Patents

Literature

37 results about "BCDMH" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

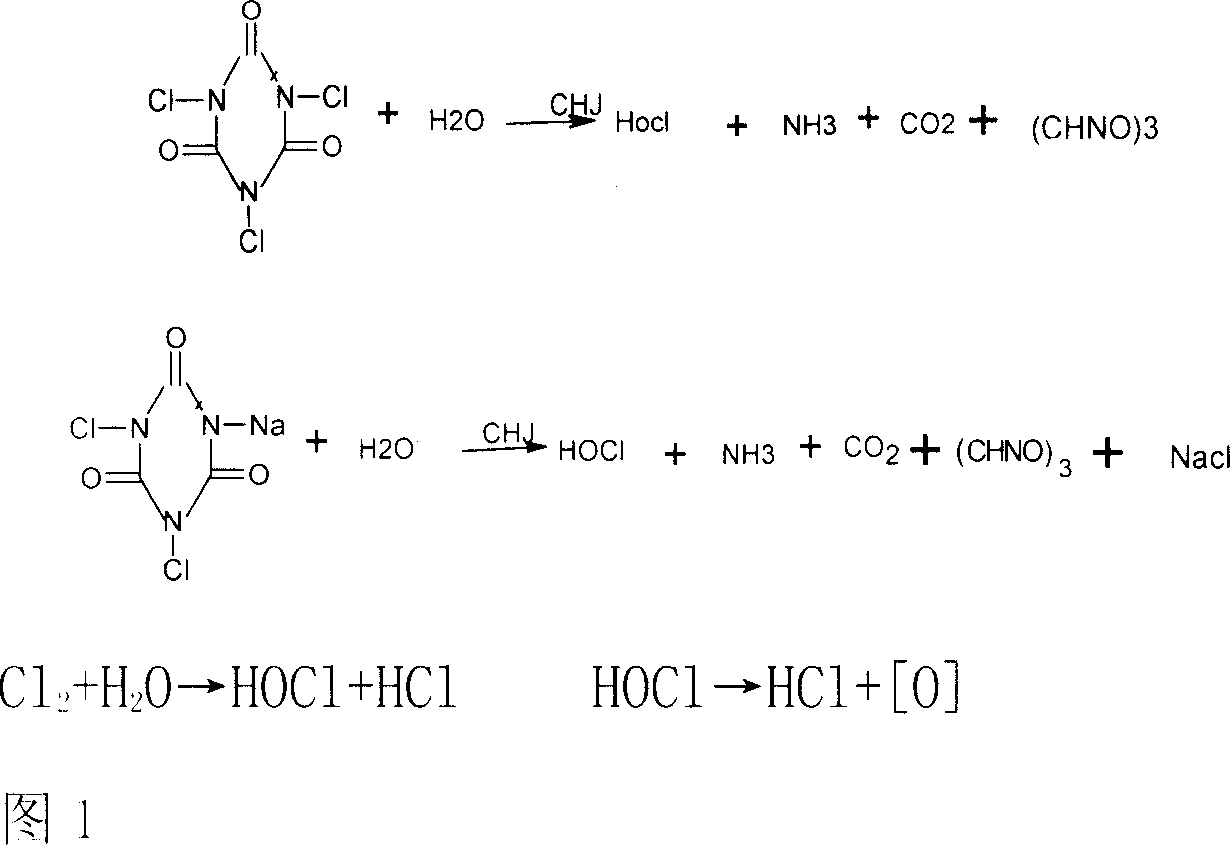

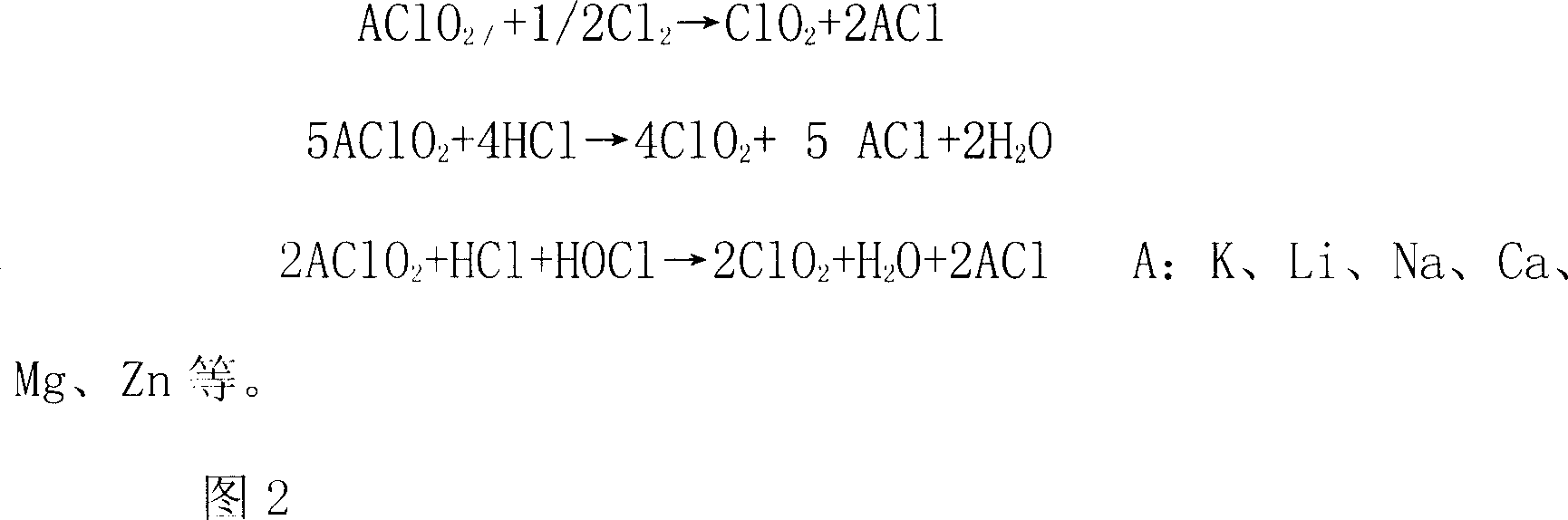

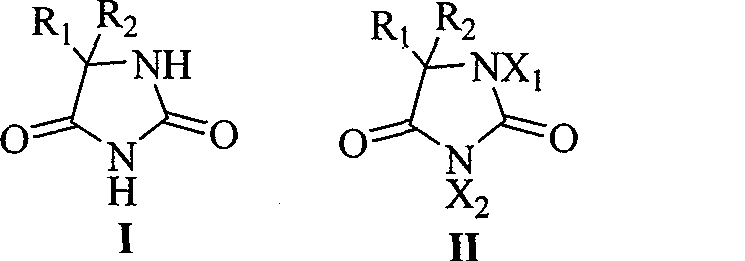

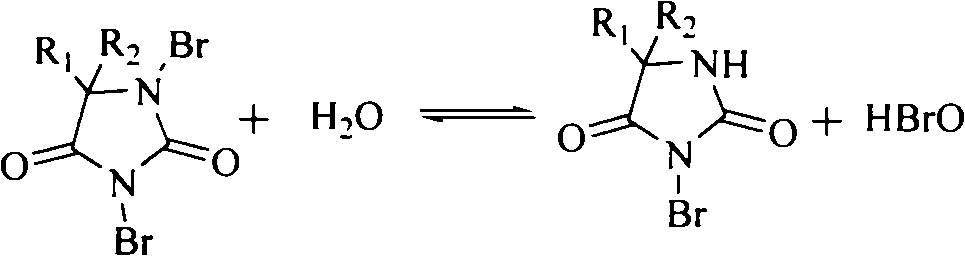

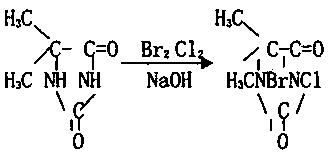

1-Bromo-3-chloro-5,5-dimethylhydantoin (BCDMH or bromochlorodimethylhydantoin) is a chemical structurally related to hydantoin. It is a white crystalline compound with a slight bromine and acetone odor and is insoluble in water, but soluble in acetone.

Dual layer tablet, method of making and use thereof

InactiveUS6863830B1Easy to optimizeComprehensive treatmentOrganic chemistryOther chemical processesPotassium persulfateLithium hypochlorite

A method for treating a recirculating water system which comprises introducing into said water system a multifunctional, multilayer tablet, wherein the multilayer tablet comprises a fast dissolving layer and a slow dissolving layer, wherein said fast dissolving layer releases a combination of active ingredients including a member selected from the group consisting of lithium hypochlorite, calcium hypochlorite, trichloroisocyanuric acid (TCCA), anhydrous sodium dichloroisocyanurate, sodium persulfate, potassium persulfate, potassium monopersulfate, sodium monopersulfate, and mixtures thereof, and at least one of a clarifier, chelating agent, sequesterant, algaestat, water softener, algaecide, corrosion inhibitor, scale inhibitor, flocculent, disintegrant, dispersant, colorant, dissolution control agent, fragrance, or surfactant and, wherein said slow dissolving layer includes a member selected from the group consisting of trichloroisocyanuric acid (TCCA), calcium hypochlorite, 1,3-dichloro-5,5-dimethylhydantoin (DCDMH), 1,3-dibromo-5,5-dimethylhydantoin (DBDMH), 1-bromo-3-chloro-5,5-dimethylhydantoin (BCDMH), 1,3-dichloro-5-ethyl-5-methylhydantoin (DCEMH), 1,3-dibromo-5-ethyl-5-methylhydantoin (DBEMH), 1-bromo-3-chloro-5-methyl-5-ethylhydantoin (BCEMH), and mixtures thereof, and at least one of a clarifier, chelating agent, sequesterant, algaestat, water softener, algaecide, corrosion inhibitor, scale inhibitor, flocculent, disintegrant, dispersant, colorant, dissolution control agent or surfactant.

Owner:BIO LAB

Dual layer tablet, method of making and use thereof

InactiveUS20050040116A1Easy to optimizeComprehensive treatmentOrganic chemistryOther chemical processesPotassium persulfateLithium hypochlorite

A method for treating a recirculating water system which comprises introducing into said water system a multifunctional, multilayer tablet, wherein the multilayer tablet comprises a fast dissolving layer and a slow dissolving layer, wherein said fast dissolving layer releases a combination of active ingredients including a member selected from the group consisting of lithium hypochlorite, calcium hypochlorite, trichloroisocyanuric acid (TCCA), anhydrous sodium dichloroisocyanurate, sodium persulfate, potassium persulfate, potassium monopersulfate, sodium monopersulfate, and mixtures thereof, and at least one of a clarifier, chelating agent, sequesterant, algaestat, water softener, algaecide, corrosion inhibitor, scale inhibitor, flocculent, disintegrant, dispersant, colorant, dissolution control agent, fragrance, or surfactant and, wherein said slow dissolving layer includes a member selected from the group consisting of trichloroisocyanuric acid (TCCA), calcium hypochlorite, 1,3-dichloro-5,5-dimethylhydantoin (DCDMH), 1,3-dibromo-5,5-dimethylhydantoin (DBDMH), 1-bromo-3-chloro-5,5-dimethylhydantoin (BCDMH), 1,3-dichloro-5-ethyl-5-methylhydantoin (DCEMH), 1,3-dibromo-5-ethyl-5-methylhydantoin (DBEMH), 1-bromo-3-chloro-5-methyl-5-ethylhydantoin (BCEMH), and mixtures thereof, and at least one of a clarifier, chelating agent, sequesterant, algaestat, water softener, algaecide, corrosion inhibitor, scale inhibitor, flocculent, disintegrant, dispersant, colorant, dissolution control agent or surfactant.

Owner:BIO LAB

Disinfectant composition with function of deodorization and bleaching effects and its prepn. method

A deodoring, bleeching and disintifecting composition in the form of powder, particle, lozenge, tablet, effervescent agent, liquid, colloid, or aerosol for various purposes is prepared from chlorinated isocyanuric acid, bromochloro hydrantoin, dibromo hydrantoin, or hypochlorite for providing hypochlorous acid component through reacting on chlorate, chlorite and tabilizer to obtain stable ClO2 system, and adding the corrosion inhibitor of metal.

Owner:高旭

Smoke type disinfectant, preparation method and application thereof

ActiveCN101796948AGood adhesionImprove permeabilityBiocideFruit and vegetables preservationSpontaneous combustionAdditive ingredient

Owner:江苏金采健康科技有限公司

Industrial producing method for powder, particle and sheet bromine-chlorine-dimethyl hydantoin disinfectant

ActiveCN101103723ANo emissionsChange the production processBiocideDisinfectantsDisinfectantFiltration

The invention discloses an industrial production method of fine powder, granular and tablet bromo-chloro-dimethyl hydantoin disinfectants, which includes the 5,5-dimethylhydantoin and the flake caustic soda put in a reaction vessel and dissolved in water. The brine is frozen for cooling. With the use of bromine and the chlorine added, the reaction solution is obtained. The reaction solution is put into a filtration tank. After the vacuum filtrating, the ionic water leaching and purification and the centrifuge dripping, the wet products enter a dryer for drying. Thus the powder bromo-chloro-dimethyl hydantoin is obtained after the crushing. A granulator is used for the powder granulation so that the granular bromo-chloro-dimethyl hydantoin can be obtained. The particles poured into a blender are mixed with the adhesives and lubricants to blend evenly, which enter a preforming machine for tabletting, thus the tablet bromo-chloro-dimethyl hydantoin can be obtained. In the invention, the prior production method feeding order of powder bromo-chloro-dimethyl hydantoin is changed, and the processes such as leaching purification, roll dry granulation are added. The degree of purity of powder and granular products produced reach 99.1%, while that of the tablet product is 98%. With low production cost and simple equipment operation, the waste gas and trash discharge almost do not occur.

Owner:河北利仕化学科技有限公司

Novel disinfection and slow-release composition containing BCDMH and its preparation method

The new type of slow released bromochloro disinfectant composition has dibromo Hydantoin or bromochloro Hydantoin as main component and polymer and forming agent as supplementary material and is prepared through conventional preparation process. It has the features of excellent control capacity of bactericidal factor release, long term stability, high bactericidal efficiency, broad bactericidal spectrum, high safety and environment friendship. It may be used in sterilizing and killing algae of water treating works, swimming pool, medical sewage treatment, fish pond, etc.

Owner:高旭

Production method of bromo-3-chloro-5,5-dimethylhydantoin (BCDMH) serving as chemical intermediate

The invention discloses a production method of bromo-3-chloro-5,5-dimethylhydantoin (BCDMH) serving as a chemical intermediate. The production method comprises the following steps that A, 5,5-dimethylhydantoin, flake caustic soda, liquid bromine and chlorine react; a reaction material is obtained; B, the reaction material is subjected to centrifugal spin-drying by a scraper bottom unloading centrifuge, subjected to centrifugal washing by deionized water, and spin-dried; a wet product after centrifugal treatment is dried to form a dry product; and C, the dry product is dissolved by acetone, and filtered; after the deionized water is added for diluting and cooling, BCDMH is separated through crystallization; and the dried wet product is BCDMH capable of serving as a chemical oxidizing agent. The content of BCDMH prepared by the method reaches above 99.3%; the content of bromine is 32.85%; the content of chlorine is 14.70%; a trichloromethane insoluble substance is less than or equal to 0.03%; iron ions are less than or equal to 8mg / kg; calcium ions are less than or equal to 24mg / kg; and BCDMH can serve as the chemical intermediate.

Owner:河北利仕化学科技有限公司

Treatment of edible crops

In the growing of crops for consumption, a method for the removal of pathogens includes the addition to irrigation water for the crops of an anti-pathogen composition and supplying the anti-pathogen composition to the crops prior to harvest while normal irrigation is effected. The anti-pathogen composition is based on halogens, such as chlorine, bromine and iodine, or mixtures of halogens or halogens combined with other organic radicals including cyanurate, hydantoin, peroxide and chlorine dioxide. BCDMH and TICA are preferred anti-pathogen components of the anti-pathogen composition and may be added to a carrier concentrate and measured and dosed into the irrigation water.

Owner:BLISS WILLIAM

Compound peracetic acid bromine chlorine hydantoin disinfectant

The invention relates to a formulation of compound peracetic acid bromine chlorine hydantoin disinfectant which is applicable to killing microorganism such as bacteria, virus and the like in an enclosing house and environment, and a preparation method thereof. The invention is characterized in that peracetic acid stock solution is diluted to be 0.1-1.5% of the original concentration; 95-99.5% of diluent is taken and added with 0.05-1g of bromine chlorine hydantoin to be evenly mixed together; and 0.5-5ml of polyoxyethylene fatty alcohol ether and 0.1-3g of sodium pyrophosphate are added into the mixture and fully and evenly mixed together. The compound disinfectant has the characteristics of being rapid, high in effect, long-acting, low in cost and interference-resistant, and is applicable to disinfection of the animal enclosing house and the environment.

Owner:SHANXI AGRI UNIV

Sterilizing agent emulsion and preparation method thereof

InactiveCN108184891APromote decompositionSolve the problem of melting waterBiocideFungicidesSolubilityPolyoxyethylene castor oil

The invention discloses a sterilizing agent emulsion and a preparation method thereof. The sterilizing agent emulsion is prepared from 10 parts of tall oil fatty acid, 1.5 parts of triethanolamine, 1.2 parts of fatty amine polyoxyethylene ether, 1.35 parts of dimethyl sulfate, 50 parts of 2-thiocyanyl methyl thiobenzothiazole, 15 parts of 2-(methoxyl carbamyl) benzimidazole (BCM), 5 parts of Casson ( active materials 14 percent), 5 parts of BCDMH, 2.5 parts of urea, 10 parts of oleic acid, 40 parts of fatty acid methyl ester, 5 parts of diethylene glycol, 5.6 parts of polyoxyethylene castor oil EL-40, 7.4 parts of stearic alcohol polyoxyethylene ether (10EO-20EO) and 3 parts of guar gum solution. Compared with the prior art, the sterilizing agent emulsion has the advantages that various ingredients are used; a recipe containing 2-thiocyanyl methyl thiobenzothiazole is made into the emulsion; the dispersion in the water is easy; the problem of water solubility is solved; a novel sterilizing agent is prepared; the popularization and application values are realized.

Owner:SHAANXI SCI TECH UNIV

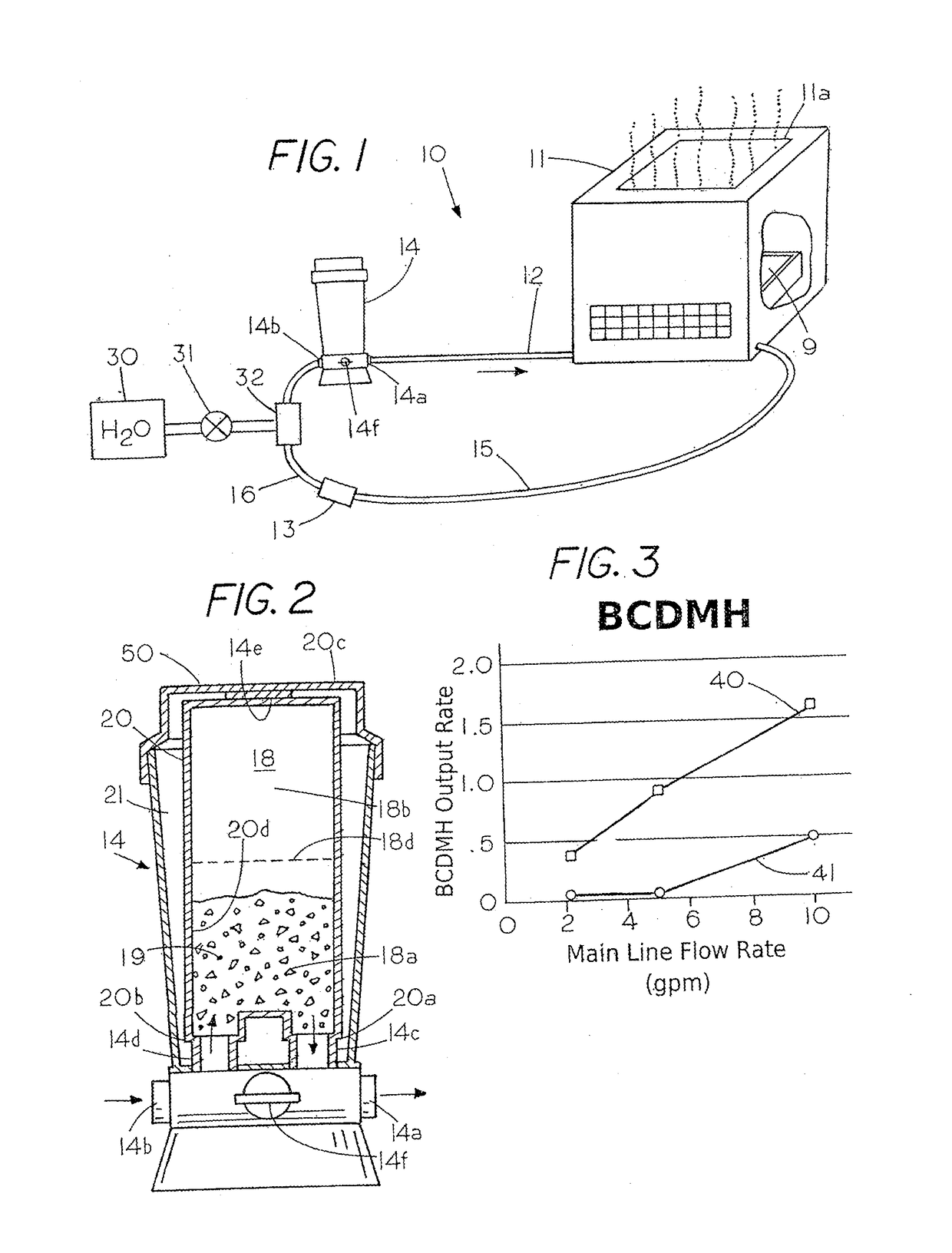

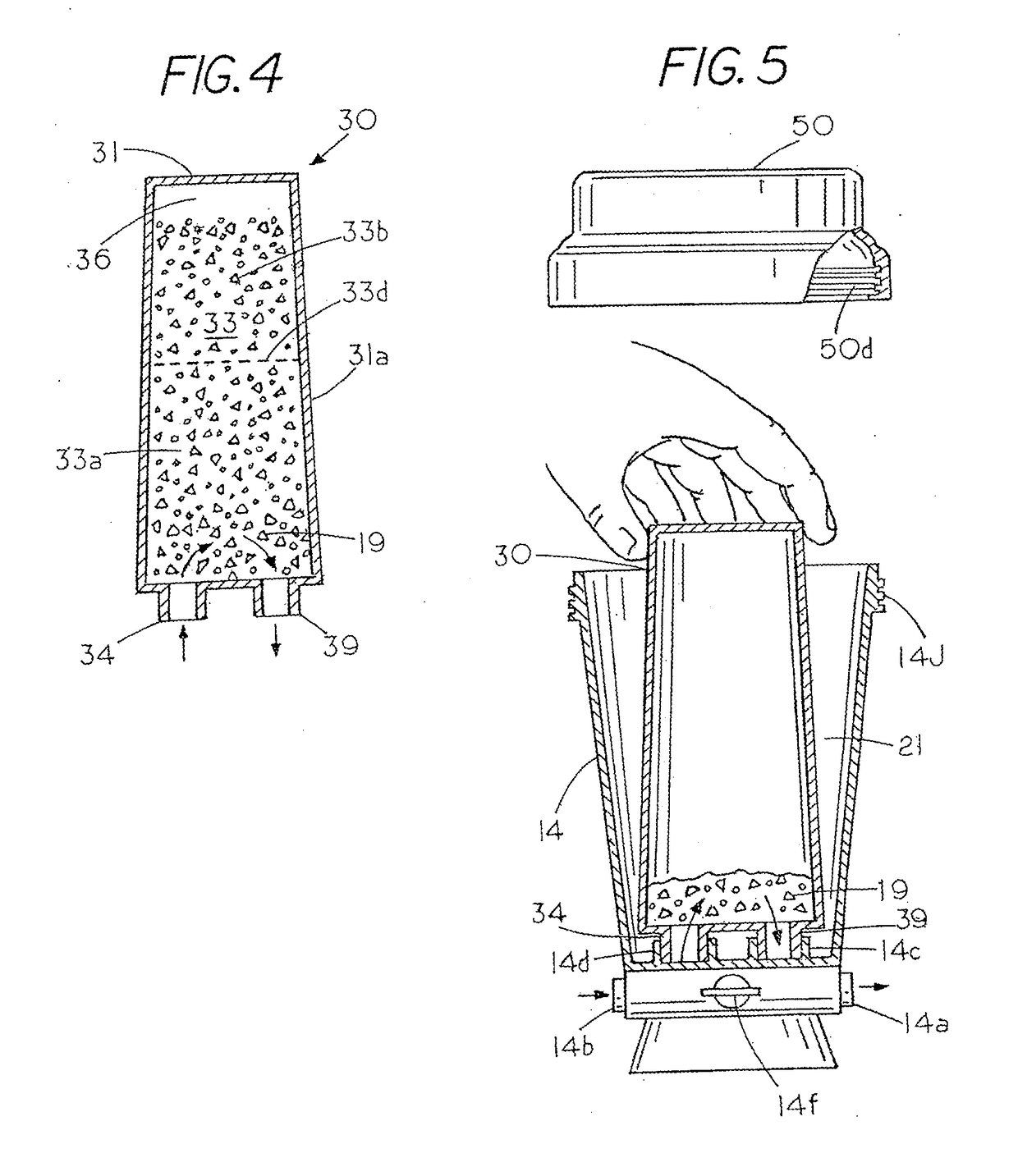

Dispenser

A system, a cartridge and a dispensing valve for eliminating a drift or sag in BCDMH output from an inline dispensing valve containing a dispensing cartridge mountable within the inline dispensing valve with the dispensing cartridge containing a batch of water erodible cluster inhibiting BCDMH particles to provide a linear output flow of BCDMH which is responsive to flow of water though a cartridge in the dispensing valve and a method of obtaining a linear output in a dispensing system by increasing the size of particles in a dispensing cartridge in the system.

Owner:KING TECH

Process to sanitize fruit and vegetables

InactiveUS20060141111A1Fruit and vegetables preservationPre-baking dough/flour preservationBCDMHChromatography

A process to sanitize fruit and vegetables, which may be used for products that are whole, diced, sliced, peeled, chopped or shredded. The process includes the use of a disinfectant agent, such as, for example, BCDMH, at a pH at, or above, 8.3. A buffer is used to obtain the correct pH and is, preferably, a mixture of calcium, sodium and potassium salts.

Owner:BLISS WILLIAM

Electrochemical synthesis method for preparing halogenated hydantoin

InactiveCN101775613BReduce usageAccurate judgmentElectrolysis componentsElectrolytic organic productionHypobromous acidElectrolysis

The invention relates to an improved synthesis method for hydantoin bromo and for preparing dibromohydantoin or bromo-3-chloro-5,5-dimethylhydantoin. The method comprises the following steps of: taking various hydantoins as raw materials, dissolving the hydantoins and the corresponding amount of bromide in 0.2g / mL saturation chlorate solution, electrolyzing the bromide solution and obtaining the corresponding hypobromite, generating hypobromous acid under the condition of addition of acid, further performing bromo reaction to the hydantoin, adjusting the bromide equivalent according to demand and synthesizing the corresponding dibromohydantoin or bromo-3-chloro-5,5-dimethylhydantoin. Reaction liquid can be repeated and used, and the reaction yield can reach more than 95%. The invention has the advantages of easy obtainment of raw materials by low cost, low production cost, simple post treatment, high yield, good purity and repetitive recycle of the mother liquid. By utilizing the electrolysis process, the process is simple, and the equipment has low requirement, safe operation and no toxicity or stimulation.

Owner:HUBEI UNIV

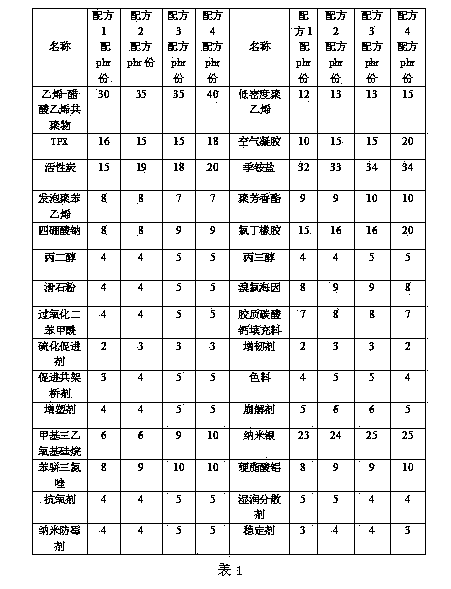

Light-weight environment-friendly foam material for car foot mat

The invention discloses a light-weight environment-friendly foam material for a car foot mat and particularly discloses a light-weight environment-friendly foam material in the field of car accessory materials. The light-weight environment-friendly foam material is prepared from the following substances in parts by weight: 30-40 parts of ethylene-vinyl acetate copolymers, 10-15 parts of low-density polyethylene, 10-20 parts of aerogel, 10-20 parts of TPX, 10-20 parts of activated carbon, 30-35 parts of quaternary ammonium salt, 5-8 parts of foamed polystyrene, 8-10 parts of polyarylester, 8-10 parts of sodium tetraborate, 10-20 parts of chloroprene rubber, 2-5 parts of propylene glycol, 2-5 parts of glycerin, 4-6 parts of talcum powder, 8-10 parts of bromochlorohydantoin, 4-6 parts of dibenzoyl peroxide, 5-8 parts of colloidal calcium carbonate filler and 2-5 parts of vulcanization accelerator. The light-weight environment-friendly foam material is light in weight, environment-friendly, healthy and safe; the weight of the light-weight environment-friendly foam material is 1 / 6 of the weight of the traditional car foot mat; the light-weight environment-friendly foam material has a sterilizing function and is capable of playing a role in preventing mildew, reducing the content of bacteria in a sealed space in a car, taking higher-safety fire-resistant and flame-resistant effects and avoiding various potential safety hazards existing in the car.

Owner:DONGGUAN CHUNQING IND

Composite antibacterial coating for children's bicycles, composite antibacterial agent and preparation method of composite antibacterial agent

ActiveCN107603315BNo pollutionHealth hazardBiocideAntifouling/underwater paintsDiacrylate esterKaolinite

The invention discloses a special composite antibacterial agent for a children bicycle. The special composite antibacterial agent comprises the following components by weight: 0.007-0.014 part of 1-bromo-3-chloro-5,5-dimethyl hydantoin, 100-200 parts of an inorganic antibacterial agent, 100-150 parts of dodecyl-dimethyl-benzyl ammonium chloride, 100-200 parts of microcrystal kaolinite powder, 50-80 parts of a fluoroalkyl silane coupling agent, 30-50 parts of 2,6-di-tert-butyl-4-methylphenol, and 10-20 parts of sulpho-bi-acrylate; the invention further provides a composite antibacterial coatingprepared from the composite antibacterial agent and a preparation method of the composite antibacterial agent. The body of the children bicycle has excellent antibacterial, bacteriostatic and sterilizing properties while the effects of attractiveness, decoration and rust resistance are achieved, various bacteria adhered to the surface of the body are effectively killed, the cross propagation of the bacteria is completely eradicated for the children in the process of touching and playing with the bicycle, the bacterial infection is avoided, and the body health of the children is guaranteed.

Owner:河北友杰节能科技有限公司

BCDMH (bromo-3-chloro-5,5-dimethylhydantoin) compound disinfection agent

InactiveCN107912432AImprove the efficiency of sterilization and disinfectionImprove water purificationBiocideFungicidesBCDMHChemistry

The invention relates to the technical field of preparation of disinfection products, and particularly discloses a BCDMH (bromo-3-chloro-5,5-dimethylhydantoin) compound disinfection agent. The BCDMH compound disinfection agent is prepared by mixing the following raw materials of BCDMH, polymerizing aluminum chloride, sodium lauryl sulfate, peregal O, sodium phytate, phytic acid, benzoic acid, succinic acid, calcium carbonate and calcium bicarbonate according to a certain proportional ratio by weight. The BCDMH compound disinfection agent has the advantages that the sterilizing effect and waterpurifying effect are good, the stability is high, the production cost is low, the quick and efficient effects are realized, most of bacteria and viruses affecting the health of a human body can be killed, the harm to the human body is avoided, and the BCDMH compound disinfection agent is suitable for being widely popularized and applied.

Owner:JUANCHENG KANGTAI CHEM

Special sterilization and deodorization composite for lobster pond

InactiveCN107549166AWell mixedImprove nutritional supplementation efficiencyBiocideWaste water treatment from animal husbandryPhosphateFreeze-drying

The invention discloses a special sterilization and deodorization composite for a lobster pond. The composite is prepared from raw materials as follows: modified filler A, modified filler B, silica gel, talcum powder, acetyl chitosan, fucoidan, lysozyme, sodium polyphosphate, hexamine, sulfamic acid, sodium percarbonate, amide percarbonate, sodium chloride, copper sulfate, ferrous sulfate, BCDMH (1-bromo-3-chloro-5,5-dimethylhydantoin), potassium permanganate, nano-silver, nano-zinc, kaolin, cellulose, freeze-dried lactobacillus powder, EDTA (ethylene diamine tetraacetic acid), octyl methoxycinnamate, sodium carbonate, glycerol, methanol, butyl acetate, potassium dihydrogen phosphate, sodium tetraborate, sodium dodecyl benzene sulfate and deionized water. The sterilization and deodorization composite is used for sterilizing the lobster pond and can slowly release sterilization raw materials, the sterilization efficiency and quality are improved, and abundant inorganic growth substancescan be provided for vegetation at the bottom of the pond.

Owner:宿松县辉煌家庭农场

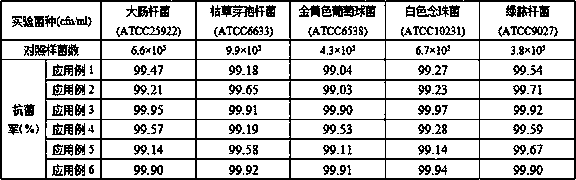

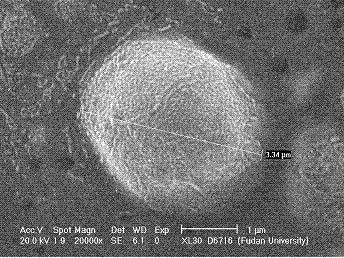

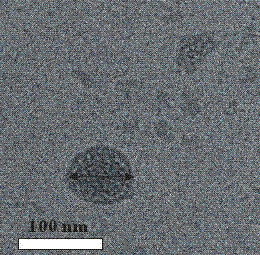

Method for controlling growth of pipeline biological film by utilizing bromine chlorine hydantoin liposome

ActiveCN102363539AProof of stabilityNo reunionScale removal and water softeningWater bathsHydantoin derivatives

A method for controlling the growth of a pipeline biological film by utilizing bromine chlorine hydantoin liposome comprises the following steps of: firstly, dissolving soybean lecithin and cholesterol into a chloroform and ether mixed solvent, adding BCDMH (Bromine Chlorine Dimethyl Hydantoin) acid salt buffer solution, carrying out water bath ultrasound treatment and forming stable emulsion; secondly, adding the emulsion into an eggplant-shaped bottle, placing the eggplant-shaped bottle on a rotary evaporator and evaporating the emulsion after pressure reduction to remove an organic solvent; thirdly, taking down the eggplant-shaped bottle, blowing by nitrogen, removing difficult-to-volatilize diethyl ether existing in the emulsion, continuing to evaporate, forming a uniform lipid membrane on the wall of the bottle, adding PBS (Phosphate Buffered Saline) and obtaining liposome suspension liquid after the membrane on the wall of the eggplant-shaped bottle is cleaned and removed; fourthly, filtering and removing large-particle impurities by using a micro-porous filtering membrane soaked in the PBS, placing at a temperature of 4 DEG C for storage and stripping the microbiological membrane of a simulated pipe network by the prepared bromine chlorine hydantoin liposome. The method has high embedding rate and high biological stripping efficiency and plays slow release and disinfection roles.

Owner:上海明诺环境科技有限公司

Bromochlorohydantoin continuous production method

ActiveCN111675656BReduce production stepsReduce manufacturing costProductsOrganic chemistryWater chlorinationCyanohydrin

Owner:河北利仕化学科技有限公司

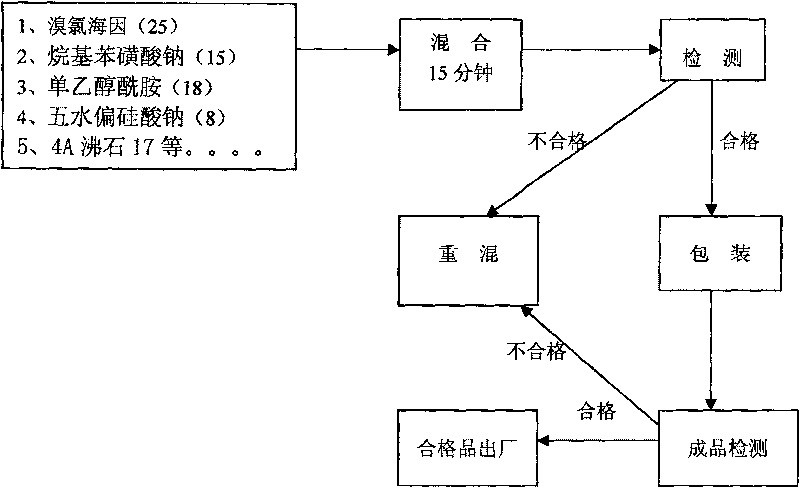

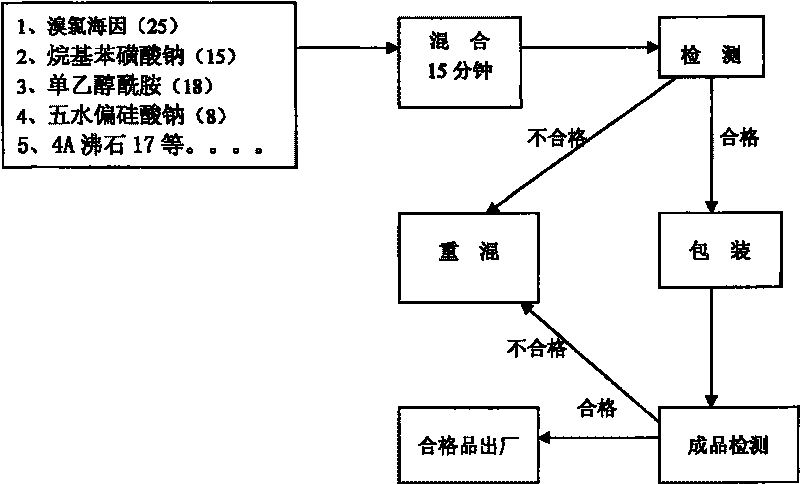

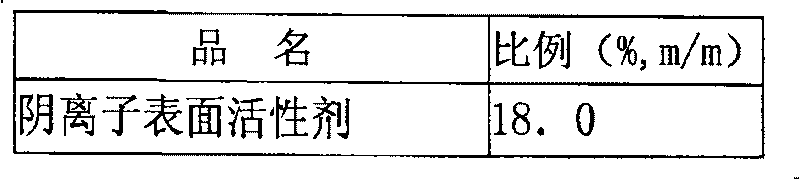

Detergent containing bromochlorohydantoin

InactiveCN101148634BMeet environmental protection requirementsNo damageInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsHydantoinChemistry

Owner:广东欧替克生物医学科技有限公司

Industrial producing method for powder, particle and sheet bromine-chlorine-dimethyl hydantoin disinfectant

ActiveCN100562517CNo emissionsChange the production processBiocideOrganic chemistryHydantoin derivativesDisinfectant

Owner:河北利仕化学科技有限公司

A kind of tail gas treatment process in bromochlorohydantoin synthesis process

ActiveCN108299306BMeet environmental emission requirementsImprove protectionOrganic chemistryAqueous sodium hydroxideEnvironmental engineering

The invention relates to a tail gas treatment process in the synthesis process of bromochlorohydantoin. The tail gas treatment process includes the first step of taking 5,5-dimethylhydantoin as a rawmaterial to prepare bromochlorohydantoin in a synthesis kettle; leading synthesis kettle tail gas into a tail gas absorption kettle, and evacuating the tail gas absorption kettle through an environmental protection absorption tower; wherein tail gas absorption liquid is disposed in the tail gas absorption tank and is aqueous solution of 5,5-dimethylhydantoin and sodium hydroxide or mixed liquid of5,5-dimethylhydantoin and dibromohydantoin mother solution of sodium hydroxide; leaching absorption liquid is disposed in the environmental protection absorption tower and is sodium hydroxide aqueoussolution and a mixture of sodium hydroxide and dibromohydantoin mother solution; the second step of transferring the tail gas absorption liquid in the tail gas absorption kettle into the synthesis kettle after the synthesis kettle is empty, transferring the leaching absorption liquid in the environmental protection absorption tower into the tail gas absorption kettle, and adding 5,5-dimethylhydantoin. According to the tail gas treatment process, the tail gas generated by the synthesis process of bromochlorohydantoin undergoes two-stage absorption by the tail gas absorption kettle and the environmental protection absorption tower and meets the requirements of environmental protection discharge.

Owner:河北鑫淘沅医药科技有限公司

Continuous production method of bromochlorohydantoin

ActiveCN111675656AReduce production stepsReduce manufacturing costProductsOrganic chemistryAcetone cyanohydrinChemistry

The invention discloses a continuous production method of bromochlorohydantoin, belonging to the technical field of disinfectant production. The continuous production method comprises the following steps: synthesizing 5,5-dimethylhydantoin, removing ammonia from an aqueous 5,5-dimethylhydantoin solution, and preparing bromochlorohydantoin. According to the method, water, ammonia gas, carbon dioxide and acetone cyanohydrin are used as raw materials for a reaction to synthesize 5,5-dimethylhydantoin; introducing inert gas into the aqueous 5,5-dimethylhydantoin solution to remove dissolved ammonia; and adding 5,5-dimethylhydantoin and inorganic base into a reaction kettle, conducting cooling, introducing bromine and chlorine, carrying out a bromination and chlorination reaction, centrifugallyspin-drying a reaction material after the reaction is finished, and conducting drying to obtain powdery bromochlorohydantoin. According to the method, dissolved ammonia in the aqueous 5,5-dimethylhydantoin solution is removed through the inert gas, and then bromochlorohydantoin is synthesized, so production steps are reduced, and production cost and potential safety hazards are reduced; and meanwhile, dimethylhydantoin synthesis to continuous bromochlorohydantoin production is realized by linking all the procedures through a conveying pipeline.

Owner:河北利仕化学科技有限公司

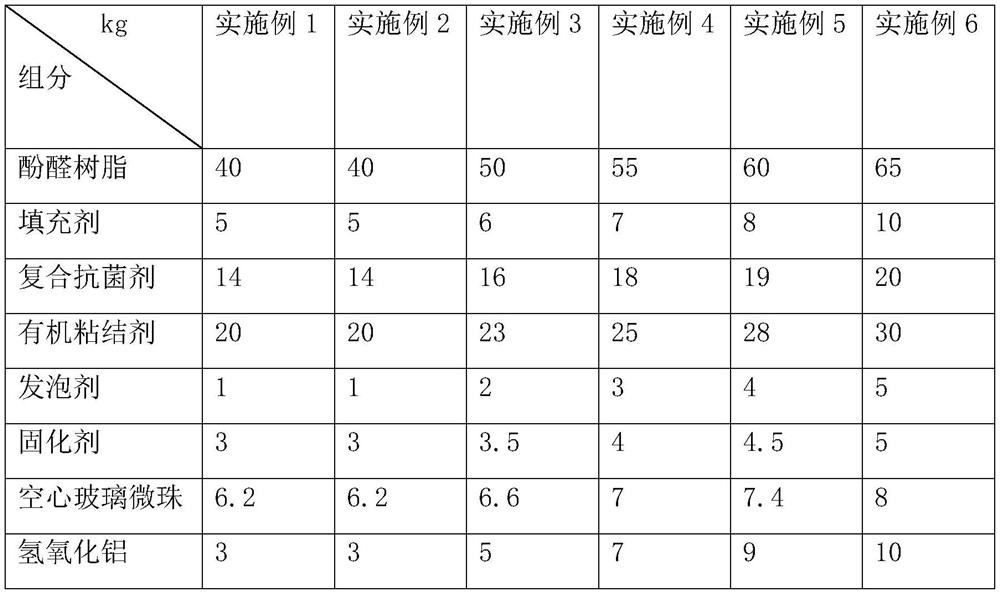

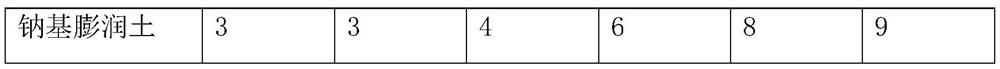

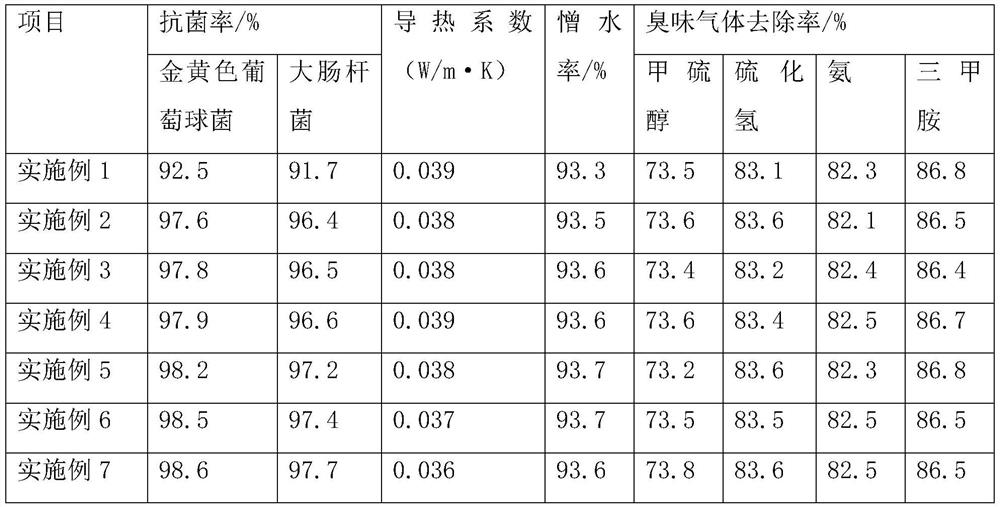

Bacteriostatic insulation board for refrigeration house and preparation method of bacteriostatic insulation board

ActiveCN112940446AImprove thermal insulation performanceImprove insulation effectThermal insulationAluminium hydroxide

The invention relates to the field of thermal insulation materials, and particularly discloses a bacteriostatic thermal insulation board for a refrigeration house and a preparation method of the bacteriostatic thermal insulation board. The bacteriostatic insulation board for the refrigeration house comprises the following components in parts by weight: phenolic resin, a filling agent, a composite antibacterial agent, a foaming agent, a curing agent, an organic binder, hollow glass beads, aluminum hydroxide and sodium bentonite. The composite antibacterial agent is prepared from the following components in parts by weight: 2.5 to 3.5 parts of modified zeolite, 5 to 8 parts of a snail extracting solution, 2.8 to 3.4 parts of graphene oxide, 1.5 to 2.5 parts of nano-hydroxyapatite and 1 to 2 parts of 3-bromo-1-chloro-5,5-dimethylhydantoin. The preparation method comprises the following steps: uniformly mixing the phenolic resin, the filling agent, the foaming agent, the hollow glass beads, the aluminum hydroxide and the sodium bentonite, adding the curing agent, the composite antibacterial agent and the organic binder, uniformly conducting stirring, and conducting foaming and curing. The bacteriostatic insulation board for the refrigeration house has the advantages of being good in mildew-proof and antibacterial effect and excellent in waterproof effect and deodorization effect.

Owner:深圳市均佳机电设备有限公司

BCDMH disinfection smoke agent

The invention discloses a BCDMH disinfection smoke agent. BCDMH is taken as an effective ingredient, the disinfection smoke agent is prepared with fuel, a combustion improver smoke producing agent, a flame retardant and a binder, and weight percents of all the components are as follows: BCDMH: 5-30%; white sugar fuel: 10-30%; a combustion improver potassium hypochlorite: 20-40%; a smoke producing agent ammonium chloride: 10-20%; a flame retardant clay: 20-40%; and a binder hydroxymethyl cellulose: 5-15%. The BCDMH disinfection smoke agent disclosed by the invention has the advantages that BCDMH is taken as the effective ingredient, the disinfection smoke agent is prepared with the fuel, the combustion improver smoke producing agent, the flame retardant and the binder, and epidemic focus disinfection is carried out on relatively airtight places such as a family, a school, a dormitory, a workshop and an underground tunnel; the BCDMH disinfection smoke agent is easy to use, the product is placed on a tile on the ground when in use, usage quantity is calculated according to the size, channels such as doors and windows are closed, and the product is ignited and fumigated. Detection by virtue of related methods of National Ministry of Health Technical Specification for Disinfection (2002) shows that the product can disinfect the air in an unmanned room, and the disinfection is qualified when natural bacterium decay rate every time is higher than or equal to 90%.

Owner:中国人民解放军62040部队

Bromochlorohydantoin disinfectant for soil treatment and preparation method thereof

PendingCN114557368AImprove decomposition rateAchieve disinfectionBiocideFungicidesSoil treatmentPesticide residue

The invention discloses a bromochlorohydantoin disinfectant for soil remediation, and the bromochlorohydantoin disinfectant is characterized by being prepared from the following components in parts by weight: 40 to 60 parts of compound probiotics, 10 to 14 parts of bromochlorohydantoin, 6 to 10 parts of a surfactant, 9 to 16 parts of an adhesive and 15 to 20 parts of effervescent tablets. The purpose of soil disinfection and insect killing is achieved, soil insect pests are reduced, the decomposition rate of bromochlorohydantoin is high, and pesticide residues in the disinfected soil are greatly reduced.

Owner:龚军旗

Production method of bromo-3-chloro-5,5-dimethylhydantoin (BCDMH) serving as chemical intermediate

ActiveCN103333115BIncrease the purification processReduce contentOrganic chemistryOxidizing agentCentrifuge

The invention discloses a production method of bromo-3-chloro-5,5-dimethylhydantoin (BCDMH) serving as a chemical intermediate. The production method comprises the following steps that A, 5,5-dimethylhydantoin, flake caustic soda, liquid bromine and chlorine react; a reaction material is obtained; B, the reaction material is subjected to centrifugal spin-drying by a scraper bottom unloading centrifuge, subjected to centrifugal washing by deionized water, and spin-dried; a wet product after centrifugal treatment is dried to form a dry product; and C, the dry product is dissolved by acetone, and filtered; after the deionized water is added for diluting and cooling, BCDMH is separated through crystallization; and the dried wet product is BCDMH capable of serving as a chemical oxidizing agent. The content of BCDMH prepared by the method reaches above 99.3%; the content of bromine is 32.85%; the content of chlorine is 14.70%; a trichloromethane insoluble substance is less than or equal to 0.03%; iron ions are less than or equal to 8mg / kg; calcium ions are less than or equal to 24mg / kg; and BCDMH can serve as the chemical intermediate.

Owner:河北利仕化学科技有限公司

Disinfector containing BCDMH (Bromochloro Hydantoin) and preparation method thereof

ActiveCN103120163BImprove stabilityQuality improvementBiocideDisinfectantsActive agentPolyethylene glycol

The invention belongs to the technical field of disinfection, and discloses a disinfector containing BCDMH (Bromochloro Hydantoin) and a preparation method thereof. The disinfector comprises 10-25wt% of BCDMH, 5-25wt% of 5, 5-dimethyl hydantoin, 2-5wt% of surfactant, 5-10wt% of bonder, 10-20wt% of stabilizer, and 30-55wt% of effervescing agent. The disinfector uses the polyethylene glycol bonder to ensure the stability of BCDMH and 5, 5-dimethyl hydantoin with a Twain surfactant based on a slow release effect, so as to further prevent BCDMH from being degraded to 5, 5-dimethyl hydantoin.

Owner:GUANGZHOU JINSHUI ANIMAL HEALTH PROD

Disinfectant for aquaculture and preparation method thereof

InactiveCN109592795AGood removal effectDisinfect thoroughlySpecific water treatment objectivesWaste water treatment from animal husbandryDisinfectantDistilled water

The invention provides disinfectant for aquaculture and a preparation method thereof, and belongs to the field of aquaculture disinfectants. The disinfectant is mainly prepared from microbial flocculant and bromo-3-chloro-5,5-dimethylhydantoin. The preparation method comprises the following steps: diluting a strain fermentation broth with distilled water, centrifuging at 2000-3000rpm to collect supernate, and concentrating the supernate at 40-50 DEG C; adding precooled alcohol into the concentrated solution, standing, centrifuging at 4000-5000rpm to collect precipitate, and suspending in alcohol containing dihydroxyethylglycinate and sugar alcohol; sanding at negative 10-negative 15 DEG C, and centrifuging at 4000-5000rpm to collect precipitate; and drying in vacuum to obtain the microbialflocculant. The disinfect has the advantages of safety, no toxicity, environmental friendliness, complete water purification / disinfection and the like; the preparation method of the disinfect has simple process and low cost, and can be widely applied to aquaculture or water environment improvement of other fields.

Owner:金华市呗力水产养殖技术有限公司

Circulating water sterilization stripping agent and application method thereof

PendingCN113854308AHigh activityStrongly electropositiveBiocideFungicidesSludgePolyhexamethylene guanidine

The invention discloses a circulating water sterilization stripping agent and an application method thereof. The circulating water sterilization stripping agent comprises guanidine salt, bromine salt and water. The guanidine salt is polyhexamethylene guanidine; the bromine salt is bromochlorohydantoin. The invention has the following beneficial effects: the foam-free sewage treatment agent has the characteristic of no foam, has small influence on COD of on-site circulating water due to a small addition amount, and does not cause pressure on sewage discharge; the sludge stripping agent is small in dosage, high in cost performance and free of influence on pollution discharge, and can be widely applied to sterilization, algae removal and slime stripping of circulating cooling water in petroleum, chemical engineering, oil fields, electric power and metallurgical industries.

Owner:洛阳强龙实业有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com