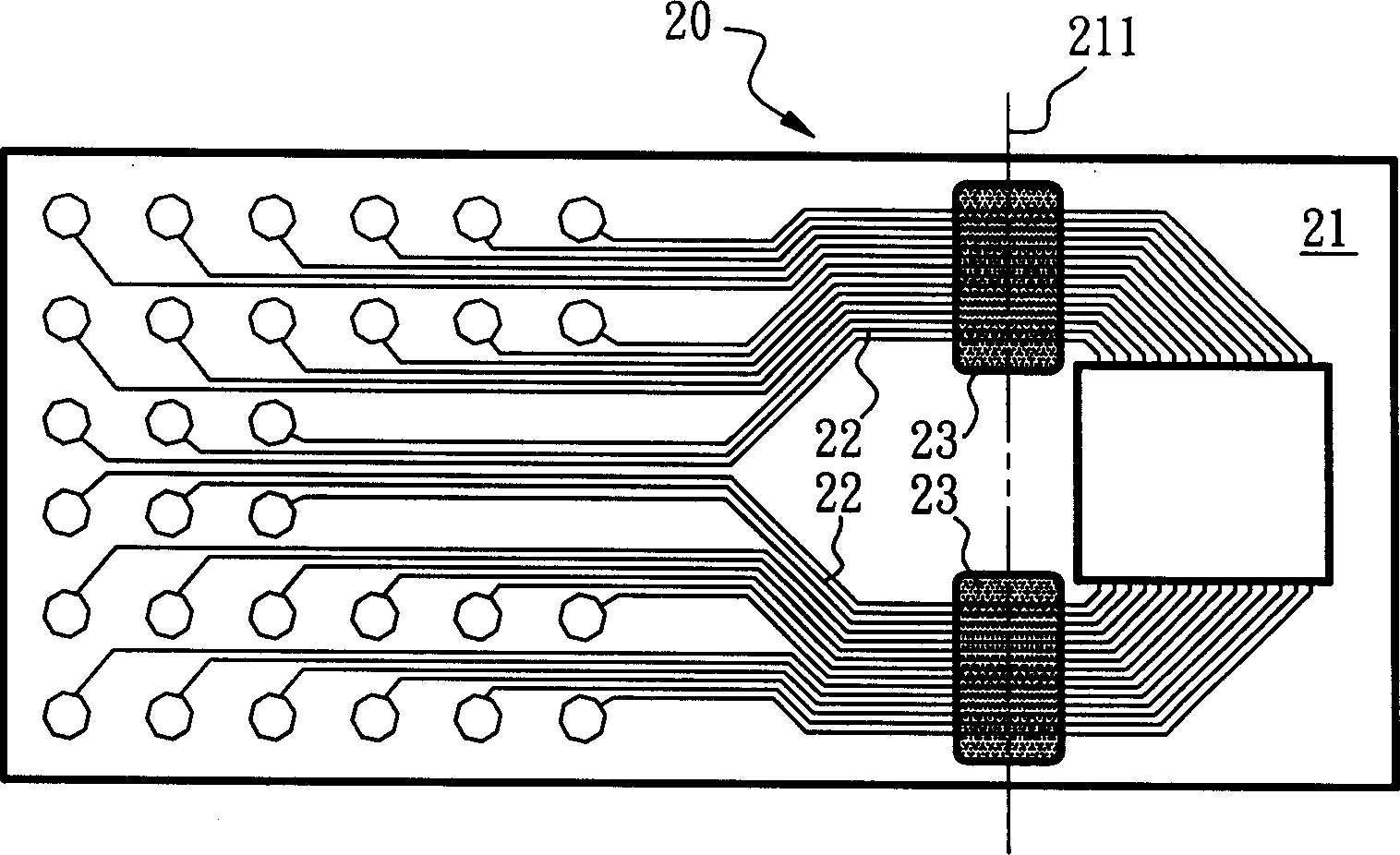

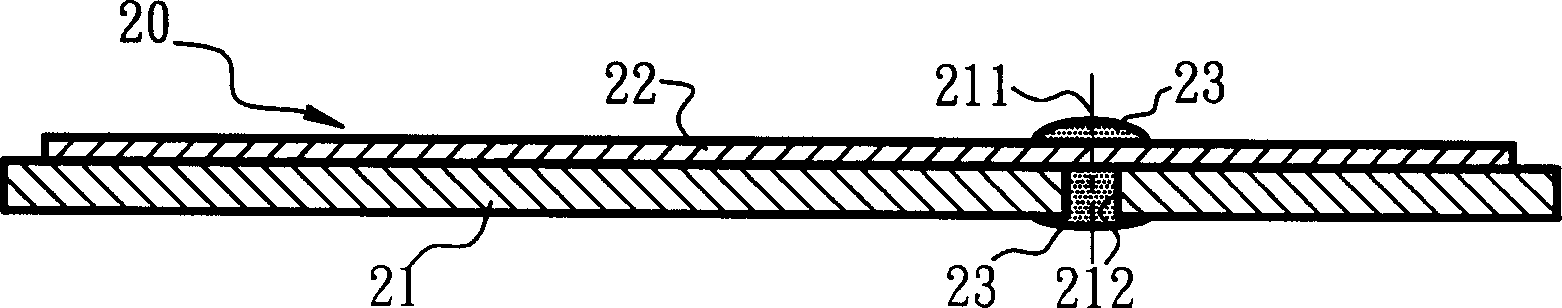

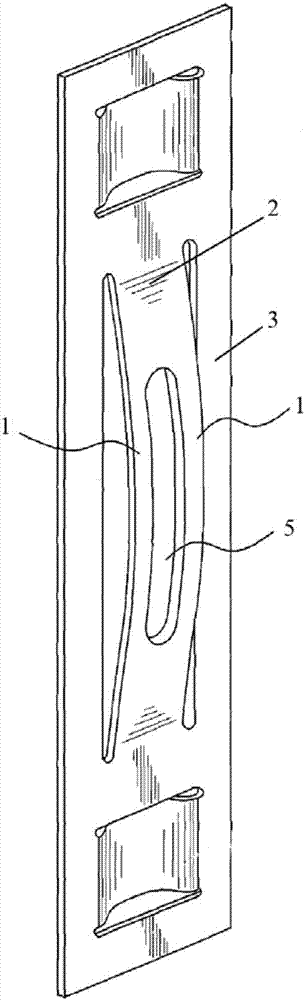

Structure and making method of flexible circuit board for ink-jet printing head

InactiveCN1435319AImprove protectionAvoid scratch damagePrinted circuit detailsPrintingSolder maskFlexible circuits

A flexible circuit board for ink-jet print head has an improved structure for decreasing the residual stress at bending position, resulting in high reliability, precision and quality. Its preparing process includes preparing a flexible substrate, making slotted holes at the position to be bent, preparing a metal layer, etching to form electrically conductive lines, and adding the solder mask material at the position where there are slotted holes.

Owner:PRINTECH INT

Glue film automatic production line

ActiveCN109573713AHigh degree of automationQuality improvementArticle deliveryProduction lineEngineering

The invention discloses a glue film automatic production line. The glue film automatic production line comprises a feeding device, a small hole die-cutting device, a first waste exhausting device, aninner frame die-cutting device, a second waste exhausting device and a release film die-cutting device, the feeding device is located at the upstream of the small hole die-cutting device, the small hole die-cutting device is located at the upstream of the first waste exhausting device, and the first waste exhausting device is located at the upstream of the inner frame die-cutting device; and the inner frame die-cutting device is located at the upstream of the second waste exhausting device, the second waste exhausting device is located at the upstream of the release film die-cutting device, the feeding device comprises a bottom material discharging roller, an edge attaching belt discharging roller, a first belt pressing mechanism, a second belt pressing mechanism and a third belt pressingmechanism in sequence according to the production process, a base material rewinding mechanism is arranged at the upper part of the second belt pressing mechanism, and an identification belt discharging roller is arranged above the third belt pressing mechanism. The glue film automatic production line is high in degree of automation, the fast, efficient and high-quality production is achieved, theartificial labor intensity is reduced, the utilization rate of the base material film is improved, and the production cost is saved.

Owner:昆山域之光电子有限公司

Electromagnetic overhead crane with rail cleaning function

InactiveCN111017720AImprove cleaning efficiencyEasy to cleanNon-rotating vibration suppressionCleaning using toolsEngineeringOverhead crane

The invention discloses an electromagnetic overhead crane with a rail cleaning function. The electromagnetic overhead crane comprises a base body and a lifting block. A working cavity is formed in thebase body and internally provided with a debris removal mechanism. A cleaning cavity is arranged below the working cavity. A sweeping cavity is arranged on the right side of the working cavity. A sweeping mechanism is arranged in the sweeping cavity. A first rectangular groove is formed in the right side of the sweeping cavity. A first rotating shaft is rotationally arranged between the first rectangular groove and the sweeping cavity. The left end of the first rotating shaft extends into the sweeping cavity and is fixedly provided with a first chain wheel. The right end of the first rotatingshaft extends into the base body and is fixedly provided with an electric push rod. A first belt wheel fixedly connected with the first rotating shaft is arranged in the first rectangular groove. A transmission cavity is formed in the right side of the first rectangular groove. A transmission mechanism is arranged in the transmission cavity. A second rotating shaft is rotationally arranged between the transmission cavity and the first rectangular groove.

Owner:东阳格盘机械科技有限公司

Vacuum absorbing template for semiconductor wafer polishing device and polishing device

PendingCN108356684APrevent slippagePrevent slippingPolishing machinesGrinding work supportsEdge structureEngineering

The invention provides a vacuum absorbing template for a semiconductor wafer polishing device and a polishing device, and belongs to the technical field of wafer polishing. The vacuum absorbing template for the semiconductor wafer polishing device comprises a ceramic disc positioned on a polishing head; a groove is formed in the disc surface of the ceramic disc; a vacuum sucker is positioned in the groove; the peripheral edge of the vacuum sucker downwards extends to form a cap edge structure; and a groove is formed in the inner surface of the vacuum sucker, and is connected with a vacuum generation structure by dint of a vacuum hole penetrating through the ceramic disc for vacuum absorption positioning of wafers. The vacuum absorbing template for the semiconductor wafer polishing device has the following beneficial effects: such process links as wax bonding and wax removal are saved, so that the machining time is shortened, and the pollution is prevented; the cap edge structure achieves an anti-scratch protecting effect on the wafers, so that the vacuum absorbing template is more suitable for polishing of semiconductor wafers with lower hardness and formed by such volatile elements as Si, Ge, GaAs and InP; and the vacuum absorbing template achieves a stable positioning maintenance effect on the wafers, improves the yield and the thickness uniformity, and reduces the productioncost.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

Robot part processing clamp with multi-angle fixing function

InactiveCN110065048AEasy to processThe processing position is accurateProgramme-controlled manipulatorGripping headsMotor driveIndustrial engineering

The invention discloses a robot part processing clamp with a multi-angle fixing function. The robot part processing clamp comprises an installing platform, a movable disc and a clamping seat, the movable disc is arranged above the installing platform, the clamping seat is arranged below one end of the movable disc, and a bottom support plate is horizontally arranged below the movable disc. The robot part processing clamp has the beneficial effects that robot parts are clamped and fixed through a plurality of equally-spaced clamping jaws, it is ensured that the robot parts can be processed by aprocessing instrument more conveniently, efficiently and stably; a transferring and connecting seat drives the clamping seat to move front and back on the installing platform to adjust the position,on one hand, the position of processing of the robot parts by the processing instrument is more precise and adjustable, on the other hand, it is ensured that after the robot parts are processed, and the robot parts can be quickly and conveniently transferred and put to the specific position to be arranged; and a first motor drives the clamping seat to rotate by 360 degrees to ensure that the moving, transferring and putting efficiency of the robot parts is high and the scope is wider.

Owner:XUZHOU COLLEGE OF INDAL TECH

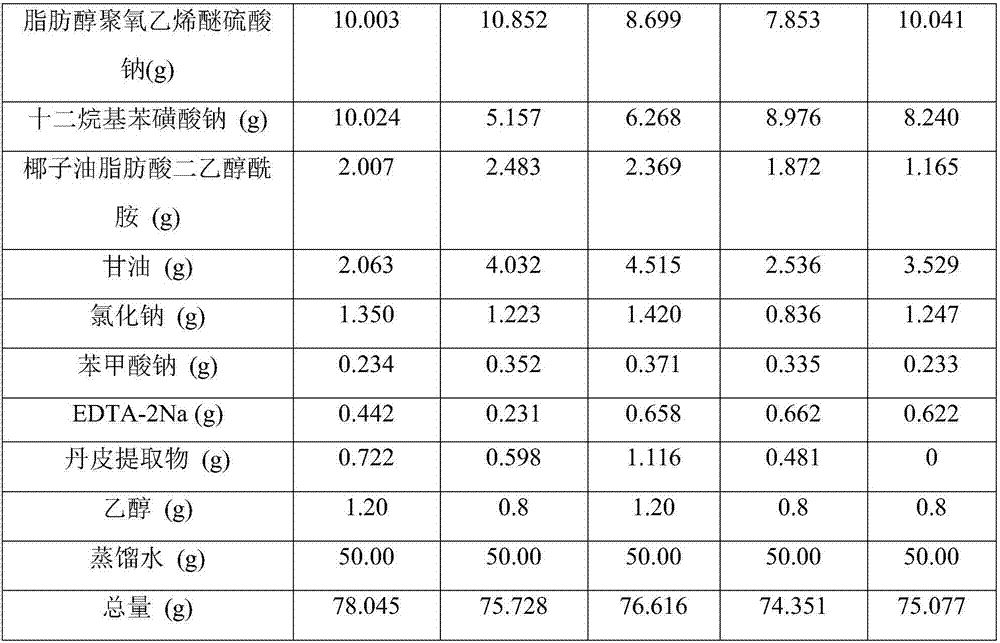

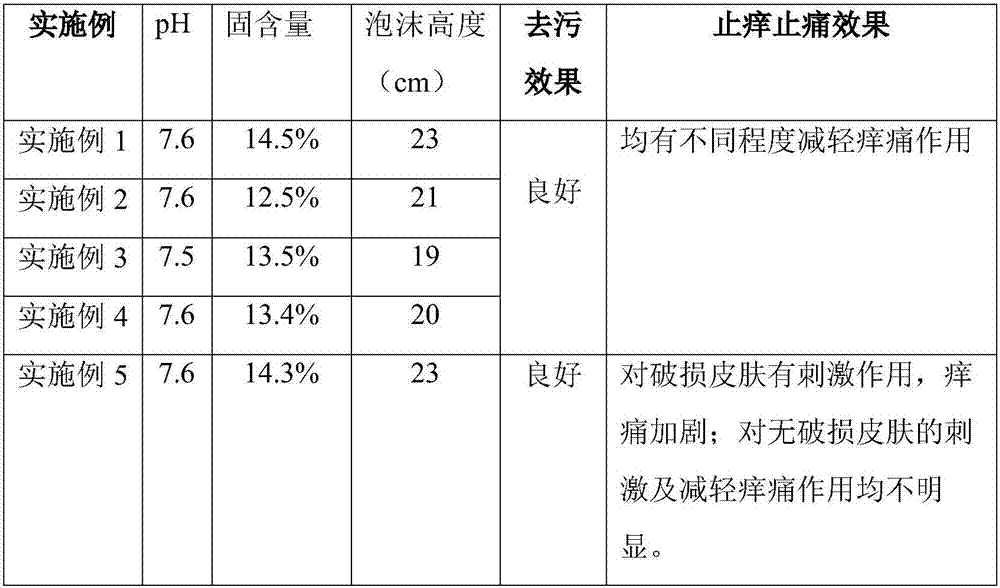

Hand sanitizer and preparation method thereof

InactiveCN107320392AImprove solubilityGood thickening effectCosmetic preparationsToilet preparationsGlycerolHand sanitizer

The invention discloses a hand sanitizer and a preparation method thereof. The hand sanitizer is composed of the following components in percentage by mass: 5%-15% of fatty alcohol polyoxyethylene ether sodium sulfate, 5%-15% of sodium dodecyl benzene sulfonate, 1.5%-3.5% of coconut oil fatty acid diethanolamide, 3.0%-6.0% of glycerol, 1.0%-2.0% of sodium chloride, 0.2%-0.5% of sodium benzoate, 0.2%-1.0% of EDTA-2Na, 0.5%-2.0% of a cortex moutan extract, 1.0%-1.5% of ethanol and the balance of distilled water, wherein the cortex moutan extract is prepared by adopting an ethanol-water-sodium chloride aqueous two phase method. The hand sanitizer is low in alkalinity and non-irritant, has the effects of relieving itching and stopping pain, can alleviate pain and itching sensations during cleaning of allergic-type and eczema-type skins and skin with mosquito bites and insect bites, has good decontamination effect, is simple to operate, and is low in cost.

Owner:CHONGQING UNIV

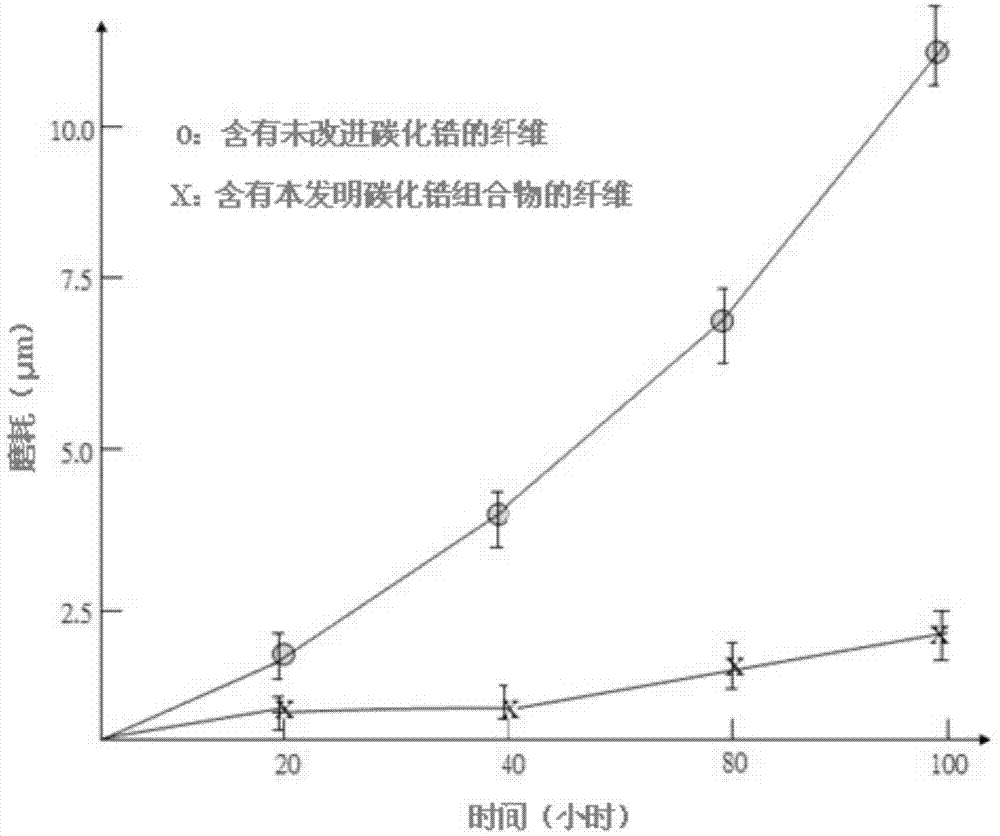

Zirconium carbide composition used in fiber material and preparation method thereof

InactiveCN103484959AReduce height differenceReduce or eliminate sharp appearanceArtifical filament manufactureFiberSpinning

The invention discloses a zirconium carbide composition used in a fiber material and a preparation method thereof. The zirconium carbide composition comprises the following components by weight: 79-89.5% of zirconium carbide, 0.5-1% of a metal oxide and 10-20% of resin. The preparation method of the zirconium carbide composition consists of: firstly, putting zirconium carbide powder in an oily solution to perform mechanical grinding, then using the metal oxide to fill the recess on a zirconium carbide surface to reduce the height difference on the zirconium carbide surface, and finally performing cladding with a resin soft material to form a relatively flat powder surface. The pointed appearance existing on the powder surface can be reduced or eliminated, thus avoiding the guide wire scratching damage problem generated in a follow-up spinning process.

Owner:周雷生

Saving type paint spraying device for tubular accessory of automobile

ActiveCN109046825AEasy to fixReduce wastePretreated surfacesLiquid spraying apparatusEngineeringWelding

The invention discloses a saving type paint spraying device for a tubular accessory of an automobile. The paint spraying device comprises an upper transverse plate, supporting rods and a tubular accessory body; a paint liquid storage box is fixedly mounted on the lower surface of the upper transverse plate; spraying connectors are fixedly mounted on the lower surface of the paint liquid storage box; the upper ends of the supporting rods are connected to the lower surface of the upper transverse plate through welding; the tubular accessory body is mounted under the spraying connectors; a limiting block is connected to the outer surface of a fixing block through welding; a fixing pipe is connected to the inner side surface of a first connecting disk through welding; a negative-pressure fan is fixedly mounted on the right side of a collecting box; a second booster pump is fixedly mounted below the left end of the collecting box; a second connecting disk is connected to the left end of a connecting shaft through welding; and a motor is fixedly connected to the right end of the connecting shaft. By the aid of the saving type paint spraying device for the tubular accessory of the automobile, the tubular accessory body can be fixed conveniently, waste of the paint liquid can be reduced, and drying of the paint liquid on the surface of the tubular accessory body can be accelerated.

Owner:新昌县维斯机械有限公司

Display screen detection device

InactiveCN113029812ASpeed up the detection progressAvoid scratch damageMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesMechanical engineeringPhysics

A display screen detection device disclosed by the present invention comprises a box body, the upper surface of the box body is fixedly connected with a bottom plate, the middle part of the upper surface of the bottom plate is fixedly provided with two mounting seats, the upper surfaces of the two mounting seats are fixedly provided with first electric cylinders, and the two first electric cylinders are oppositely arranged. A concave sliding groove is formed in the middle of the upper surface of the bottom plate. The first electric cylinders are matched with the lifting assemblies, so that the display screen can be tested at different bending angles, the detection device is suitable for bending tests of display screens of different sizes, damage-free tests are achieved when the display screen is tested through the adsorption mechanism, the phenomenon that the display screen is scratched and damaged during testing is avoided, the air cylinder is matched with the second electric cylinder and the supporting plate, pressure testing of the display screen is achieved, a detector does not need to place the display screen on another test workpiece for testing, and the detection efficiency is greatly improved.

Owner:林贵滨

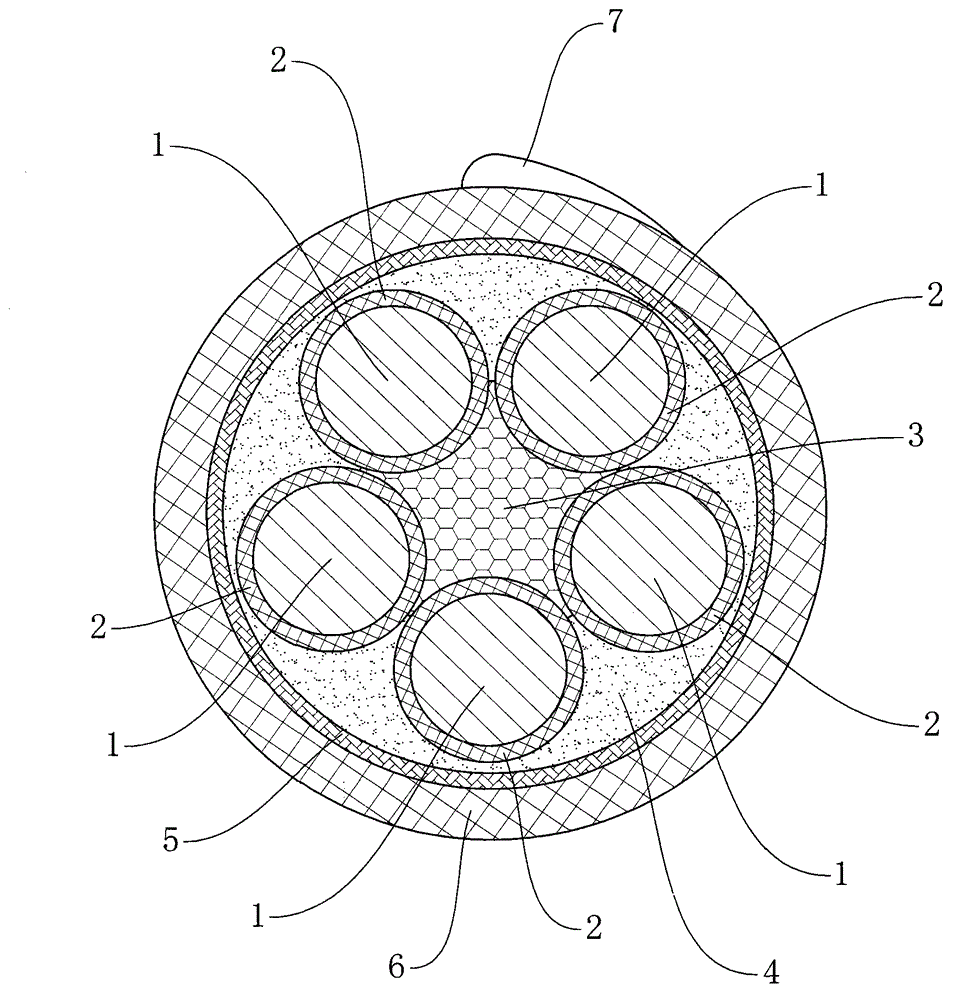

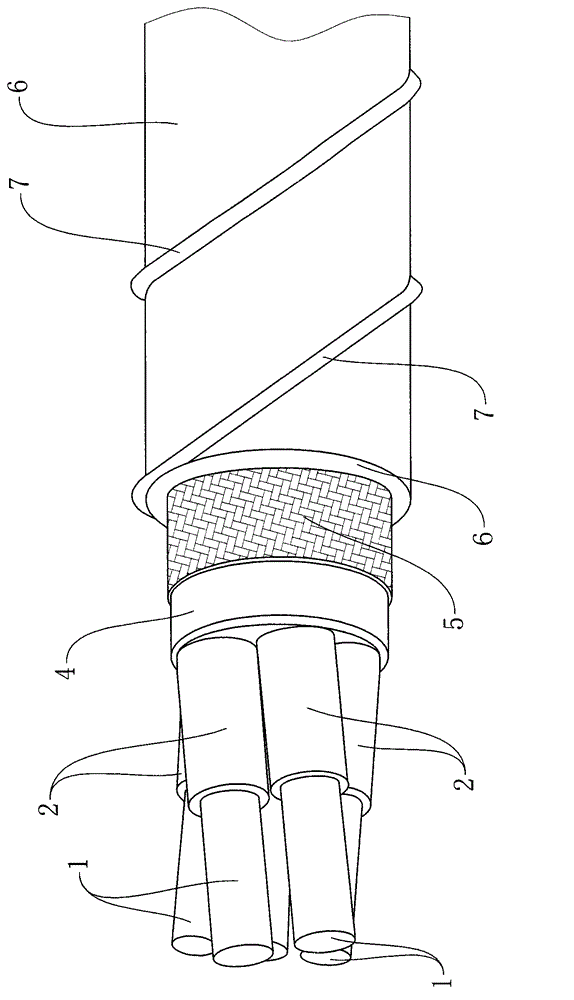

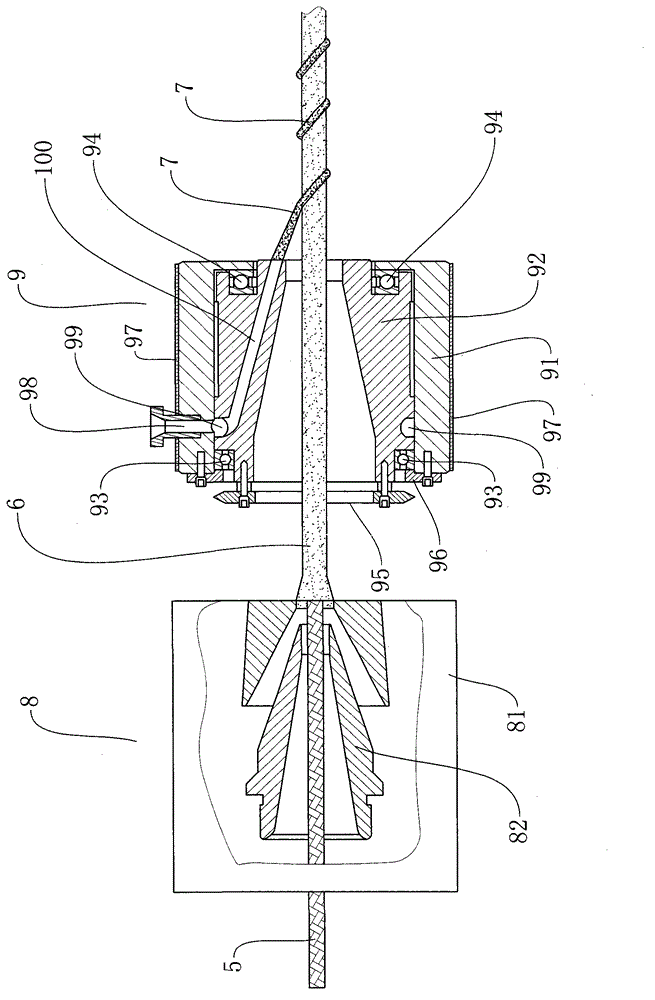

Movable cable of resistance to drag and scraping prevention and extrusion forming mould device thereof

InactiveCN103151106ANot easy to scratchExcellent qualityInsulated cablesInsulated conductorsCopper conductorWear resistant

The invention relates to a movable cable of resistance to drag and scraping prevention and an extrusion forming mould device of the movable cable of resistance to drag and scraping prevention. The movable cable of resistance to drag and scraping prevention and an extrusion forming mould device of the movable cable of resistance to drag and scraping prevention are characterized in that the movable cable is composed of a plurality of soft qualitative copper conductor, an insulation coated layer, a filling rope, a rubber and plastic lining layer, an aramid fiber weaving strengthening layer, an elastic soft outer protecting sleeve layer, a wear-resistant rubber and plastic rib strip and the like. The extrusion forming mould device is composed of an extrusion forming front mould with the elastic soft outer protecting sleeve layer and an extrusion forming back mould of the wear-resistant rubber and plastic rib strip. The extrusion forming back mould of the wear-resistant rubber and plastic rib strip is composed of a mould seat, an inner mould, a front bearing, a back bearing, a ratchet wheel, a pressing cover and an electric heating coil. A rubber and plastic rib strip with a spiral shaped structure is arranged on the surface of a movable cable protecting sleeve layer. The movable cable of resistance to drag and scraping prevention is pulled and moved, a cable body is hung in the air from the ground, thus occurrence of scraping and breakage that the cable body is directly rubbed with the ground and hard objects is avoided. A contact area of the cable and the ground is greatly reduced at the same time, thus labor intensity when the cable is constructed and moved is relieved with a large degree.

Owner:广东中宝联合电缆有限公司

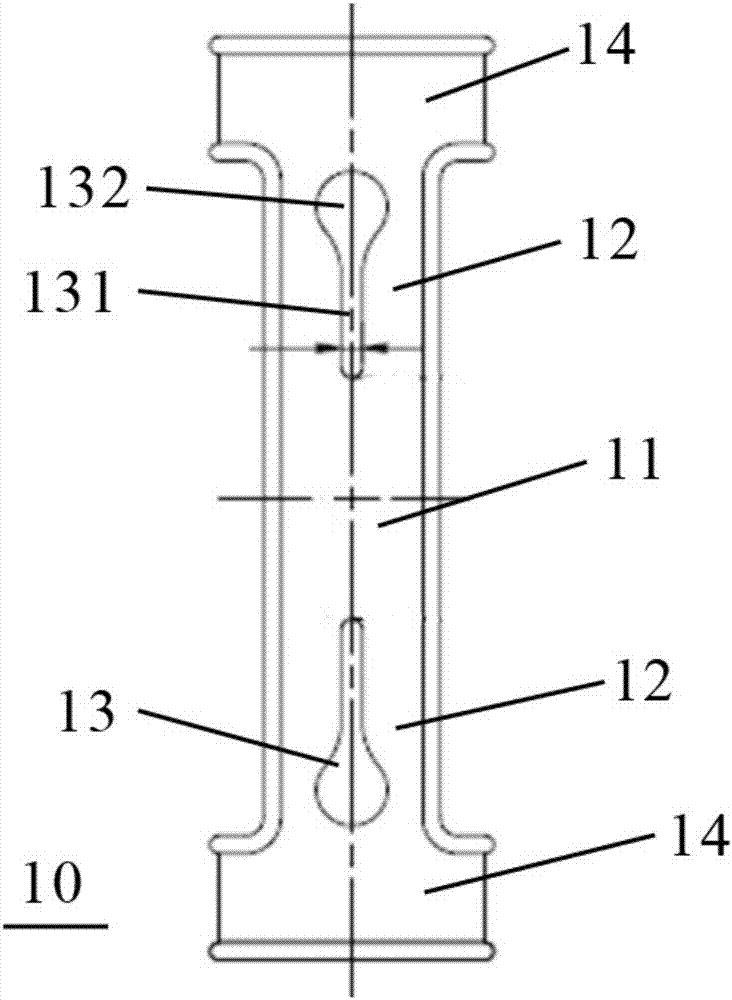

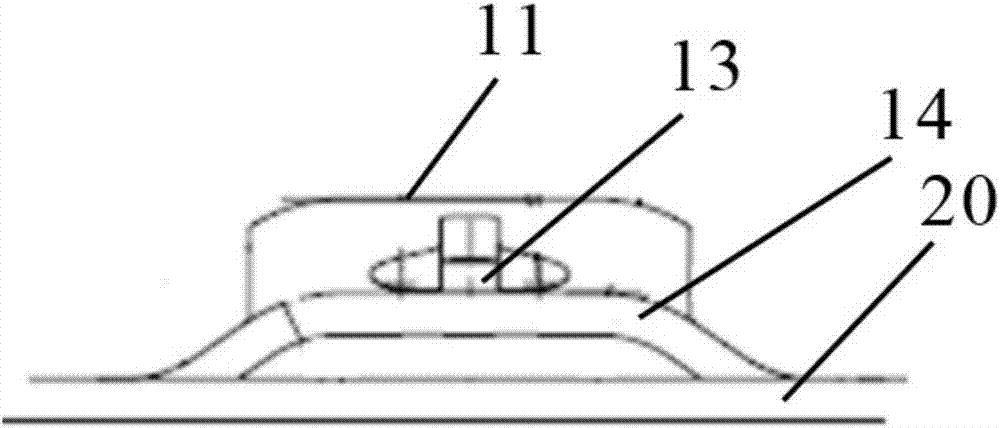

Nuclear fuel component, positioning grid and spring

PendingCN107221358AReduced choke areaAvoid scratch damageNuclear energy generationFuel element assembliesWater flowMechanical engineering

The invention relates to a nuclear fuel component, a positioning grid and a spring. The spring comprises a contact part and two connecting parts, wherein the contact part is in tight pressing and contact with a fuel rod of a fuel component; the two connecting parts are arranged at two ends of the contact part in directions far away from the fuel rod; and water flowing holes are formed in positions close to the contact part, in the connecting parts. As the water flowing holes are formed in the connecting parts of the spring in positions close to the contact part, the flowing blocking area of the spring is reduced, and furthermore the pressure loss of the positioning grid is reduced; in addition, as the water flowing holes are not formed in the contact part, scratching of the fuel rod in the insertion process is avoided; and furthermore, due to formation of the water flowing holes, the rigidity of the spring is degraded, the elastic clamping force of the spring is increased, and the fuel rod can be relatively well clamped.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com