Circulating water sterilization stripping agent and application method thereof

An application method and stripping agent technology, applied in the direction of fungicide, application, biocide, etc., can solve the problems of insufficient sterilization persistence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: a kind of circulating water bactericidal stripping agent, comprises guanidinium salt, bromide salt and water; Described guanidinium salt is polyhexamethylene guanidine; Described bromine salt is bromochlorohydantoin;

[0027] Further, according to parts by weight, it includes 20-35 parts of polyhexamethyleneguanidine and 1-15 parts of bromochlorohydantoin;

[0028] Further, according to parts by weight, it includes 25-30 parts of polyhexamethyleneguanidine and 5-10 parts of bromochlorohydantoin;

[0029] Further, according to parts by weight, it includes 28 parts of polyhexamethyleneguanidine and 7 parts of bromochlorohydantoin;

[0030] Further, the application method of the circulating water bactericidal stripping agent is used for sterilization, algae removal, and slime stripping in industrial circulating cooling water systems, industrial direct-flow water systems, sewage treatment systems, sewage reuse water systems, and oilfield water injection system...

Embodiment 2

[0039] Embodiment 2: a kind of circulating water bactericidal stripping agent, comprises guanidine salt, bromide and water; Described guanidine salt is polyhexamethylene guanidine; Described bromine salt is bromochlorohydantoin; According to parts by weight, includes There are 25-30 parts of polyhexamethyleneguanidine and 5-10 parts of bromochlorohydantoin.

[0040] The circulating water sterilizing and stripping agent is used for sterilization, algae removal and slime stripping in industrial circulating cooling water systems, industrial direct-flow water systems, sewage treatment systems, sewage reuse water systems and oil field water injection systems.

Embodiment 3

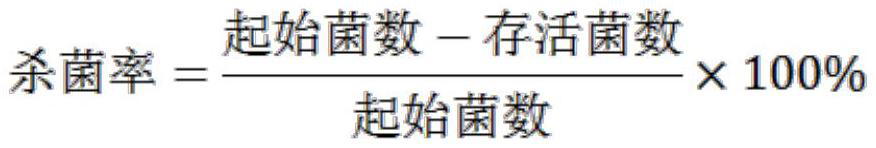

[0041] Embodiment 3: Static sterilization experiment of heterotrophic bacteria

[0042] Test method: GB / T 14643.1-2009 Determination of bacteria and algae in industrial circulating cooling water Part 1: Determination of slime-forming bacteria Plate count method (heterotrophic bacteria).

[0043] The test directly uses on-site circulating cooling water. The circulating water of the ethylene circulating water field is used. In order to control the total number of heterotrophic bacteria in the range of 105-107 / ml in the test, culture medium was added to the recovered circulating water for 2 days of enrichment.

[0044]Experimental group: the circulating water sterilizing stripping agent prepared in Example 2.

[0045] Control group: compound bactericidal stripping agent, the main component is dodecyl benzyl ammonium chloride, accounting for 90%.

[0046] The experiment is carried out according to the following steps:

[0047] (1) The algae killing steps such as vessel prepara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com