Multiple industrial sewage filtration method

A technology for cleaning and filtering industrial sewage, applied in the direction of water/sewage multi-stage treatment, separation methods, chemical instruments and methods, etc., can solve problems such as unfavorable environmental protection, pollute the environment, affect the use effect of recycled water, and achieve environmental protection The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further illustrated below in conjunction with specific embodiments, and it should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0022] The industrial sewage multiple cleaning method of the present invention, this method comprises the steps:

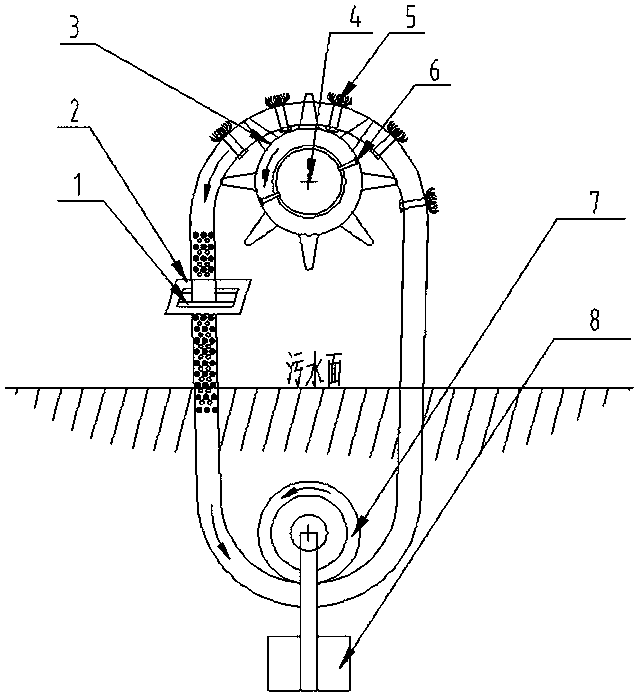

[0023] (1) Use a steel belt oil scraper to remove heavy oil and sundries contained in the industrial sewage in the sedimentation tank;

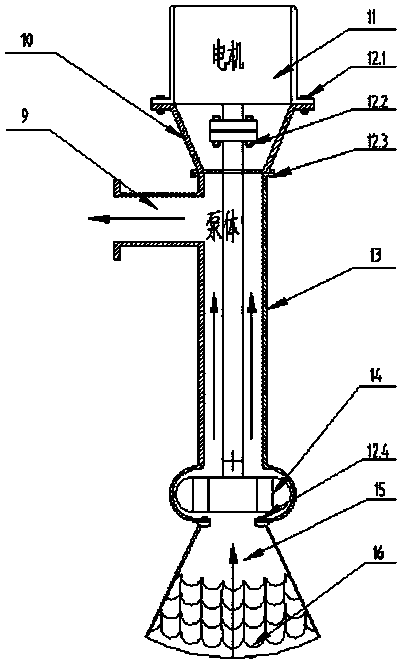

[0024] (2) The corrugated filter is installed at the water inlet at the bottom of the long-axis pump for conveying industrial sewage to prevent the strip-shaped debris overflowing from the overflow pool (entering the body of the conveying and recycling water equipment, and then entering the production system;

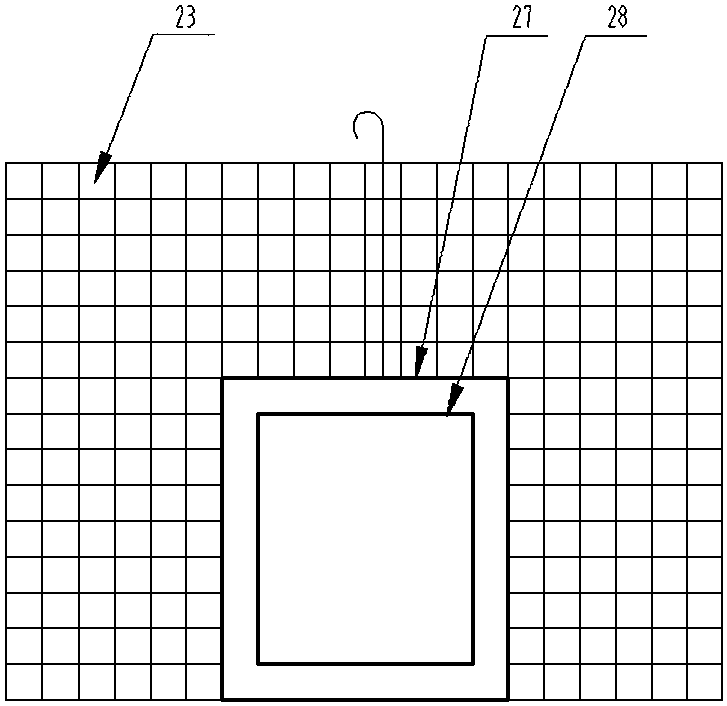

[0025] (3) The movable magnetic mesh grille is installed on the inner side of the overflow pool to control all kinds of sundries to fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com