Glue film automatic production line

An automatic production line and adhesive film technology, applied in the direction of sending objects, thin material processing, transportation and packaging, etc., can solve the problems of not being able to observe whether waste materials are cut, increase production costs, and low material utilization, so as to facilitate automated production , Save production costs, improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

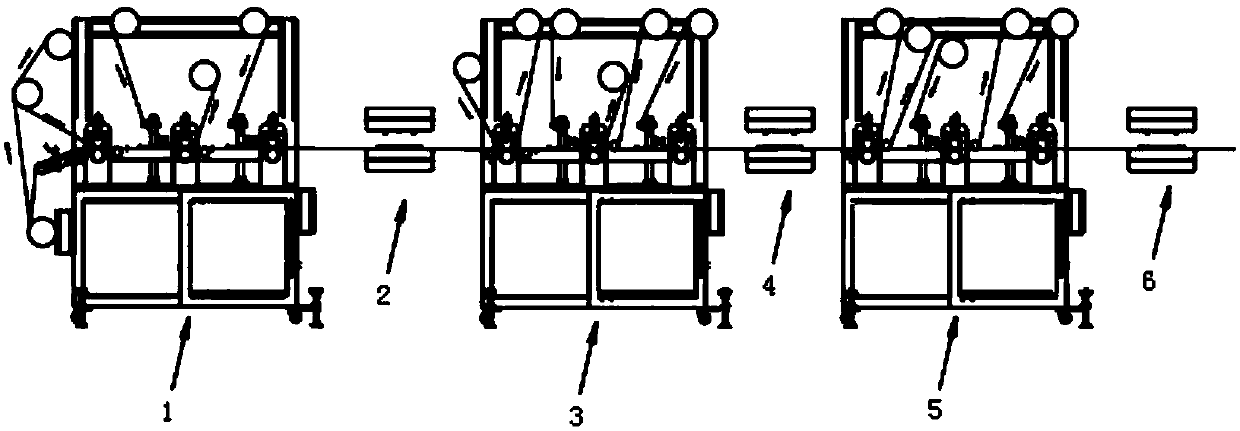

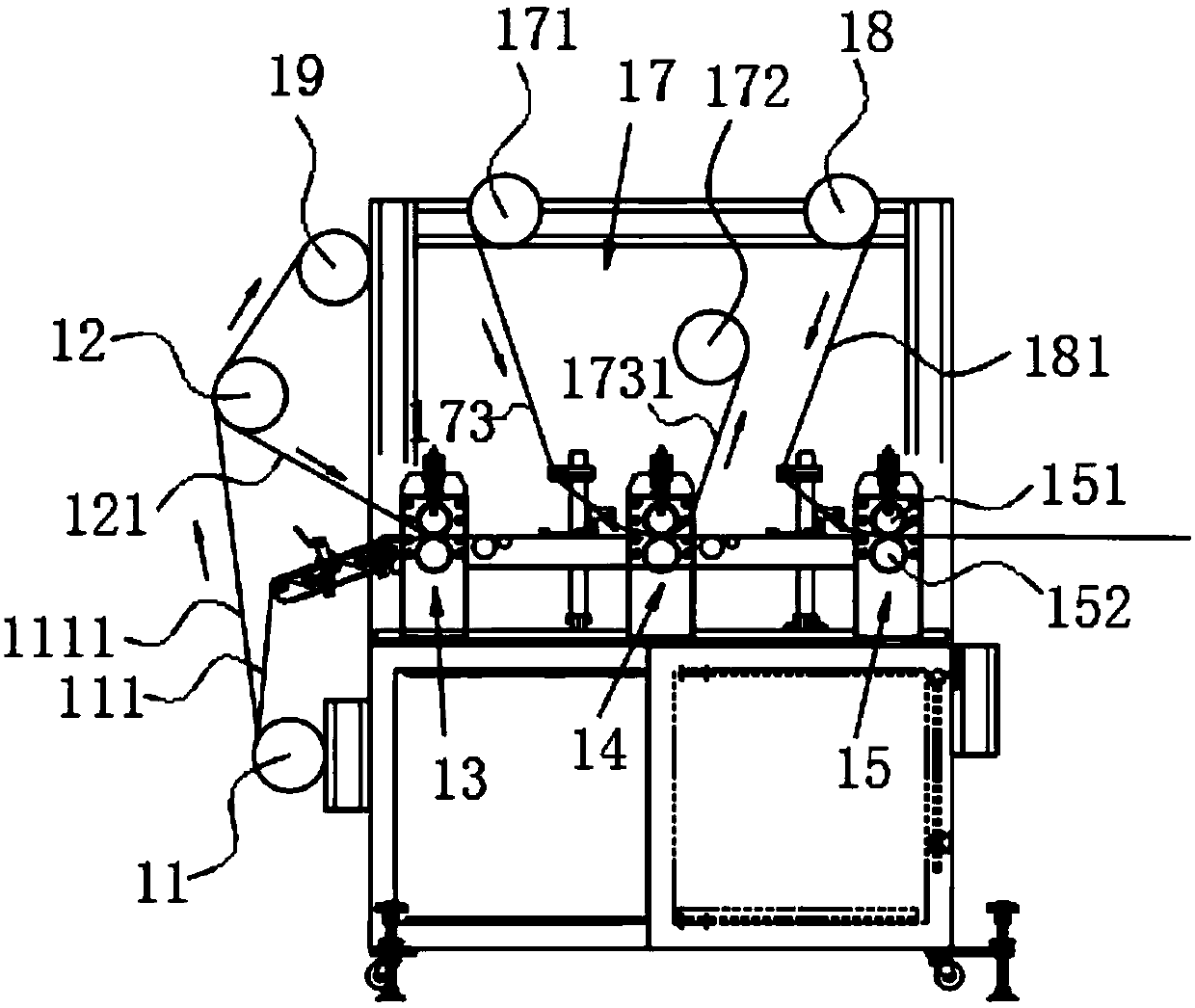

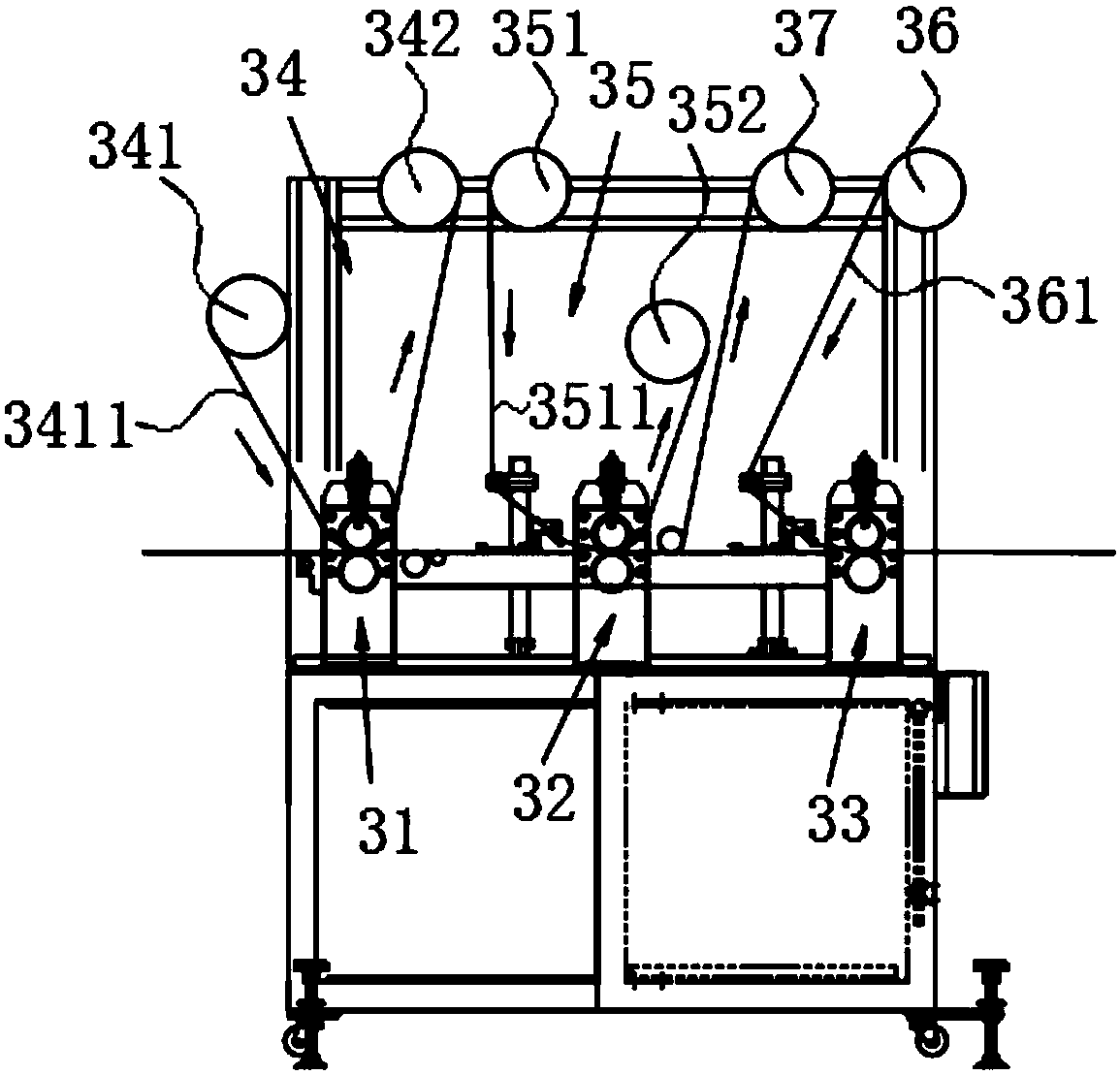

[0049] Embodiment: a kind of film automatic production line, as Figure 1-Figure 12 As shown, it includes a feeding device 1, a small hole die-cutting device 2, a first waste discharge device 3, an inner frame die-cutting device 4, a second waste discharge device 5 and a release film die-cutting device 6, and the feeding device 1 is located upstream of the small hole die-cutting device 2, the small hole die-cutting device 2 is located upstream of the first waste discharge device 3, and the first waste discharge device 3 is located at the inner frame die-cut device 4 Upstream of the inner frame die-cutting device 4 is located upstream of the second waste discharge device 5, and the second waste discharge device 5 is located upstream of the release film die-cutting device 6;

[0050] The feeding device 1 includes a substrate discharge roller 11, a welt tape discharge roller 12, a first belt pressing mechanism 13, a second belt pressing mechanism 14 and a third belt pressing mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com