Turntable type full-automatic blade grinding machine

A fully automatic grinding machine technology, which is applied to the parts of grinding machine tools, grinding drive devices, grinding/polishing equipment, etc., which can solve the problem that it is difficult to accurately control the edge accuracy and ensure the consistency of the blade edge shape in batches. , low efficiency and other issues, to achieve the effect of improving grinding accuracy and processing efficiency, improving product quality and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

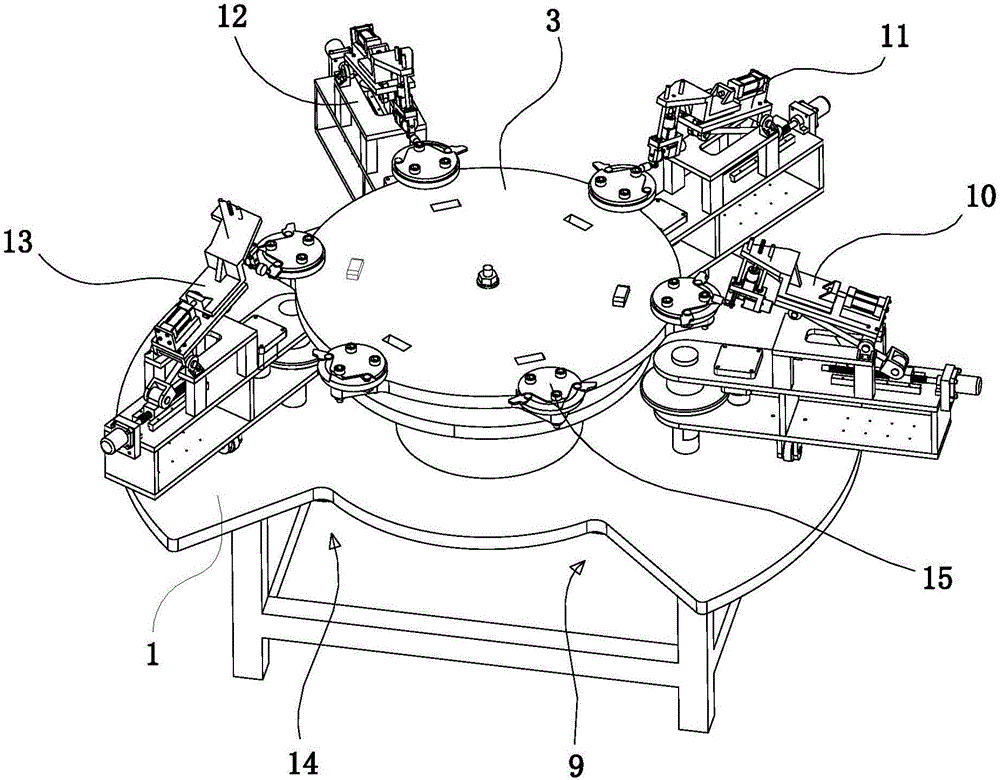

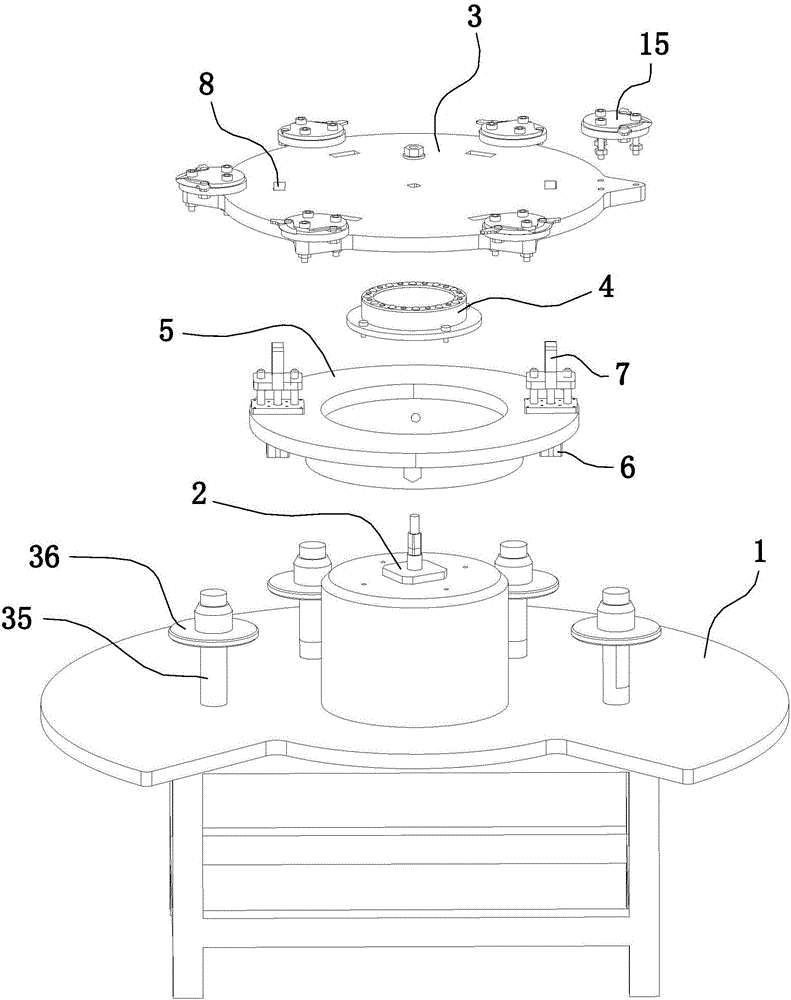

[0029] see Figure 1-Figure 13 , a turntable type fully automatic blade grinder.

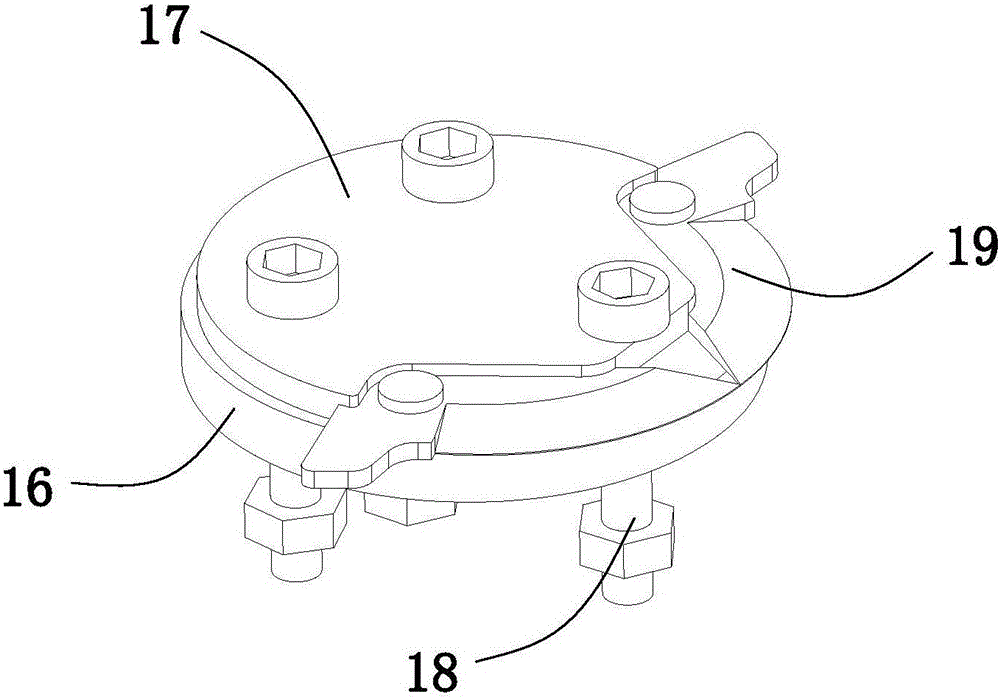

[0030] It includes the operator station, see figure 1 , figure 2 and Figure 7 , the operating table 1 is provided with an indexing plate 3 controlled by a stepping motor 2, the stepping motor 2 is fixedly arranged on the operating table 1, and a turntable 4 for carrying the indexing plate 3 is installed on the upper end of the stepping motor 2, and the stepping The drive shaft of the motor 2 passes through the center of the turntable 4 and is connected with the indexing plate 3 , and the stepping motor 2 drives the indexing plate 3 to rotate stepwise on the turntable 4 . The operating table 1 is also fixedly connected with a positioning plate 5, the positioning plate 5 is provided with a positioning block 7 driven and control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com