Zirconium carbide composition used in fiber material and preparation method thereof

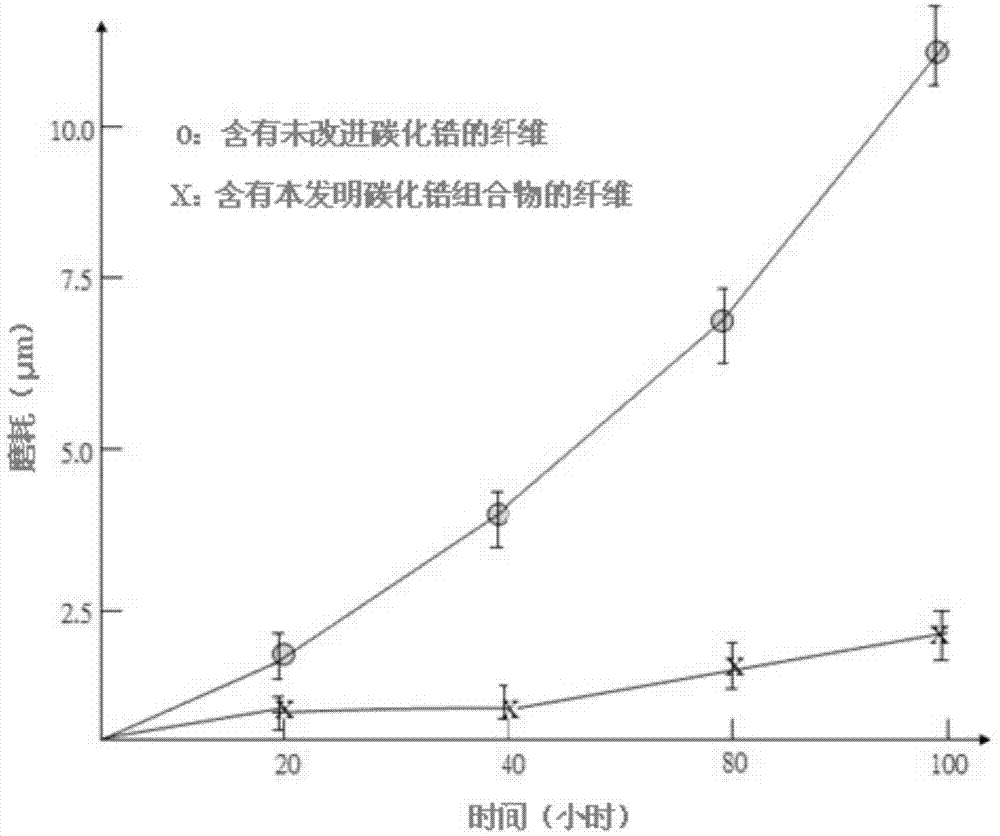

A fiber material, zirconium carbide technology, applied in the field of fiber applications, can solve problems such as damage, high hardness, and unsmooth continuity of the textile process, and achieve the effect of avoiding scratches and damage of wire guides and reducing height differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The invention relates to a zirconium carbide composition used in fiber materials, which comprises the following components in weight percentage: 79% of zirconium carbide, 1wt% of titanium oxide and 20wt% of phenolic resin.

[0026] A kind of preparation method of above-mentioned zirconium carbide composition, it comprises the following steps:

[0027] 1) First, put 79% zirconium carbide powder in methyl acetate solution for grinding, and the particle size of zirconium carbide after grinding is 0.2 μm;

[0028] 2) Add the ground zirconium carbide to an aqueous solution containing a reducing agent (glucose), then filter and dry, the reducing agent is deposited on the surface of the zirconium carbide, and then add the dried zirconium carbide to a salt containing 1wt% titanium oxide Aqueous solution, the reducing agent on the surface of zirconium carbide precipitates titanium oxide, because titanium oxide precipitates on the sharp part of the surface of zirconium carbide an...

Embodiment 2

[0032] The invention relates to a zirconium carbide composition used in fiber materials, which comprises the following components in weight percentage: 89.5% of zirconium carbide, 0.5wt% of titanium oxide and 10wt% of phenolic resin.

[0033] A kind of preparation method of above-mentioned zirconium carbide composition, it comprises the following steps:

[0034] 1) First, put 89.5% zirconium carbide powder in ethyl acetate solution for grinding, and the particle size of zirconium carbide after grinding is 0.6 μm;

[0035] 2) Add the ground zirconium carbide to an aqueous solution containing a reducing agent (glucose), then filter and dry, the reducing agent is deposited on the surface of the zirconium carbide, and then add the dried zirconium carbide to a salt containing 0.5wt% titanium oxide As an aqueous solution, the reducing agent on the surface of zirconium carbide precipitates titanium oxide, and because titanium oxide precipitates on the sharp part of the surface of zir...

Embodiment 3

[0039] The present invention is a zirconium carbide composition used in fiber materials, which comprises the following components in weight percent: 86% zirconium carbide, 0.8wt% titanium oxide and 13.2wt% phenolic resin.

[0040] A kind of preparation method of above-mentioned zirconium carbide composition, it comprises the following steps:

[0041] 1) First, put 86% zirconium carbide powder in propyl acetate solution for grinding, and the particle size of zirconium carbide after grinding is 0.4 μm;

[0042] 2) Add the ground zirconium carbide to an aqueous solution containing a reducing agent (glucose), then filter and dry, the reducing agent is deposited on the surface of the zirconium carbide, and then add the dried zirconium carbide to a salt containing 0.8wt% zinc oxide As an aqueous solution, the reducing agent on the surface of zirconium carbide precipitates zinc oxide. Since zinc oxide precipitates on the sharp point on the surface of zirconium carbide, it is easy to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com