Bacteriostatic insulation board for refrigeration house and preparation method of bacteriostatic insulation board

A technology of thermal insulation board and cold storage, applied in the field of thermal insulation materials, can solve the problems of high temperature and humidity, antibacterial performance needs to be improved, easy to breed mold, etc., and achieves low thermal conductivity, enhanced odor removal effect, and enhanced antibacterial stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

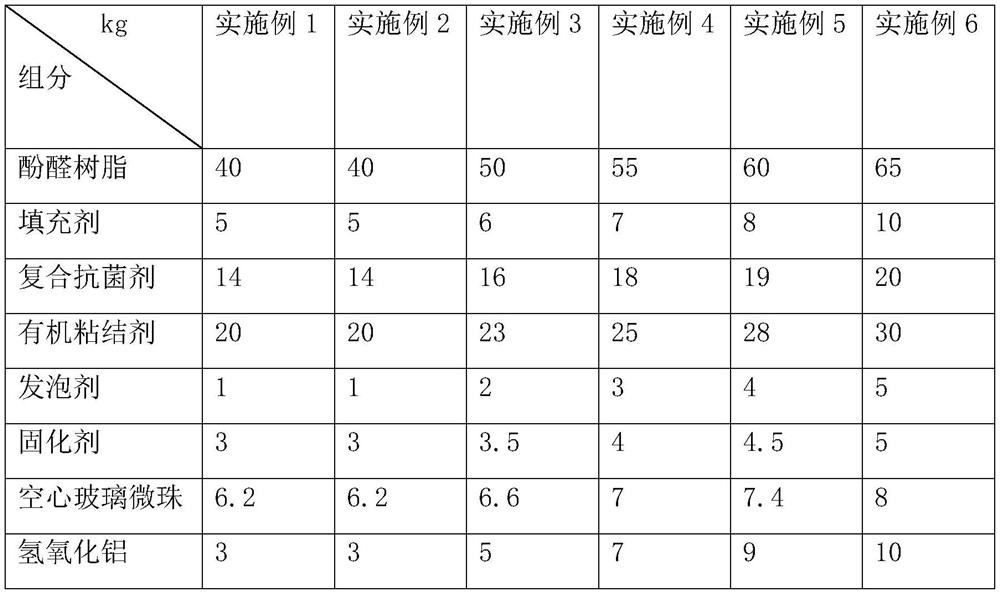

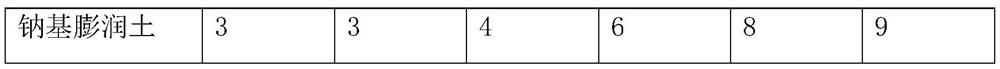

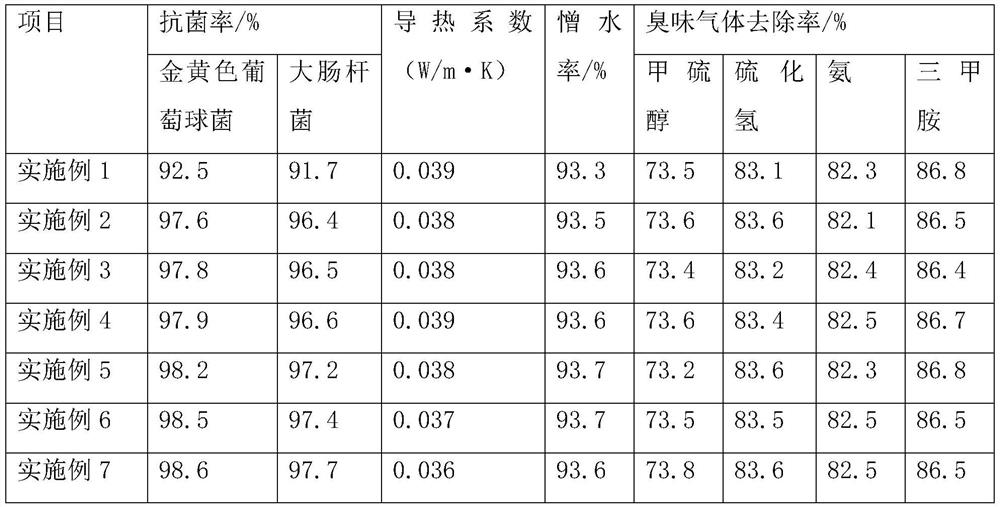

Examples

preparation example 1-3

[0043] In the preparation example 1-3, the graphene oxide in the preparation example is selected from Hunan Fenghua Material Development Co., Ltd., the model is FH-661, the snail extract is selected from Guangzhou Yulu Chemical Co., Ltd., the model is 100G, and the hydroxyapatite is selected from Xi'an Binghe Biotechnology Co., Ltd., model BQQJLHS, bromochlorohydantoin was selected from Shandong Kepler Biotechnology Co., Ltd., product number BCDMH, modified zeolite was selected from Jiangxi Xintao Technology Co., Ltd., model XT31001, silane coupling The joint agent was selected from Guangzhou Zhongjie Chemical Technology Co., Ltd., and the model was 550.

preparation example 1

[0044] Preparation Example 1: (1) 2.5kg of modified zeolite was added to 5kg of snail extract, soaked for 20 hours at room temperature, and vacuum-dried at 60°C to prepare pretreated modified zeolite;

[0045] (2) Mix the pretreated modified zeolite and 1.5kg of nano-hydroxyapatite, stir evenly at 60°C, add 1kg of bromochlorohydantoin, 2.8kg of graphene oxide and 0.5kg of silane coupling agent, and heat up to 80°C , stir evenly, grind, and obtain compound antibacterial agent.

preparation example 2

[0046] Preparation Example 2: (1) 3kg of modified zeolite was added to 6kg of snail extract, soaked at room temperature for 22 hours, and vacuum-dried at 70°C to prepare pretreated modified zeolite;

[0047] (2) Mix the pretreated modified zeolite and 2kg of nano-hydroxyapatite, stir evenly at 65°C, add 1.5kg of bromochlorohydantoin, 3.1kg of graphene oxide and 0.8kg of silane coupling agent, and heat up to 85°C , stir evenly, grind, and obtain compound antibacterial agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com