Patents

Literature

504results about How to "Increased drug resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

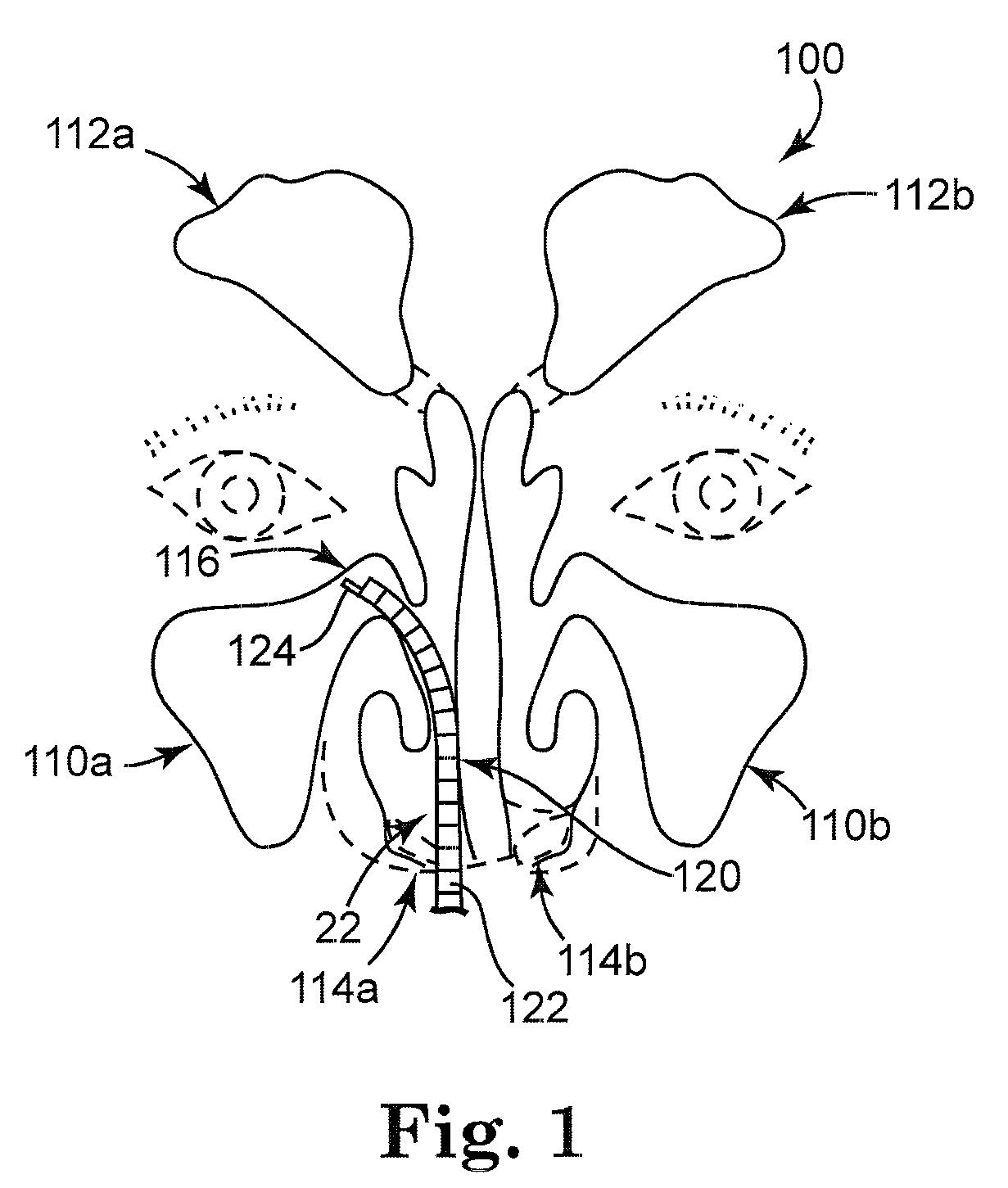

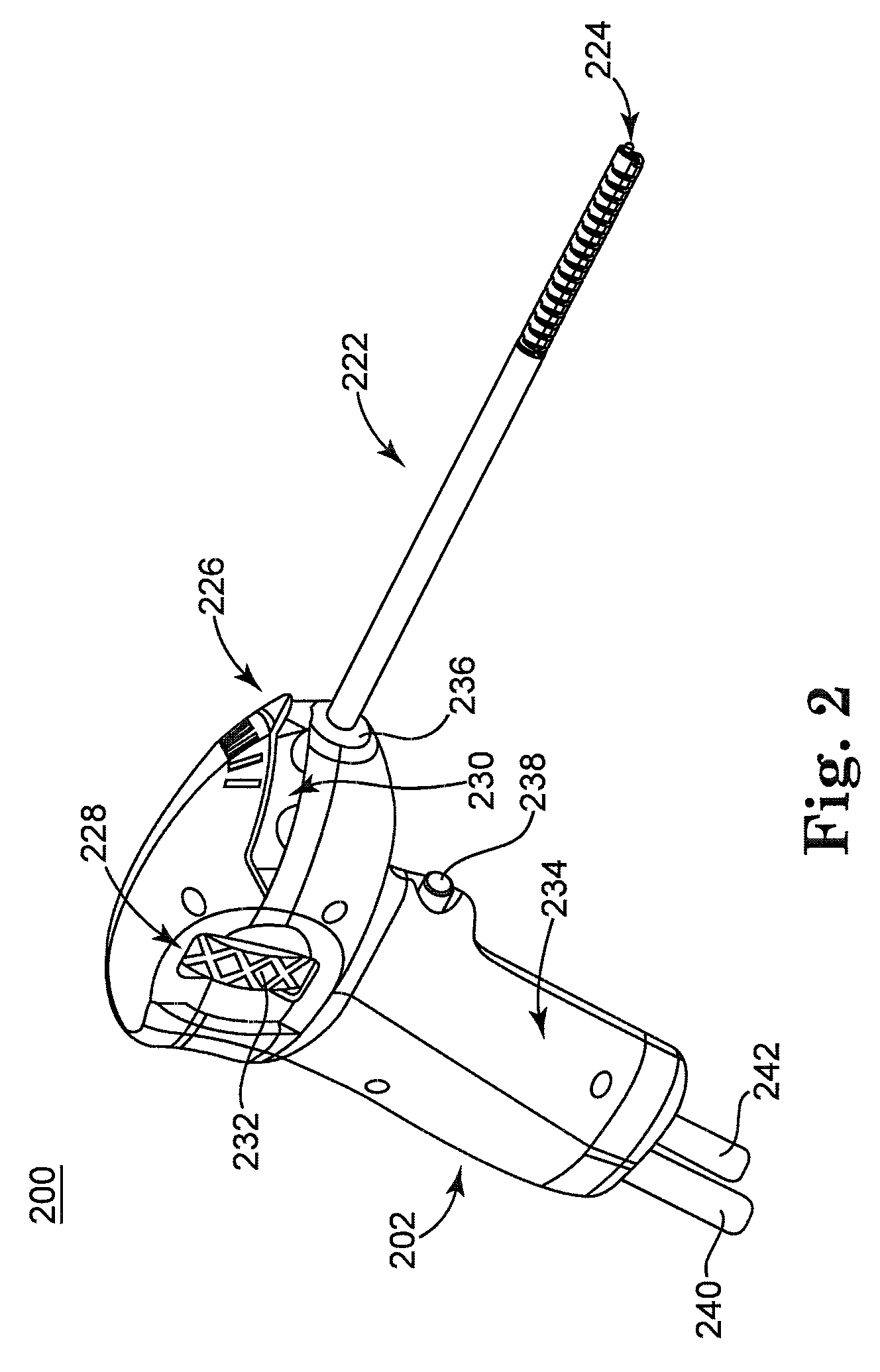

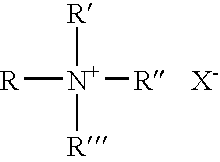

Solvating system and sealant for medical use in the sinuses and nasal passages

ActiveUS7993675B2Increased drug resistanceReduction and elimination in amountAntibacterial agentsPowder deliveryBiofilmNasal passage

Chronic rhinosinusitis and other bacterial sinus conditions may be treated by applying a solvating system containing a surfactant to a bacterial biofilm in a nasal or sinus cavity, disrupting the biofilm, and applying a protective layer of a polymeric film-forming medical sealant.

Owner:MEDTRONIC XOMED INC

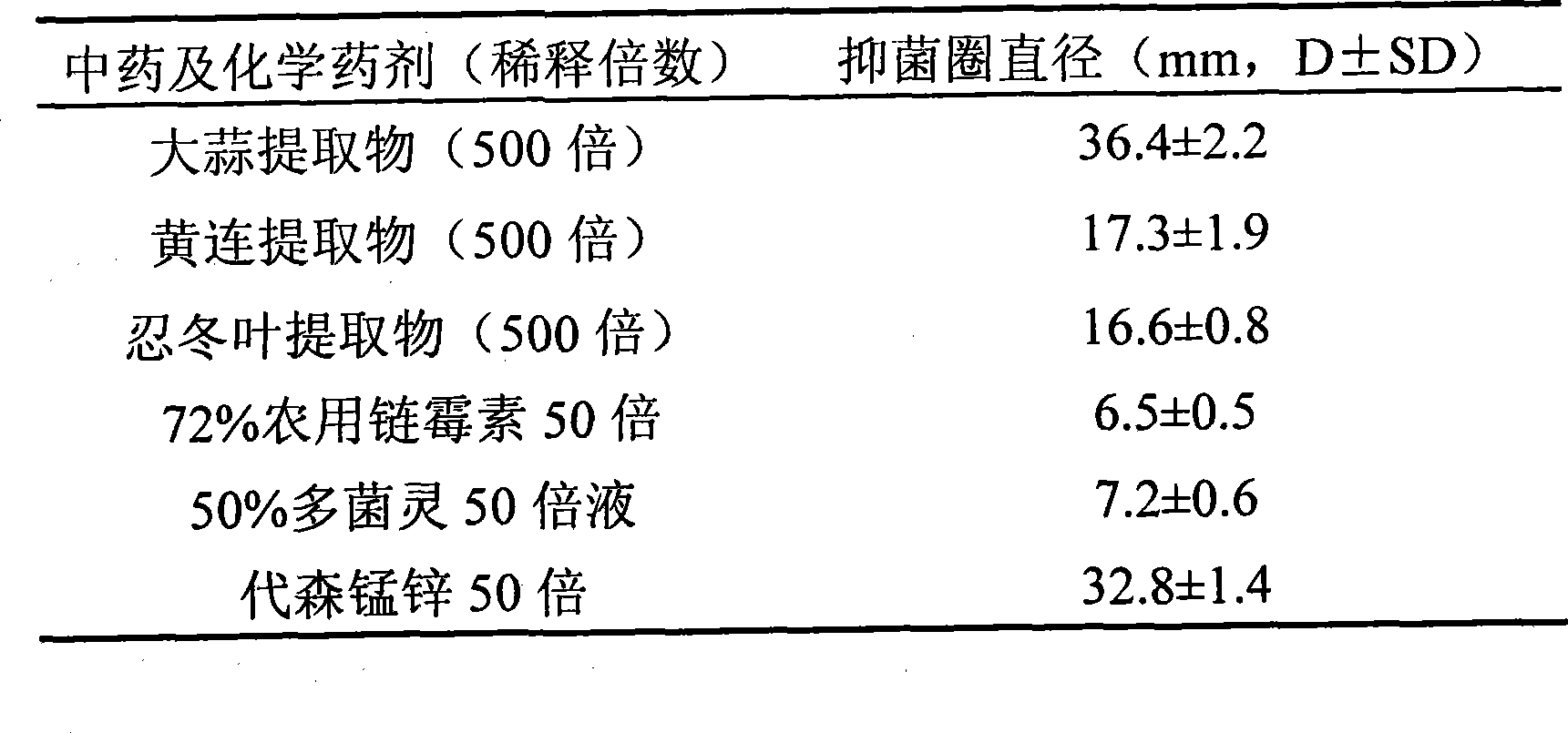

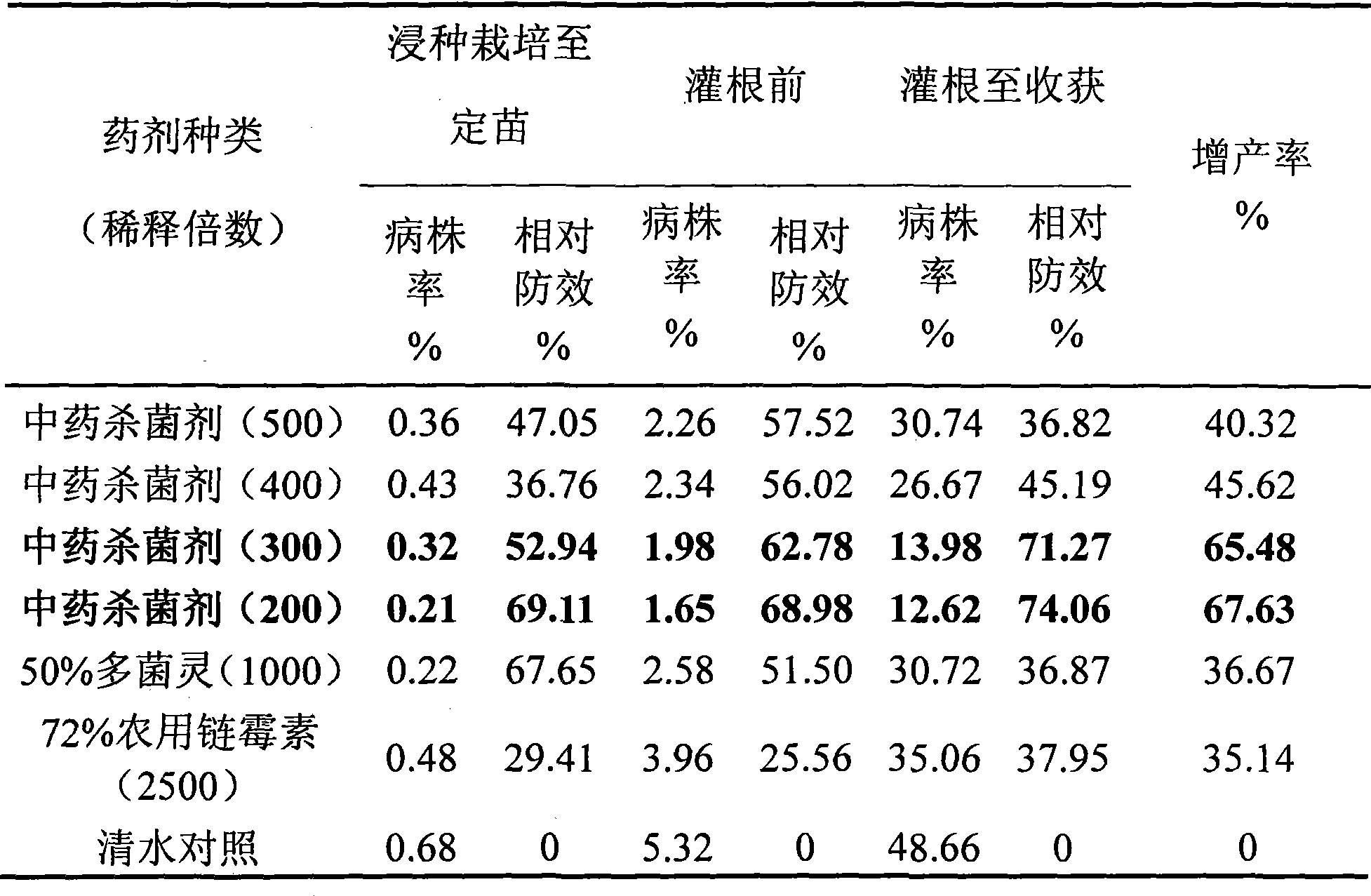

Chinese medicine bactericidal agent for preventing and treating soft rot of konjak

InactiveCN101433221AStrong specificityIncrease drug resistanceBiocideFungicidesPathogenTraditional Chinese medicine

The invention relates to a traditional Chinese medicine bactericide for preventing and controlling soft rot of konjak, and belongs to the filed of insect pests and plant disease prevention and control and biological pesticide. The traditional Chinese medicine bactericide comprises the following components by weight percentage: 12 to 36 percent of garlic extract, 3 to 12 percent of Chinese goldthread rhizome extract, 3 to 10 percent of Flos Lonicerae leave extract, 3 to 5 percent of wettable powder accessory ingredient for farm chemical, and the balance being packing carrier for the farm chemical. The components are compounded into the traditional Chinese medicine bactericide wettable powder which has obvious sterilizing effect on pathogen of the soft rot of konjak, namely Erwinia Aroideae Holland for preventing and controlling the soft rot of konjak. The traditional Chinese medicine bactericide wettable powder is environment-friendly, has strong specificity, is better than chemical agents to prevent and control the soft rot of konjak, has more than 65 percent of relative prevention effect, and can improve the yield of konjak when applied to konjak production, as proved by experiments.

Owner:HUAZHONG UNIV OF SCI & TECH

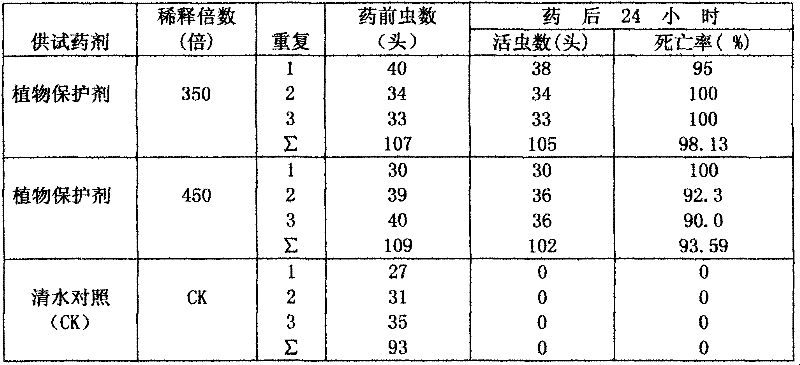

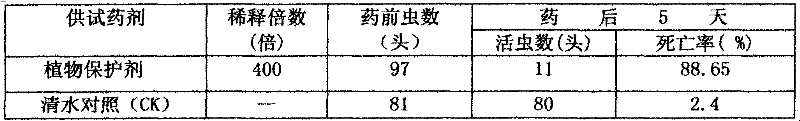

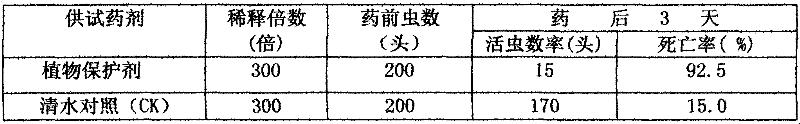

Botanical plant protection agent and preparation method thereof

InactiveCN102283258AOvercome the disadvantage of slow insecticidal effectProlong the action timeBiocidePlant growth regulatorsPlant SourcesTackifier

The invention discloses a botanical plant protection agent, whose raw material components and parts by weight include: 1-3 parts of litsea cubeba oil, 1-8 parts of azadirachtin, 3-5 parts of silicate, 0.5 parts of surfactant -1 part, 5-10 parts of tackifier and 500-700 parts of water. The preparation method comprises the steps of dissolving the tackifier raw material with water to form a tackifier solution, then emulsifying the litsea cubeba oil and azadirachtin with water, adding the tackifier solution solution and silicate, fully stirring and mixing uniformly to obtain the product . The botanical plant protection agent of the present invention maintains the characteristics of low toxicity, high efficiency, easy degradation, and no residue of botanical pesticides, is not easy to produce drug resistance to pests, does not pollute the environment, and has a good control effect on crops. It is a broad-spectrum new pesticide preparation for pest, sterilization and anti-virus, which can be used alone or / and mixed with common insecticides and pesticides.

Owner:NANNING GUANHUA AGRI TECH

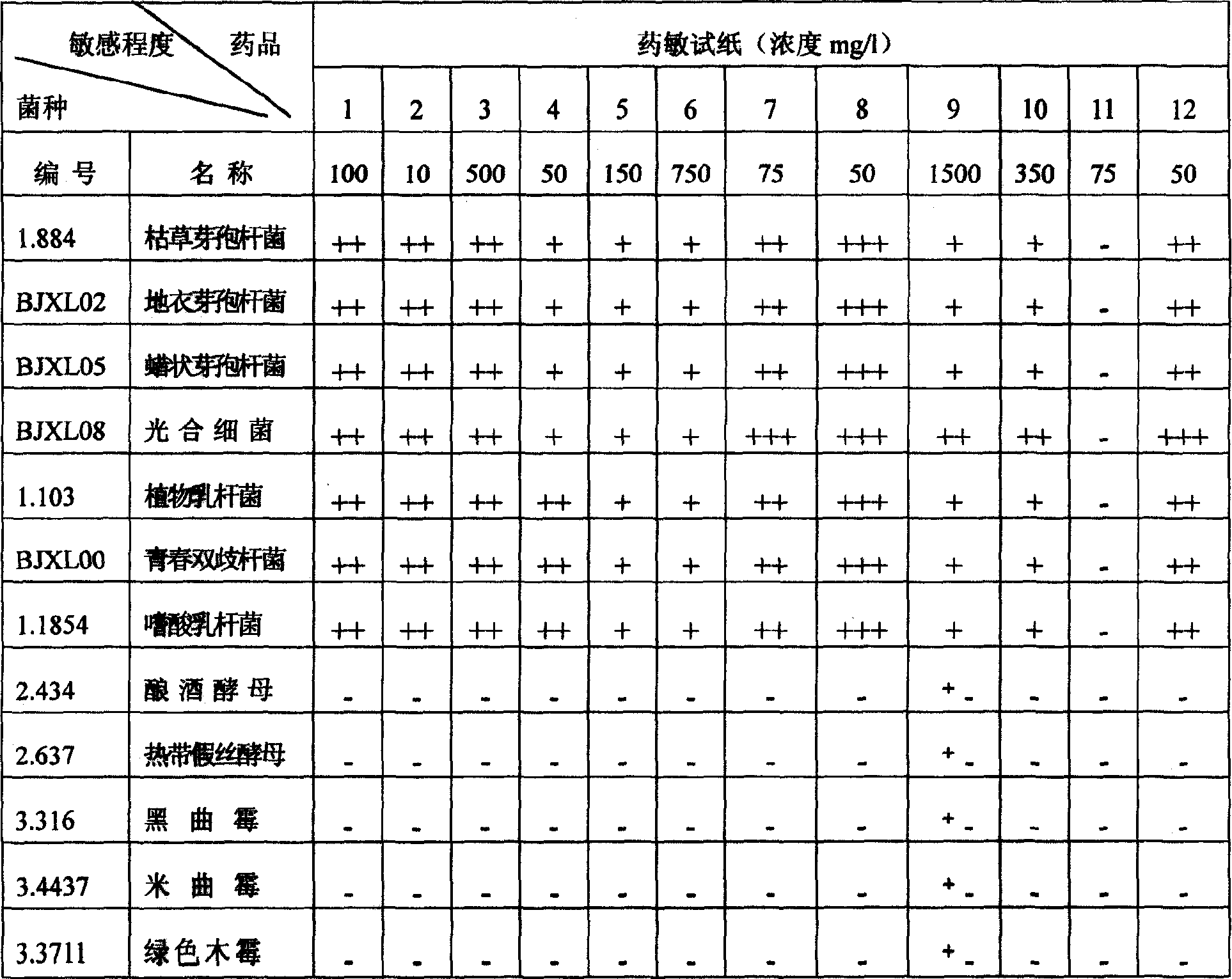

Highly efficient oligosaccharide high yielded enzyme composite animal microecological formulation without public hazard and its preparing method

InactiveCN1653932AHigh activityStrong ColonizationAnimal feeding stuffAccessory food factorsBacillus licheniformisCandida tropicalis

The composite microecological animal preparation consists of Bacillus cereus 10-15 wt%, Bacillus subtilis 10-15 wt%, Bacillus licheniformis 10-15 wt%, Saccharomyces cerevisiae 1-5 wt%, Candida Tropicalis 1-5 wt%, photosynthetic bacterium 1-5 wt%, plant lactobacillus 0.5-3 wt%, acidophilic lactobacillus 0.5-3 wt%, ephebic bifidobacterium 1-3 wt%, Aspergillus niger 0.5-3 wt%, Aspergillus oryzae 0.5-3 wt%, viridin 0.5-3 wt%, oligosaccharide 5-10 wt% and carrier 30-50 wt%. Its preparation process includes the following steps: 1) high temperature resisting domestication of the said strain, drug resisting domestication, preservation and strain passage; 2) activating the preserved strain, fermentation, coating with microcapsule and drying; and 3) crushing dried strain, and mixing with oligosaccharide and carrier. The present invention is one kind of high efficiency green feed additive.

Owner:宝鸡市星星协力生物有限公司

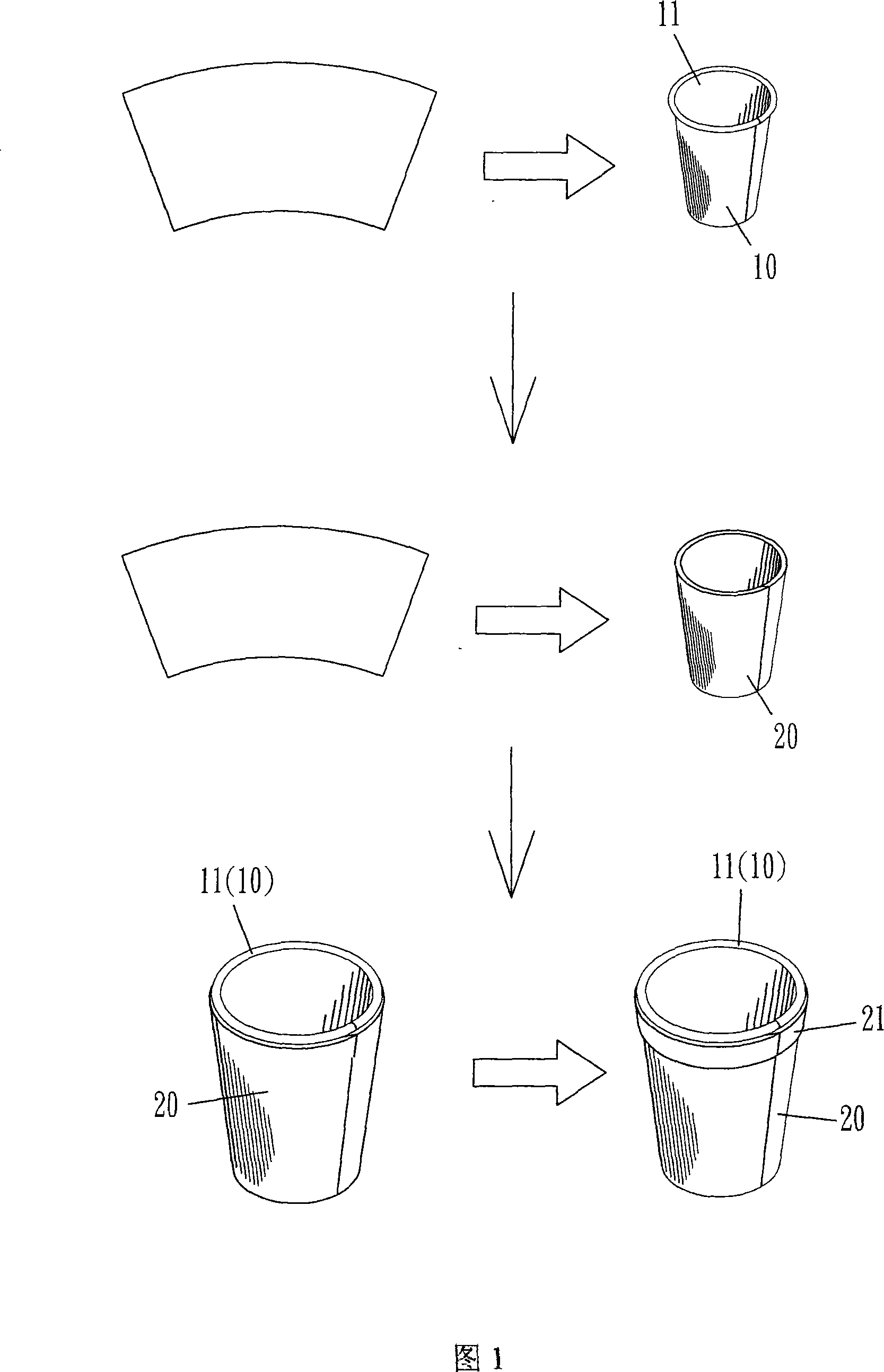

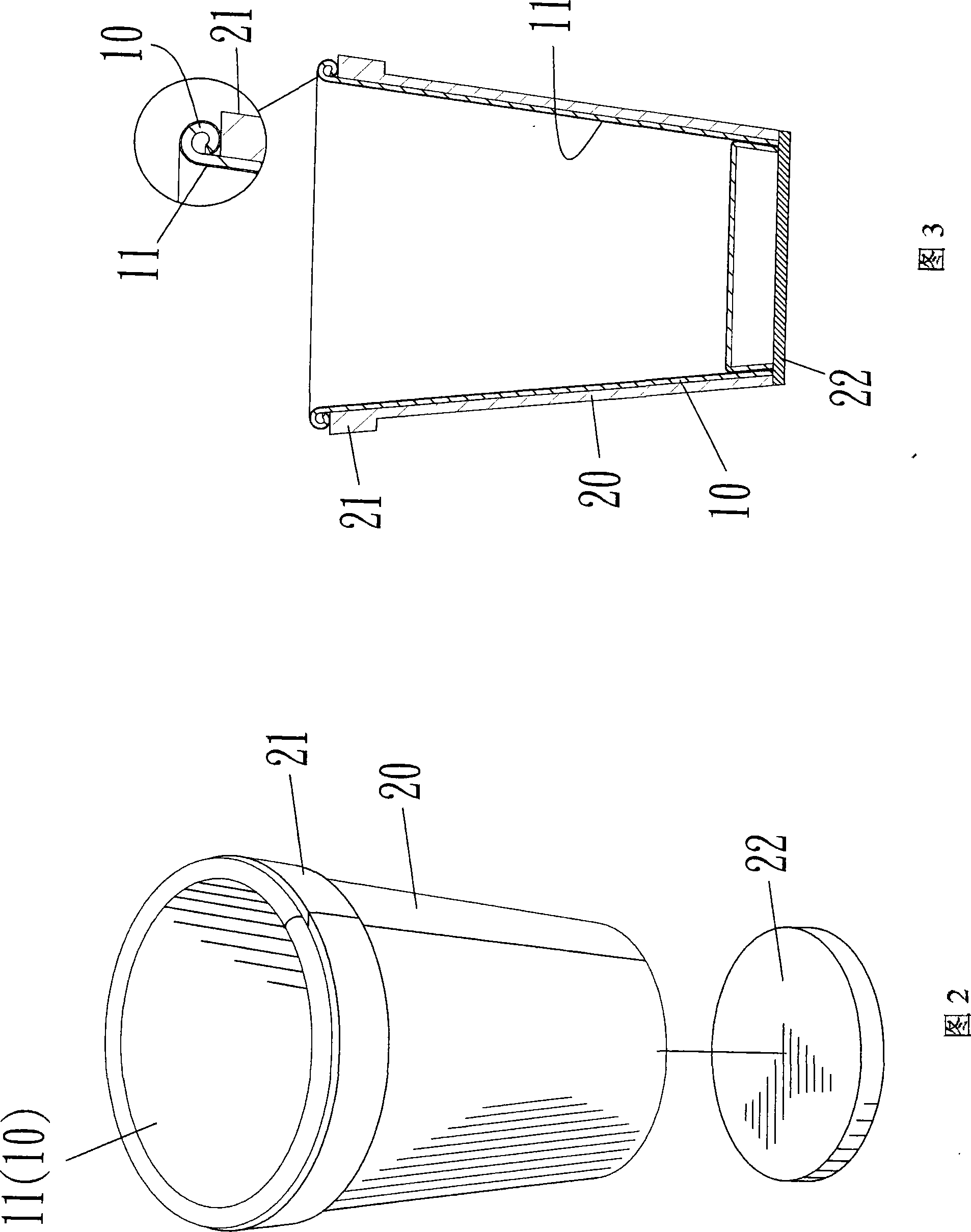

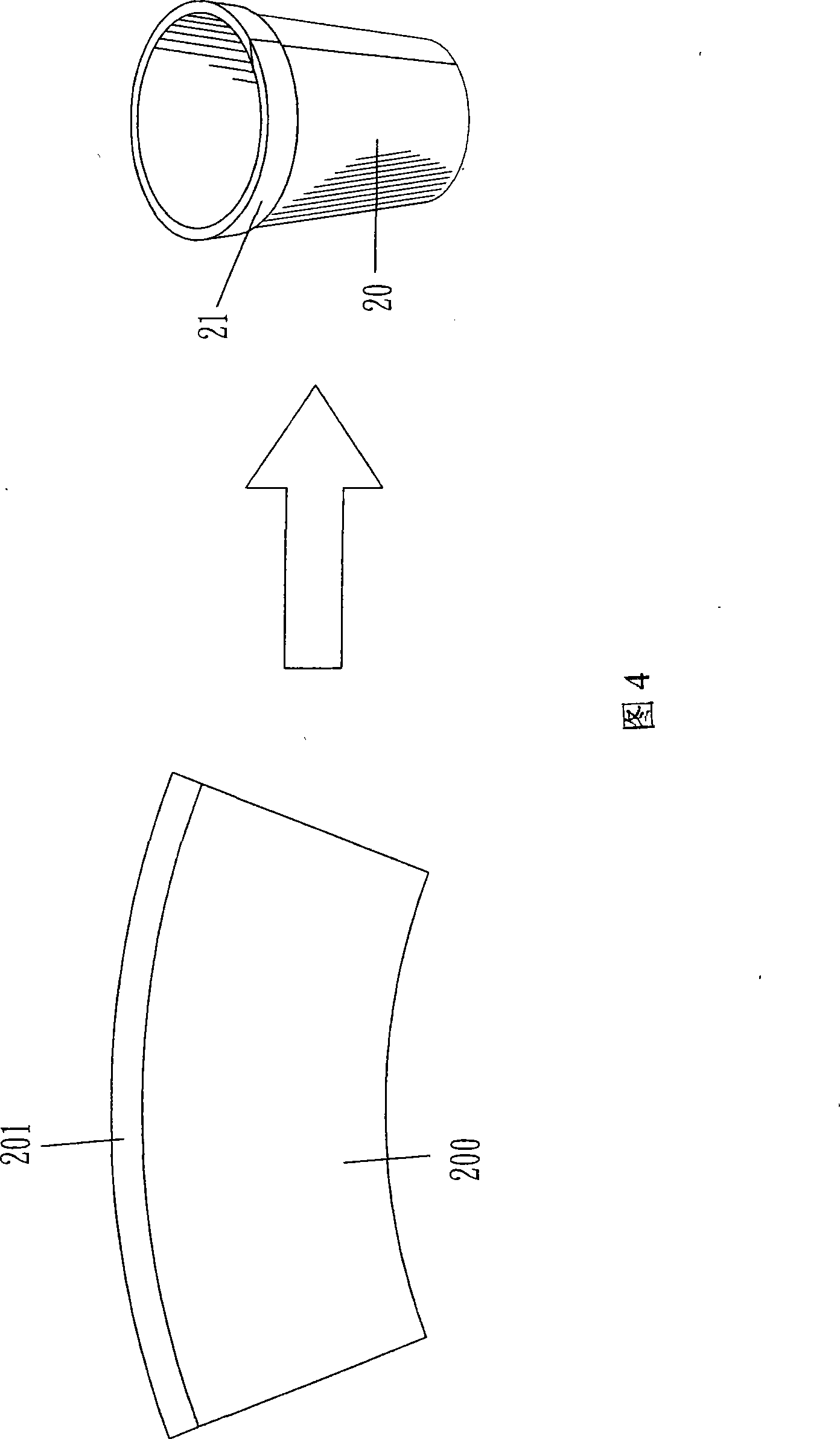

Method for making container cup and structure thereof

InactiveCN101249732APrevent tight fittingEasy to take outBoxes/cartons making machineryThermal insulationPulp and paper industry

The invention relates to a manufacturing method of a container cup and a structure thereof, which belongs to the daily article class. The invention comprises a paper cup and a cup-shaped electronic bridging foaming body, wherein the inner surface or the outer surface of the paper cup is sprinkled and covered with a film layer, and is pressed into the paper cup through shape cutting; the cup-shaped electronic bridging foaming body is formed by being bonded in a hot pressing way after an electronic bridging foaming plate is manufactured into a sector body through printing, shape cutting and stripe pinching, the inner peripheral of the cup-shaped electronic bridging foaming body is ensured to produce softening viscosity in the hot pressing way, then the paper cup is directly covered on and bonded with the inside of the cup-shaped electronic bridging foaming body, and meanwhile a convex ring with a oversize diameter is formed at the outer part of the paper cup lip where the cup-shaped electronic bridging foaming body is positioned. The structure has the advantages that the protective effect is good, the thermal insulation function is good, the water absorbability is low, the appearance is smooth and artistic, the structure is not easy to be metamorphic, the drug fastness is good, the processing is easy, etc.

Owner:张锡卿

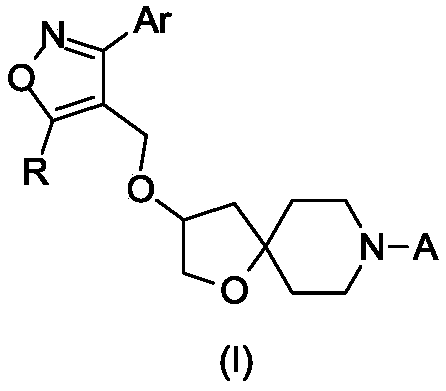

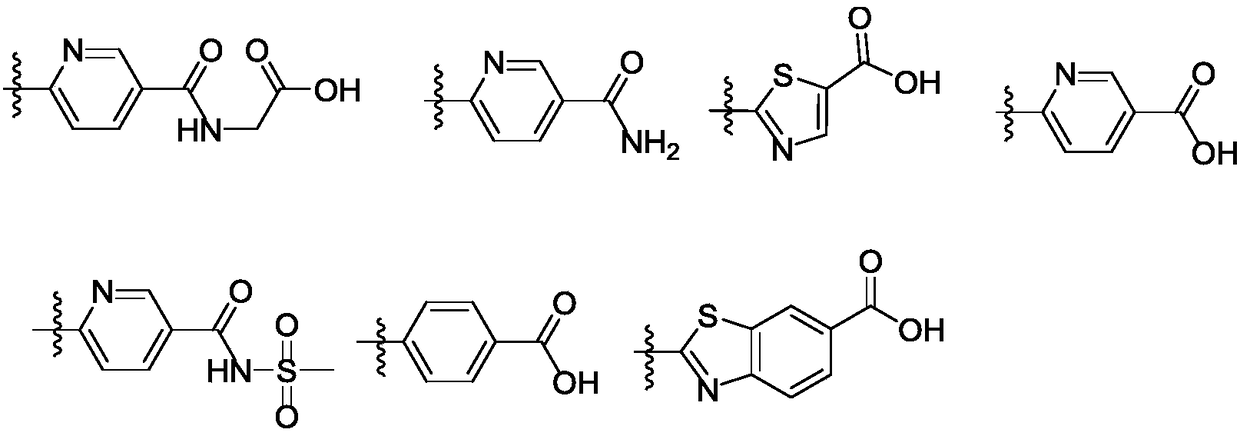

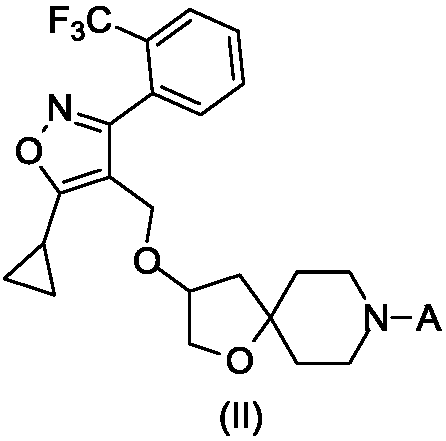

FXR regulator with spirane structure

InactiveCN109053751AExcellent FXR receptor agonistic activityPrevent non-alcoholic fatty liver diseaseOrganic active ingredientsNervous disorderDiseaseHepatic Diseases

The invention provides a new compound which has certain agonist activity on a Farnesoid X receptor (FXR) and is used for treating FXR mediated diseases and / or symptoms such as liver disease and gastrointestinal disease. (The formula is shown in the description.).

Owner:SCINNOHUB PHARM CO LTD

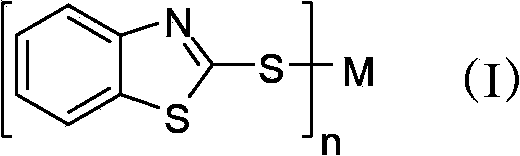

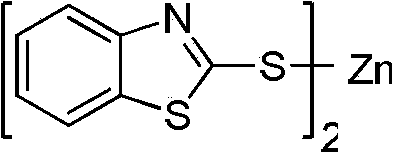

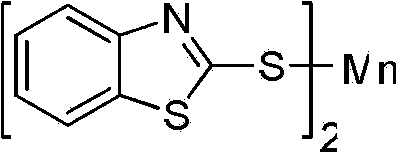

Use of 2-mercaptobenzothiazole metal salt

ActiveCN103461348AImprove biological activityIncreased drug resistanceBiocidePlant growth regulatorsDiseaseMercaptobenzothiazole

The invention relates to use of a 2-mercaptobenzothiazole metal salt, and especially provides a crop disease prevention and treatment bactericide. The bactericide is characterized in that the bactericide includes the 2-mercaptobenzothiazole metal salt represented by formula (I) and a pesticide carrier; and in the formula (I), M is Zn, Mn, Fe, Sn or Al, and n is 2, 3 or 4. The bactericide has a very high biological activity against most bacteria and an excellent inhibition effect on fungi, and is an ideal drug for comprehensively preventing and treating diseases of crops.

Owner:ZHEJIANG XINNONG CHEM CO LTD +1

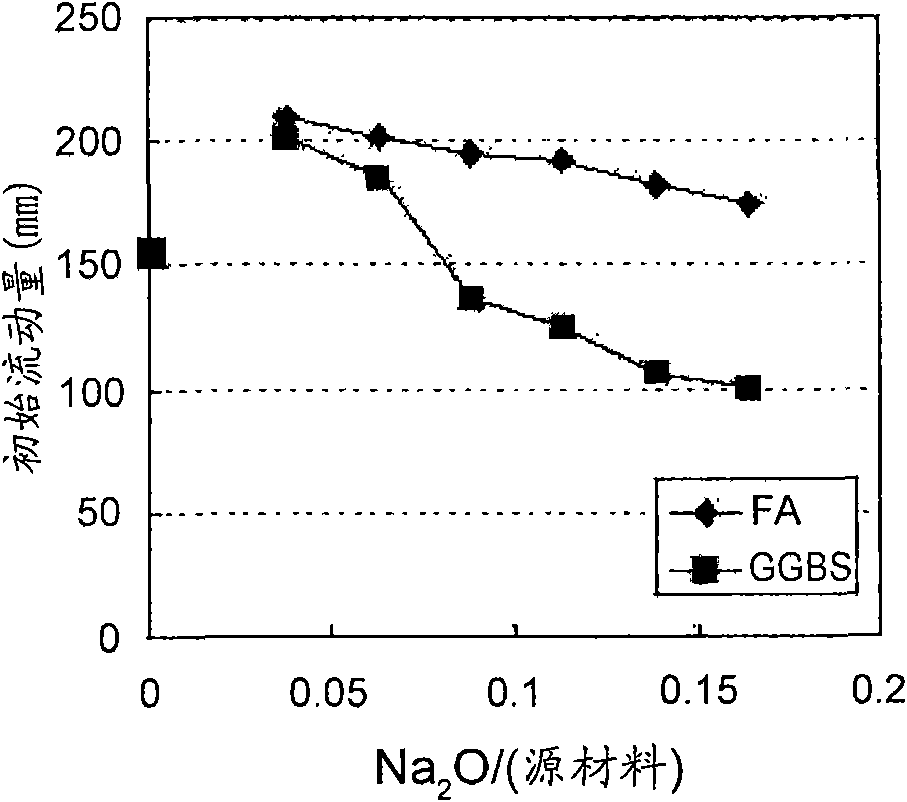

Alkali-activated binder with no cement, method for fabricating mortar using it, and method for fabricating alkali-activated reinforcement mortar with no cement

InactiveCN101687704AImprove initial strengthLow heat of hydrationSolid waste managementCement productionPortland cementKaolin clay

The present invention relates to a cement-free alkali activated binder in which alkaline inorganic materials are appropriately added to an industrial waste such as blast furnace slag, fly ash, meta kaolin and the like, a method for producing mortar using the same and a method for producing cement-free alkali activated reinforcement mortar. Specifically, the present invention relates to a cement-free alkali activated binder that is not only environmentally friendly as being capable of dramatically reducing the carbon dioxide emission, which has been remained as a problem for producing Portlandcement, but also has an excellent property, a method for producing mortar using the same and a method for producing cement-free alkali activated reinforcement mortar.

Owner:IND FOUND OF CHONNAM NAT UNIV

Crop equilibration nourishment protecting agent

InactiveCN101186541AIncreased drug resistanceAdd bactericidal ingredientsAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersLipid filmCypermethrin

The invention discloses a nutrition-balanced protective agent of crops, which is generated mainly by raw materials in the following portions by weight: 0.5-2.5 portions of amino acid, 0.5-2.5 portions of potassium dihydrogen phosphate, 0.5-2.0 portions of carbamide, 1.5-3.0 portions of trace elements, 2-5 portions of lipid film and 200-1000 portions of water. In order to achieve much better effect, the protective agent of the invention is combined with disinsection and sterilization components such as avermectin or cypermethrin, etc., as well. The protective agent has balanced and comprehensive nutrition, high fertilizer effect, good protective property, safe application, low cost and convenient application; the invention has double effects of nutrition and protection and is easy to be absorbed by crops, and has unique effects especially on improving crop photosynthesis, strengthening crop stress resistance, guaranteeing blossoms to bear fruit, expanding fruit, improving the color, polish and plumpness of the fruit, improving quality, developing marketability, etc.

Owner:NORTHWEST A & F UNIV

Antibacterial composition for skin and mucous membrane

ActiveCN105148253AImprove stabilityEnhance tissue immune functionAntibacterial agentsCosmetic preparationsIrritationAntibacterial effect

The invention provides antibacterial composition for the skin and the mucous membrane. The composition comprises antimicrobial peptide with the sequence shown as SEQ ID NO.1 as well as a proper additive which adopts a stabilizer and can further comprise a skin and mucous membrane recovery conditioner. Aiming at the defects of high side effects, high irritation and high drug resistance of the conventional antimicrobial products, the antibacterial composition for the skin and the mucous membrane has the advantages of low irritation, drug resistance avoidance, good effect and the like due to scientific component matching, has the antibacterial effect on multiple microbes and can be used for antibacterial cleaning, nursing and treatment of the skin, the mucous membrane and the like of a human body.

Owner:HANGZHOU ADVANCED BIOSCIENCE CO LTD

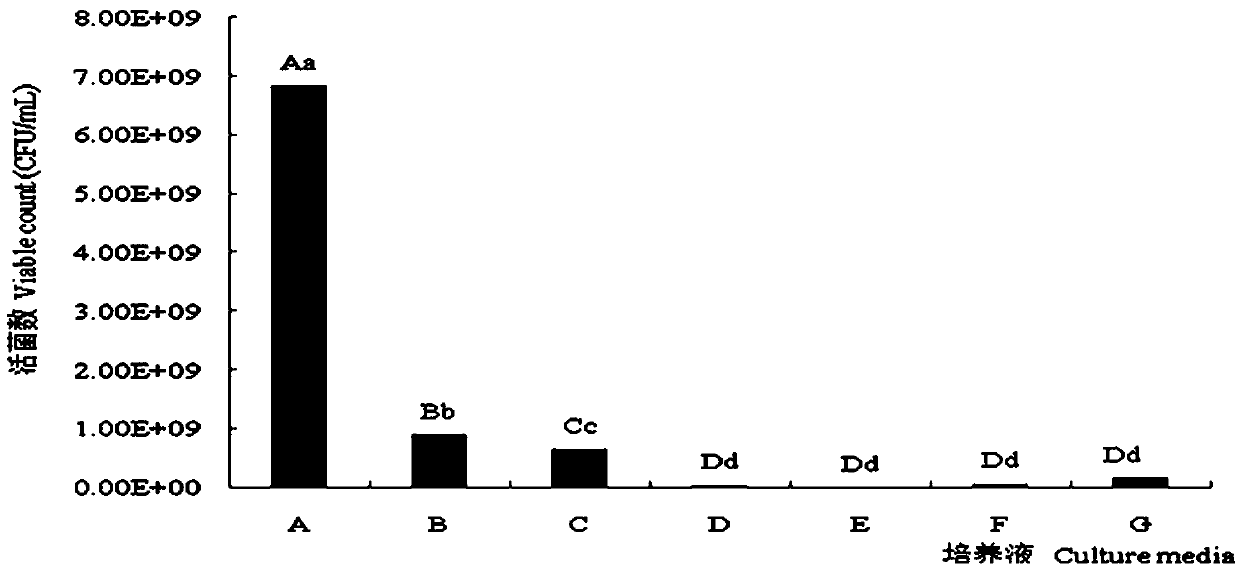

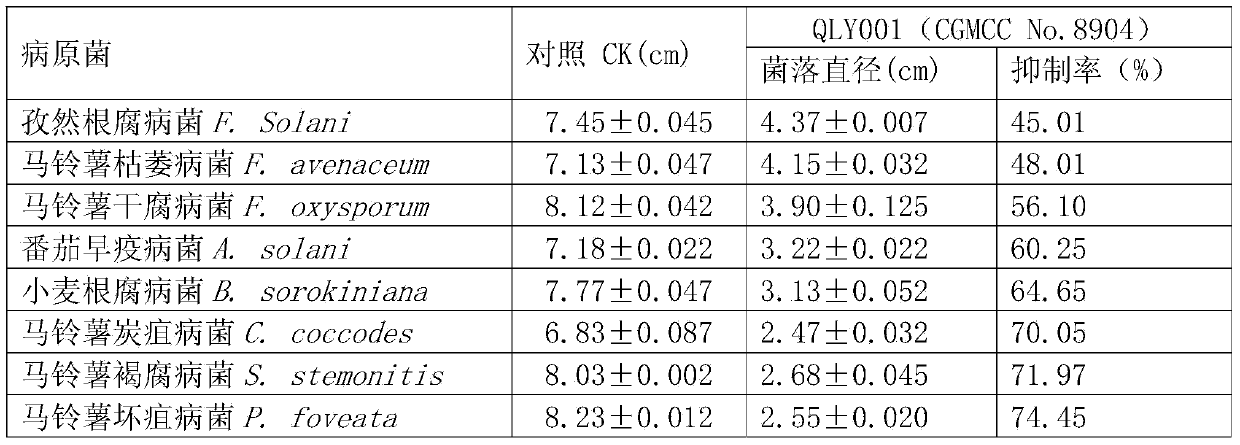

Endophytic bacteria bacillus atrophaeus bacterial strain of forage in alpine grassland, microbial agent as well as preparation method and application of microbial agent

The invention discloses an endophytic bacteria bacillus atrophaeus bacterial strain of forage in alpine grassland, and also provides a microbial agent prepared by virtue of fermentation of the endophytic bacteria bacillus atrophaeus bacterial strain and application of the microbial agent. The endophytic bacteria bacillus atrophaeus bacterial strain is named a bacillus atrophaeus bacterial strain QLY001 with a preservation number: CGMCC No.8904. The bacillus atrophaeus bacterial strain QLY001 microbial agent has a bacteriostatic action, and can be used as a microbial pesticide to inhibit monilinia fructicola of potatoes, phoma exigua, wheat root rot, early blight pathogenic bacteria of tomatoes and colletotrichum coccodes, wherein a bacteriostatic ratio can reach over 60%. Moreover, the defects that the chemical pesticide in the prior art is poor in environmental protection, easily produces drug resistance and poor in safety are overcome to realize the advantages that the environmental protection is good, the drug resistant is not easy to produce and the safety is good.

Owner:GANSU AGRI UNIV

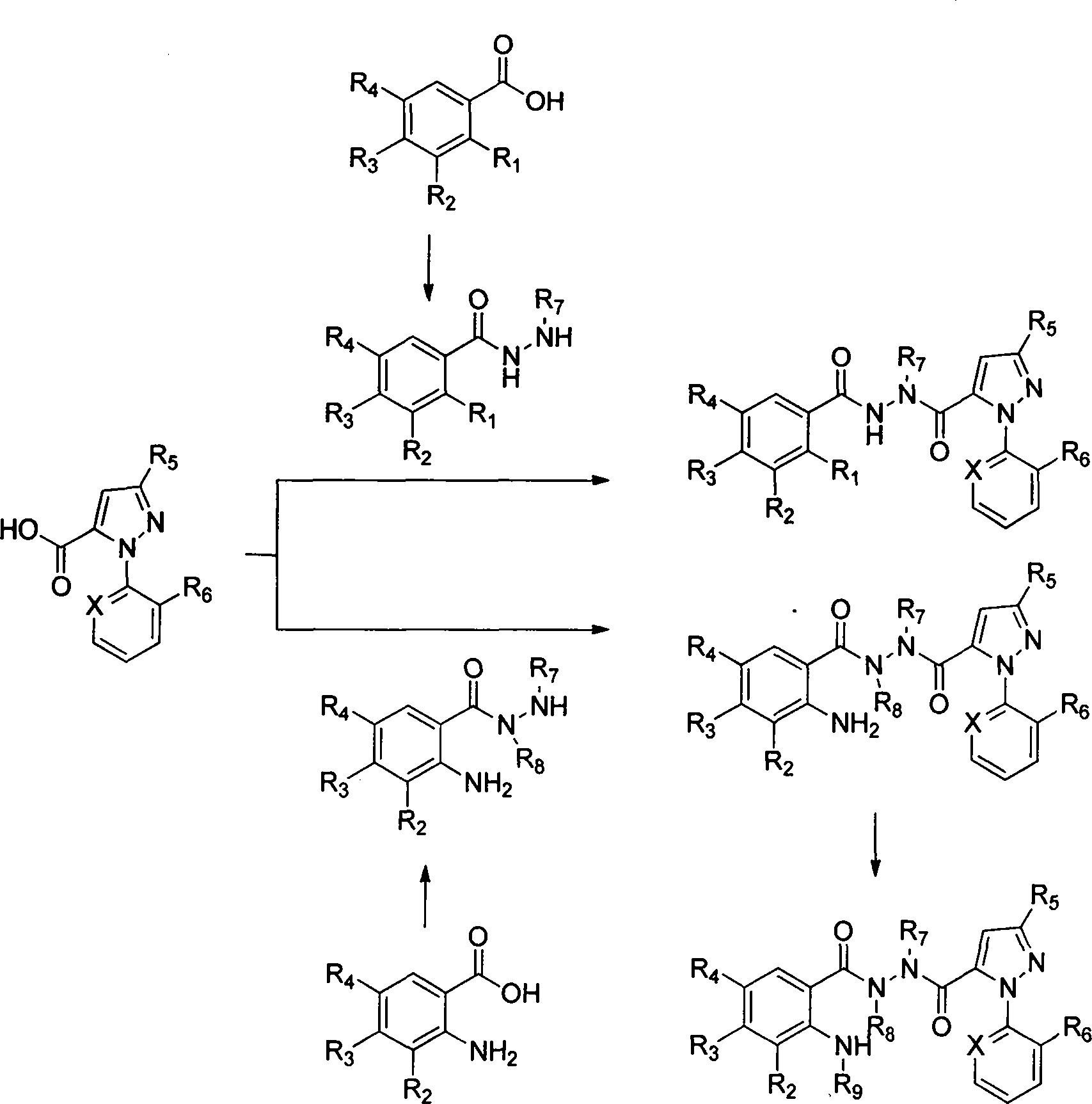

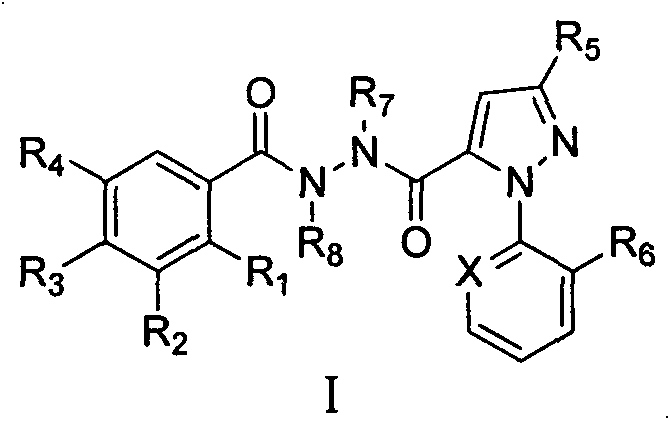

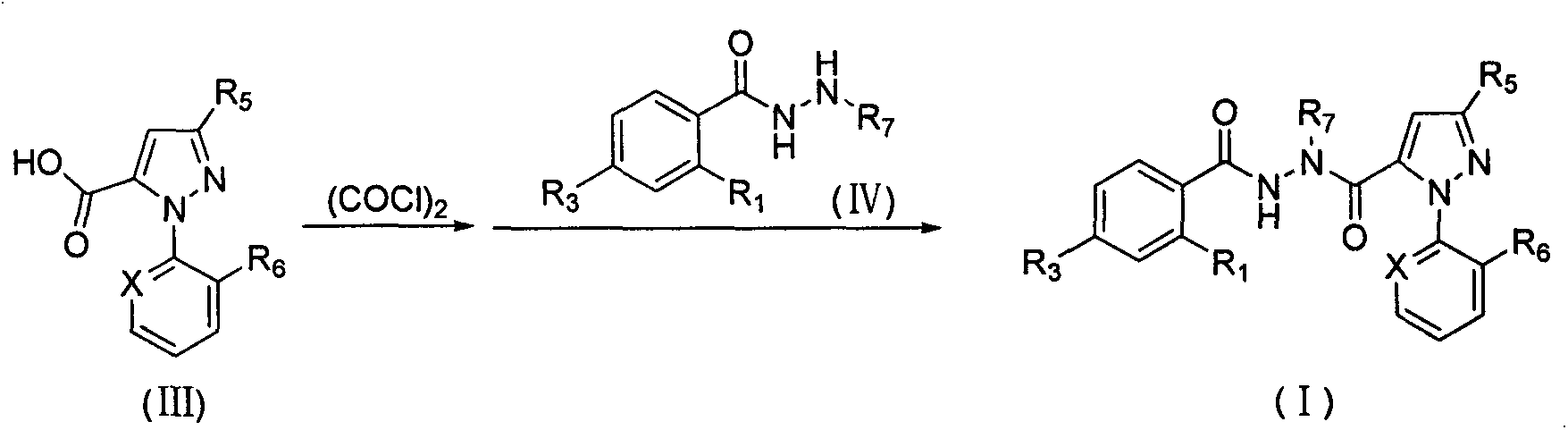

Novel hydrazide derivatives as well as preparation method and application thereof

InactiveCN103483313AHigh insecticidal activityIncreased drug resistanceBiocideOrganic chemistryOrder LepidopteraChemical compound

The invention relates to novel hydrazide derivatives as well as a preparation method and application thereof. The novel hydrazide derivatives have a general formula as shown in the specification, wherein each group is as shown in the claim 1. The novel hydrazide derivatives provided by the invention are improved in insecticidal activity while the previous compound lipid solubility thereof is improved; the derivatives have excellent insecticidal activity; instantly after the derivatives are applied, insects can lose control on muscle and stop eating, and are obviously shrank and paralyzed; at last, the insects can be caused to die, and in the meantime, abnormal ecdysis of insects also can be induced; the novel hydrazide derivatives are very effective especially for lepidoptera pests such as mythimna separata, plutella xylostella and asparagus caterpillar, and thus are pesticides having wide application prospect.

Owner:NANKAI UNIV

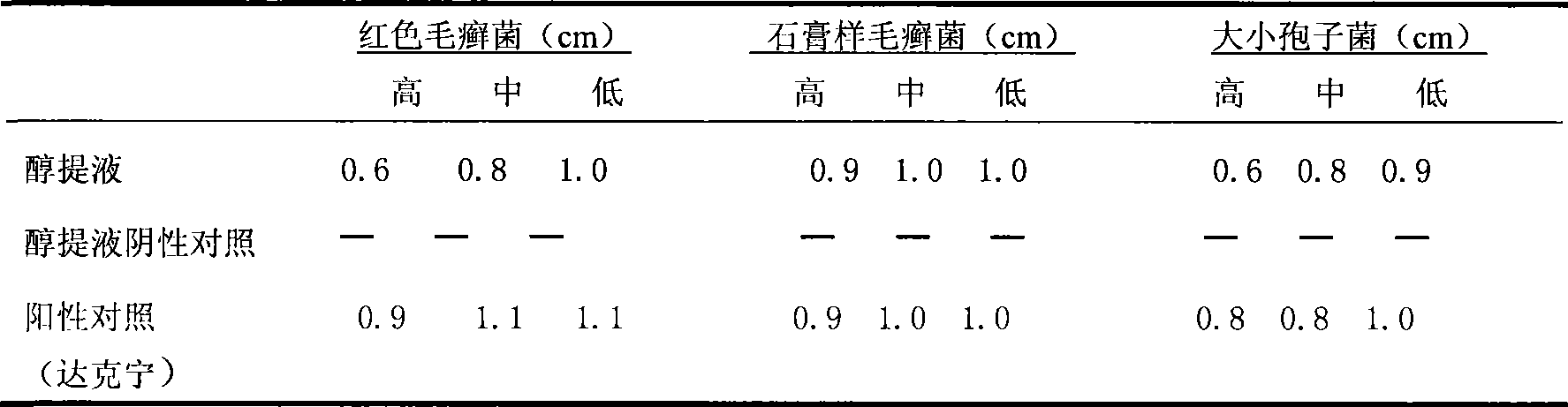

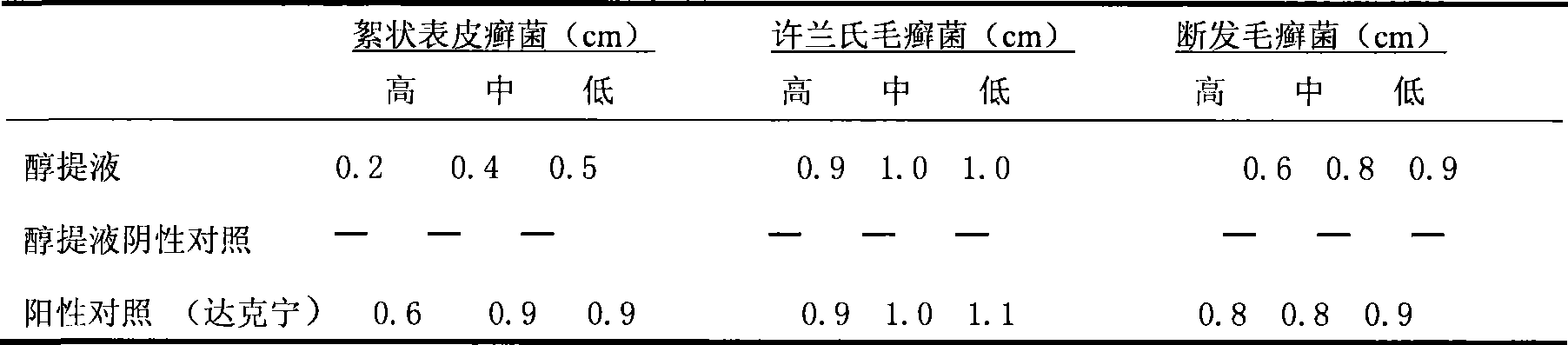

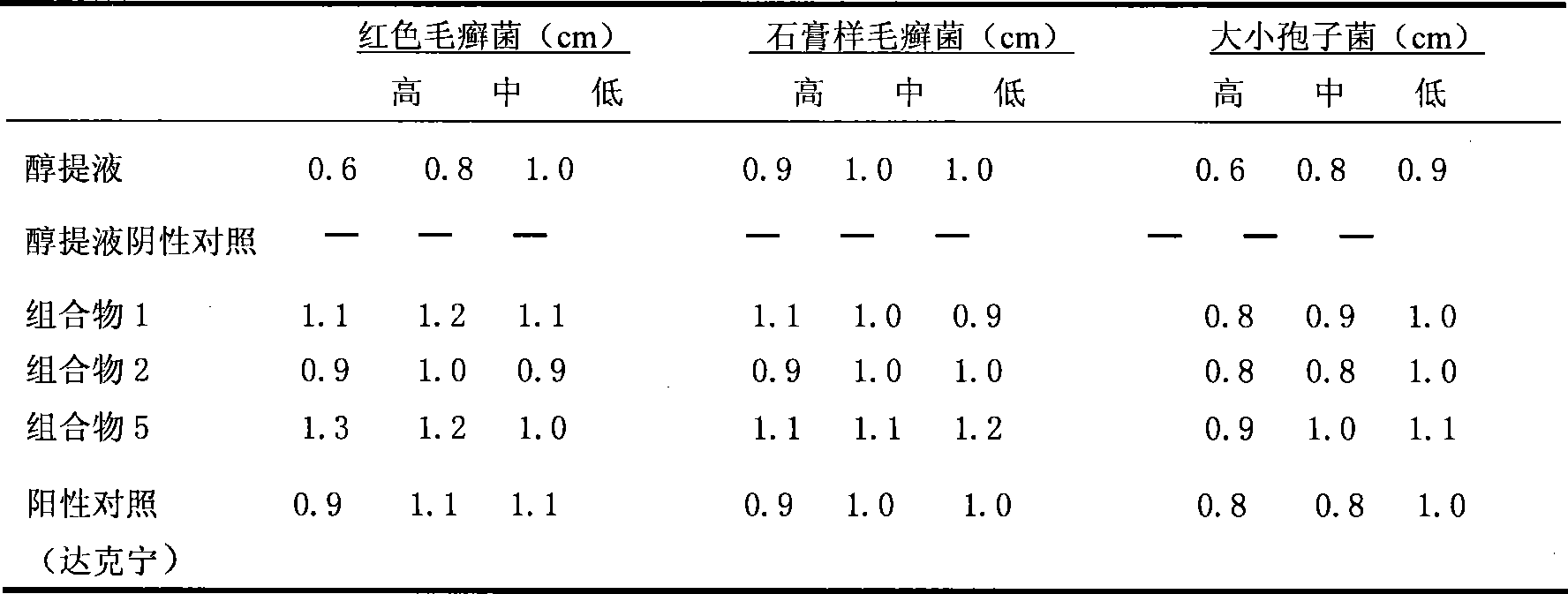

Botanical fungicide, extracting method and usage thereof

InactiveCN101623013AHas antibacterial and bactericidal activityGood antibacterial and bactericidal activityBiocideFungicidesFungicideGinger Rhizome

The invention relates to the field of agricultural fungicide, in particular to a botanical fungicide, an extracting method and the usage thereof. The botanical fungicide adopts extracts of plant raw materials such as sisal leaves, wild chrysanthemum, Chinese parasol leaves, ginger, bitter gourd or the like; the original preparation technology is improved, and the botanical fungicide is used for controlling agricultural diseases and has good environmental compatibility; the three-time extracting technique is adopted, and ultrasound-assisted extraction is applied, so that the maximum extraction capacity of active ingredient can be ensured; the technique is simple and seldom affects the environment, and the extracts have good effect on sterilization and bacteriostasis.

Owner:QINGDAO STAR CROPSCI

Anti-infective medicament composition and application

ActiveCN101502501ABroad spectrum antibacterialGood resistance to multidrug resistanceHydroxy compound active ingredientsAerosol deliveryDiseaseAspidin BB

The invention discloses an anti-infective drug combination and an application thereof. The anti-infective drug combination comprises a dryopteris fragrans extract with the weight percentage being 1% to 99% of the drug combination, and pharmaceutically conventional auxiliary materials. The dryopteris fragrans extract comprises the following components: dryopteris fragrans essence, aspidin AB, aspidin PB, aspidin BB, aspidinol and albicanol. The anti-infective drug combination is applicable in the preparation of drugs for curing bacterial, fungal or viral infection diseases; and the anti-infective drug combination has the advantages that the anti-bacterial spectrum is wide, the anti-multidrug resistance is good and the safety is high because the anti-infective drug combination is derived from the natural plant resources.

Owner:广东恒健制药有限公司

Mouth rinse for removing halitosis and preparation method thereof

ActiveCN101897658AWide applicationEffective in removing bad breathCosmetic preparationsToilet preparationsAdditive ingredientTherapeutic effect

The method discloses a mouth rinse for removing halitosis and a preparation method thereof. The mouth rinse for removing halitosis comprises nidazole medicines, Chinese herbal medicine extracts, menthol, glycerin, a surface active agent and deionized water. In the invention, the mouth rinse for removing halitosis takes the nidazole medicines as a main therapeutic ingredient, and enhances therapeutic effect by adding the Chinese herbal medicine extracts for health care. Compared with the mouth rinse with a single active ingredient, the mouth rinse of the invention can be applicable to more indications, has more obvious therapeutic effect on removing oral abnormal odor, can effectively improve oral inflammation without destroying normal oral floras, and has the advantages of short use time, good drug resistance, convenient use, good mouth feel and easy acceptance of patients.

Owner:GUANGZHOU INST OF BIOMEDICINE & HEALTH CHINESE ACAD OF SCI

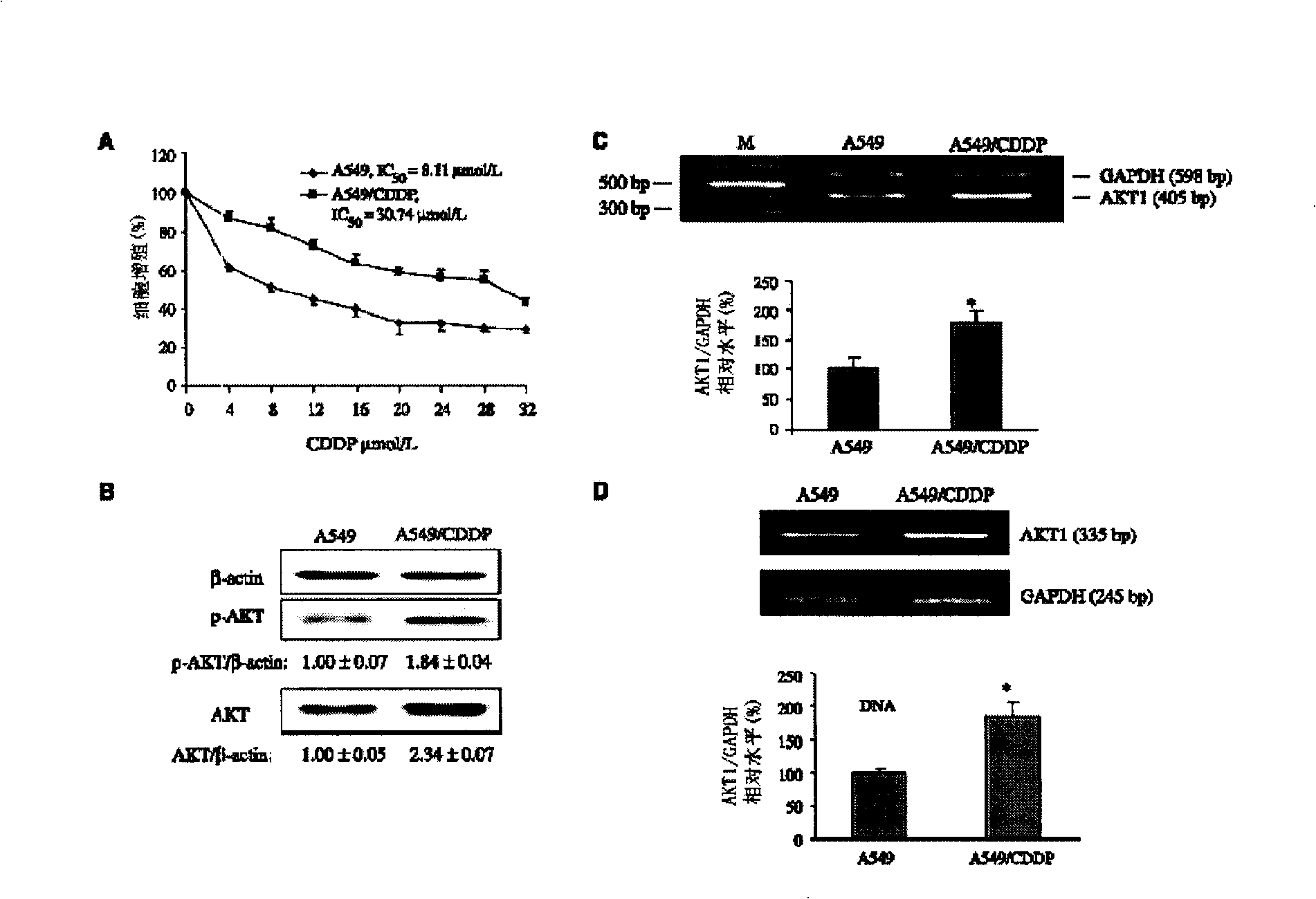

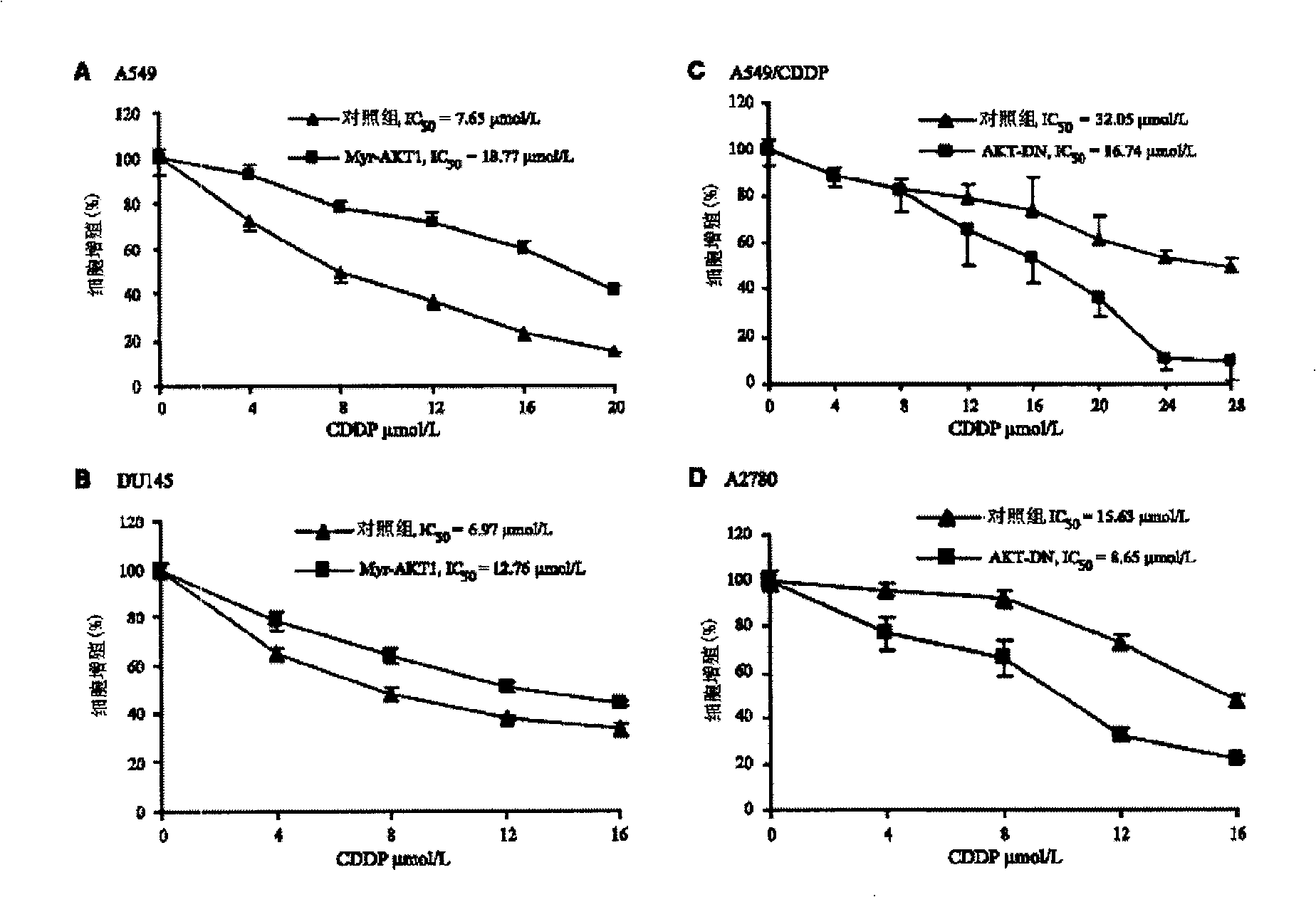

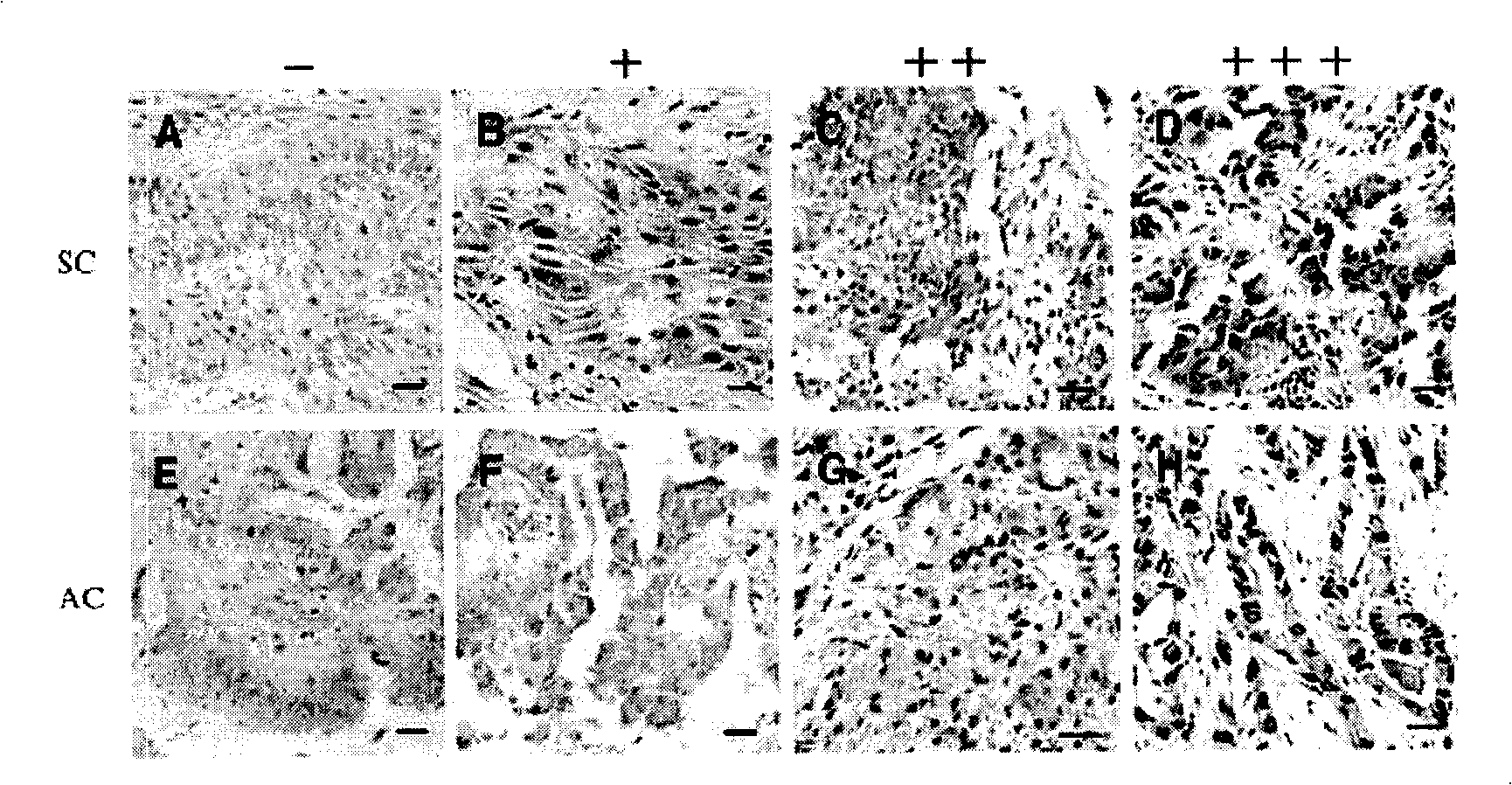

Antineoplastic composition and use thereof

InactiveCN101332301AIncreased drug resistanceEnhanced inhibitory effectHeavy metal active ingredientsAntineoplastic agentsMalignant lymphomaProstate cancer

The invention discloses an anti-tumor combination and the application thereof; the anti-tumor combination which includes effective dose of platinum-based chemotherapy and AKT inhibitor and / or p70S6K1 inhibitor has the function of inhibiting the drug resistance of the tumor to the platinum-based chemotherapy, improves the effects of anti-tumor drugs, and can be used for preparing drugs that can resist various tumors, such as lung cancer, ovarian cancer, prostate cancer, breast cancer, stomach cancer, nasopharyngeal cancer, esophageal cancer, malignant lymphoma, head and neck squamous cell carcinoma, thyroid cancer, osteosarcoma, etc.

Owner:NANJING MEDICAL UNIV

High-strength and high-toughness composite material

The invention discloses a high-strength and high-toughness composite material, the raw material of which comprises the following components: polyvinyl chloride, polyurethane elastomer, chlorinated polyethylene, EPDM rubber, silicone-acrylate copolymer, α-methyl Styrene Acrylonitrile, Tetraacicular Zinc Oxide Whiskers, Plant Fiber, Basalt Fiber, Nano Calcium Carbonate, Diatomaceous Earth, Organically Modified Montmorillonite, Zinc Hydroxide Stannate, Calcium Stearate, Zinc Stearate , molybdenum trioxide, acetyl tributyl citrate, soybean oil, polyepichlorohydrin, coupling agent, dioctyl sebacate, oxidized polyethylene wax, hydroxypropyl methylcellulose, triethanolamine. The high-strength and high-toughness composite material of the invention has high strength, good toughness, good heat resistance and strong aging resistance.

Owner:ANHUI RUIXIN AUTOMATION INSTR

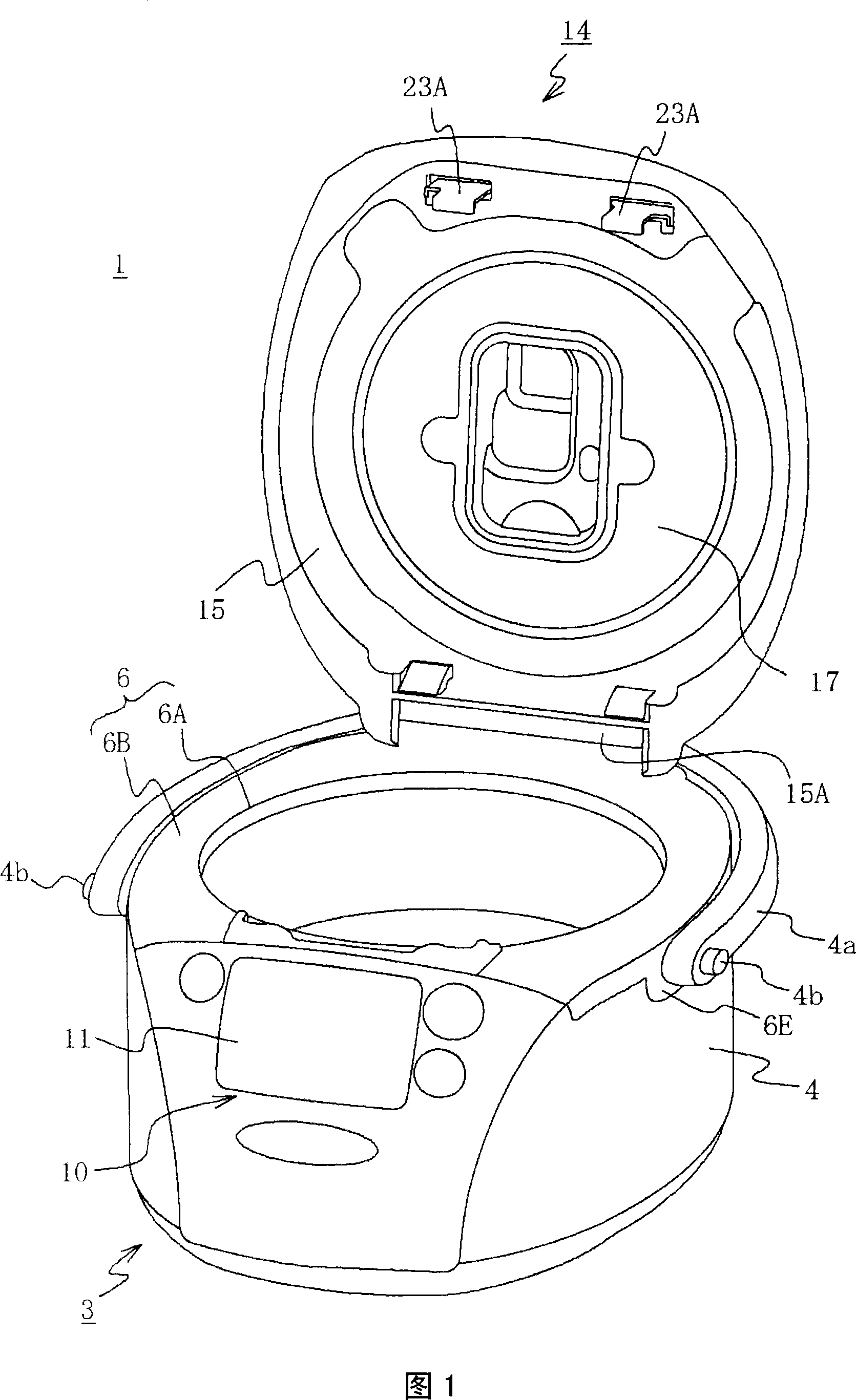

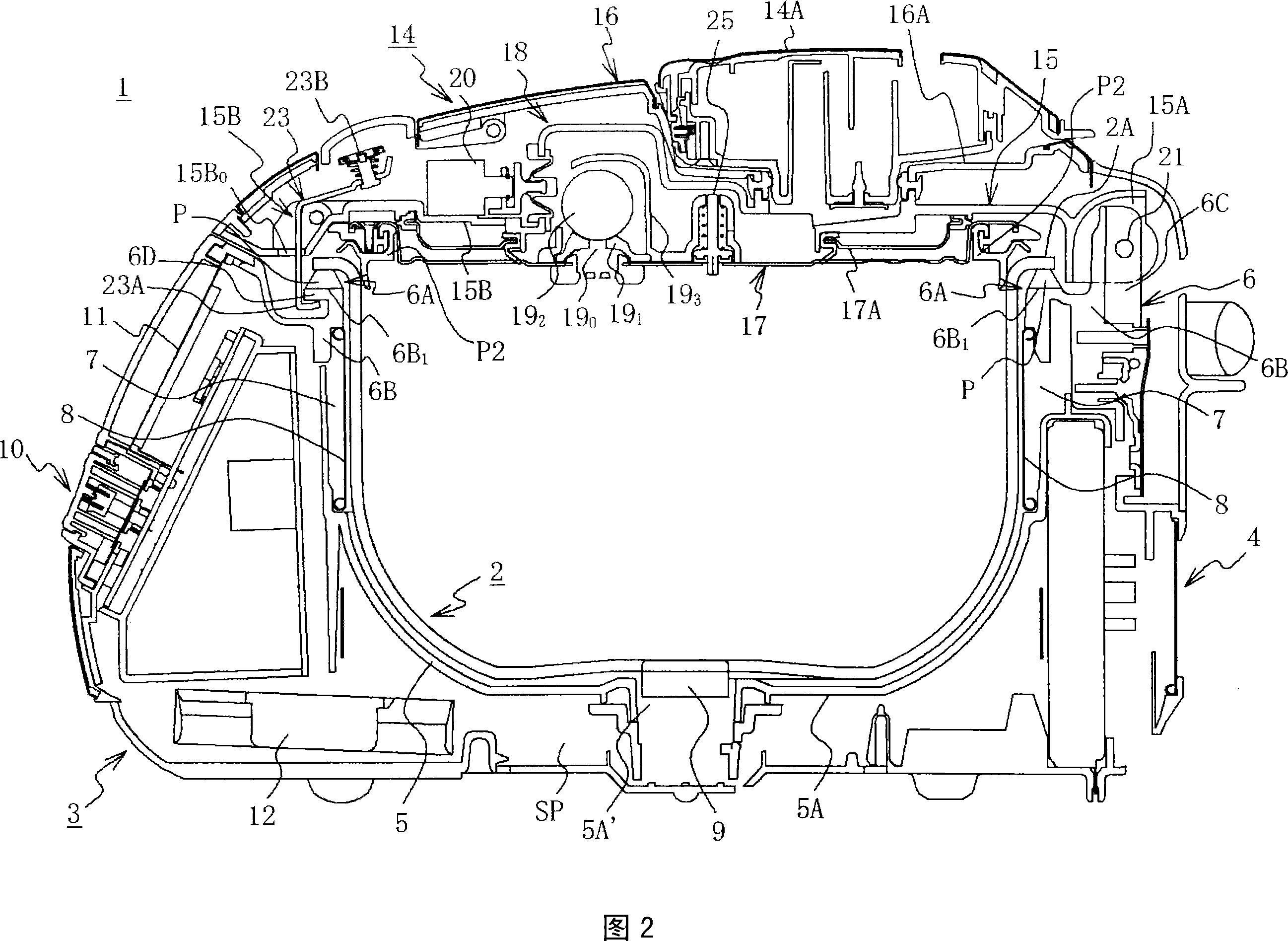

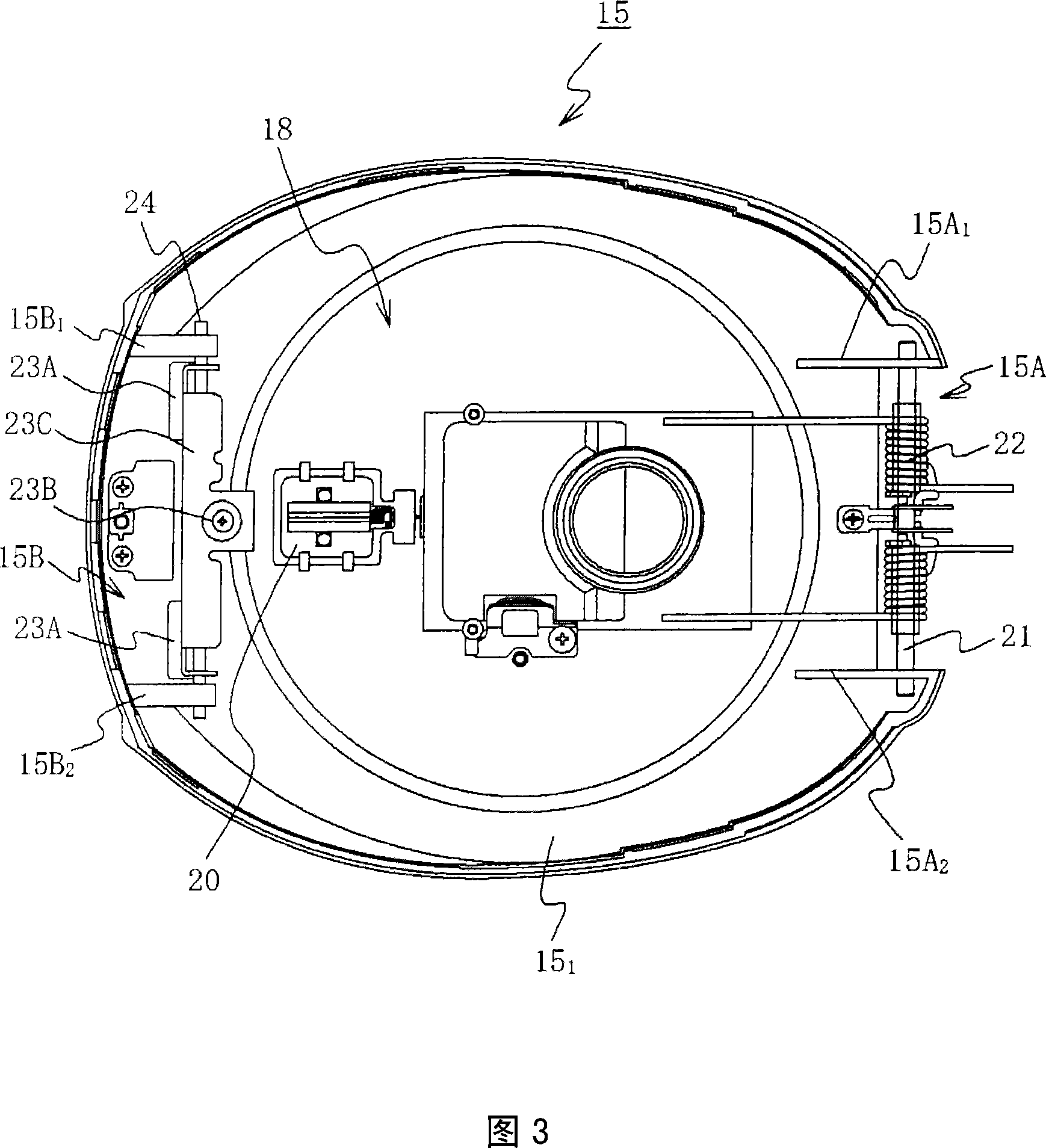

Rice cooker

ActiveCN101238949AIncreased durabilityHigh mechanical strengthCooking-vessel materialsCooking-vessel lids/coversHeat resistanceCooker

A cooking device is provided to improve the mechanical stiffness and the heat resistance by forming at least any one side of a frame cover, an opening, and a cover of stiff metal material. A cooking device comprises a pot having a cylindrical container, an opening(6A) wherein the pot is placed, a main body(3) having a heating unit for cooking a material to be cooked inside the pot, and a cover(14). The cover, whose one end is supported by the main body and other end is engaged with the main body by a locking device, covers the opening of the pot and the main body. The periphery of the opening of the main body is covered by a frame cover(6). At least any one side of the frame cover and the cover is made of stiff metal material.

Owner:SANYO ELECTRIC CO LTD +1

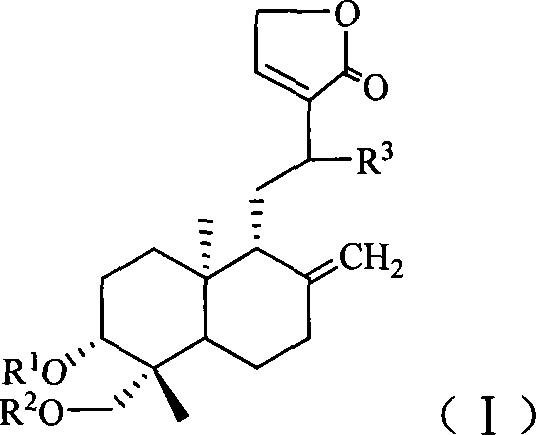

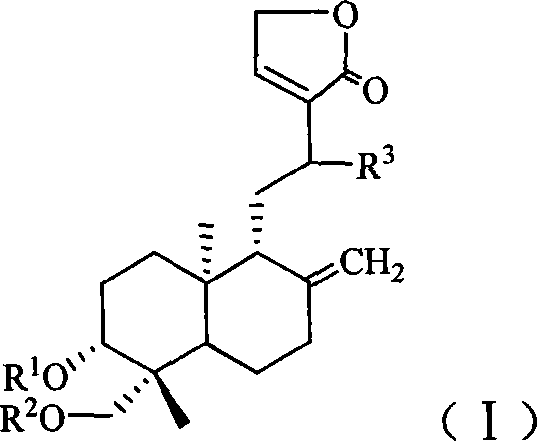

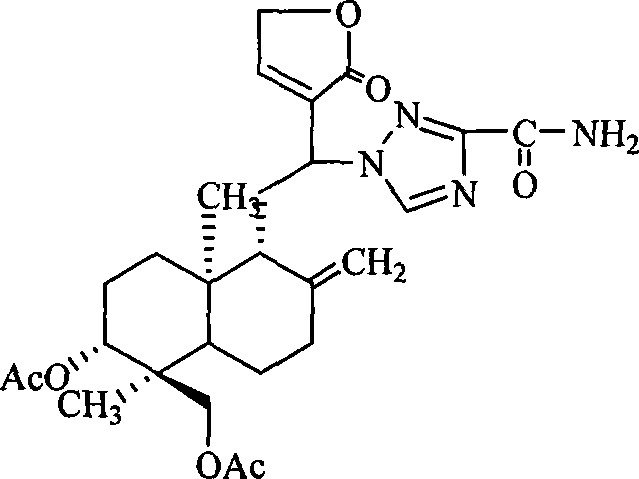

Antiviral compound and preparation method thereof

InactiveCN101190912AStrong antiviral activityIncreased drug resistanceOrganic chemistryAntipyreticCombinatorial chemistryViral infection

The invention pertains to the field of medical technology and relates to novel compounds with antiviral activity, isomer or pharmaceutically acceptable salts thereof shown in the formula (I), wherein, R<1>, R<2> and R<3> are defined as the instruction. The invention also relates to preparation methods of the compounds, a medical composition which contains the compounds and the application of the compounds in preparation of drugs which are used for curing and / or preventing diseases caused by viral infection.

Owner:SHANDONG XUANZHU PHARMA TECH CO LTD

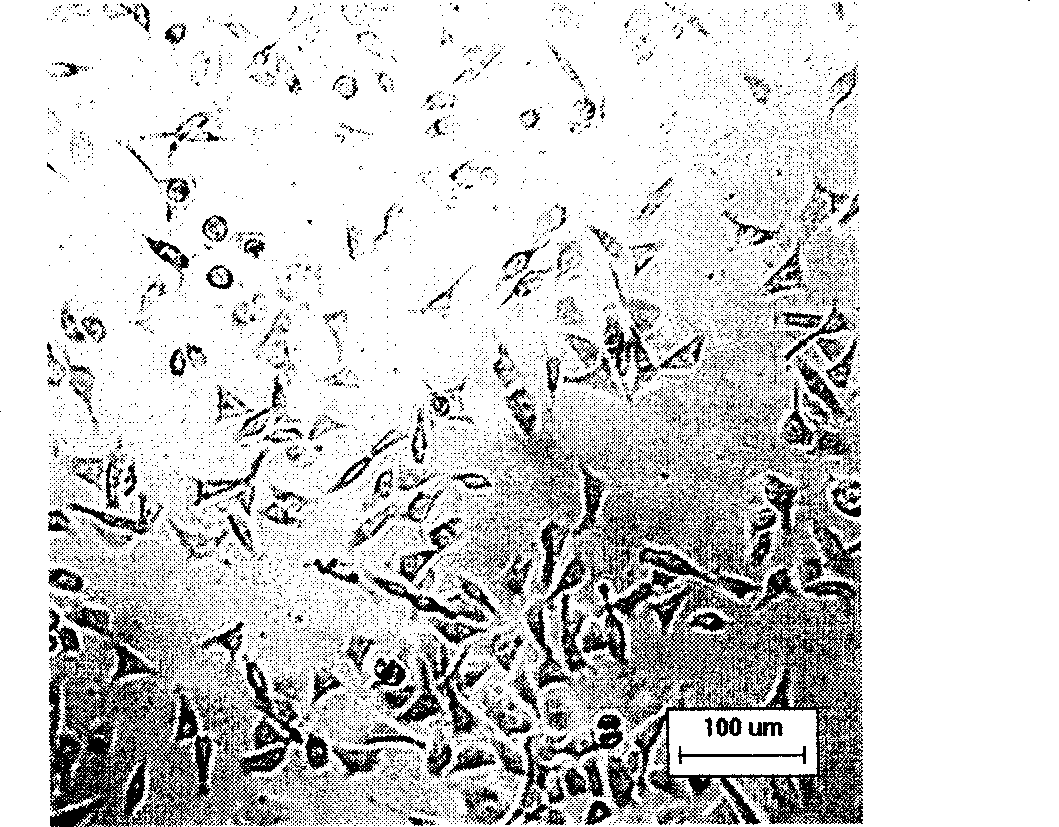

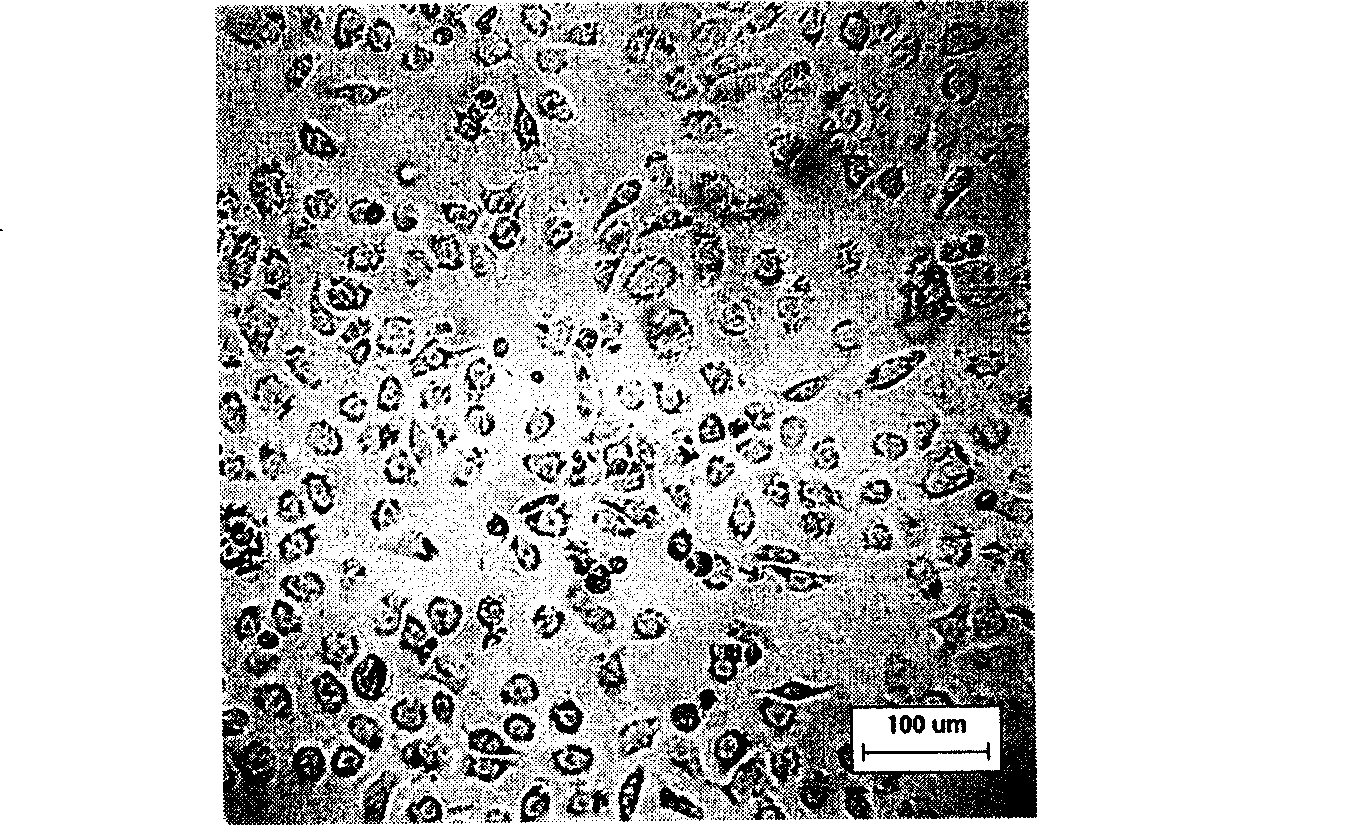

Oophoroma multidrug resistance cell strain established by etoposide induction

The invention relates to a multidrug resistant cell strain for oophoroma, which is characterized in that a human oophoroma SKOV3 cell strain is selected as a parental cell; the action concentration of chemotherapeutics of etoposide (VP16) is gradually increased from 0.1 mu g / ml to 3 mu g / ml; and drug resistant SKOV3 / VP16 cell strain is established. The SKOV3 / VP16 cell can stably grow, transfer and reanimate in 3 mu g / ml VP16, makes the VP16 generate drug resistant index (RI) of 21.548, and performs intersect drug on MTX, DOX, DDP, VCR, 5-Fu and MMC except the VP16. The invention aims to provide a drug resistant tumor cell model for relative study on the tumor.

Owner:THE WEST CHINA SECOND UNIV HOSPITAL OF SICHUAN

PC (polycarbonate) insulation release film

InactiveCN105440641AImprove insulation performanceImprove water resistancePolymer sciencePolyethylene terephthalate glycol

The invention discloses a PC (polycarbonate) insulation release film. The release film comprises a film layer comprising components in parts by weight as follows: PC, boron nitride, epoxy resin 6101, phenolic resin 2124, melamine, polyacrylamide, polyamide 66, mica powder, talcum powder, polyvinyl butyral, TFE (tetrafluoroethylene) powder, polymethyl methacrylate, polyphenylene sulfide, PET (polyethylene terephthalate), polyethylene glycol monomethyl ether, organic montmorillonite, polyether-ether-ketone fibers, nano-silica, polyethylene glycol, natural latex, an anti-foaming agent, a thickener and a coupling agent. The release film has excellent insulativity, water resistance, solvent resistance, chemical resistance, corrosion resistance, temperature resistance, adhesiveness, cooling and energy storage effects and more diversified functions.

Owner:TAICANG CUSTOM NEW MATERIALS CO LTD

Aptamer for recognizing adriamycin-resistant breast cancer cells as well as screening method and application of aptamer

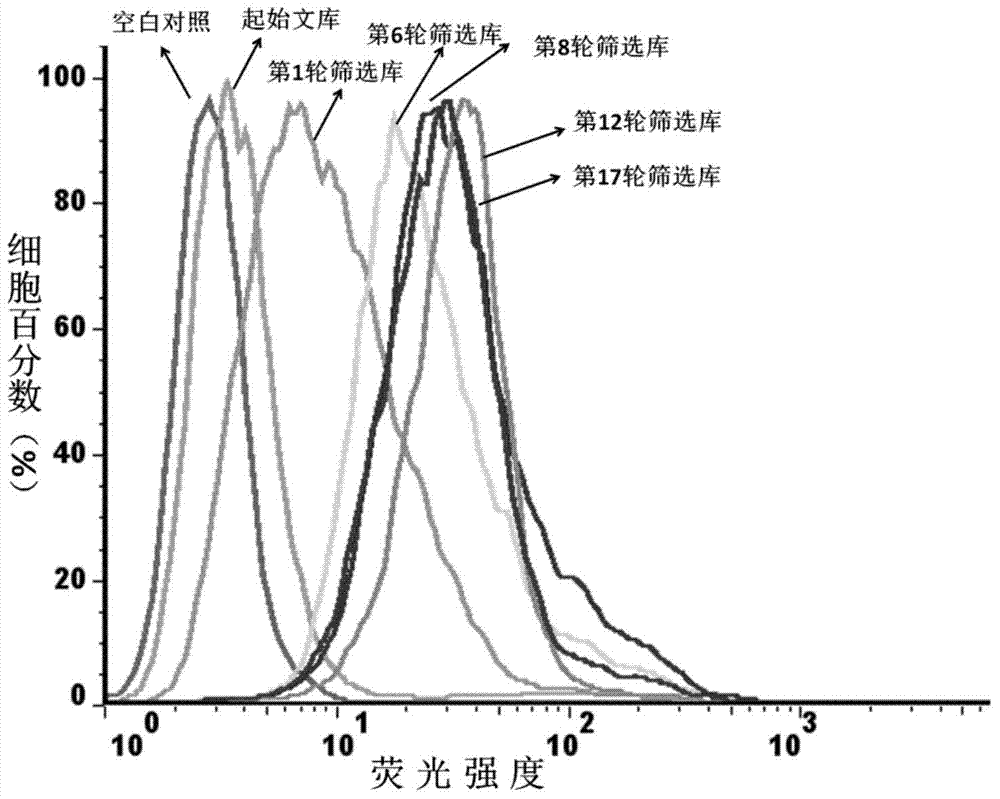

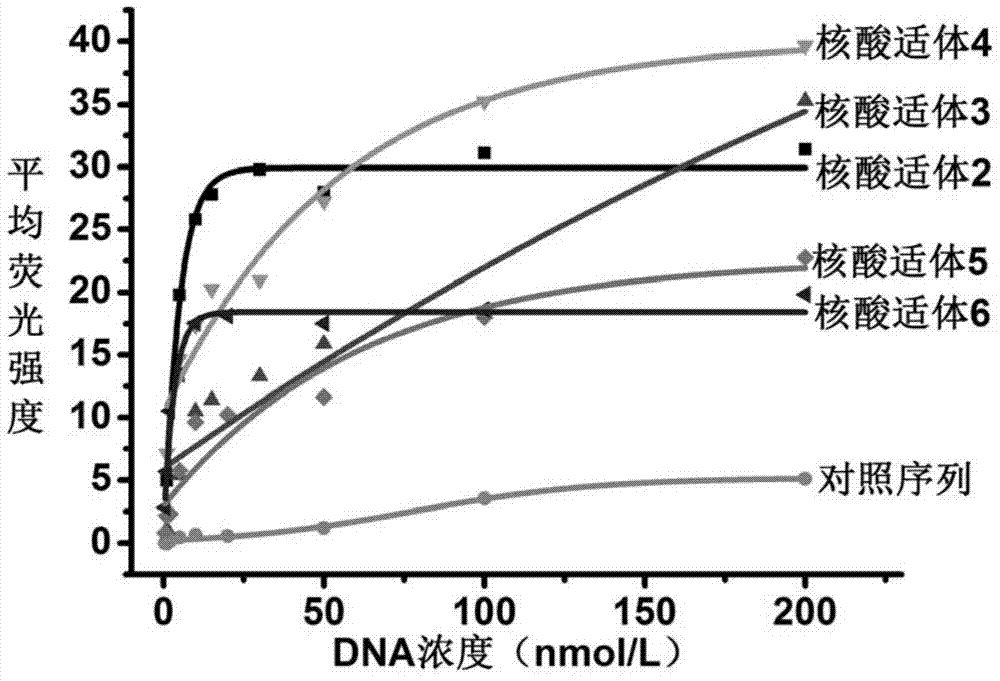

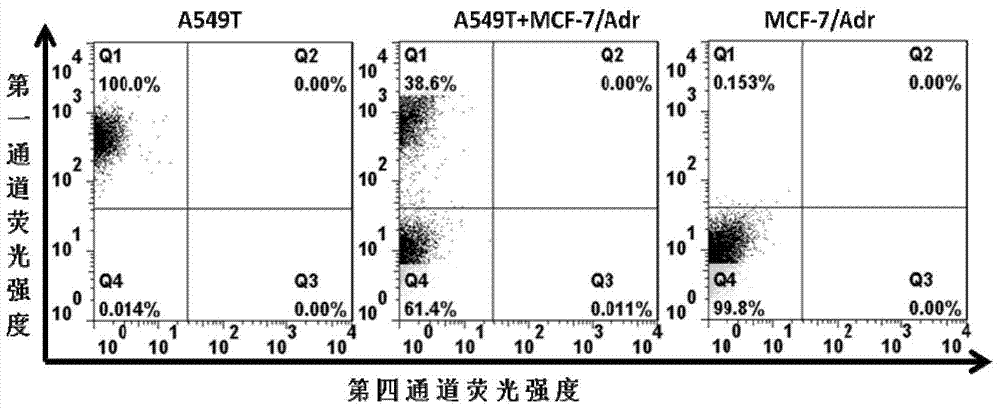

ActiveCN104498500AHigh affinityIncreased drug resistanceMicrobiological testing/measurementDNA/RNA fragmentationAptamerNucleotide

The invention discloses an aptamer for recognizing adriamycin-resistant breast cancer cells. The aptamer can be a single-stranded DNA molecule. Particularly, the aptamer can be an aptamer (1) formed by nucleotide molecules as shown in SEQ ID No. 1, an aptamer (2) formed by nucleotide molecules as shown in SEQ ID No. 2, an aptamer (3) formed by nucleotide molecules as shown in SEQ ID No. 3, an aptamer (4) formed by nucleotide molecules as shown in SEQ ID No. 4, an aptamer (5) formed by nucleotide molecules as shown in SEQ ID No. 5 and an aptamer (6) formed by nucleotide molecules as shown in SEQ ID No. 6. By adopting the aptamer disclosed by the invention, the resistance to medicines of tumors can be monitored in real time according to molecular response signals under the condition that the medicine resistance mechanism is unknown so that the treatment scheme can be changed timely and the success rate of chemotherapy can be increased.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Multiple-gene helicobacter pylori detection system and kit and application thereof

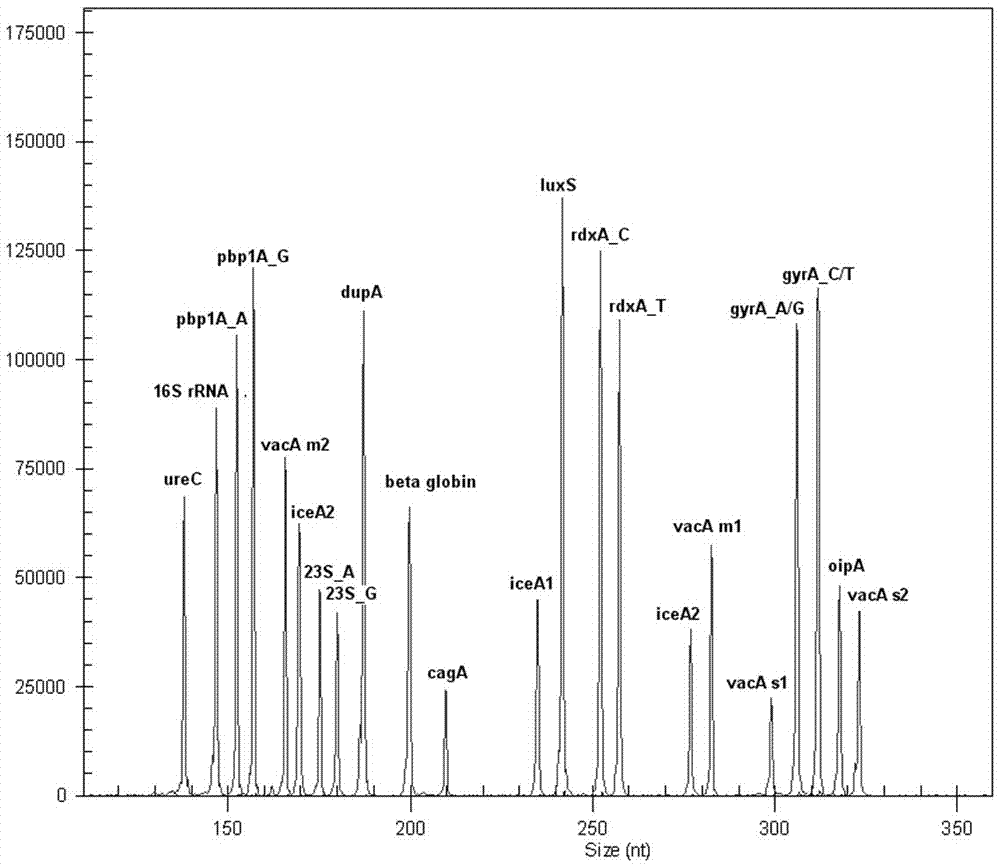

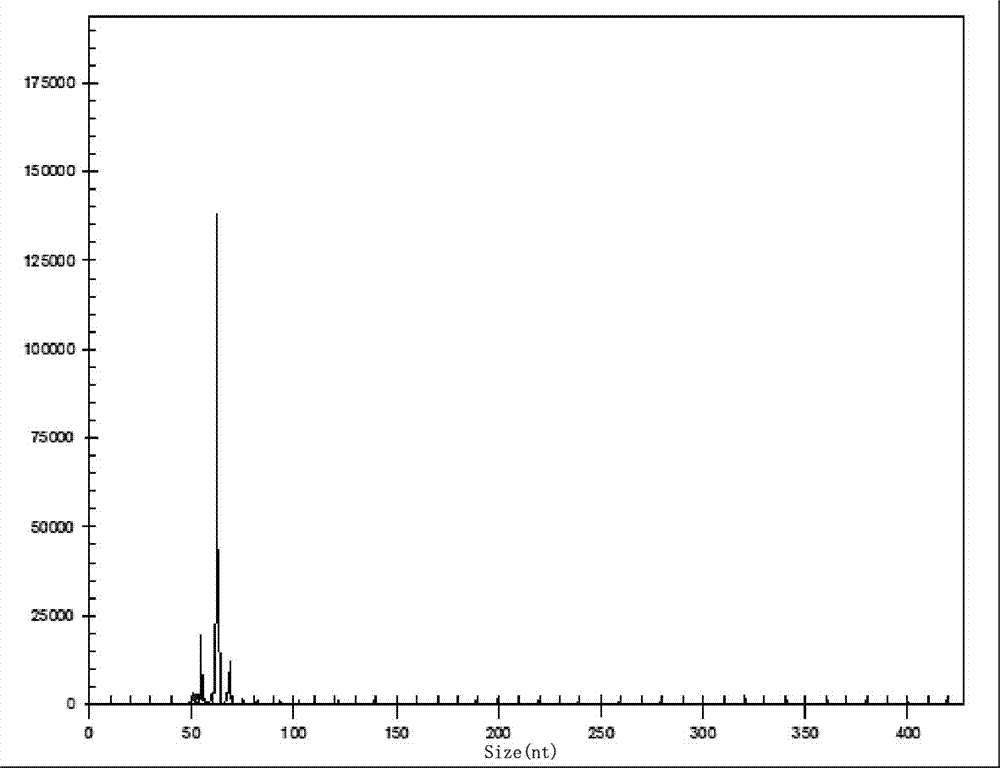

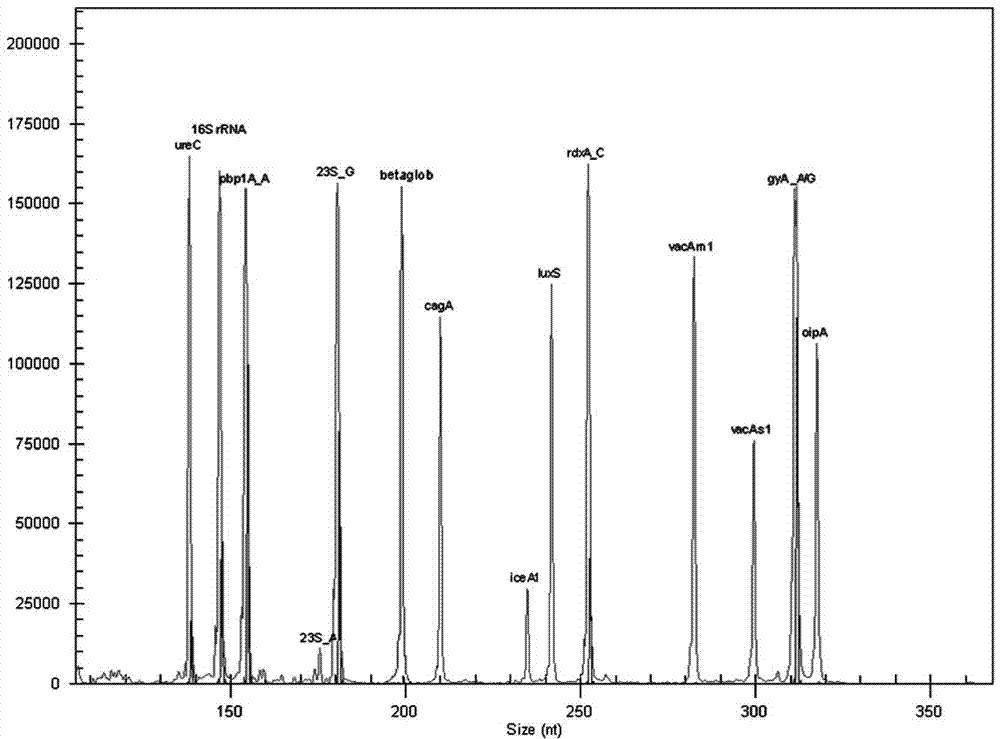

ActiveCN105441583AThe test result has no impurityHigh sensitivityMicrobiological testing/measurementTissue sampleCagA

The invention relates to a multiple-gene helicobacter pylori detection system and a kit and application thereof. The helicobacter pylori detection system includes 21 pairs of primers respectively for a strain identification gene (16S rRNA), virulence genes (cagA, vacA-s1, vacA-s2, vacA-m1, vacA-m2, iceA1, iceA2, dupA, oipA and luxS), drug resistance genes (2143 locus of 23S rRNA, 148 locus of rdxA, 1777 locus of pbp1A and polymorphism of the 261 locus of gyrA) and quantitative analysis genes ureC and beta-globin of the helicobacter pylori. The multiple-gene helicobacter pylori detection system and the kit of the system do not need the steps including conventional isolated culture and the like, synchronous detection and analysis on strain identification, quantification, virulence and medicine resistance can be directly conducted on tissue samples in the same reaction system, the shortcomings of low flux, long consumed time, low detection rate and the like of a conventional detection method are overcome, a comprehensive, accurate and low-cost etiological diagnosis is clinically provided for the first time, and important references are provided for individualized diagnosis and accurate treatment of helicobacter pylori infection.

Owner:HUADONG HOSPITAL +1

Copper conductor slurry, conductor circuit board and electronic elements

ActiveCN101236797AImprove performanceImprove reliabilityFixed capacitor electrodesNon-conductive material with dispersed conductive materialCopper conductorSolubility

A copper conductor sizing agent is able to form a copper conductor film which the atmosphere be controlled to obtain a high density force while not strictly sintering, and less reduction of the density force because of the plating process. The copper conductor sizing agent contains conductive powder with the core of the copper powder, the first glass melting material which is helpful for enhancing the wetting quality, the second glass melting material which is helpful for enhancing resistance to chemical reagents, organic medium. (1) the first glass melting material, the softening point is below 800 centigrade, in the nitrogen atmosphere at 900 centigrade, the contact angle corresponding to the copper powder which is not oxidized superficially is below 60 degrees; (2) the solubility of the second glass melting material is below 1mg / cm2hr corresponding to the 10 quality% sulphuric acid aqueous solution at 25 centigrade; (3) the difference between the softening point of the first glass melting material and the softening point of the second glass melting material is below 150 centigrade; (4) relevant to the total quantity of the glass melting material, the content of the first glass melting material is 10-70 quality%; the content of the second glass melting material is 30-90 quality%.

Owner:MITSUBOSHI BELTING LTD

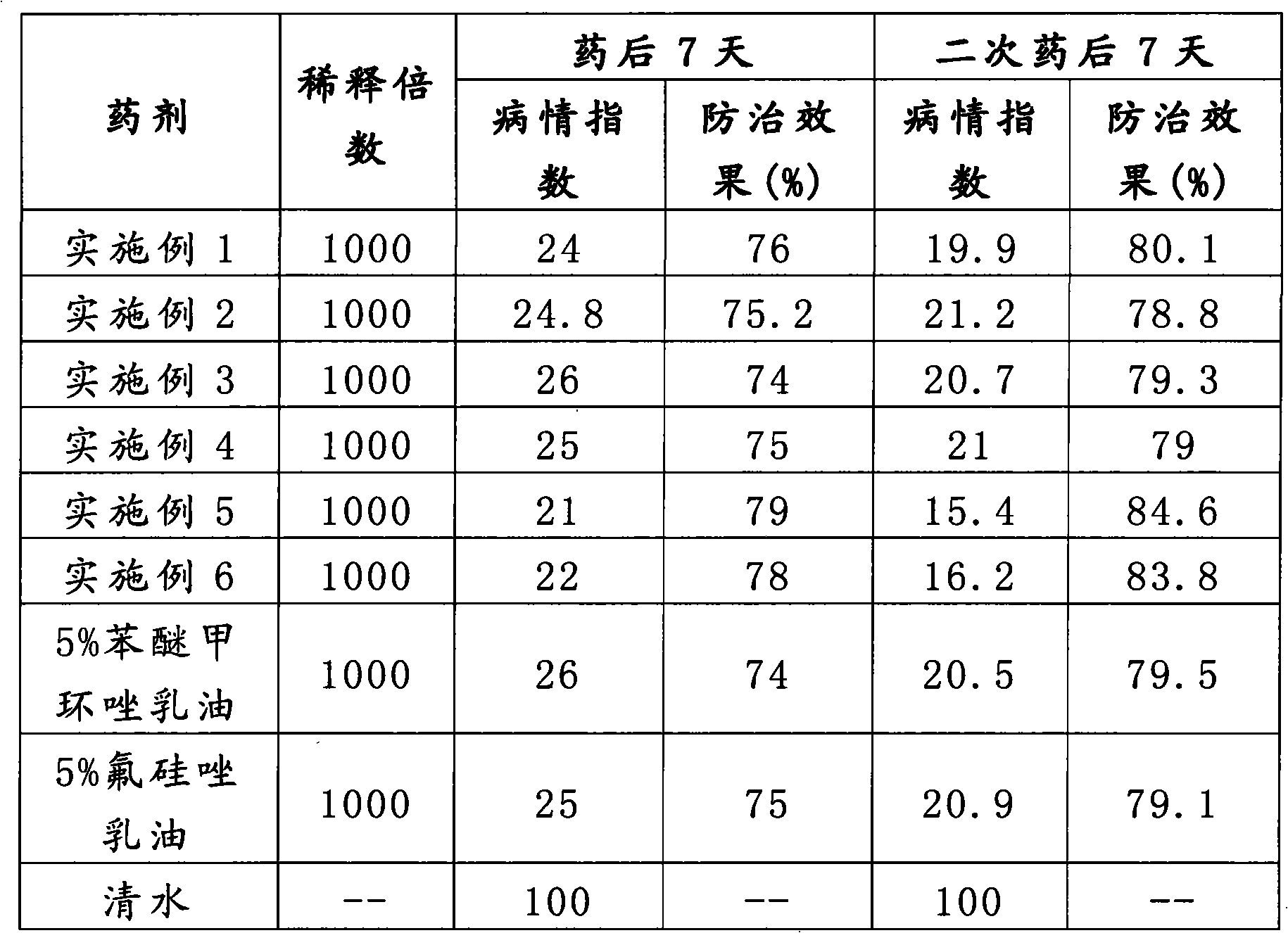

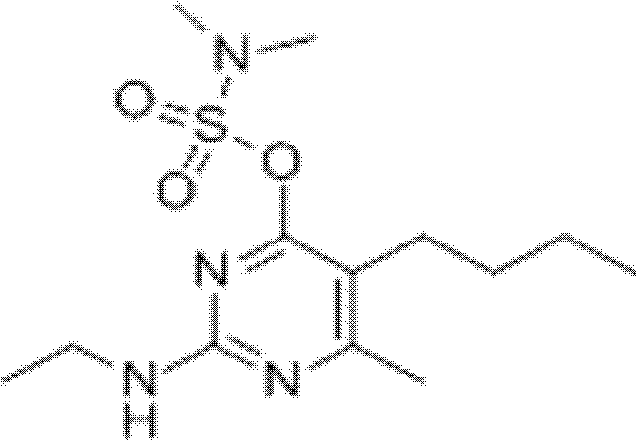

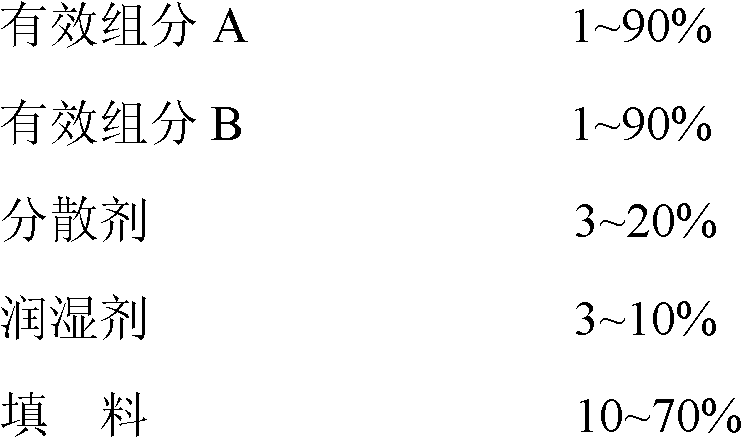

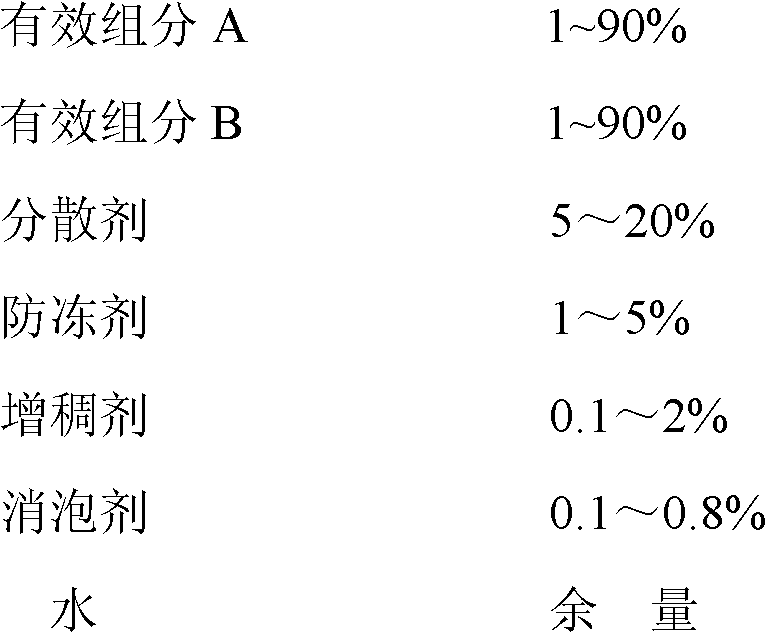

Germicide composition in combination with bupirimate

The invention relates to a germicide composition in combination with bupirimate, comprising bupirimate and partial methacrylic acid ester antiseptic mixing pairwise as effective components, wherein, the weight ratio of bupirimate to methacrylic acid ester antiseptic us 90:1-1:90, preferred 60:3-3:60. The total weight content of the effective components in the germicide composition is 1-90 %, preferred 5-75 %, and the balance consists of allowed and acceptable auxiliary elements in pesticides. The germicide composition can be prepared into wettable powder, suspending agent, soluble liquid formulation, missible oil, emulsion in water, and water dispersible granule with known methods. The germicide composition is mainly used for controlling fungal and bacterial diseases of vegetable, fruit tree, corn and other crops.

Owner:HAILIR PESTICIDES & CHEM GRP

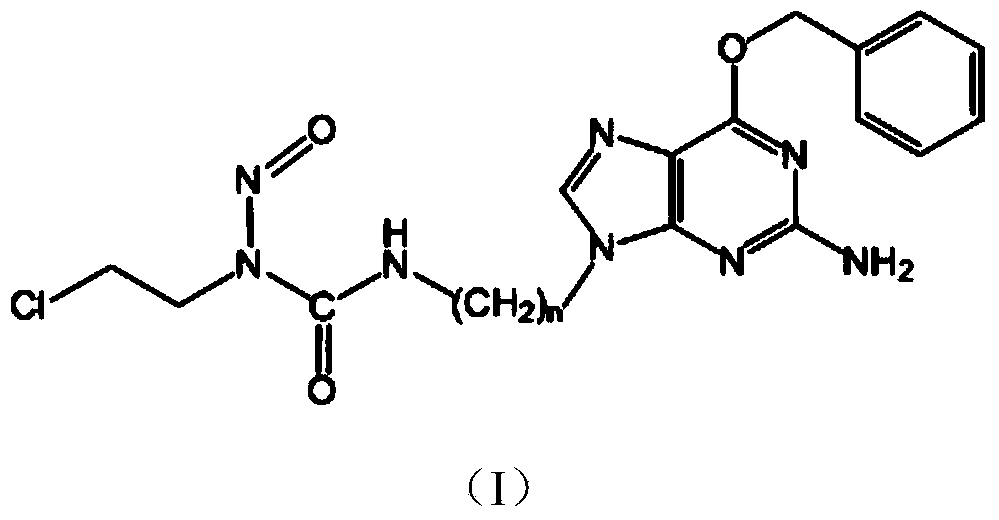

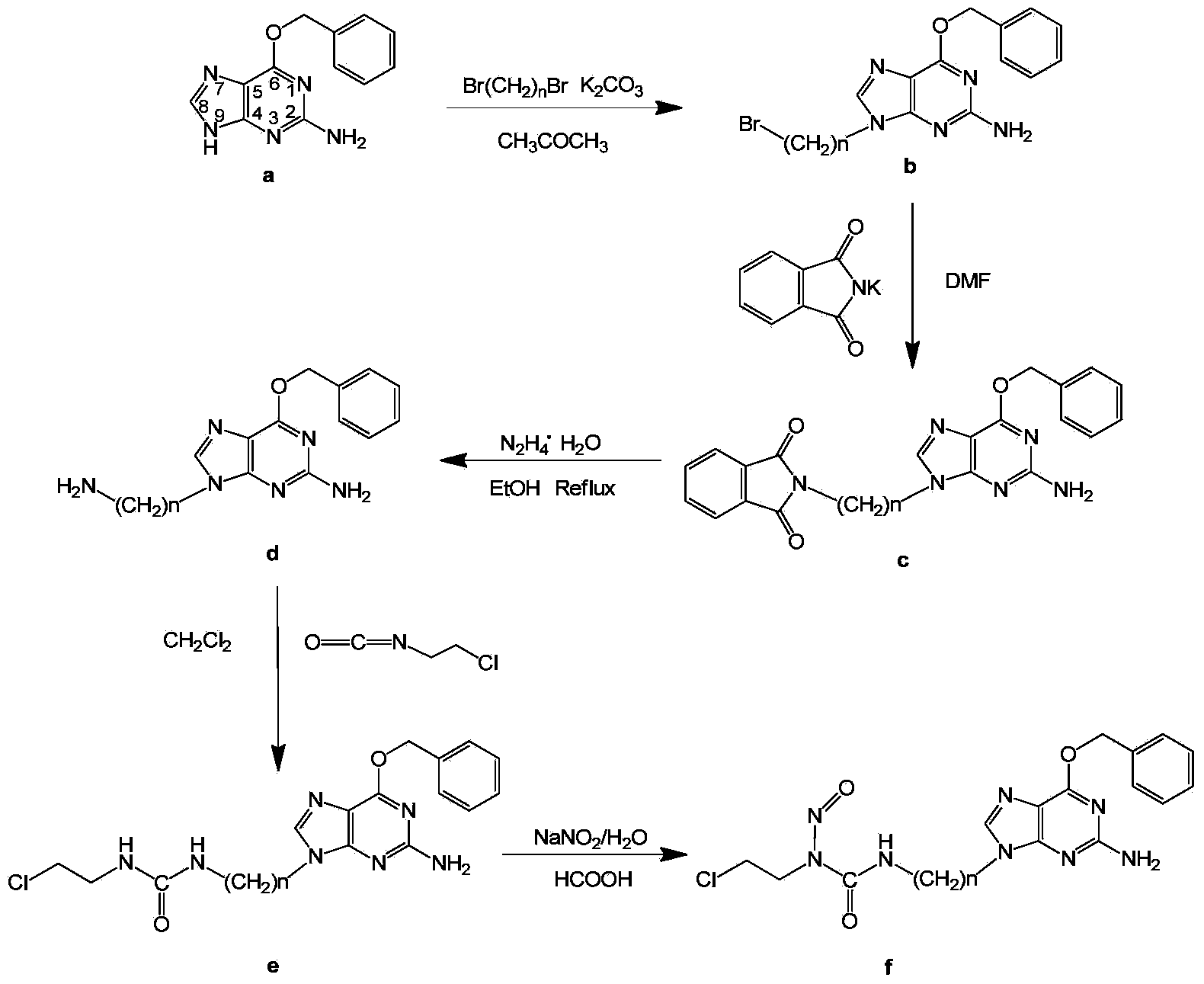

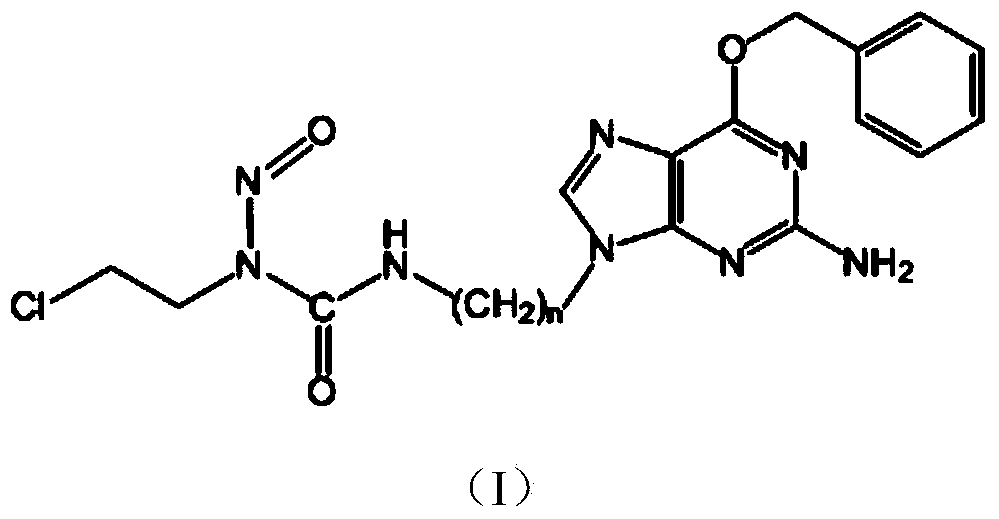

Low-oxygen activated joint chloroethane nitrourea compound and preparation method and application

ActiveCN105503874AGrowth inhibitionDelay drug resistanceOrganic chemistryInorganic non-active ingredientsIonChemistry

The invention relates to a compound with a formula (II) structure or a pharmaceutically accepted salt. The formula (II) structure is shown in the attached figure. The compound with the formula II structure has good targeting property and tumor cell killing capability, and can be used for preparing targeting tumor chemotherapy drugs. The compound has the advantages that on one hand, chloroethene-based carbon positive ions can be decomposed in vitro, the crosslinking with DNA (deoxyribonucleic acid) is caused, and the function of inhibiting the growth of tumor cells is realized; on the other hand, an O6-benzylguanine similar drug effect group is selectively released in cancer cells under the low-oxygen condition, the function of inhibiting the AGT (angiotensinogen) activity of the tumor cells is realized in a targeting way, and the drug resistance of the tumor cells to nitrosourea drugs is decreased.

Owner:BEIJING UNIV OF TECH

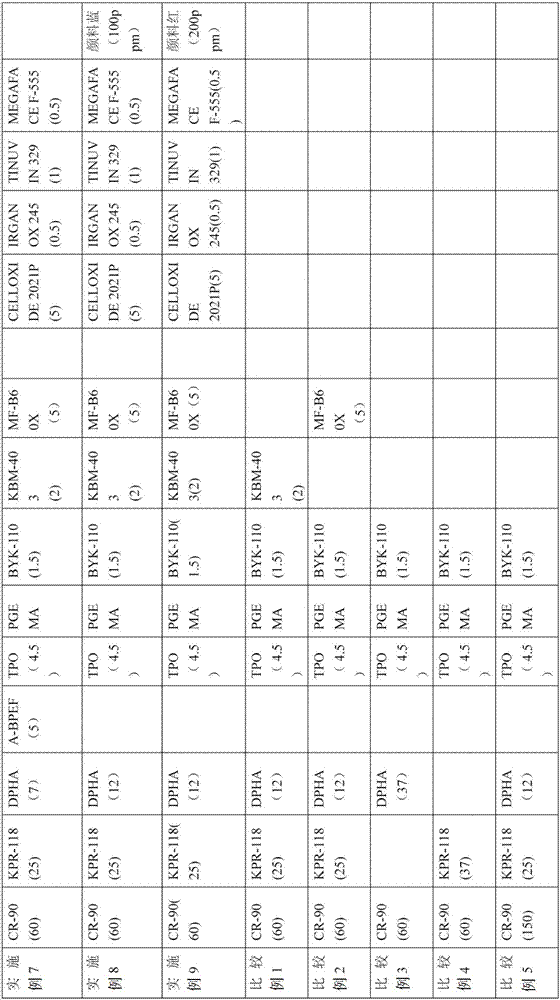

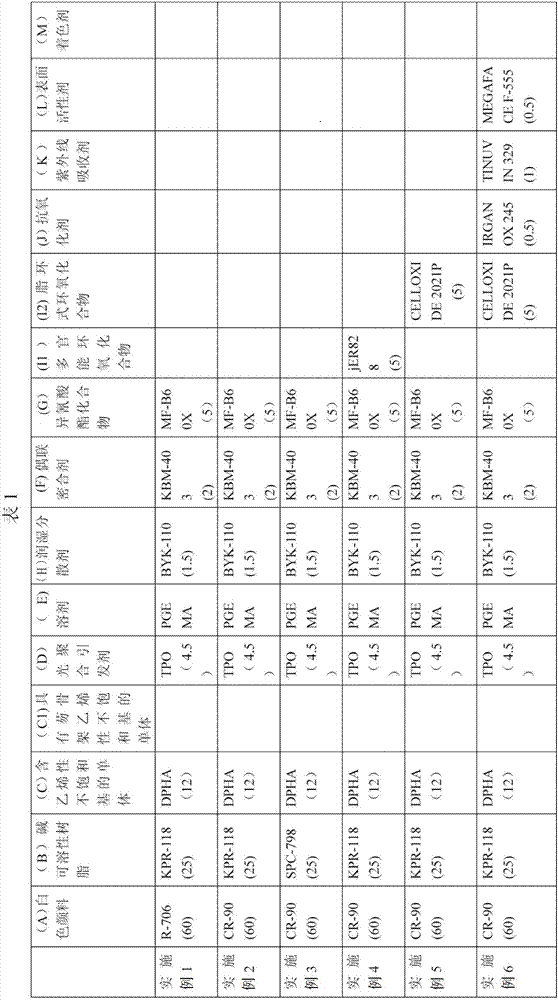

Negative photosensitive white ink for 3D cover plate glass and preparation method and application method thereof

InactiveCN107957655ALess prone to yellowingSimple processInksPhotosensitive materials for photomechanical apparatusCouplingHigh reflectivity

Negative photosensitive white ink for 3D cover plate glass and a preparation method and application method thereof are provided. The negative photosensitive white ink for 3D cover plate glass comprises a white pigment, alkali-solvable resin, a monomer containing ethylene unsaturated groups, a photopolymerization initiator, a solvent, a coupling sealant, and isocyanate compounds. By spraying the ink to 3D cover plate glass and using exposure-development process, a white shade pattern having good film thickness, high resolution, high reflectivity and good shading property can be formed. A pattern formed via the ink is rarely suffered from yellowing, stripping, line breakage or the like.

Owner:广州亦盛环保科技有限公司

Novel chloroethyl nitrosourea with anticancer activity and synthesizing method thereof

ActiveCN104031047ADelay drug resistanceHigh anticancer activityOrganic active ingredientsOrganic chemistrySynthesis methodsTherapeutic effect

The invention relates to novel chloroethyl nitrosourea with anticancer activity and a synthesizing method thereof. The chloroethyl nitrosourea is a compound with a structure of the general formula (I), wherein n is an integer of 2 to 6. The chloroethyl nitrosourea can be used for treating gliomatosis cerebri, colon cancer and leukemia; compared with the existing nitrosourea-type anticancer medicine, the drug resistance is lower, the chemical therapy effect is better, the preparation method is simple in operation, the reaction yield is high, the toxicity is small, the cost is low, the method is suitable for the industrialized production, the development prospect is wide, and the application value is good.

Owner:BEIJING UNIV OF TECH

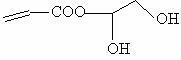

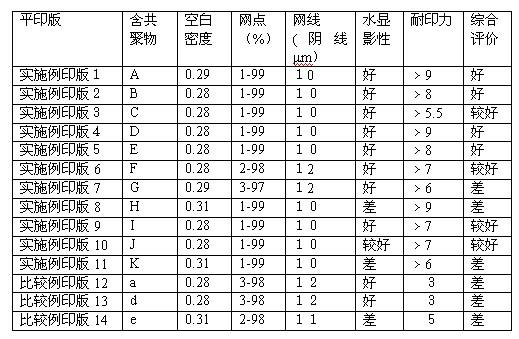

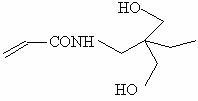

Urethanated unsaturated water-soluble vinyl multipolymer and preparation method thereof

ActiveCN102030855AImprove thermoplasticityIncreased drug resistancePhotomechanical apparatusAcrylonitrileWater soluble

Owner:LUCKY HUAGUANG GRAPHICS +1

Nano antibacterial agent and preparation method thereof

ActiveCN108837159ALower doseRestore validityAntibacterial agentsPowder deliveryBiocompatibility TestingAntibiotic Y

The invention discloses a nano antibacterial agent and a preparation method thereof and relates to an antibacterial agent and a preparation method thereof. The invention aims to solve the problems that the conventional nanometer material modified antibiotics applied to the antibacterial field have poor biocompatibility and do not have targeting property and the utilization rate of the antibioticsis low. The nano antibacterial agent is prepared by performing surface modification on a synergetic system of MOF and antibiotics with sodium hyaluronate, wherein the synergetic system of the MOF andantibiotics with sodium hyaluronate is formed by encapsulating the antibiotics in a zeolite imidazate framework structure material ZIF-8. The method comprises the following steps: 1, preparing the synergetic system of the MOF and antibiotics; 2, performing surface modification on the prepared synergetic system of the MOF and antibiotics with a sodium hyaluronate solution, and performing vacuum drying, thereby obtaining the nano antibacterial agent. According to the preparation method disclosed by the invention, the nano antibacterial agent can be obtained.

Owner:NORTHWEST A & F UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com