Circular revolution grinding equipment

A kind of equipment and circumference technology, which is applied in the field of circumferential revolution grinding equipment, can solve the problems of low grinding precision and low work efficiency, and achieve the effects of improving efficiency, reducing labor intensity and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

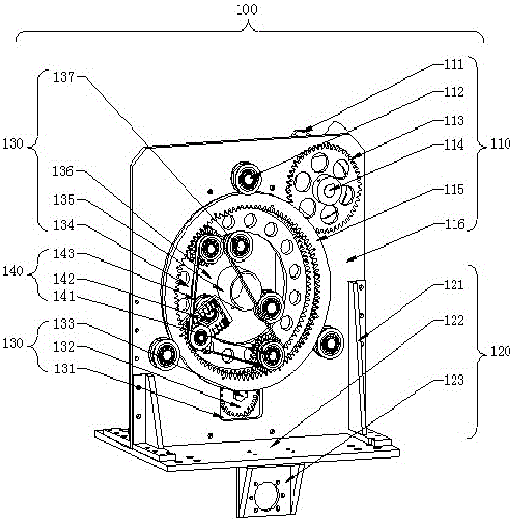

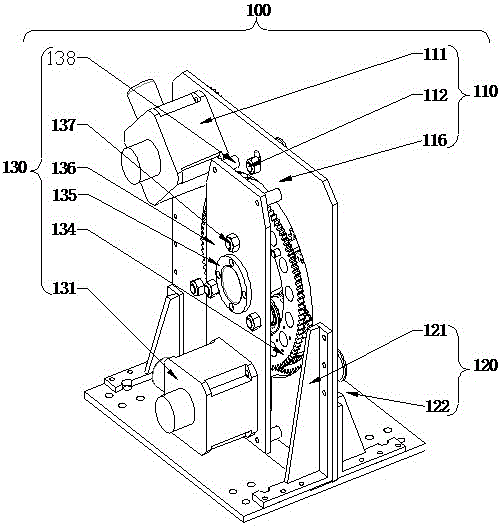

[0059] In order to describe in detail the technical content, structural features, goals and effects achieved by a kind of circular revolution grinding equipment of the present invention, the following will be further described in conjunction with the embodiments and accompanying drawings.

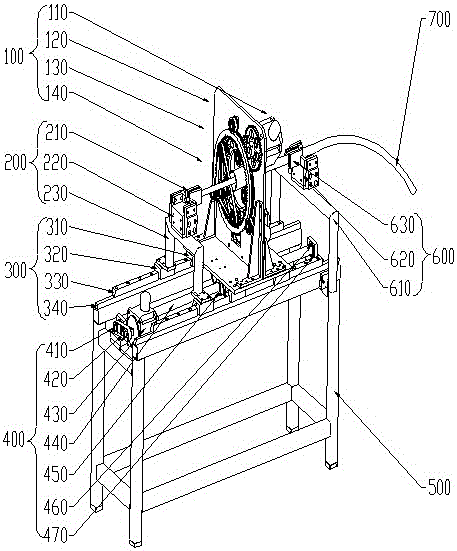

[0060] like figure 1 As shown, an embodiment of a circular revolution grinding device of the present invention and its application are disclosed, including: a grinding device 100, a clamping device I 200, a sliding device 300, a moving device 400, a support mechanism 500, and a clamping device II 600 and the object to be polished 700; the grinding device 100 is connected with the ball screw 440 through the screw nut seat 123 and can rotate relatively; I 200 is connected to two bracket sliders 320 through the cylinder sliding bracket 230 and bolts, and one end of the object 700 to be polished is clamped by the pneumatic claw I 210; connection, two pairs of substrate sliders 310 and a pair o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com