Patents

Literature

89results about How to "Excellent quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

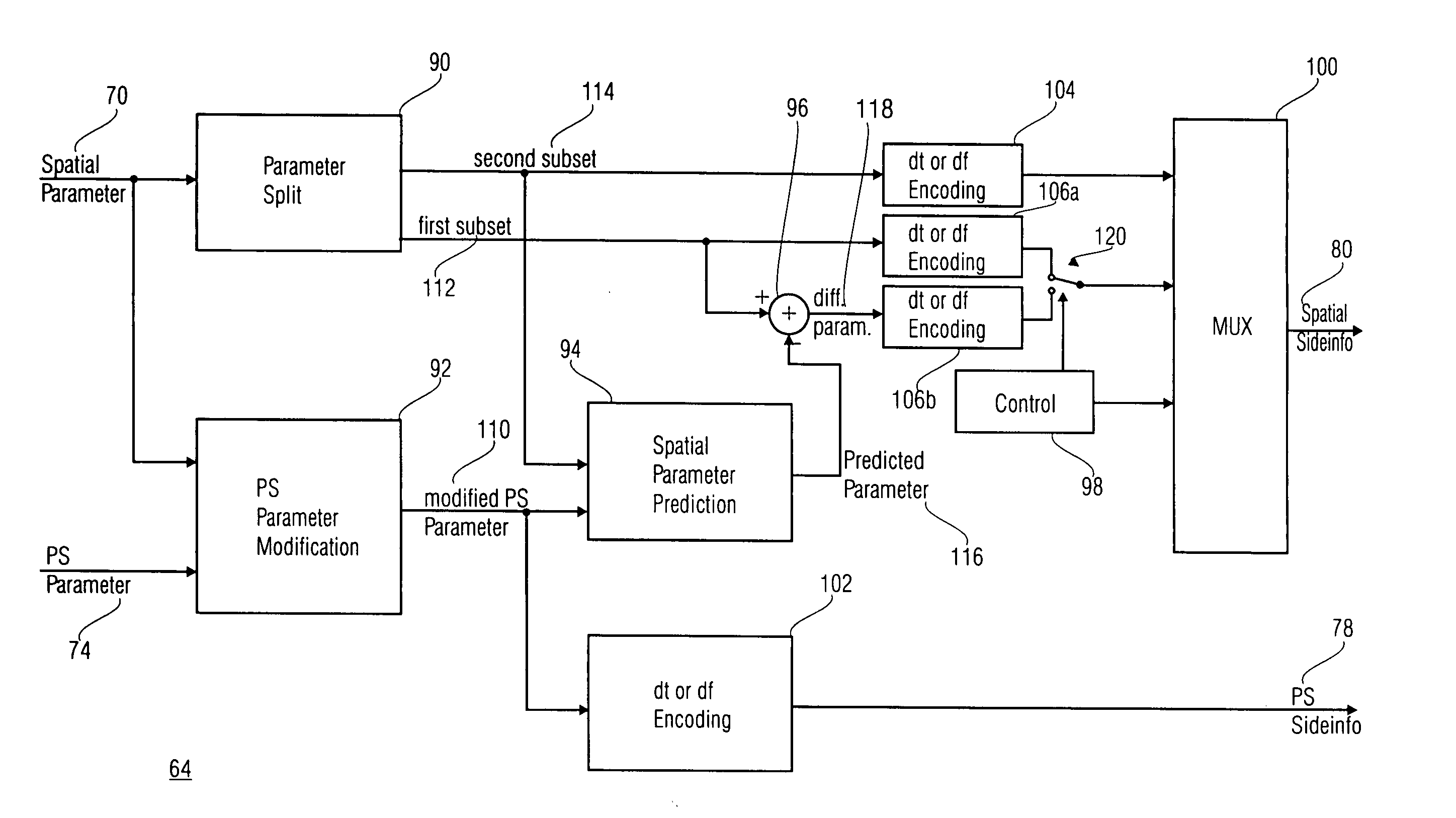

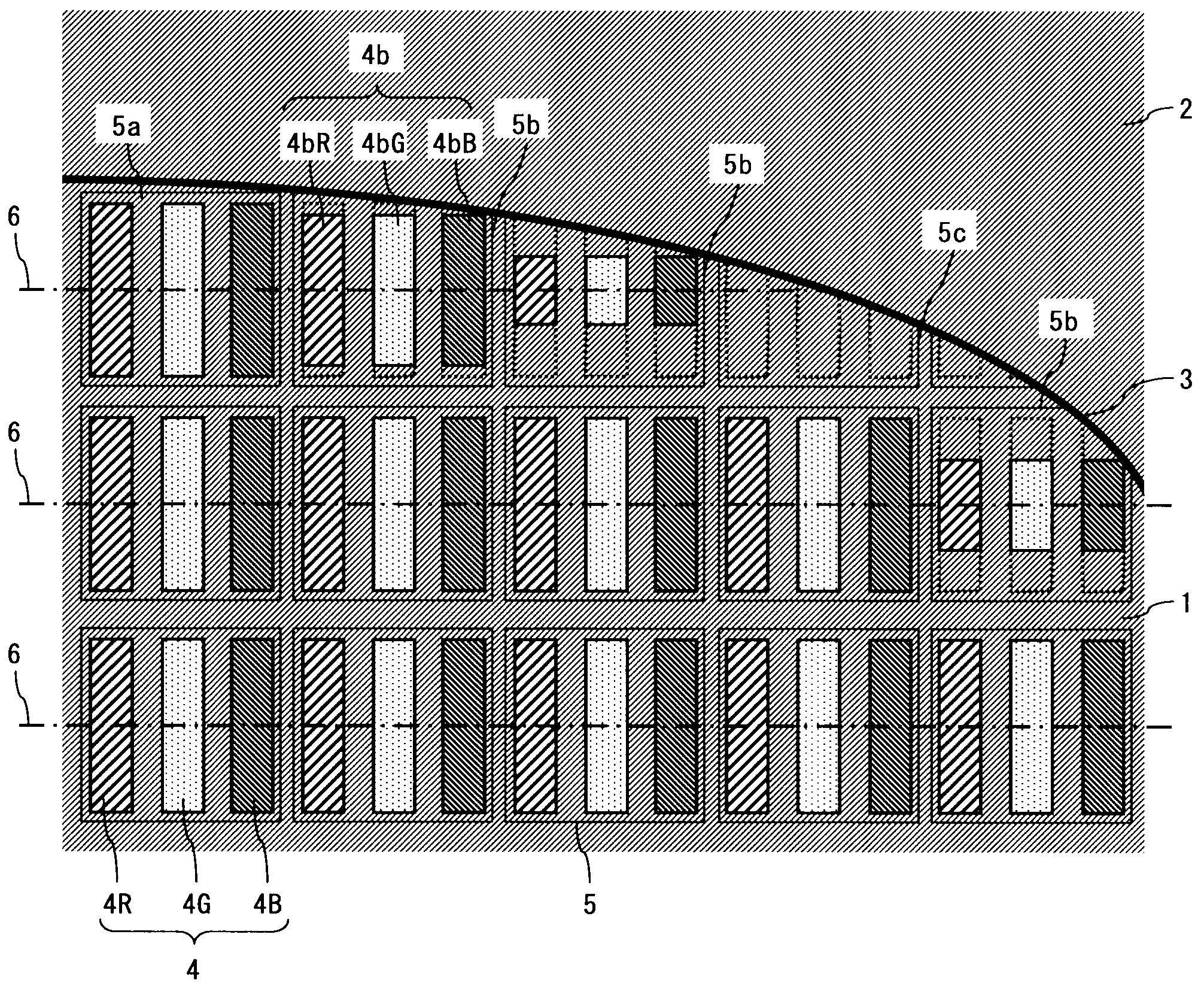

Stereo compatible multi-channel audio coding

ActiveUS20060133618A1High qualityExcellent qualitySpeech analysisCode conversionStereophonic soundAudio signal

A parametric representation of a multi-channel audio signal having parameters suited to be used together with a monophonic downmix signal to calculate a reconstruction of the multi-channel audio signal can efficiently be derived in a stereo-backwards compatible way when a parameter combiner is used to generate the parametric representation by combining a one or more spatial parameters and a stereo parameter resulting in a parametric representation having a decoder usable stereo parameter and an information on the one or more spatial parameters that represents, together with the decoder usable stereo parameter, the one or more spatial parameters.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV +2

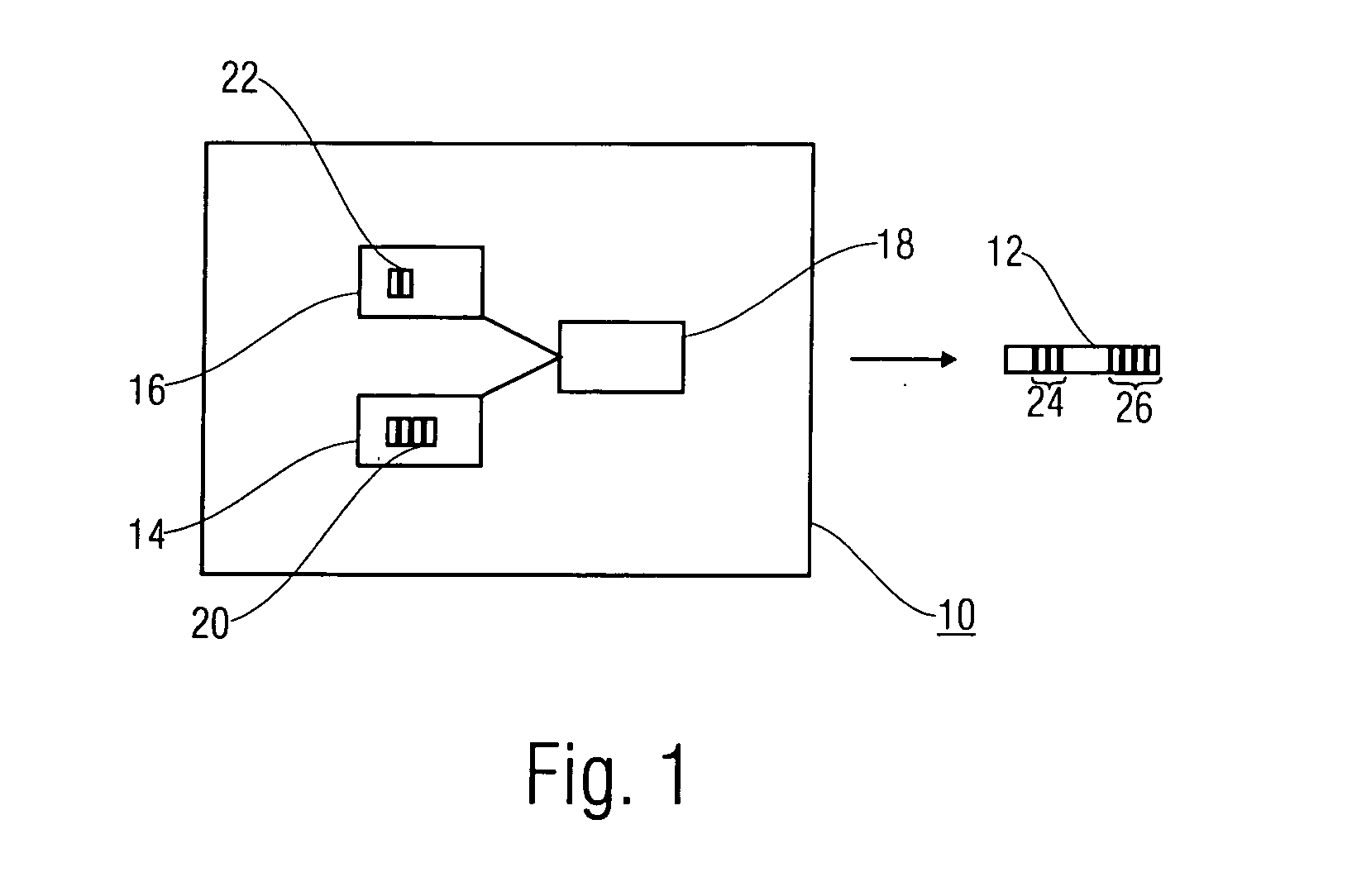

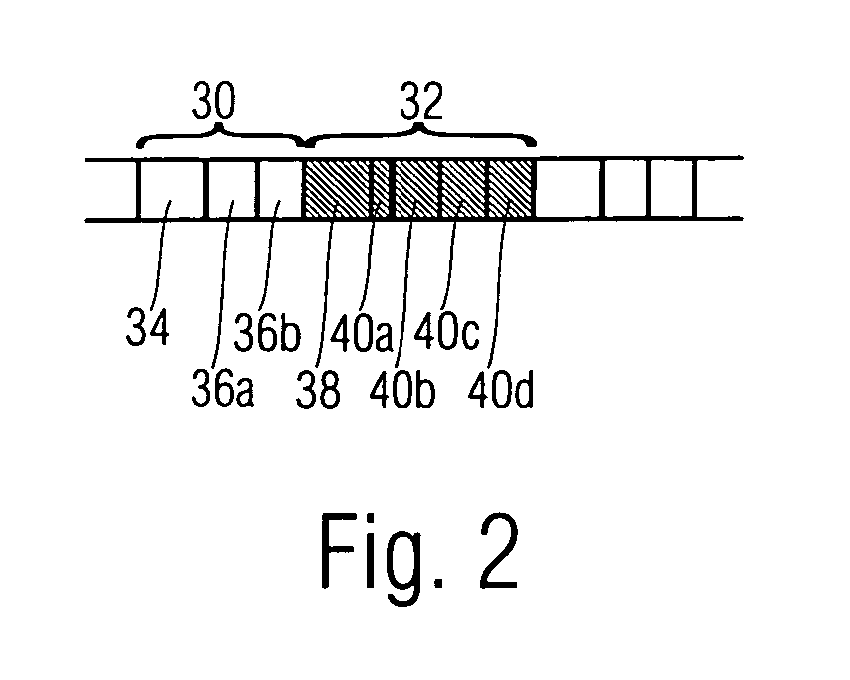

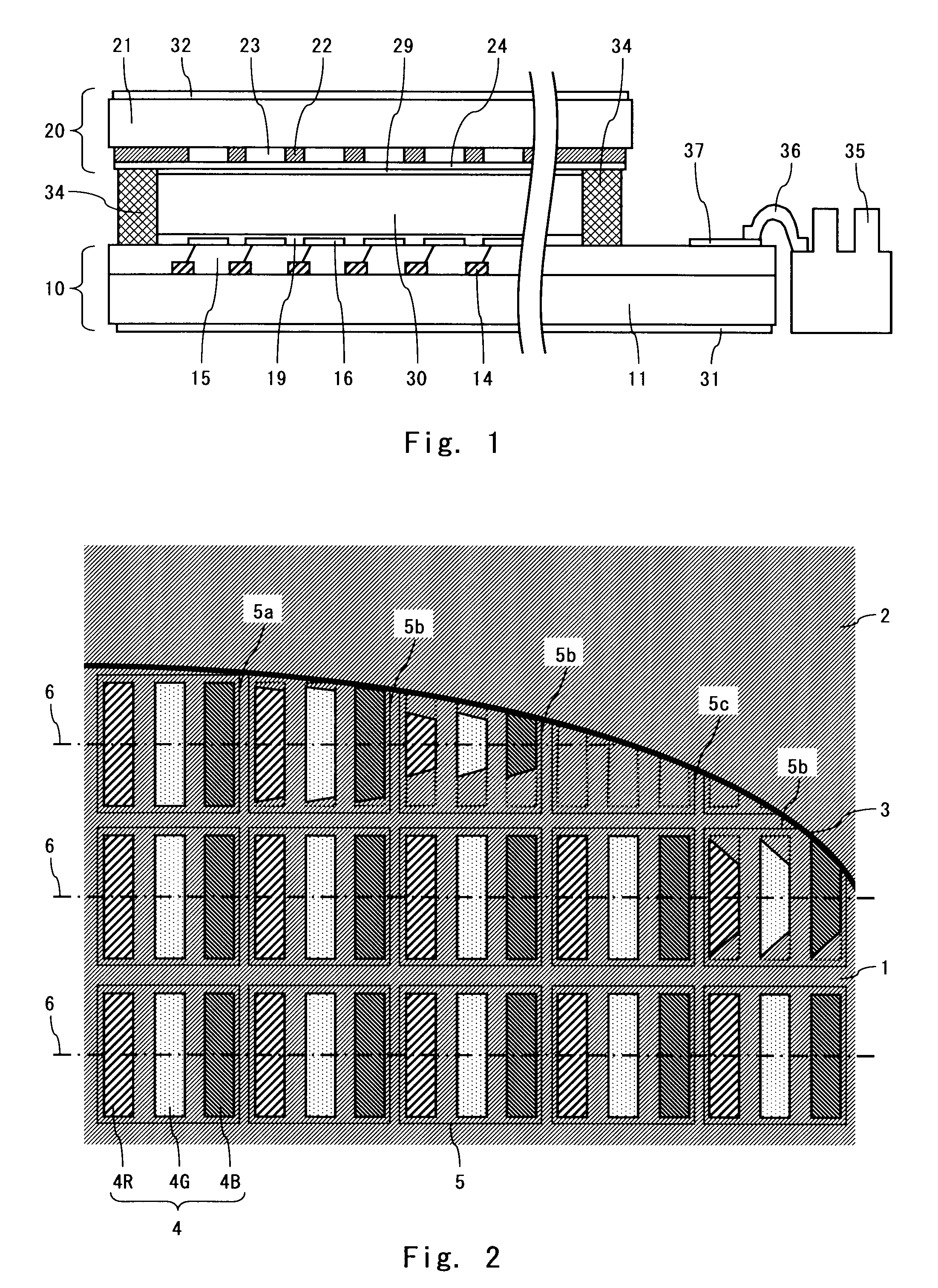

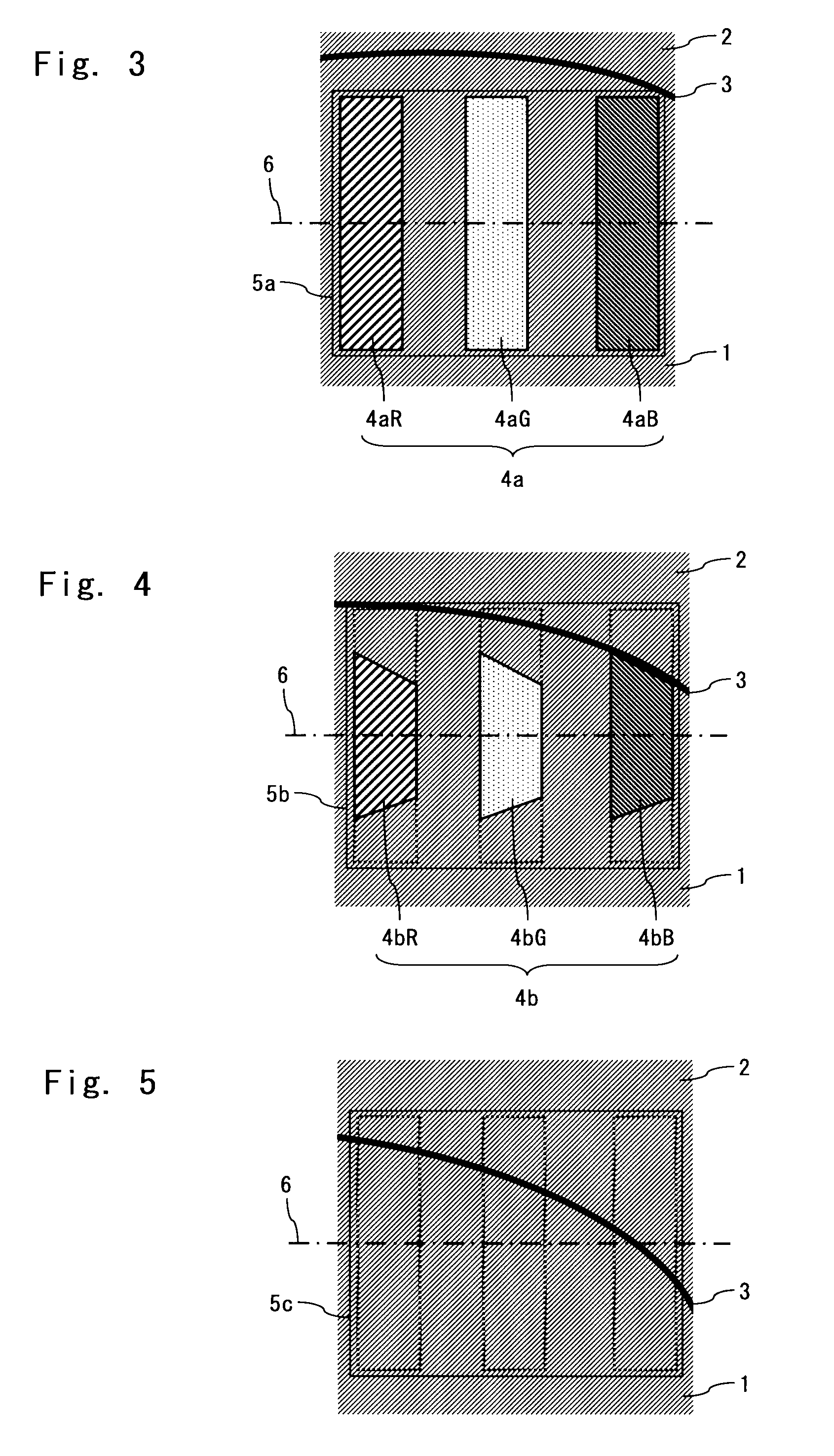

Display device

ActiveUS20090309813A1Excellent qualityImprove display qualityStatic indicating devicesNon-linear opticsDisplay deviceComputer graphics (images)

A display device in accordance with an exemplary aspect of the present invention includes a non-rectangular display area, a frame area surrounding the display area, a plurality of picture elements arranged in the display area, and a plurality of effective display areas having respective colors provided in the picture elements, wherein each of the plurality of effective display areas having respective colors provided in the picture element located in a boundary portion of the display area (display-area edge) is formed such that aperture ratios are the same within one picture element and that center lines in terms of a second direction (longitudinal direction) perpendicular to a first direction along which each color of the effective display areas having respective colors is lined up are located on an extension line of the center line of effective display areas provided in the picture element adjacent in a first direction (lateral direction).

Owner:MITSUBISHI ELECTRIC CORP

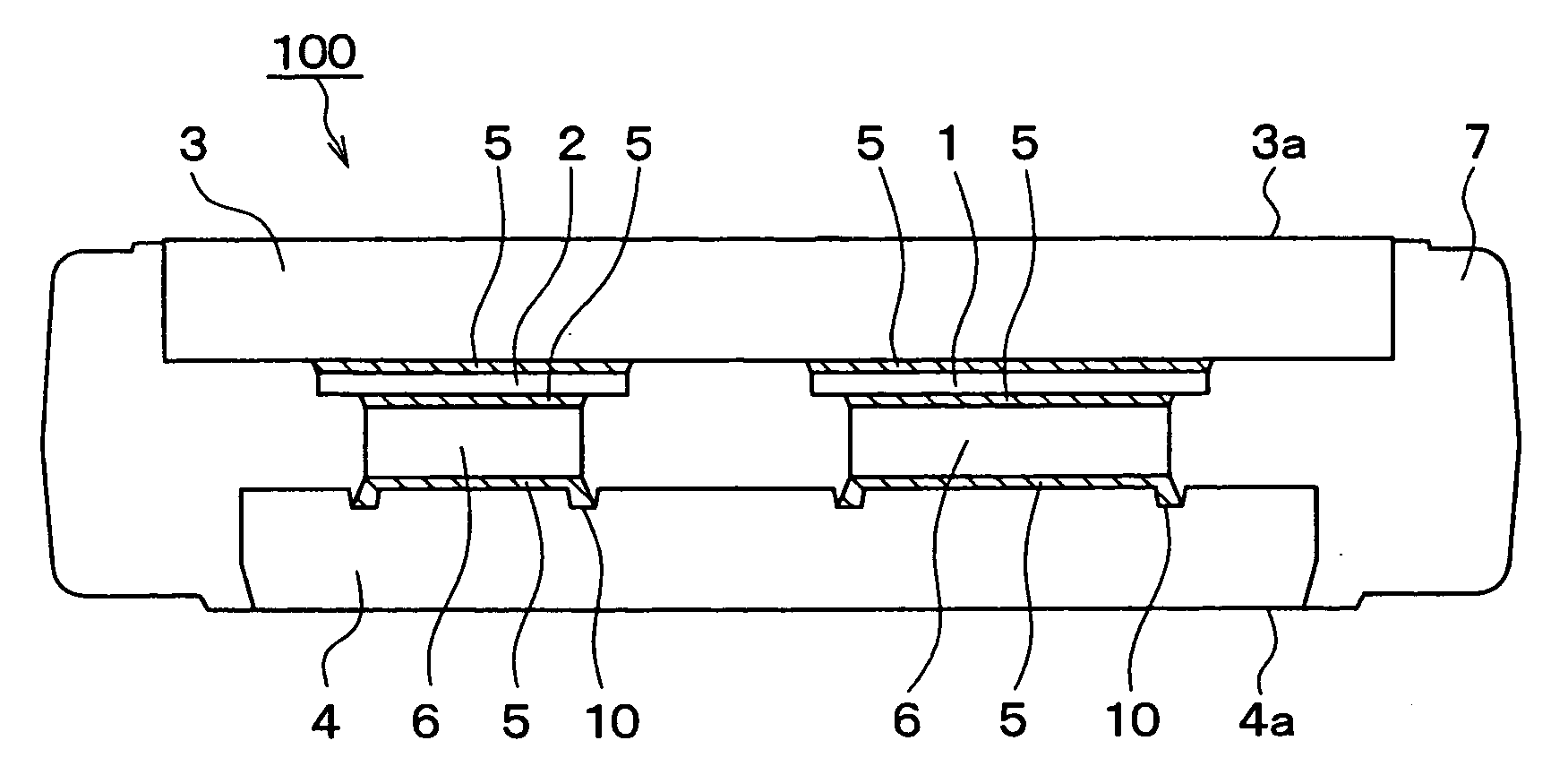

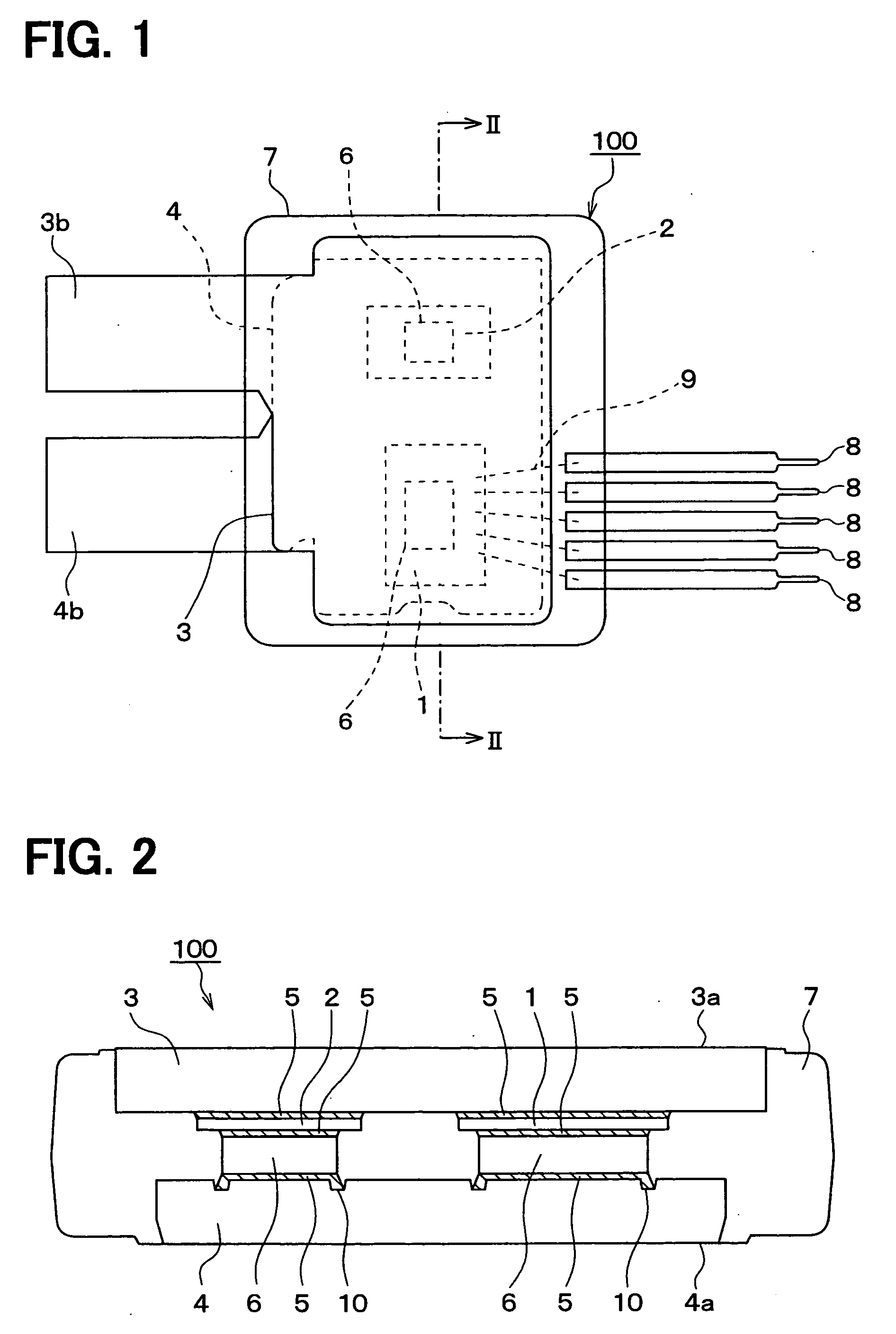

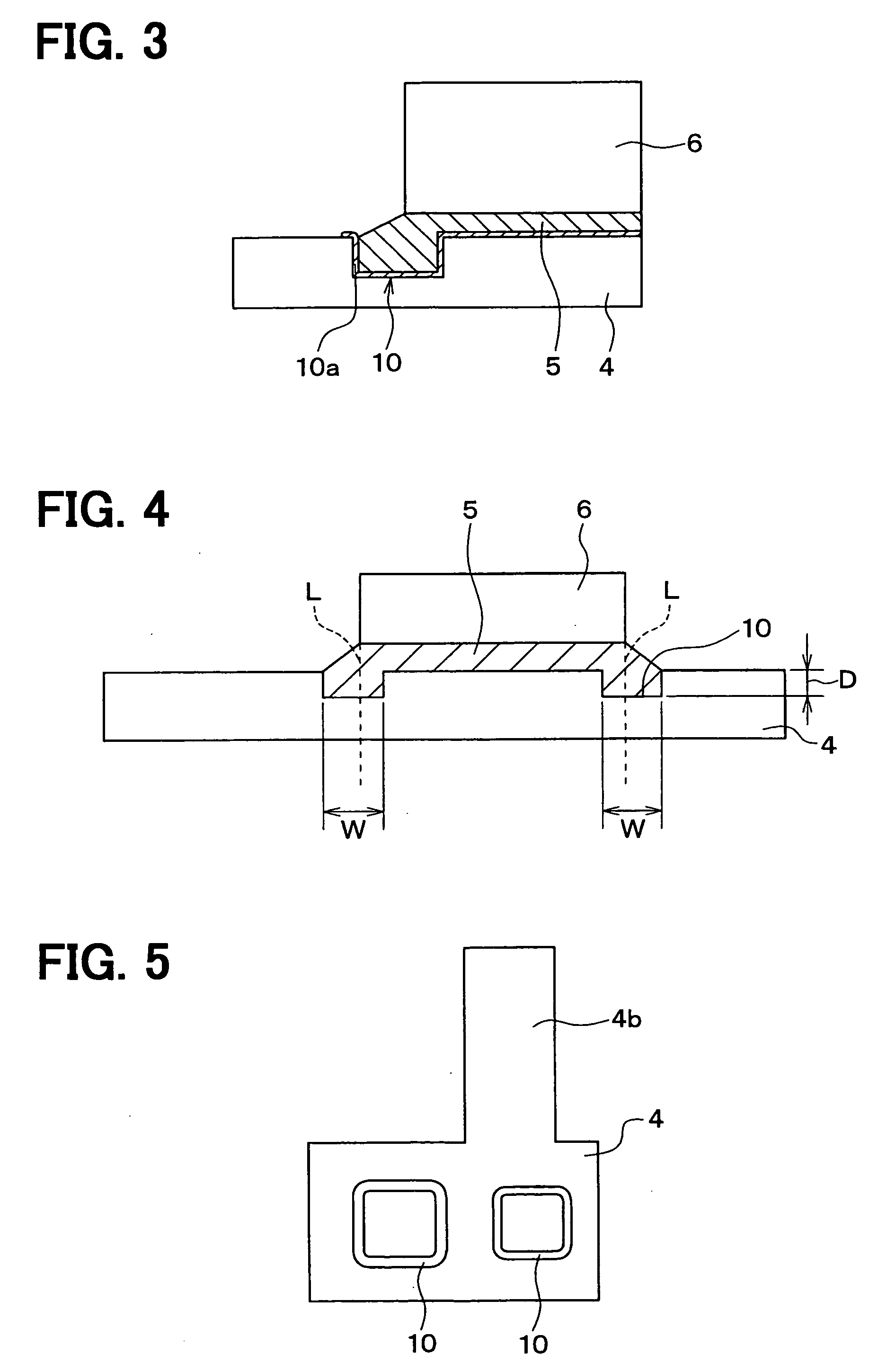

Semiconductor device having metallic plate with groove

ActiveUS20070057373A1Excellent qualityQuality improvementSemiconductor/solid-state device detailsSolid-state devicesThermal radiationSemiconductor components

A semiconductor device includes: first and second metallic plates, each of which includes a heat radiation surface and an inner surface; a semiconductor element between the metallic plates; a block between the second metallic plate and the semiconductor element; a solder member between the second metallic plate and the block; and a resin mold. The heat radiation surface is exposed from the resin mold. The second metallic plate includes a groove for preventing the solder member from expanding outside of the block. The groove is disposed on the inner surface and disposed on an outer periphery of the block. The second metallic plate further includes an inner surface member on an inner surface of the groove. The inner surface member has a solder wettability, which is larger than a solder wettability of the block.

Owner:DENSO CORP

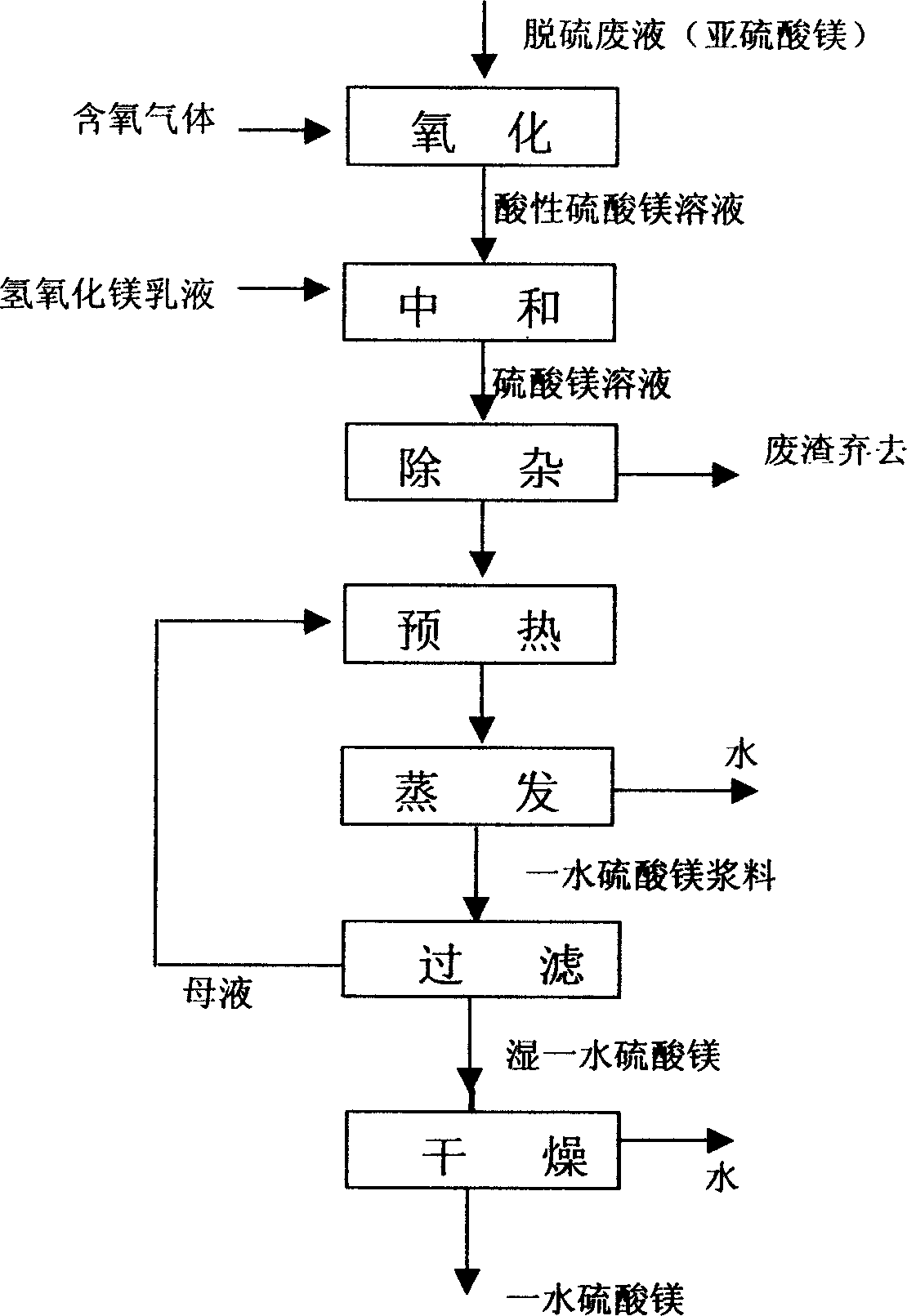

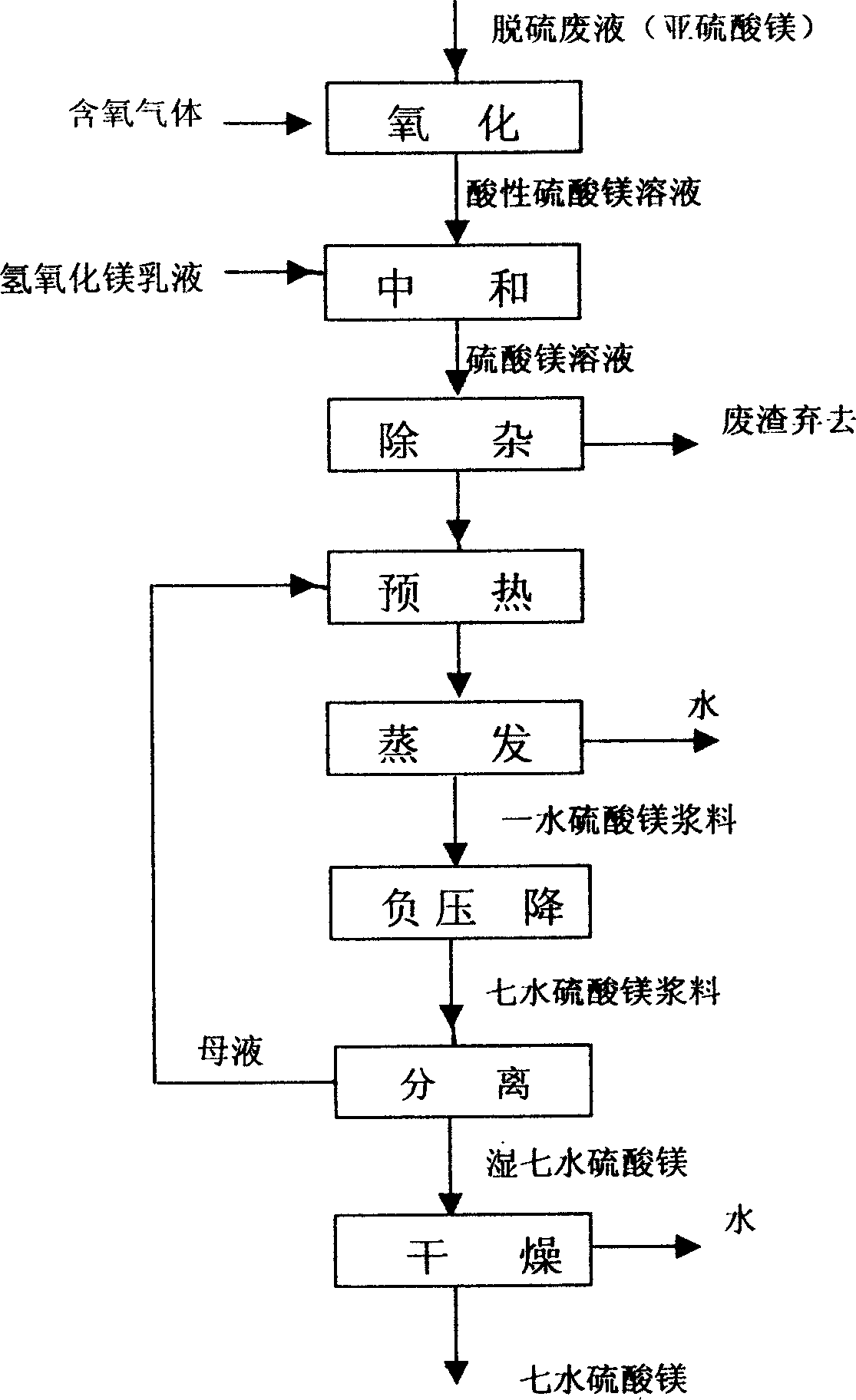

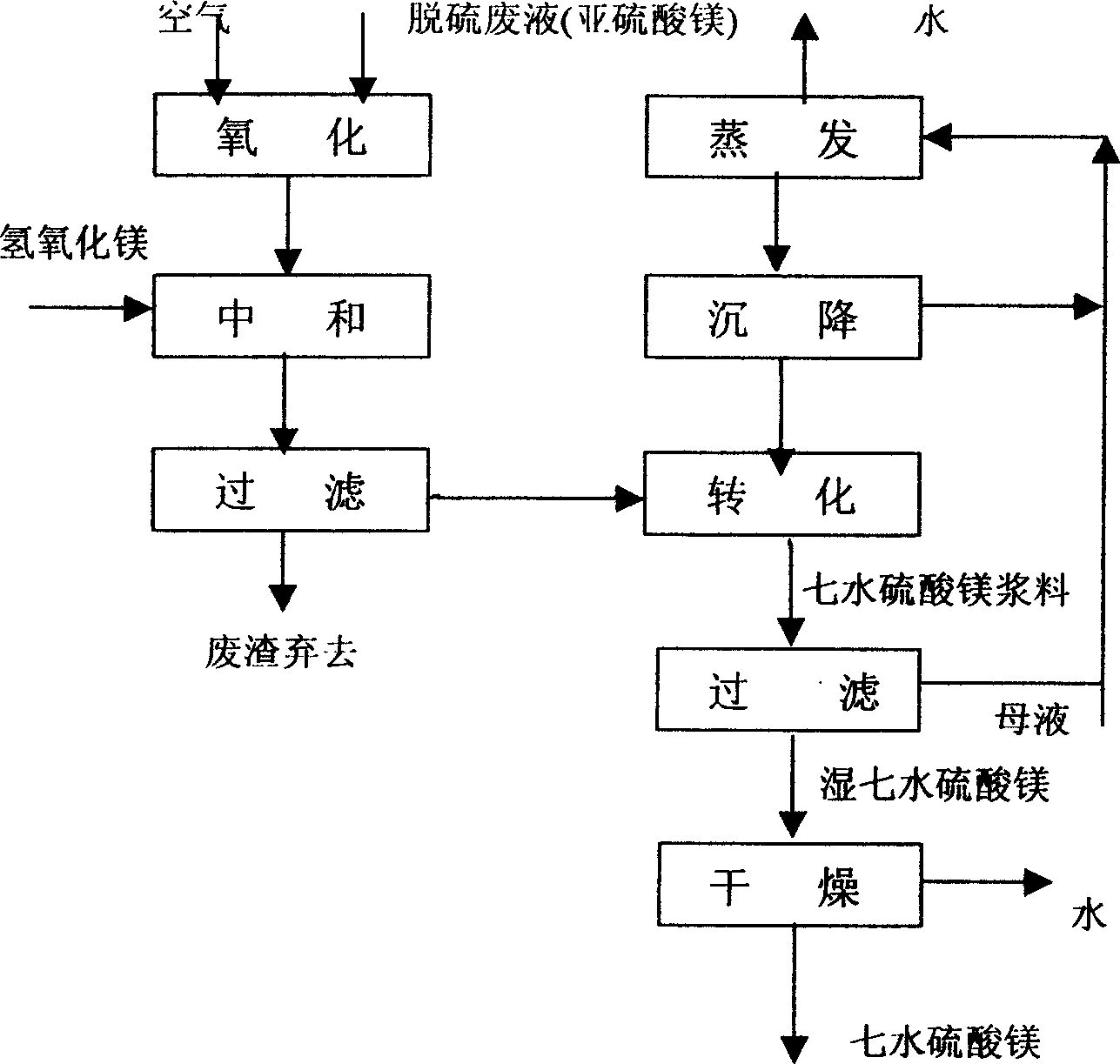

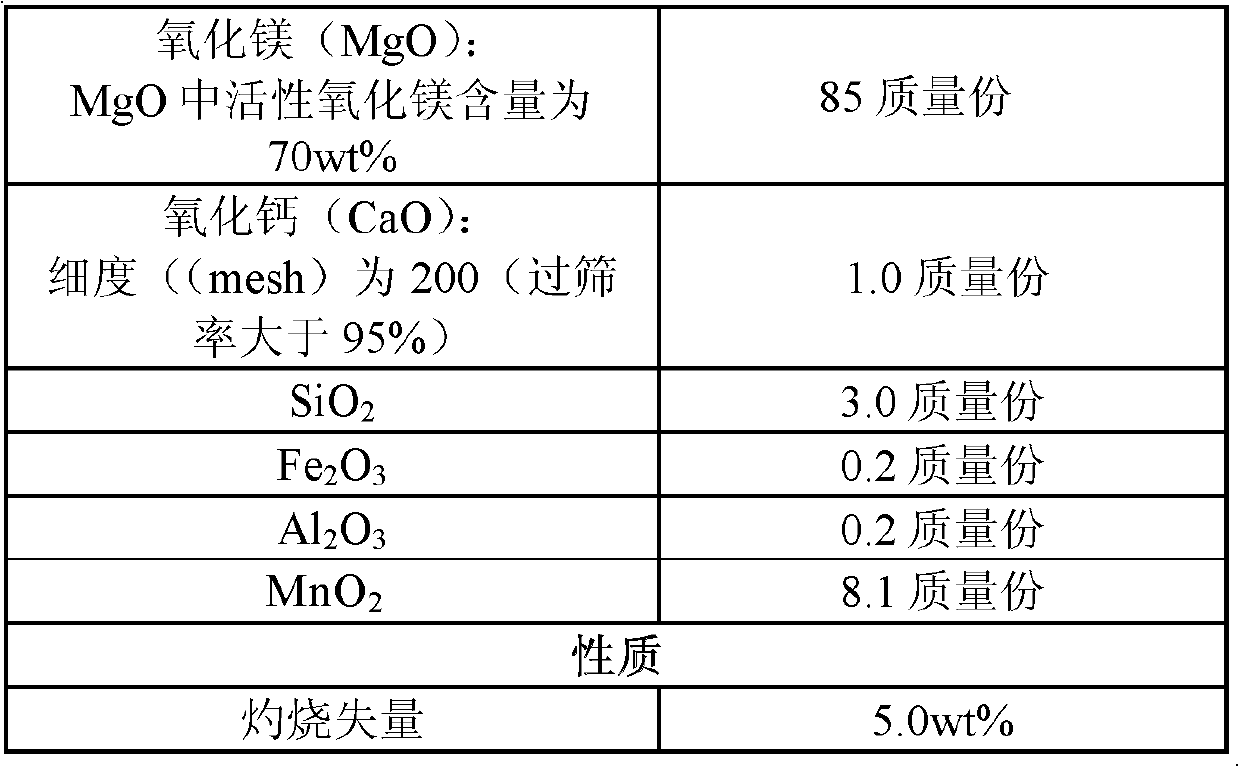

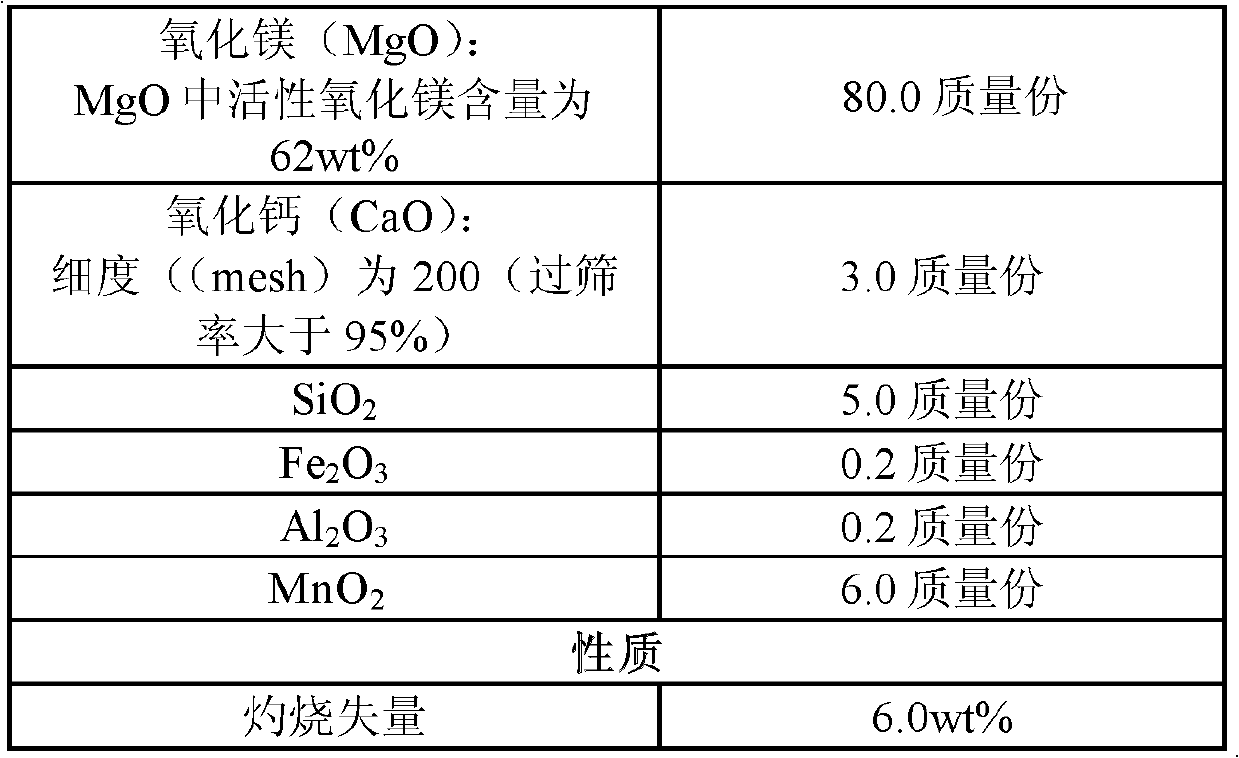

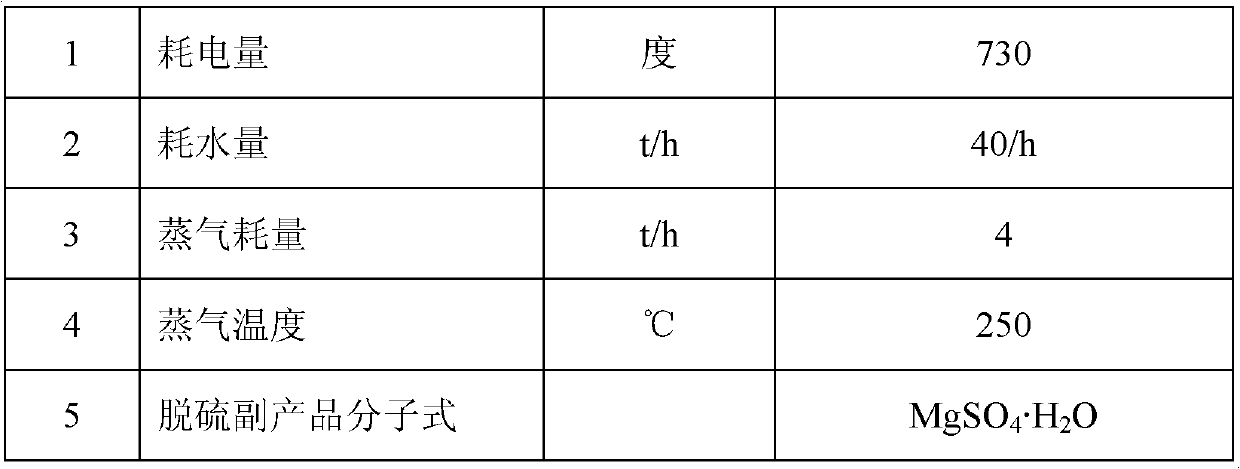

Magnesium sulfate production method using magnesium oxide and desulfurated waste fluid

InactiveCN1544331ASolve the problem of discharge into the seaExcellent energy consumptionDispersed particle separationWater/sewage treatmentLiquid wasteSulfur

The invention provides a process for preparing magnesium sulphate by utilizing magnesium oxide desulfurized exhausted liquid comprising the steps of oxidation step, neutralization step, edulcoration step, evaporation concentration, solid-liquid separation step, drying and packing step. By controlling different evaporation temperature, discharging condition and various equipment, kieserite and magnesium sulphate can be prepared respectively.

Owner:天津市昌昊化工股份合作公司

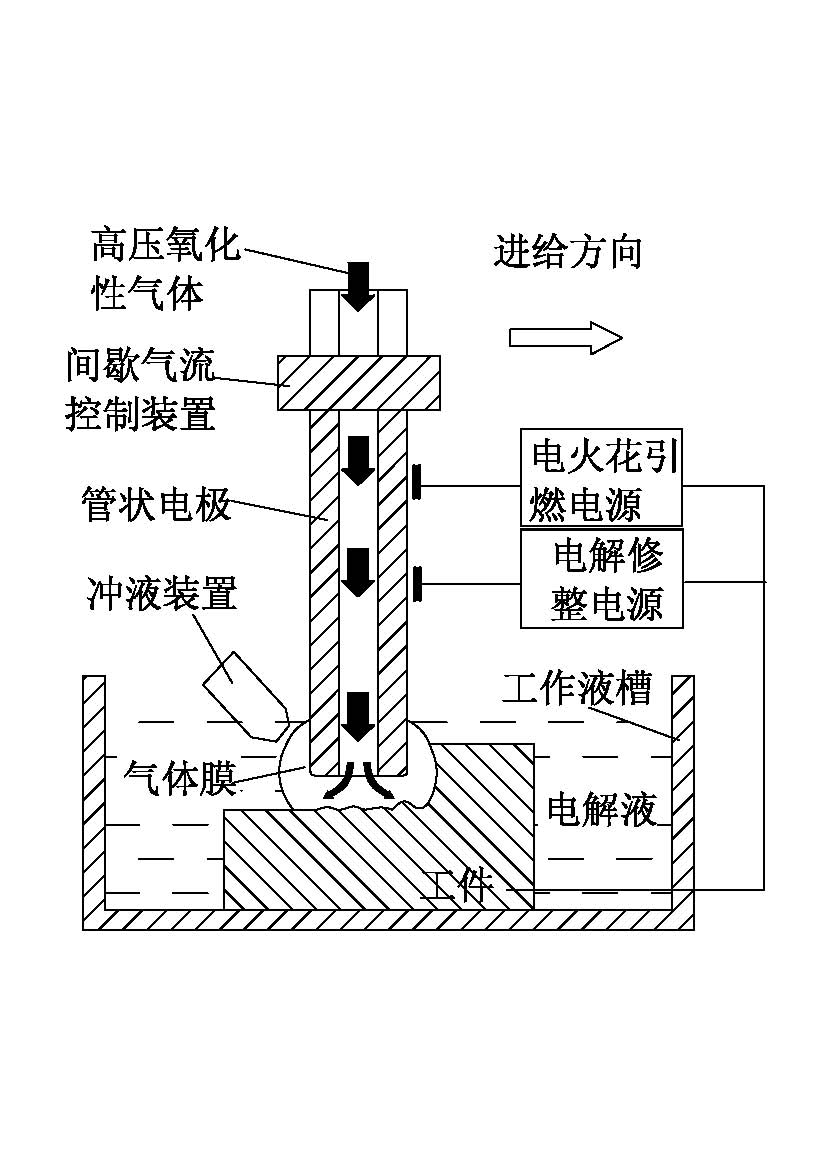

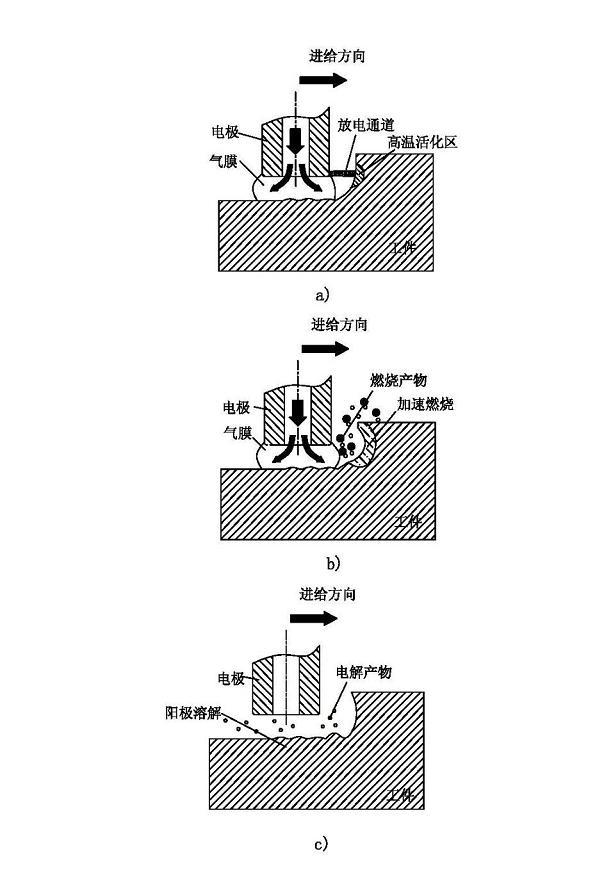

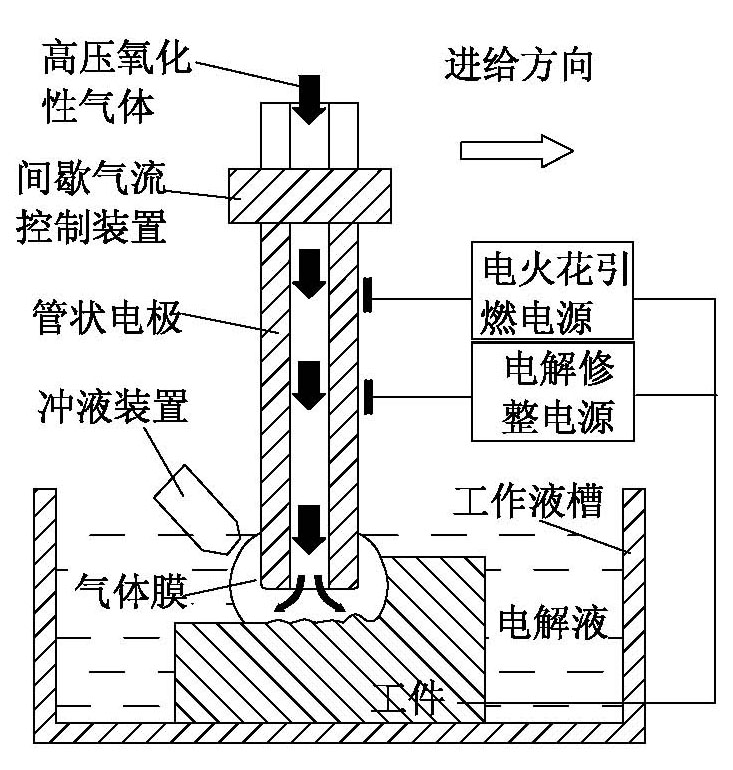

Electric spark induction controllable erosion and electrolysis compound efficient machining method

The invention discloses an electric spark induction controllable erosion and electrolysis compound efficient machining method which is characterized by comprising the steps of: with electrolyte as a working medium, immersing one end of a to-be-machined workpiece electrode and a tool electrode in the working medium, intermittently introducing air to a machining area and forming an air film between the to-be-machined workpiece electrode and the tool electrode; generating electric spark discharge between the to-be-machined workpiece electrode and the tool electrode under the action of an electric spark power supply to ensure that the to-be-machined workpiece generates an oxidation exothermic reaction with the introduced air under the action of electric spark discharge ignition and forms a burning effect so that efficient ablation is realized; in an air closed stage, carrying out electrochemical machining and surface dressing on the ablation surface under the action of an electrolysis power supply; and alternating to start an electric spark ignition pulse power supply and an electrolysis eroding power supply and moving the tool electrode until machining is finished. The invention has the advantages of high material eroding efficiency up to be several times, even tens of times of that of the conventional electric spark machining and also be higher than that of the conventional electrolysis machining under the same electrical parameters on the premise of ensuring machining quality and precision, good surface quality, precision and controllability and capability of eliminating surface residual stress.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

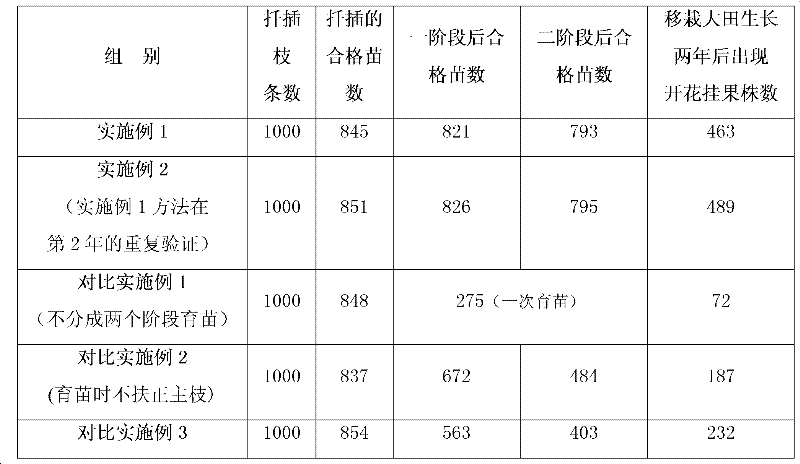

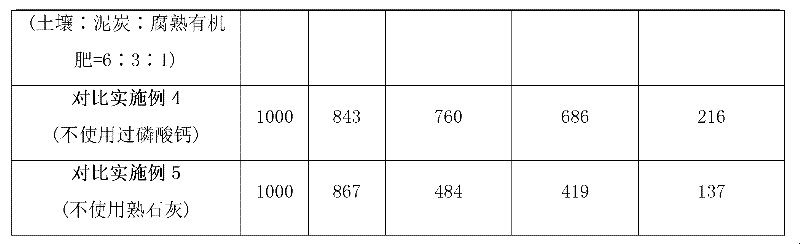

Method for raising seedlings of olive oil cuttings

ActiveCN102293111AIncrease the number ofQuality improvementCultivating equipmentsHorticulture methodsPhacusSeedling

The invention belongs to the plant growing field, and in particular relates to a method for raising seedlings by cutting olives. The technical problem to be solved in the invention is that the seedling cultivating quality of the olives is low in the prior art. A technical scheme for solving the problem in the invention is as follows: the method for raising seedlings by cutting the olives is provided. The method comprises the following steps of: a, cutting, b, domesticating the seedlings, c, cultivating in a first stage; and d, cultivating in a second stage. Compared with the prior art, the method can be used for effectively increasing the number and quality of the qualified olive seedlings; and both the number of early blossoming and early bearing and the quality of the cultivated qualified seedlings after growing for two years in a field are superior to those in the prior art. The method provided by the invention has the advantages of easiness in operation, low cost and good application prospects.

Owner:凉山州中泽新技术开发有限责任公司

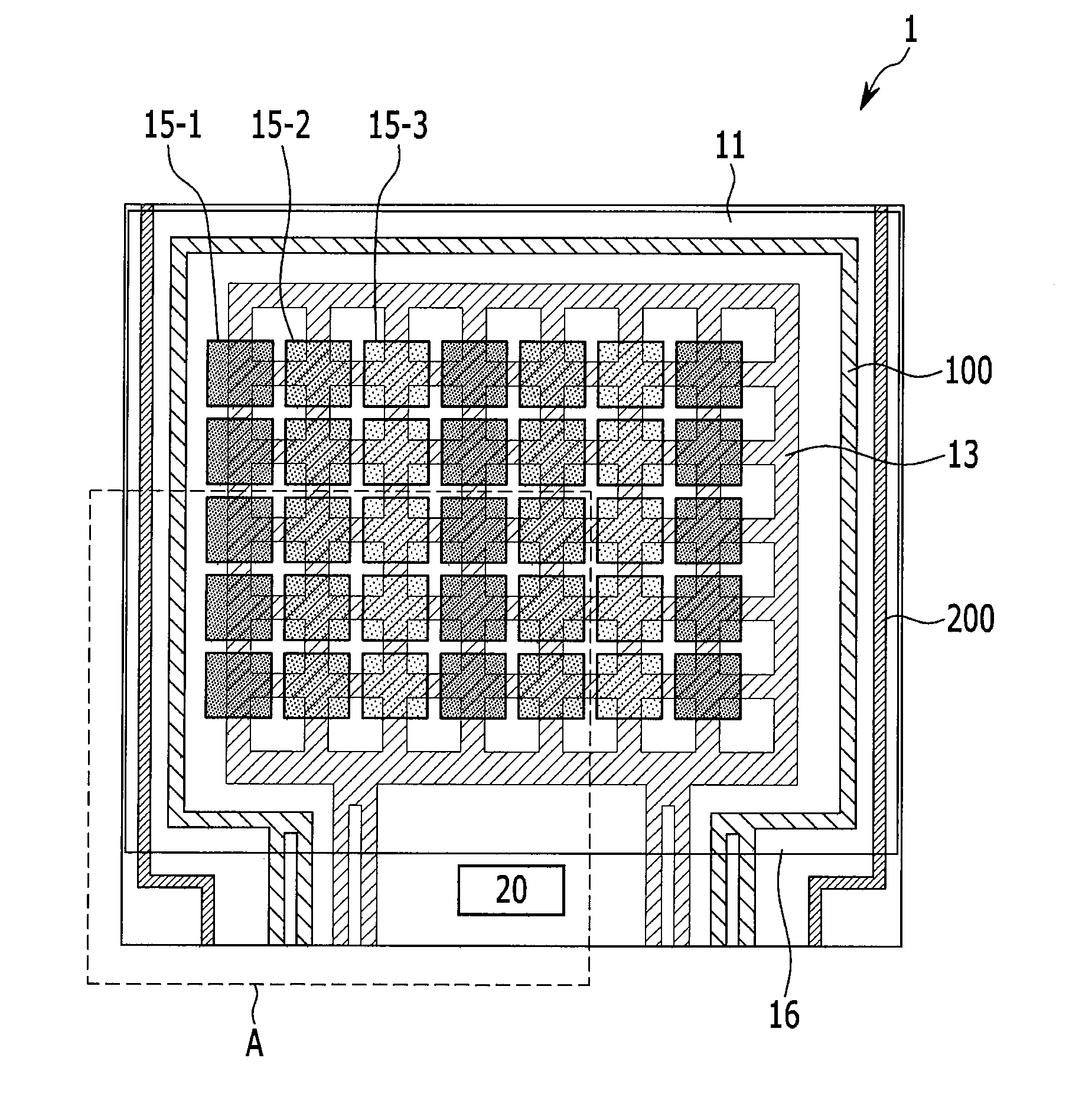

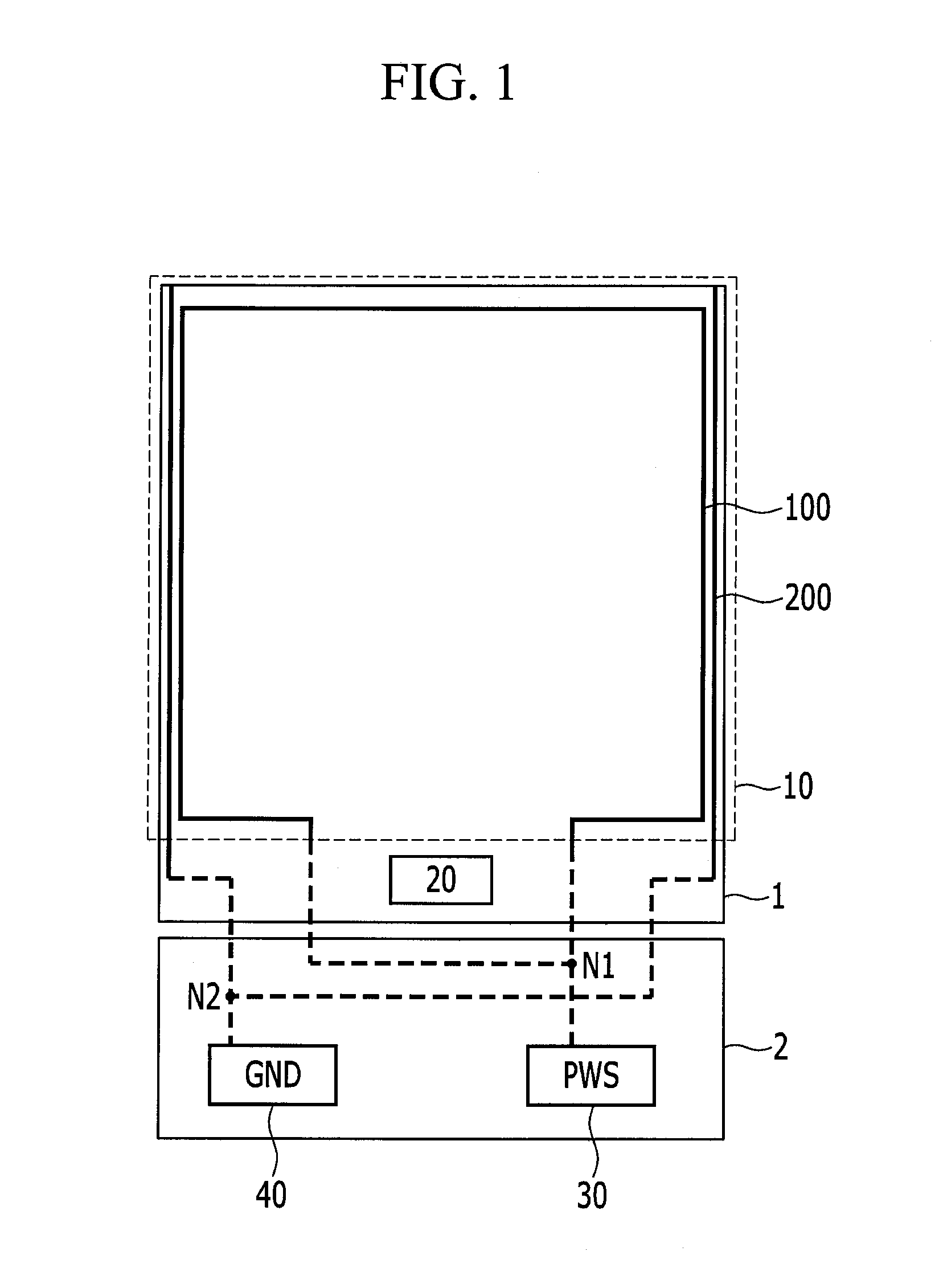

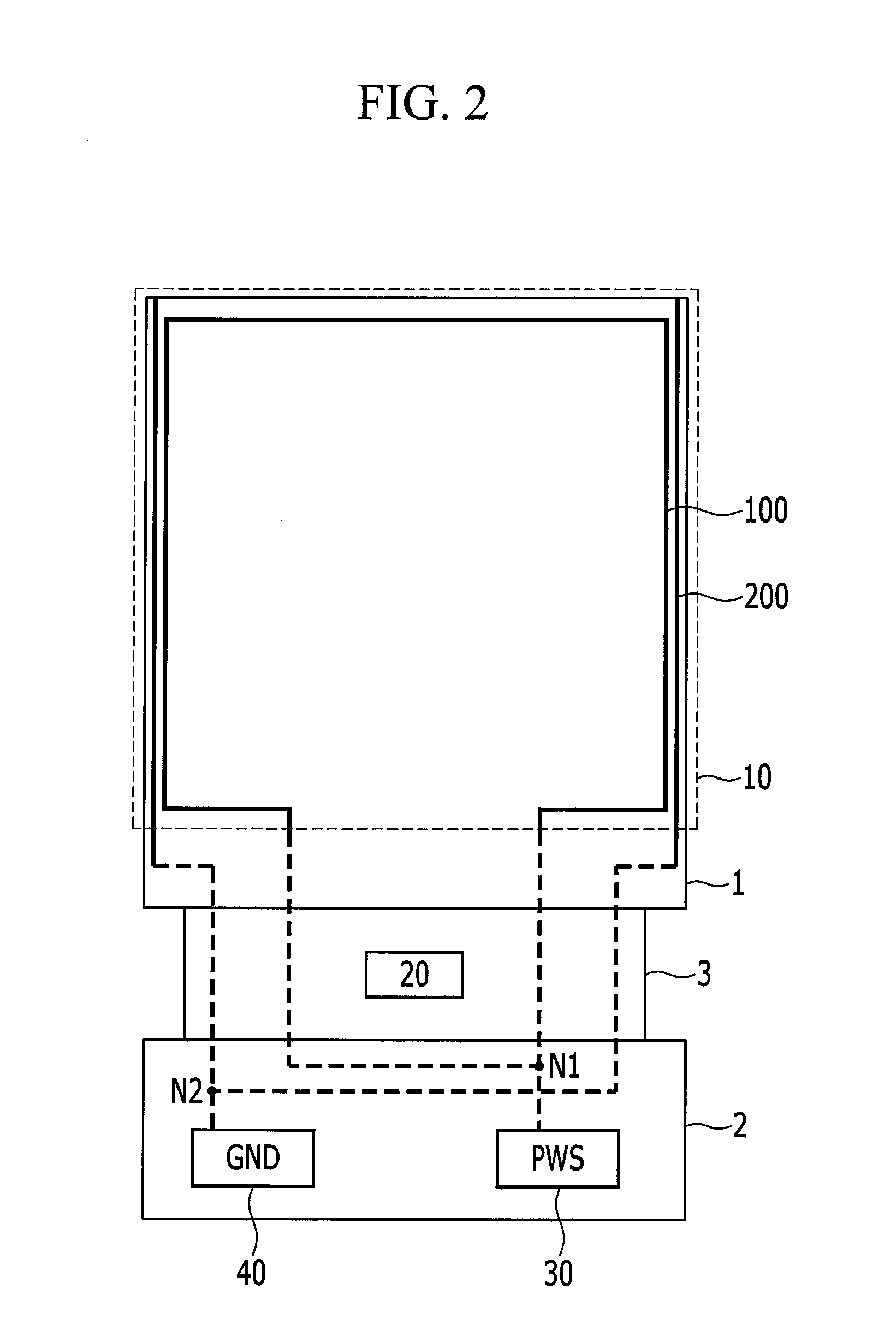

Display panel for preventing static electricity, method for manufacturing the same, and display device including the display panel for preventing static electricity

InactiveUS20140001966A1Efficiency reduce and eliminateExcellent qualitySparking plugsStatic indicating devicesEngineeringDisplay device

A display panel, a manufacturing method of the display panel, and a display device including the display panel are provided. The display panel includes: a substrate; a display unit on the substrate and including a plurality of pixels for displaying an image according to a video signal; a power supply wire on the substrate, coupled to the plurality of pixels, and configured to transmit a driving voltage for driving the plurality of pixels; and a dummy wire on the substrate, separated from the display unit and the power supply wire, and coupled to a ground electrode or a power supply unit for supplying the driving voltage.

Owner:SAMSUNG DISPLAY CO LTD

Method for producing magnesium sulfate monohydrate by using desulfurization wastewater

ActiveCN102745725AQuality up to standardGuaranteed uptimeMagnesium sulfatesWastewaterCrystallization

The present invention discloses a method for producing magnesium sulfate monohydrate by using desulfurization wastewater. The method comprises the following steps: (1) pulping, (2) carrying out desulfurization, (3) discharging the pulp, (4) filtering, (5) carrying out concentration, and (6) carrying out crystallization. With the method of the present invention, high value byproducts can be synchronously produced during a flue gas desulfurization process by using a magnesium oxide method. In addition, with the method of the present invention, a stable running characteristic is provided, and quality of the produced magnesium sulfate monohydrate after desulfurization reaches standards.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

Biological pesticideíñfoliage fertilizer

A ''biopesticide is multiplied by foliar fertilization'' innovative product is provided, which adopts the Chinese herb simple prescription or the polypharmaceutical with special biotoxin. The invention utilizes the marsh gas fermentation method in the breeding farm radical treatment breeding ''three wastes'' process marsh liquid fully degraded by the anaerobe and the marsh gas flora as the drug preparation mother liquid. The effective toxin in the Chinese herb in the prescription is extracted through natural fermentation of the microorganism and is fully dissolved and uniformly spread in the mother liquid of the drug preparation marsh liquid to acquire the ''biopesticide is multiplied by foliar fertilization'' plant protection novel product which is rich in a plurality of phytotoxin and biotoxin substances, a plurality of B-group vitamins of the animo acid, a plurality of water fresh enzyme and a plurality of plant growth hormones and can be used in developing and producing various green farm produce, various high grade organic agricultural products instead of the traditional chemical pesticide, has disinfecting, killing and inactivating effects on a plurality of plant diseases and insect pests of the crops and provides good nutrient sources for the crops.

Owner:郭以强

Manufacturing method for combined ceramic tile with complete pattern, spliced by plurality of ceramic tiles

InactiveCN103241049AStrong three-dimensional senseStrong sense of transparencyDecorative surface effectsClaywaresMetallurgyNatural stone

The invention relates to a manufacturing method for a combined ceramic tile with a complete pattern, which is spliced by a plurality of ceramic tiles. The method comprises the following steps of: mixing raw materials to prepare a powder material, pressing the powder material to obtain green tiles, carrying out printing and glaze spraying on the green tiles, sintering the obtained tiles to obtain the ceramic tiles, and performing seamless splicing on the plurality of ceramic tiles with different or identical figures to obtain the combined ceramic tile with the complete pattern. Compared with the prior art, the combined ceramic tile can fully display the real effect of natural stones by means of large format splicing, is strong in three-dimensional effect and rich in layering, can better adapt to current market trend, and is grand and very impressive after being paved.

Owner:SHANGHAI YUEXIN HEALTH GRP CO LTD

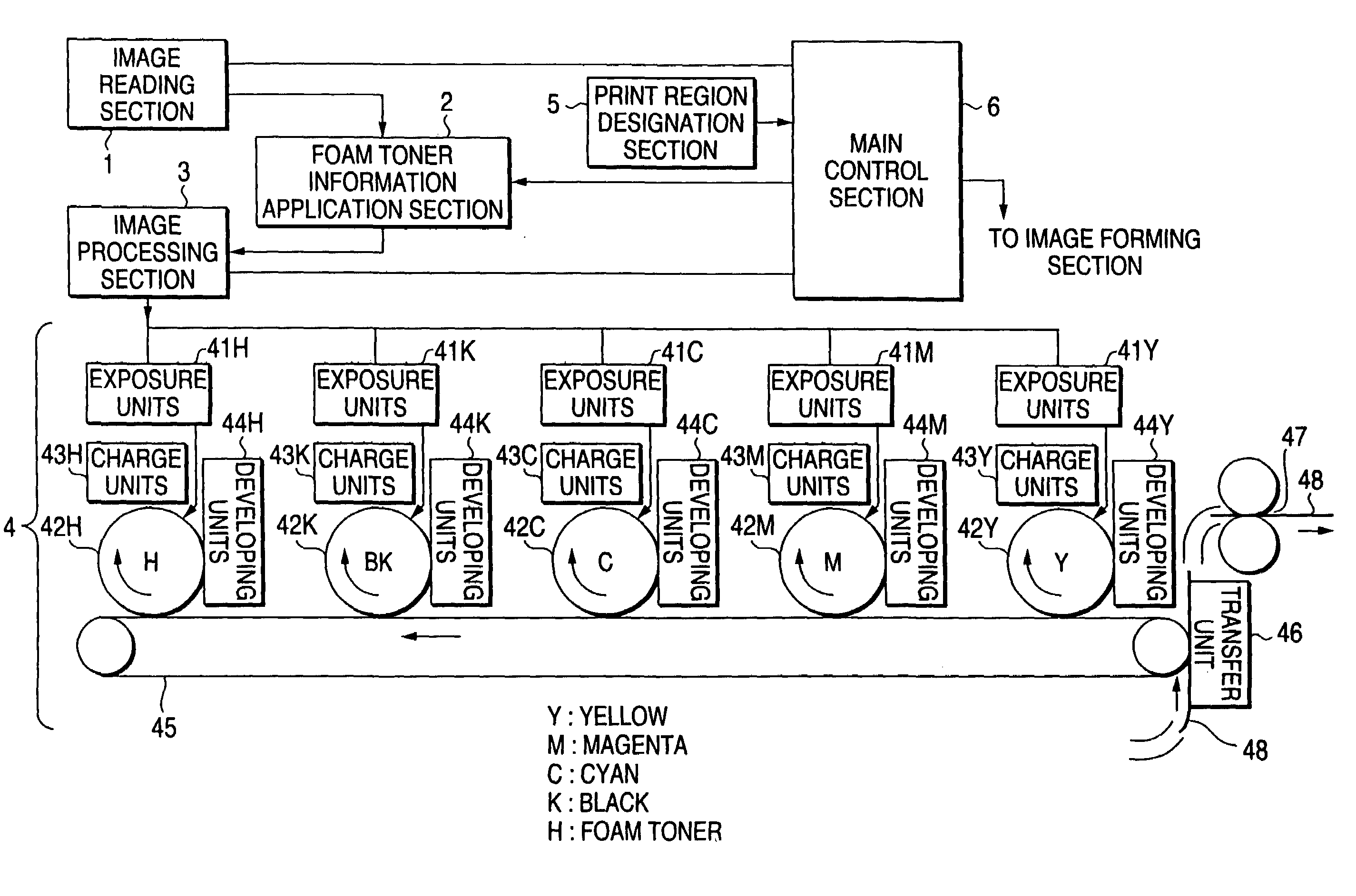

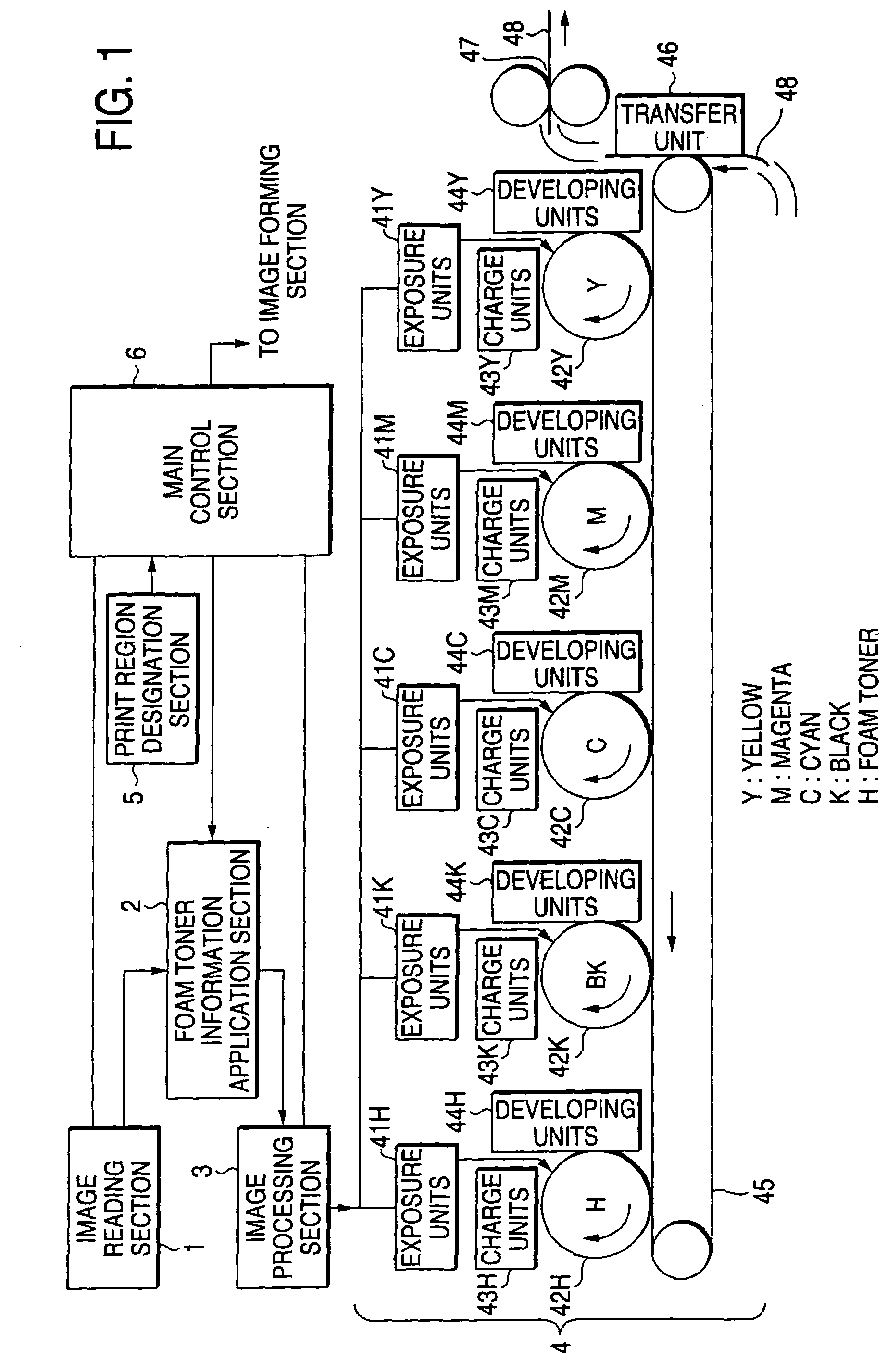

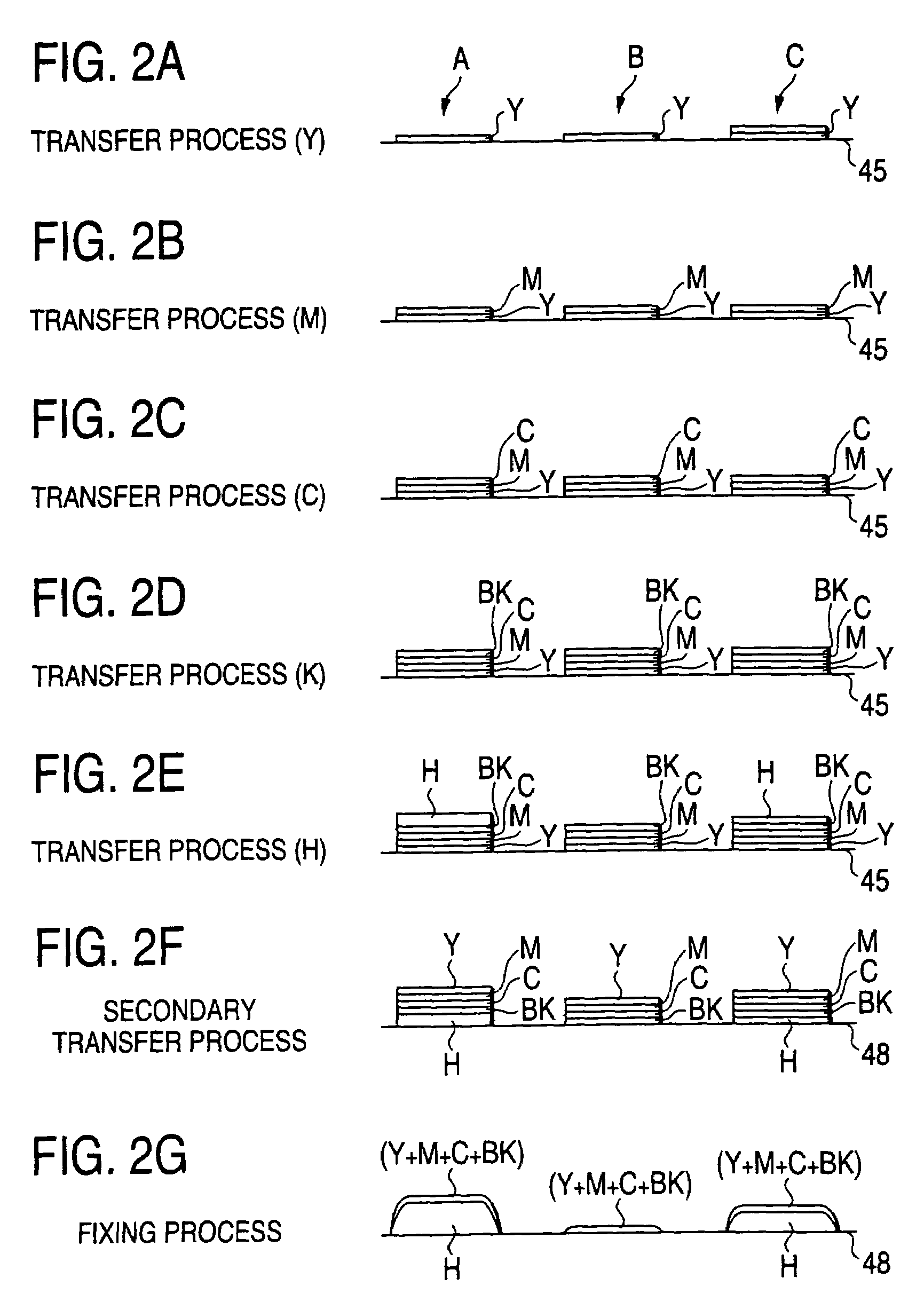

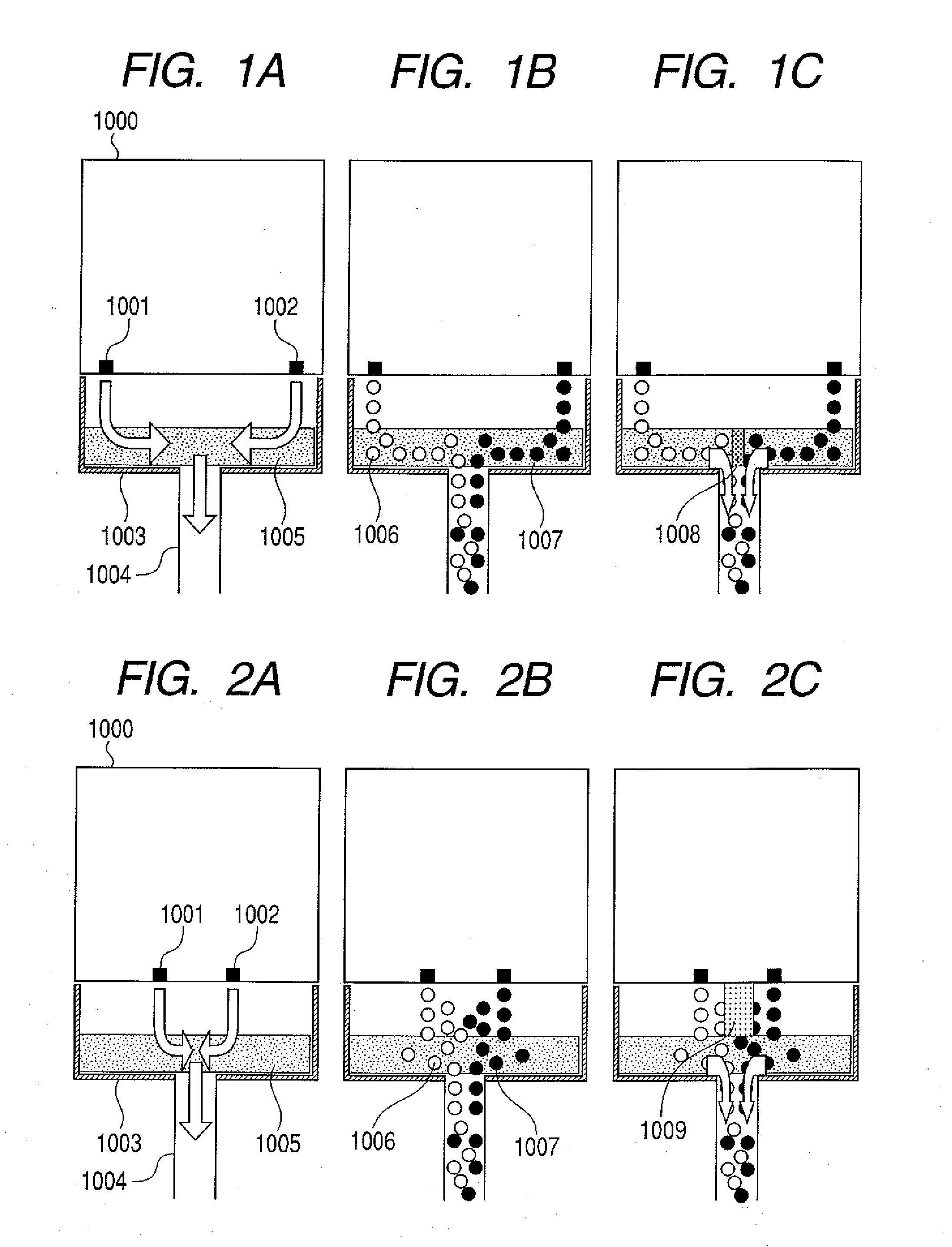

Image forming apparatus, image processing apparatus, image forming method and image processing method for forming/processing a three-dimensional image

InactiveUS6993269B2Excellent qualityEliminate differencesTypewritersElectrographic process apparatusEngineeringDiscriminator

In an image processing section, a foam toner signal generator generates a foam toner signal corresponding to a foam toner amount to be transferred to a three-dimensional print designation region discriminated at a three-dimensional print region discriminator, and a foam toner interpolation signal generator generates a foam toner interpolation signal corresponding to a foam toner amount to be transferred to an image region equal to or greater than a constant area in an ordinary print region discriminated at the three-dimensional print region discriminator. Foam toner of a predetermined amount corresponding to the foam toner signal is transferred to the three-dimensional print region, and foam toner of an amount that is less (of a lower height) than the predetermined amount and corresponds to the foam toner interpolation signal is transferred to the ordinary print region.

Owner:FUJIFILM BUSINESS INNOVATION CORP

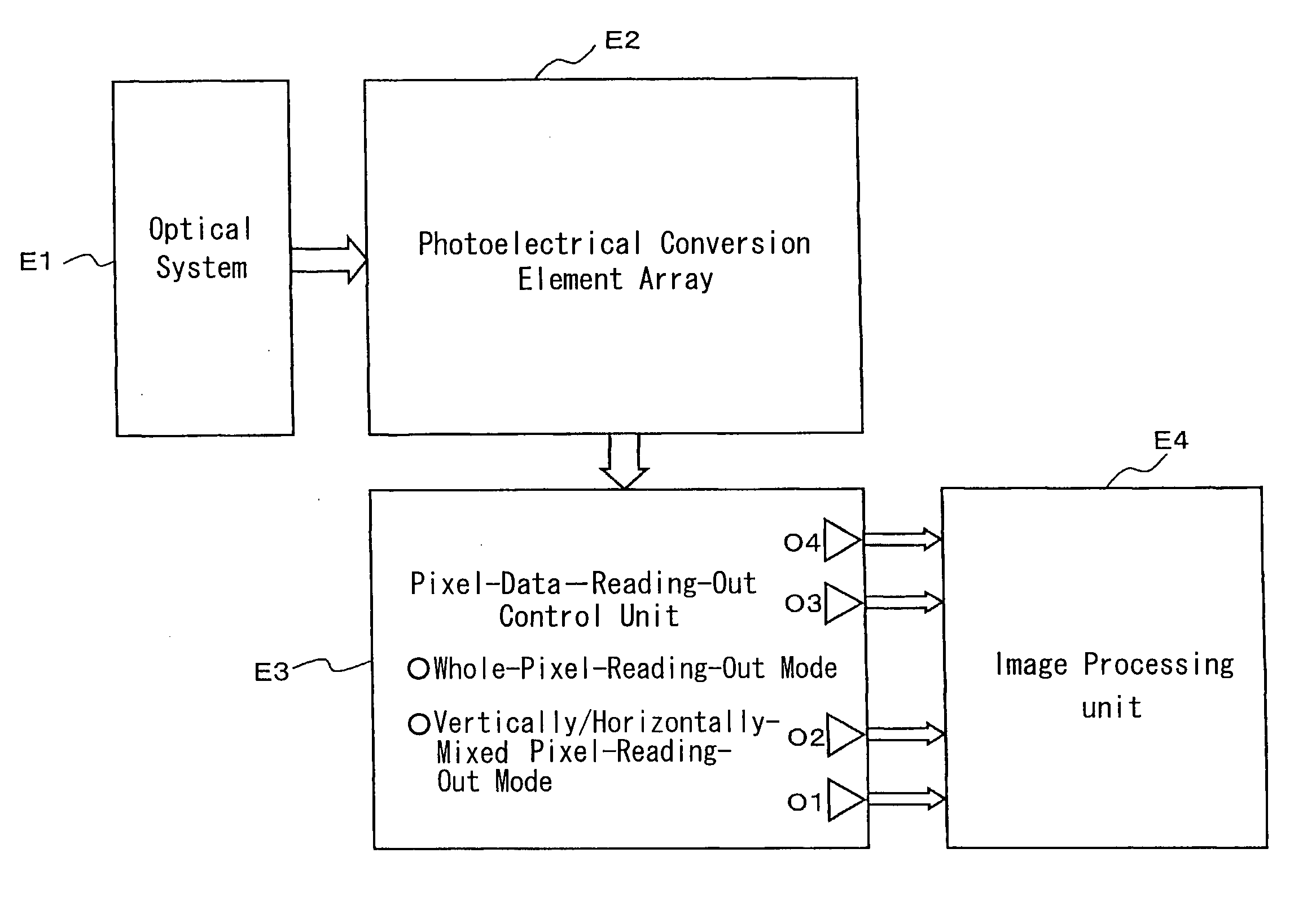

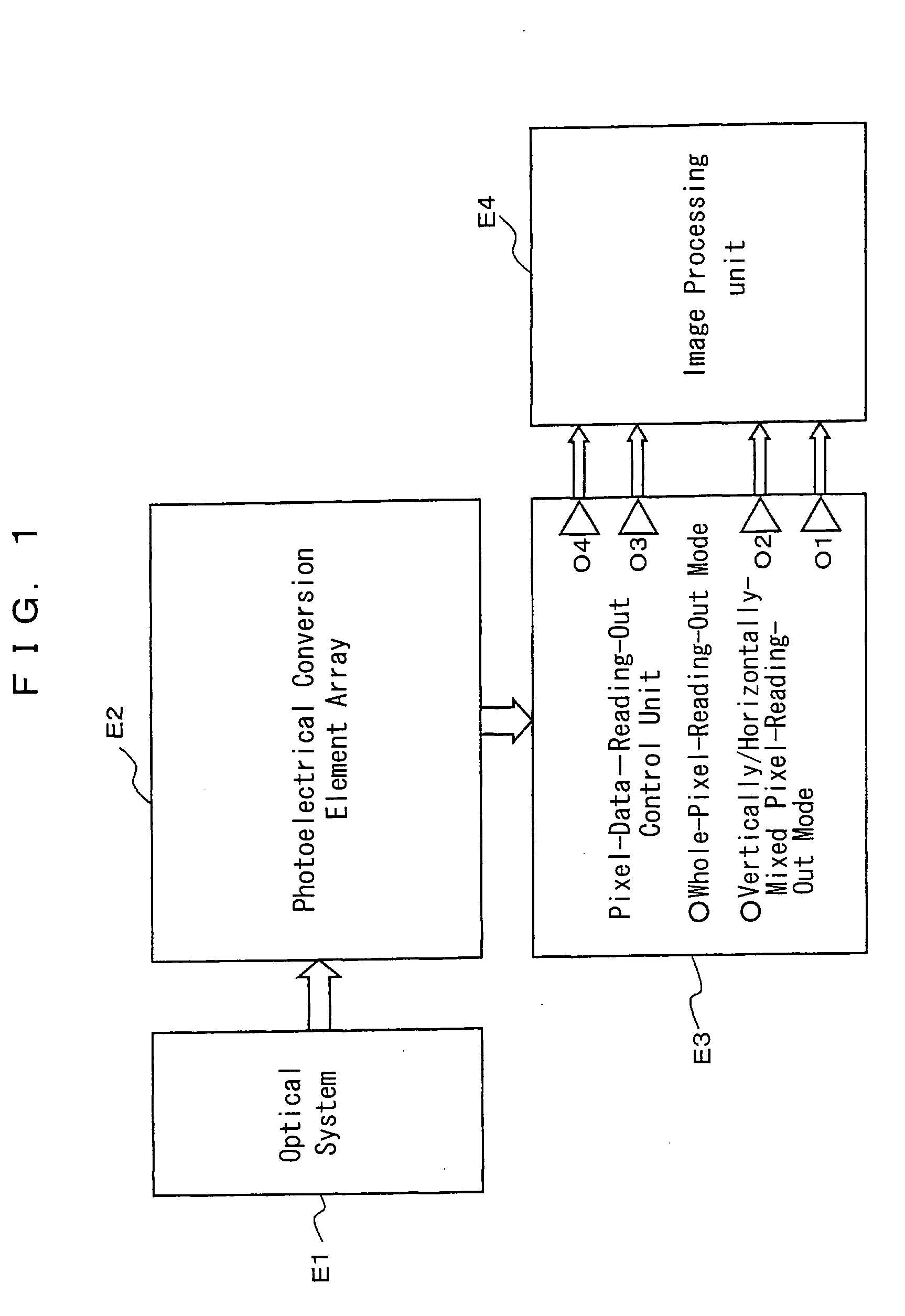

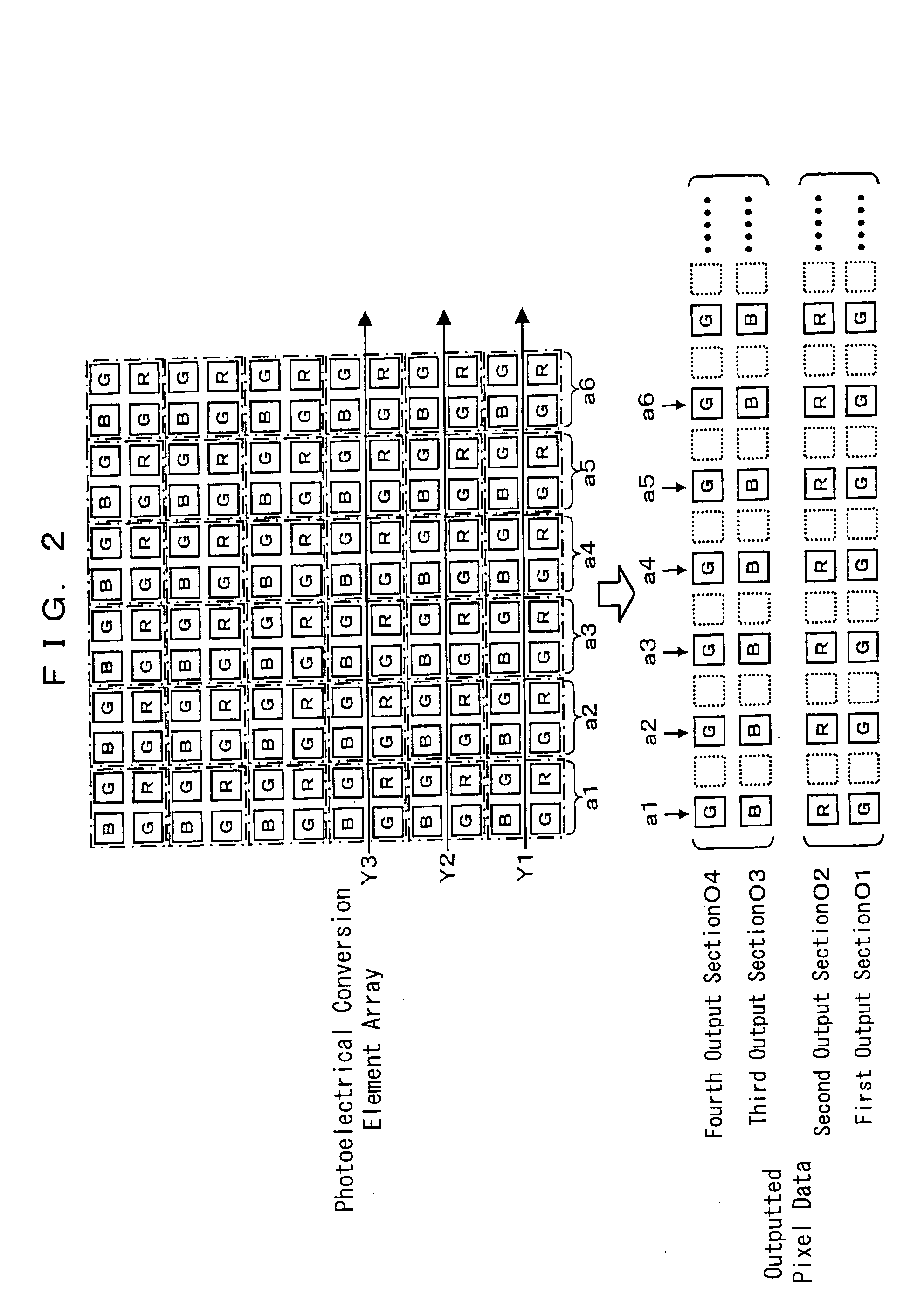

Color solid state image pickup device

InactiveUS20050068434A1Excellent qualityImprove qualityTelevision system detailsTelevision system scanning detailsColor solidControl unit

Provided is a color solid state image pickup device which comprises a photoelectrical conversion element array and a control unit for controlling reading-out of pixel data. The control unit has a whole-pixel-reading-out mode and vertically / horizontally-mixed-pixel-reading-out mode, by which data are simultaneously outputted from four channels of output sections. In the whole-pixel-reading-out mode, separate and parallel output of GRBG pixel data is simultaneously performed using the four channels of output sections with a group of pixels in two lines and two rows in the photoelectrical conversion element array being a first output unit. Meanwhile, in the vertically / horizontally-mixed-pixel-reading-out mode, separate and parallel output of GRBG mixed pixel data is simultaneously performed using the four channels of output sections with a group of pixels in 2n lines and 2n rows in the photoelectrical conversion element array being a second output unit.

Owner:PANASONIC CORP

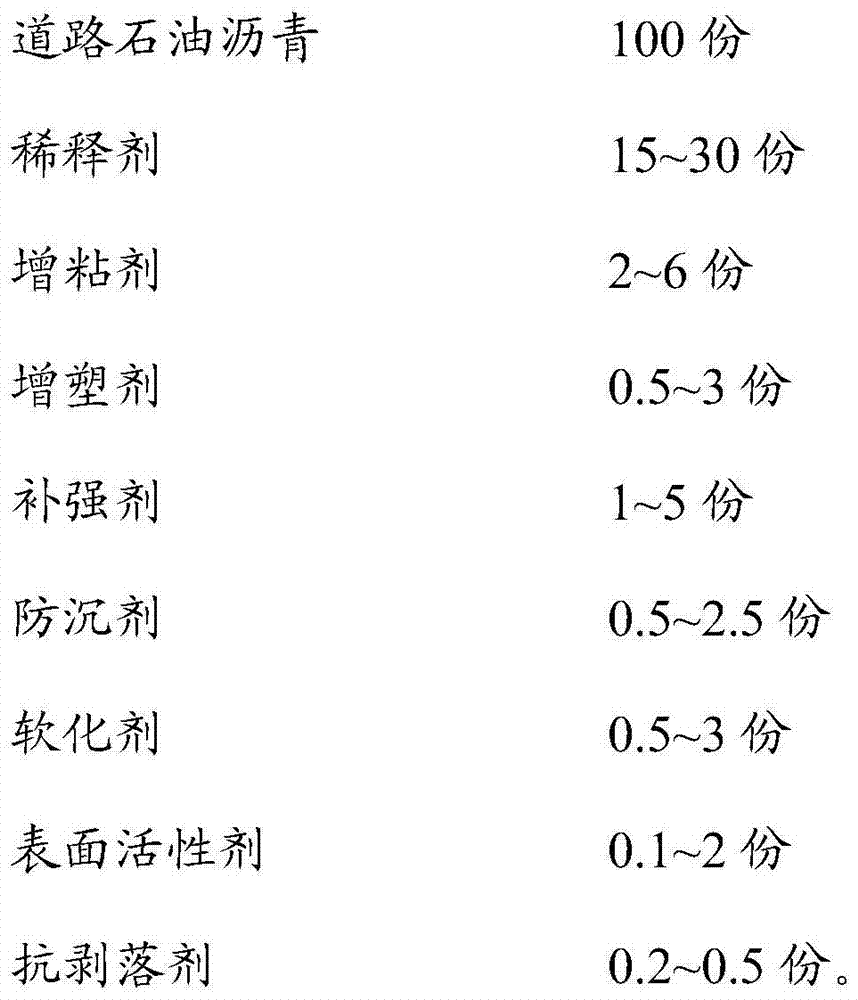

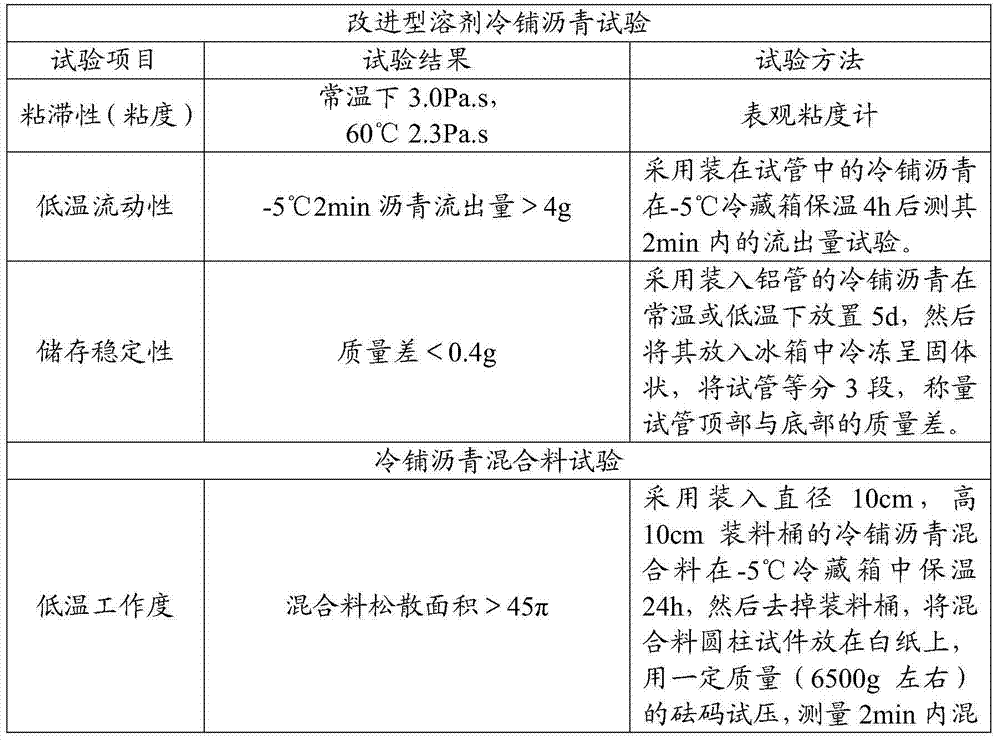

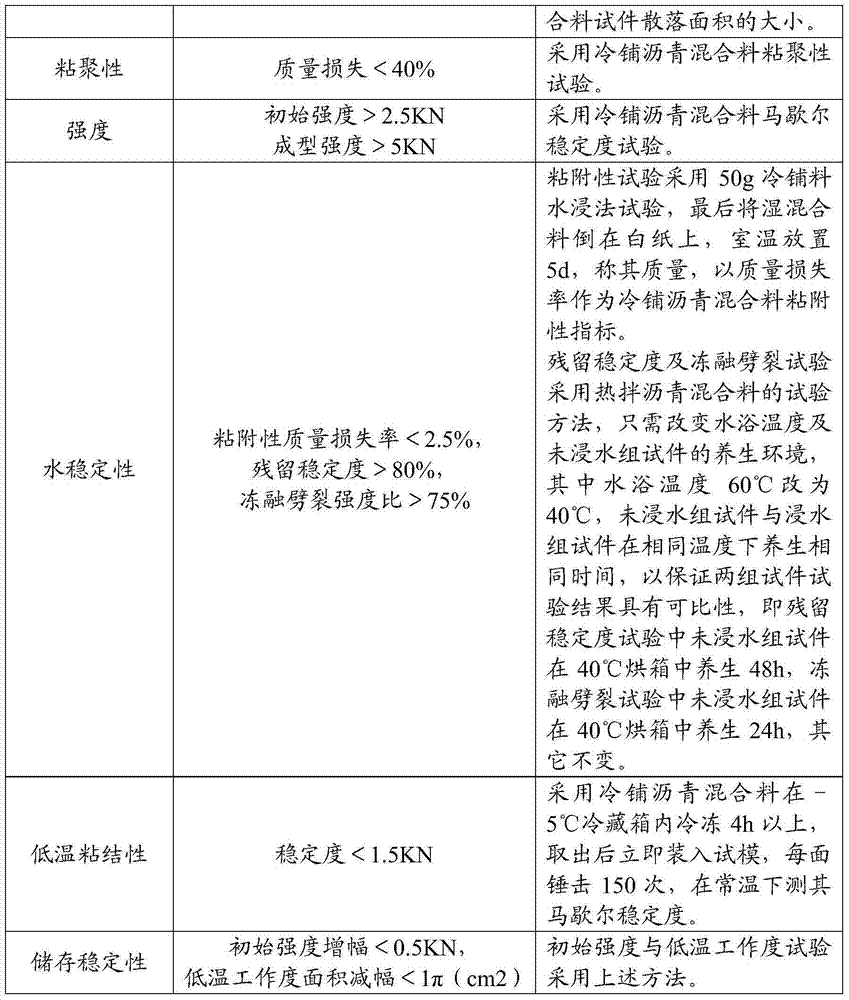

Improved solvent cold laid asphalt as well as preparation process and using method thereof

InactiveCN103923475AImprove adhesionImprove liquidityIn situ pavingsBuilding insulationsLiquid stateEngineering

The invention discloses an improved solvent cold laid asphalt as well as a preparation process and using method thereof. The improved solvent cold laid asphalt is at a liquid state under normal temperature or low temperature; cold oil and cold materials can be directly blended for construction on the spot without heating, and the construction can be carried out at high / low temperature seasons and rain / snow weather, and a large number of machinery and labor are not required in the construction process, the construction is simple and convenient and the repair effect is good; traffic can be immediately opened after repair without affecting the travel of people; the improved solvent cold laid asphalt is usually used for daily maintenance, such as pot slot repair and emergency repair; meanwhile, the improved solvent cold laid asphalt has the advantages of no deterioration, no layering and the like after being stored for a long time.

Owner:CHANGAN UNIV

Solid-phase sintering silicon carbide bulletproof ceramic and preparation method thereof

The invention relates to a preparation method of silicon carbide ceramic, and particularly relates to solid-phase sintering silicon carbide bulletproof ceramic and a preparation method thereof. The silicon carbide bulletproof ceramic comprises the following raw materials by weight percent: 70-90% of submicron alpha-silicon carbide, 0.1-5% of boron carbide, 4-20% of resin and 5-20% of organic binder, wherein the density of the solid-phase sintering silicon carbide bulletproof ceramic is 3.14-3.16 g / cm<3>; the relative density is 97-98%; the three-point bending strength is 480-560 Mpa. The preparation method of the solid-phase sintering silicon carbide bulletproof ceramic comprises the following steps: mixing the raw materials, spray drying, compression molding and vacuum sintering. The technical scheme disclosed by the invention has simple and reasonable craft processes; the production cost can be effectively reduced; the density, the HRA hardness and three-point bending of the product are higher than the performance of the existing solid-phase sintering and reaction sintering silicon carbide ceramic; meanwhile, the corrosion resistance and the surface quality are also superior to those of the product produced by the existing method.

Owner:NINGXIA MACHINERY RES INST

Fine and rough feed composition for latter fattening period of high-quality beef cattle and feeding method of fine and rough feed composition

InactiveCN103704481AGet rid of dependenceEnsure ad libitum feedingFood processingAnimal feeding stuffFiberHydrogen phosphate

The invention relates to a fine and rough feed composition for a latter fattening period of high-quality beef cattle and a feeding method of the fine and rough feed composition. A fine feed is prepared by taking corns and corn germ cakes as main materials, and adding brans, cottonseed cakes, soybean cakes, calcium hydrogen phosphate, table salt, baking soda, microelements, vitamin AD3 powder and the like. A rough feed is prepared from 50% of ensiling corn straws and 50% of fresh brewer's grain. The feed resources including the ensiling corn straws, the fresh brewer's grain, the cottonseed cakes and the like are sufficiently utilized so that the cost of the feed is greatly reduced and a feeding method of free feeding of the fine feed for the latter fattening period of the high-quality beef, quantity-limiting and fixed-time feeding, and first-rough feed and second-fine feed feeding is realized; nutrition needed by muscle growth of the beef cattle and deposition of fat between muscle fibers is sufficiently met; the synchronization of the muscle growth and the rapid deposition of the fat between the muscle fibers is realized; the beef color and the fat color and luster meet the standard requirements. The dependence on barley and straws by the latter fattening period of the high-quality beef cattle is completely removed; the beef performance indexes including daily gain of the beef cattle, the slaughter performance, the high-quality beef block yield and the like are improved.

Owner:QINGDAO AGRI UNIV

Process for preparing porous collagen matrix from connective tissue

ActiveUS20060235205A1Excellent qualityPowder deliveryConnective tissue peptidesChemistryConnective tissue fiber

The subject invention provides a process for preparing a porous collagen matrix from connective tissue, said process comprising: a porous structure forming step to treat said connective tissue with poring agent in situ; and a washing step to remove the impurity from said porous connective tissue thereby obtaining a porous collagen matrix.

Owner:NAT CHENG KUNG UNIV

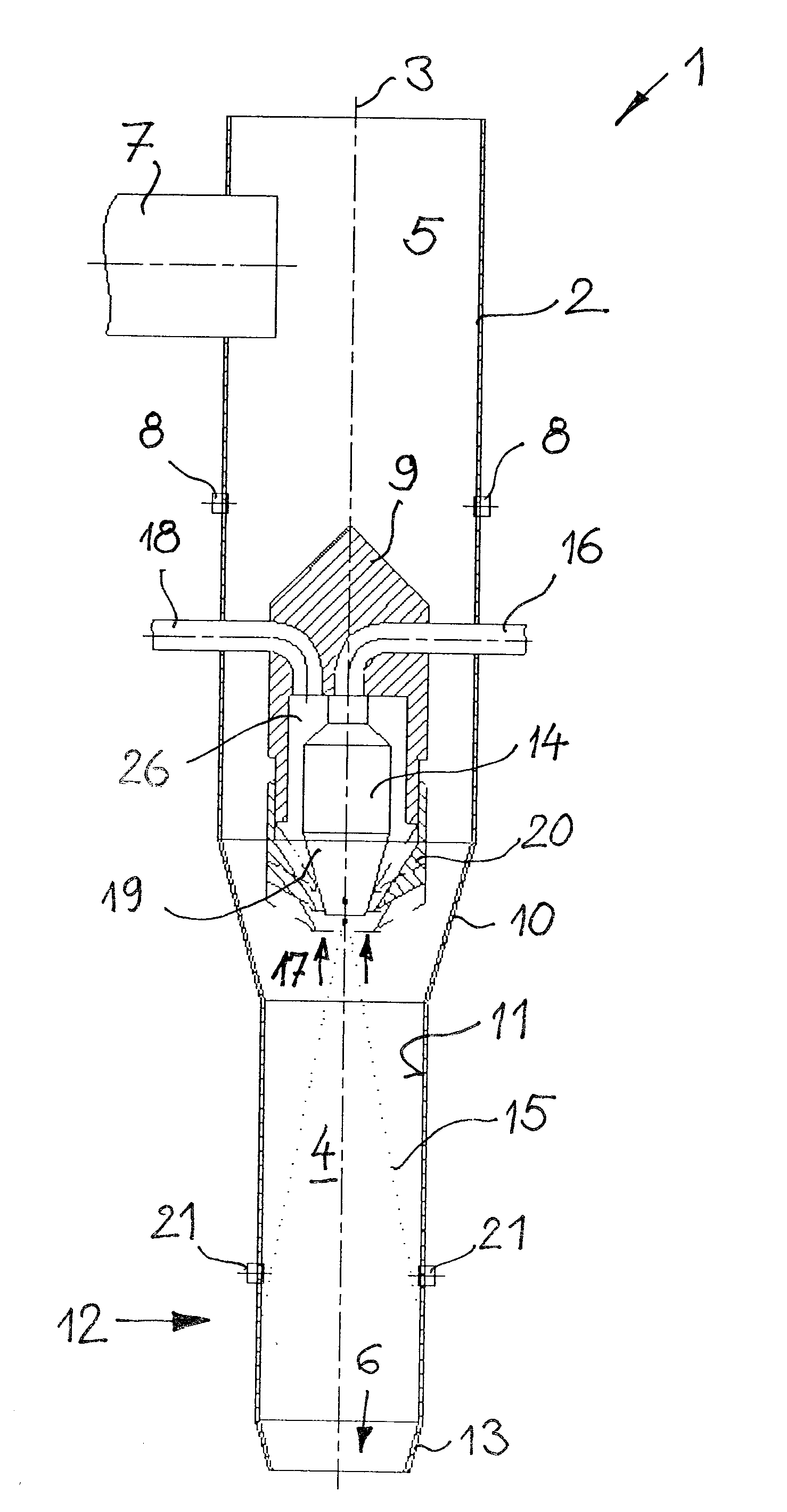

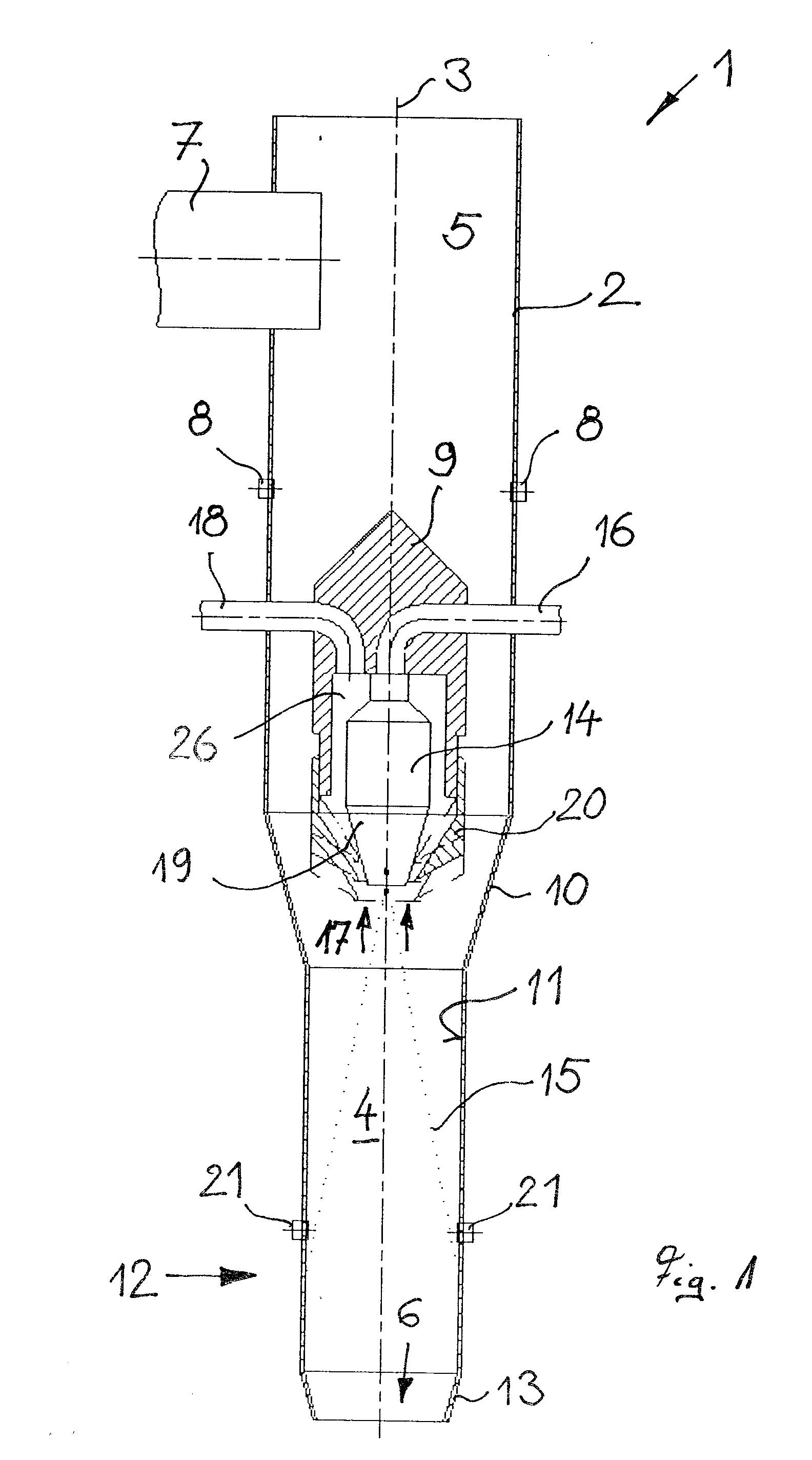

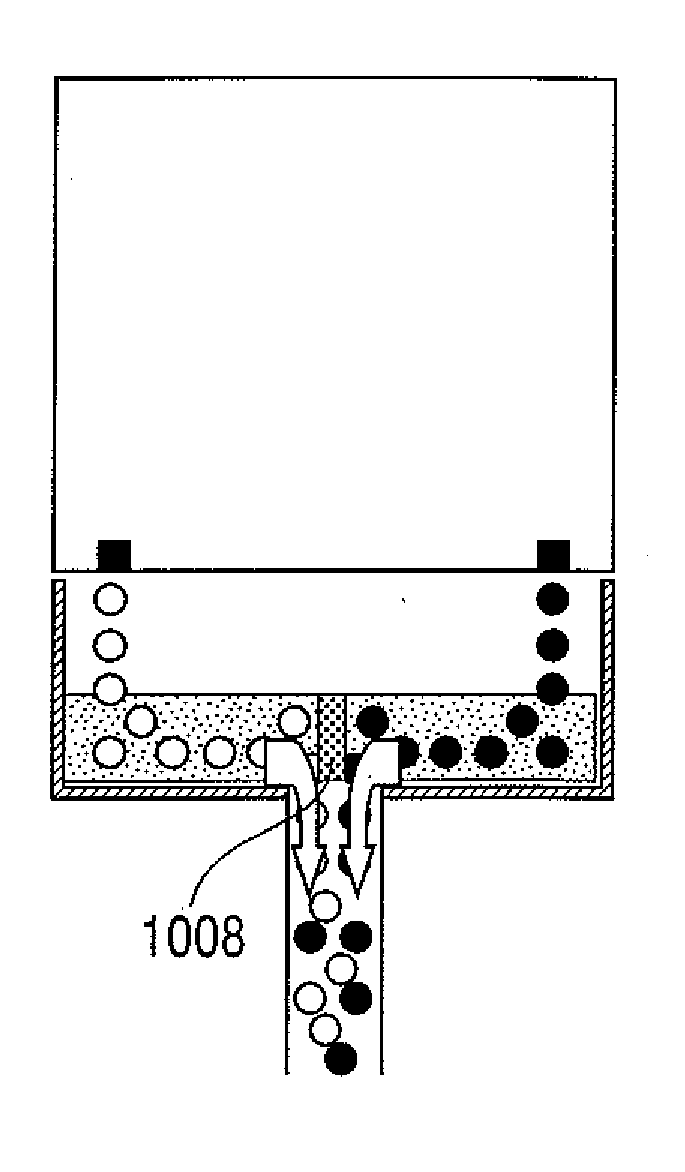

Device and Method for Admixing Liquids into Flowable Bulk Material

ActiveUS20080144425A1High demandExcellent qualityMixing/kneading structural elementsFlow mixersSpray nozzleEngineering

A device for admixing a liquid into flowable dry materials has a housing with a mixing chamber having an inner wall with an impact area and an exit opening at a bottom end of the mixing chamber. Dry material is supplied from above into the mixing chamber and falls downwardly toward the impact area in front of the inner wall of the mixing chamber and exits through the exit opening. A nozzle generates a pressurized high-speed jet of a liquid impacting on the inner wall of the mixing chamber in the impact area and wetting the dry material with the liquid as the jet passes through the dry material and impacts against the inner wall. An opening inside the housing is provided for supplying liquid and pasty additives, wherein the opening is directed toward an area of the mixing chamber between the nozzle and the impact area.

Owner:DIERKS & SOHNE

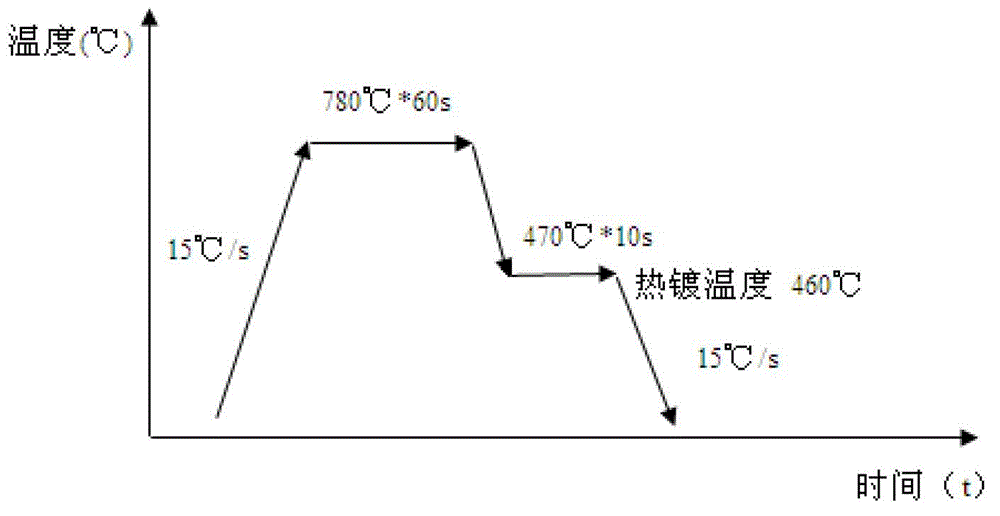

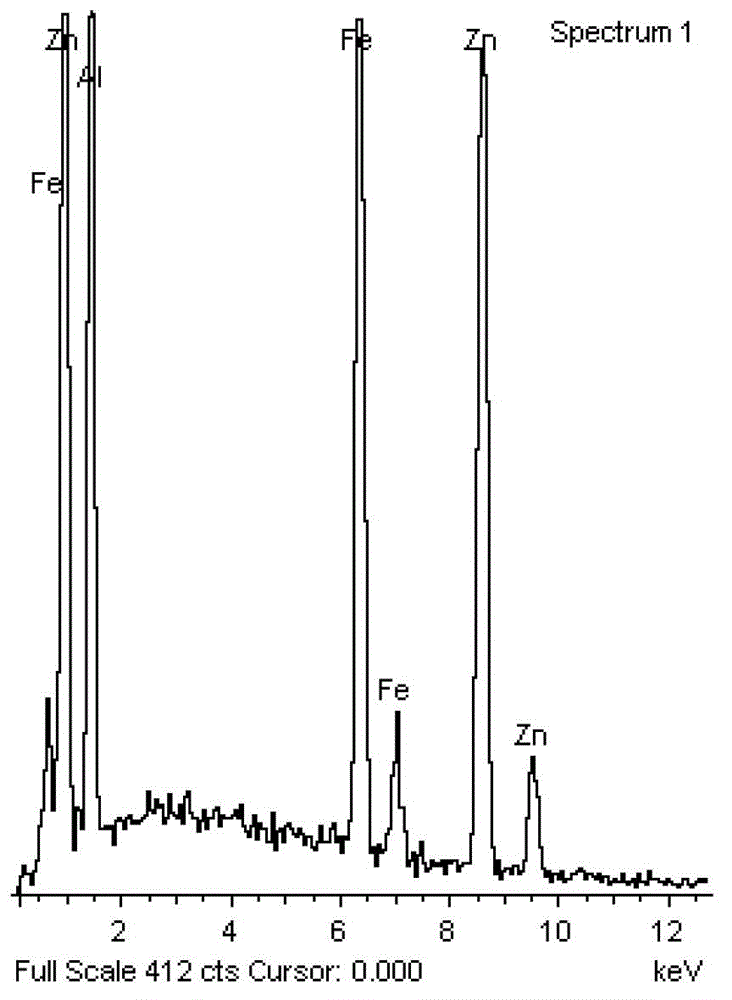

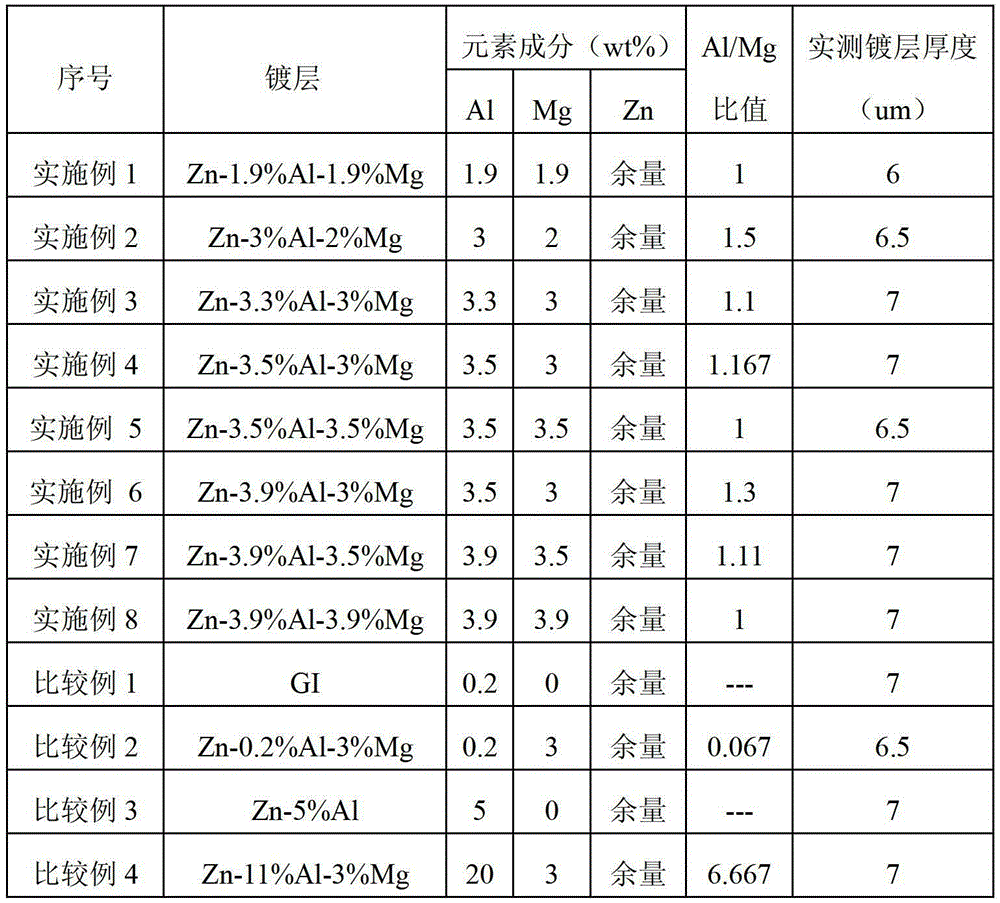

Galvalized aluminum magnesium steel plate and manufacture method thereof

InactiveCN104060209AExcellent corrosion resistanceExcellent qualityHot-dipping/immersion processesSheet steelDross

The invention discloses a galvalized aluminum magnesium steel plate, which comprises a substrate and a coating layer coating on the substrate, the coating layer comprises the following chemical element components: 1.9-3.9wt% of Al, 1.9-3.9wt% of Mg, and the balance of Zn and other inevitable impurities; and the mass percentage of Al to Mg is greater than or equal to 1. The invention also discloses a method for manufacturing the galvalized aluminum magnesium steel plate, which comprises the following steps: 1)manufacturing the substrate; 2)degreasing and cleaning the surface of the substrate; 3)continuously annealing; 4)galvalizing the substrate in a heat galvalizing pool; and 5)galvalizing and cooling. The galvalized aluminum magnesium steel plate has good corrosion resisting performance, clunging performance, weldability and manufacturability, can satisfy the plate usage requirement in automobile industry, building field and household electrical appliance industry, the manufacture method of the galvalized aluminum magnesium steel plate can avoid the scum problem of a plating liquid due to addition of Mg, production cost is reduced, and equipment life is prolonged.

Owner:BAOSHAN IRON & STEEL CO LTD

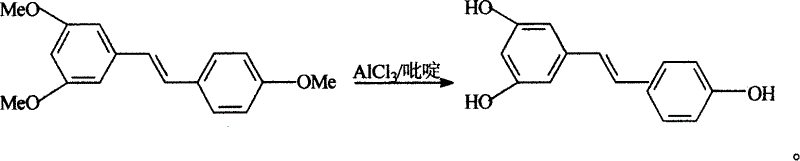

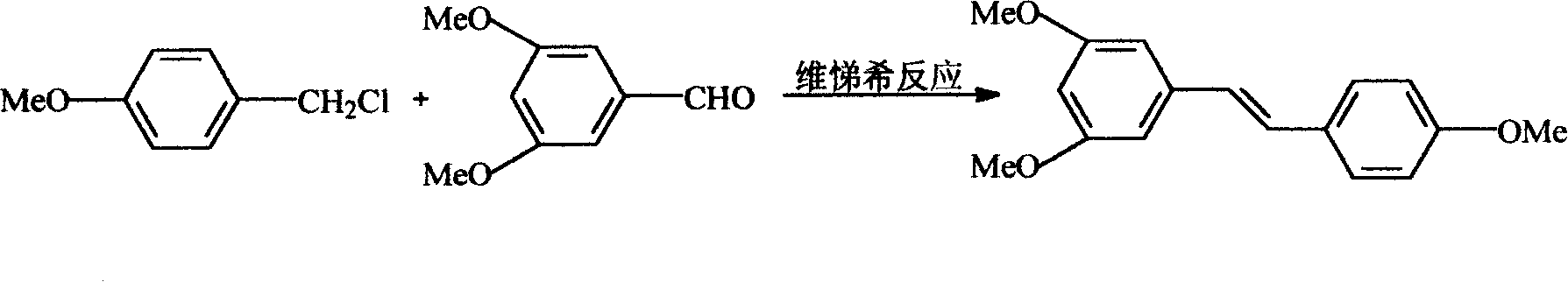

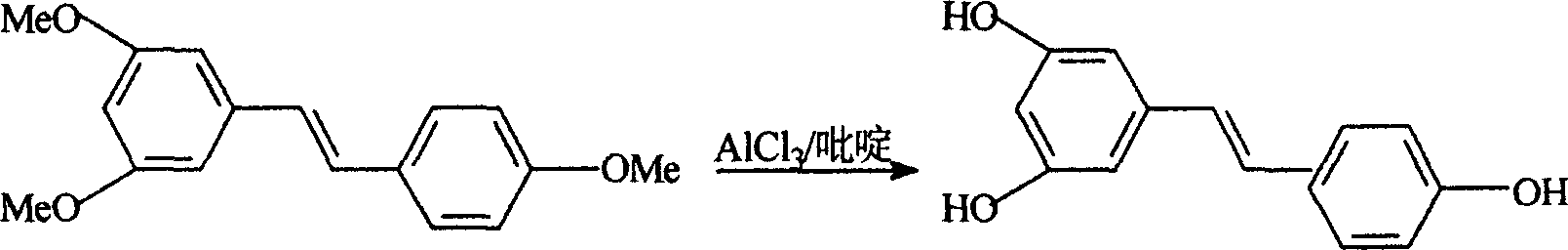

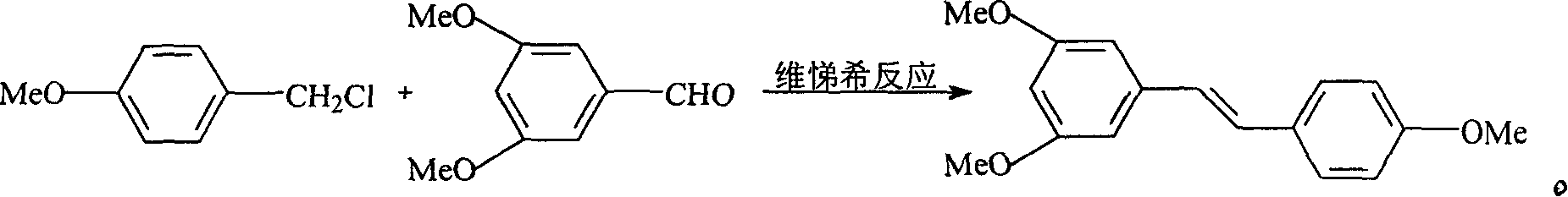

Process for synthesizing resveratrol by using de-methylation technology

InactiveCN1663939AExcellent qualityExcellent yieldOrganic chemistryOrganic compound preparationAluminium chlorideWittig reaction

The invention relates to a process for synthesizing resveratrol by using de-methylation technology, which comprises using 3,5,4'-trimethoxyl diphenyl ethylene as raw material, using aluminium chloride / pyridine as catalyst for synthesizing Resveratrol through demethyl process, and employing market available methoxyl benzyl chloride for Wittig reaction with 3,5- dimethoxybenzaldehyde, thus preparing intermediate 3,5,4'-trimethoxyl diphenyl ethylene.

Owner:NANJING RALLY BIOCHEM

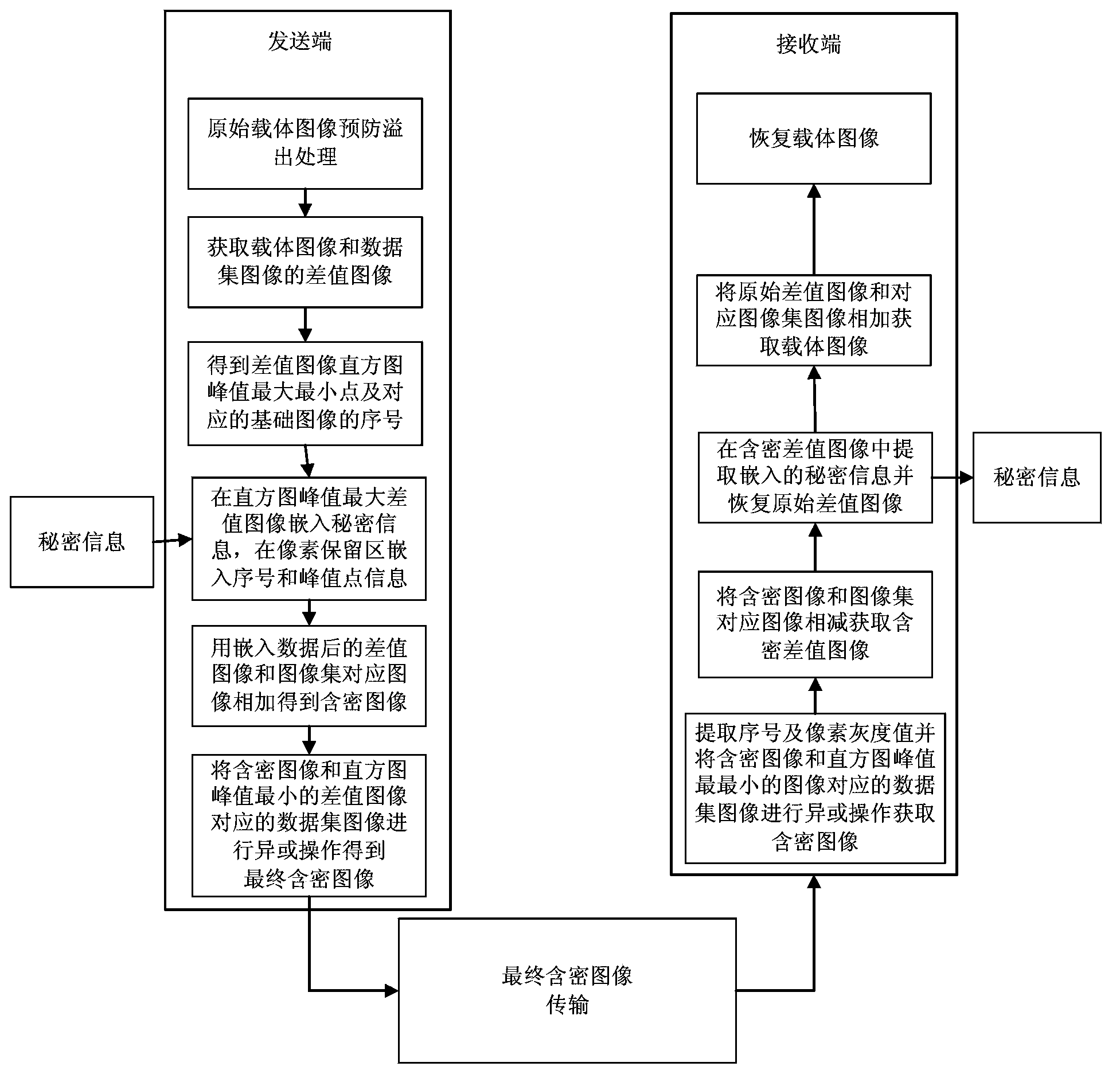

Data hiding method based on image set

ActiveCN103414840AExcellent hidden capacityExcellent qualityImage enhancementPictoral communicationImage extractionHidden data

The invention discloses a data hiding method based on an image set. The data hiding method comprises the step of carrying out anti-overflow process on an original carrier image, the step of developing a reserved pixel area, the step of generating a carrier image, the step of respectively carrying out subtraction on the carrier image and a basic image in the built image set to obtain difference images and histogram information, the step of regarding the difference image which has largest peak value of a histogram as a carrier and hiding data based on the information hiding method of the histogram, the step of hiding label information corresponding the difference image which has the largest peak value of the histogram and the difference image which has the lowest peak value of the histogram based on the reserved pixel area serving as the carrier, the step of adding a secret containing difference image and the corresponding image in the image set to obtain a secret containing image, the step of carrying out xor operation on the secret containing image and the basic image corresponding to the lowest histogram peak value to obtain a secret containing carrier image to be transmitted, and the step of extracting label information from the secret containing carrier image through a receiving terminal, carrying out the information hiding inverse process and recovering hidden data and hidden carrier images. The capacity of information hiding is improved through the image set, and safer lossless data hiding is achieved.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

Pigment ink, ink set, ink jet recording method, ink cartridge, recording unit, ink jet recording apparatus, and image forming method

ActiveUS20080136862A1Achieves compatibilityExcellent qualityMeasurement apparatus componentsInksEngineeringPigment

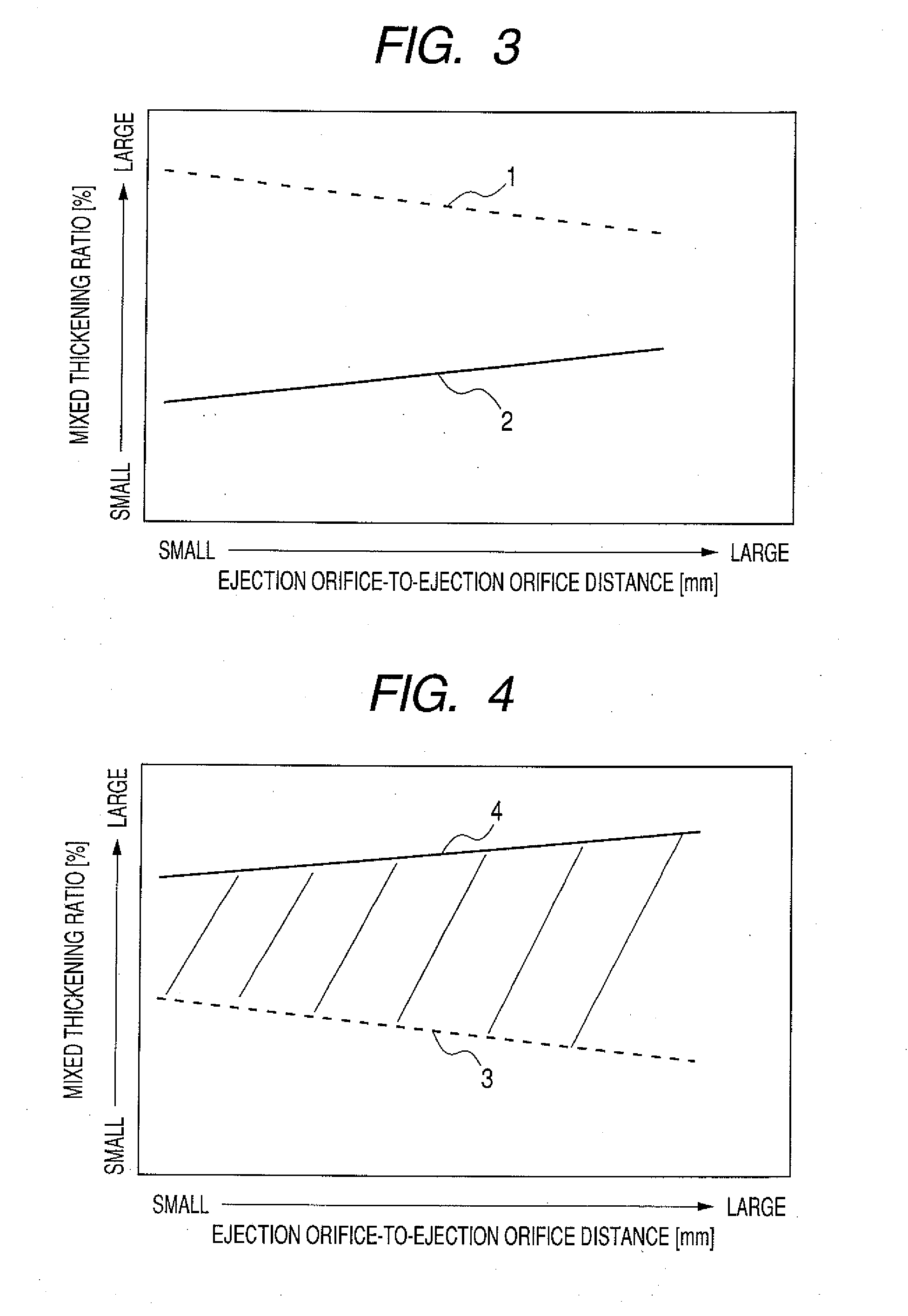

A pigment ink is provided which is used in an ink jet recording apparatus in which ejection orifices for a pigment ink and ejection orifices for at least one type of reactive ink that destabilizes a dispersed state of pigment in the pigment ink are capped with the identical cap provided with a unit for removing an ink in the cap, achieving compatibility between bleeding resistance and reliability. Where a mixed thickening ratio upon mixing the pigment ink and the reactive ink in equal volumes is represented by Y (%) and an ejection orifice-to-ejection orifice distance between the ejection orifice for the pigment ink and the ejection orifice for the reactive ink is represented by X (mm) (provided that X>0), Y and X satisfy a specific relationship.

Owner:CANON KK

Method for modifying synthetic veratric alcohol

InactiveCN101033172AExcellent qualityExcellent yieldOrganic chemistryOrganic compound preparationAlcoholWittig reaction

This invention relates to an improved method for synthesizing resveratrol, which takes 3, 5, 4'-methylate toluylene as the raw material, 1, 3, 5-trimethylbenzene as the solvent and hydroquinone as the antioxidant to synthesize resveratrol with alchlor / pyridine as the catalyst and applies commercial cheap anisyl chlorben and 3, 5-dimethoxy benzene formaldehyde for wittig reaction to prepare an intermediate 3, 5, 4'-methylate toluylene.

Owner:NANJING RALLY BIOCHEM

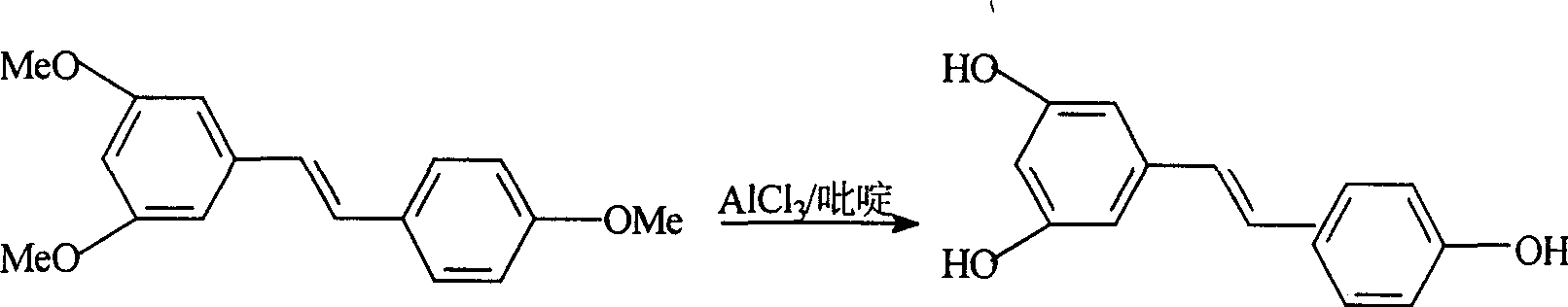

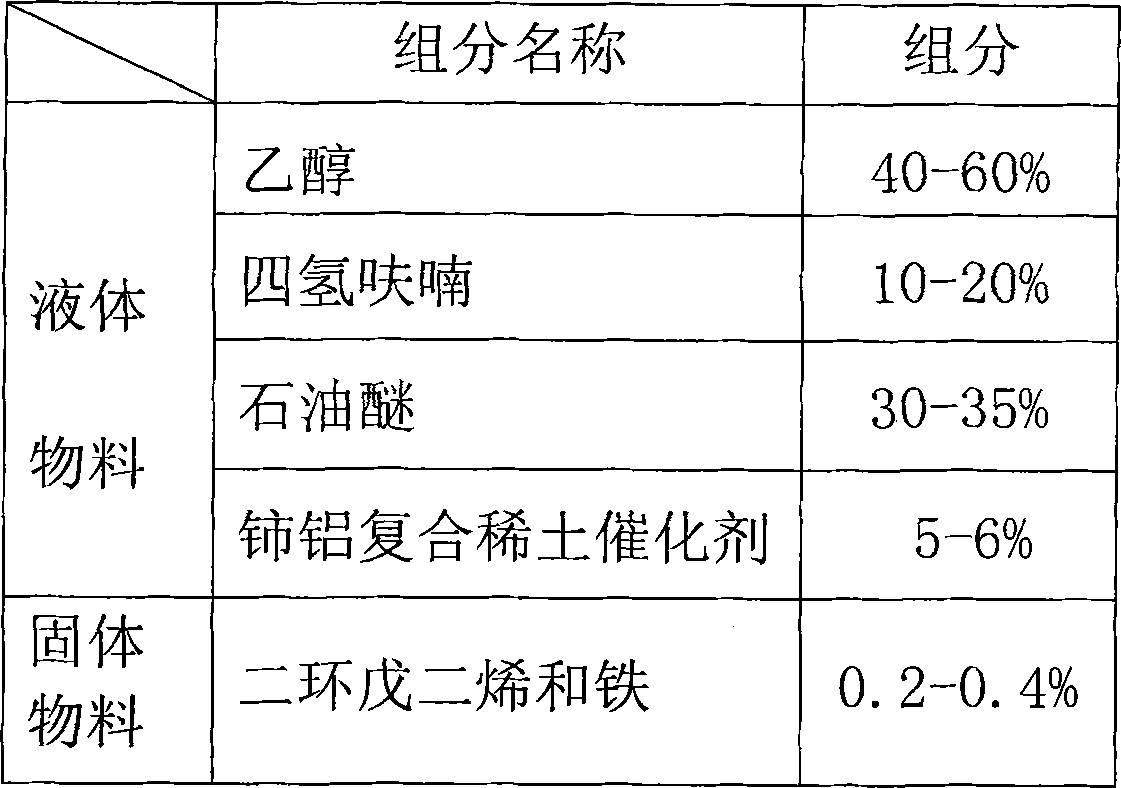

Synergistic additive of natural-gas as welding and cutting gas

The invention discloses a synergistic additive of natural-gas as welding and cutting gas, and relates to the technical field of the synergistic additives of the natural-gas as the welding and cutting gas, wherein a preparation process of the synergistic additive comprises the following steps: uniformly mixing ethanol with petroleum ether for later use; adding tetrahydrofuran into a reaction kettle, adding bis(cyclopentadienyl) iron and a liquid cerium-aluminum composite rare earth catalyst into the reaction kettle to stir, and mixing with the mixed solution after dissolving completely; and standing for 4 hours and discharging clear liquid through a liquid discharge valve at the side of the reaction kettle, and filling the clear liquid into a package bucket to obtain the synergistic additive. The synergistic additive combines a catalytic activation principle of the cerium-aluminum composite rare earth and special organic chemical materials to play roles of increasing the temperature and assisting the combustion in the natural gas, resisting against explosion and increasing the flame temperature of the combustion of the natural gas in oxygen. In addition, the synergistic additive can be gasified under certain pressure and mixed with the natural gas to increase the activity coefficient index of the natural gas and increase the temperature of the combustion of the natural gas in oxygen to about 3430 DEG C, which is at an advanced level in the industry. The synergistic additive can completely replace acetylene in cutting, welding, baking and flame spraying functions.

Owner:赵志鑫 +3

Production technology of sweet potato vermicelli

ActiveCN103734580AGuaranteed colorIntrinsic Quality GuaranteeFood freezingFood shearingWarm waterInternal quality

The invention relates to a production technology of sweet potato vermicelli, which comprises the processes of starchy sauce preparation, dough preparation, vermicelli preparation, cooling and drying, wherein the processes of starchy sauce preparation and dough preparation comprise the following steps: 1) starchy sauce preparation: pouring a fixed quantity of starch into a starchy sauce jar, adding 35-45 DEG C warm water of which the weight is 1.5-2 times the weight of the starch, and stirring uniformly; and adding 94-97 DEG C hot water of which the weigh is 4.5-5.5 times the weight of the starch in weight, stirring uniformly into a paste, and cooling to 68-70 DEG C; and 2) dough preparation: based on 100kg of starch with over 99% of fineness, adding 20-24kg of prepared starchy sauce paste and 52-55kg of 35-45 DEG C warm water, and stirring for 10-12 minutes while ensuring that the temperature in dough preparation is 40-45 DEG C; and pouring the prepared dough into a vacuum machine, and performing vacuumizing treatment through a vacuumizing machine to finish the dough preparation process. In the production technology of sweet potato vermicelli provided by the invention, no additive is added in the starchy sauce preparation process, the color and internal quality of the vermicelli are guaranteed, and the mouthfeel and toughness of the vermicelli are increased by the vacuumizing treatment.

Owner:河南新天豫食品有限公司

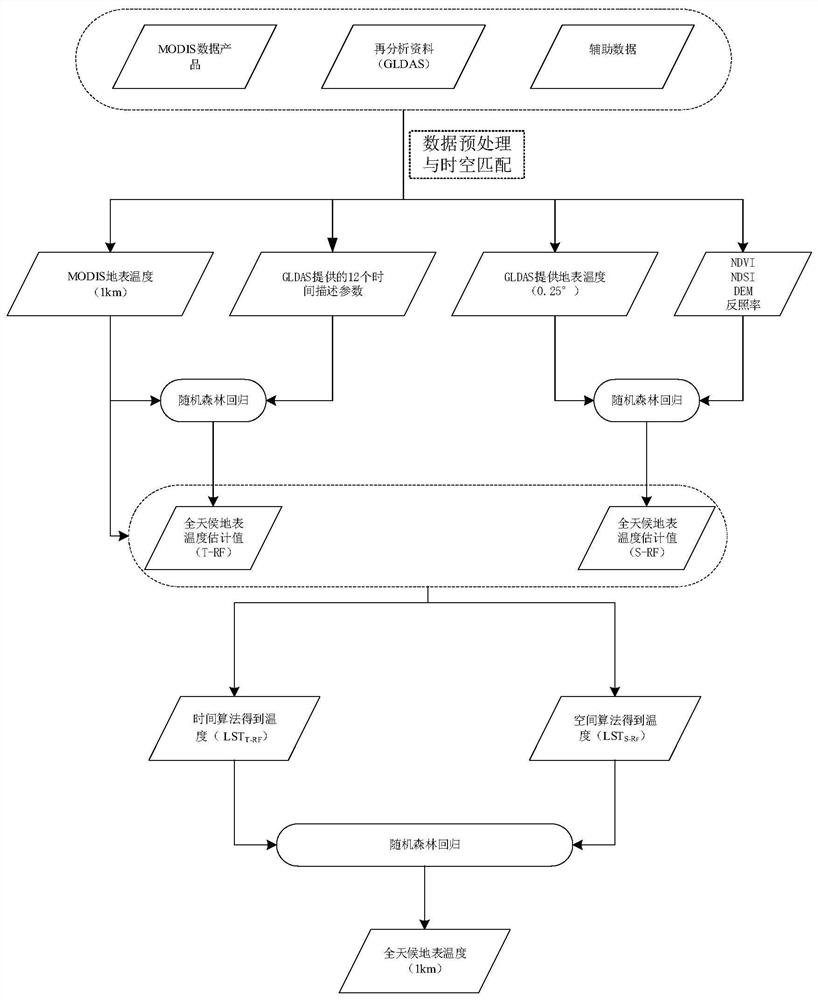

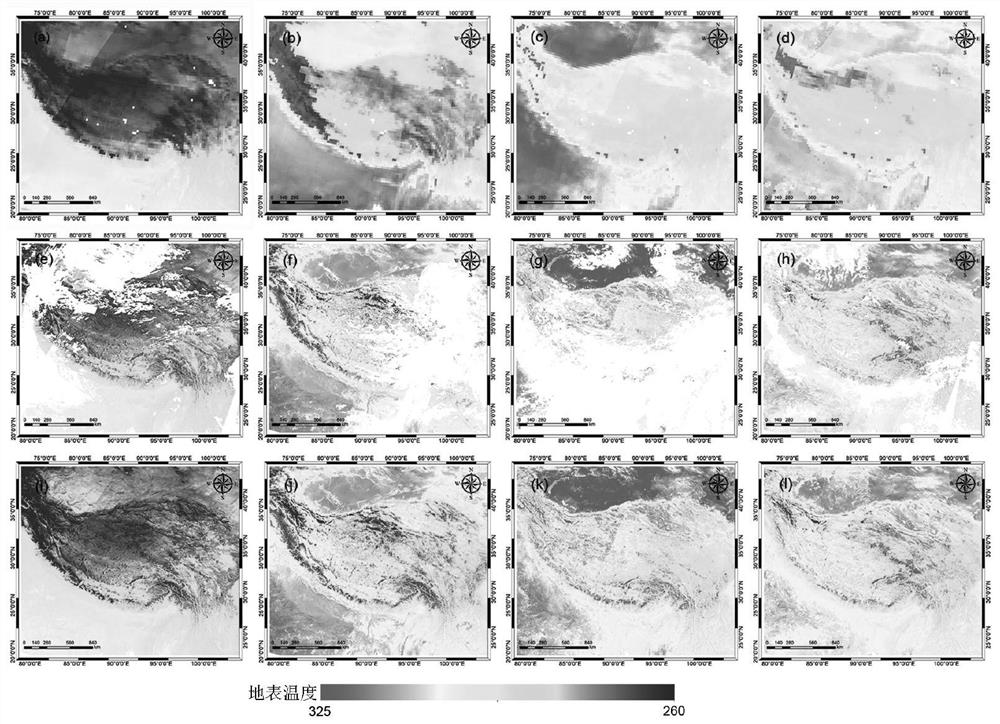

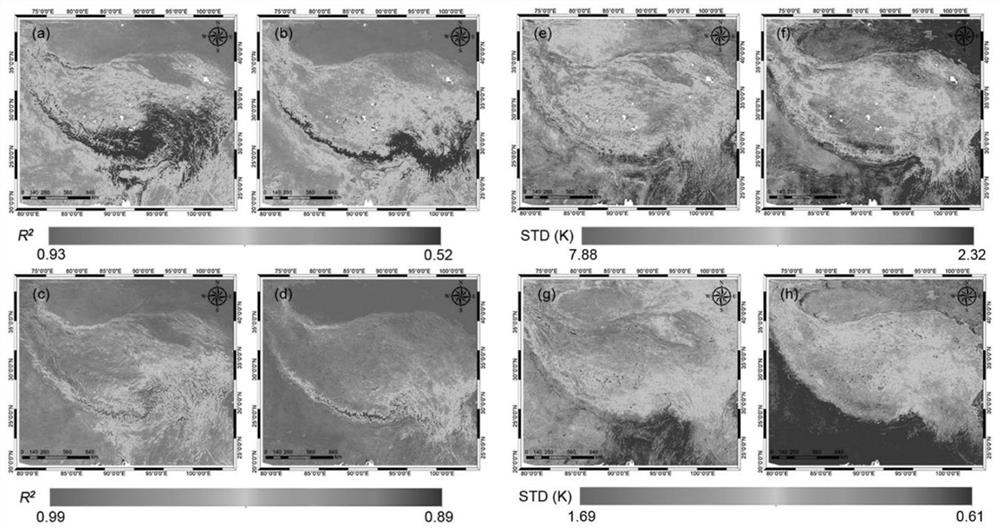

All-weather surface temperature generation method integrating thermal infrared and reanalysis data

ActiveCN111982294AImprove consistencyExcellent qualityPyrometry for temperature profileMachine learningImaging qualityThermal infrared

The invention provides an all-weather surface temperature generation method integrating thermal infrared and reanalysis data, which is realized on the basis of random forest integrated thermal infrared remote sensing and reanalysis data. The method specifically comprises the following steps: performing data preprocessing and space-time matching; implementing a time algorithm; implementing a spacealgorithm; and generating the final 1km all-weather surface temperature. According to the invention, reanalysis data is introduced, a long surface temperature and related observation data can be provided, the data is integrated with thermal infrared satellite remote sensing to obtain all-weather surface temperature with long time sequence and high temporal-spatial resolution. The obtained surfacetemperature has good consistency with a traditional thermal infrared satellite remote sensing surface temperature product, and through the inspection of the actually measured surface temperature, theprecision is within an acceptable range, the image quality is higher, more space detail information of the surface temperature can be displayed, and the overall quality and precision are superior to those of a method for integrating thermal infrared satellite remote sensing data and passive microwave data.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

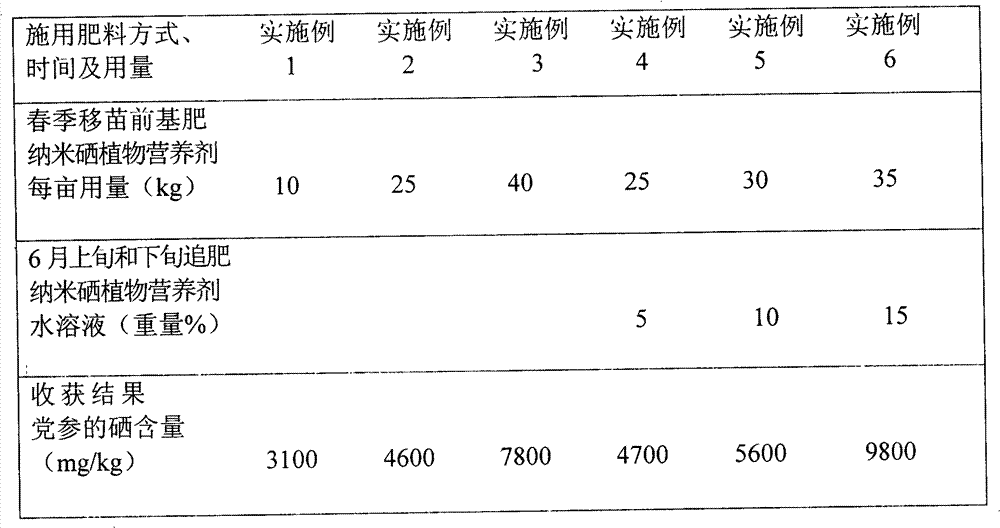

Artificially cultivated selenium-rich radix codonopsitis and cultivating process thereof

InactiveCN102784185AExcellent appearanceExcellent qualityMetabolism disorderDigestive systemCodonopsis pilosulaPest control

The invention relates to an artificially cultivated selenium-rich radix codonopsitis and a cultivating process of the artificially cultivated selenium-rich radix codonopsitis. The content of selenium in the artificially cultivated selenium-rich radix codonopsitis is 3,100-9,800mg / kg, and the content of organic selenium takes up not less than 70% of the selenium total content. The cultivating process of the artificially cultivated selenium-rich radix codonopsitis is implemented in the way of seedling, ditching and transplanting. In the cultivating step, the nano-selenium plant nutrients are uniformly applied into ditches before the radix codonopsitis seedlings are transplanted, and the dose of the nano-selenium plant nutrients is 10-40kg / mu; and then the radix codonopsitis seedlings are obliquely transplanted into ditches so as to turn the soil and bury the seedlings, and then are subjected to field managements, such as weeding, stem cutting, fertilizer applying, irrigation and pest control, and finally foliar application by using 5-15% of aqueous solution of the nano-selenium plant nutrients during a full-bloom stage of the radix codonopsitis. The cultivating method is strong in operability, suitable for standardizing and scale product of the traditional Chinese medicinal materials, and the appearance and quality indexes of the selenium-rich radix codonopsitis cultivated by the method are prior to that of the ordinary radix codonopsitis.

Owner:渭源县莲峰镇绽坡村康荣中药材专业合作社

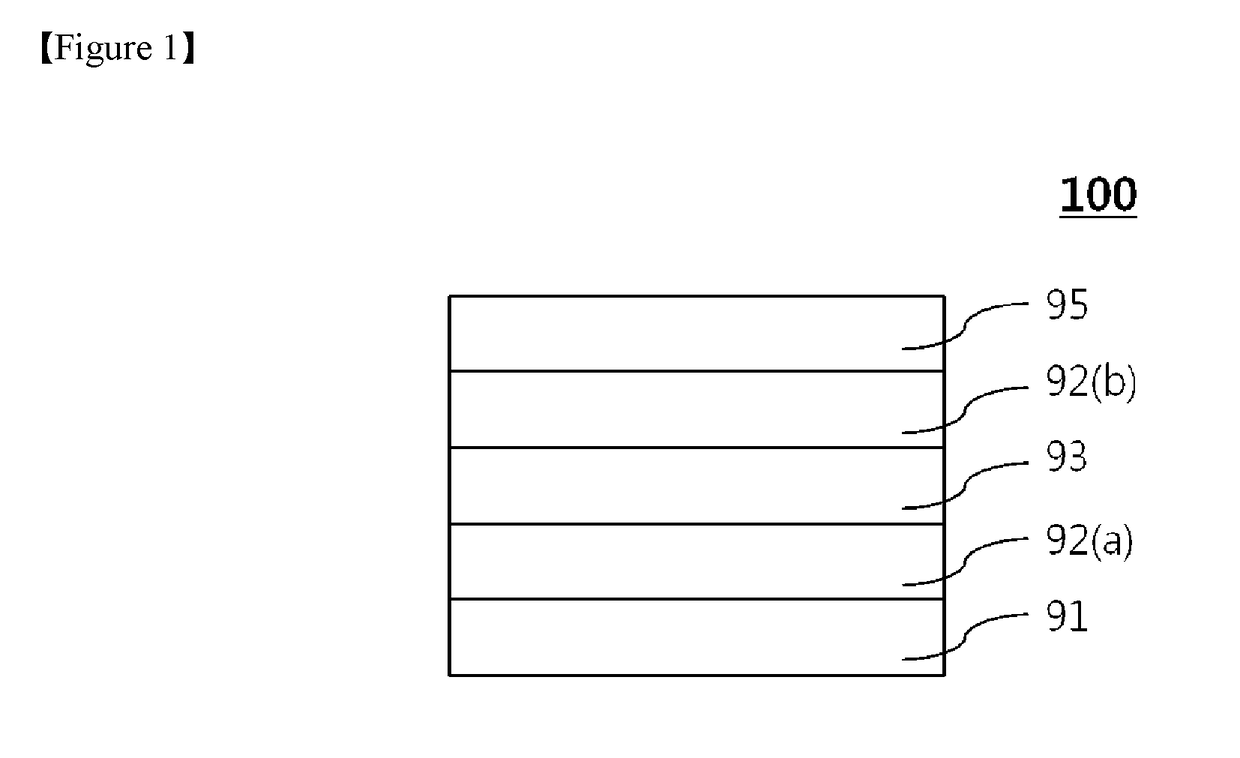

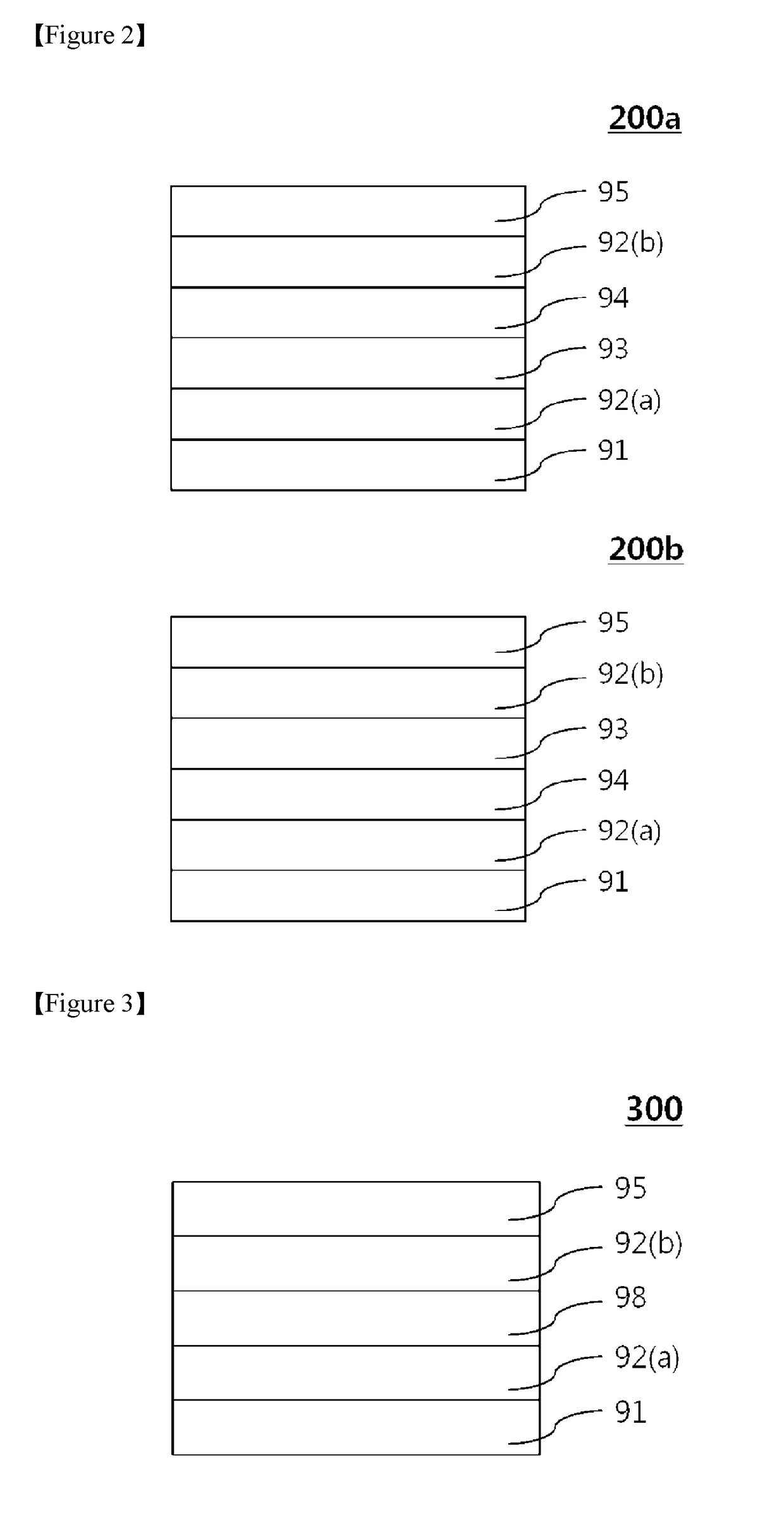

Flexible display device

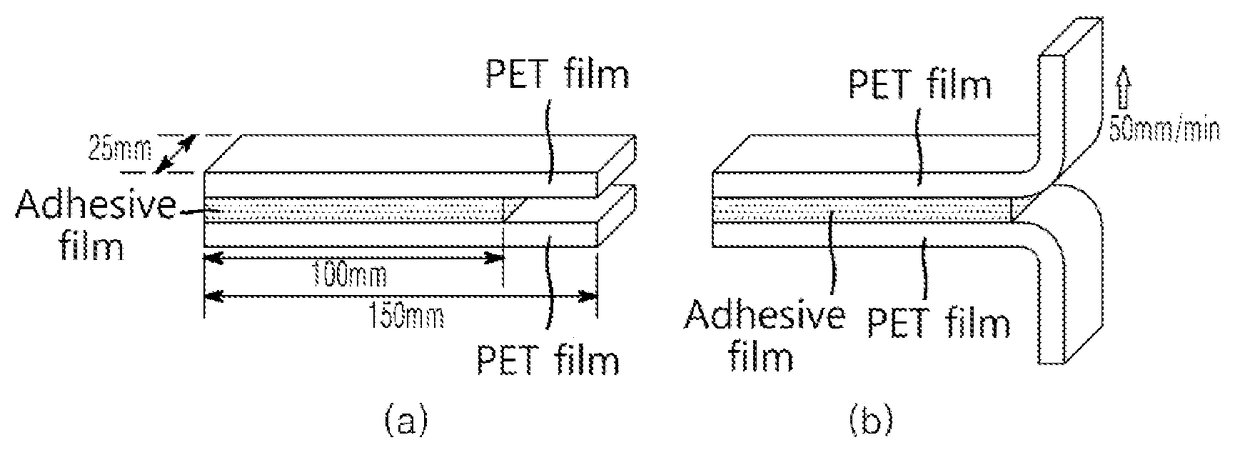

ActiveUS20170321087A1Excellent reliability and durabilityExcellent qualityNon-macromolecular adhesive additivesDigital data processing detailsOpto electronicEngineering

A flexible display device of the present invention comprises a photoelectric element part; a first adhesive film formed on the photoelectric element part; a touch function part formed on the first adhesive film; a second adhesive film formed on the touch function part; and a window film formed on the second adhesive film; wherein the first adhesive film or the second adhesive film has an average slope of about −9.9 to about 0 at −20° C. to 80° C. based on x-axis for the distribution of storage modulus versus temperature in the function of x-axis of temperature (° C.) and y-axis of storage modulus (KPa) and wherein the first adhesive film or the second adhesive film has a storage modulus of about 10 KPa or more at 80° C.

Owner:SAMSUNG ELECTRONICS CO LTD +1

Preparation method for 4-chlorophenylhydrazine hydrochloride

InactiveCN103910650AEliminates the problem of easy agglomeration and difficult operation of feedingEasy dischargeHydrazine preparationSolubilityHydrogen Sulfate

A provided preparation method for 4-chlorophenylhydrazine hydrochloride comprises the following steps: 1) under an acidic condition, at 5-10 DEG C, dropwise adding a sodium nitrite aqueous solution with a concentration of 20% into 4-chloroaniline to perform a diazo reaction and to generate a diazo salt; 2) under a room temperature condition, dropwise adding an ammonium sulfite aqueous solution into a solution of the diazo salt obtained in the step 1, heating to 50-60 DEG C and keeping the temperature for 3-4 h; and 3) at 50-70 DEG C, dropwise adding a hydrochloric acid solution with a concentration of 20% into the solution obtained in the step 2, keeping the temperature for 1-2 h, reducing the temperature, filtering, washing, discharging the material, and drying to obtain a finished product. The beneficial effects comprise that by using ammonium sulfite aqueous solution as a reducing agent in the reduction reaction, the problems are solved that sodium sulfite solid is easy to cake during material charging in a conventional technology and material charging is not easy to operate; ammonium chloride and ammonium hydrogen sulfate which are generated in the acidification reaction have high solubility in water, and crystallization precipitation is late, thereby facilitating performing of the acidification reaction in the solution and reducing side reactions; and the product crystallizes loosely, is good in fluidity, easy for material discharging and washing, and product quality and yield are both better than conventional production levels.

Owner:TIANJIN QIDONG CHEM PLANT

Disinfector containing BCDMH (Bromochloro Hydantoin) and preparation method thereof

The invention belongs to the technical field of disinfection, and discloses a disinfector containing BCDMH (Bromochloro Hydantoin) and a preparation method thereof. The disinfector comprises 10-25wt% of BCDMH, 5-25wt% of 5, 5-dimethyl hydantoin, 2-5wt% of surfactant, 5-10wt% of bonder, 10-20wt% of stabilizer, and 30-55wt% of effervescing agent. The disinfector uses the polyethylene glycol bonder to ensure the stability of BCDMH and 5, 5-dimethyl hydantoin with a Twain surfactant based on a slow release effect, so as to further prevent BCDMH from being degraded to 5, 5-dimethyl hydantoin.

Owner:GUANGZHOU JINSHUI ANIMAL HEALTH PROD

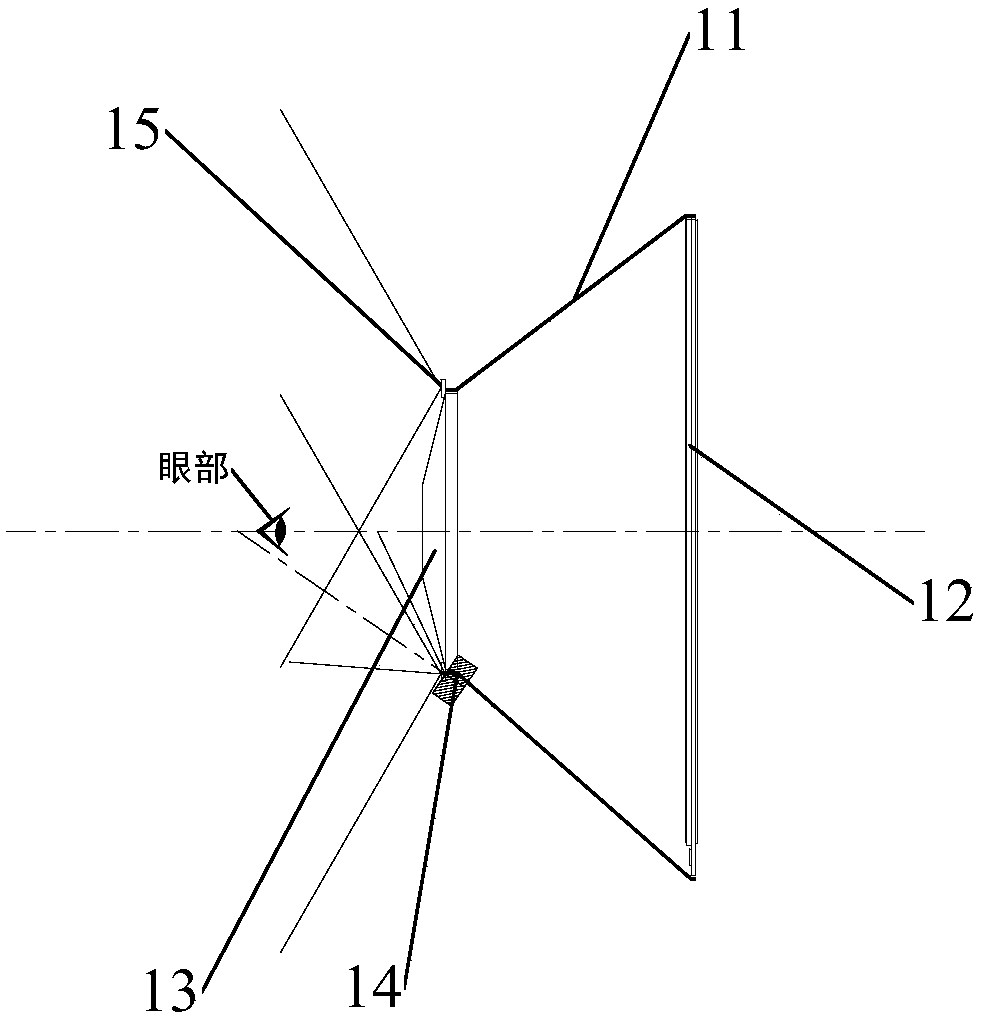

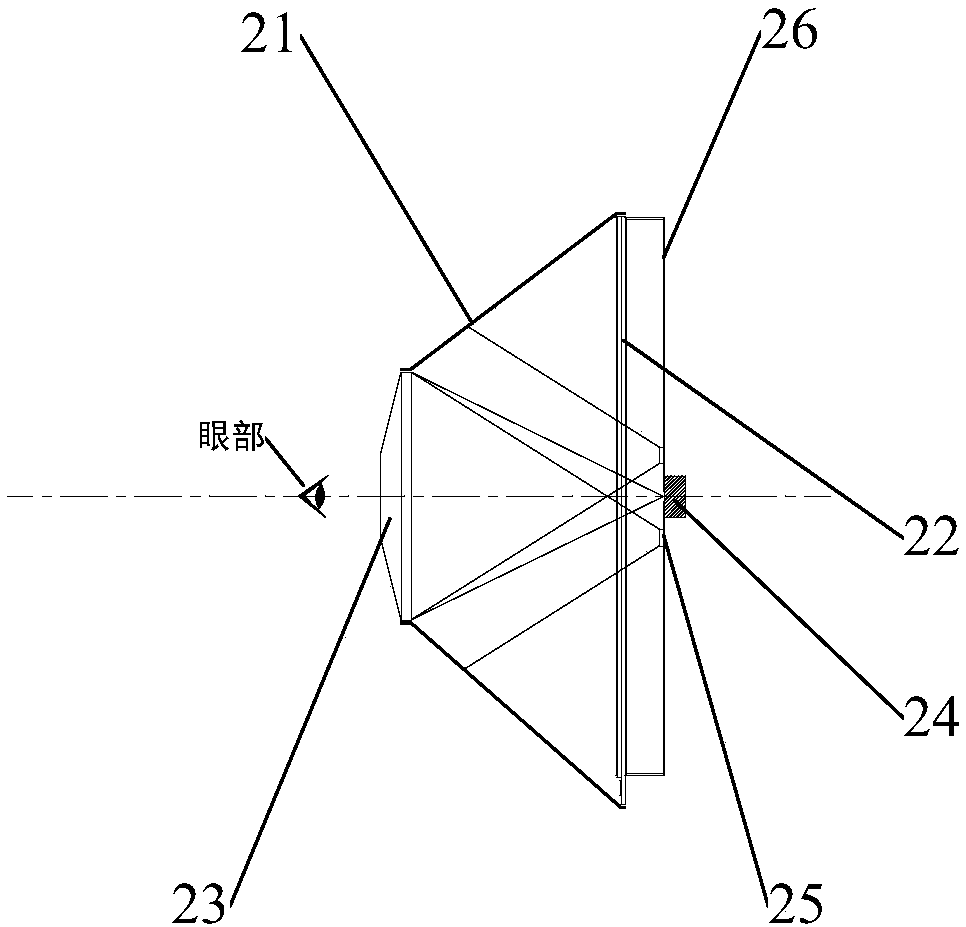

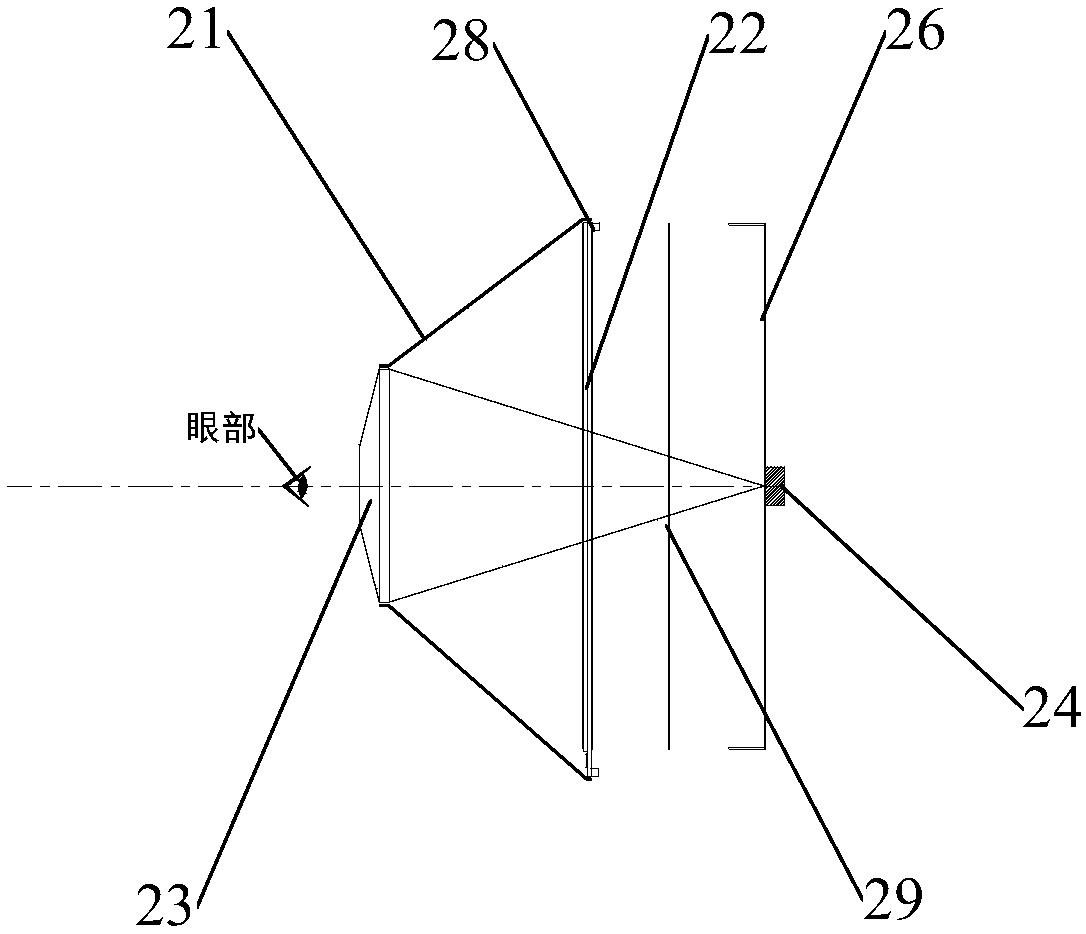

Virtual reality display device and equipment and sight angle calculation method

ActiveCN108519824AReduce viewing angleReduce size requirementsInput/output for user-computer interactionImage enhancementImaging qualityDisplay device

The invention discloses a virtual reality display device. The device comprises a display screen for displaying a frame to a user, at least one infrared light source and an infrared camera; the infrared camera is arranged at the side, away from the eyes of the user, of the display screen and used for collecting an eye image of the eyes of the user under the irradiation of at least one infrared light source. The invention further discloses a sight angle calculation method and display equipment comprising the virtual reality display device. The requirement of the infrared camera for the eyeball tracking function of the display device is lowered, and therefore the cost is lowered; the eyeball imaging quality is improved, a photographing blind region is avoided, and then the eyeball tracking precision is improved.

Owner:BOE TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com