Scatheless grinding method for rigid, fragile crystal wafer

A substrate and crystal technology, applied in the field of ultra-precision processing of hard and brittle crystal substrates, can solve the problems of environmental pollution, low processing efficiency, high processing cost, etc., and achieve high material removal rate, high grinding precision, and low processing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

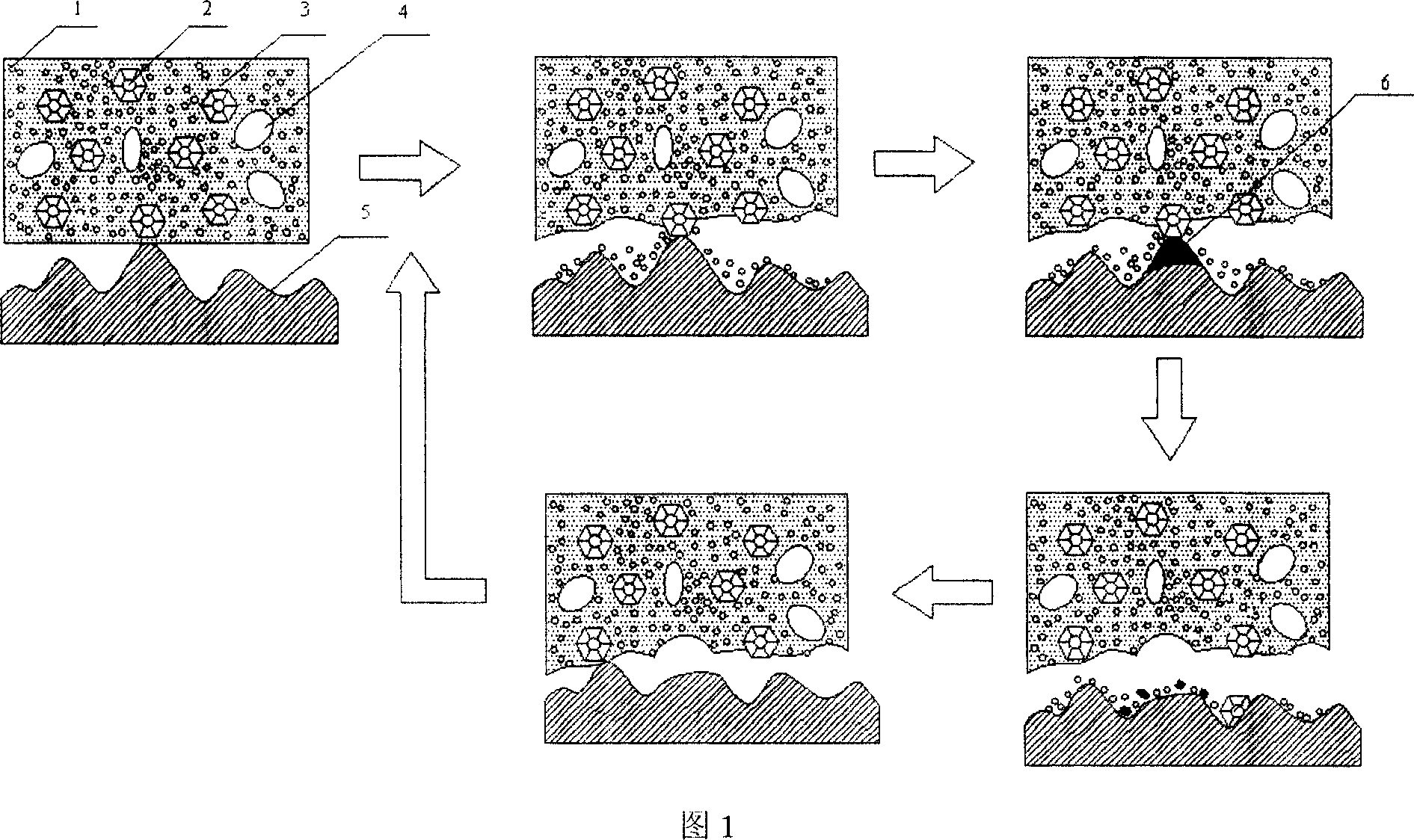

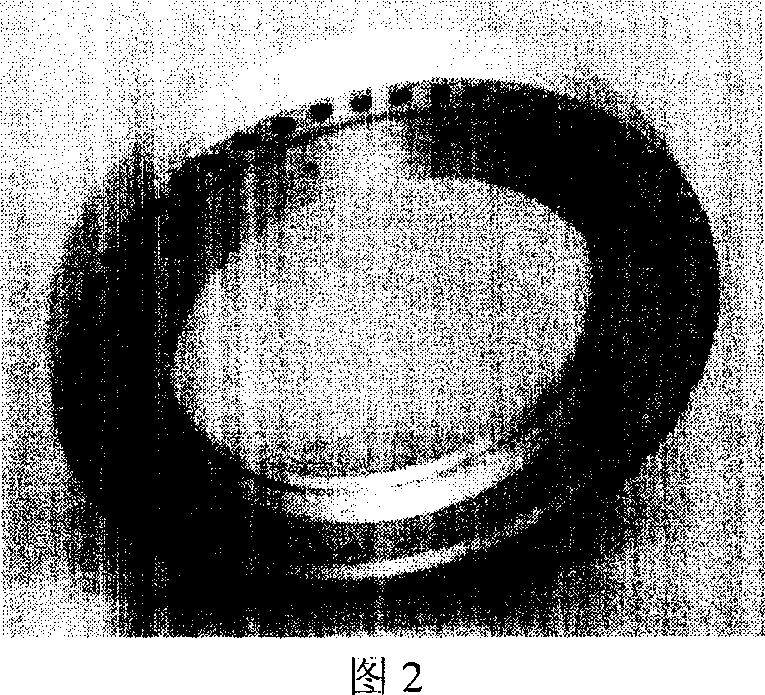

[0012] The specific implementation of the present invention will be described in detail in conjunction with the accompanying drawings. Using VG401 MKII ultra-precision wafer grinder, using a single crystal silicon substrate as a sample, using #3000 ceria abrasive (harder than single crystal silicon substrate), resin adhesive and surfactant, strong acid and weak alkali salt The grinding wheel made of fillers such as pH regulator, oxidizing agent, etc., the actual grinding wheel is shown in Figure 2. Install the grinding wheel on the spindle of the VG401MKII ultra-precision grinding machine. The dressing disc adopts a diamond grinding wheel electroplated on the metal substrate. Next, the monocrystalline silicon substrate is fixed on the grinding machine on the clamping table; the grinding feed rate is selected as 1 μm / min, the rotation speed of the grinding wheel is 600 n / min, and the rotation speed of the hard and brittle crystal substrate is 80 n / min. Ionized water is used as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com