A kind of tail gas treatment process in bromochlorohydantoin synthesis process

A technology of bromochlorohydantoin and synthesis process, applied in the field of tail gas treatment technology, can solve problems such as being unfavorable to environmental protection, increase production costs and the like, and achieve the effects of being beneficial to environmental protection, improving utilization rate and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

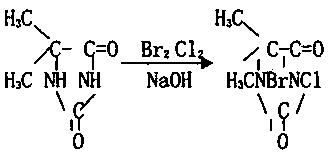

[0039] The synthesis of bromochlorohydantoin in this example is carried out according to conventional methods. 5,5-Dimethylhydantoin, water, sodium hydroxide, bromine and chlorine are used as raw materials. Firstly, 5,5-dimethylhydantoin and all the sodium hydroxide are dissolved in water according to the preset ratio, the temperature is controlled, bromine is added dropwise, and chlorine gas is introduced to carry out bromination and chlorination reactions. The halogenated product is centrifuged, washed with water, and dried to obtain bromochlorohydantoin.

[0040] The synthetic method of preparing bromochlorohydantoin in step (1) is,

[0041] Dissolve 5,5-dimethylhydantoin and sodium hydroxide in water according to the conventional ratio, and use bromine and chlorine as halogenating agents to carry out bromination and chlorination reactions;

[0042] The tail gas absorbing liquid is added 5,5-dimethylhydantoin, sodium hydroxide and water according to the synthetic ratio; ...

Embodiment 2

[0054] The synthesis of bromochlorohydantoin in this embodiment is carried out according to conventional methods. 5,5-Dimethylhydantoin, water, sodium hydroxide, bromine and chlorine are used as raw materials. The synthesis method for preparing bromochlorohydantoin in step (1) is to dissolve 5,5-dimethylhydantoin and 15-25% of the total weight of the total weight of 5,5-dimethylhydantoin in water according to the conventional ratio, and add While adding bromine and chlorine gas into this solution dropwise, add the remaining aqueous sodium hydroxide solution dropwise;

[0055] The tail gas absorbing liquid is a mixture of 5,5-dimethylhydantoin, water and 15-25% of the total weight of the process ratio prepared according to the synthetic ratio;

[0056] The washing and absorbing liquid is a mixture of water prepared according to the synthetic ratio and 15-25% of the total weight of the technical ratio.

[0057] In step (2), when the synthesis kettle in step (1) completes the s...

Embodiment 3

[0067] The synthesis of bromochlorohydantoin in this embodiment is carried out according to conventional methods. The synthesis method for preparing bromochlorohydantoin in step (1) is to dissolve 5,5-dimethylhydantoin in the mother liquor containing sodium bromide produced during the production of dibromohydantoin according to the conventional ratio, and use chlorine gas as Halogenating agent, while adding dropwise a mass fraction of 30-37% sodium hydroxide solution to carry out bromination and chlorination reactions;

[0068] The tail gas absorbing liquid is 5,5-dimethyl hydantoin prepared according to the synthetic proportion, the mother liquor containing sodium bromide and the hydrogen with a mass fraction of 30-37% of 15-25% of the total weight of the process proportion Sodium oxide solution mixture;

[0069] The rinsing and absorbing liquid is a mixture of water prepared according to the synthetic ratio and a sodium hydroxide solution with a mass fraction of 30-37% of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com